Method for controlling viscosity of molybdenum-based catalytic butadiene polymerization system

A technology for catalytic polymerization and catalytic system is applied in the field of controlling the viscosity of molybdenum-based catalytic polymerization of butadiene system, which can solve the problems of high Mooney viscosity and dynamic viscosity, difficulty in heat dissipation and transportation, and difficulty in industrialization, and achieves wide molecular weight distribution and increased Heat dissipation and delivery performance, the effect of extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of molybdenum-based catalysts

[0037] Preparation of the main catalyst: In the reaction flask after deoxidation and water removal, under the protection of nitrogen, sequentially add molybdenum pentachloride, tributyl phosphate TBP, n-hexane solution, wherein TBP and MoCl 5 The molar ratio of the catalyst is 2:1, and the catalyst is reacted at room temperature for 12 hours.

[0038] Preparation of the co-catalyst: under the protection of nitrogen, m-cresol was added to triisobutylaluminum, and m-cresol and triisobutylaluminum were reacted at a molar ratio of 3:1 for 6 hours.

[0039] 2. Preparation of low-viscosity high-vinyl polybutadiene glue

[0040] The experiment was carried out in a polymerization kettle with a volume of 500L. The catalytic system uses tributyl phosphate (TBP) as ligand, MoCl 5 Main catalyst, m-cresol aluminum as co-catalyst to illustrate:

[0041] (1) The 500L polymerization kettle is purged with nitrogen, replaced and airtight qu

Embodiment 2-5

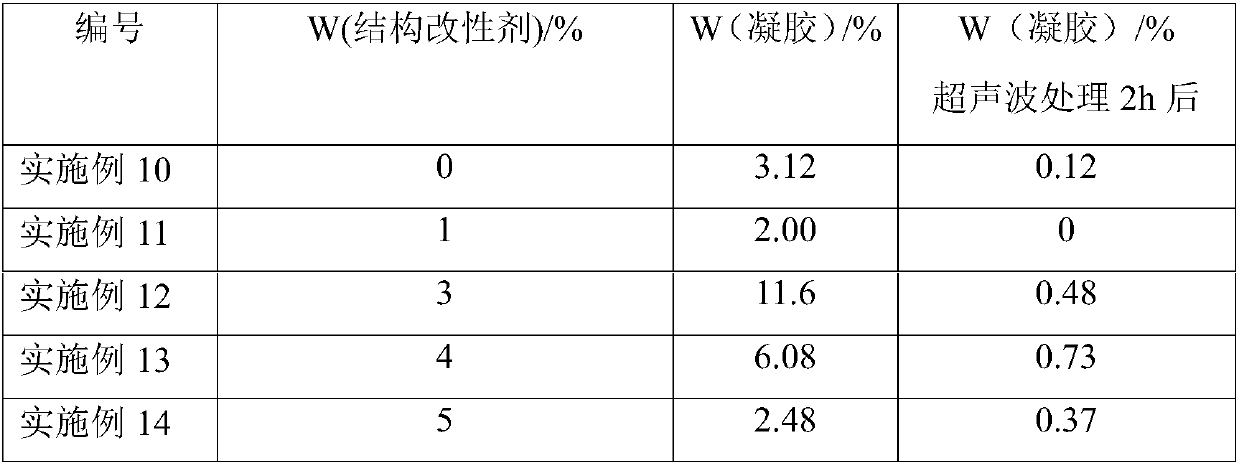

[0050] The preparation method of embodiment 2-5 is the same as that of embodiment 1, the difference is: according to butadiene adding mass 0, 2, 3, 4% dosage is added structural modifier, carries out butadiene polymerization test, analysis and detection embodiment 1-5 Viscosity of the polymerization system.

Embodiment 1~5

[0051] Table 1 embodiment 1~5 polymerization system viscosity test result

[0052] Numbering W(structure modifier) / % Viscosity / (mPa*s) Example 2 0 8.00×10 4

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap