Method for preparing double-stress thin film

A dual-stress, thin-film technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of plasma damage, increase the difficulty of process control, and the device speed cannot meet the process requirements, so as to solve the loss of yield rate , to avoid the effect of overlapping area problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

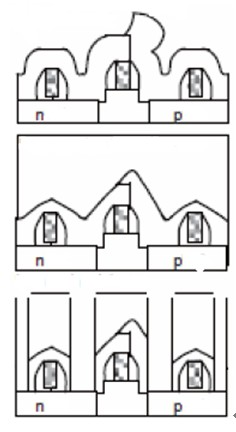

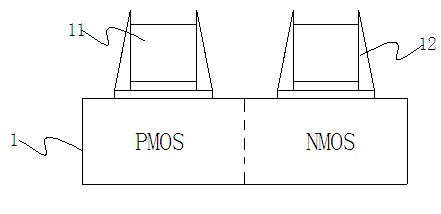

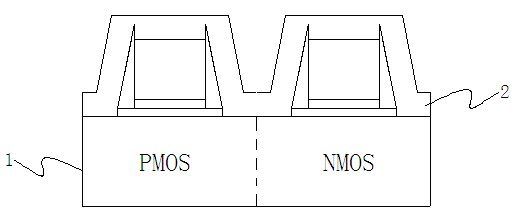

[0019] Figure 2-8 It is a schematic structural diagram of the technological process of the preparation method of a double stress thin film of the present invention.

[0020] like Figure 2-8 As shown, first, nitrogen-doped silicon carbide (Nitrogen Doped Carbide, NDC for short) 2 is deposited on the PMOS and NMOS structures 1 including the gate 11 and sidewalls 12, and the nitrogen-doped silicon carbide film 2 covers the gate 11 and sidewalls 12; after that, spin-coat photoresist to cover the upper surface of the nitrogen-doped silicon carbide film 2, remove the remaining photoresist after exposure and development, and form the first photoresist 3 covering the PMOS structure.

[0021] Then, using the first light source 3 as a mask, an ultraviolet (UV) light irradiation process 4 is performed on the nitrogen-doped carbide film 2, so that the nitrog

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap