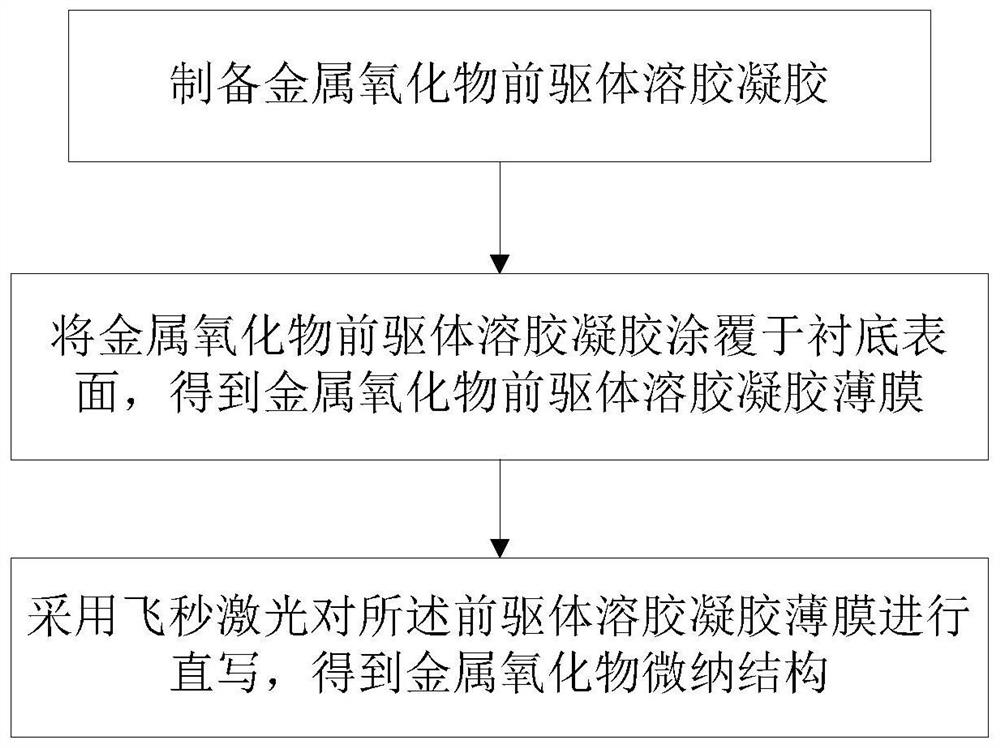

Metal oxide micro-nano structure based on laser direct writing as well as preparation and application thereof

A micro-nano structure and oxide technology, applied in the field of laser applications, can solve the problems of inapplicability to flexible substrates, poor controllability, and low precision, and achieve the effects of simple and efficient integration, high peak power, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

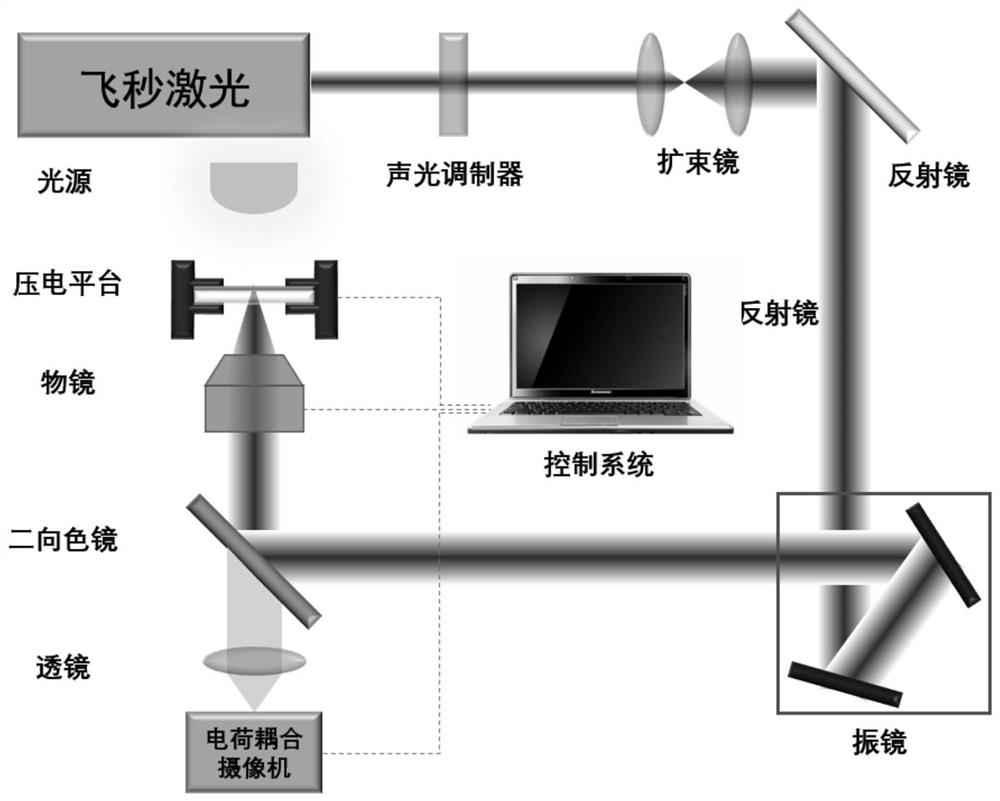

Method used

Image

Examples

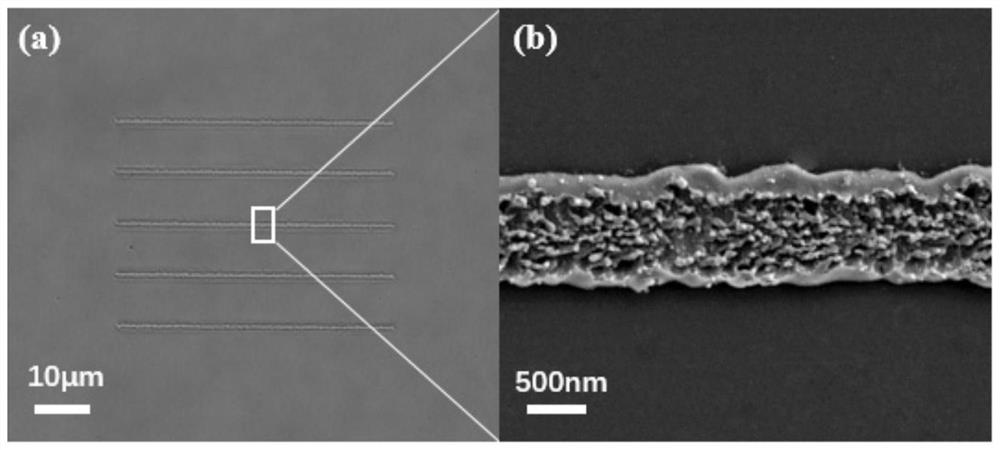

Embodiment 1

[0063] Using tin dioxide sol as a precursor, using a femtosecond laser to directly write tin dioxide micro-wire structures, the steps are as follows:

[0064] 1. Dissolve 8.37g of stannous chloride dihydrate powder in 75mL of absolute ethanol, heat to about 78°C and reflux for 3 hours;

[0065] 2. Heat and stir the above solution in the air to evaporate to 50mL to control the SnCl 2 The concentration is 0.74mol / L, and then placed in a constant temperature water bath at 30°C for 24 hours, at this time the solution turns light yellow, and the sol-gel preparation is complete;

[0066] 3. Clean the glass slides ultrasonically with ethanol and deionized water, then set the parameters of the homogenizer to 1000r / min, 5s and 2000r / min, 30s, and use the homogenizer to spin-coat the stannous chloride sol on the glass slides , to obtain a sol-gel film with a thickness of 4 microns;

[0067] 4. Place the sample on the optical table, find the sample under the low magnification object

Embodiment 2

[0073] Femtosecond laser direct writing experiments were carried out using tin dioxide sol as a precursor, and the morphology was improved by adding polyethylene glycol (Mn 400). The steps are as follows:

[0074] 1. Dissolve 8.37g of stannous chloride dihydrate powder in 75mL of absolute ethanol, heat to about 78°C and reflux for 3 hours;

[0075] 2. Heat and stir the above solution in the air to evaporate to 50mL to control the SnCl 2The concentration is 0.74mol / L, and then placed in a constant temperature water bath at 30°C for 24 hours of static aging. At this time, the solution turns light yellow, and then 0.5g polyethylene glycol (Mn400) is added, stirred for 5 hours, and the sol-gel Preparation completed;

[0076] 3. Clean the glass slides ultrasonically with ethanol and deionized water, then set the parameters of the homogenizer to 1000r / min, 5s and 2000r / min, 30s, and use the homogenizer to spin-coat the stannous chloride sol on the glass slides , to obtain a sol

Embodiment 3

[0081] Using tin dioxide sol as a precursor, draw graphics through CAD, use femtosecond laser to directly write tin dioxide micro-nano structures, and control the shape and arrangement of micro-nano structures. The steps are as follows:

[0082] 1. Use CAD to design spiral lines and letter structure patterns;

[0083] 2. Dissolve 8.37g of stannous chloride dihydrate powder in 75mL of absolute ethanol, heat to about 78°C and then reflux and stir for 3 hours;

[0084] 3. Heat and stir the above solution in the air to evaporate to 50mL, control the SnCl 2 The concentration is 0.74mol / L, and then placed in a constant temperature water bath at 30°C for 24 hours of static aging. At this time, the solution turns light yellow, then add 0.5g polyethylene glycol (Mn400), stir for 5 hours, and the sol is prepared ;

[0085] 4. Use ethanol and deionized water to ultrasonically clean the glass slides, and then use a homogenizer to spin-coat the sol onto the glass slides at a speed of 2000

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap