Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "High polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

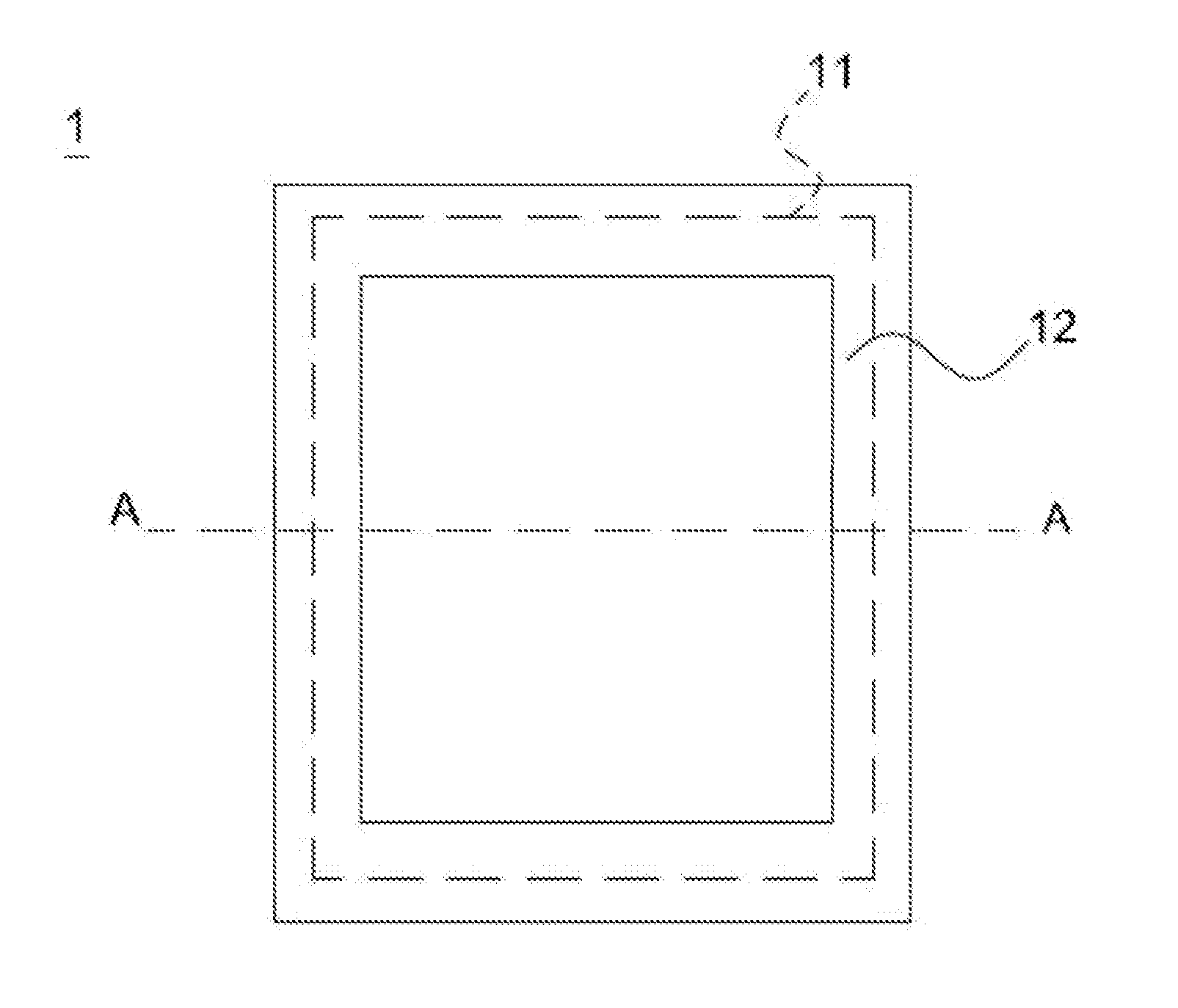

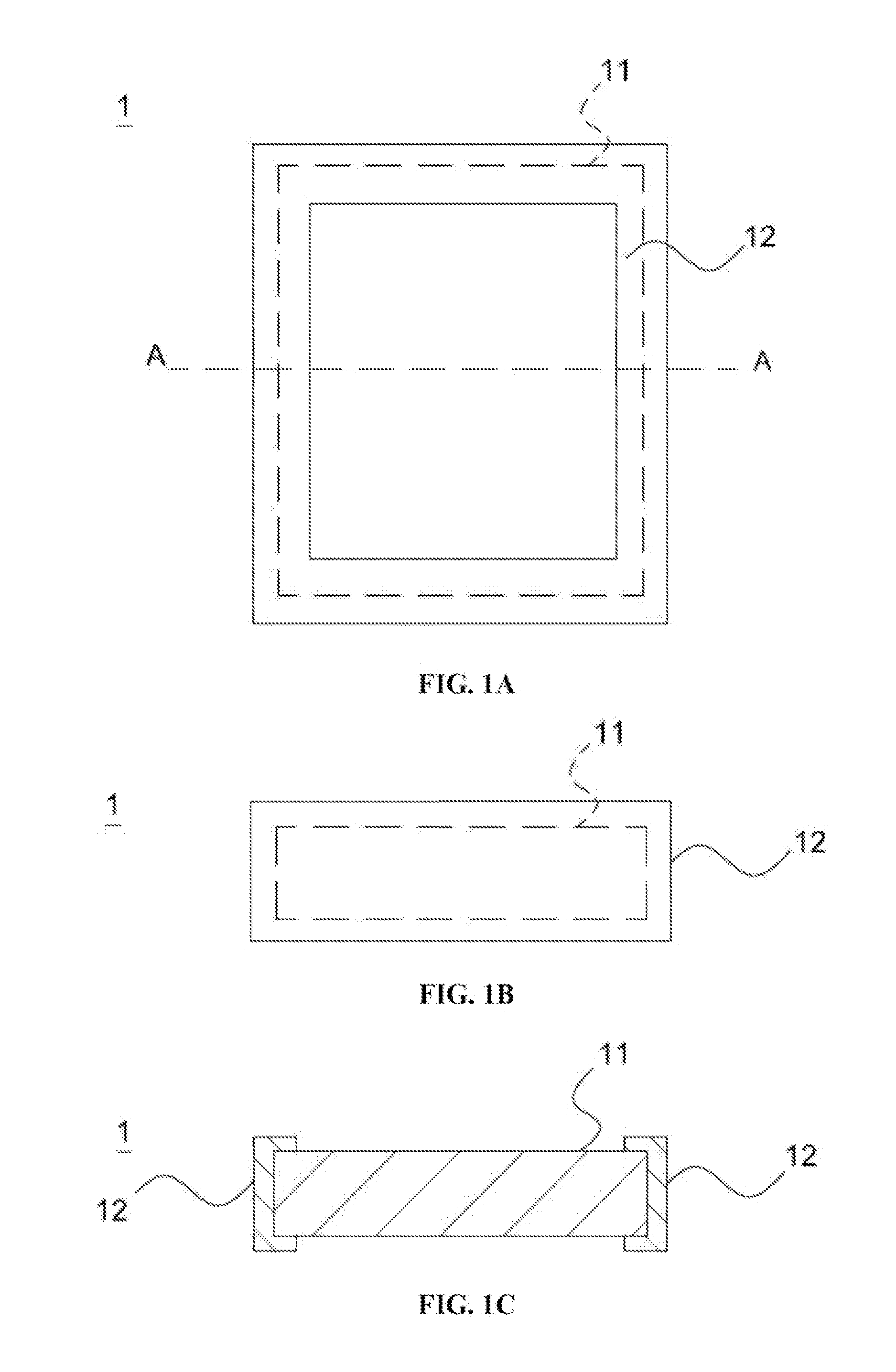

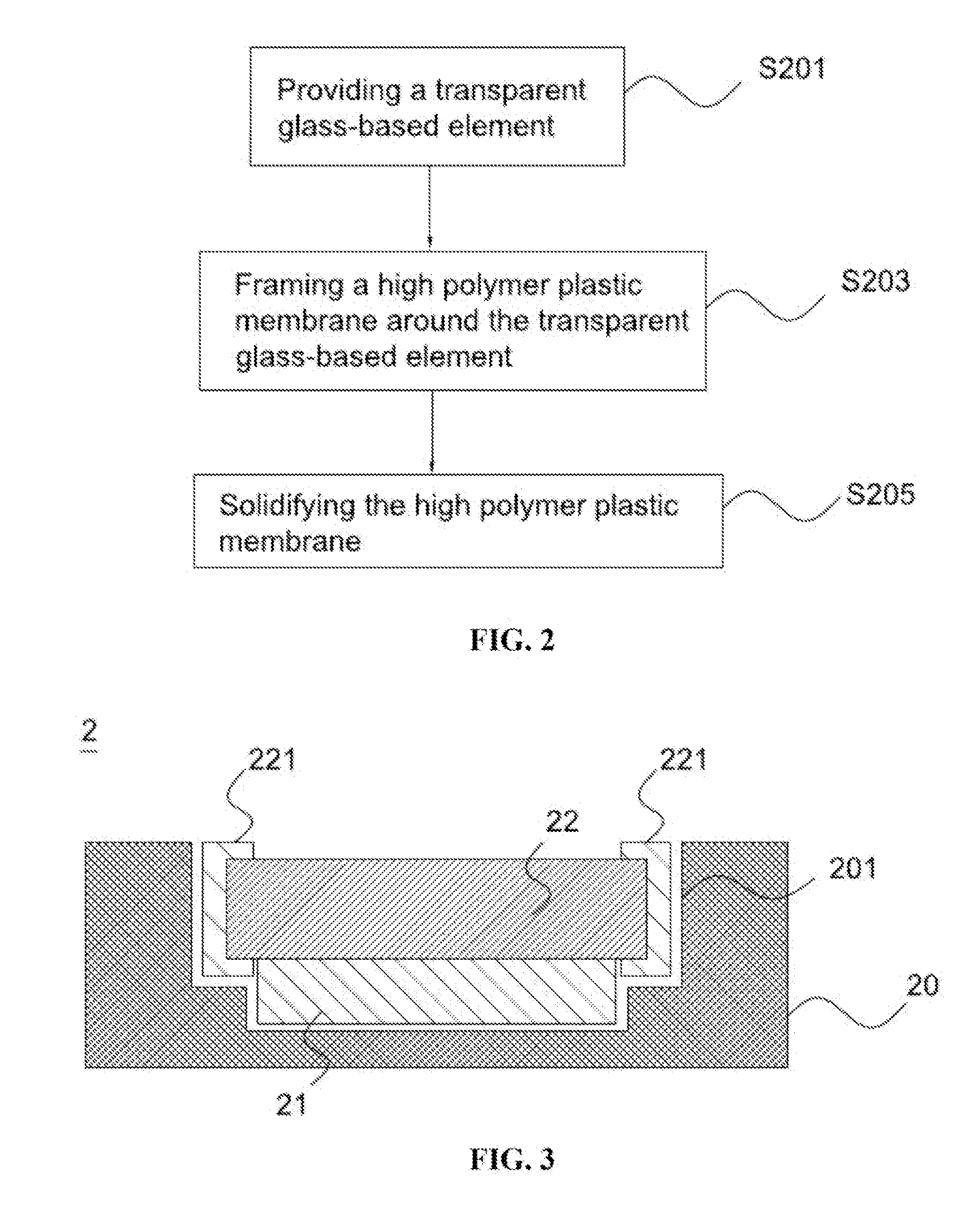

Glass plate, method for manufacturing the same, and display device, touch sensitive display using the same

ActiveUS20120135247A1High anti-cracking abilityHigh strengthGlass/slag layered productsSpecial surfacesLiquid stateDisplay device

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Small pore diameter silicone rubber sponge and preparation method thereof

The invention discloses small pore diameter silicone rubber sponge and a preparation method thereof and relates to the field of processing of high polymer materials. The small pore diameter silicone rubber sponge comprises the following components in parts by weight: a component A: 100 parts of liquid organic silicone rubber; a component B: 3-8 parts of hydrogen-containing silicone oil; a component C: 0.5-10 parts of an emulsifier; a component D: 2-4 parts of a catalyst; a component E: 1-2 parts of an inhibitor; and a component F: 0-35 parts of a silicon resin. An emulsion dispersion mode is adopted, the dispersion phase size is small, and the silicone rubber sponge prepared by the method has the characteristics of bubble dispersion uniformity, small pore diameter and controllable density; and moreover, water serves as a foaming agent, and the sponge has the advantage of environment friendliness. The silicone rubber sponge material prepared by the method can serve as shock absorption, insulating, sound insulation and heat insulation materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

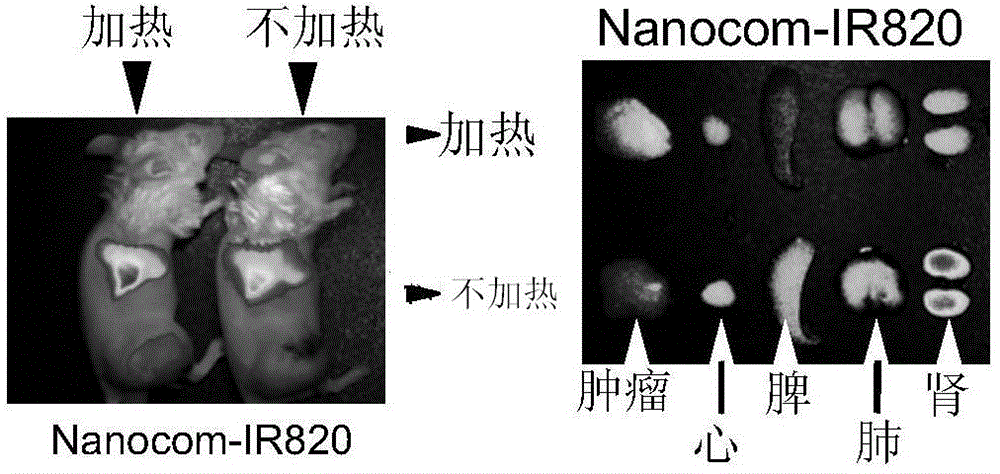

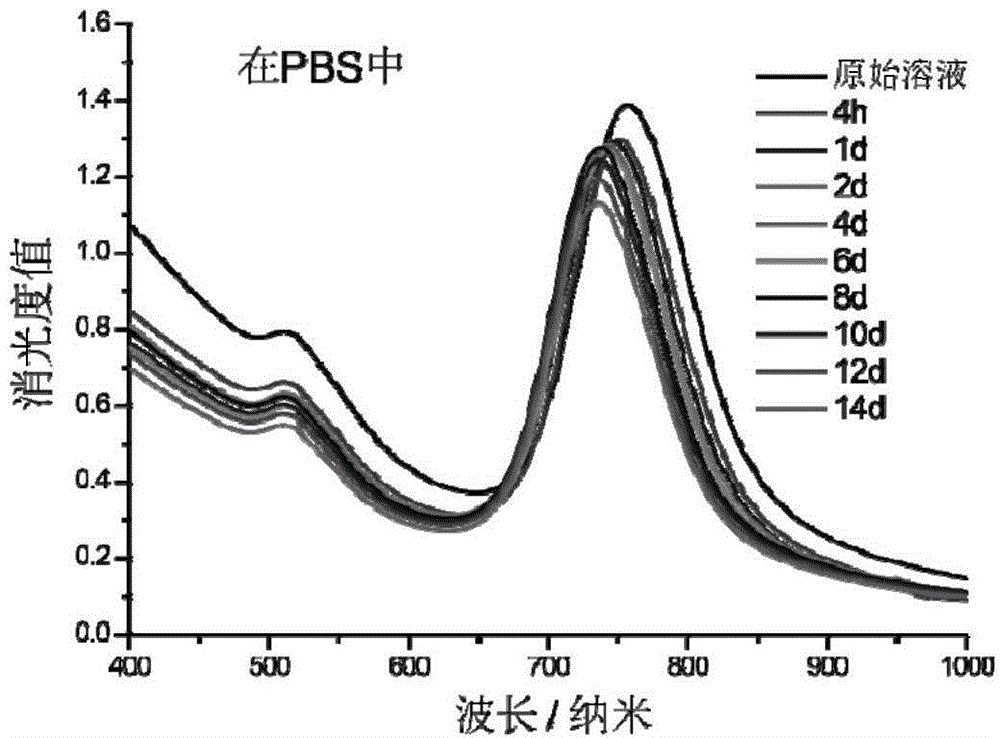

Gold-core-composite nano-carrier as well as preparation method and application thereof

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Hyperbranched polyborosiloxane containing functional groups, and preparation method thereof

Owner:QUANZHOU NORMAL UNIV

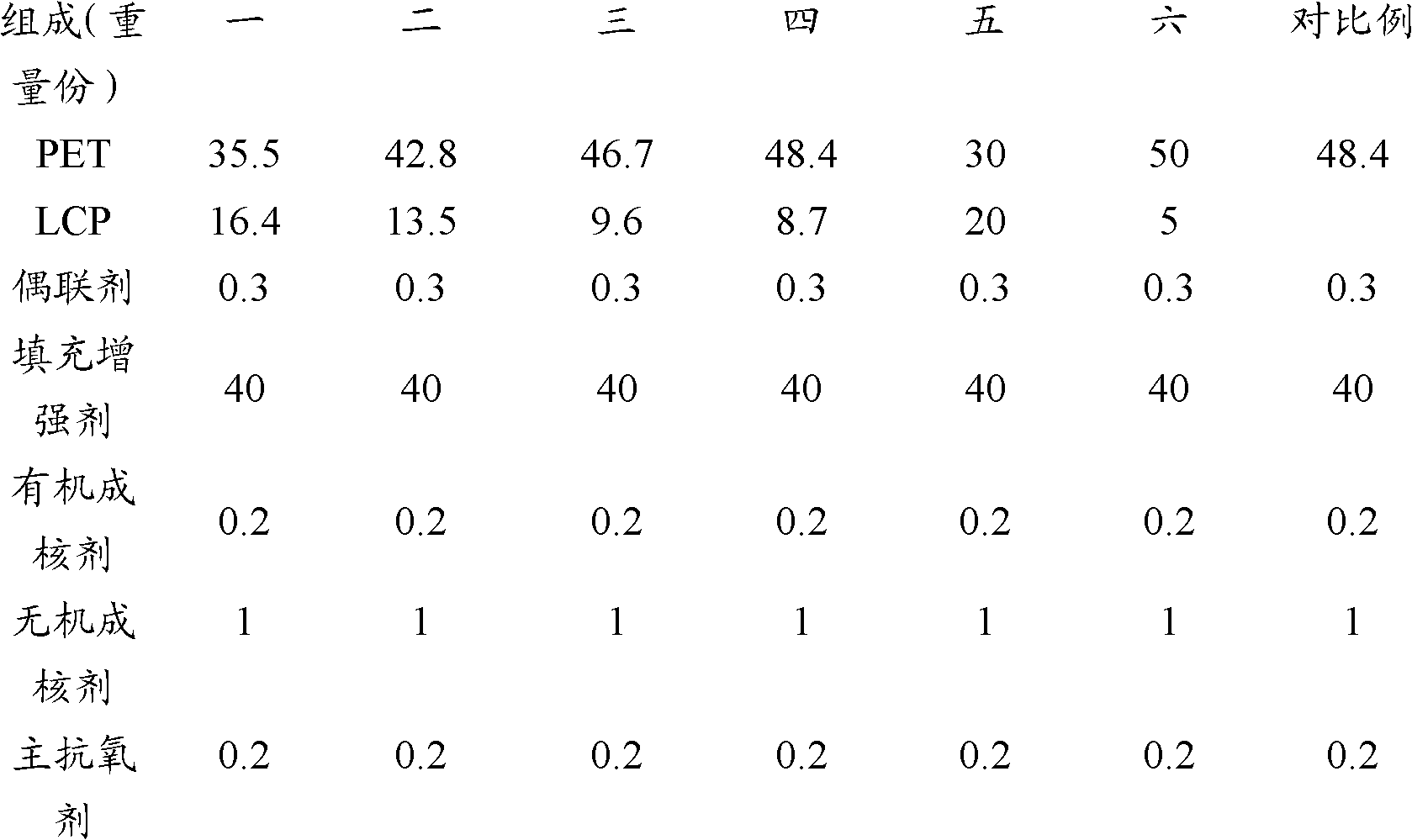

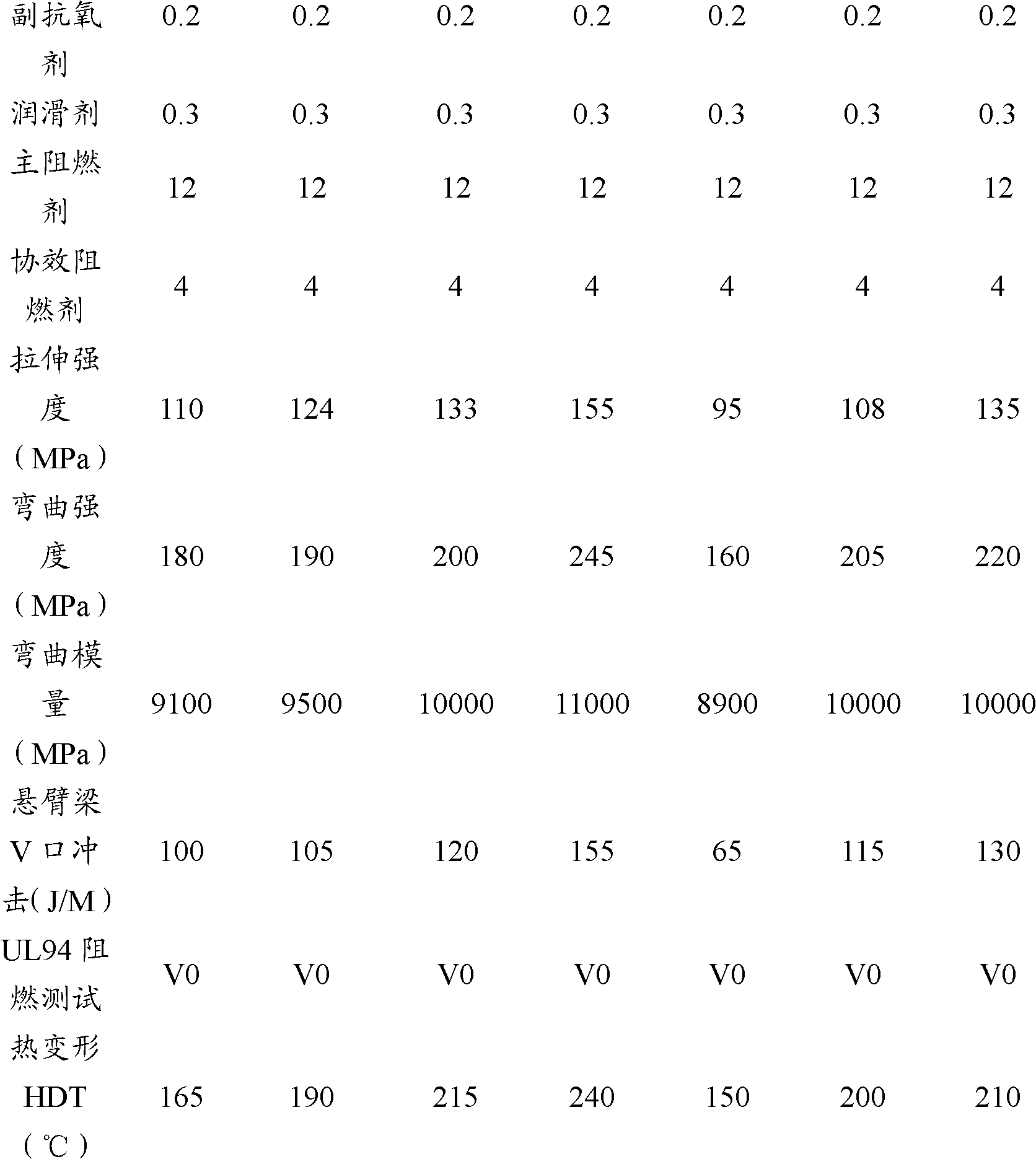

Polyethylene terephthalate (PET)/liquid crystal polymer (LCP) engineering plastics as well as preparation method and application thereof

InactiveCN102040812AImprove performanceHigh crystallinityPolyethylene terephthalate glycolAntioxidant

Owner:SHENZHEN KEJU NEW MATERIAL

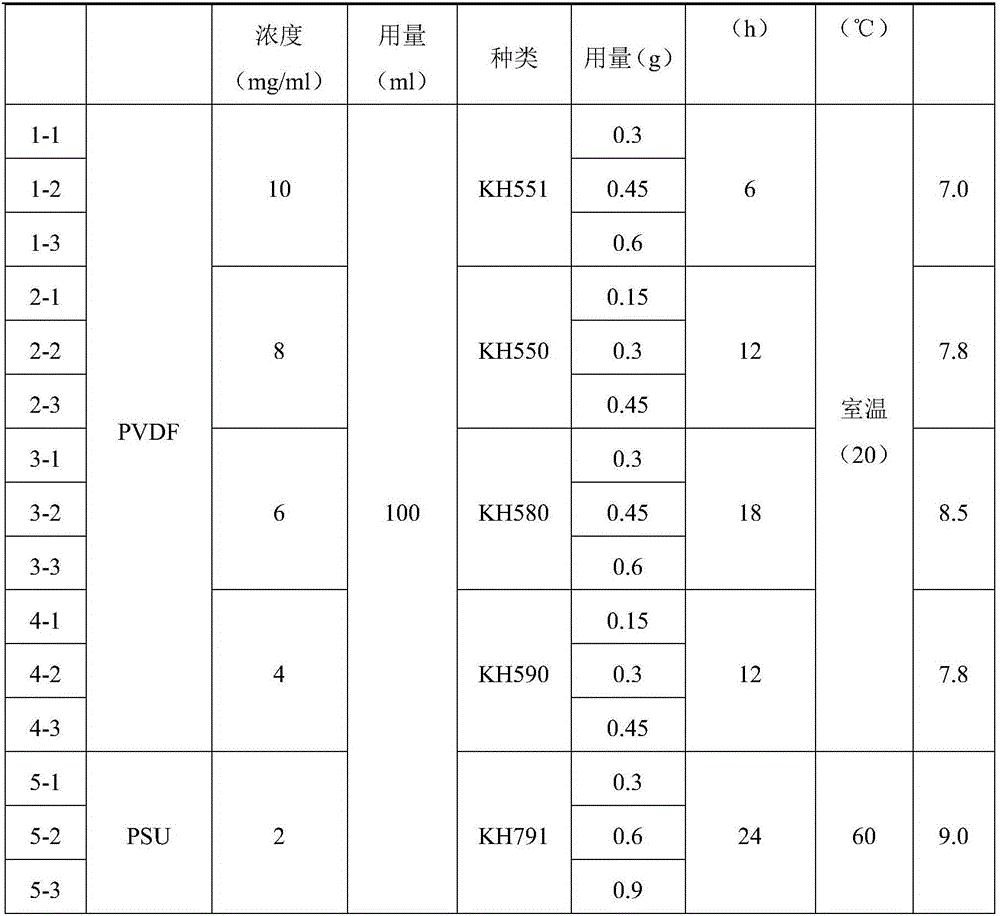

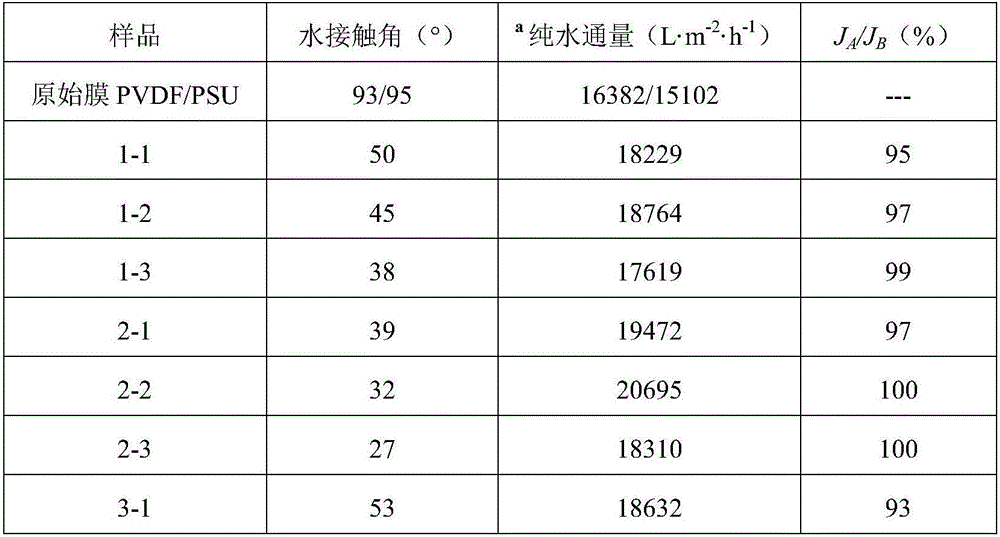

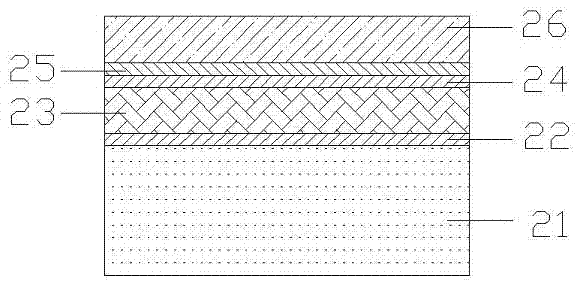

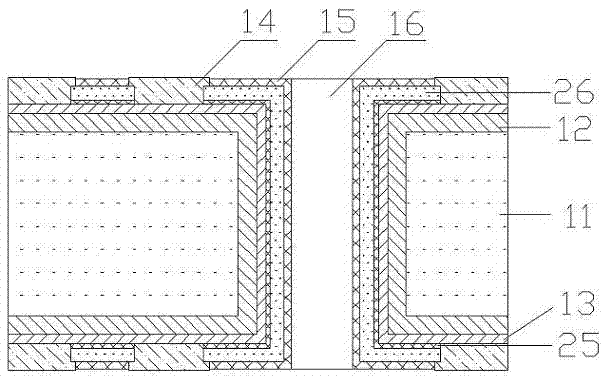

Hydrophobic polymer film composite coating hydrophiling modification method

ActiveCN106310958AImprove hydrophilicityImprove stabilityMembranesSemi-permeable membranesPolymer scienceHydrophobic polymer

Owner:WUHAN UNIV OF TECH

Double-sided aluminum base circuit board with super-high thermal conductivity and preparation method thereof

InactiveCN102740591ASimple processImprove yieldPrinted circuit detailsPrinted element electric connection formationDlc coatingInsulation layer

Owner:苏州热驰光电科技有限公司

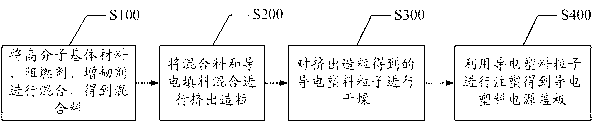

Conductive plastic for processing power supply cover plate, and fabrication method of power supply cover plate

InactiveCN103214718AStrong acid and alkali corrosion resistanceResistivity adjustableConductive polymerEngineering

Owner:SHENZHEN FRD SCI & TECH

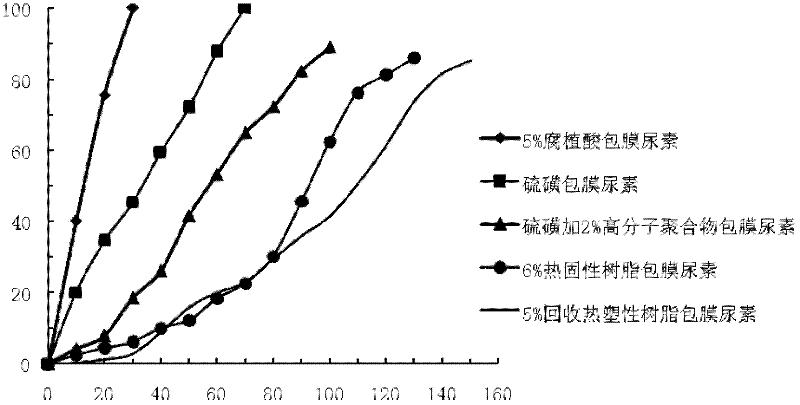

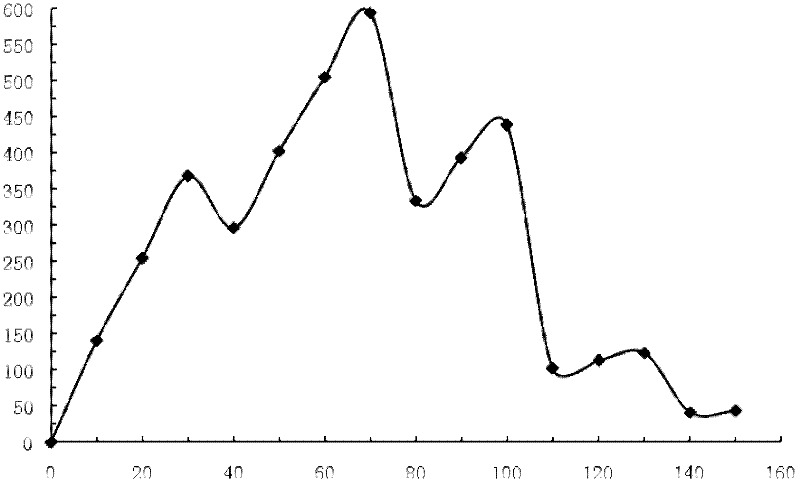

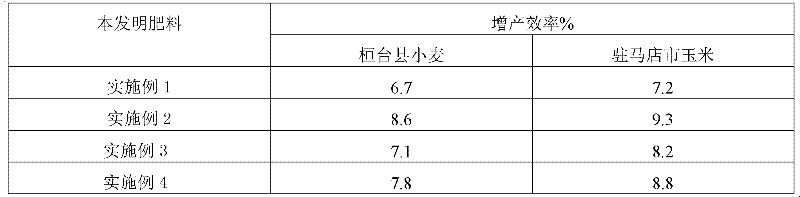

Compound type sustained or controlled release nitrogen fertilizer special for crops in Huang huai hai area, preparation method and applications thereof

ActiveCN102584492ASuit one's needsImprove utilization efficiencyFertilizer mixturesControl releaseCoated urea

Owner:菏泽金正大生态工程有限公司

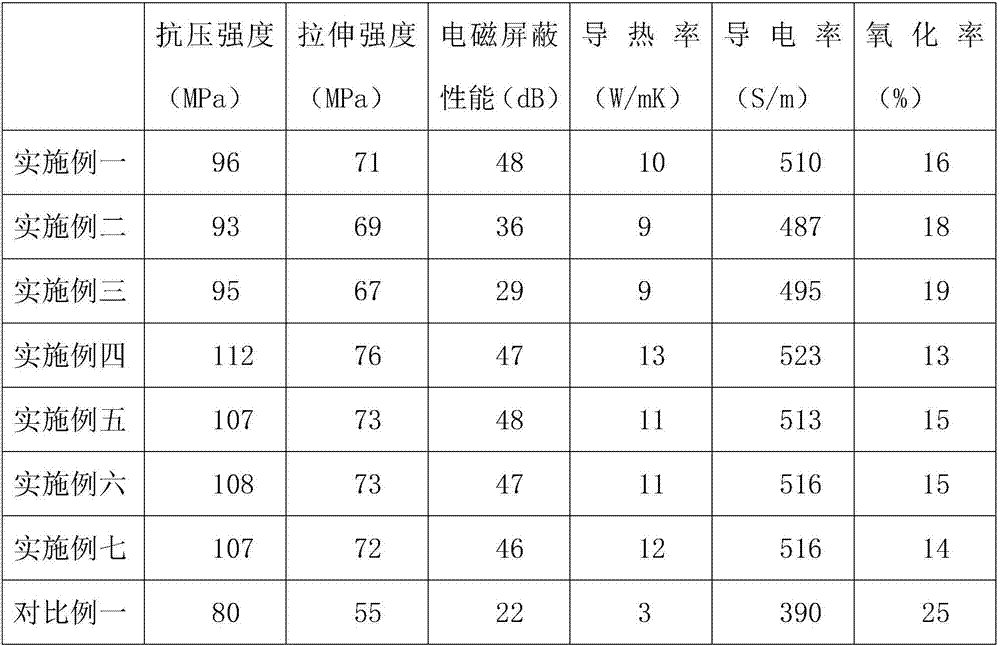

Preparation method of heat-conducting, electricity-conducting and electromagnetic-shielding multifunctional composite material

InactiveCN108003612AImprove electromagnetic shielding performanceImprove tensile propertiesHeat-exchange elementsElectricityHeat conducting

Owner:江西伟普科技有限公司

High-rigidity and high-toughness resin material for clothing buttons

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Nanoscale activated calcium carbonate and processing method thereof

InactiveCN110358328AReduce surface polarityOleophilic and hydrophobicMaterial nanotechnologyPigment physical treatmentCalciteHigh velocity

The invention discloses nanoscale activated calcium carbonate. The nanoscale activated calcium carbonate comprises calcite, a dispersant and a coupling agent; a mass part ratio of the calcium carbonate to the dispersant in a grinding process is 100:(0.2-5); and a mass part ratio of the dried nanometer calcium carbonate to the coupling agent in a high-speed mixing and stirring process is 100:(0.5-8). The method reduces the surface polarity of the nanometer calcium carbonate, so the surface of the nanometer calcium carbonate has strong oleophilic and hydrophobic properties, the dispersion property is improved, the dispersibility of the nanometer calcium carbonate in the composite material and the compatibility of the nanometer calcium carbonate with an organic high polymer are improved, andthe nanoscale activated calcium carbonate is obtained. The invention also discloses a processing method of the nanoscale activated calcium carbonate. The processing method comprises the following steps: 1, raw material washing; 2, choosing; 3, coarse crushing; 4, intermediate crushing; 5, addition of the dispersant, and grinding; 6, ATP grading (fine powder + coarse powder); 7, addition of the coupling agent, and high-speed mixing and stirring; and 8, cooling and packaging. The processing method adopting dry process modification has the advantages of low production cost, and suitableness for large-scale industrial production.

Owner:LIANG DE NANO POWDER LNNOVATION & TECH (ANHUI) CO LTD

Impact-resistant conductive polyphenylene sulfide material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and relates to an impact-resistant conductive polyphenylene sulfide material and a preparation method thereof. The impact resistant conductive polyphenylene sulfide material is prepared from the following components in parts by weight: 60-75 parts of PPS, 0.5-1 part of a lubricant, 0.5-0.8 part of epoxy resin, 8-15 parts of a toughening agent, 17-25 parts of carbon black and 0.5-2 parts of a coupling agent. The impact-resistant conductive polyphenylene sulfide material is prepared by using a high-speed pre-mixing dispersion one-step extrusion process. The impact-resistant conductive polyphenylene sulfide material provided by the invention has the characteristics of being good in mechanical property, good in flame retardancy, good in stability, easy to process, good in impact resistance and the like, and is applicable to packages of precise and advanced products of the electronic industry, the war industry and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

High-impact-resistance high-flowability ABS resin and preparation method thereof

InactiveCN108329646ASolve the problem of low impact strengthLiquidPolymer scienceBulk polymerization

The invention specifically relates to a preparation method for a high-impact-resistance high-flowability ABS resin, belonging to the technical field of high-molecular materials. The preparation methodcomprises the following steps: preparing ABS resin with high impact strength by using a DOW continuous bulk polymerization process, adding bulk ABS resin, SAN resin, a plasticizer, a lubricant and acompatibilizer in a certain mass ratio into a mixer for thorough mixing so as to obtain a mixed material; and then feeding the obtained mixed material into a twin-screw extruder for mixing, extruding,drawing, cooling and pelletizing so as to obtain the high-impact-resistance high-flowability ABS resin. The ABS resin prepared in the invention has superior impact performance; at the same time, thecompatibilizer is added during blending, so the compatibility between the ABS resin and the SAN resin is improved, the adhesion between the two polymers is increased, and a more stable structure is formed.

Owner:NORTH HUAJIN CHEM IND CO LTD

Preparation method of polyester fiber with rough surface

InactiveCN106978645AConducive to fixationGood removal effectFibre typesHollow filament manufactureActivated sludgePolyester

Owner:SHANGHAI NEW TECHTEXTILES +1

Oil-resistant ABS modified material

Owner:NINGBO HENGTUO POLYMER MATERIAL

A New Method of Preventing Coal Dust Explosion in Underground Coal Mine

InactiveCN102261260AReduce concentrationLower explosion limitDust removalFire preventionSprayerPolyvinyl alcohol

Owner:梁红

PC/ABS composite with low-temperature impact resistance and product thereof

The invention specifically relates to a PC / ABS composite with low-temperature impact resistance and a product thereof, belonging to the technical field of high polymer materials. The PC / ABS compositewith low-temperature impact resistance comprises organosilicon-copolymerized PC resin, ABS resin, a flexibilizer, a fire retardant and an inorganic filling material. The product is prepared by moldingthe PC / ABS composite with low-temperature impact resistance. According to the invention, the organosilicon-copolymerized PC resin and the compound flexibilizer with low-temperature impact resistanceare used for the PC / ABS composite, so the PC / ABS composite has excellent notch impact strength at a low temperature after addition of the inorganic filling material.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Method for continuously preparing oligomeric proanthocyanidins

Owner:HUNAN HUACHENG BIOTECH

Preparation method of low water absorption sleeper

InactiveCN105459234ALow water absorptionGood dimensional stabilityWood treatment detailsPretreatment apparatusPreservativeCell wall

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

Preparation method of high-polymer self-sealing hot melt adhesive powder for raising safety level of automobile tire

Owner:LUOYANG JUNTENG ENERGY TECH +1

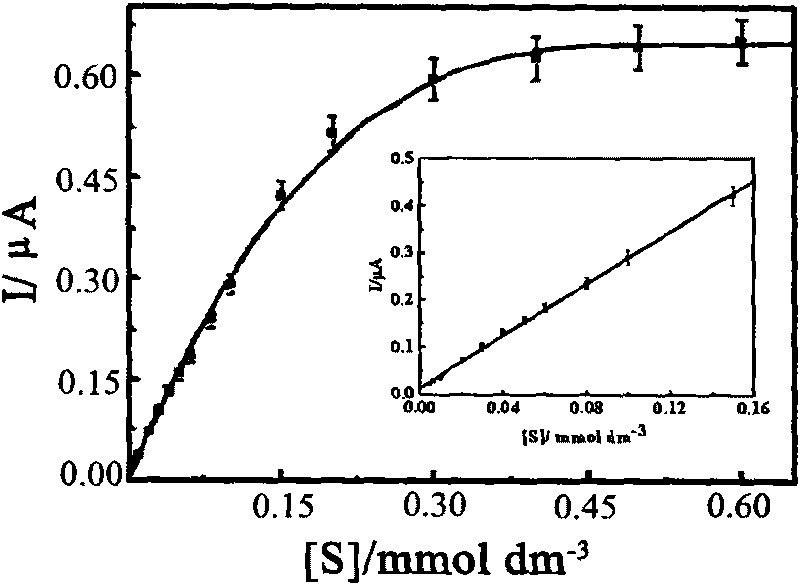

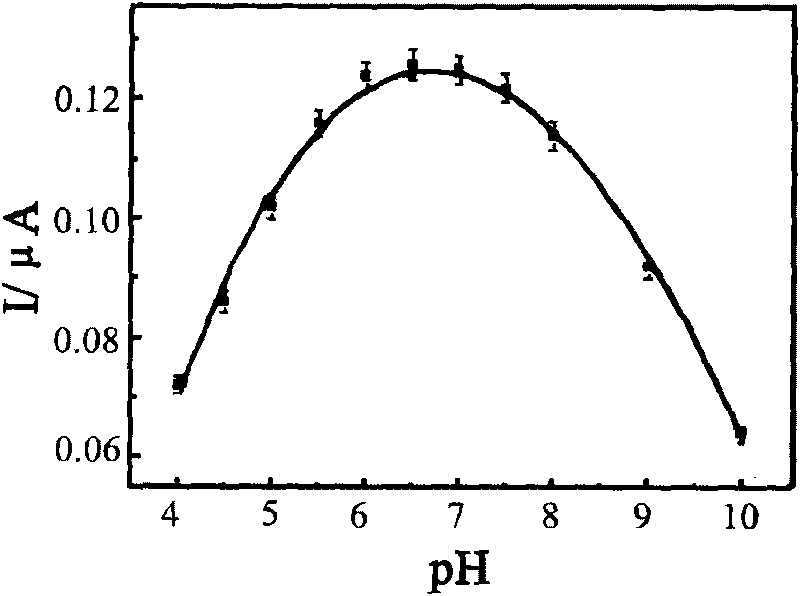

Preparation method for polyaniline-polyphenol oxidase sensor

Owner:YANGZHOU UNIV

Silk fibroin-PLGA composite material having ordered micro-groove structures, and preparation method and application thereof

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Ultraviolet-resistant polychromatic fiber

Owner:RUGAO FUDA ENG & TECH RES INST CO LTD

Wound bandage and plaster

InactiveCN1813688APromote circulationRelief the painPharmaceutical non-active ingredientsDermatological disorderFiberWound healing

The present invention relates to an adhesive plaster for treating wound. It is characterized by that it includes two layers of inner layer and outer layer, the described inner layer and outer layer are adhered into one whole body, its inner layer is made up by using fabric material containing natural marine high-polymer chitoamine fibre and its outer layer is made up by using microporous teflon film material. Said adhesive plaster has the functions of resisting bacteria, relieving inflammation, arresting bleeding, promoting wound healing and promoting tissue growth, etc.

Owner:李强

Functional accessory ingredient for plastic processing and preparation method thereof

Owner:ANHUI HUAYU PIPELINE MFG

Portable type steel bar telegraph pole

InactiveCN107191052AImprove mechanical propertiesPlay an insulating roleTowersYarnMoisture resistance

Owner:HEFEI HAIYIN TOWER

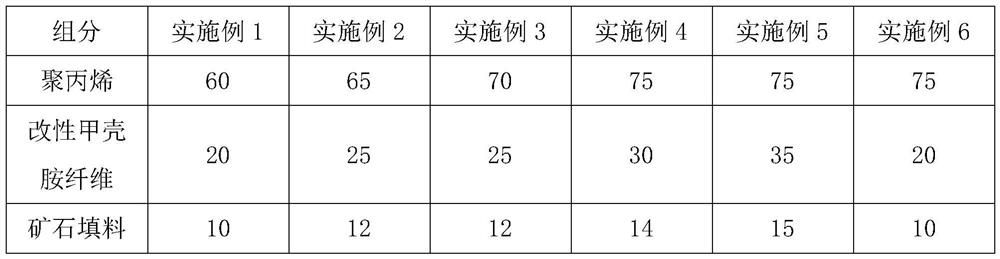

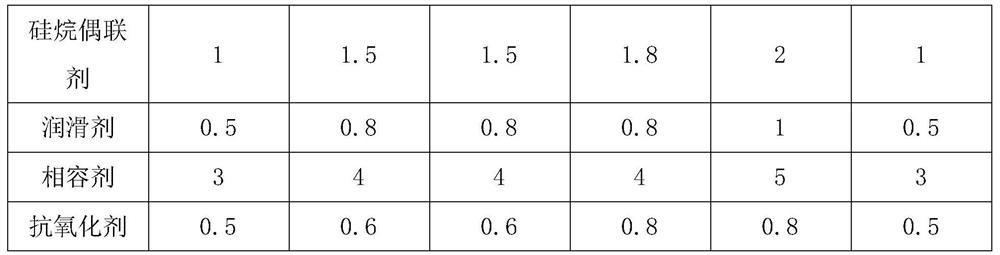

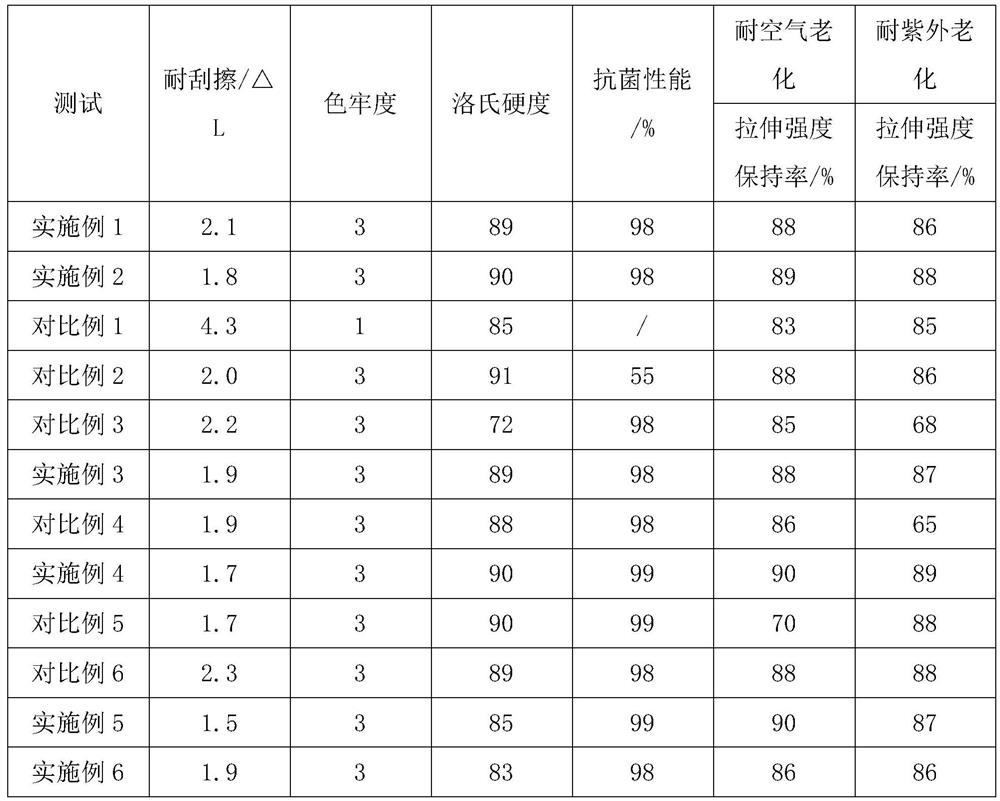

Scratch-resistant polypropylene material and preparation method thereof

ActiveCN111925591AImprove scratch resistanceEfficient deliveryPolypropylene compositesPolymer science

Owner:宁波精诚塑胶制品有限公司

Method for controlling viscosity of molybdenum-based catalytic butadiene polymerization system

InactiveCN111019031AWide molecular weight distributionViscosity is easy to controlPolymer adhesivePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap