Solvent-free isocyanate prepolymer, preparartion method of solvent-free isocyanate prepolymer and isocyanate composition

A kind of isocyanate prepolymerization, isocyanate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

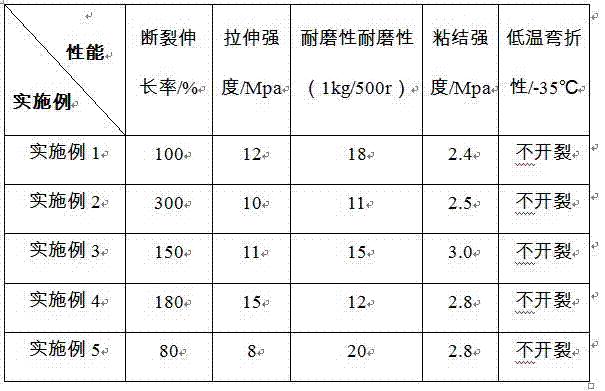

Examples

preparation example Construction

[0022] The embodiment of the present invention provides a method for preparing a solvent-free elastic isocyanate prepolymer. The method comprises the steps of:

[0023] S01: divide the glycol polymer into three parts after dehydration treatment;

[0024] S02: react the isocyanate monomer with the first diol polymer at room temperature for the first time;

[0025] S03: raising the temperature of the reactants of the first reaction to 40-70°C, adding the second part of glycol polymer to carry out the second reaction;

[0026] S04: raising the temperature of the reactant in the second reaction to 70-120° C., adding a third part of glycol polymer to carry out the third reaction until the content of NCO in the reactant reaches the theoretical value to end the reaction.

[0027] Specifically, the dehydration treatment of the glycol polymer in the above-mentioned step S01 is preferably carried out as follows:

[0028] The glycol polymer is dehydrated for 2-4 hours in an environment w

Embodiment 1

[0055] Solvent-free elastic isocyanate prepolymer and its preparation method:

[0056] S11: Take 1mol of PPG-1000 in a flask with heating and vacuum distillation, remove water for 2 hours at a pressure of 1000pa and a temperature of 120°C, cool and add it to a constant pressure funnel for use;

[0057] S12: Add 2.5 mol of TDI into the flask, start stirring, quickly add 1 / 4 mol of PPG-1000 into the flask, react at room temperature for 1 hour, then raise the temperature to 60°C, and slowly add 2 / 4 mol of PPG-1000 dropwise after the temperature stabilizes , after the dropwise addition, react at 60°C for 1h, continue to add dropwise to complete the remaining 1 / 4molPPG-1000; after the dropwise addition, raise the temperature to 75°C, and react for 2h after the temperature stabilizes, the NCO value is 8.8%, stop the reaction, after cooling down , put the product into a thin-film evaporator to evaporate the unreacted TDI monomer, and the NCO value of the final product is 6.2%, whi

Embodiment 2

[0063] Solvent-free elastic isocyanate prepolymer and its preparation method:

[0064] S21: Take 1molPPG-2000 in a flask with heating and vacuum distillation, remove water for 2 hours at a pressure of 2000pa and a temperature of 120°C, cool and add it to a constant pressure funnel for use;

[0065] S22: Add 3 mol of HTDI into the flask, start stirring, quickly add 1 / 4 mol of PPG-2000 into the flask, react at room temperature for 0.5h, then raise the temperature to 70°C, and slowly add 2 / 4 mol of PPG-2000 dropwise after the temperature stabilizes , After the dropwise addition, react at 70°C for 1 hour, continue dropwise to complete the remaining 1 / 4mol PPG-2000. After the dropwise addition, raise the temperature to 85°C, and react for 2 hours after the temperature stabilizes. The NCO value is 6.6%, stop the reaction, and cool down , put the product into a thin film evaporator to evaporate the unreacted HTDI monomer, and the final product has a detected NCO value of 3.6%, whi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap