Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about "Polyurea/polyurethane coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

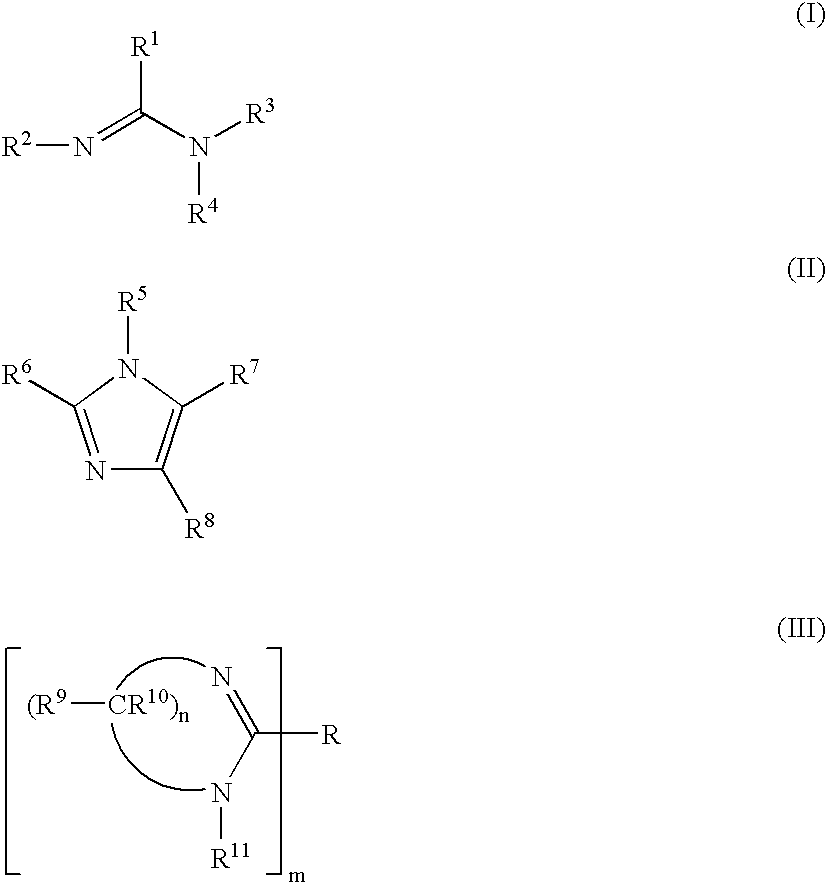

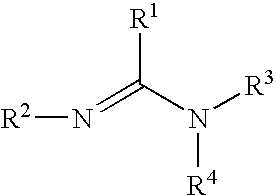

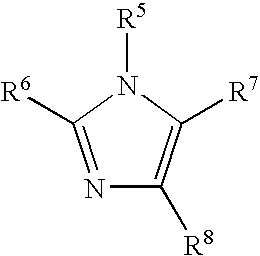

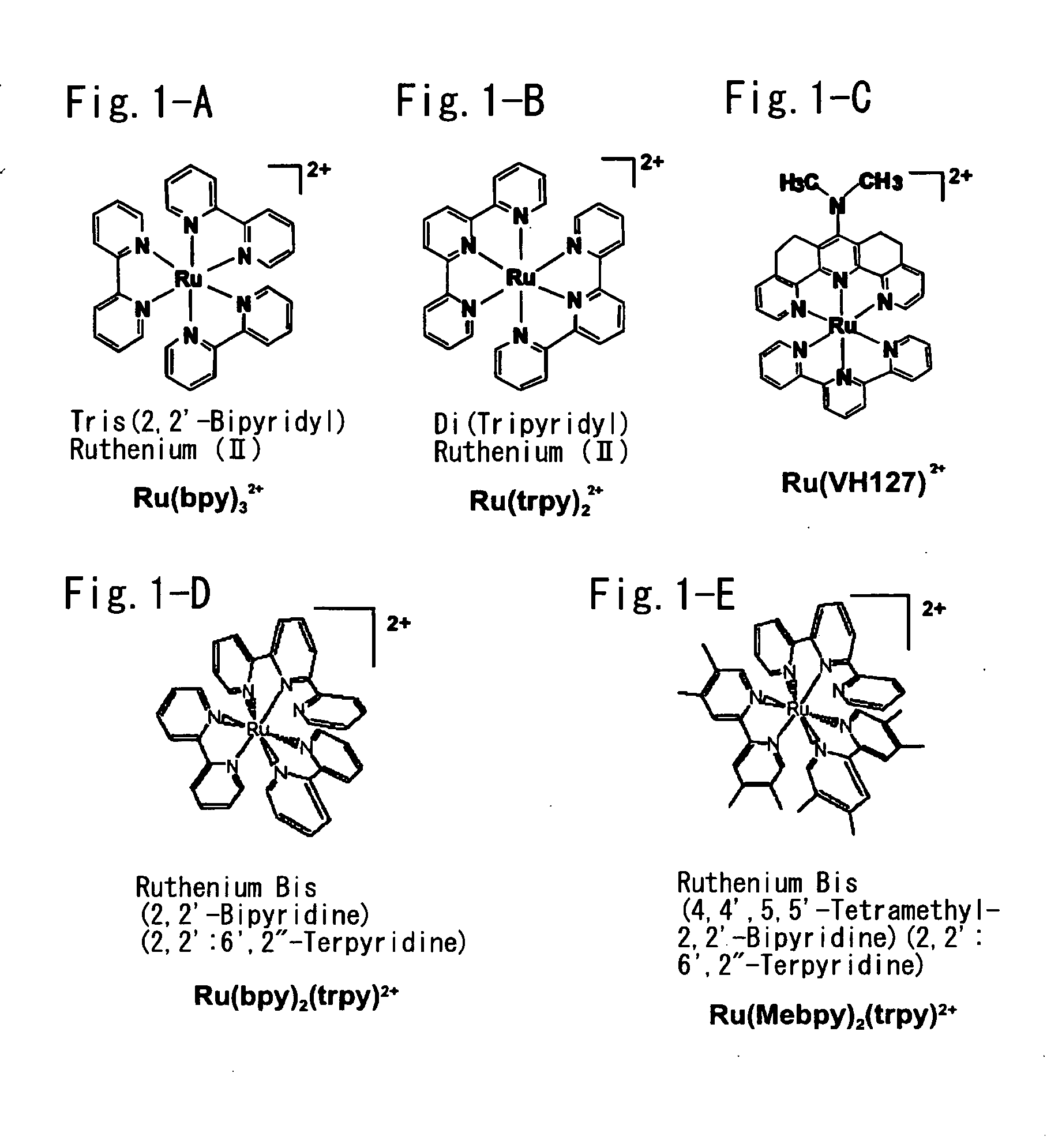

Organometallic compositions and coating compositions

InactiveUS20060036007A1Reduce yellowingImprove moisture resistanceOrganic-compounds/hydrides/coordination-complexes catalystsPolyurea/polyurethane coatingsCarbamateZinc

Owner:KING INDUSTRIES INC

Preparation method of novel cloudy-surface release paper

Owner:太仓斯迪克新材料科技有限公司

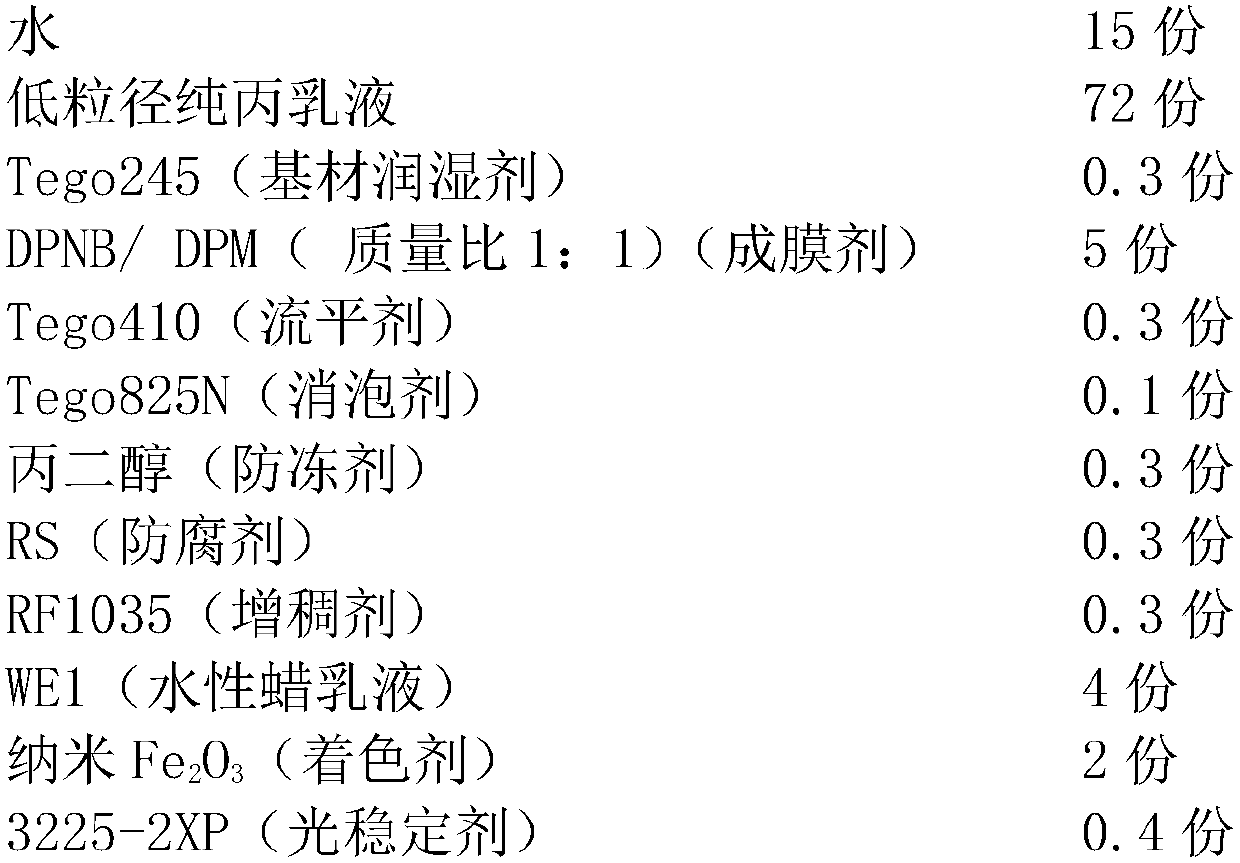

Outdoor waterborne woodenware penetration paint and preparation method thereof

InactiveCN107936742AReduced shear damageResist moisture intrusionPolyurea/polyurethane coatingsEmulsionLacquer

The invention belongs to the field of coatings for architectural ornament, and particularly relates to an outdoor waterborne woodenware penetration paint and a preparation method thereof. The penetration paint is prepared from the following components by weight: 10 to 15 parts of water, 65 to 80 parts of waterborne emulsion, 2 to 5 parts of coalescing agent, 2 to 25 parts of coloring agent and 4.5to 9 parts of other aids. The outdoor waterborne woodenware penetration paint prepared by the method has good base material closing property, excellent weather fastness and water resistance on the basis of a traditional woodenware paint; in addition, the cracking of a substrate can be reduced and the substrate can be protected from being corroded to a certain extent.

Owner:SHENYANG RES INST OF CHEM IND

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AInstant cureReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationUltraviolet lights

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

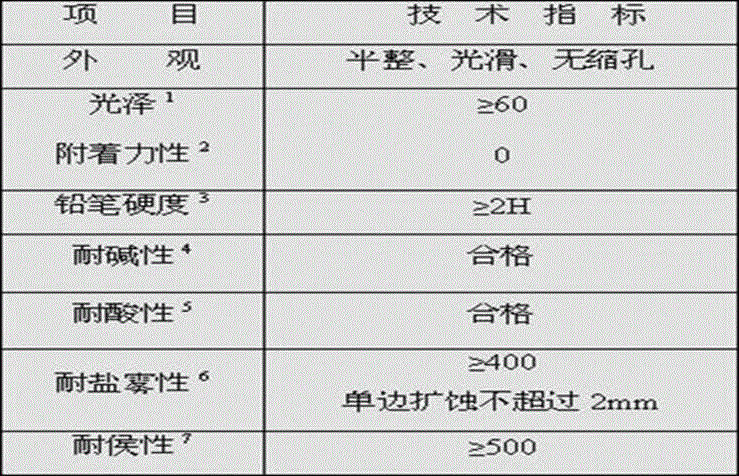

Cathode electrophoresis paint with combined bottom surfaces and preparation method and application method thereof

ActiveCN103333595APolyurea/polyurethane coatingsPaints for electrolytic applicationsWeather resistanceFirming agent

Owner:GUANGDONG KODEST EP SC CO LTD

Sandy paint made of color paint flakes

InactiveCN1974696APolyurea/polyurethane coatingsMulticolor effect coatingsMilk paintMaterials science

Owner:巢启

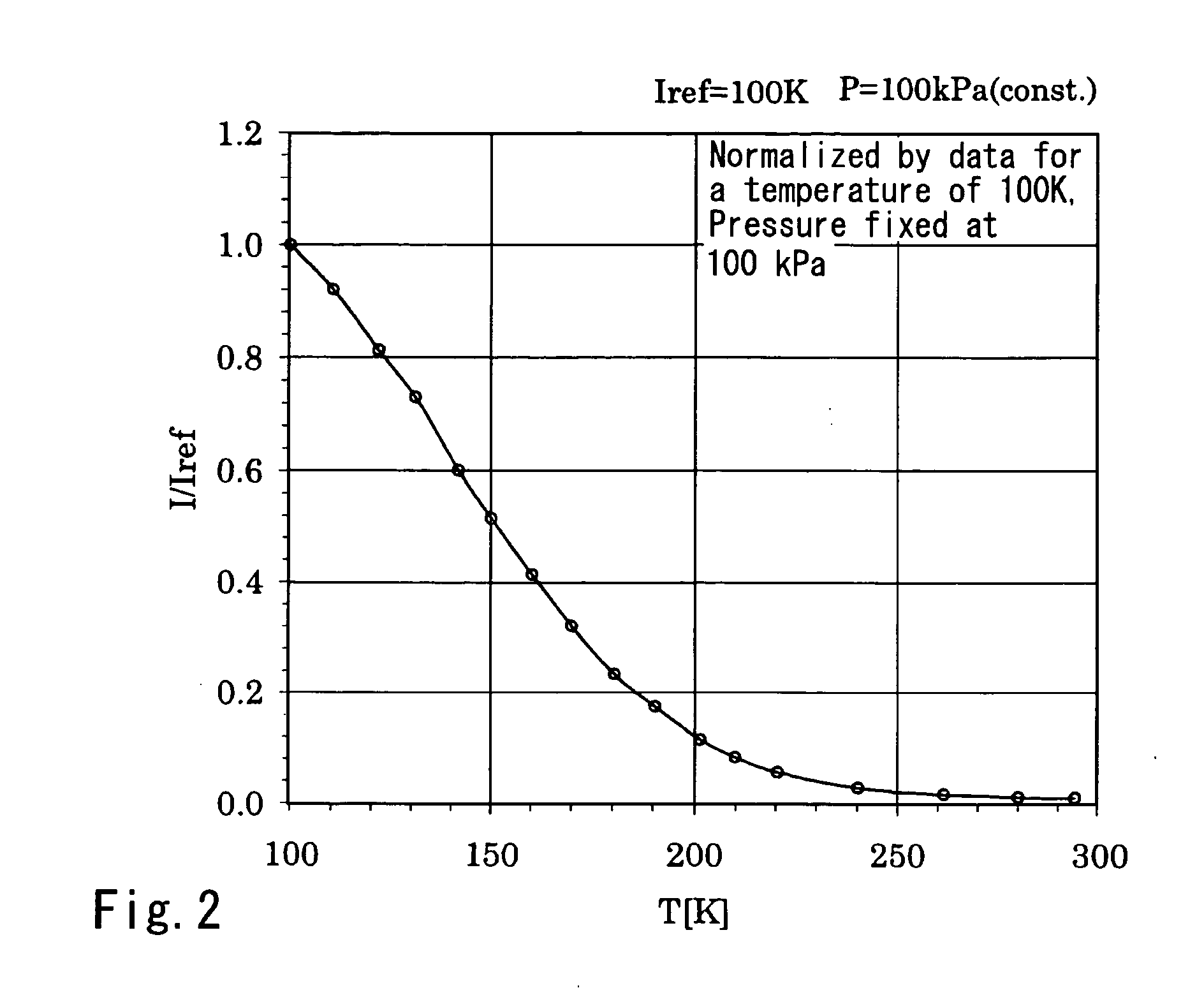

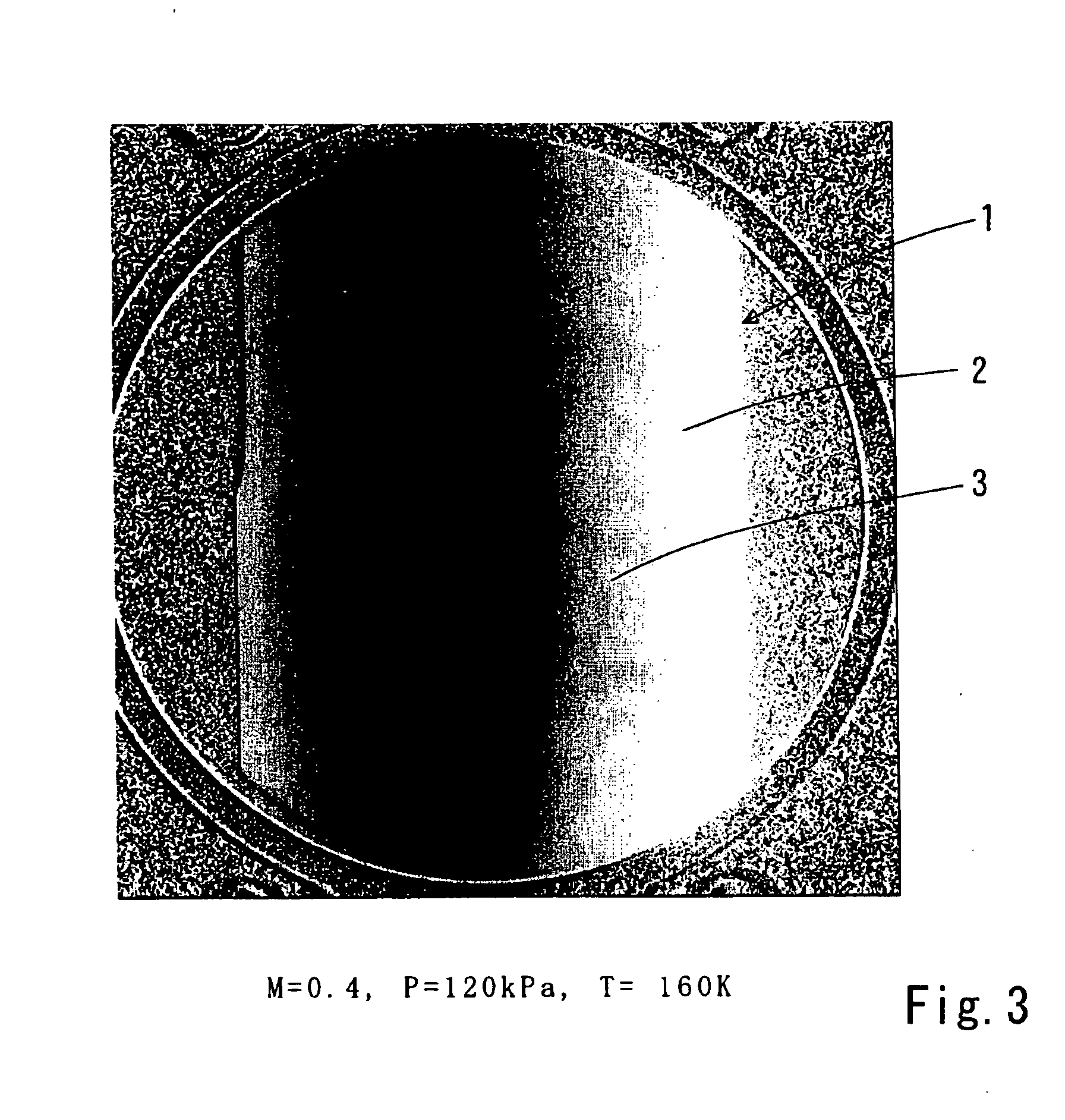

Temperature sensitive paint for low-temperature use

InactiveUS20050040368A1High luminous intensityLarge variation in light emission intensityAnalysis using chemical indicatorsLuminescent paintsSolubilityLuminous intensity

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsWater dispersibleSolvent

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

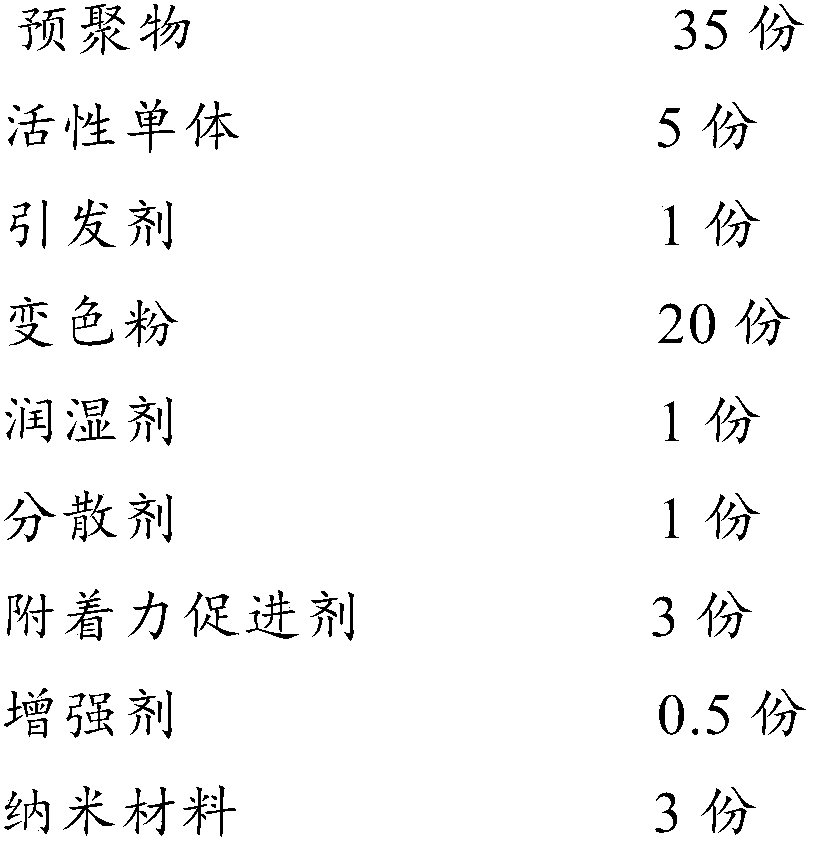

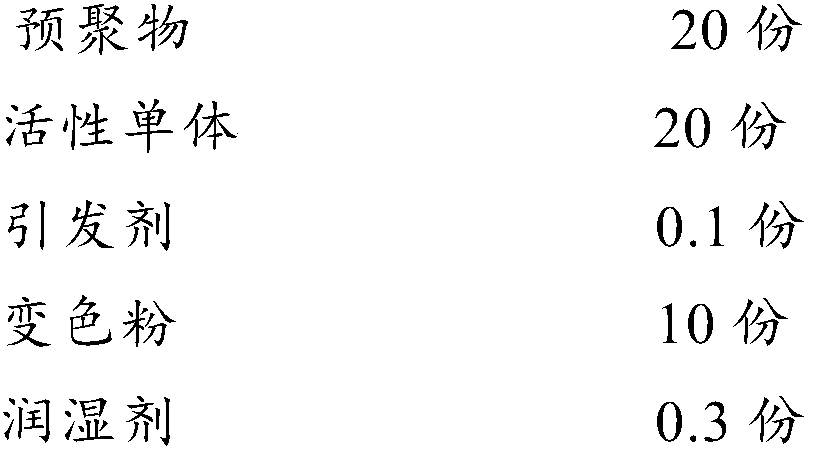

Photochromic glass paint and preparation method thereof

Owner:北京首创纳米科技有限公司

Inkjet printing fluid

InactiveUS20120277366A1High optical densityPolyurea/polyurethane coatingsWater dispersiblePolymer science

An inkjet printing fluid composition comprising water, colorant, acrylic latex polymer, and a water dispersible polyurethane additive having an acid number greater than 50, preferably between 50 and 150, more preferably from 60 to 100, and most preferably from 60 to 90. The invention provides inkjet printing fluid compositions, such as pigment-based inkjet printing inks, which contain an acrylic latex polymer which provides increased optical density for printed images, and a water dispersible polyurethane additive that enables the latex-containing printing fluid to be recirculated for extended periods in a recirculating printing fluid printing system without significant fluid destabilization or pressure build up or filter clogging. The invention further provides a method for printing an inkjet image comprising: I) providing an inkjet printing fluid according to the invention; and II) jetting the inkjet printing fluid in the form of ink drops onto a recording element to form a printed image.

Owner:EASTMAN KODAK CO

Simple and convenient synthesis method and application of waste grease based polyhydric alcohol

InactiveCN104262561ALow costSolve pollutionFatty acid esterificationPolyureas/polyurethane adhesivesTransesterification reactionAlcohol products

Owner:ZHEJIANG HENGFENG NEW MATERIAL

Solvent-free isocyanate prepolymer, preparartion method of solvent-free isocyanate prepolymer and isocyanate composition

InactiveCN103755920ALow viscosityAdjustable performancePolyurea/polyurethane coatingsPolymer scienceAlcohol

Owner:SHENZHEN JIADA HIGH TECH IND DEV

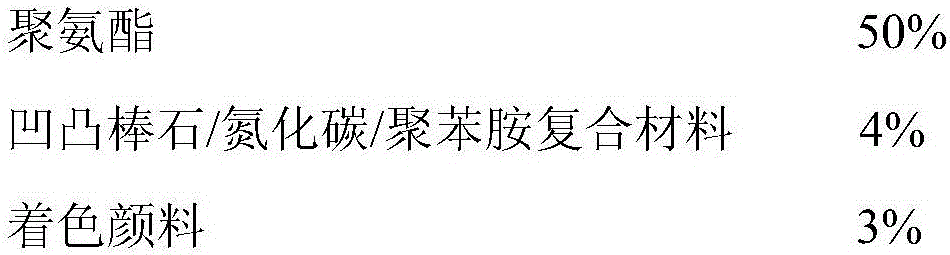

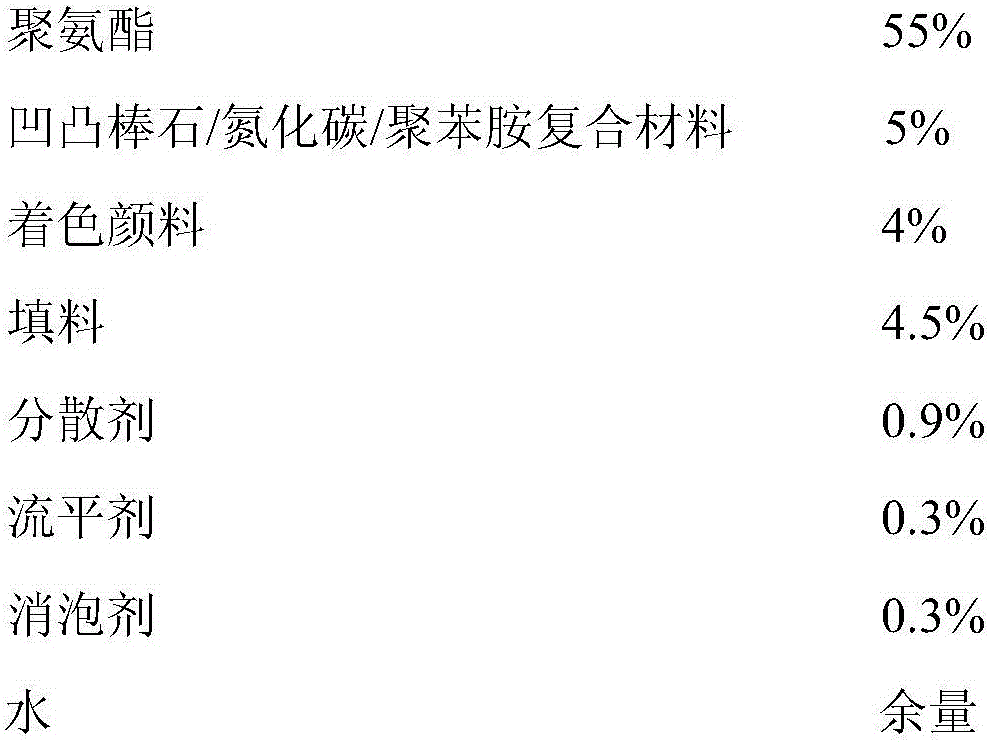

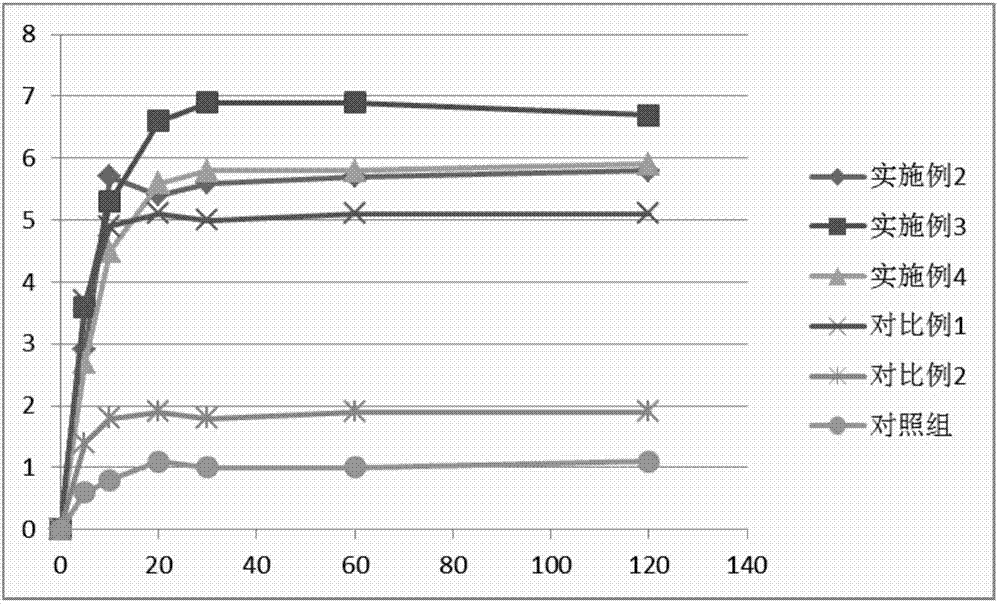

Preparation method of attapulgite-carbon nitride-polyaniline composite material and application thereof in anticorrosive paint

InactiveCN105754092AAvoid reunionReduce manufacturing costAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nitrideGraphite

Owner:CHANGZHOU UNIV

High infrared shielding rate thermal insulation paint and preparation method thereof

InactiveCN107880672AEffective insulationEven and stable insulationPolyurea/polyurethane coatingsIndiumMicrosphere

Owner:GUANGDONG VALSPAR CHEM IND

Polyurethane ionomer blends and methods for their preparation and formation

InactiveUS6949604B2Improve homogeneityGood physical propertiesPolyurea/polyurethane coatingsSolid ballsIonomerPolymer chemistry

Owner:BROWN UNIVERSITY +1

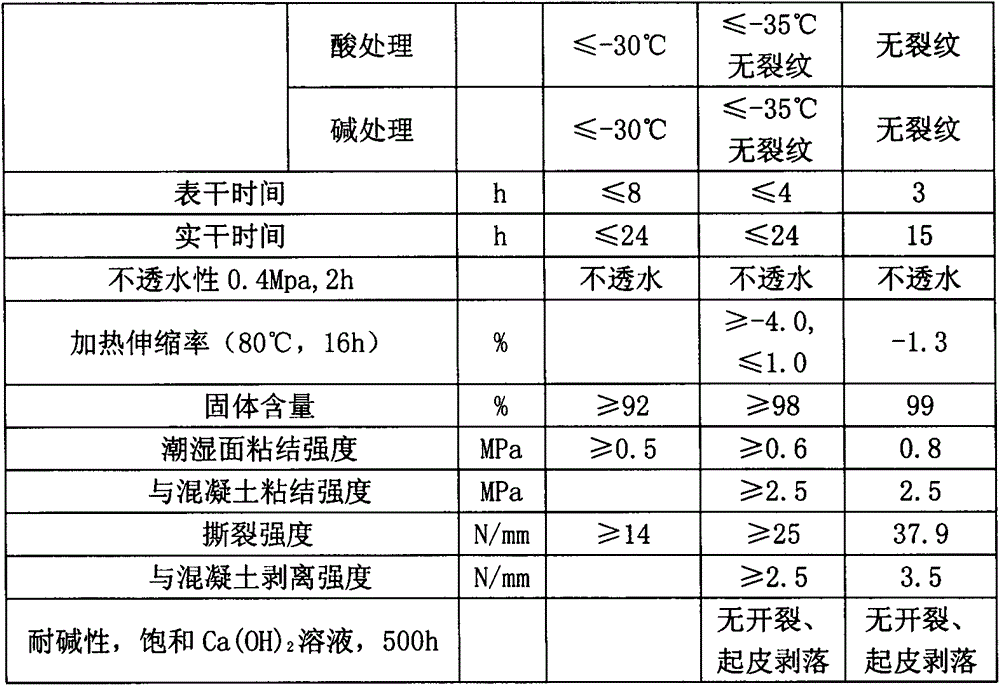

High-strength polyurethane waterproof paint

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Constant temperature curing high-bearing and anti-adhering wear resistant lubricating paint

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Bi-component polyurethane coating

InactiveCN104987819AReduces pungent odorsIncrease crosslink densityPolyurea/polyurethane coatingsHydrogenToluene diisocyanate

The invention provides a bi-component polyurethane coating, and relates to the field of coating. The bi-component polyurethane coating is composed of a component A and a component B. The component A comprises, by weight, 5-10 parts of acrylic resin dispersoid, 4-6 parts of glycol ether acetate, 5-9 parts of resin containing active hydrogen, 12-15 parts of padding, 8-10 parts of chitin derivative formaldehyde removal additives, 1-4 parts of anti-settling agents, 1-3 parts of defoaming agents and 2-3 parts of dryer. The component comprises, by weight, 7-13 parts of isocyanate and 10-12 parts of toluene diisocyanate capable. The bi-component polyurethane coating can reduce harm to the environment and the human body effectively and is suitable for being widely popularized.

Owner:SICHUAN ZHENFUTANG TRADING CO LTD

High-fidelity durable lightfast UV/UVLED curing coating for note and preparation method thereof

InactiveCN107325691ALow VOC/NOVOCWith transparentWax coatingsPaper coatingMethacrylateVinyl ether

Owner:XIAN BANKNOTE PRINTING +1

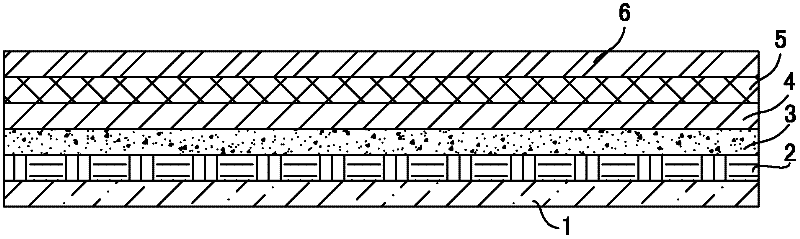

Method for forming multilayer coating film

InactiveUS20200010698A1Nice appearanceImprove chip resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer sciencePolyolefin

Owner:HONDA MOTOR CO LTD +1

Photocurable fluorinated copolymer composition

InactiveUS20140212673A1High transparencyExcellent abrasion resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsSilane compoundsEpoxy

Owner:ASAHI GLASS CO LTD

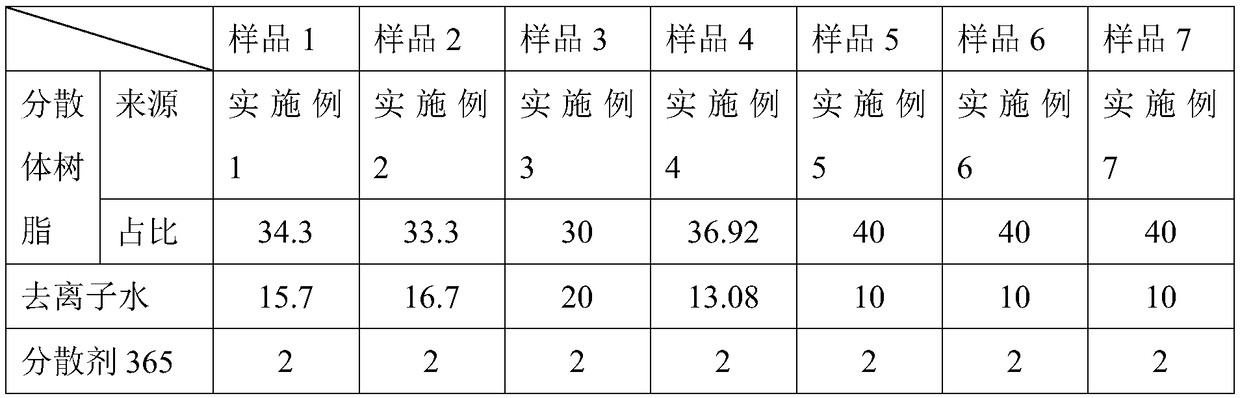

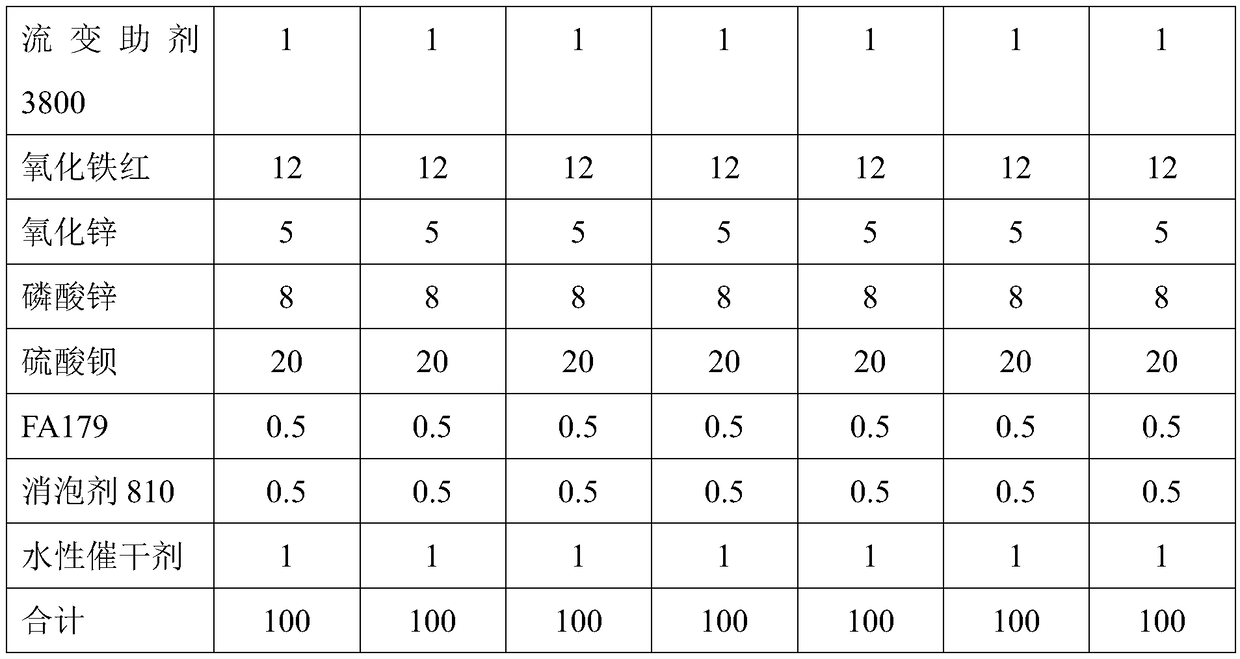

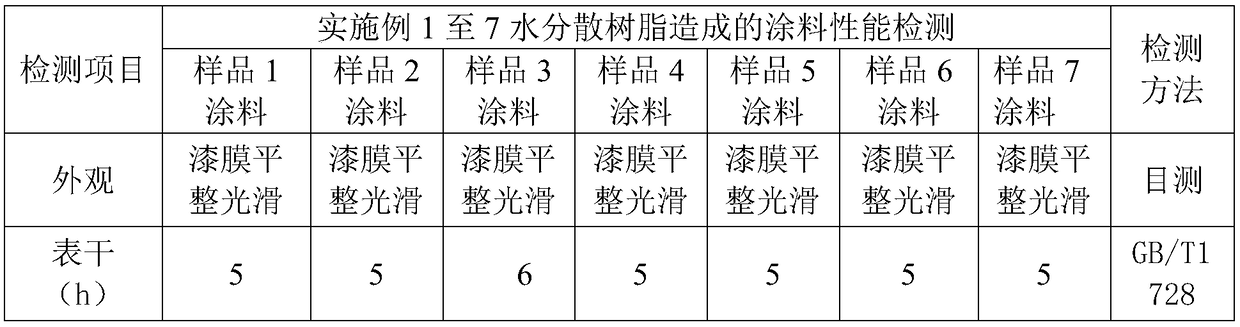

Water dispersible rein and a preparing method thereof

PendingCN108949000AWide variety of sourcesReduce pollutionAnti-corrosive paintsPolyurea/polyurethane coatingsWater dispersibleChemistry

Water dispersible rein is provided. The water dispersible rein is prepared mainly from, by weight, 25-40 parts of cardanol, 15-40 parts of epoxidized vegetable oil, 3-6 parts of diisocyanate, 2-5 parts of polyethylene glycol or hydroxy-terminated polymer and 40-60 parts of deionized water. A preparing method of the water dispersible resin is also provided. The water dispersible rein is prepared from purely-natural biologically extracted raw materials which are wide in source, high in quality and low in cost and are ideal biological-based raw materials. The water dispersible resin prepared fromnatural raw materials can reduce environment pollution, plays a role of continuously improving ecological environment and protecting the nature, and is a novel green product. The water dispersible resin, as a film forming substance in coating, can greatly reduce harm to environment or human during production or construction, and can be used for producing coating products which are nearly VOC-zero, and paint films are decorative, anticorrosion, and environmentally friendly. The resin is a newest environmentally friendly product at present.

Owner:山东奔腾漆业股份有限公司

UV (ultraviolet)-highly-clear curtaining finish

Owner:JIANGSU HIMONIA TECH

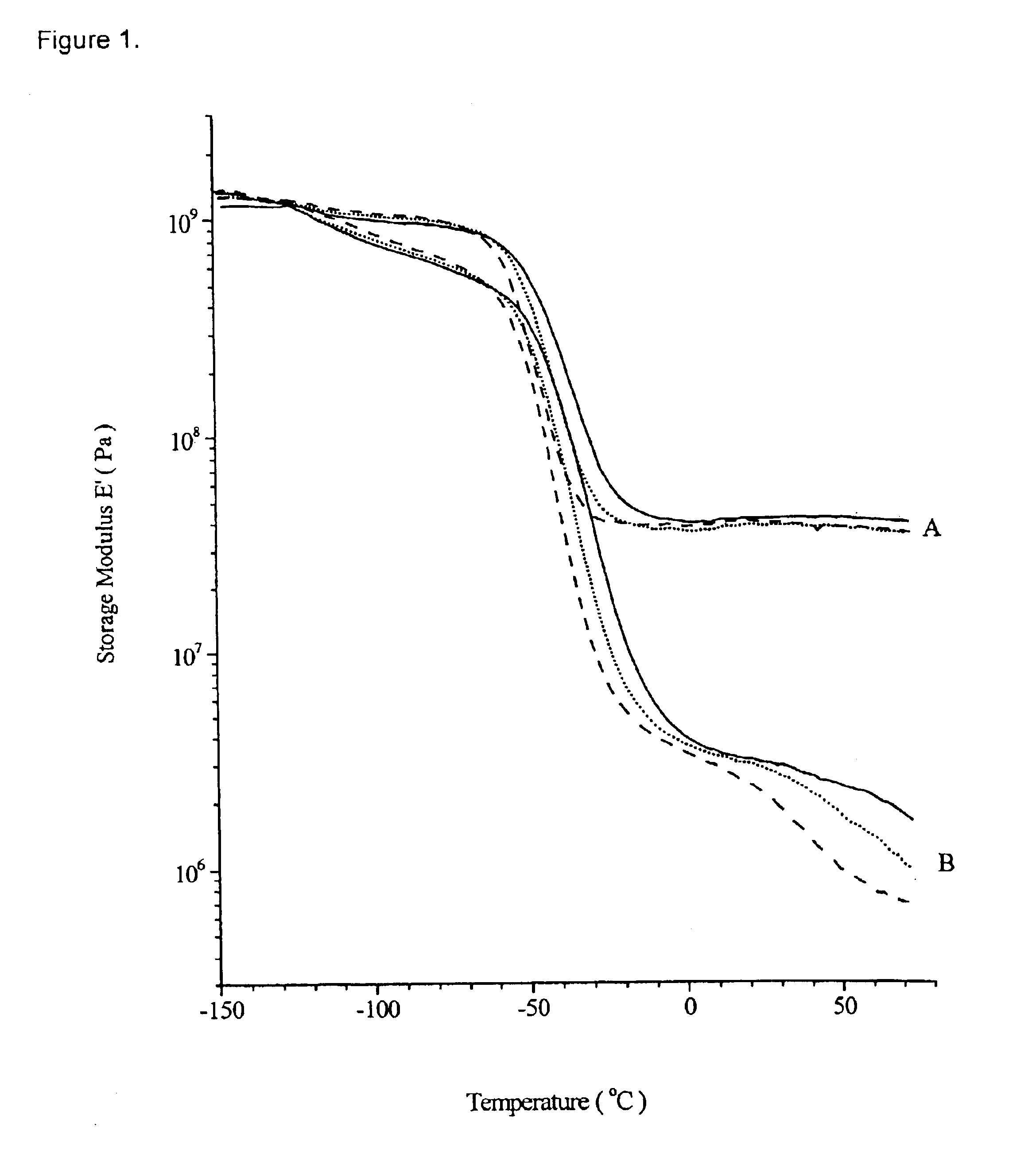

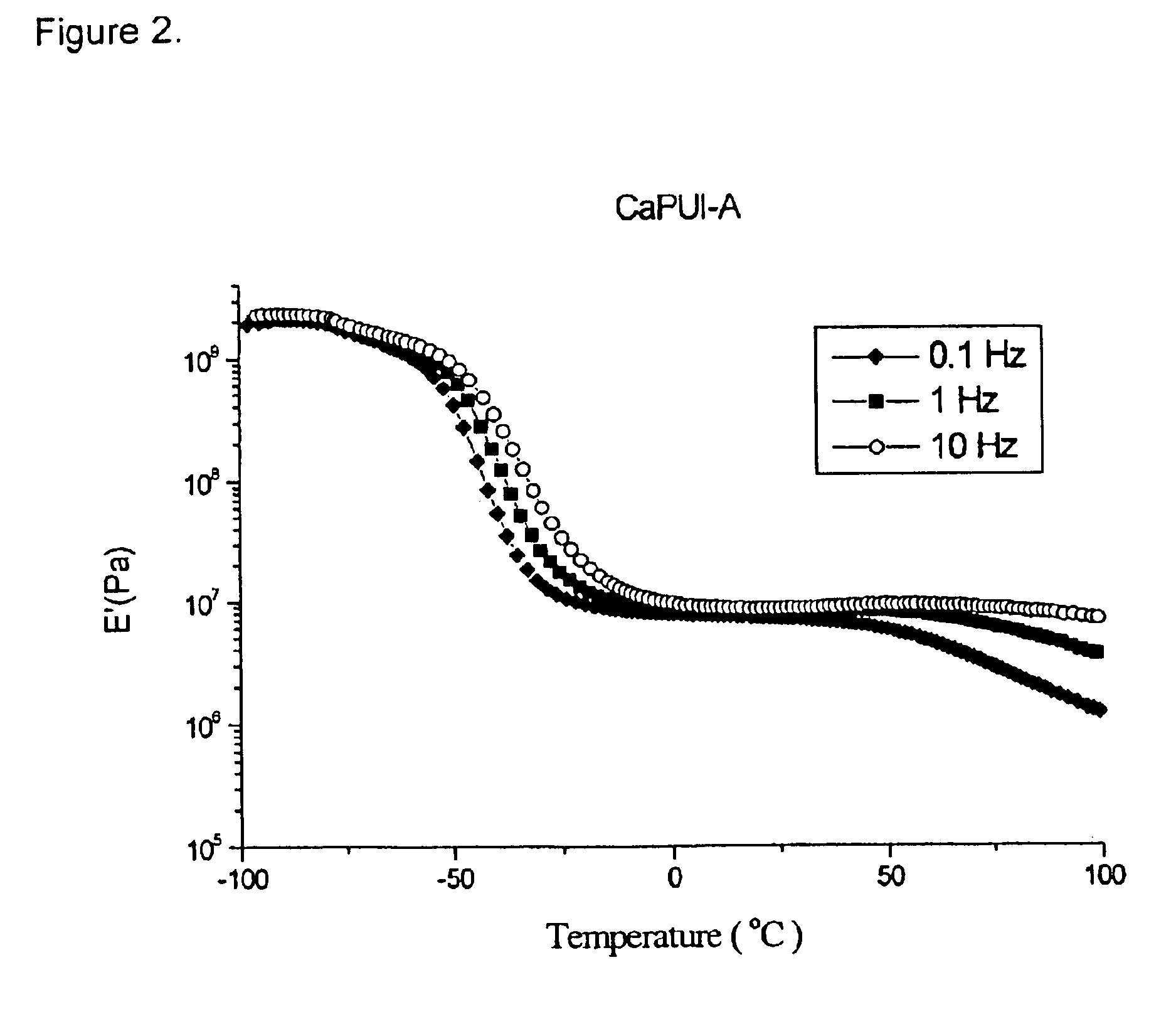

Fiber coatings with low modulus and high critical stress

Fiber coatings with low Young's modulus, high tear strength, and / or high critical stress are achieved with coating compositions that include an oligomeric material formed from an isocyanate, a hydroxyacrylate compound and a polyol. The oligomeric material includes a polyether urethane acrylate and a di-adduct compound. The reaction mixture used to form the oligomeric material includes a molar ratio of isocyanate:hydroxy acrylate:polyol of n:m:p, where when p is 2, n is in the range from 3.0 to 5.0 and m is in the range from 1.50n-3 to 2.50n-5. Control of the n:m:p ratio leads to compositionsthat, when cured, provide coatings and cured products having high critical stress, high tear strength, and a high ratio of tear strength to Young's modulus.

Owner:CORNING INC

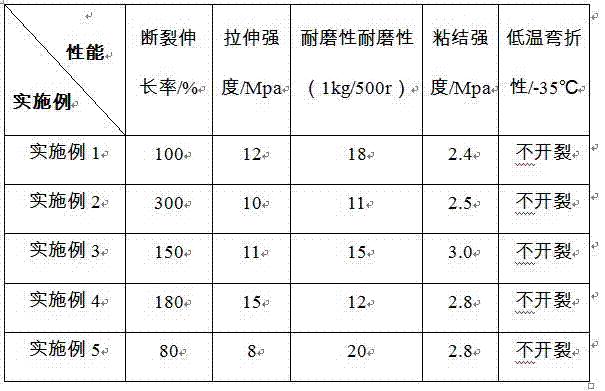

Waterborne polyurethane super wear-resistant finish paint and preparation process thereof

ActiveCN109456690ASmall particle diameterGood dispersionPolyurea/polyurethane coatingsWear resistantWear resistance

The invention discloses waterborne polyurethane super wear-resistant finish paint and a preparation process thereof, and relates to the technical field of preparation of finish paint, aiming at solving the problem that the finish paint is poorer in wear resistance, so that local damage is easily caused in a using process. The finish paint is prepared from a component A and a component B, wherein the component A is prepared from the following raw materials: 50-60 parts of waterborne polyurethane resin AH-1618, 12-18 parts of polyurethane color paste, 0.8-1.2 parts of a leveling agent BYK346, 0.3-0.5 part of an aqueous leveling agent BYK333, 0.3-0.6 part of a polyurethane rheological agent SN612NC, 0.3-0.5 part of a defoaming agent BYK024, 0.08-0.1 part of a defoaming agent Tego901W, 0.8-1.5parts of rutile titanium dioxide, 8-10 parts of wear-resistant ball powder, 0.8-1.5 parts of an aqueous scratch-resistant agent, 1.2-1.6 parts of propylene glycol methyl ether and 12-18 parts of deionized water; the component B is prepared from 95-100 parts of a polyurethane curing agent; the ratio of parts by weight of the component A to parts by weight of the components B is equal to (4-6) to 1. The waterborne polyurethane super wear-resistant finish paint has good wear resistance after being cured.

Owner:SHANGHAI BOGE BUILDING MATERIALS CO LTD

Seal primer added polymer with formaldehyde catching function and preparation method of polymer

InactiveCN104311737ASignificant and durable capture and removal capabilitiesClosed influencePolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterOrganic solvent

The invention discloses a seal primer added polymer with a formaldehyde catching function. The seal primer comprises acrylamide, an acrylate soft monomer, an acrylate hard monomer, an acrylate long-chain monomer, an initiator and an organic solvent. The invention further discloses a preparation method of the seal primer added polymer with the formaldehyde catching function. Resin prepared by adopting the seal primer added polymer with the formaldehyde catching function and the preparation method thereof has good compatibility with existing wooden ware primers (nitro wooden ware primer, polyester two-component wooden ware primer, acrylic emulsion type wooden ware primer, epoxy two-component wooden ware primer and the like); according to the formaldehyde content of a wooden ware base material, the polymer is added into the traditional wooden ware primer; and the wooden ware seal primer prepared by adding the polymer has obvious and lasting formaldehyde catching and clearing capability on the premise that obvious poor influence is not produced on the aspects of closure, adhesion, flexibility, polishing property and the like.

Owner:GUANGZHOU UNIVERSITY

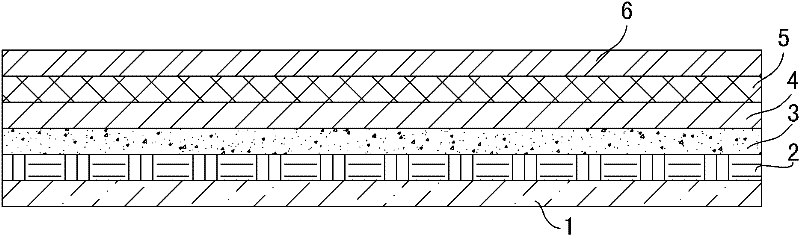

Fabrication technique of antiskid polyurea terrace paint surface

InactiveCN101476380AFast constructionIncrease elasticityPolyurea/polyurethane coatingsFlooringParking areaSurface layer

Owner:BEIJING BAIZHENGWEI SYNTHETIC RUBBER MFG

Wear-resistant and high-temperature resistant capacitor aluminum case film coating paint and preparation method thereof

InactiveCN102373006AEffective protectionExtended service lifePolyurea/polyurethane coatingsMeth-Ketone

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Preparation method of silicon-free PET release film

InactiveCN111410925AImprove toughnessIncreased drug resistancePolyurea/polyurethane coatingsFilm/foil adhesive release linersDrug resistancePolymer chemistry

Owner:苏州市奥贝新材料科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap