Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "Thin membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for depositing silicon-free carbon-containing film as gap-fill layer by pulse plasma-assisted deposition

ActiveUS20200013612A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolymer scienceWafering

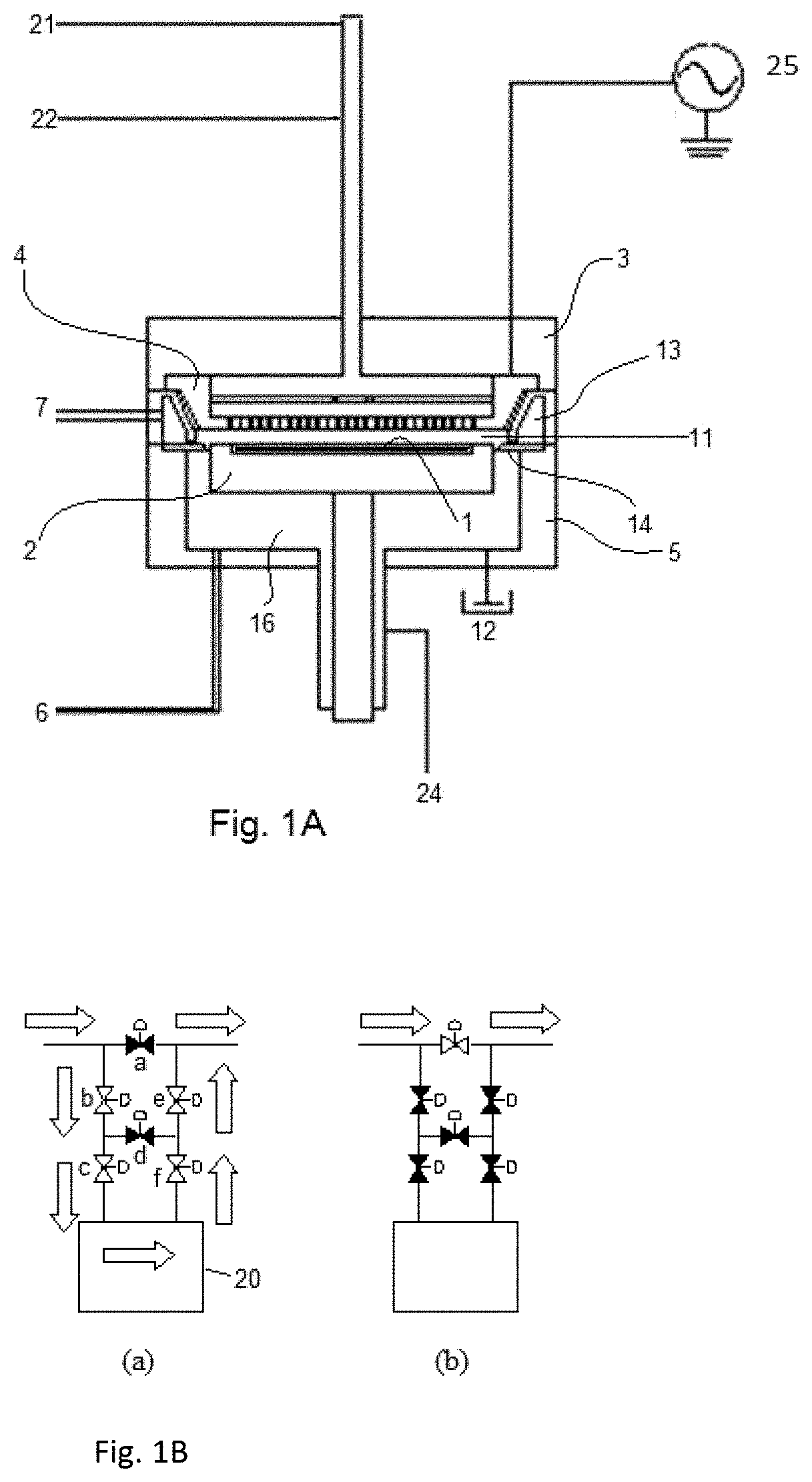

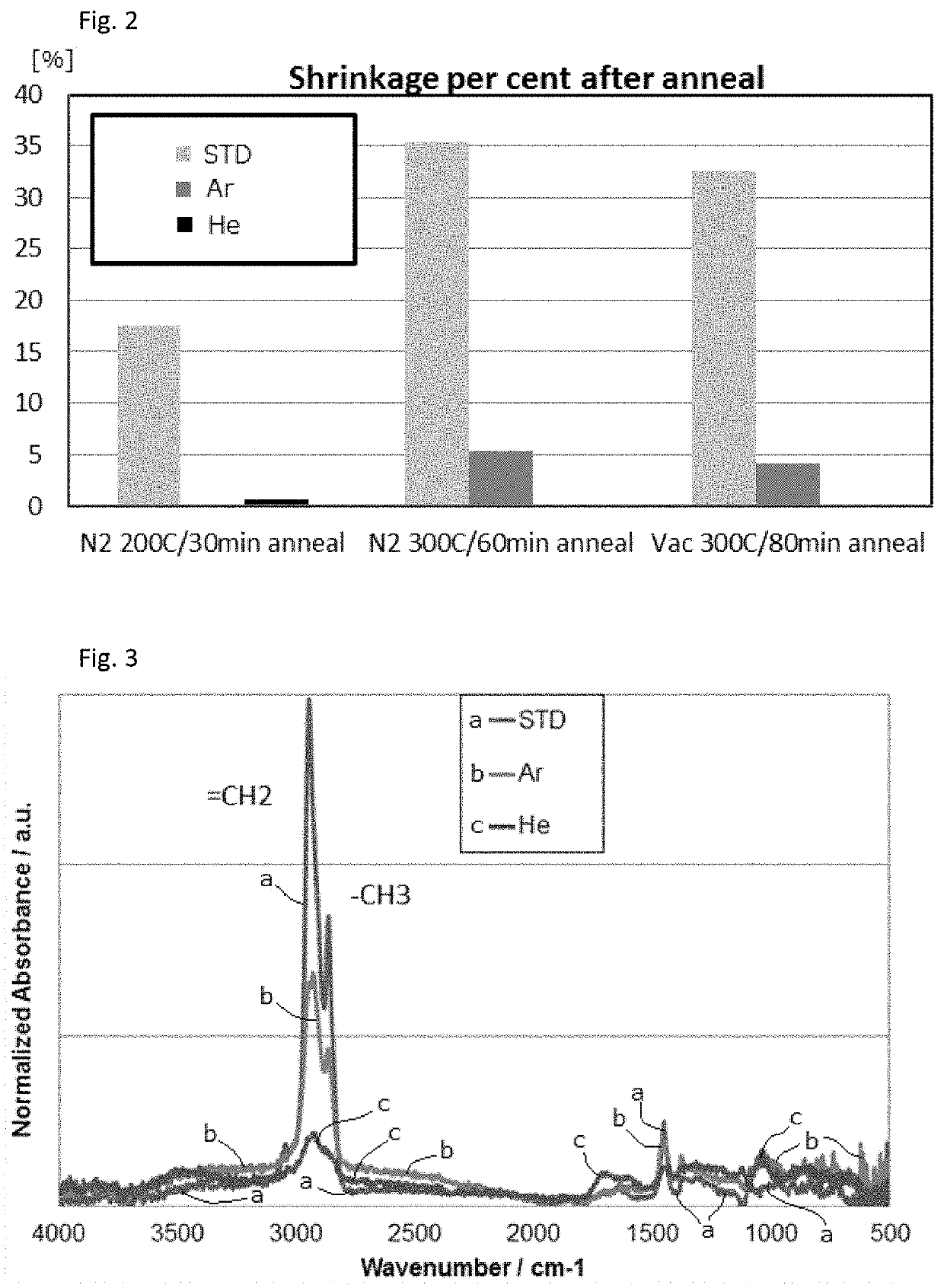

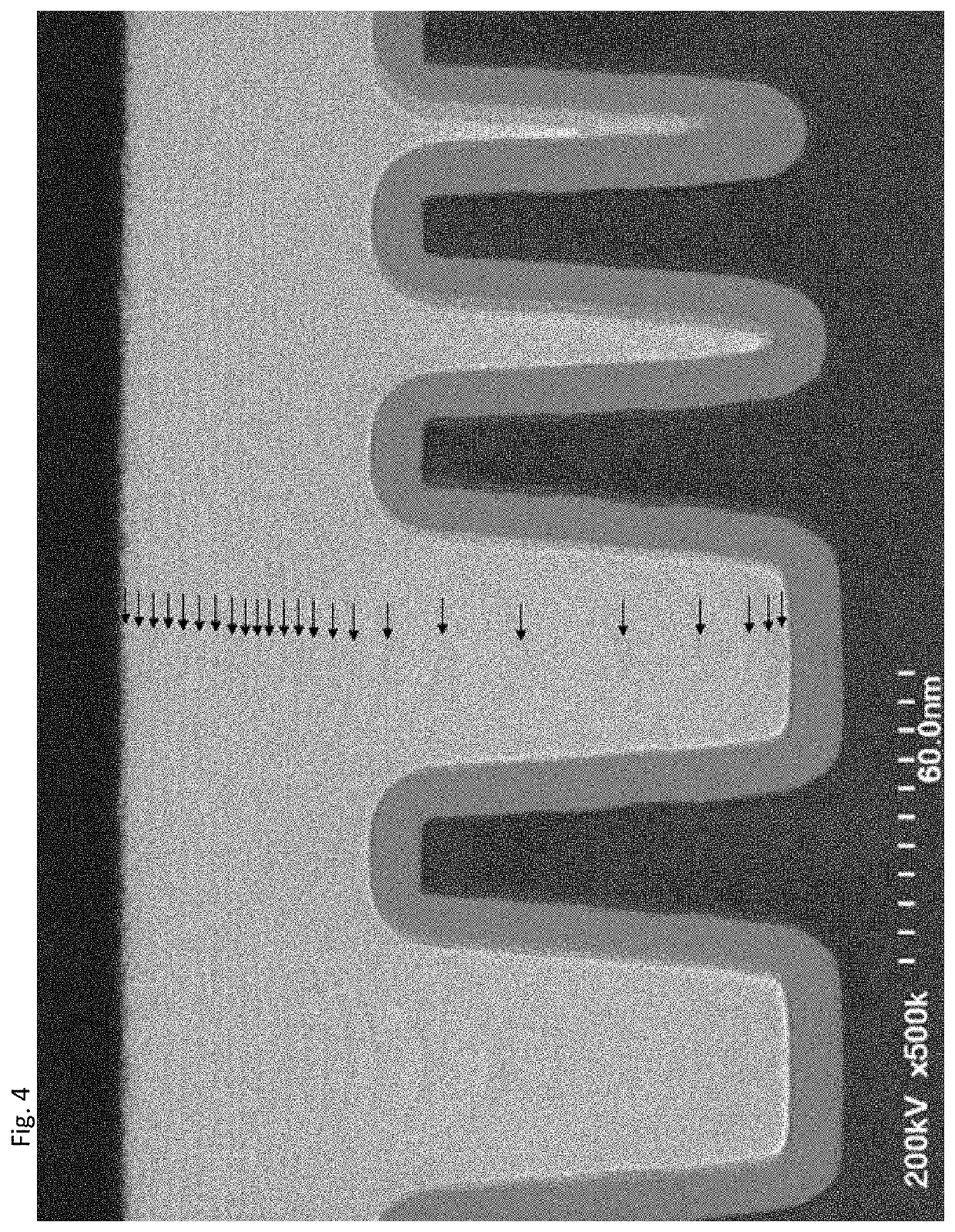

A film having filling capability is deposited by forming a viscous polymer in a gas phase by striking an Ar, He, or N2 plasma in a chamber filled with a volatile hydrocarbon precursor that can be polymerized within certain parameter ranges which define mainly partial pressure of precursor during a plasma strike, and wafer temperature.

Owner:ASM IP HLDG BV

Method for reforming amorphous carbon polymer film

ActiveUS20210043444A1Improve thermal stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon filmThin membrane

Owner:ASM IP HLDG BV

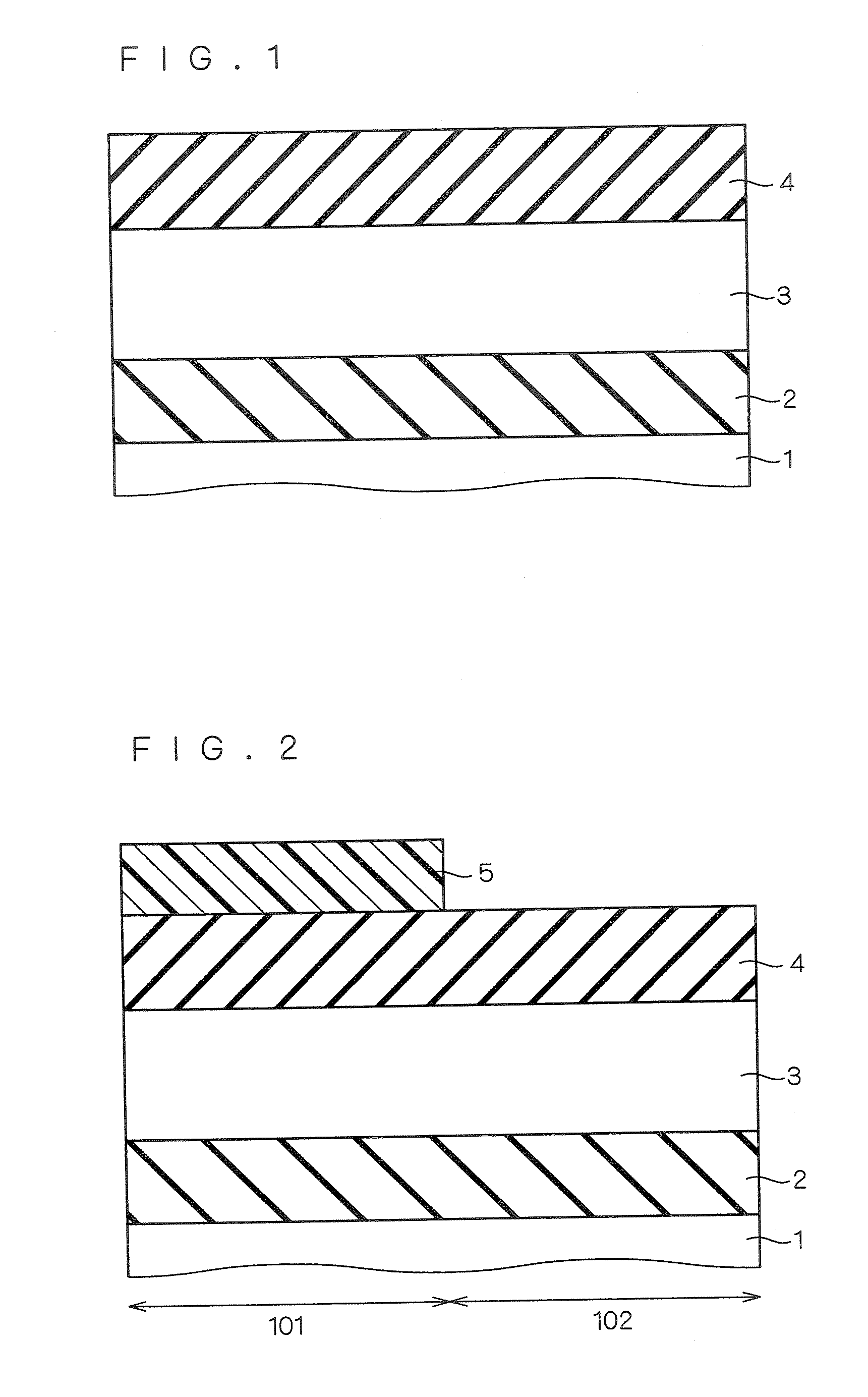

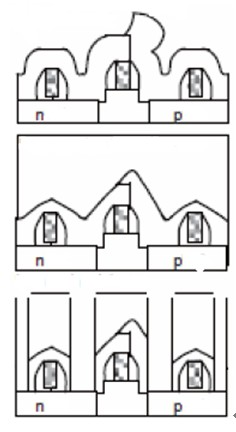

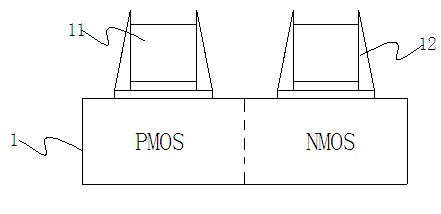

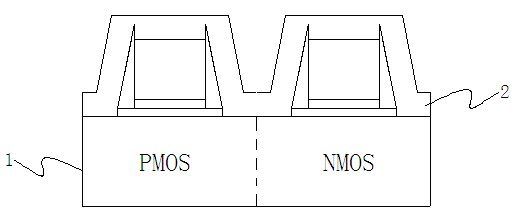

Semiconductor device and manufacturing method for the same

InactiveUS20070176235A1Improve stabilityReduce resistanceSolid-state devicesSemiconductor/solid-state device manufacturingBody regionPhysics

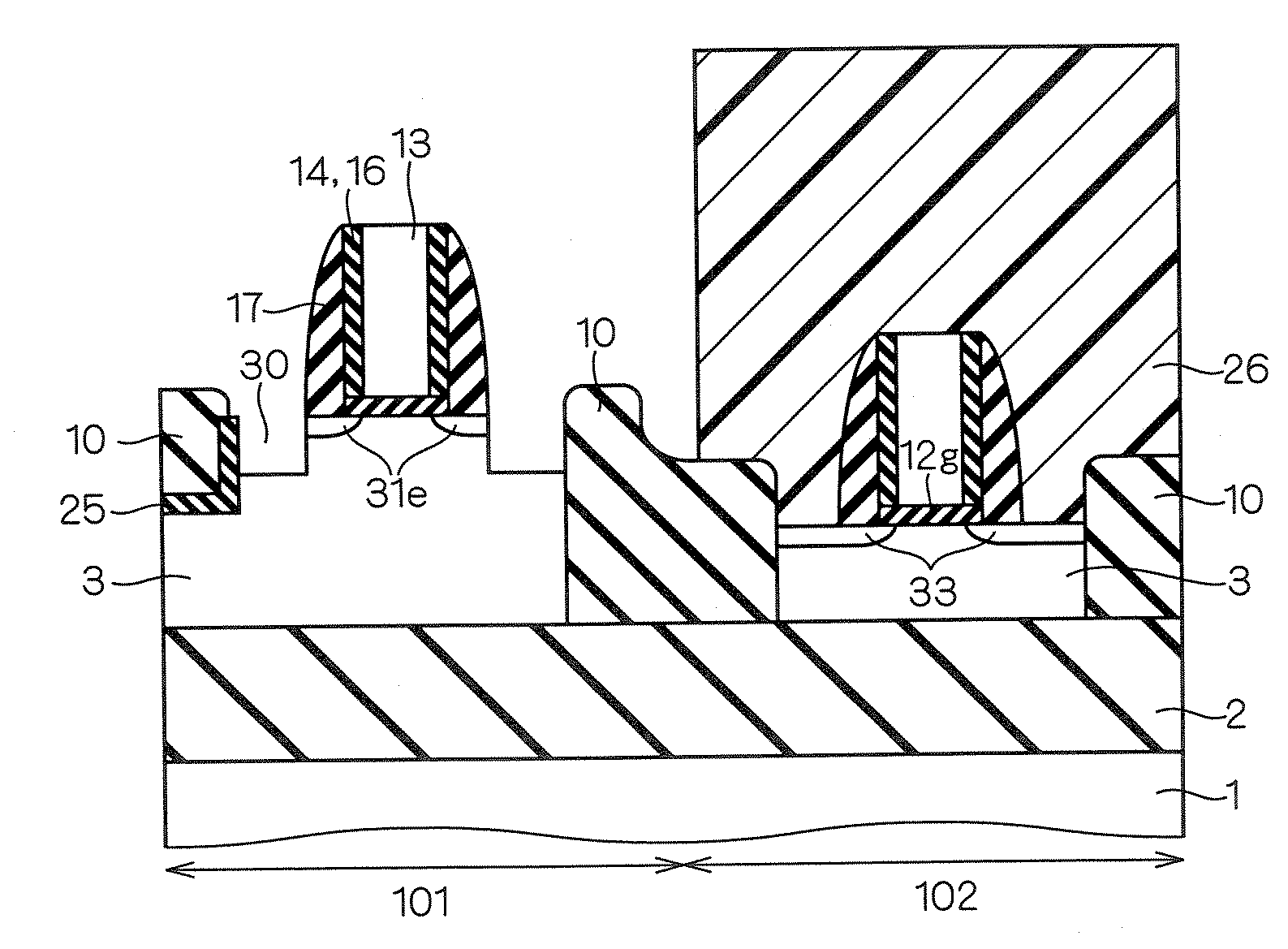

In a semiconductor device, a body thick film transistor and a body thin film transistor having a different body film thickness are formed on the same SOI substrate (silicon support substrate, buried oxide film and silicon layer). The body film is formed to be relatively thick in the body thick film transistor, which has a recess structure where the level of the surface of the source / drain regions is lower than the level of the surface of the body region, and thus, the SOI film in the source / drain regions is formed to be as thin as the SOI film in the body thin film transistor. On the other hand, the entirety of the SOI film is formed to have a relatively thin film thickness in the body thin film transistor. In addition, the source / drain regions are formed to penetrate through the silicon layer.

Owner:RENESAS ELECTRONICS CORP

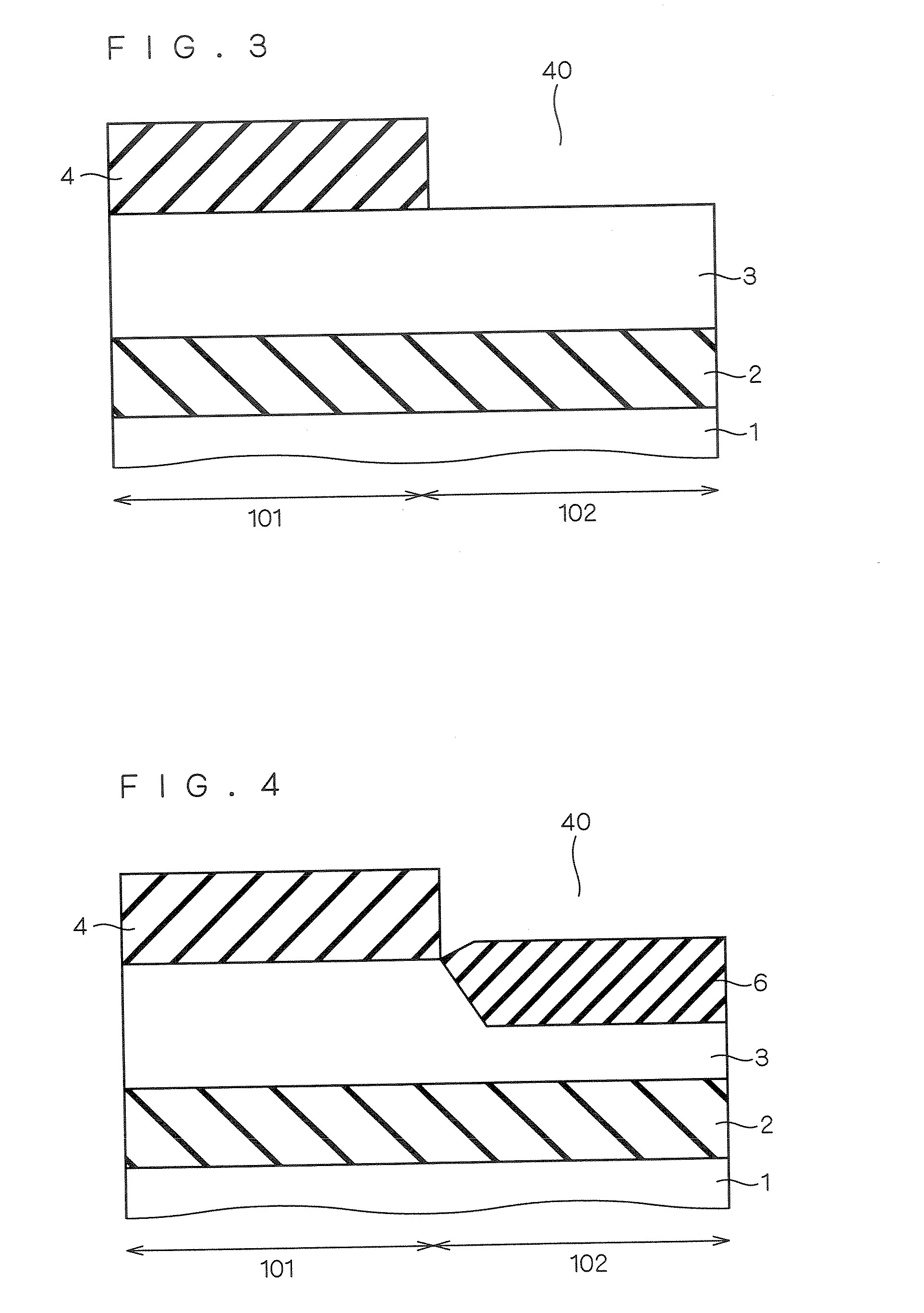

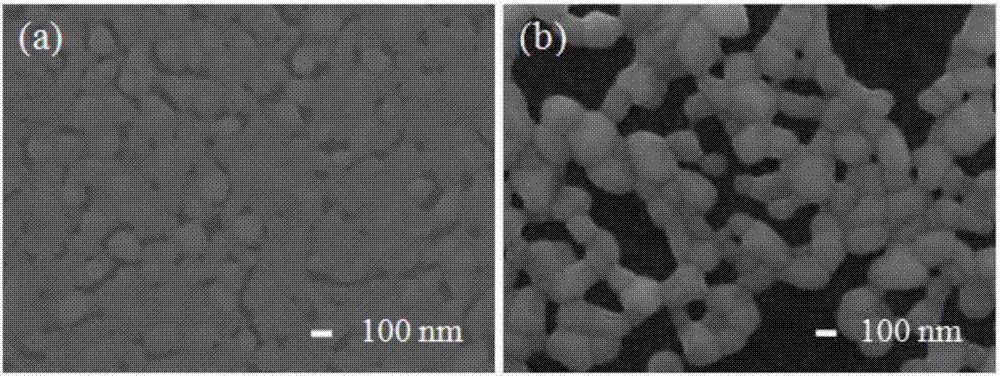

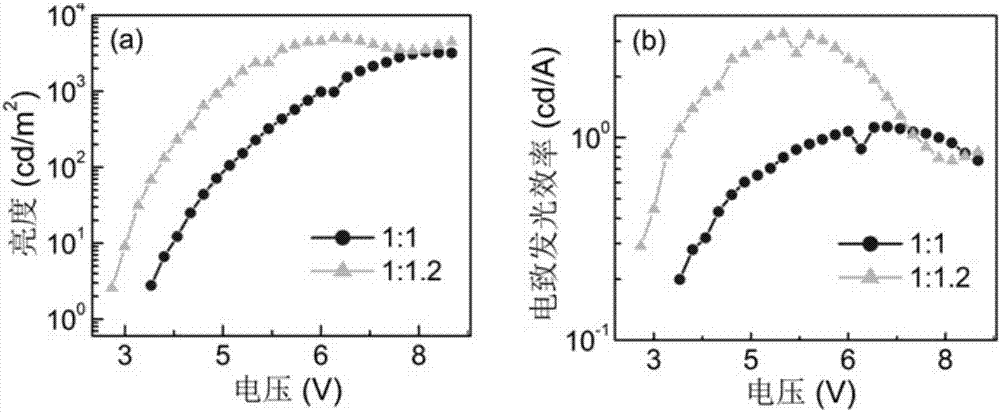

Method for preparing all-Inorganic perovskite film

InactiveCN107221612AEasy to prepareEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingTemperature controlOrganic solvent

Owner:SOUTHWEST UNIVERSITY

Polysilicon thin film transistor and method of fabricating the same

A method of fabricating a polycrystalline silicon thin film transistor is disclosed. One embodiment of the method includes: forming an amorphous silicon layer on a panel; scanning a continuous wave laser beam having a wavelength range of about 600 to about 900 nm between a visible light range of a red color and a near infrared range onto the amorphous silicon layer to preheat the amorphous silicon layer; overlappingly scanning a pulse laser beam having a wavelength range of about 100 to about 550 nm between a visible light range and an ultraviolet range in addition to the continuous wave laser beam on the panel to melt the preheated amorphous silicon layer; and stopping scanning the pulse laser beam to crystallize the molten silicon layer.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

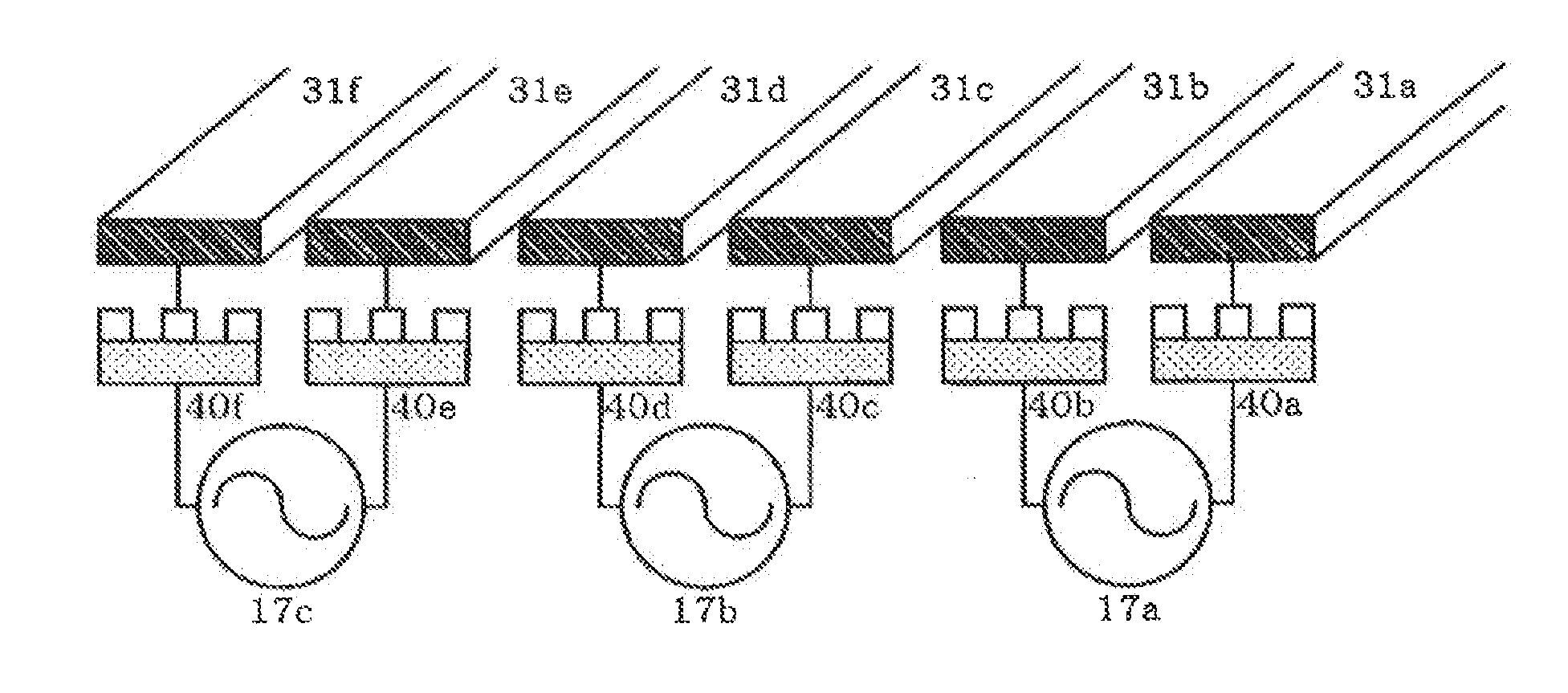

Thin film forming device for forming silicon thin film having crystallinity

InactiveUS6192828B1Electric discharge tubesSemiconductor/solid-state device manufacturingElectric dischargeSilicon thin film

An insulating member is interposed between a film formation chamber container and a plasma chamber container. Both containers are adjacent to and communicated with each other. In the film formation chamber container, a base material holder is provided for holding the base material. Raw material gas is introduced into the plasma chamber container and ionized by high frequency electric discharge, to generate plasma. A high frequency electrode and a high frequency electric power source are provided as a plasma generating unit. There is provided a porous electrode 30, the electric potential of which is the same as that of the plasma chamber container 24, between both chambers 22, 24 to partition both chambers. A pulse electric powder source for impressing bipolar pulse voltage, in which a positive polarity portion and a negative polarity portion are alternately repeated, is provided between the base material holder and both of the plasma chamber container and the porous electrode 30, the electric potential of which is the same as that of the plasma chamber container 24.

Owner:NISSIN ELECTRIC CO LTD

Compound biochip based on photon crystal

InactiveCN101358242AImprove performanceEnhanced signal selectivityMicrobiological testing/measurementMicrosphereComposite substrate

Owner:SOUTHEAST UNIV

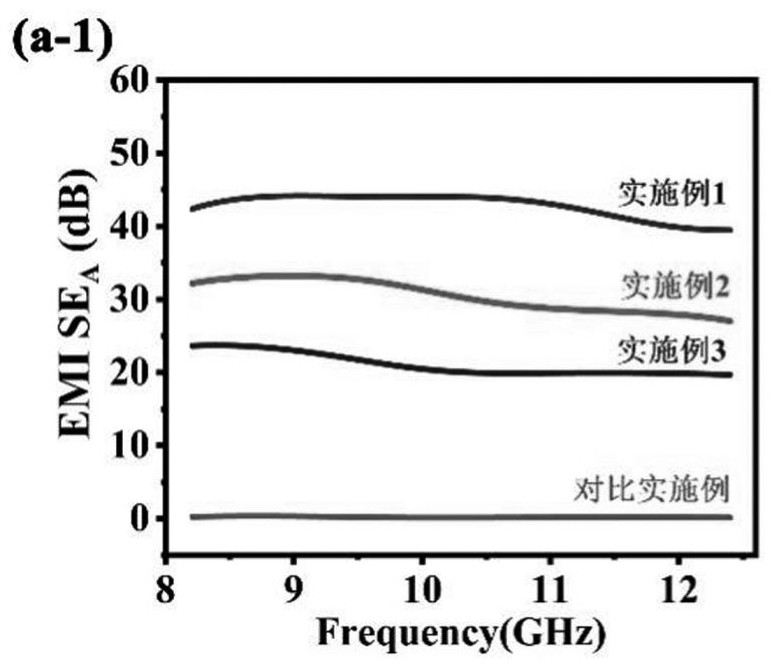

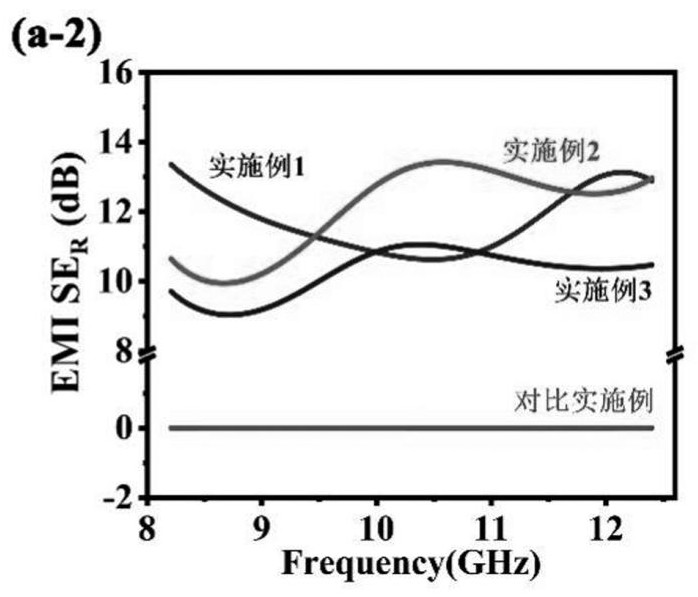

Lightweight porous MXene-based composite film electromagnetic shielding material and preparation method thereof

ActiveCN113329603APlay a supporting rolePromote absorptionMagnetic/electric field screeningClimate change adaptationComposite filmThin membrane

The invention discloses a lightweight porous MXene-based composite film electromagnetic shielding material and a preparation method thereof, and belongs to the technical field of film electromagnetic shielding materials and preparation thereof. Self-assembly of MXene and graphene oxide is realized by taking electrostatic interaction force as driving force on MXene modified by a cationic surface modifier and graphene oxide, and then the lightweight porous MXene-based composite electromagnetic shielding material with ultrahigh specific performance is obtained through film casting and high-temperature annealing. The prepared composite film material has excellent electromagnetic shielding effectiveness and specific effectiveness, and when the thickness is only 15 [mu]m, the porous MXene-based composite film obtained by adding 5 wt% of graphene oxide can keep the electromagnetic shielding effectiveness of 49 dB or above in the whole X wave band. The preparation process is simple and easy to operate, and the material is expected to be applied to the fields of aerospace, military equipment, micro electronic equipment, civil electric appliances and the like.

Owner:JIANGNAN UNIV

Preparation scheme of novel high-transmittance vanadium dioxide thin film element

Owner:SHENZHEN UNIV

Method for preparing double-stress thin film

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

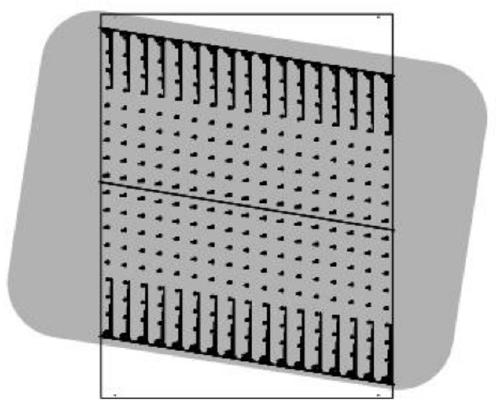

Microporous polyolefin film, separator for battery, and production processes therefor

ActiveUS20170274329A1Increase capacityReduce the numberMembranesSemi-permeable membranesPolymer sciencePolyolefin

A polyolefin microporous membrane is disclosed. The membrane has a width of not less than 100 mm, and a variation range of an F25 value in a width direction is not greater than 1 MPa. The F25 value is a value obtained by dividing a load at 25% elongation of a sample of the laminated polyolefin microporous membrane as measured with a tensile testing machine by a cross-sectional area of the sample.

Owner:TORAY IND INC

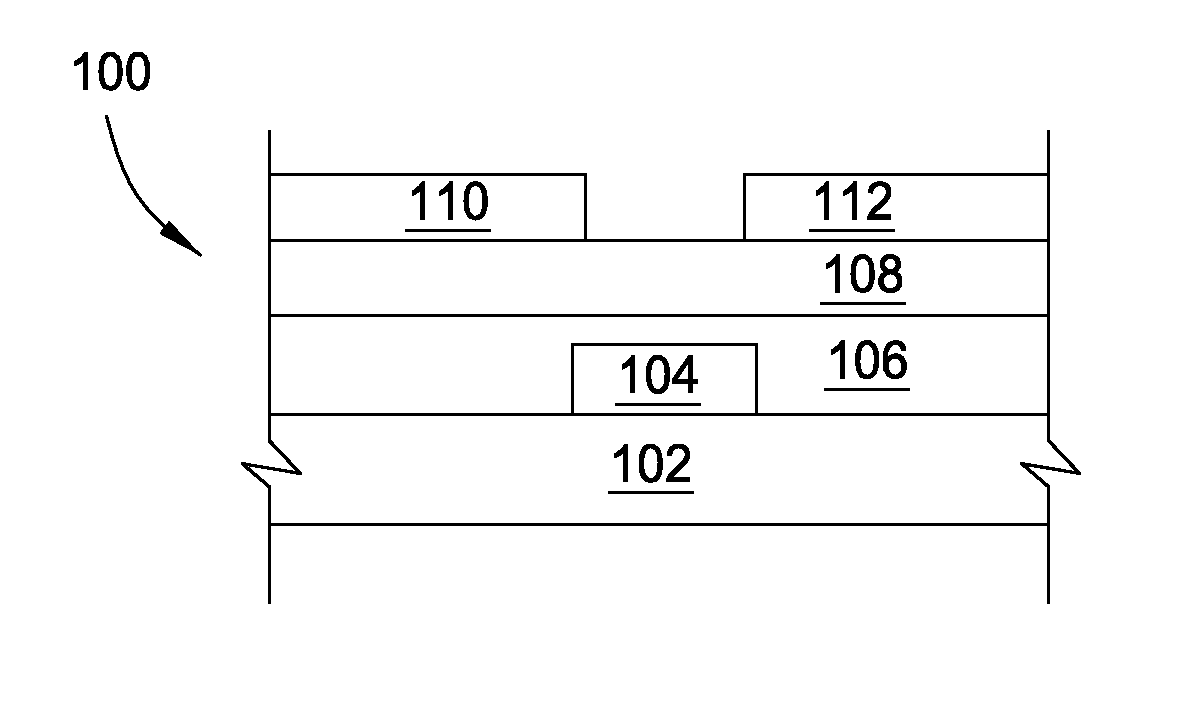

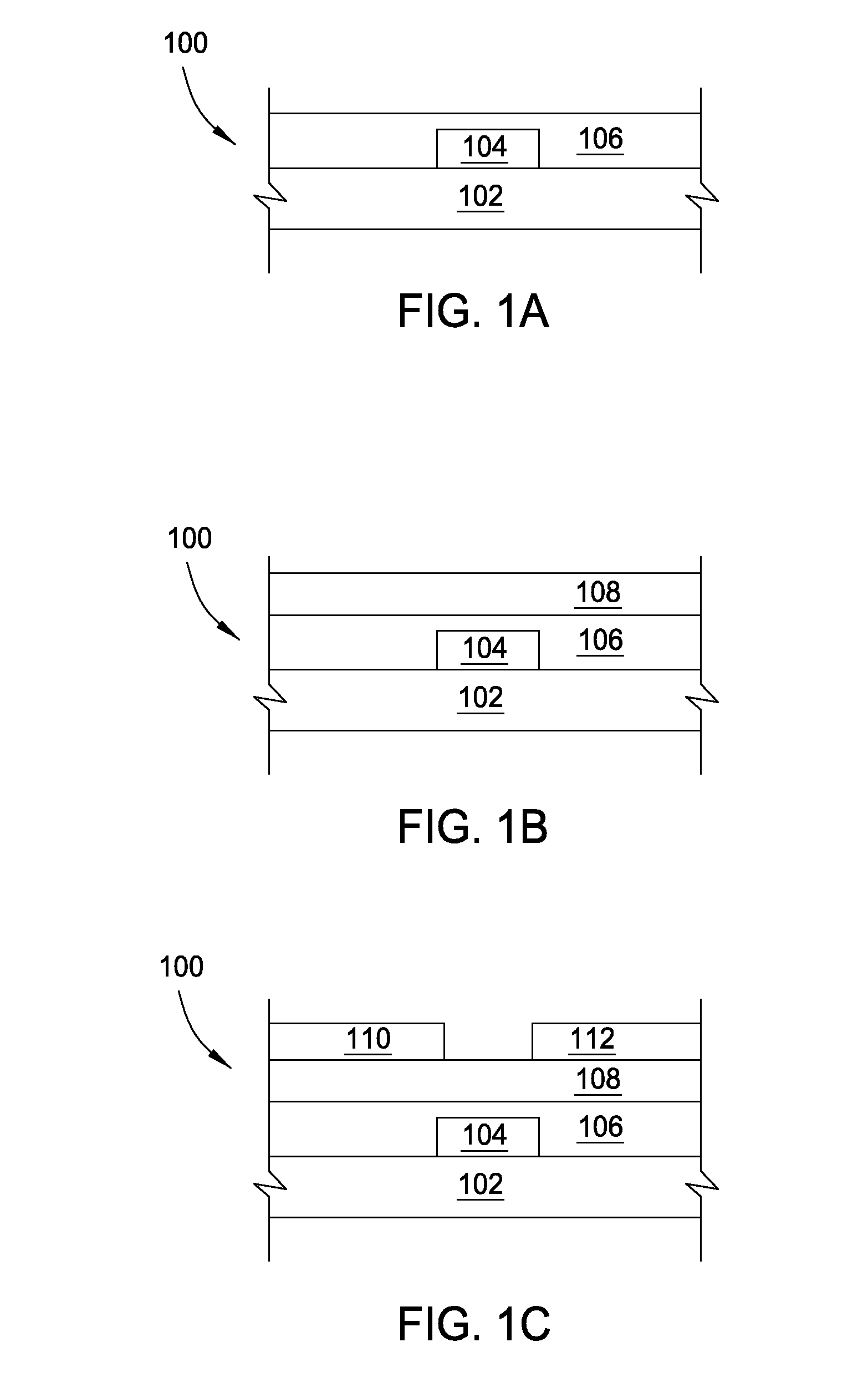

Thin film semiconductors made through low temperature process

ActiveUS20140363934A1Semiconductor/solid-state device manufacturingSemiconductor devicesZinc nitrideDeposition temperature

Owner:APPLIED MATERIALS INC

Manufacturing method of special-shaped transparent display screen

InactiveCN111105723AReasonable manufacturing process designHigh implementabilityGlass severing apparatusIdentification meansAdhesive beltThin membrane

Owner:TIANJIN CECEP BRILLSHOW

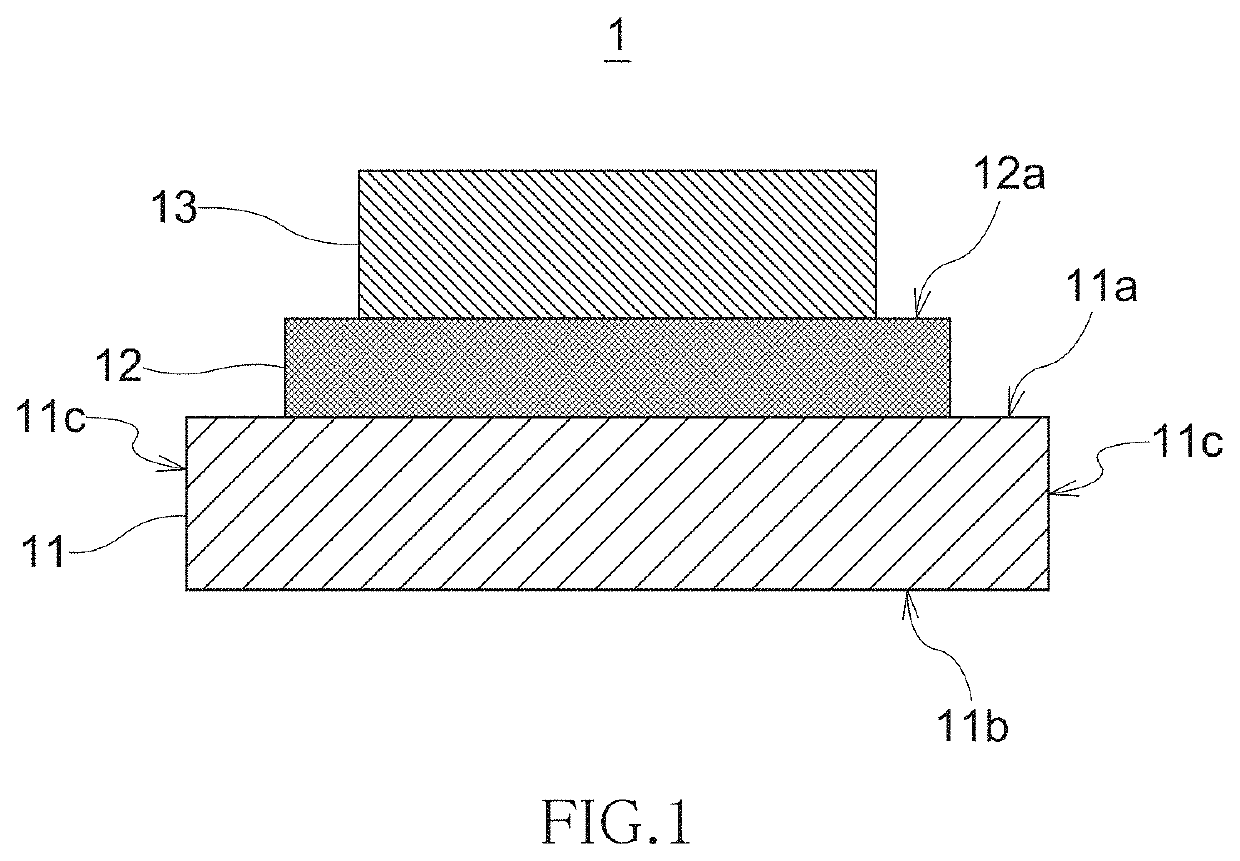

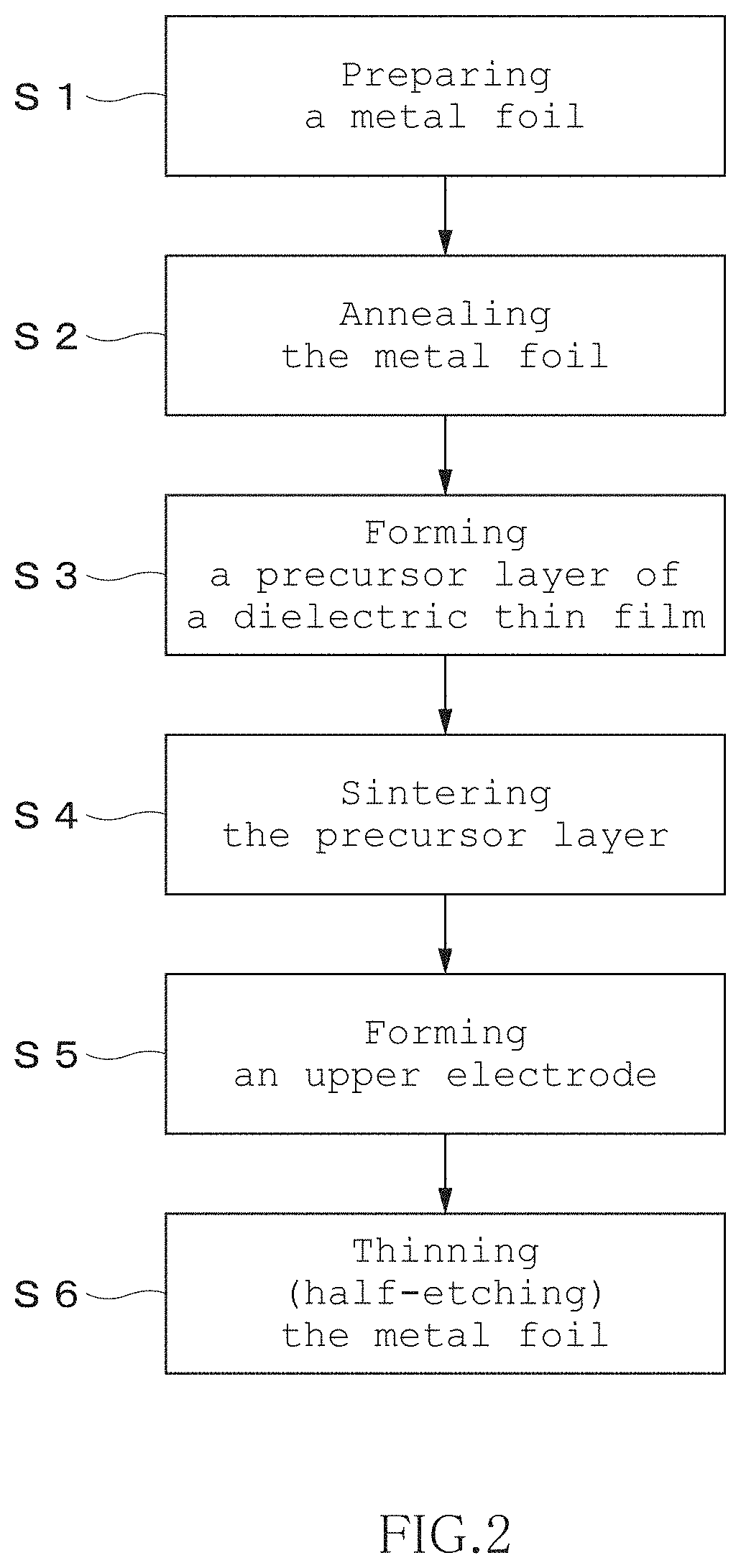

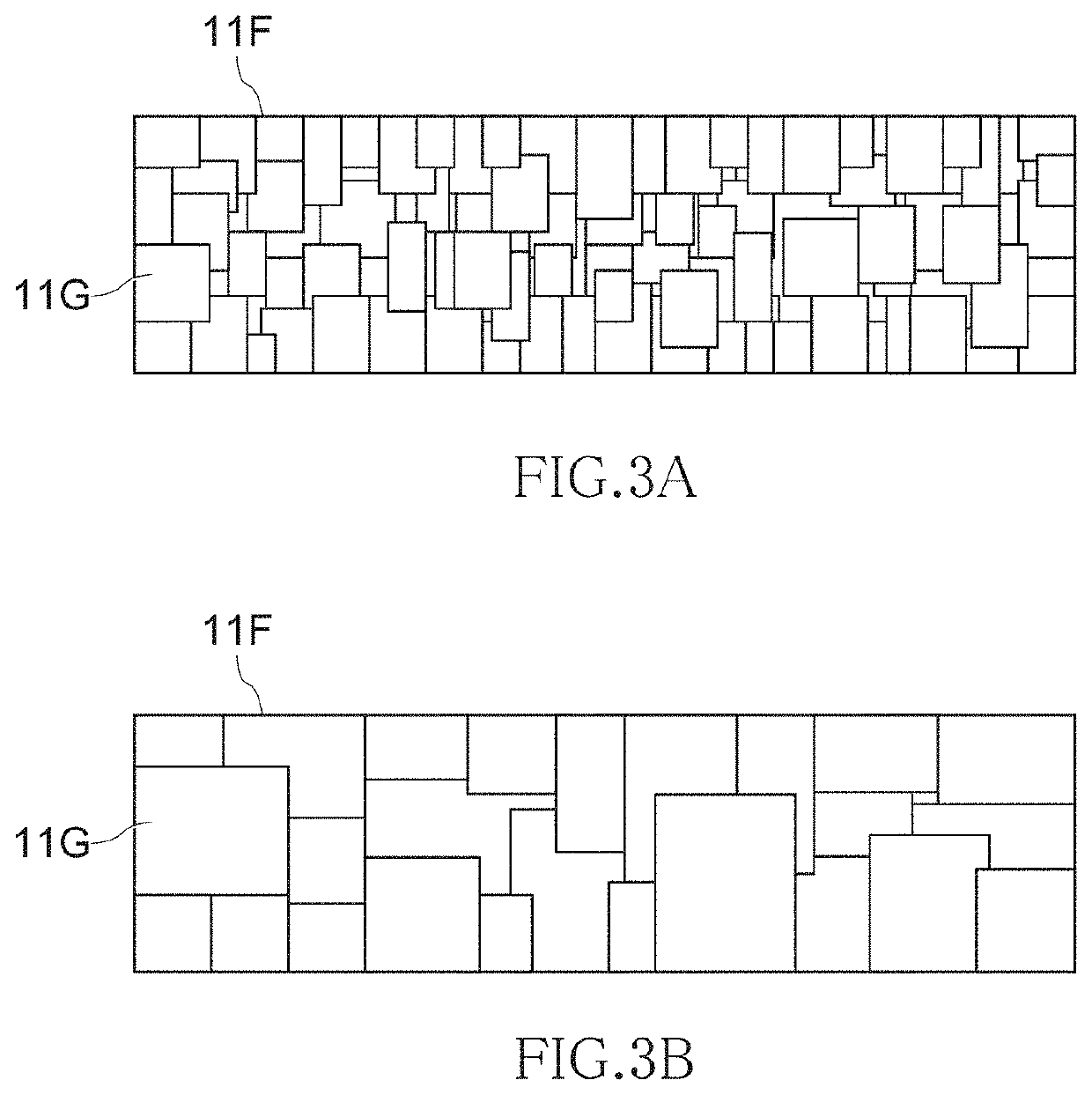

Thin film capacitor, manufacturing method therefor, and substrate with built-in electronic component

ActiveUS20200135406A1Reduce thicknessImprove cooling effectFixed capacitor electrodesThin/thick film capacitorMetal foilThin membrane

Owner:TDK CORPARATION

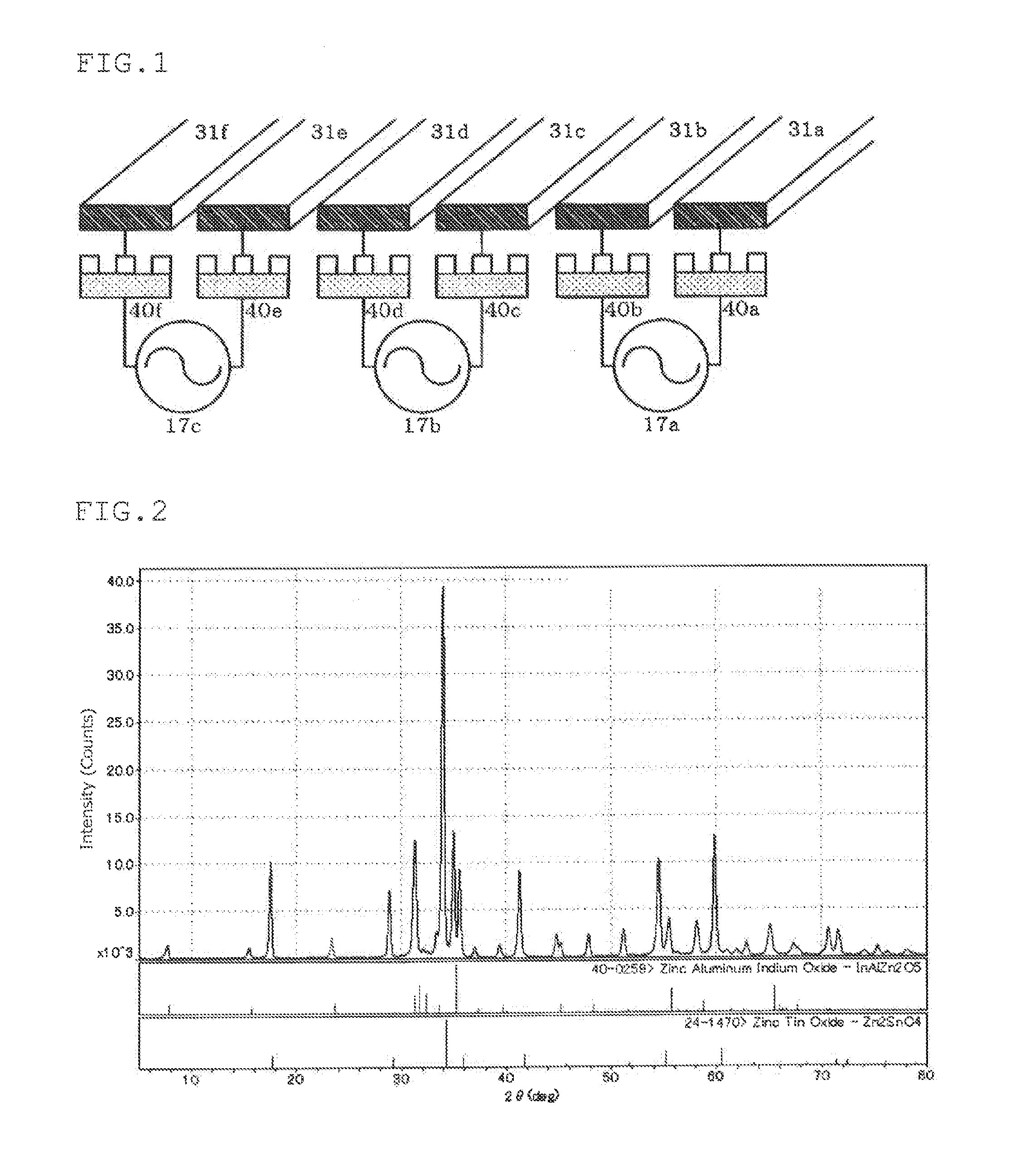

Sputtering target, oxide semiconductor thin film, and method for producing oxide semiconductor thin film

InactiveUS20150311071A1Increase productionSuppress abnormal dischargeTransistorCellsIndiumThin membrane

Owner:IDEMITSU KOSAN CO LTD

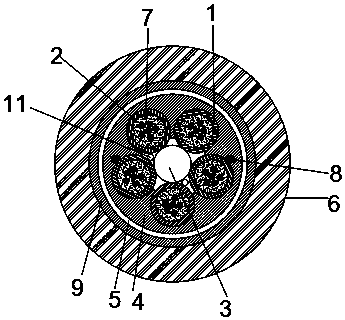

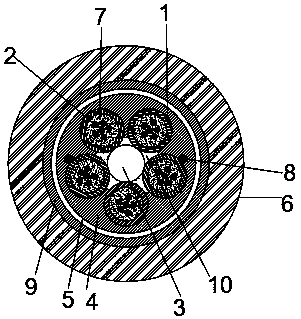

Optical cable with new structure and production method thereof

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

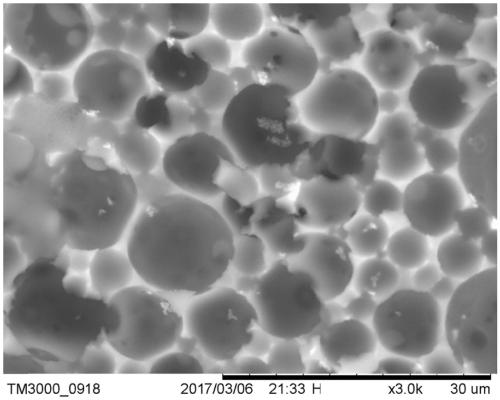

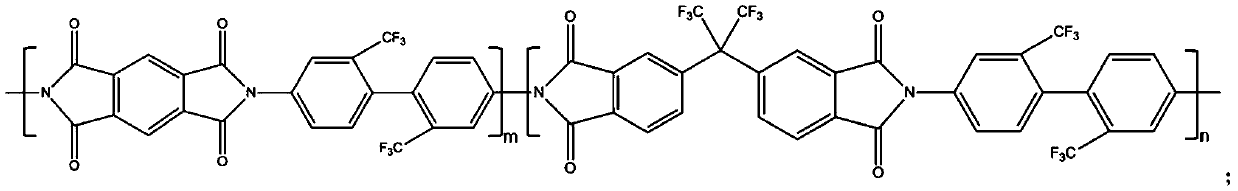

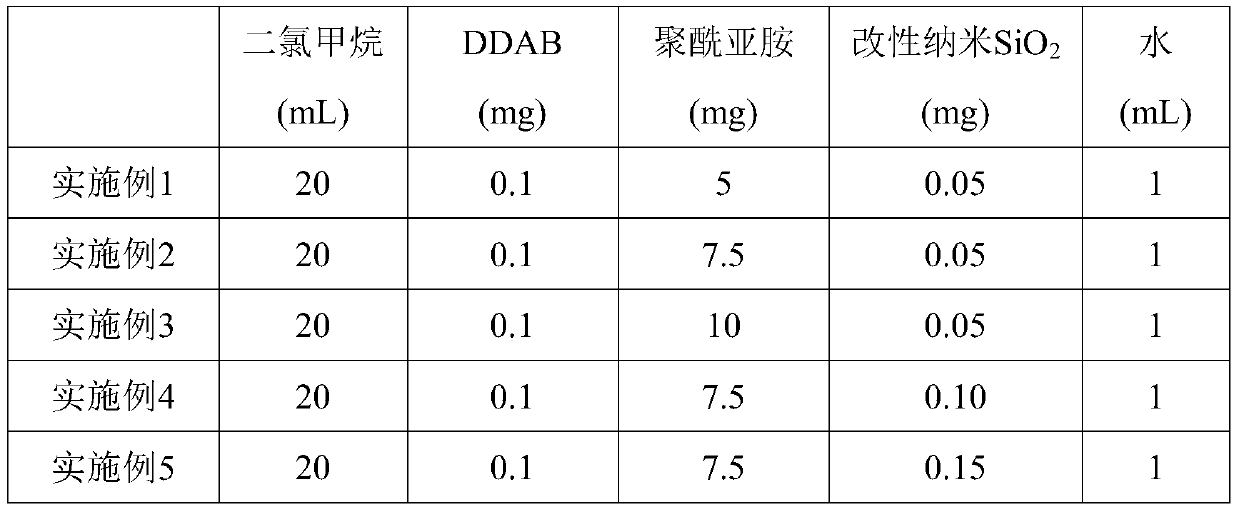

Nano-composite porous polyimide film and preparation method thereof

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

False proof thin film and producing method thereof

InactiveCN101314311AImprove visual effectsRealize three-line anti-counterfeitingVacuum evaporation coatingSputtering coatingThin membraneEngineering

The invention discloses an anti-fake film and a method for making the same. The method comprises the following steps of: depositing a layer of metal film by vacuum roll coating technique on a flexible base material, producing a group of invisible codes which can only be read by machines after the dealing the metal film by a pulsed laser source or a pulsed ion source. The anti-fake film of the invention can play an anti-fake function by both naked eye visualization and machine reading, and can be analyzed by experts finally, with ideal results. Therefore, the anti-fake film can be applied widely to the prevention of fake commodities, ID cards, securities and paper money.

Owner:CHINA BANKNOTE PRINTING & MINTING

High and low temperature flexible fibrous supercapacitor and preparation method and application thereof

InactiveCN108447701AEasy to operateGood flexibilityHybrid capacitor electrodesHybrid/EDL manufactureFiberElectrolytic agent

The invention provides a preparation method of a high and low temperature flexible fibrous supercapacitor, two conductive polymer composite fiber electrodes are parallelly arranged at a certain interval, two ends are fixed on a PET film by use of a conductive adhesive tape and conductive silver adhesive, surfaces are coated with aqueous gel electrolytes, and thus a high and low temperature flexible fibrous supercapacitor integrated device is prepared. The invention also provides a high and low temperature flexible fibrous supercapacitor and application thereof. The high and low temperature flexible fibrous supercapacitor still maintains high energy density in a wide-temperature range environment from 60 to 100 DEG C, and has ultrahigh safety performance, and the performance is not affectedwhen the supercapacitor is bent at an arbitrary angle.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Nano-porous anodic aluminum oxide membrane for healthcare and biotechnology

ActiveUS20200392639A1Safe working environmentLow costAnodisationMembranesNano structuringThin membrane

Owner:NANOPEC INC

Vanadium dioxide intelligent thermal control device with longhorn beetle-imitating multistage structure and preparation method thereof

ActiveCN111005001ACosmonautic environmental control arrangementVacuum evaporation coatingThin membraneMicrostructure

Owner:HARBIN INST OF TECH

All-organic composite material film and preparation method and application thereof

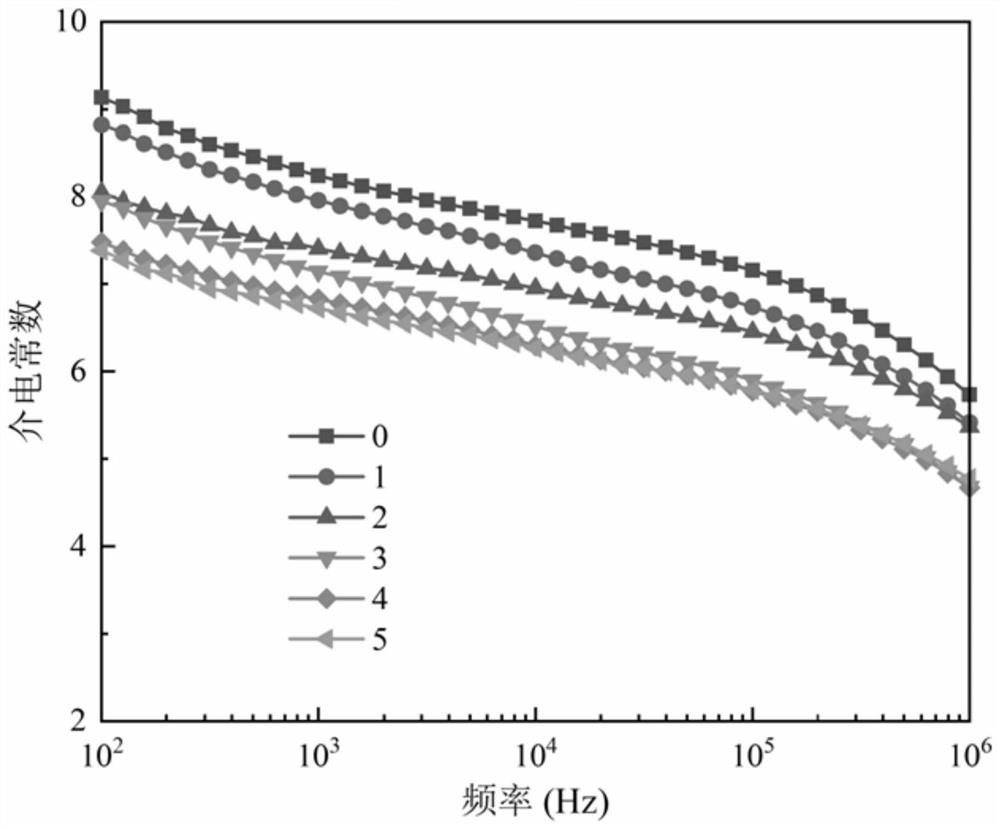

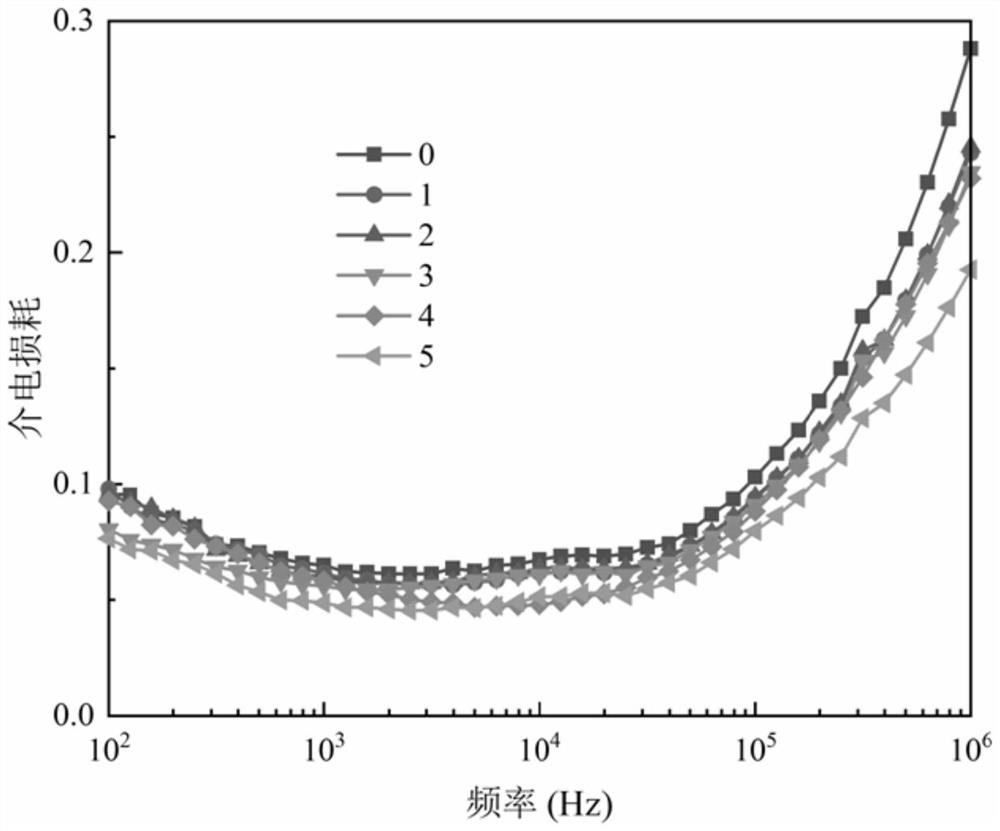

InactiveCN113121936AThin/thick film capacitorFixed capacitor dielectricPolyvinylidene fluorideThin membrane

Owner:TSINGHUA UNIV +3

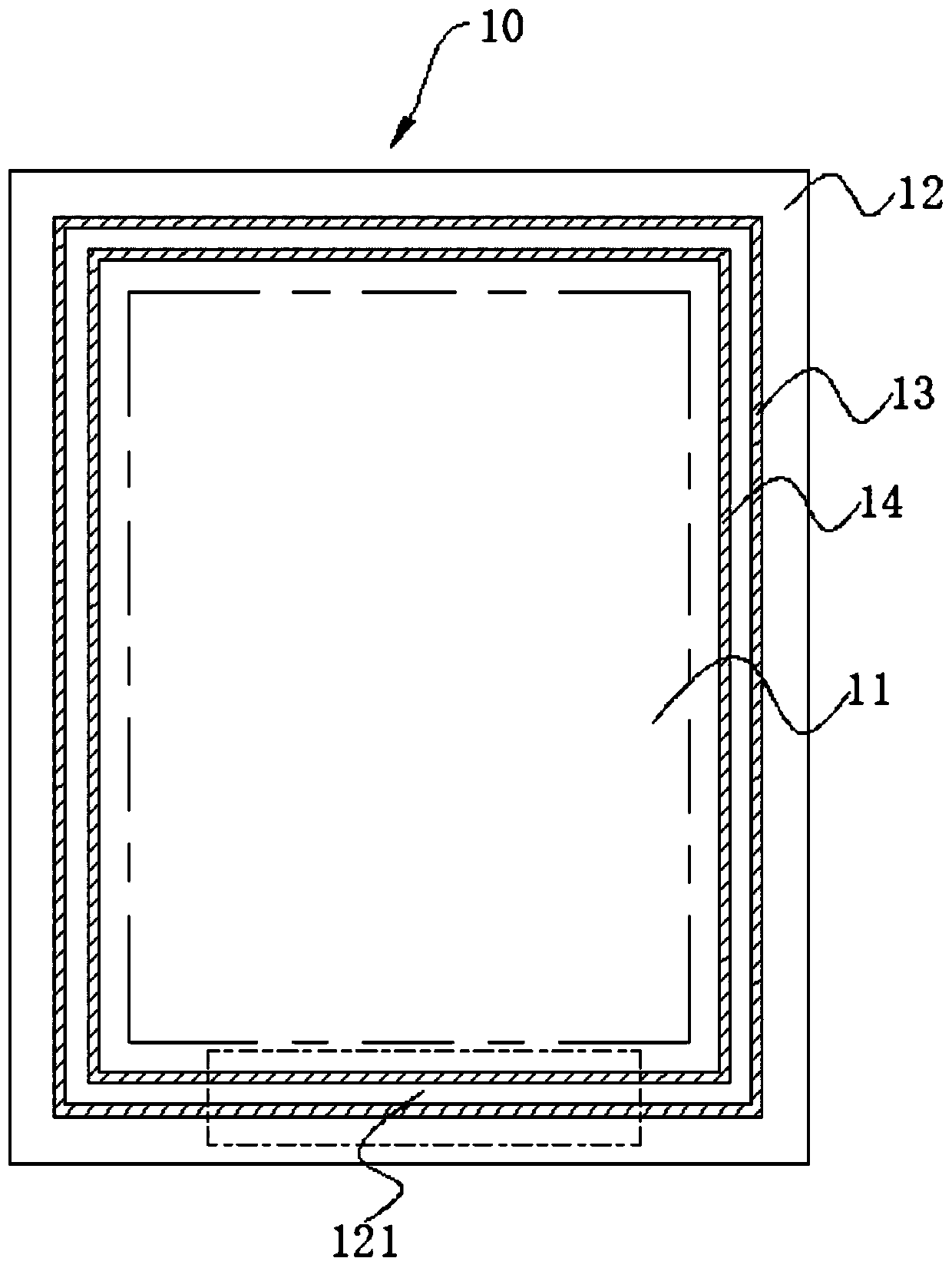

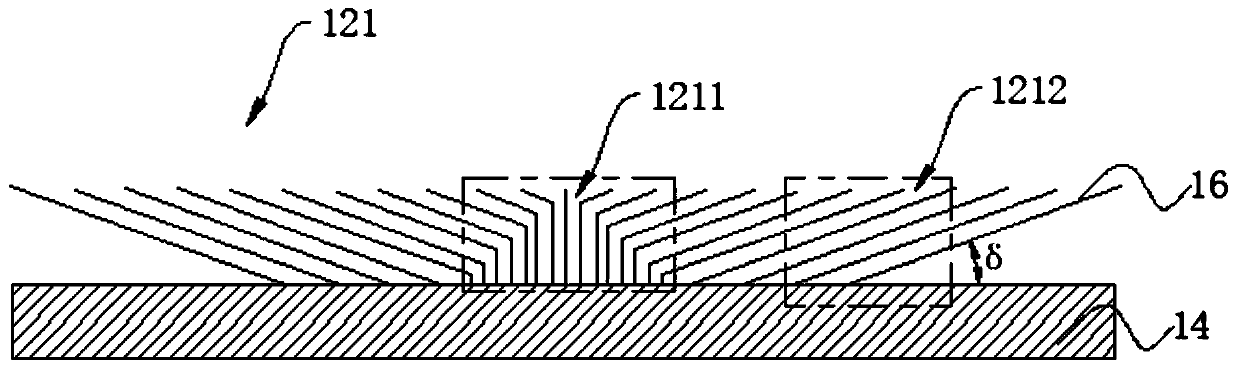

OLED display panel

ActiveCN110993817AExtended service lifeImprove liquiditySolid-state devicesSemiconductor/solid-state device manufacturingAcute angleThin membrane

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

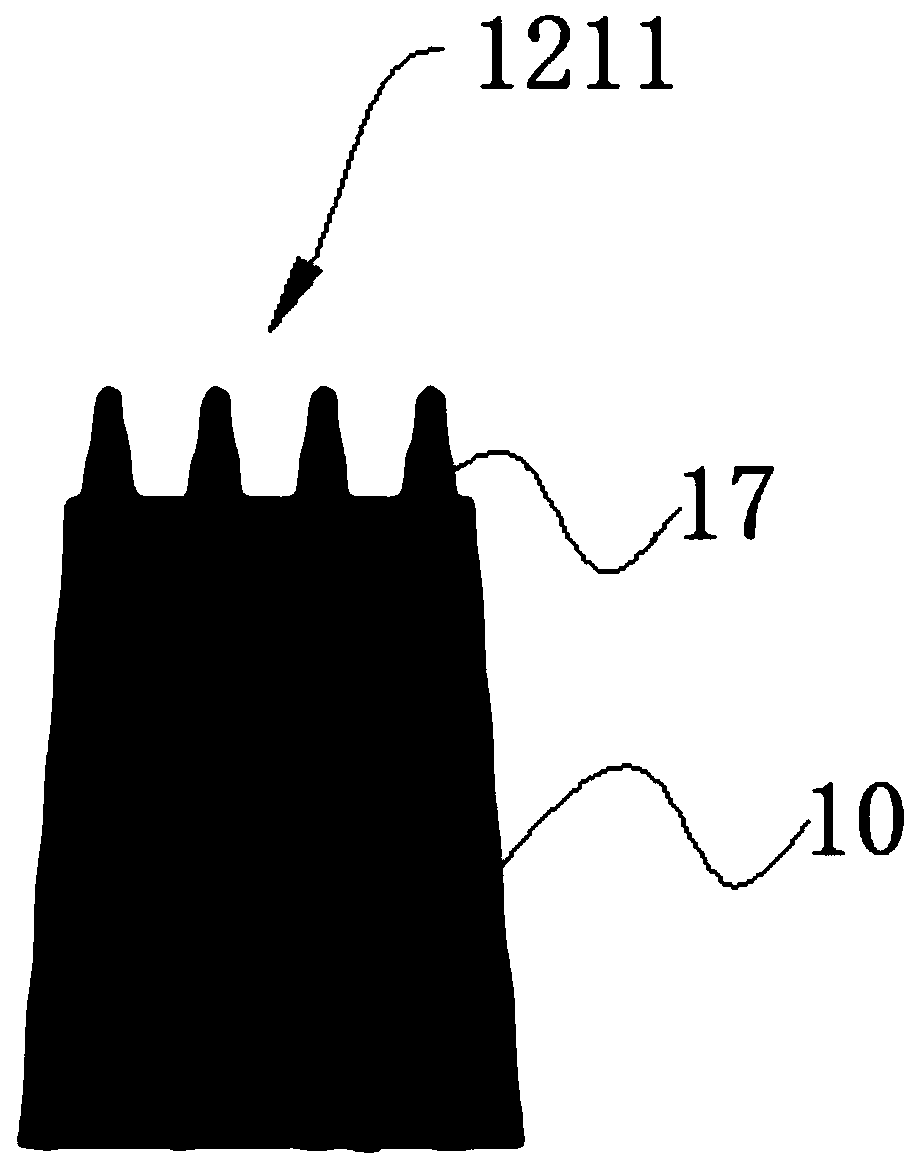

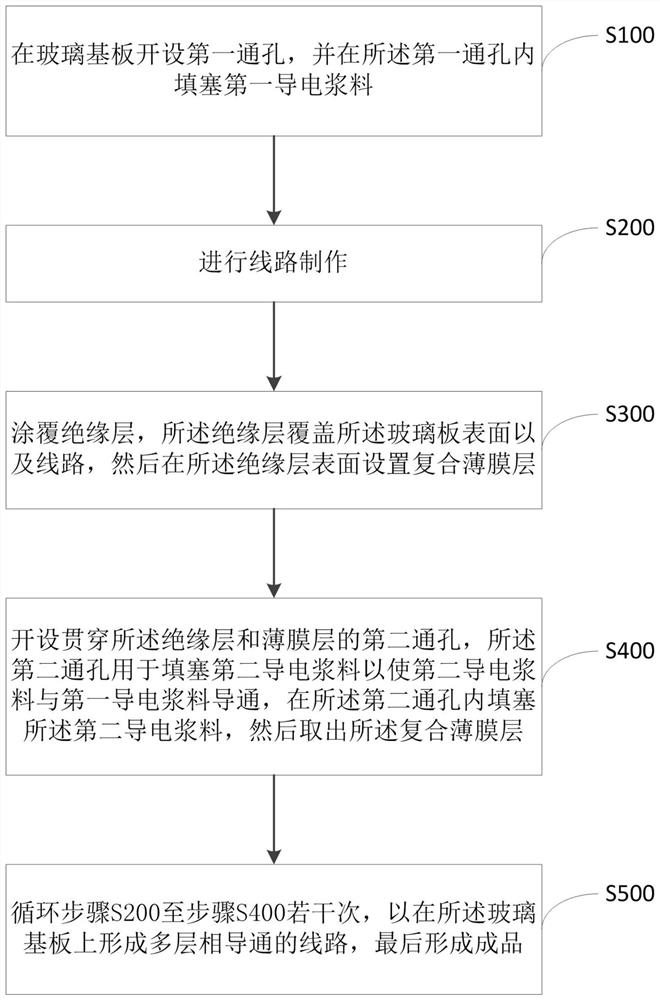

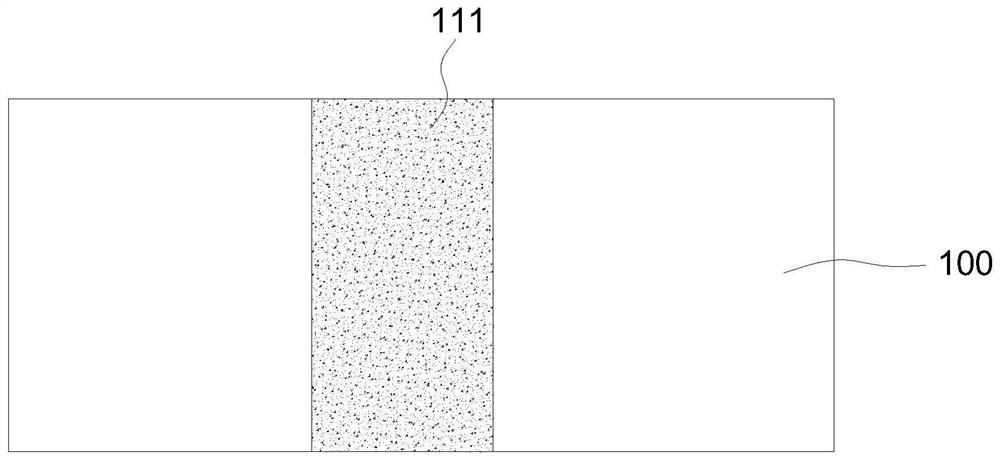

Preparation method of multi-layer glass substrate, glass substrate and Mini-LED glass substrate

PendingCN113873788ACircuit optical detailsConductive pattern formationThin membraneElectrically conductive

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

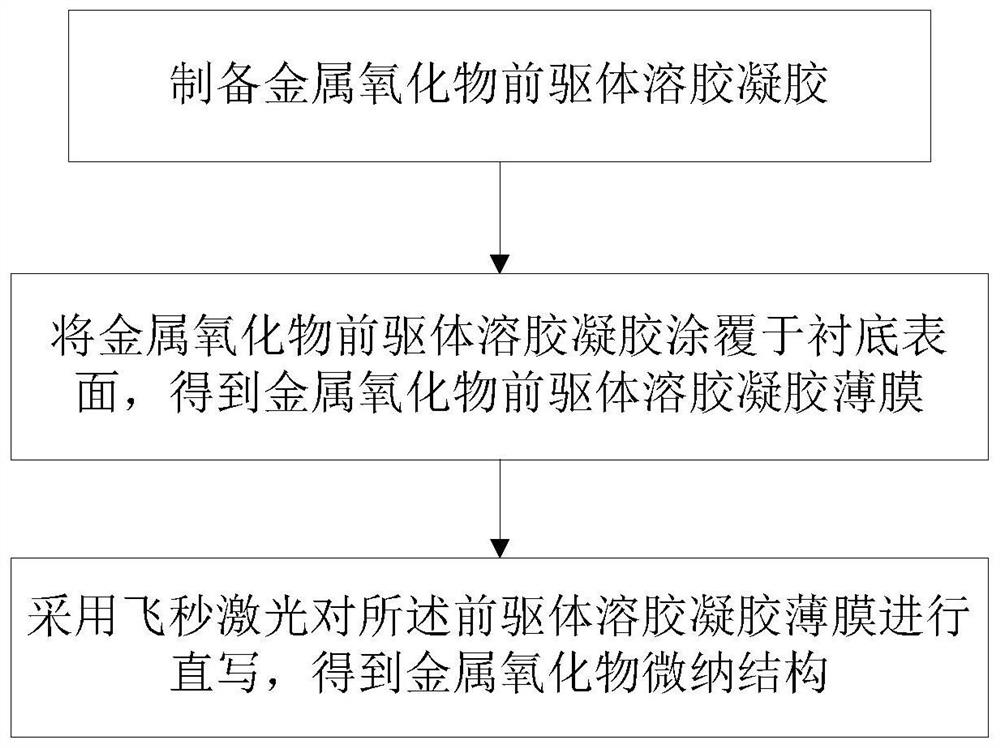

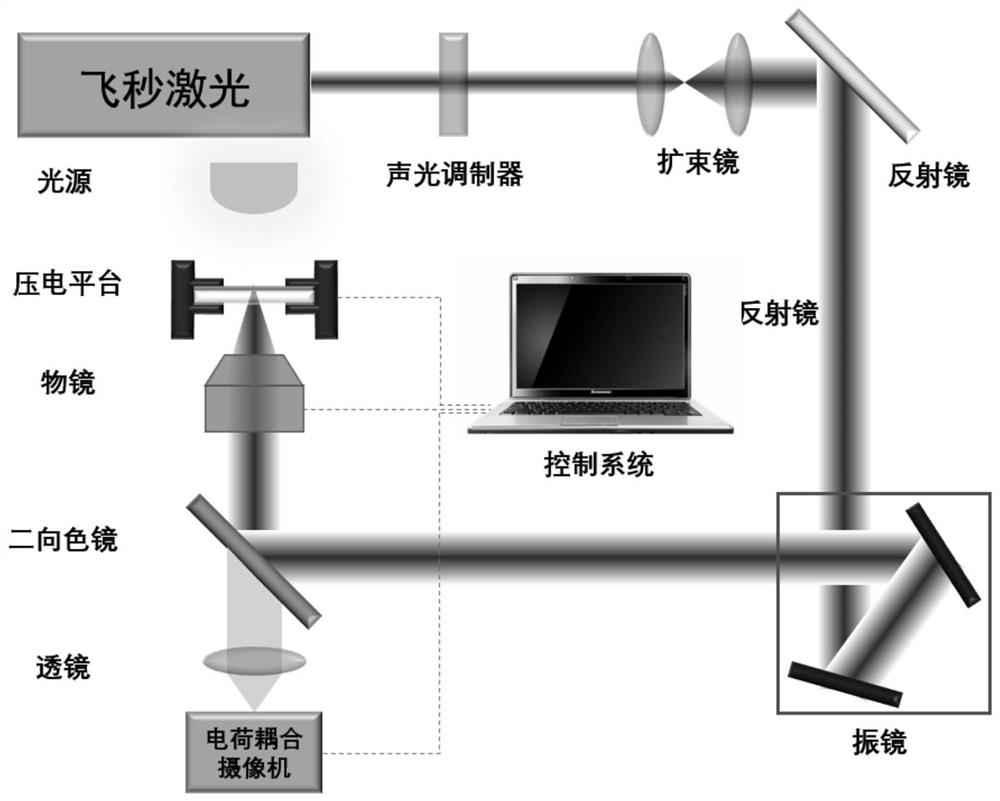

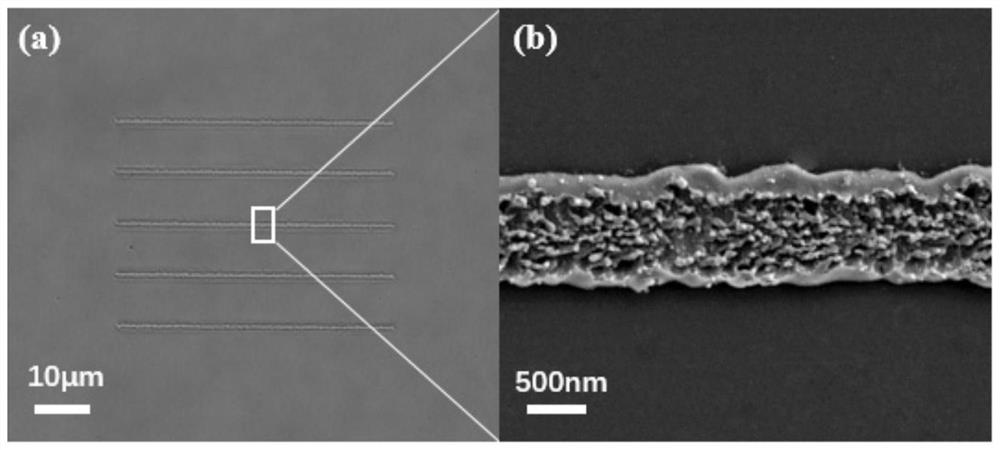

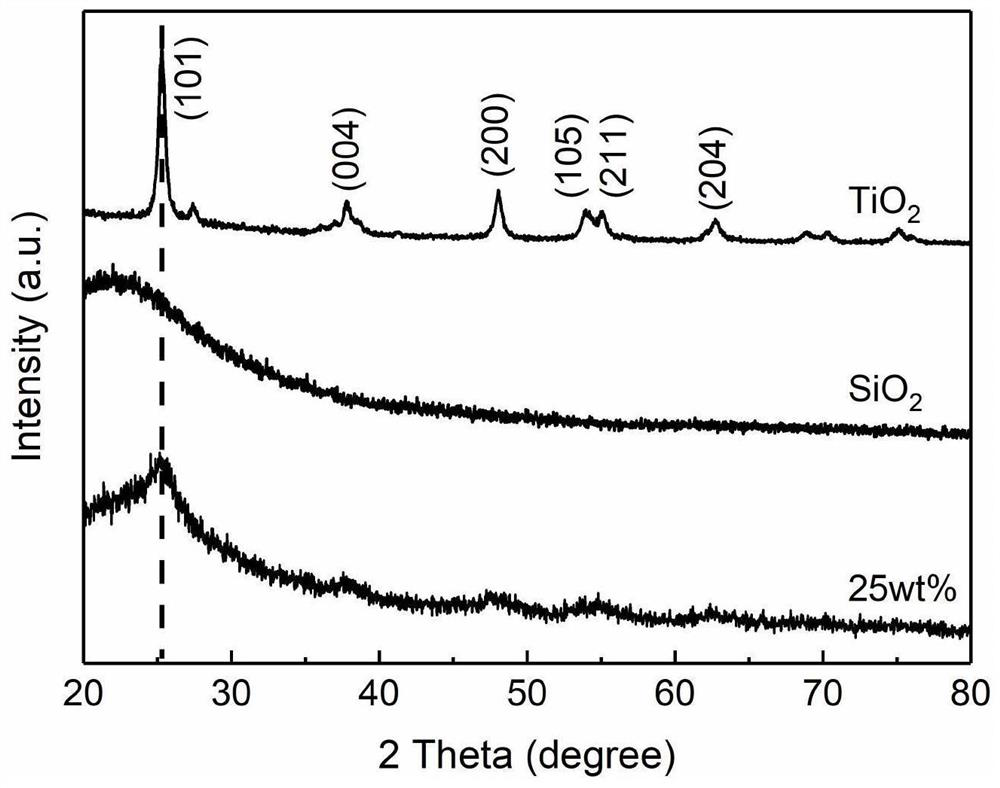

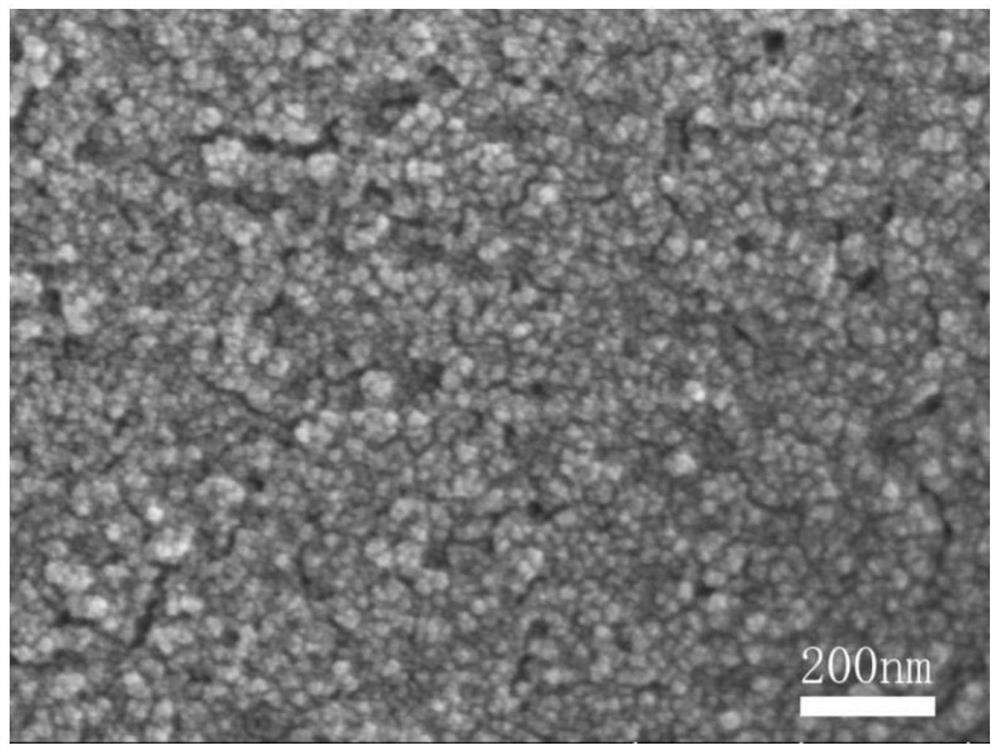

Metal oxide micro-nano structure based on laser direct writing as well as preparation and application thereof

PendingCN112028013AWon't breakSimple processing methodDecorative surface effectsCoupling light guidesNano structuringFemto second laser

Owner:HUAZHONG UNIV OF SCI & TECH

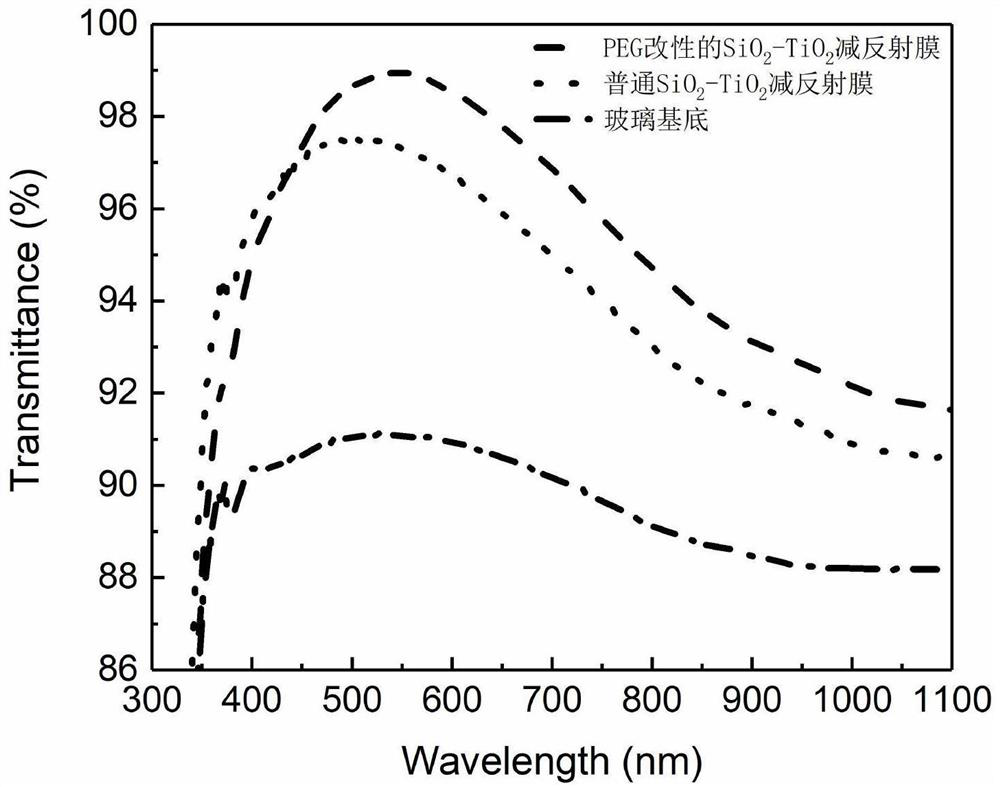

PEG modified SiO2-TiO2 composite self-cleaning antireflection film and preparation method thereof

ActiveCN111718129AHas superhydrophilic propertiesLimited superhydrophilicCoatingsRefractive indexThin membrane

Owner:上海西源新能源技术有限公司

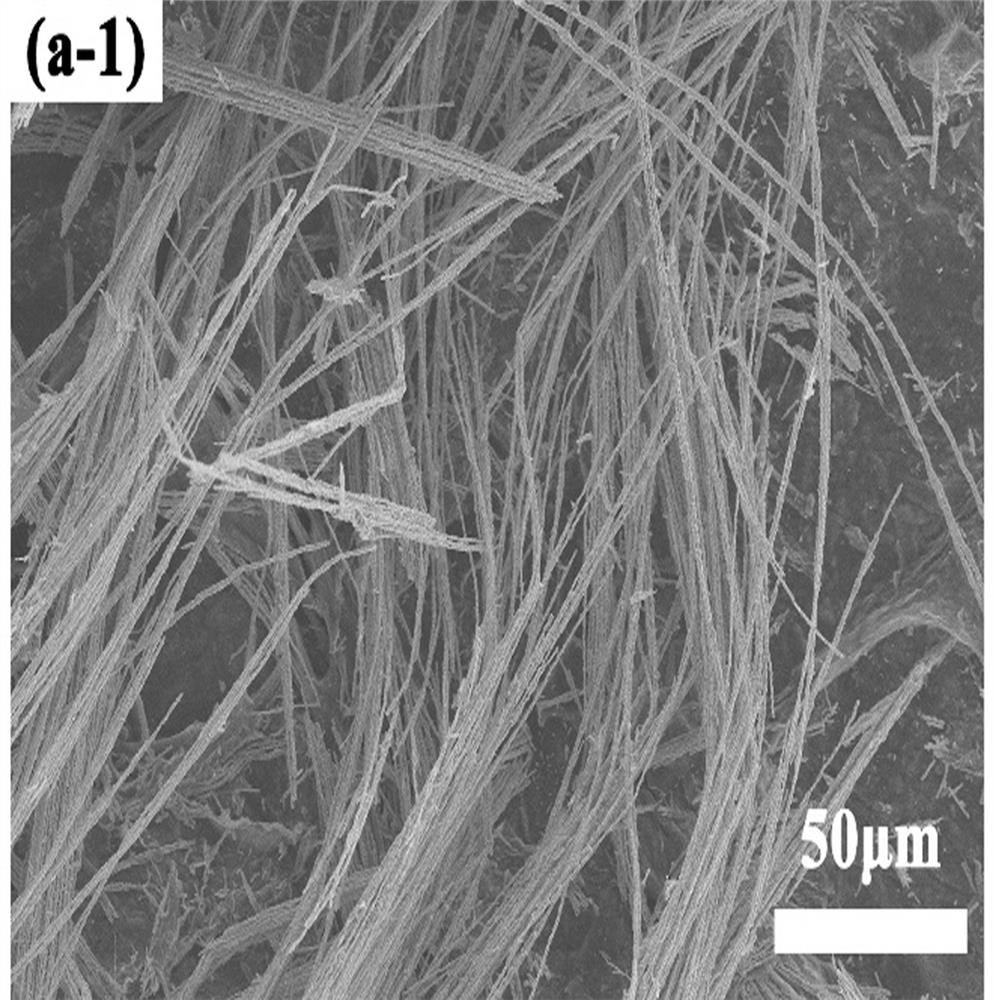

Chitin@MXene@Ni chain thin film material and preparation method and application thereof

PendingCN113817195AEasy to prepareImprove shielding effectMagnetic/electric field screeningThin membraneFilm material

Owner:浙江优可丽新材料有限公司

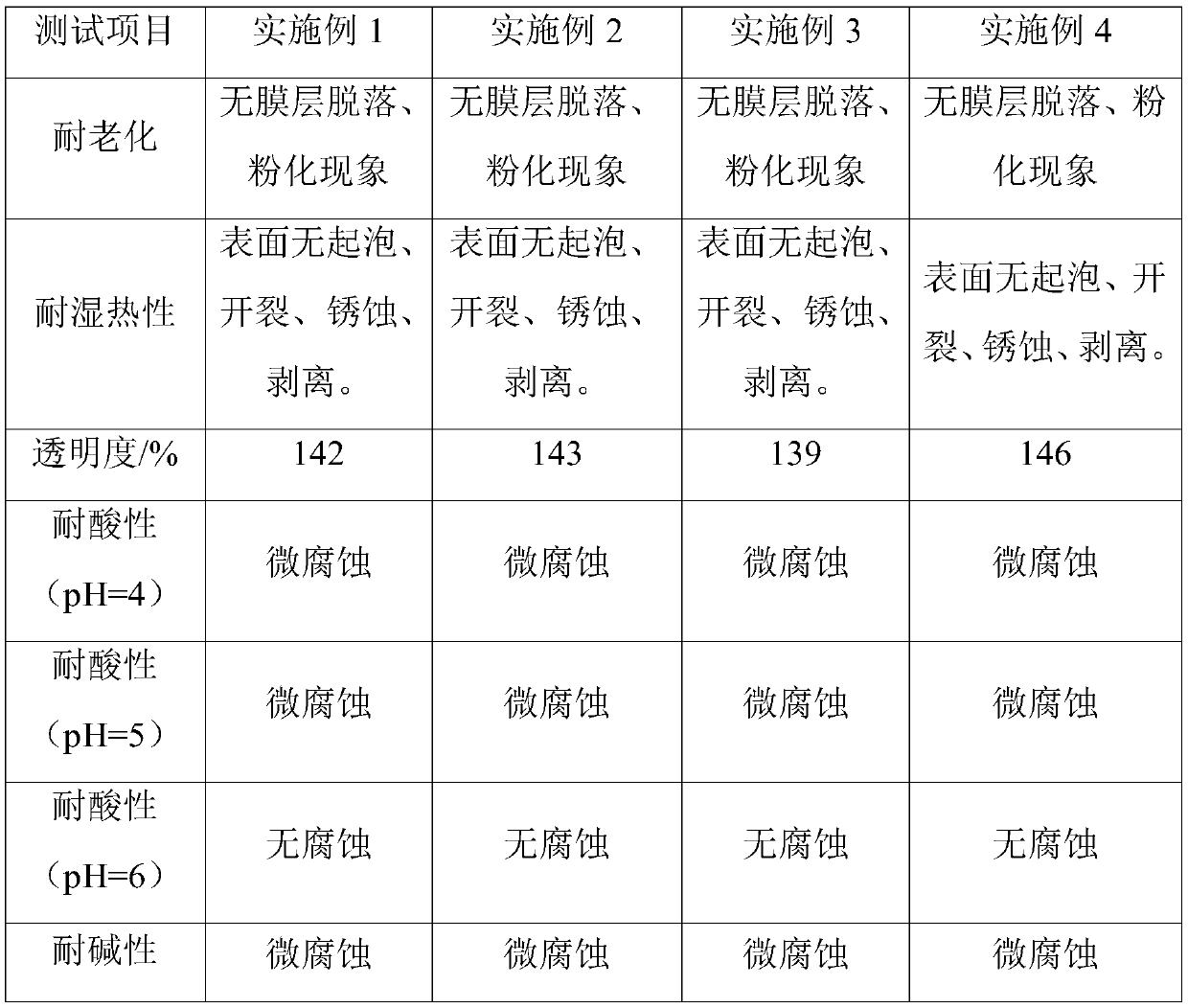

Weather-proof building material film and preparation method thereof

ActiveCN111376560ASynthetic resin layered productsConstructions elementsThin membraneBuilding material

Owner:福建宏翔塑胶有限公司

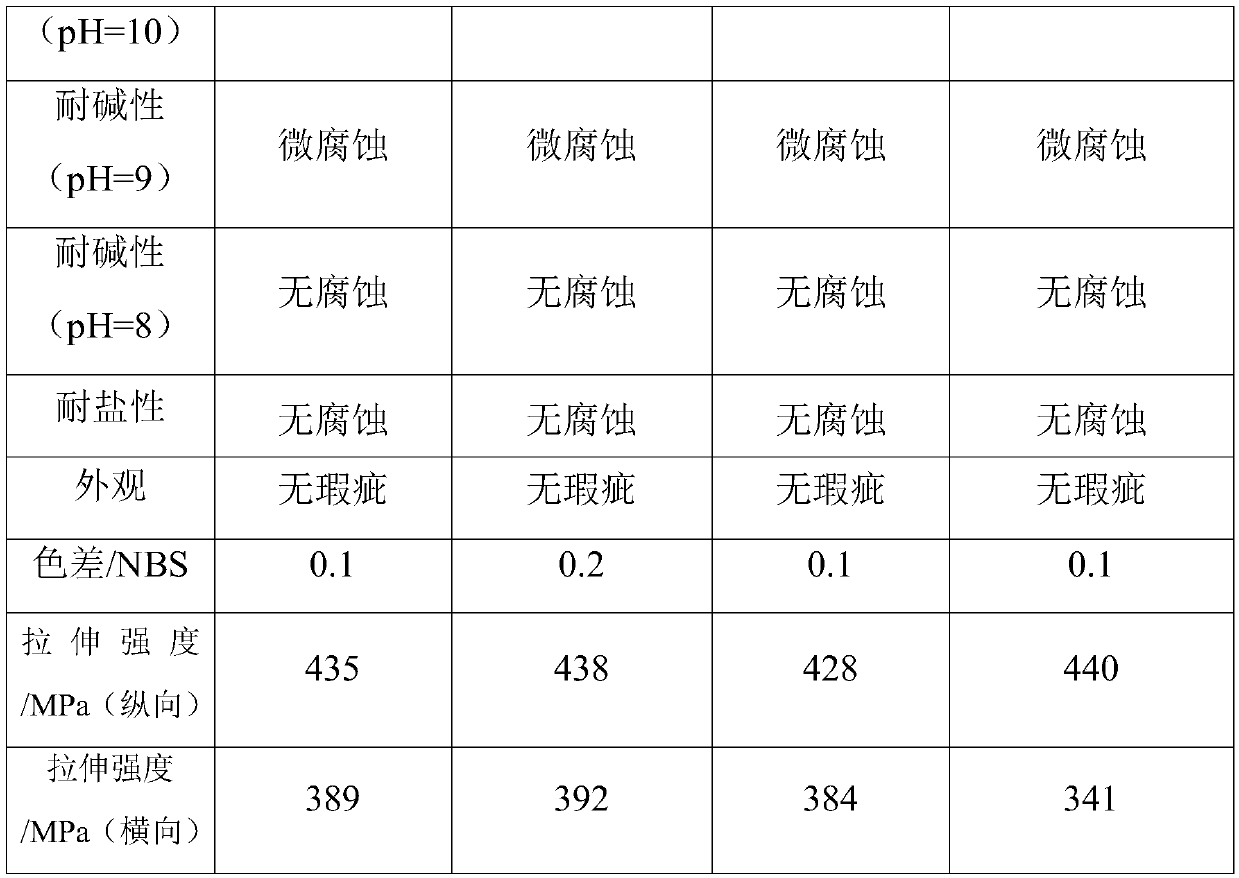

High-temperature-resistant, water-oxygen-resistant and low-infrared-emissivity composite film for ceramic-based composite material and preparation method

ActiveCN113403594AReduce IR emissivityEasy to useVacuum evaporation coatingSputtering coatingComposite filmLow emissivity

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-friction thin film for inner wall of solar panel driving bearing and preparation method of low-friction thin film

ActiveCN114107906AReduce coefficient of frictionExtended service lifeVacuum evaporation coatingSputtering coatingComposite filmThermodynamics

The invention provides a low-friction thin film for the inner wall of a solar panel driving bearing and a preparation method of the low-friction thin film, and relates to the technical field of material thin films. The low-friction thin film is of a multi-layer structure, the bottom layer of the thin film is attached to the surface of the inner wall of the bearing, a Ti layer, a MoS2-Ti / Pb layer, a graphene layer and grooves distributed in the surface of the inner wall of the bearing are sequentially arranged from the inner wall of the bearing to the outside, and the grooves are filled with lubricating materials. The preparation technology is simple, the composite film is of a three-layer structure, the thickness is only 2.5 microns, the good low-friction and high-mechanical-strength effects can be achieved, the roughness of the film is lower than 6 nm, the hardness is higher than 7 Gpa, the friction coefficient is lower than 0.03 in the vacuum 7 * 10 <-4 > Gpa environment, and the composite film can be suitable for various complex external environments and has the wear-resisting and lubricating effects.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap