Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157 results about "Silicon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon is a chemical element with the symbol Si and atomic number 14. It is a hard and brittle crystalline solid with a blue-grey metallic lustre; and it is a tetravalent metalloid and semiconductor. It is a member of group 14 in the periodic table: carbon is above it; and germanium, tin, and lead are below it. It is relatively unreactive. Because of its high chemical affinity for oxygen, it was not until 1823 that Jöns Jakob Berzelius was first able to prepare it and characterize it in pure form. Its melting and boiling points of 1414 °C and 3265 °C respectively are the second-highest among all the metalloids and nonmetals, being only surpassed by boron. Silicon is the eighth most common element in the universe by mass, but very rarely occurs as the pure element in the Earth's crust. It is most widely distributed in dusts, sands, planetoids, and planets as various forms of silicon dioxide (silica) or silicates. More than 90% of the Earth's crust is composed of silicate minerals, making silicon the second most abundant element in the Earth's crust (about 28% by mass) after oxygen.

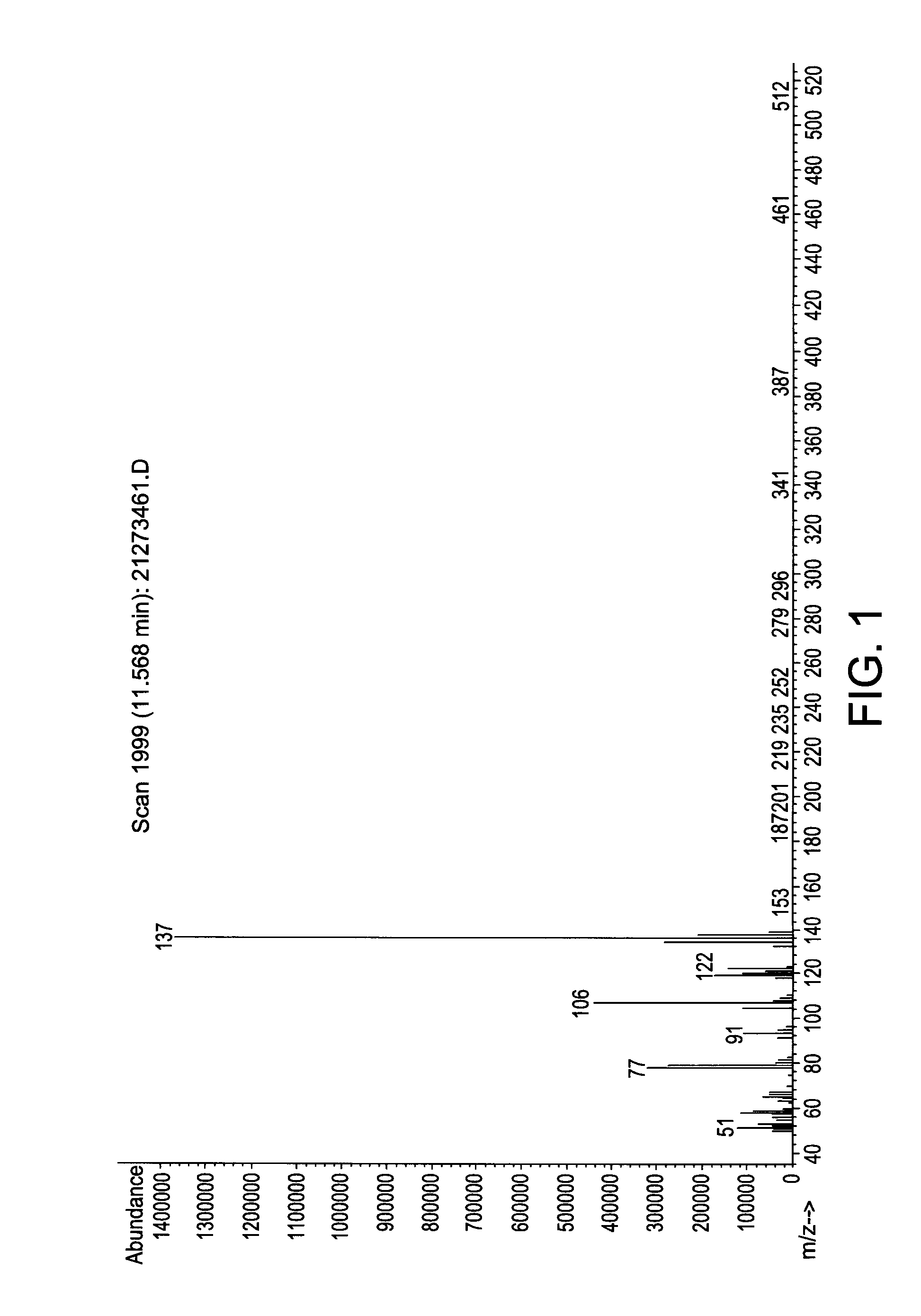

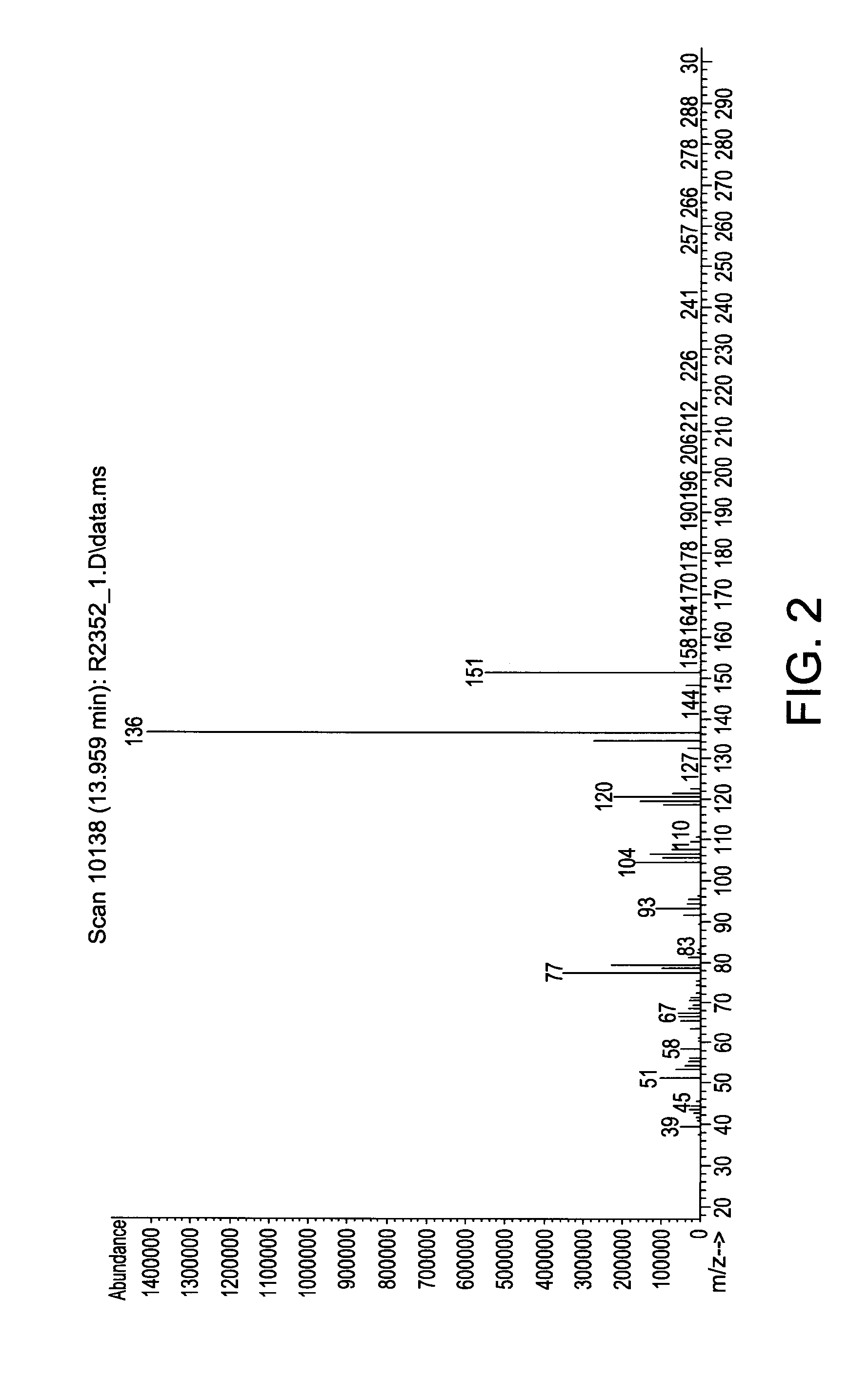

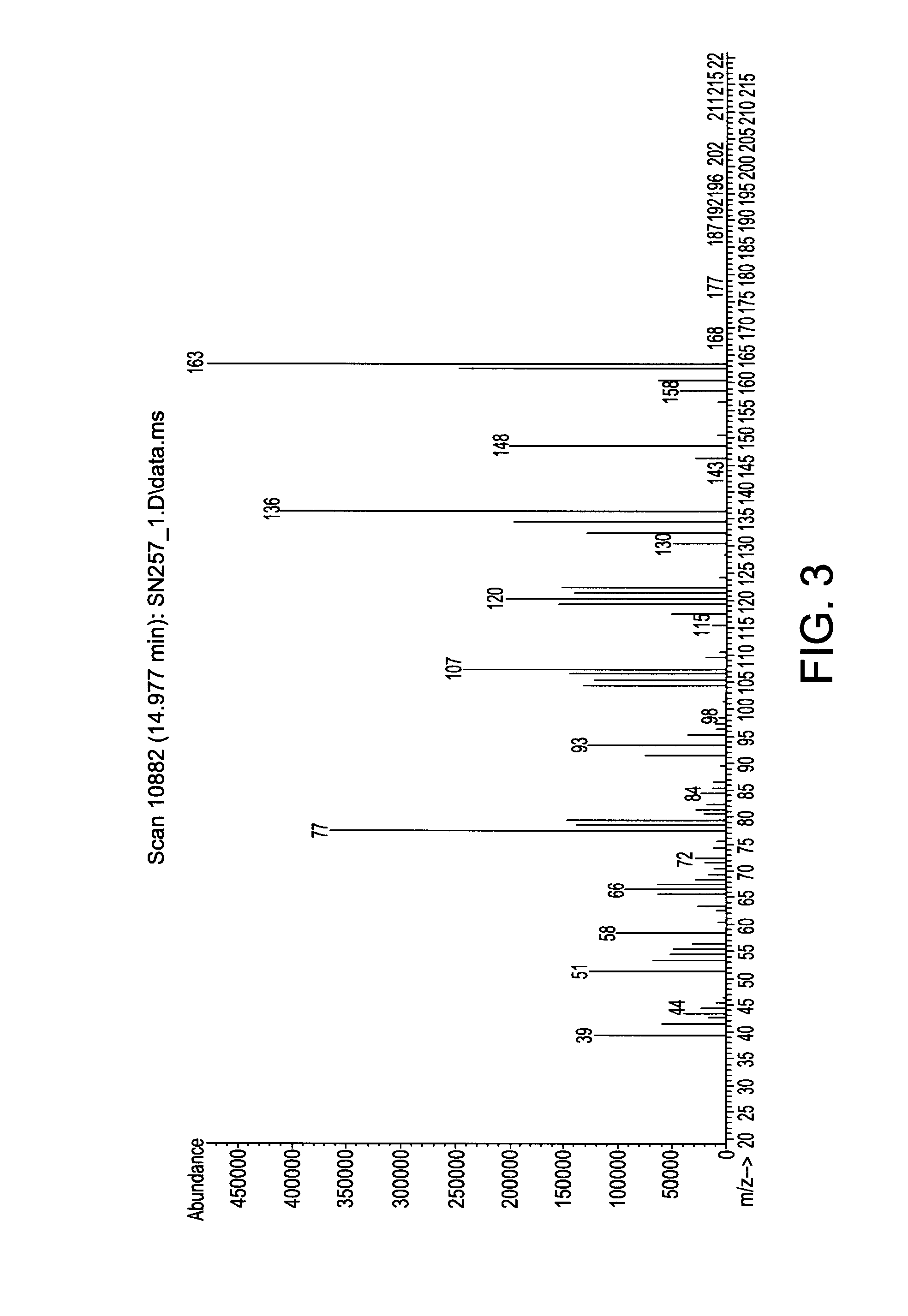

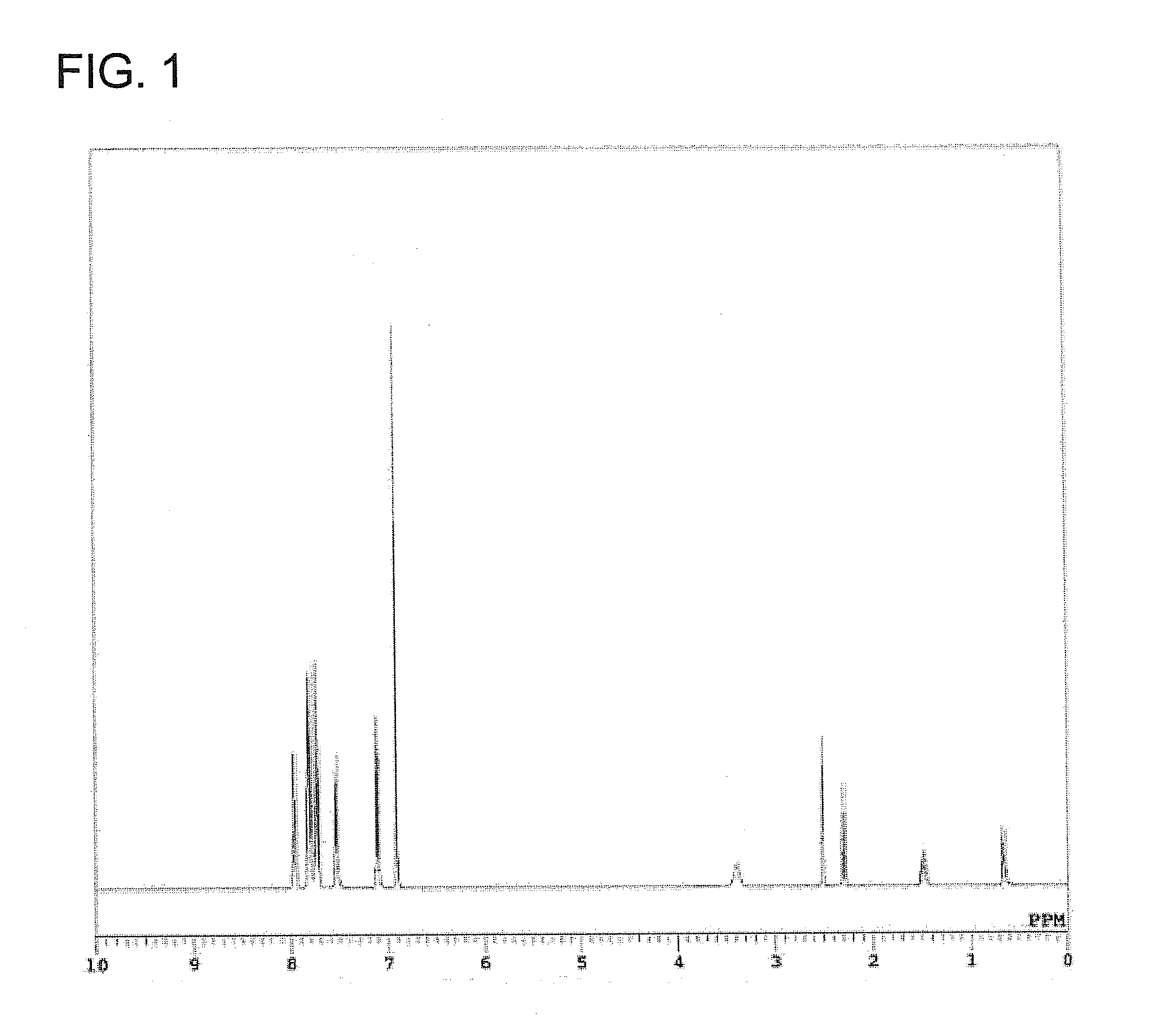

Organoaminosilane Precursors and Methods for Depositing Films Comprising Same

Owner:VERSUM MATERIALS US LLC

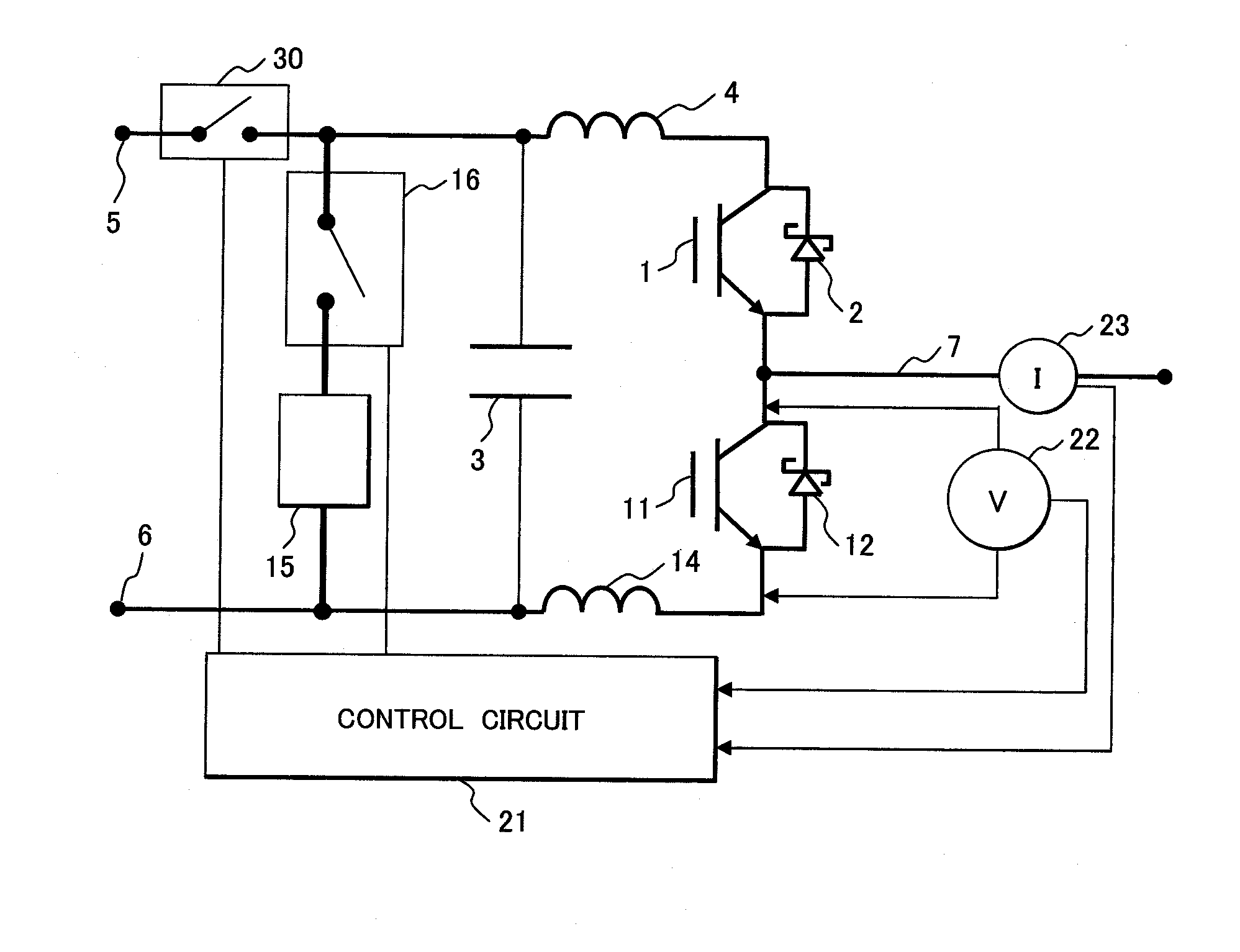

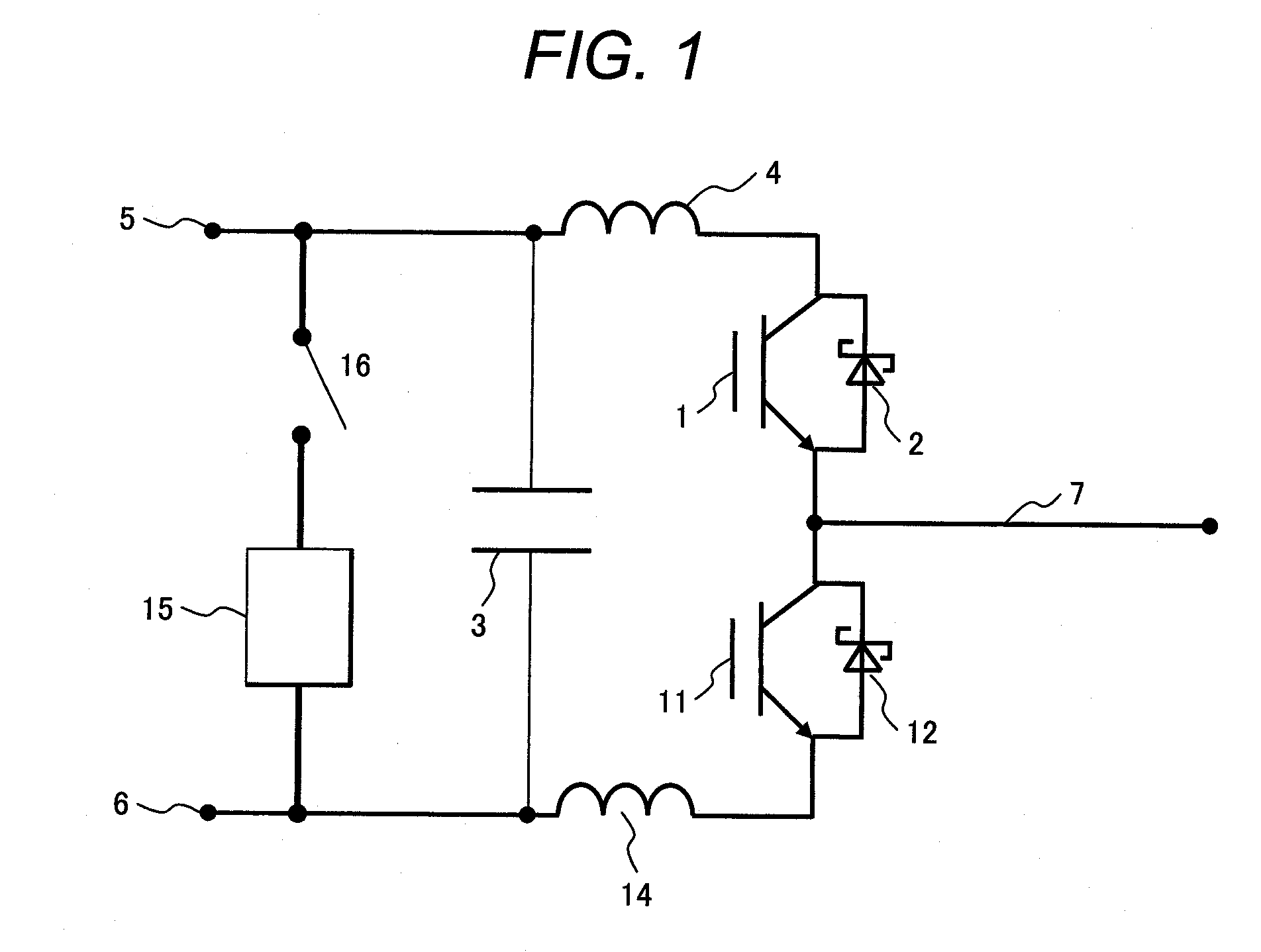

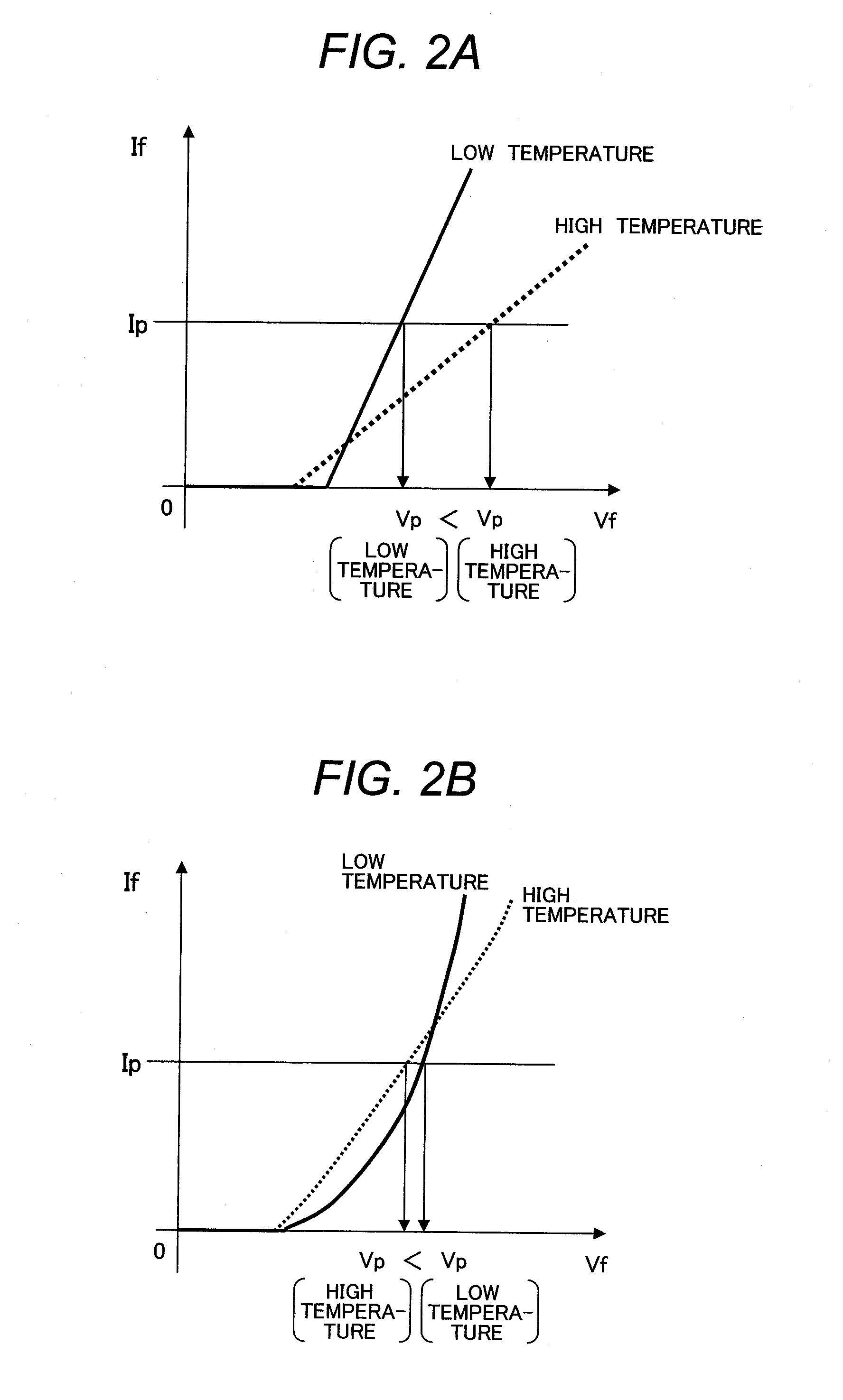

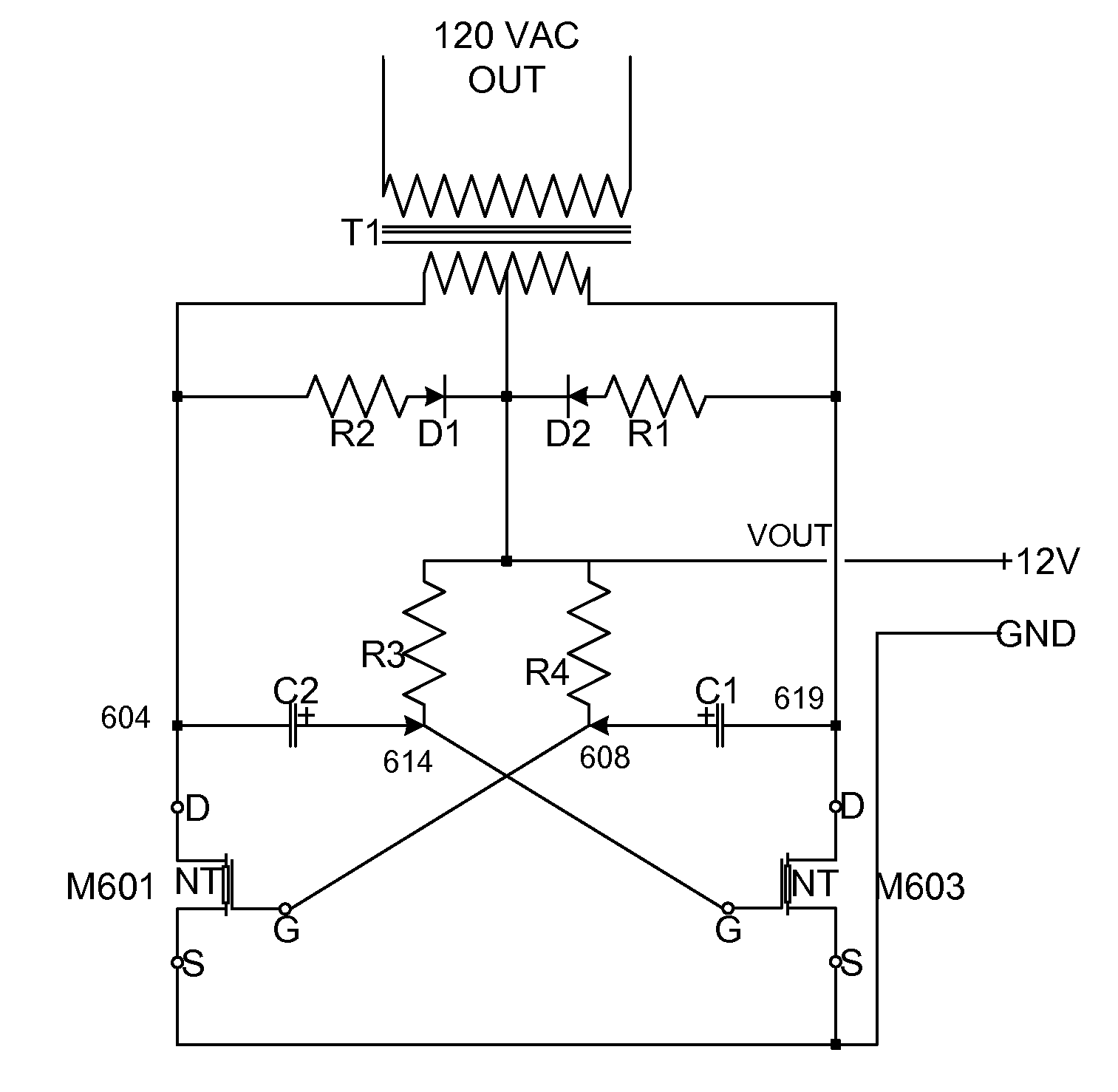

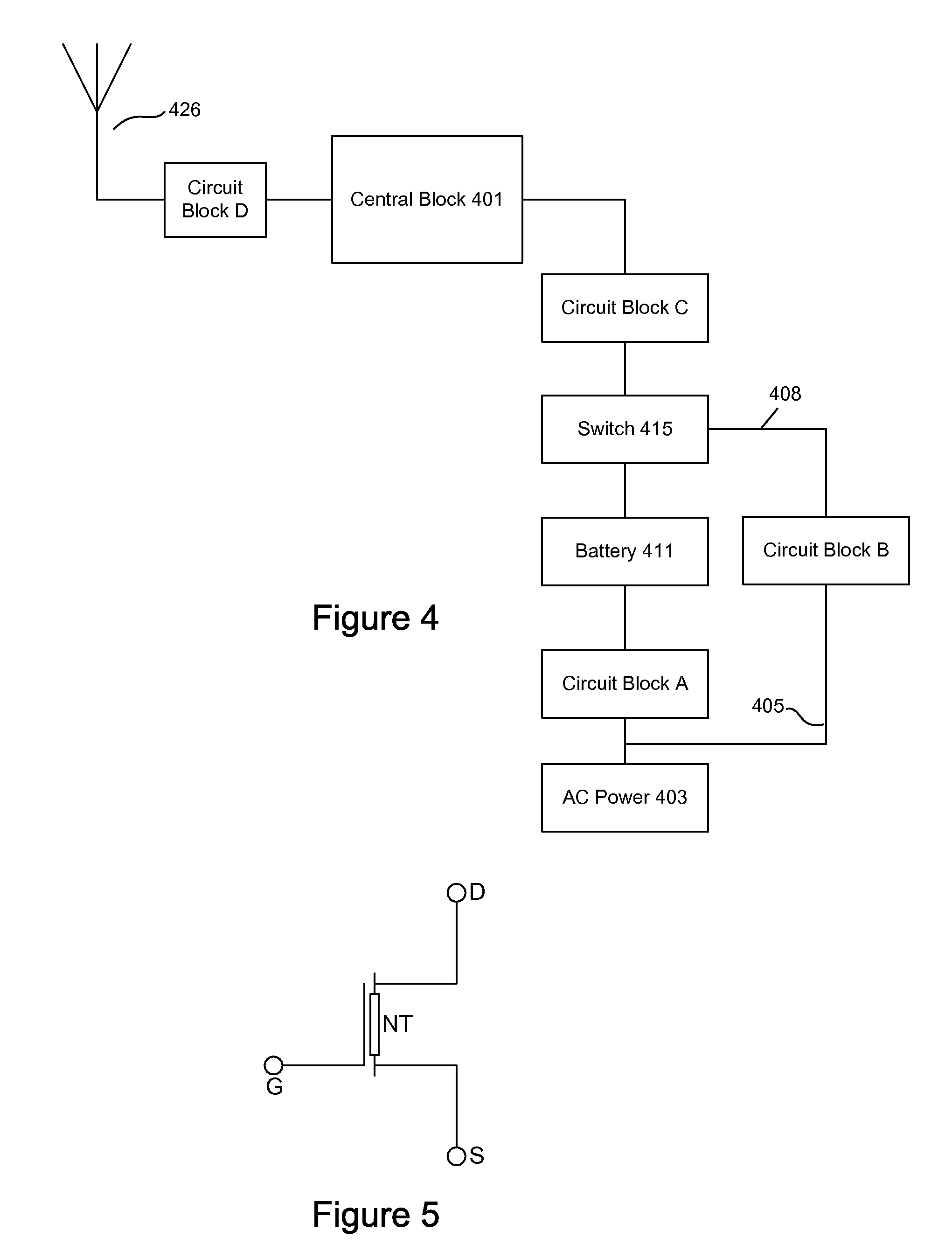

Power converter for traction control and transportation system

InactiveUS20100327837A1Simple circuitEasy temperatureSolid-state devicesAc-dc conversionVoltage dropSilicon

Owner:HITACHI LTD

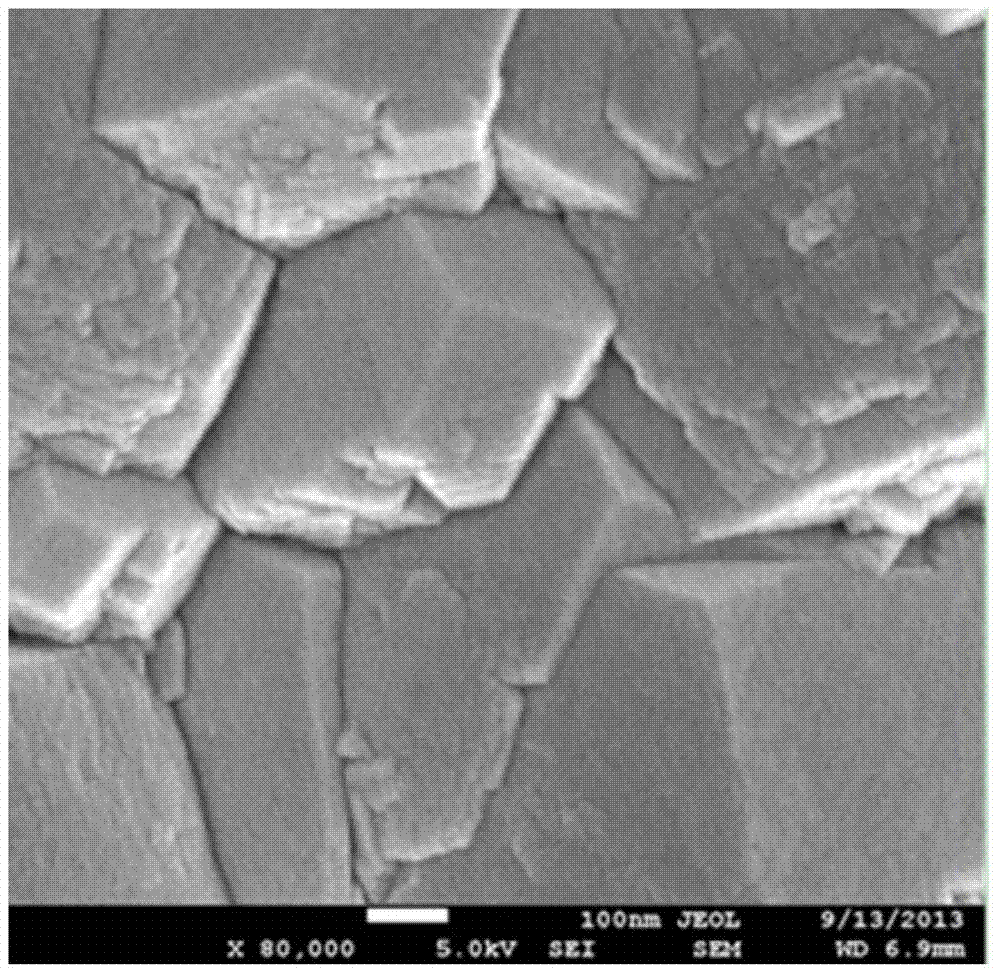

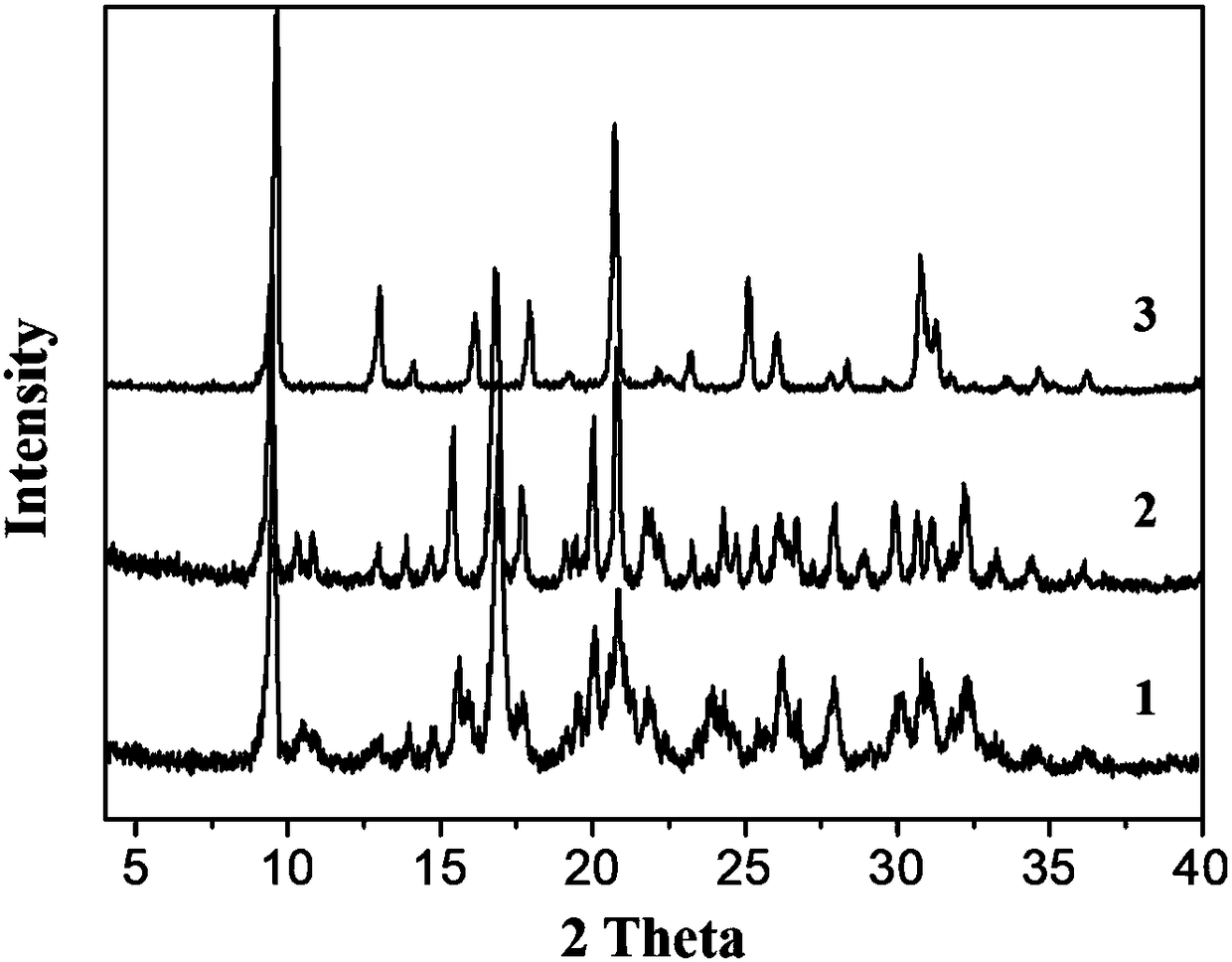

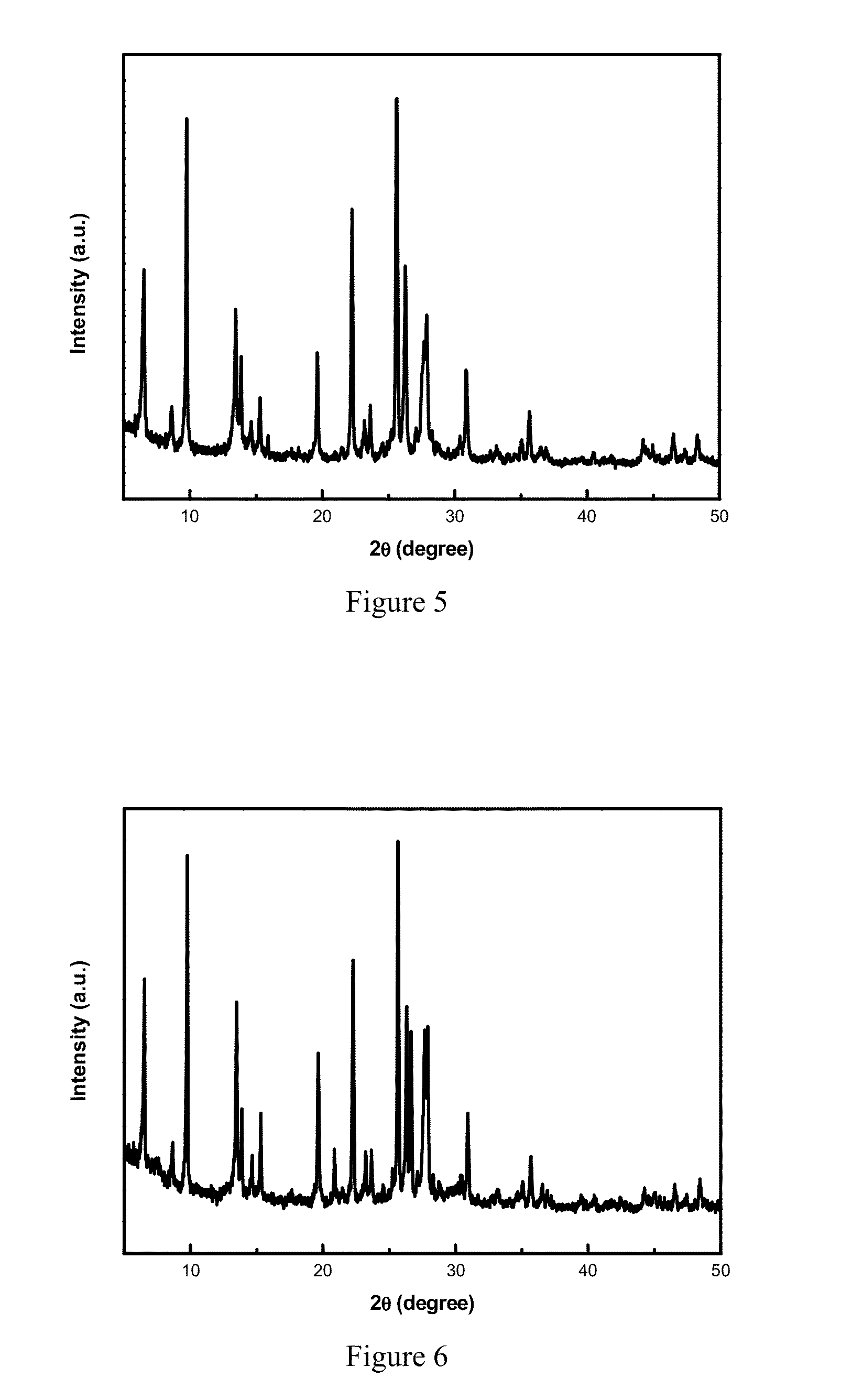

A kind of preparation method of chabazite and chabazite membrane

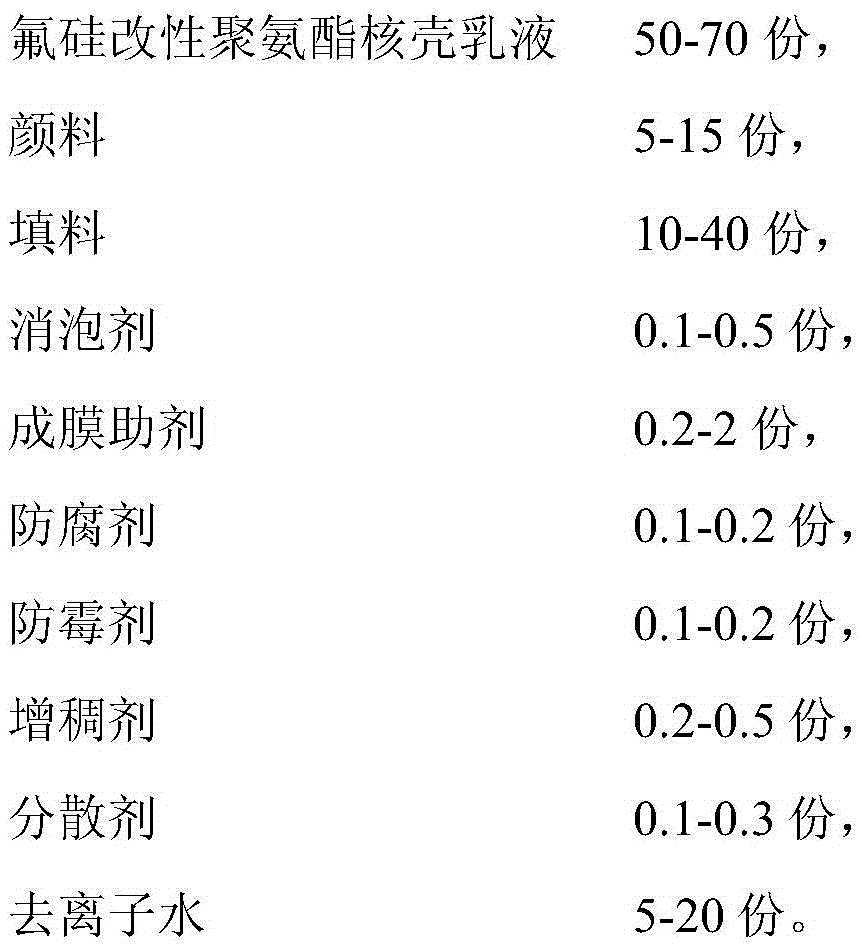

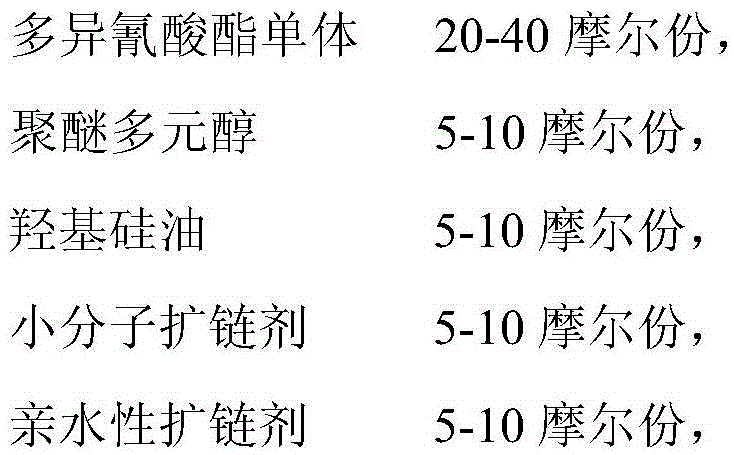

The invention provides a method for preparing chabazite and a chabazite film in the absence of a template agent. Pure chabazite is formed through induction of out-of-phase crystal nucleus T-shaped zeolite under the condition of not adding an organic template agent. The chabazite molecular sieve film is formed through induction by loading formed chabazite on the outer surface of a porous support as a crystal seed. The method is characterized in that: silicon powder and sodium metaaluminate are used as a silicon source and an aluminum source; based on the molar ratio of oxides, the ratios of components which are prepared into sol are that: the molar ratio of SiO2 to Al2O3 is equal to 15-30, the molar ratio of OH<-> to SiO2 is equal to 0.9-1.5, the molar ratio of Na<+> to K<+> is equal to 0.1-1, and the molar ratio of H2O to SiO2 is equal to 18-40; the sol for coating the crystal seed is subjected to hydrothermal synthesis at the temperature of 100-160 DEG C for 16-72 hours; and a compact chabazite film is synthesized on a porous carrier. Through the method for preparing the chabazite and the chabazite film, the expensive organic template agent is prevented from being added, the synthesis process is simple, and the repeatability is high. The synthesized film shows better stability in an inspection acid medium and can be widely applied to a pervaporation separation process and a pervaporation film reactor of an acidic system.

Owner:JIANGXI NORMAL UNIV

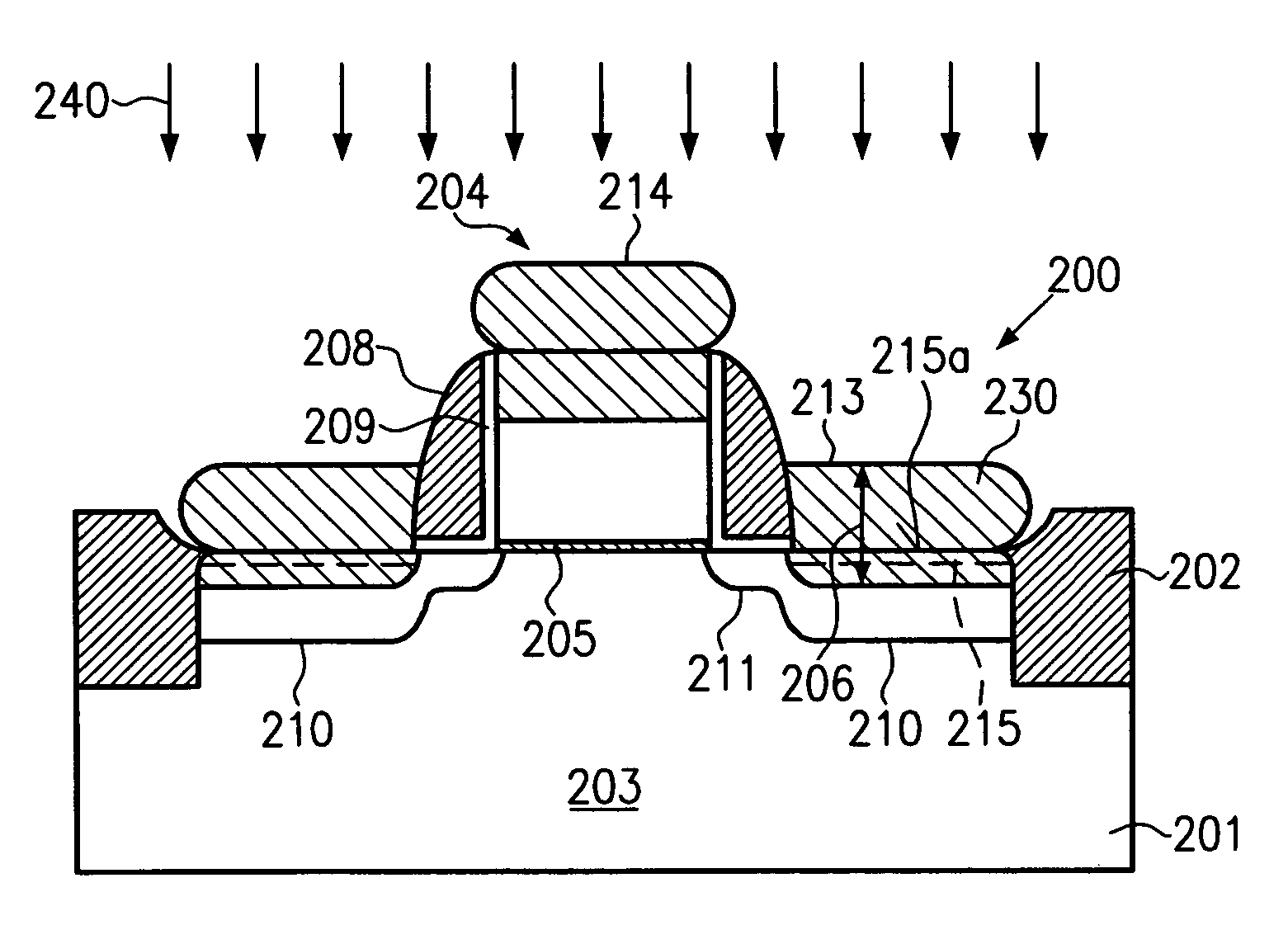

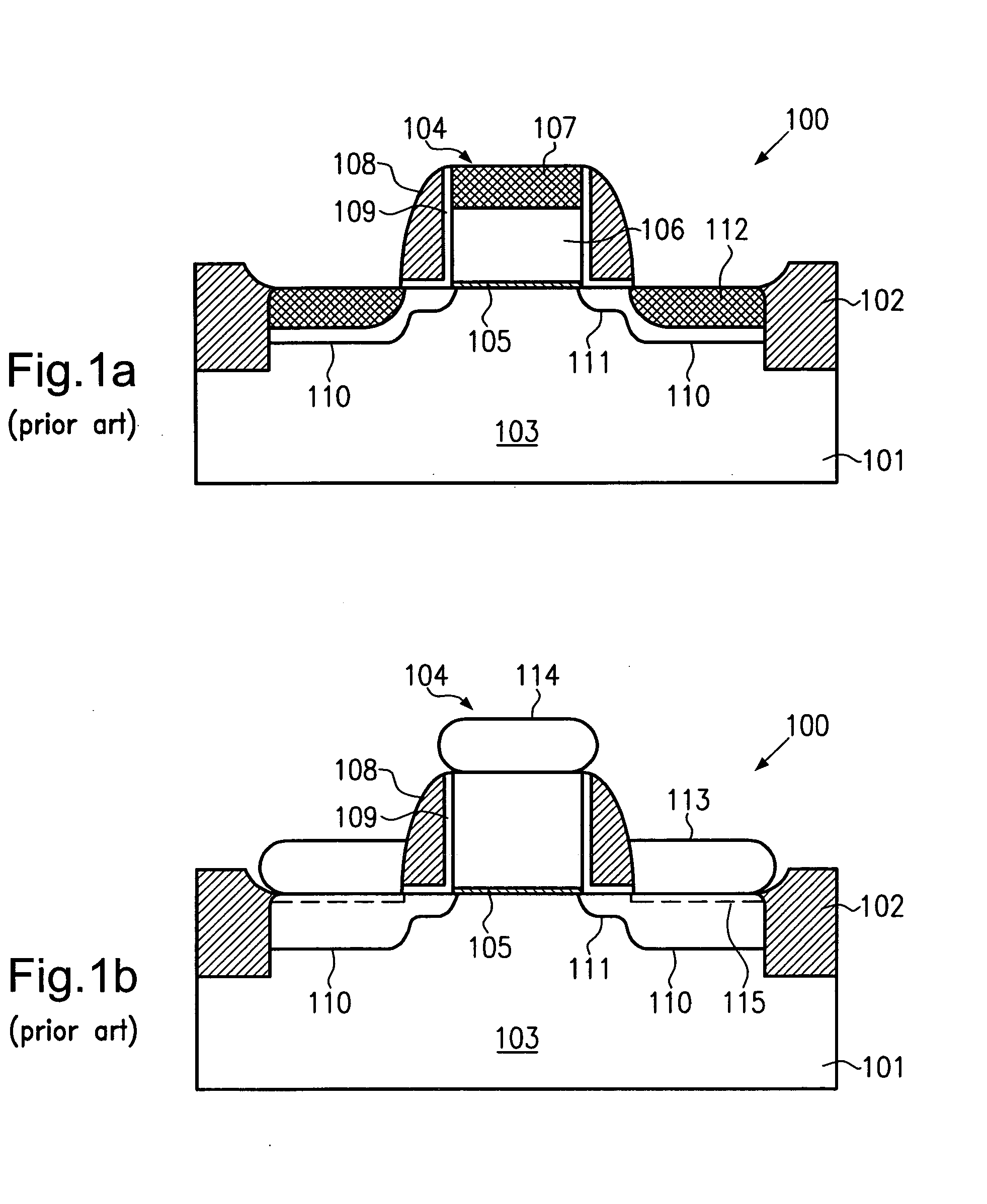

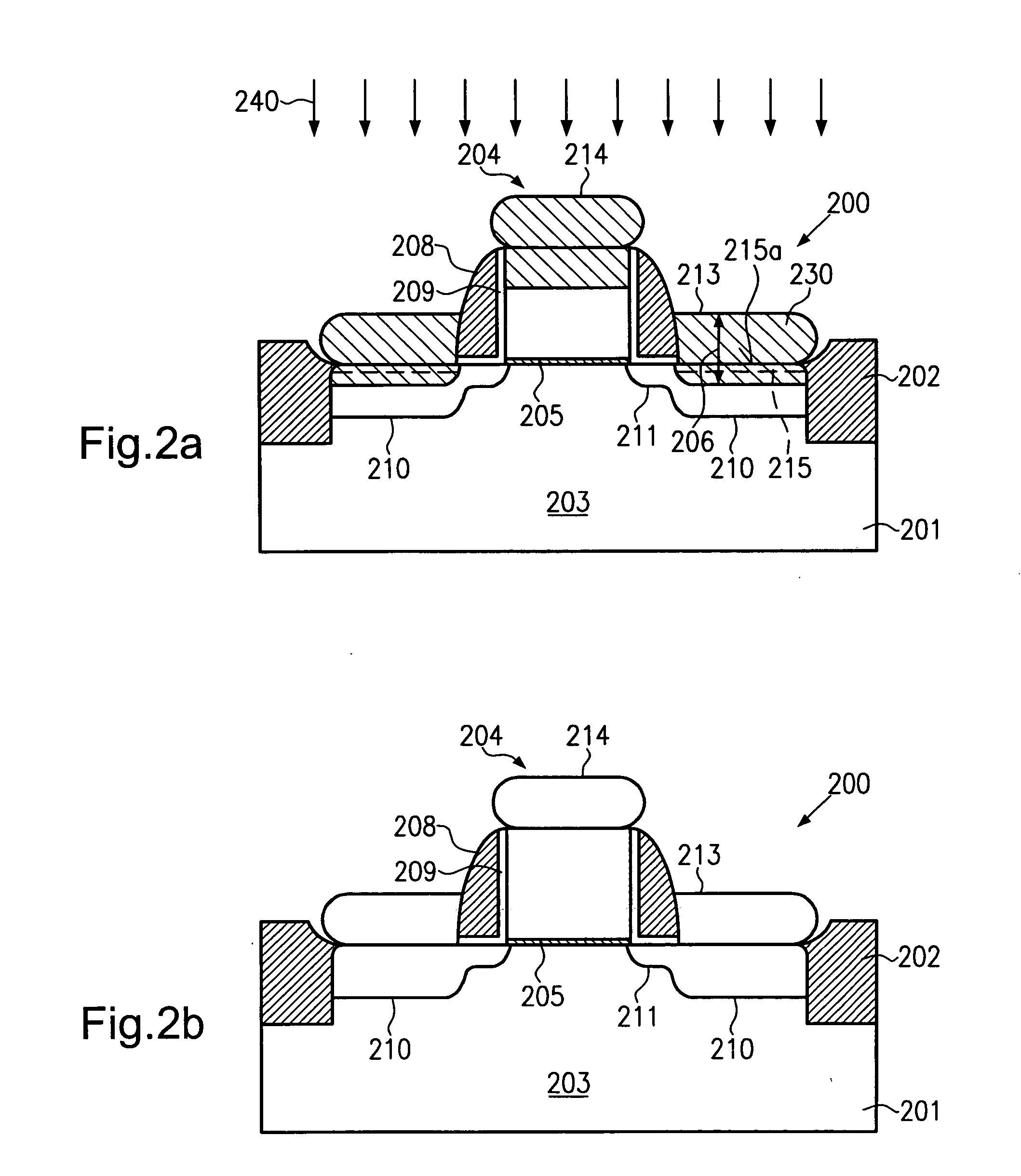

Method of forming an epitaxial layer for raised drain and source regions by removing surface defects of the initial crystal surface

ActiveUS20060003533A1Semiconductor/solid-state device manufacturingSemiconductor devicesDopantCharge carrier

Owner:TAIWAN SEMICON MFG CO LTD

High Density Nanotube Devices

InactiveUS20080272361A1Improve device densityHigh densitySemiconductor/solid-state device detailsSolid-state devicesHigh densityNanowire

Owner:ETAMOTA CORP

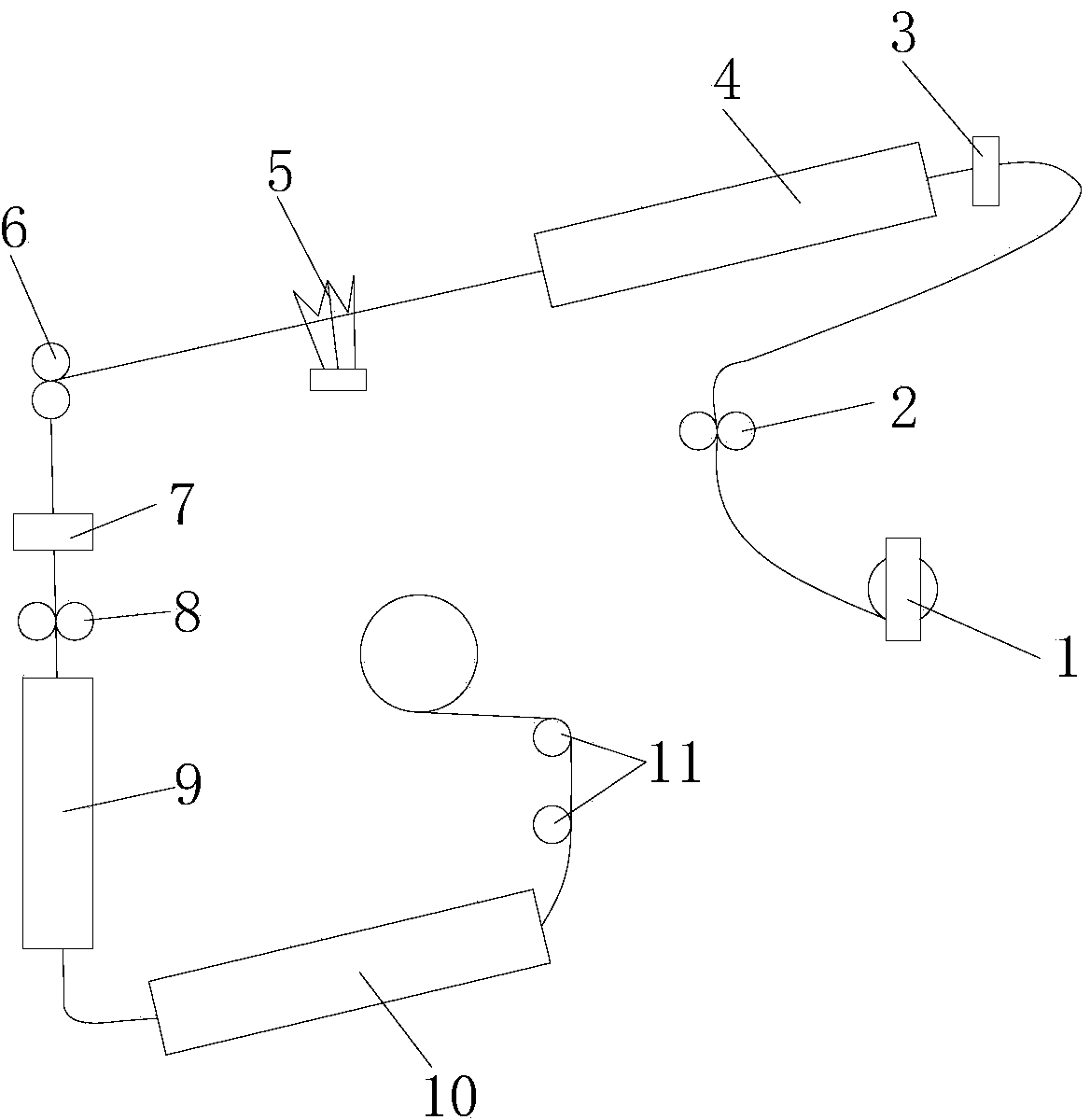

Processing technology for super-imitated-cotton/fine-denier damp conduction polyester comfortable mercerized velvet warp knitting fabric

ActiveCN103859664AEasy to takeGood flexibilitySucessive textile treatmentsWarp knittingHeat resistanceEngineering

Owner:ZHEJIANG QINGSONG TEXTILE

Method for preparing silicon carbide ceramic material with low residual silicon by adopting multi-step reaction sintering method

ActiveCN106478105ASolve the mechanical propertiesSolving Elasticity ProblemsHeat conductingYoung's modulus

Owner:咸阳瞪羚谷新材料科技有限公司

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

Castable for blast-furnace tapping channel and preparation method thereof

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

Integrally Molded Body of Silicone Resin and Silicone Rubber, Method of Manufacture, and Curable Silicone Resin Composition

Owner:DOW CORNING TORAY CO LTD

Silver nano lattice surface enhanced raman active substrate and preparation method thereof

InactiveCN102590179AUniform shapeOptimal Control StructureRaman scatteringNanotechnologyNanodotSingle crystal

The invention discloses a silver nano lattice surface enhanced raman active substrate and a preparation method thereof. According to the substrate, silicon single crystal is used as an underlay; a silver nanoparticle array structure is deposited on the silicon surface; the particle size of the silver nanoparticles is 30-90 nm; and the center distance of the particles is 99-111 nm. The silver nano lattice surface enhanced raman active substrate provided by the invention has a uniform shape and a controllable structure, and has an obvious surface raman enhancement effect on analytes of different concentrations, and an enhancement signal is uniform and stable. According to the method, the structural parameters and the shape of a silver nano lattice can be adjusted according to structural parameters of an ultra-thin aluminum oxide template, so that different influences of different metal nano lattice substrates on a raman surface enhancement effect are realized. The substrate and the method have the advantages of easiness for operation, low cost and easiness for industrial production.

Owner:SHANGHAI UNIV

Multistage porous ZSM-5 molecular sieve and preparation method thereof as well as method for preparing PX catalyst using same

ActiveCN108178164AReduce economic costsThe synthesis process is simpleMolecular sieve catalystsMolecular sieve catalystMolecular sievePolyol

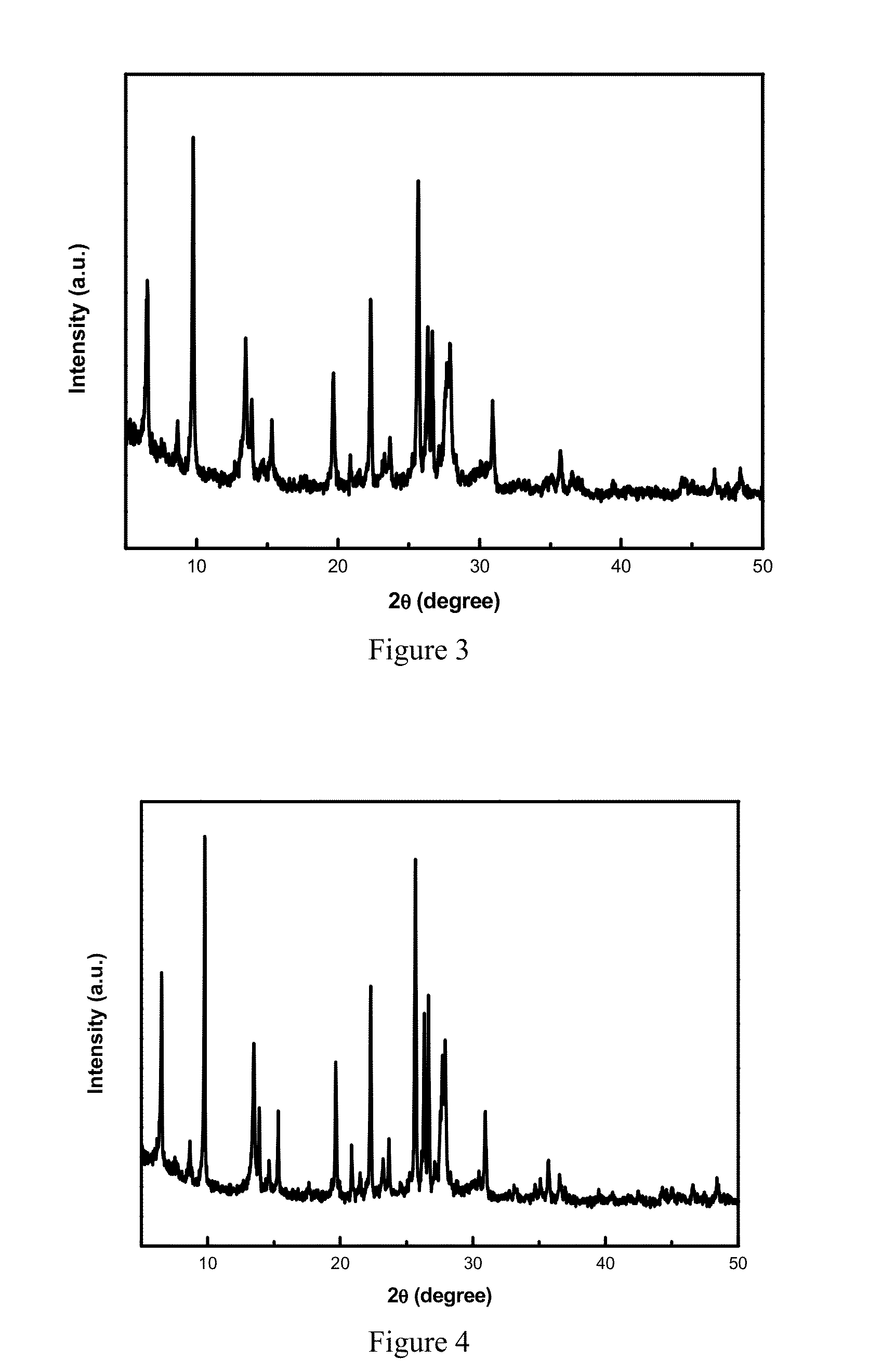

The invention relates to a multistage porous ZSM-5 molecular sieve. The molecular sieve comprises the following raw materials: a silicon source, an aluminum source, a template agent, water, an alkalisource, polyether polyol, a seed crystal, a cosolvent and a mineralizer. The invention provides a preparation method of the multistage porous ZSM-5 molecular sieve with a high silicon-aluminum ratio.The synthesis process is simple, and cheap template agent and porous agent are adopted, so that the economic cost of the molecular sieve is reduced. The ZSM-5 molecular sieve obtained by the method has a multistage pore channel structure, the relative crystallinity is higher than 90%, and the specific surface area is greater than 420m<2> / g.

Owner:REZEL CATALYSTS CORP

Small pore diameter silicone rubber sponge and preparation method thereof

The invention discloses small pore diameter silicone rubber sponge and a preparation method thereof and relates to the field of processing of high polymer materials. The small pore diameter silicone rubber sponge comprises the following components in parts by weight: a component A: 100 parts of liquid organic silicone rubber; a component B: 3-8 parts of hydrogen-containing silicone oil; a component C: 0.5-10 parts of an emulsifier; a component D: 2-4 parts of a catalyst; a component E: 1-2 parts of an inhibitor; and a component F: 0-35 parts of a silicon resin. An emulsion dispersion mode is adopted, the dispersion phase size is small, and the silicone rubber sponge prepared by the method has the characteristics of bubble dispersion uniformity, small pore diameter and controllable density; and moreover, water serves as a foaming agent, and the sponge has the advantage of environment friendliness. The silicone rubber sponge material prepared by the method can serve as shock absorption, insulating, sound insulation and heat insulation materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Preparation method of porous diamond film

ActiveCN104498894AImprove hydrophilicityIncrease contentChemical vapor deposition coatingAir atmosphereMicrowave

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

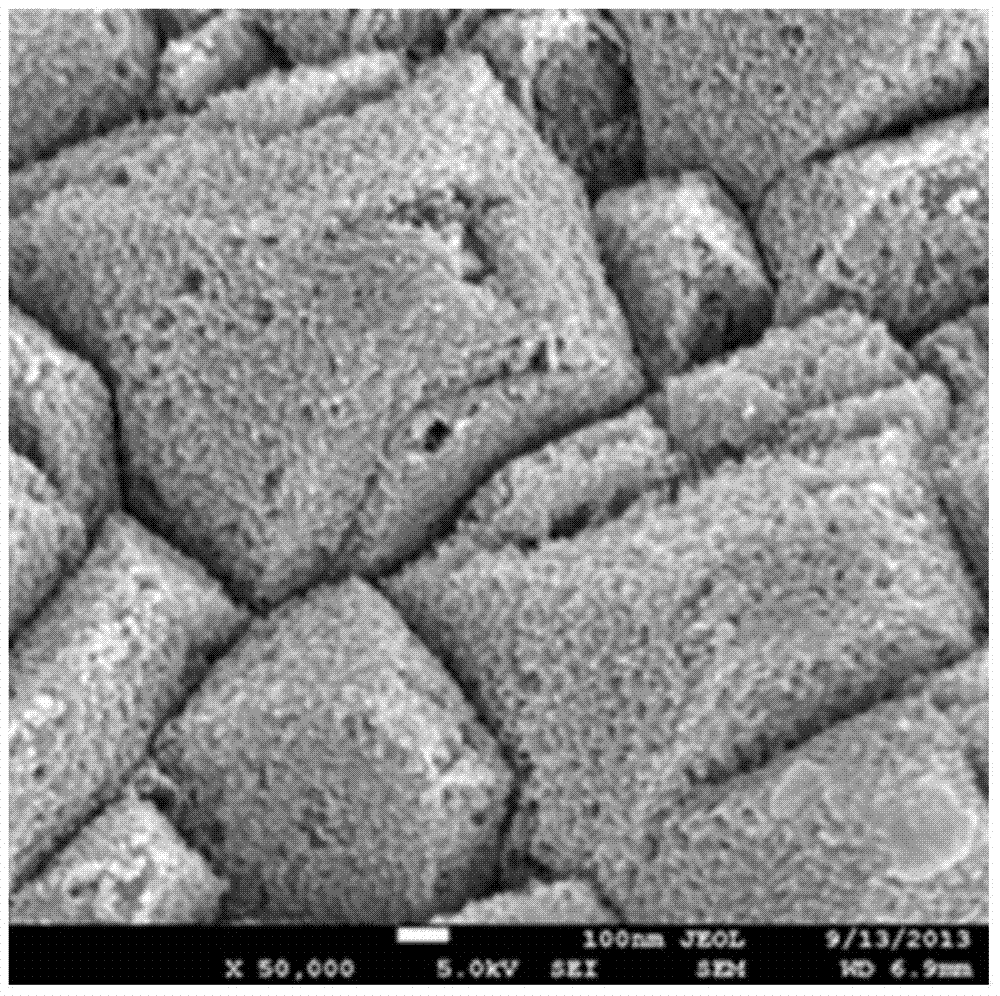

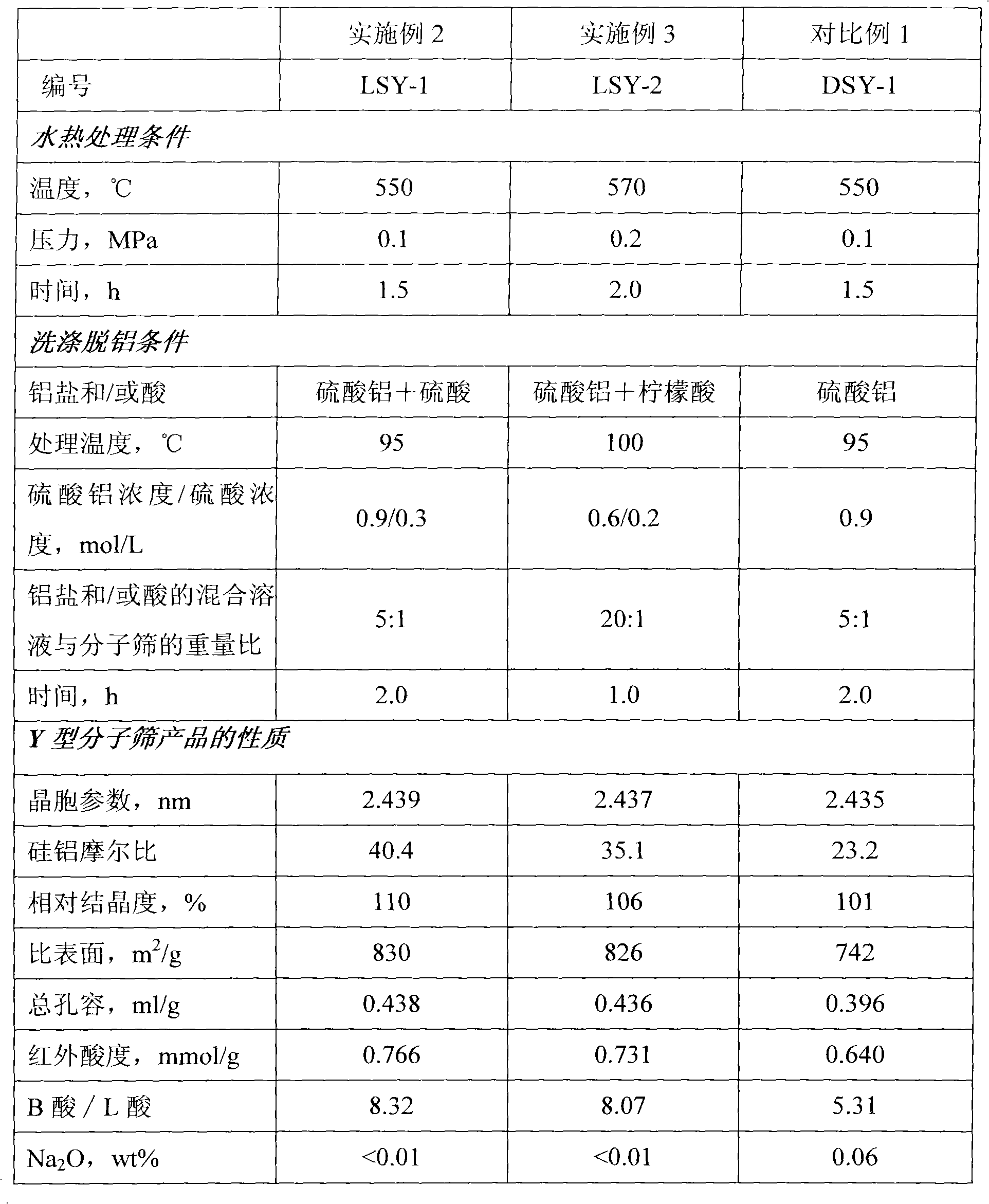

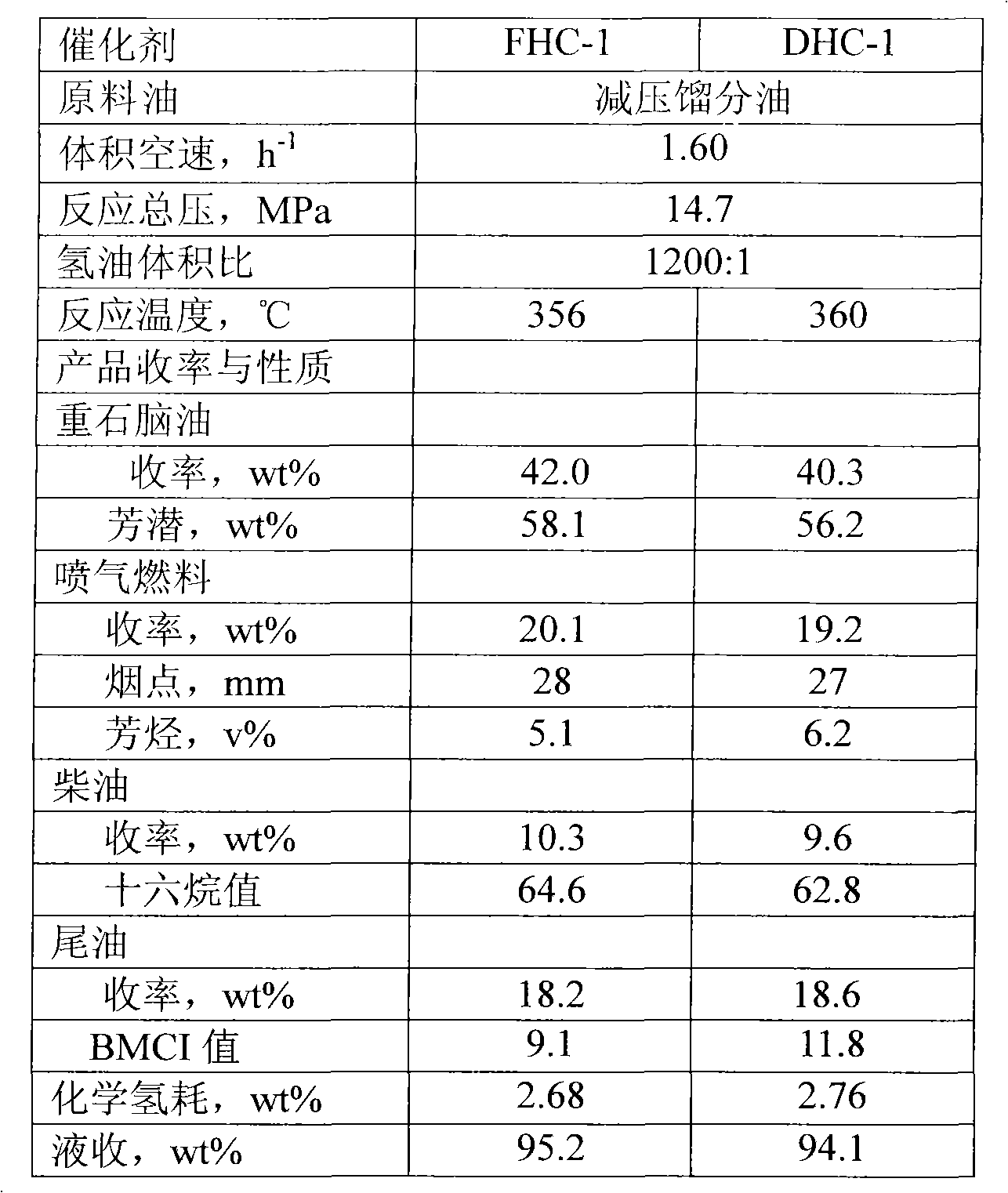

Y-type molecular sieve-containing hydrocracking catalyst carrier and preparation method thereof

ActiveCN101618347AHigh ratio of silicon to aluminumLarger than surfaceCatalyst carriersMolecular sieve catalystsCrystallinityCell parameter

Owner:CHINA PETROLEUM & CHEM CORP +1

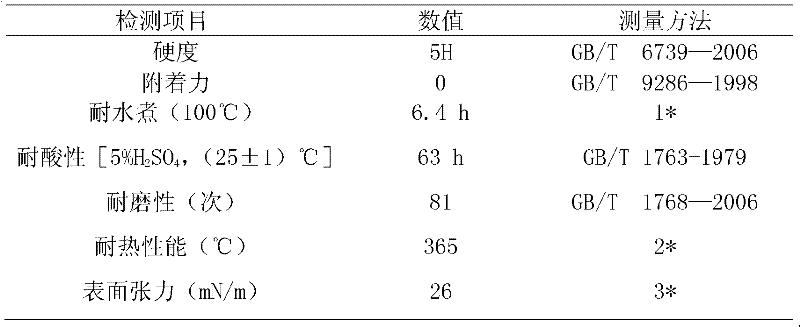

Preparation method of hyperbranched polyester modified organic silicon resin and coating comprising resin

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Method of Fabricating Thin Film by Microplasma Processing and Apparatus for Same

InactiveUS20120021132A1Reduce necessityLiquid surface applicatorsMolten spray coatingIonRaw material

Provided is a method of fabricating, with satisfactory adhesion, a thin film of a metal or a metallic-compound, such as a metal oxide or nitride, on a substrate made of a high-melting-point material such as silicon or ceramics by using a metal or metallic-compound target as the primary raw material so as to eliminate the necessity of using harmful gases such as organometallic gas, and by using an atmospheric-pressure plasma generated under atmospheric pressure as a reaction field and also as a heat source. Additionally provided is an apparatus for fabricating the thin film. The thin-film fabrication method by microplasma processing includes the steps of disposing a raw material for thin-film fabrication in one or more tubes (A) having a uniform inner diameter throughout, introducing an inert gas and applying a high-frequency voltage to the narrow tubes (A) to generate high-frequency plasma in the narrow tubes (A), heating / evaporating the raw material while maintaining the flow rate of the plasma gas in the narrow tubes (A) and maintaining the plasma gas temperature high, ejecting the evaporated material from the narrow tubes (A) to spray it onto the substrate, heating the substrate with the plasma, and depositing the sprayed material on the substrate under atmospheric pressure.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Quartz type pressure sensor, and production method therefor

InactiveCN1813179AEasy to strictly manage the thicknessLittle change over the yearsFluid pressure measurement using capacitance variationDielectricCapacitance

Owner:SEIKO EPSON CORP

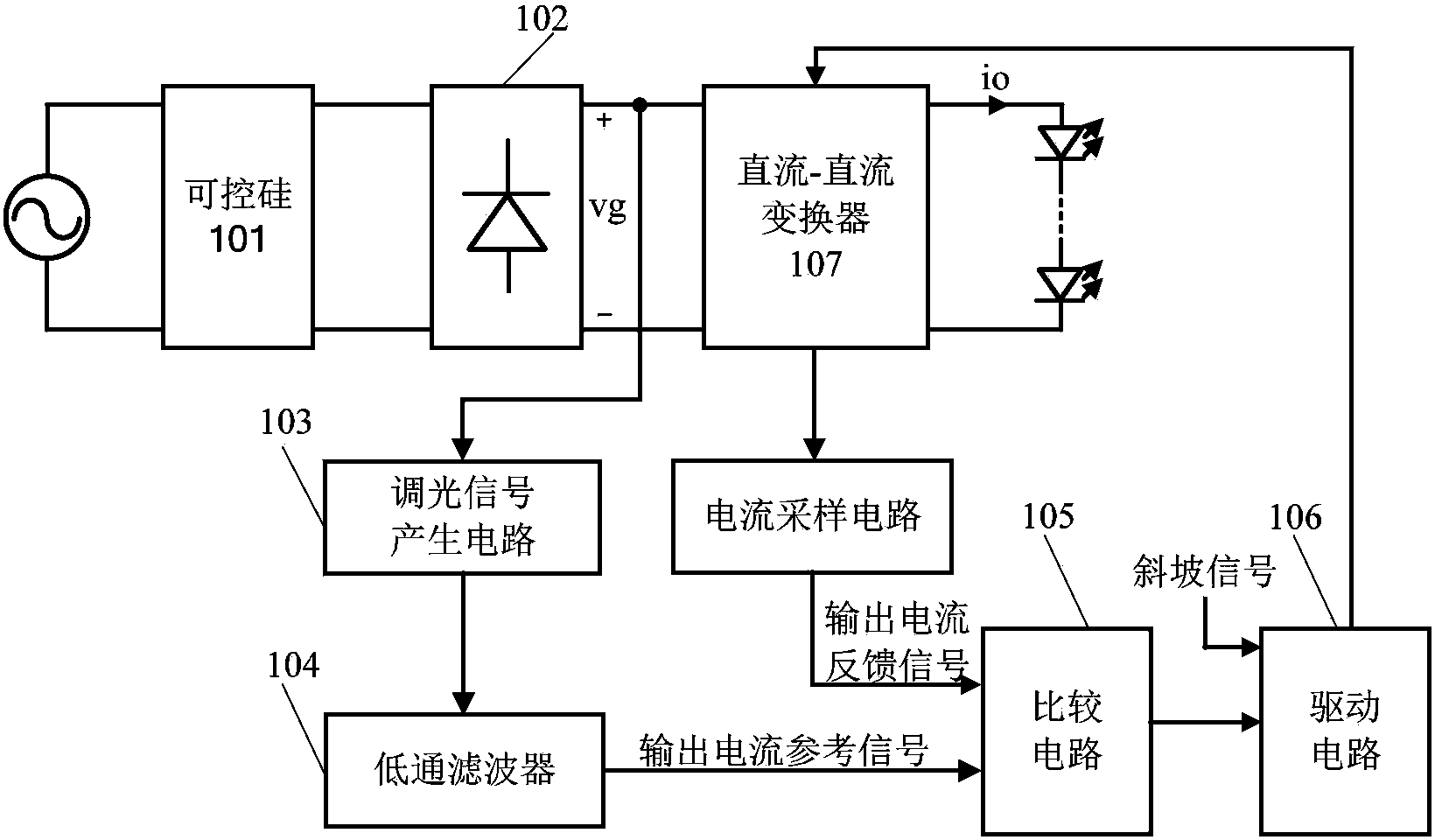

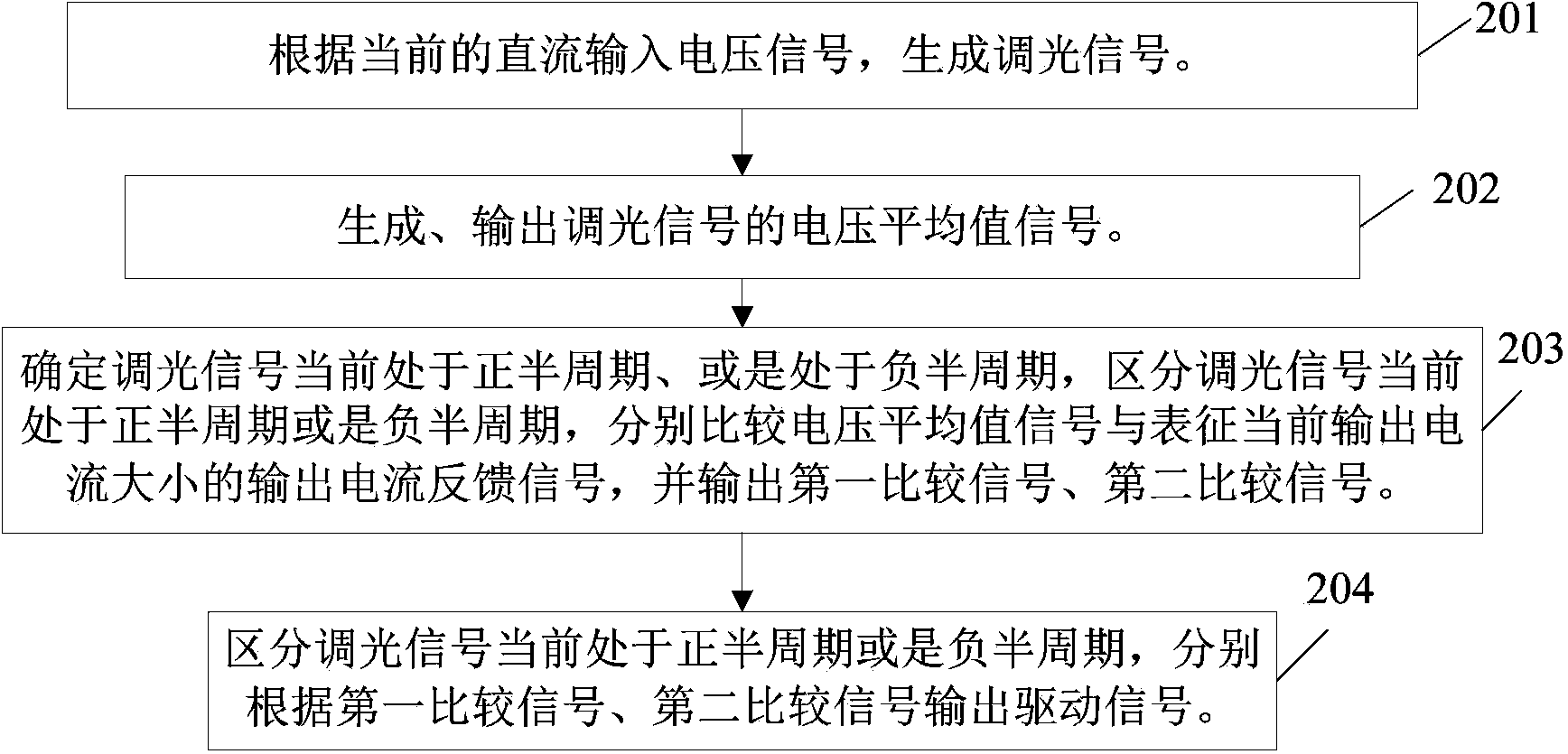

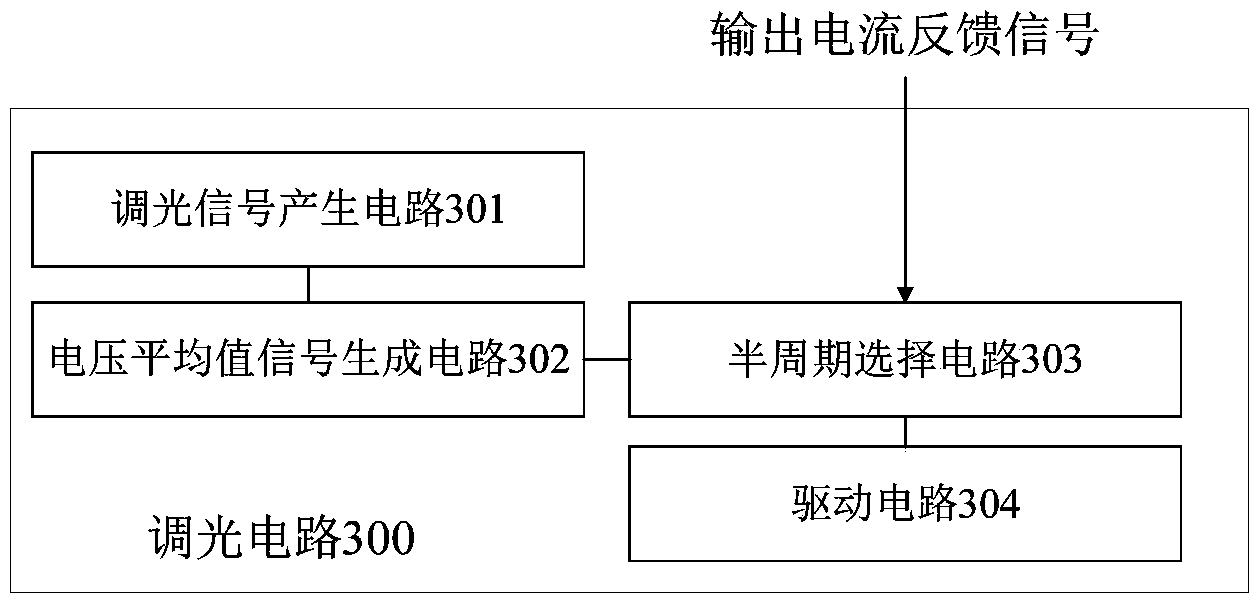

Dimming method and circuit and controllable silicon dimming circuit with circuit

InactiveCN103517531AEliminate flickeringElectrical apparatusElectroluminescent light sourcesEngineeringSilicon

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

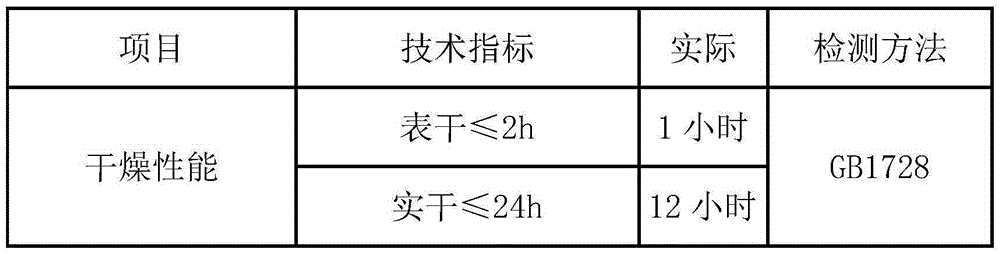

Good-weather and water resistance water-based alkyd resin

Owner:深圳海德新材料科技有限公司

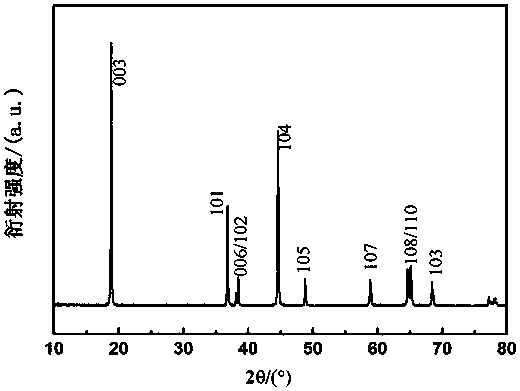

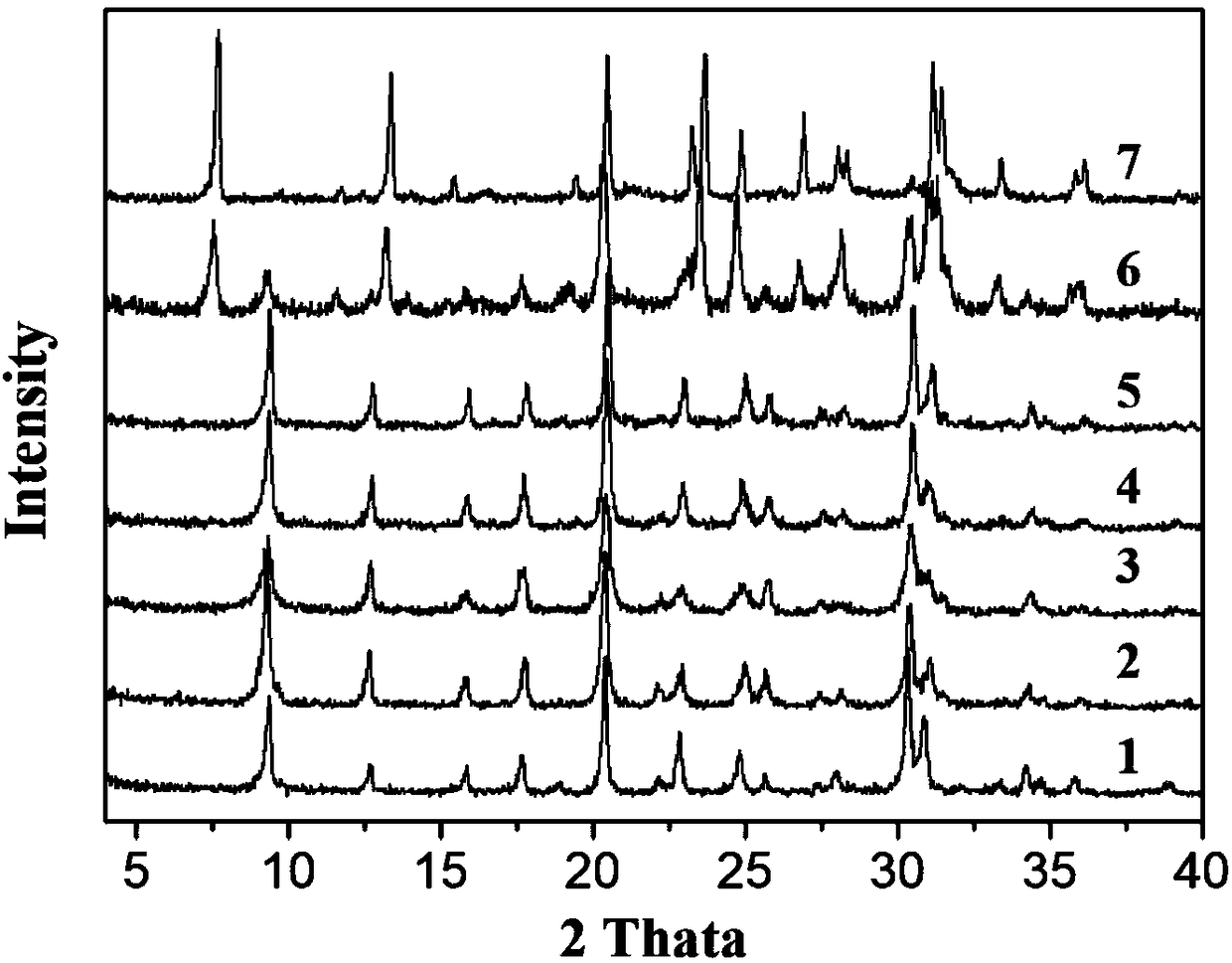

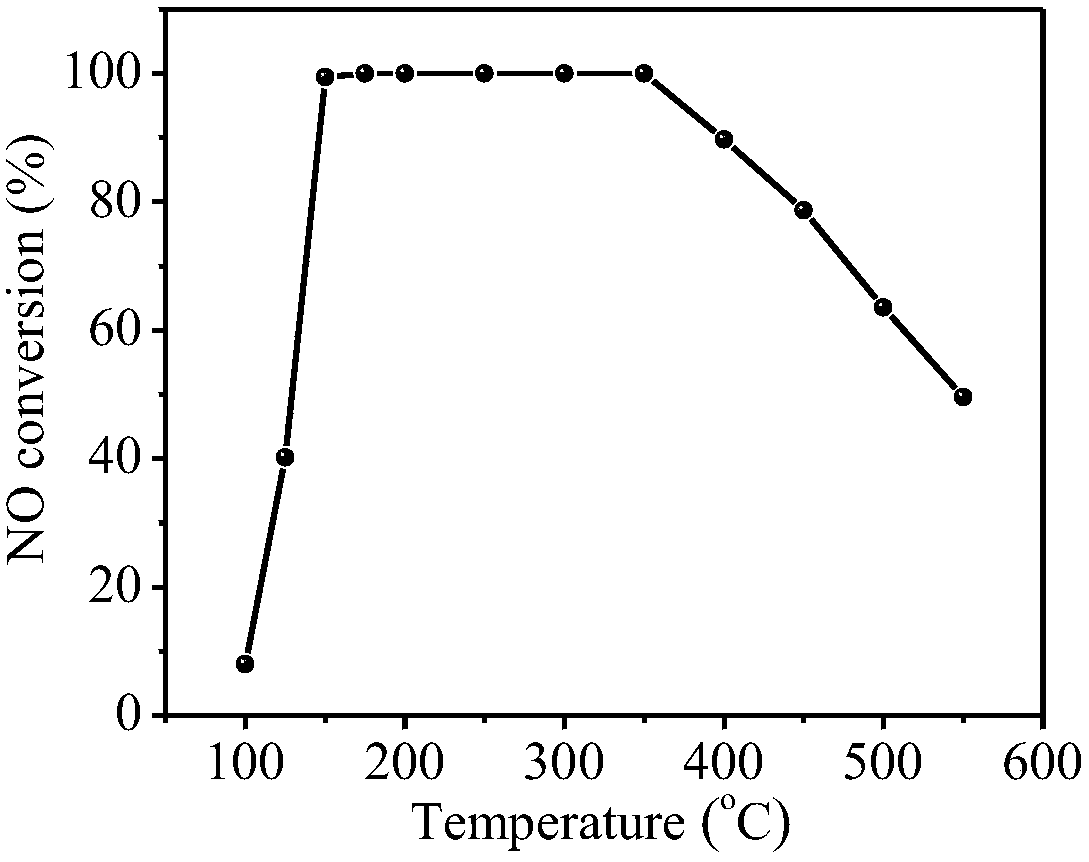

Phosphor-doped CHA molecular sieve, and preparation method and application thereof

ActiveCN108083292AGood activity at low temperatureMolecular sieve catalystsDispersed particle separationPotassium hydroxideCrystallinity

Owner:LUOYANG JALON MICRO NANO NEW MATERIALS CO LTD

Synthetic method for phosphorus-containing ZSM-5 molecular sieve

ActiveCN103964465ALower synthesis costReduce pollutionPentasil aluminosilicate zeoliteALUMINUM PHOSPHATESilicon

The invention discloses a synthetic method for a phosphorus-containing ZSM-5 molecular sieve. The method comprises the following steps: mixing a first organic template with an aluminum source, wherein in the obtained mixture, a mol ratio of the first organic template to Al2O3 in the aluminum source is 0.2-40: 1; treating the mixture in an enclosed reaction vessel at a temperature of 50 to 190 DEG C for 0.1 to 5 h and then carrying out cooling so as to obtain an intermediate product; and uniformly mixing the intermediate product with a second organic template, a silicon source and water and carrying out hydrothermal crystallization so as to obtain the phosphorus-containing ZSM-5 molecular sieve; wherein the aluminum source is an aluminum phosphate molecular sieve and / or silicon-phosphorus-aluminum molecular sieve. The method adopts a synthetic process route different from that in the prior art, abandons usage of high-cost silica-alumina gel as the silicon source and the aluminum source and can directly prepare the phosphorus-containing ZSM-5 molecular sieve, so synthesis cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ferrierite molecular sieve, preparation method thereof and application

ActiveCN107010636AGood choiceImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationCrystallinity

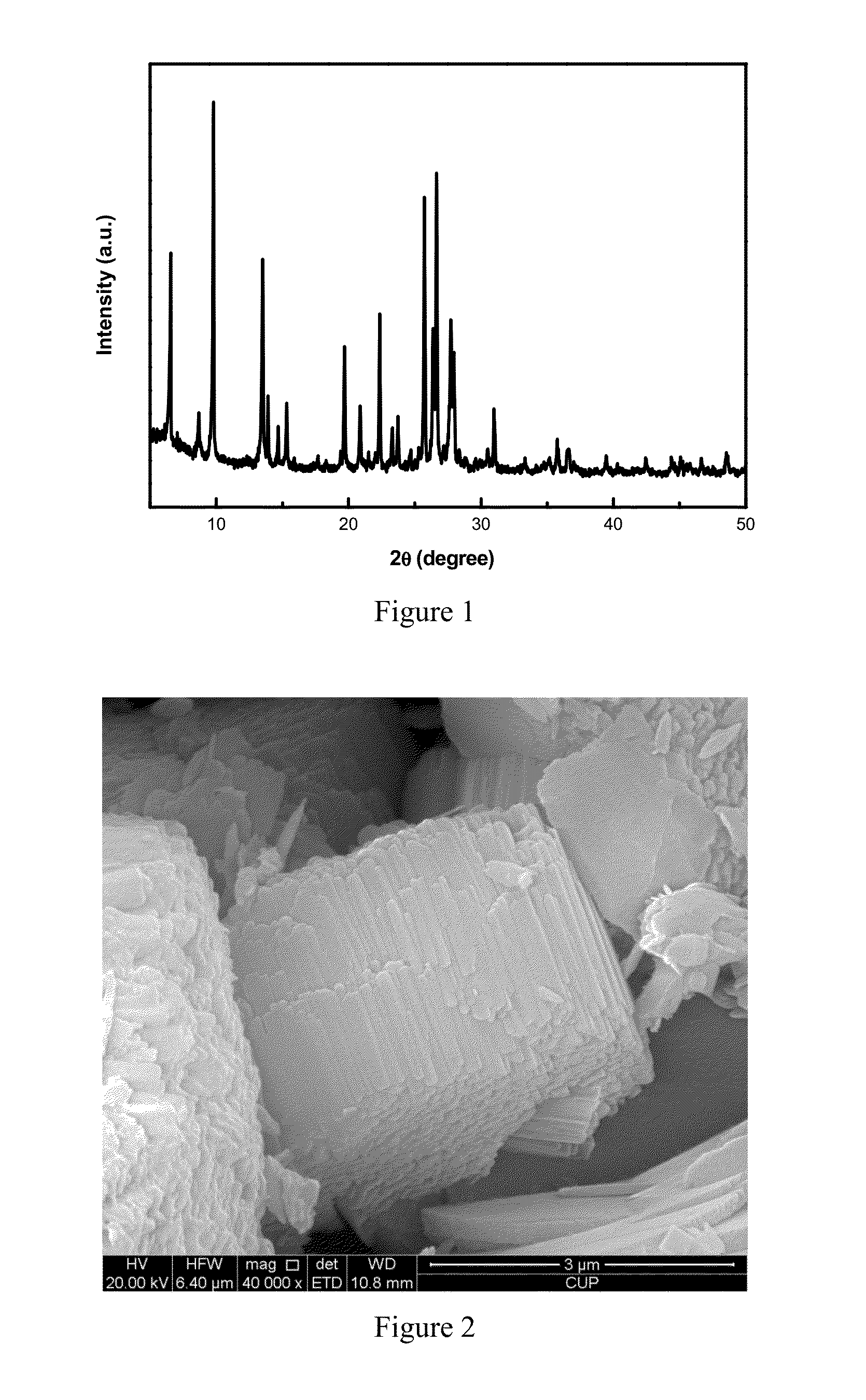

The invention provides a ferrierite molecular sieve, a preparation method thereof and an application. The preparation method includes the steps: mixing silicon sources, alkalinity conditioning agents, aluminum sources, template agents and water to form uniform sol; controlling the molar ratio of SiO2, Al2O3, R, Na2O to H2O to be 1.0:(0.005-0.10):(0.05-1.2):(0.03-0.50):(5.0-100.0), and enabling a pH (potential of hydrogen) value to be lower than 12.8; performing pre-crystallization, crystallization, drying and calcination to obtain molecular sieve raw powder; performing acid treatment on the obtained molecular sieve raw powder; mixing the molecular sieve raw powder, the template agents and the water or further mixing the molecular sieve raw powder, the template agents, the water and the silicon sources to form water solution; performing water-heat treatment, drying and calcination to obtain the ferrierite molecular sieve. R is the template agents. The prepared ferrierite molecular sieve is high in relative crystallinity and silica alumina ratio, large in specific surface area and crystal particle and adjustable in acidity and has excellent selectivity and stability when being applied to linear-chain olefin skeletal isomerization reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Process for producing latent catalyst and epoxy resin composition

InactiveUS20090234080A1High yieldGood fluidityOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyPhosphonium

Owner:SUMITOMO BAKELITE CO LTD

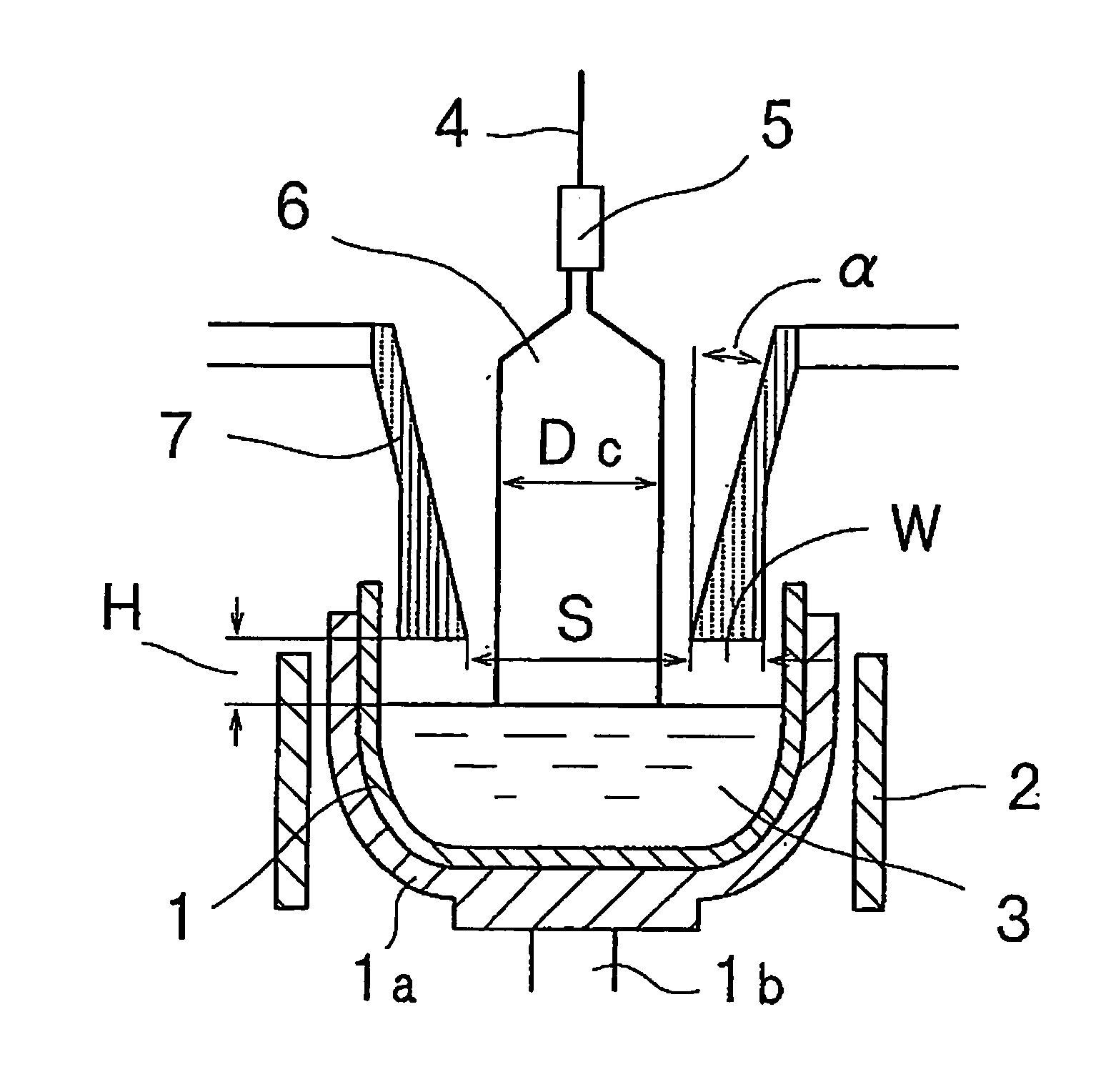

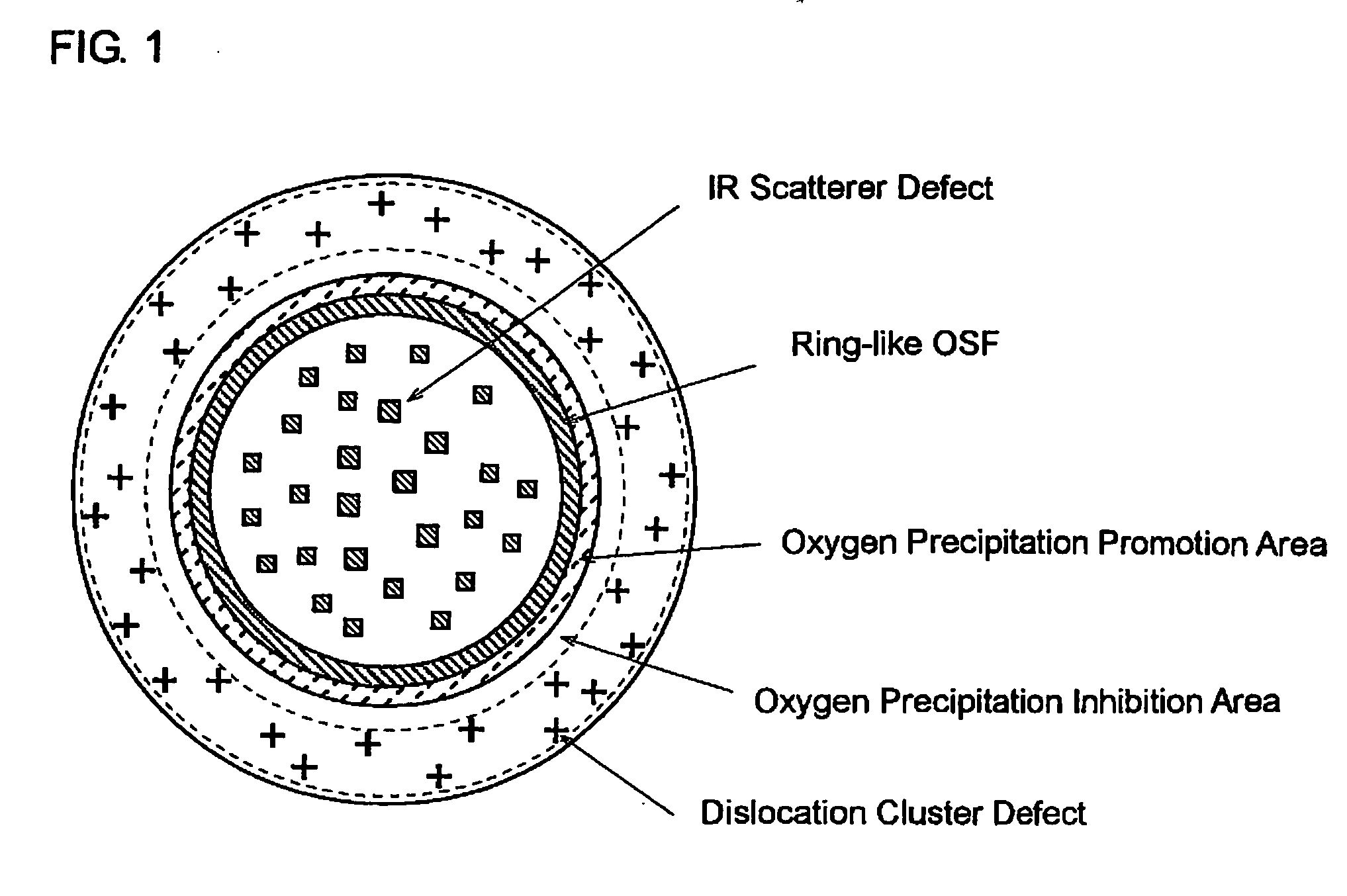

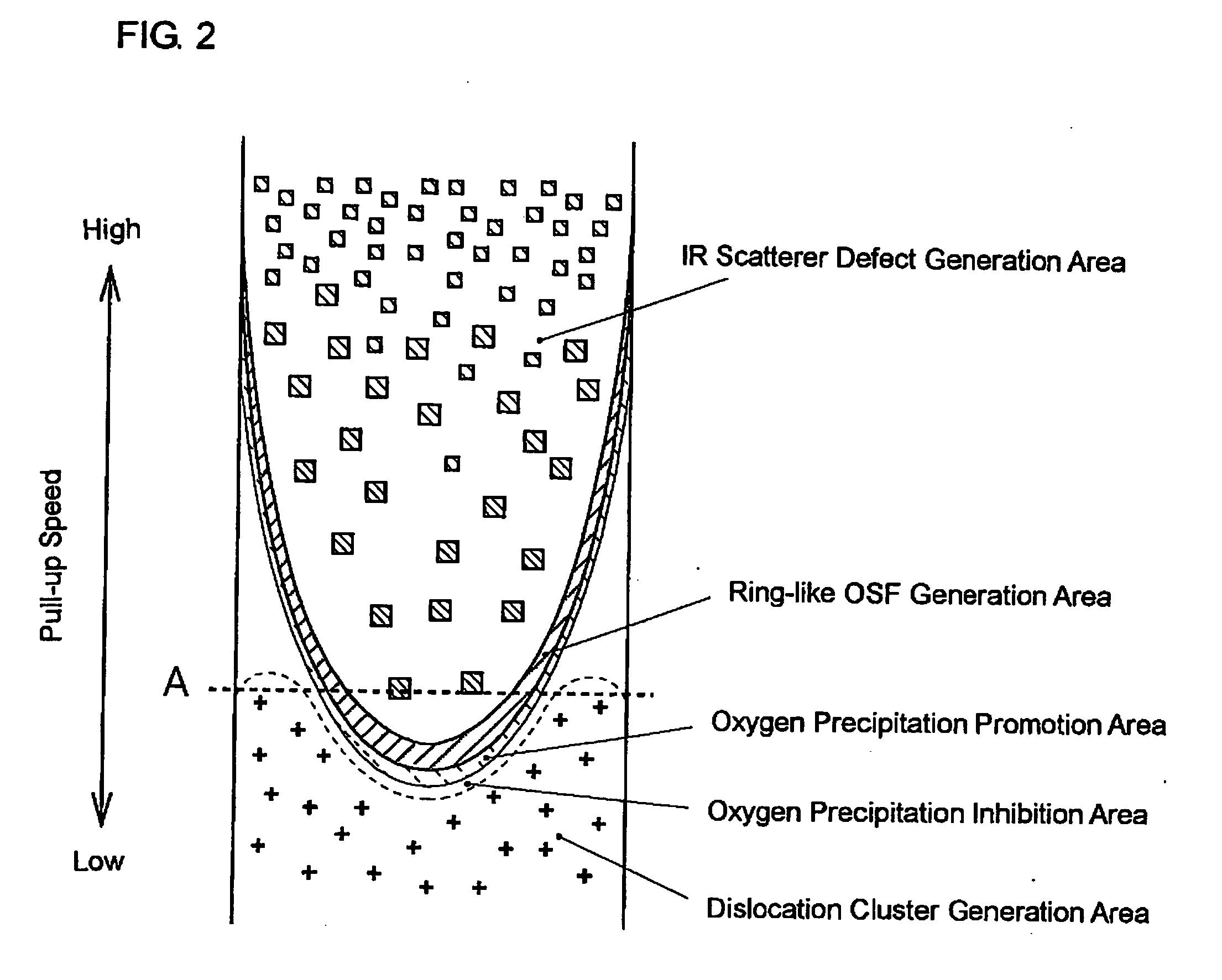

Method for growing silicon single crystal, and silicon wafer

InactiveUS20060225639A1Stable productionEasy to adaptPolycrystalline material growthBy pulling from meltHigh densityMiniaturization

Owner:SUMCO CORP

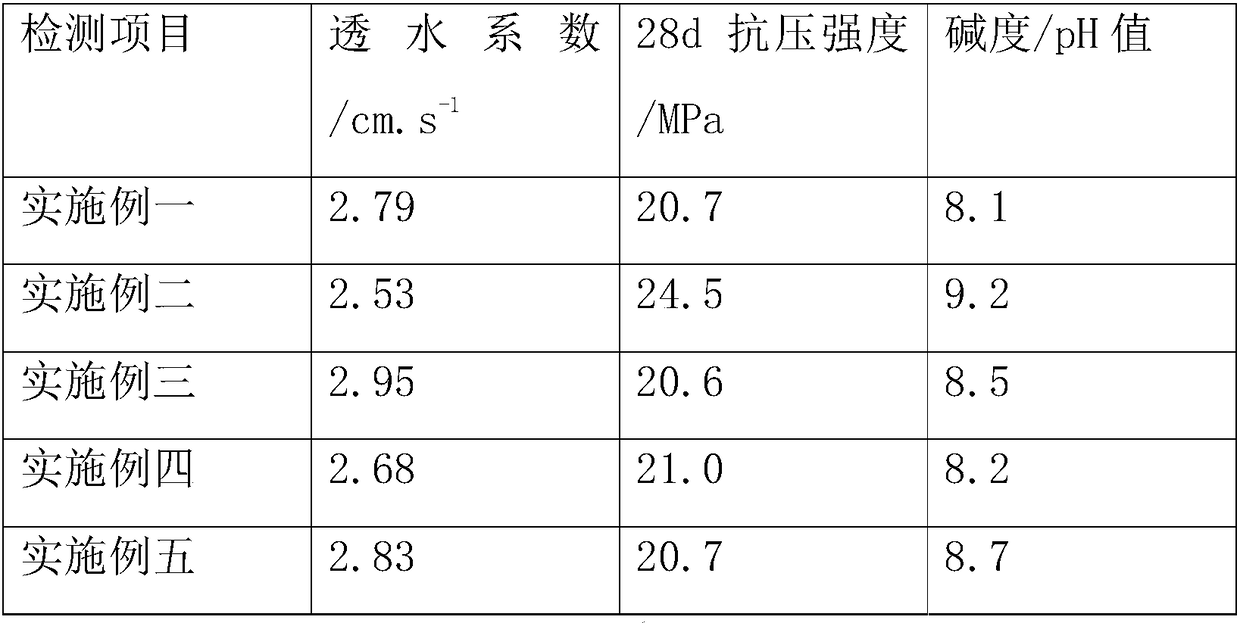

Plant growth type porous concrete suitable for plant growth

ActiveCN108101452AHigh compressive strengthHigh strengthExcrement fertilisersBioloigcal waste fertilisersFiberCompost

Owner:CHONGQING JIAOTONG UNIVERSITY

Water-based anti-doodling paint and preparation method thereof

ActiveCN105482604ALow VOC emissionsLow weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedDefoaming Agents

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Method for preparation of mordenite

ActiveUS20160207787A1Enlarges available source of raw materialLow costAluminium compoundsMordenite aluminosilicate zeoliteMordeniteBiological activation

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Ferroferric oxide magnetic nanometer particles decorated with tetraazacalix [2] arene [2] triazine as well as preparation method and application thereof

ActiveCN103187134AIncrease surface areaEasy to separateMaterial nanotechnologyFerroso-ferric oxidesTriazineOrganic matter

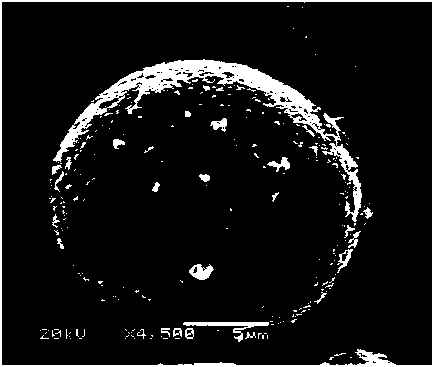

The invention discloses ferroferric oxide magnetic nanometer particles decorated with tetraazacalix [2] arene [2] triazine. A preparation method of the ferroferric oxide magnetic nanometer particles comprises the following steps of: firstly, covering a silicon shell by using the ferroferric oxide magnetic nanometer particles; decorating with amino to obtain amino-modified ferroferric oxide magnetic nanometer particles; and reacting the ferroferric oxide magnetic nanometer particles with the tetraazacalix [2] arene [2] triazine at 110 DEG C under a nitrogen condition to prepare the ferroferric oxide magnetic nanometer particles decorated with tetraazacalix [2] arene [2] triazine. The ferroferric oxide magnetic nanometer particles integrate the advantages of large superficial area of the original and easiness of separation of the original ferroferric oxide magnetic nanometer particles, and also have a new function characteristic, so that the extraction selectivity of a characteristic target is enhanced; and the ferroferric oxide magnetic nanometer particles are used for extracting and separating, and have the advantages of easiness and convenience in operation, and capability of extracting, enriching and separating organic matters and inorganic cations. And moreover, the ferroferric oxide magnetic nanometer particles can be totally separated from a base solution under an external magnetic field function, so that the ferroferric oxide magnetic nanometer particles are economic, environment-friendly and high in recovery rate and have a good popularization and application prospect.

Owner:ZHENGZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap