Hydrophobic polymer film composite coating hydrophiling modification method

A technology of polymer membrane and hydrophobic type, which is applied in the field of hydrophilic modification of composite coating of hydrophobic polymer membrane, can solve the problems of restricting large-scale application, achieve mild conditions, improve hydrophilicity, and simple modification process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

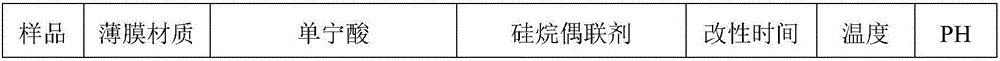

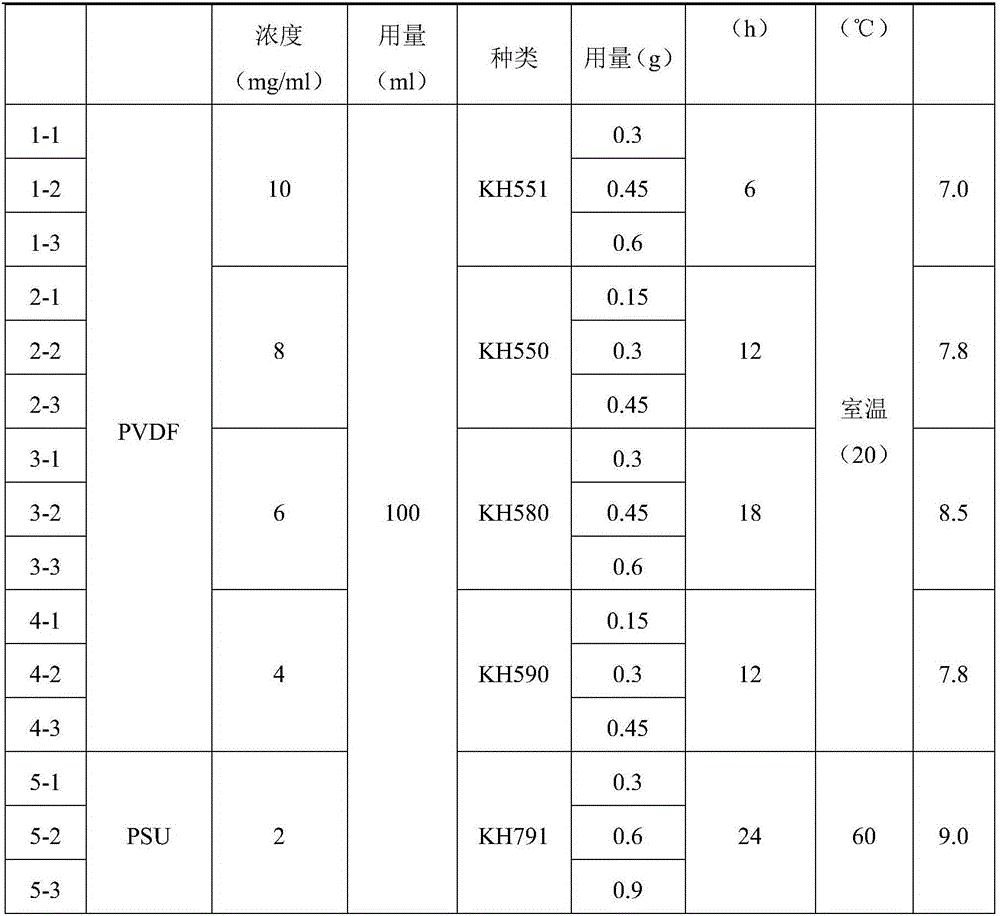

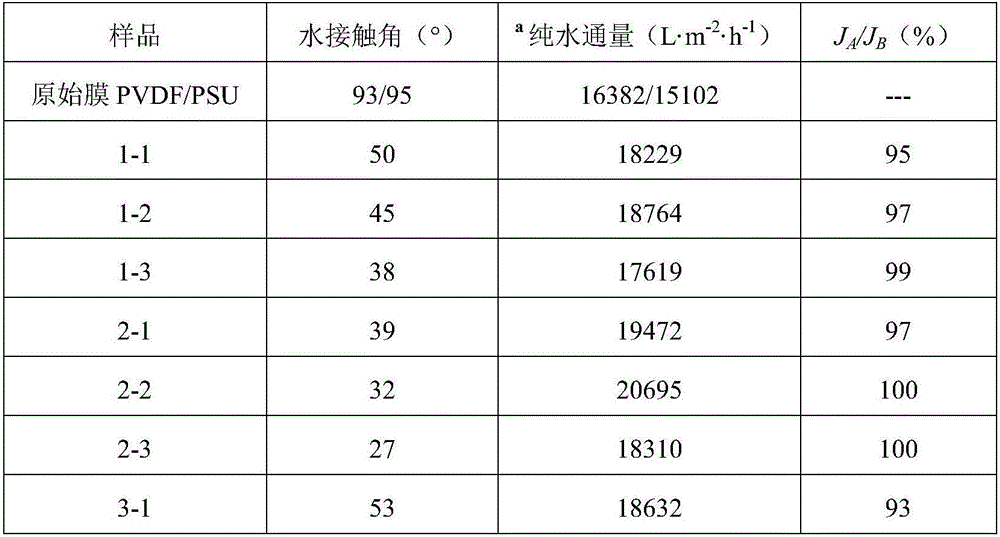

[0019] Prepare a tannin solution with a concentration of 10mg / ml, take 0.3g, 0.45g, and 0.6g of silane coupling agent KH551 respectively and dissolve them in 20ml of ethanol, then add the alcohol solution of this silane coupling agent to 100ml of prepared tannin solution, and finally adjust the pH of the solution to 7.0 with TRIS buffer to obtain a tannin-silane coupling agent solution. Soak and clean the PVDF membrane in isopropanol for 0.5h, then soak the wet film in deionized water for 1h, put the treated PVDF membrane in the tannin-silane coupling agent solution for 6h at room temperature Perform surface modification. After the modification is completed, the film is taken out and rinsed with deionized water for several times, and stored in deionized water or dried at room temperature to obtain a hydrophilic modified PVDF film sample. The specific modification conditions are shown in Table 1, samples 1-1, 1-2, and 1-3.

Embodiment 2

[0021] Prepare a tannin solution with a concentration of 8mg / ml, take 0.15g, 0.3g, and 0.45g of silane coupling agent KH550 respectively and dissolve them in 20ml of ethanol, then add the alcohol solution of this silane coupling agent to 100ml of prepared tannic acid solution, and finally adjust the pH of the solution to 7.8 with TRIS buffer to obtain a tannin-silane coupling agent solution. Soak and clean the PVDF membrane in isopropanol for 0.5h, then soak the wet film in deionized water for 1h, put the treated PVDF membrane in the tannin-silane coupling agent solution for 12h at room temperature Perform surface modification. After the modification is completed, the film is taken out and rinsed with deionized water for several times, and stored in deionized water or dried at room temperature to obtain a hydrophilic modified PVDF film sample. The specific modification conditions are shown in Table 1, samples 2-1, 2-2, and 2-3.

Embodiment 3

[0023] Prepare a tannin solution with a concentration of 6mg / ml, take 0.3g, 0.45g, and 0.6g of silane coupling agent KH580 respectively and dissolve them in 20ml of ethanol, then add the alcohol solution of the silane coupling agent to 100ml of prepared tannin solution, finally adjust the pH of the solution to 8.5 with TRIS buffer to obtain a tannin-silane coupling agent solution. Soak and clean the PVDF membrane in isopropanol for 0.5h, then soak the wet film in deionized water for 1h, put the treated PVDF membrane in the tannin-silane coupling agent solution for 18h at room temperature Perform surface modification. After the modification, the film was taken out and rinsed with deionized water several times, and stored in deionized water or dried at room temperature to obtain a hydrophilic modified PVDF film sample. The specific modification conditions are shown in Table 1, samples 3-1, 3-2, and 3-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap