Optical cable with new structure and production method thereof

A new structure, optical cable technology, applied in fiber mechanical structure, light guide, optics, etc., can solve the problem of loose tube deformation, achieve the effect of improving performance, improving mechanical stretching and high and low temperature shrinkage performance, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

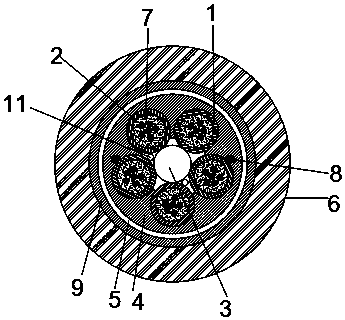

[0032] Such as figure 1 As shown, the present embodiment provides a new structural optical cable, including a loose tube 1, an optical fiber 2, a strength member 3, a PP film 4, a water blocking layer 5 and an outer sheath 6, and the strength member 3 is located at the center of the optical cable , five loose tubes 1 surround the reinforcement 3, the water blocking cable paste 10 is filled between the loose tube 1 and the reinforcement 3, six optical fibers 2 are embedded in the loose tube 1, and the loose tube 1 is filled with The fiber paste 7, the fiber paste 7 wraps the optical fiber 2, and the fiber paste or 7 can seal and waterproof, resist stress and buffer, protect the optical fiber 2, improve the stability of the transmission performance of the optical fiber 2 and the service life of the optical cable.

[0033] In this implementation, the fiber paste can also be replaced by other water-blocking materials.

[0034] The periphery of the five loose tubes 1 is wrapped with

Embodiment 2

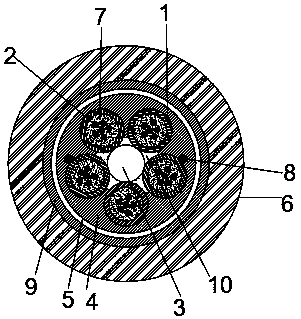

[0050] Such as figure 2 As shown, a new structure optical cable of this embodiment, the structure and production method are basically the same as the embodiment, the difference is that a water blocking yarn 11 is arranged between the loose tube 1 and the reinforcing member 3, and the water blocking yarn 11 is provided with two, and one is vertically arranged, and the other is wrapped around and arranged.

[0051] The water-blocking layer on the periphery of the cable core also uses water-blocking yarn 11 to replace the water-blocking cable paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap