Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Prepolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term pre-polymer refers to a monomer or system of monomers that have been reacted to an intermediate molecular mass state. This material is capable of further polymerization by reactive groups to a fully cured high molecular weight state. As such, mixtures of reactive polymers with un-reacted monomers may also be referred to as pre-polymers. The term “pre-polymer” and “polymer precursor” may be interchanged.

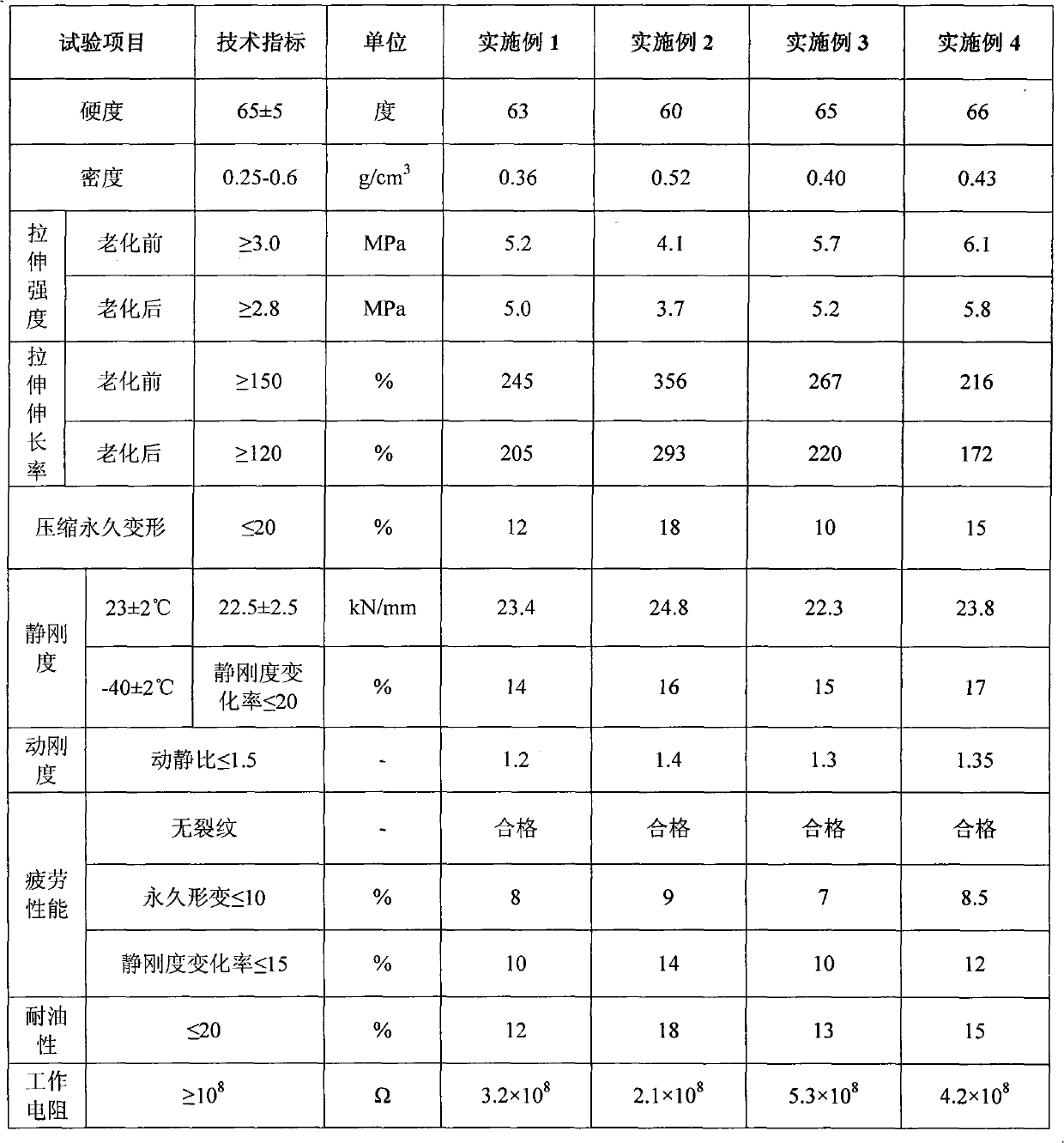

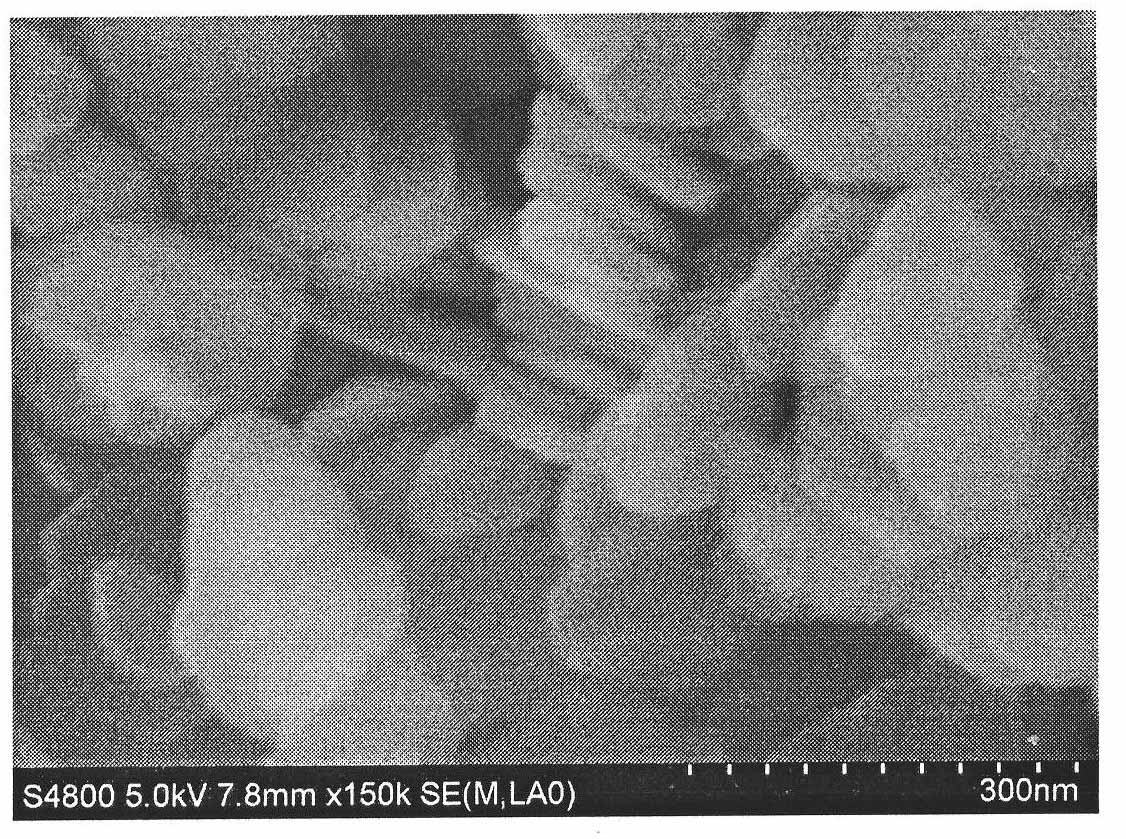

Microporous polyurethane elastomer shock absorption element for high-speed railway and preparation method thereof

Owner:ANHUI UNIVERSITY +1

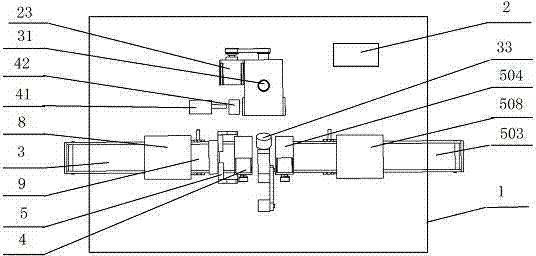

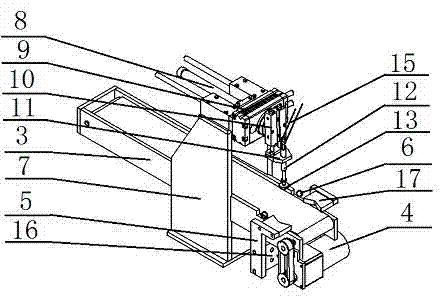

Full-automatic resin lens casting machine

Owner:LINHAI JINZHENG MACHINERY

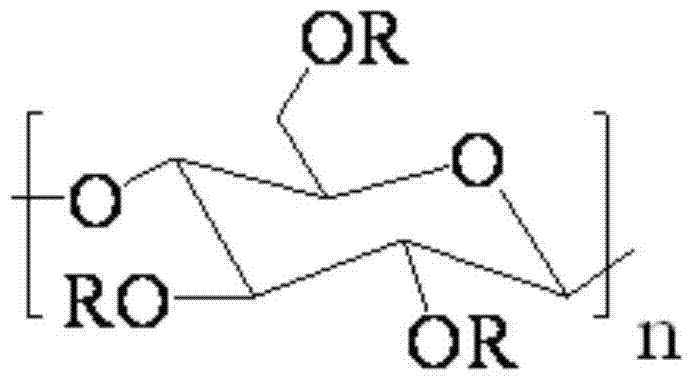

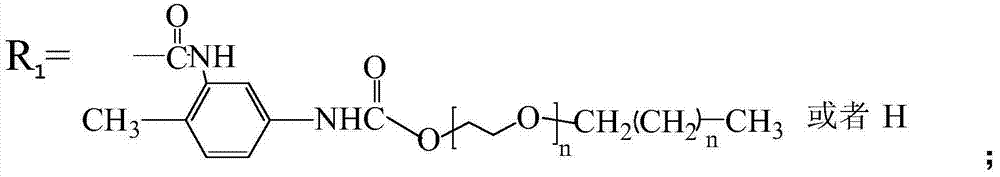

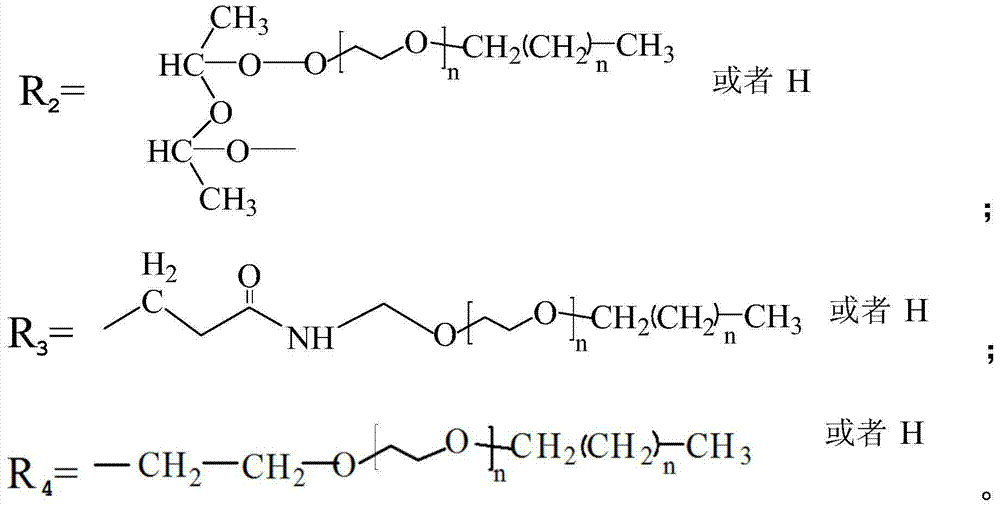

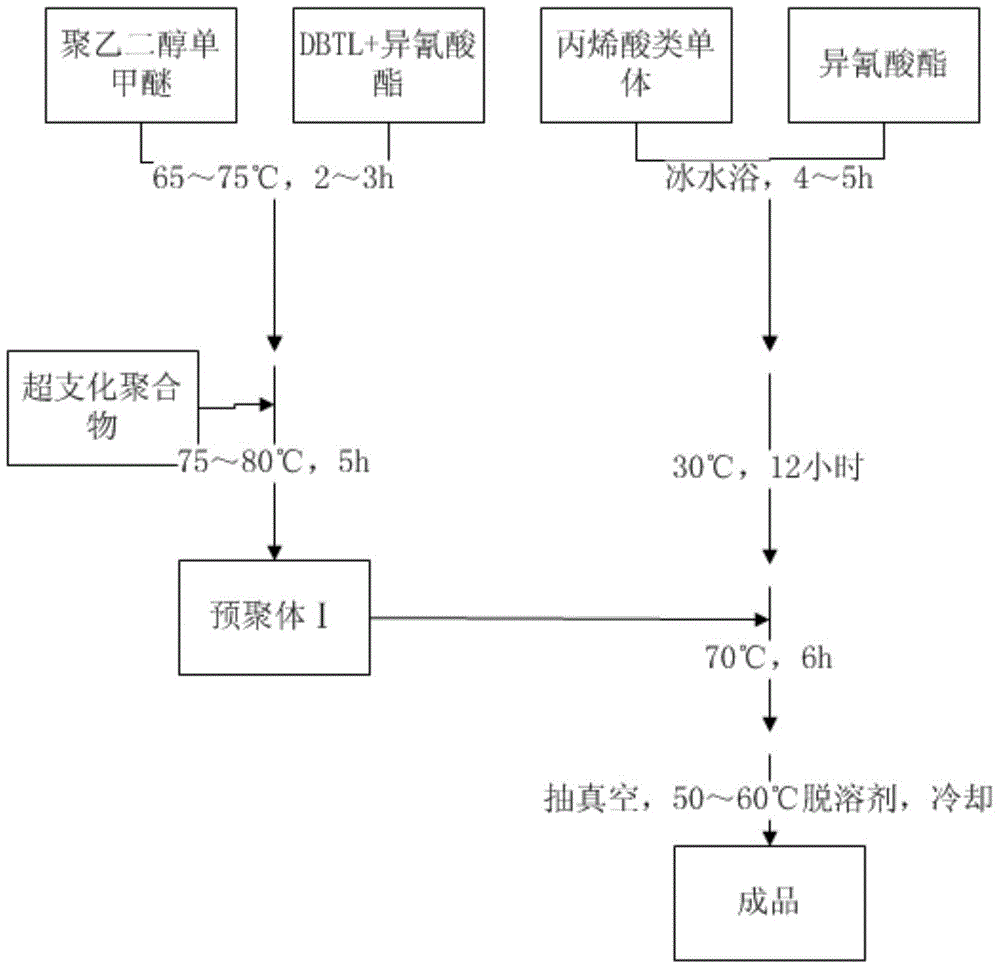

Thermoplastic cellulose-based solid-solid phase transition material and preparation method thereof

Owner:TIANJIN POLYTECHNIC UNIV +1

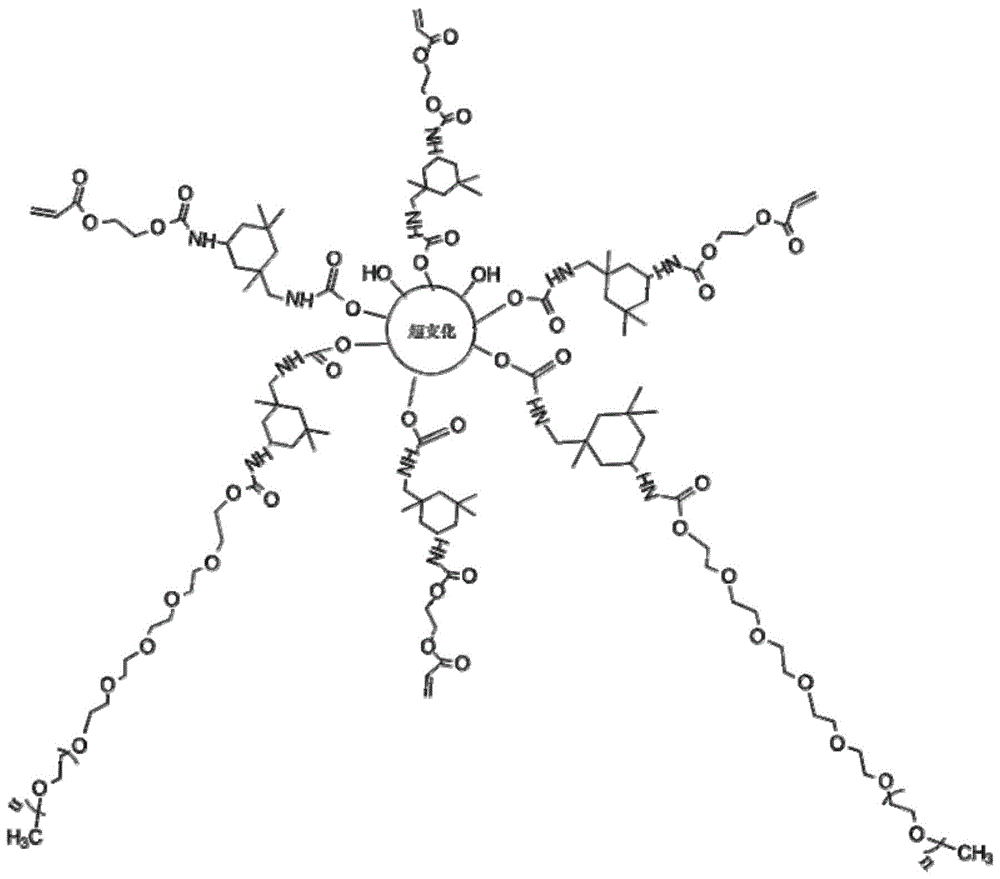

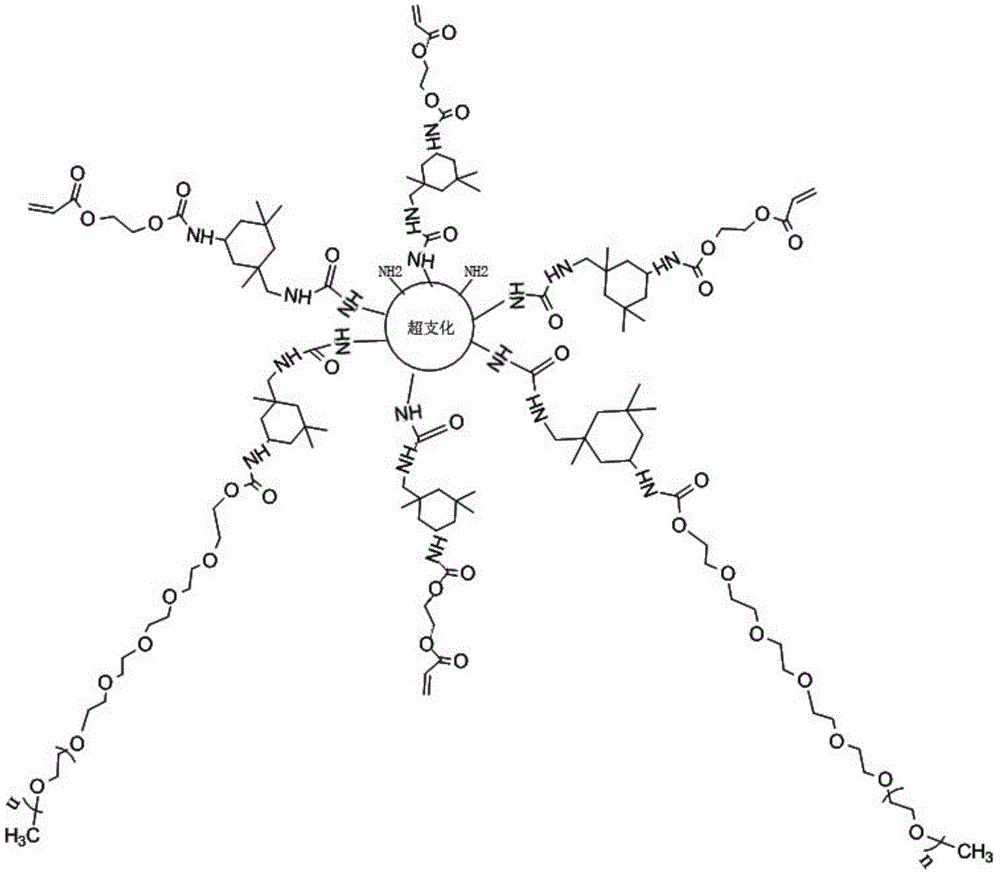

Hydrophilic UV (Ultraviolet) coating hardness assistant and preparation method thereof

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

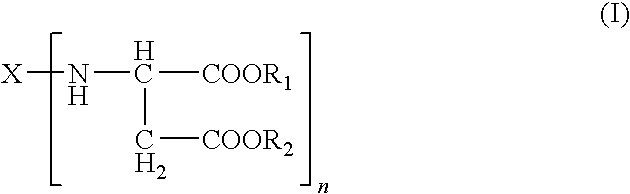

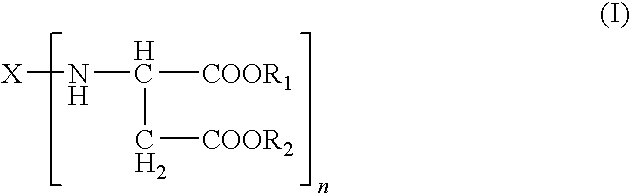

Adhesive systems containing polyisocyanate prepolymers and aspartate-ester curing agents, processes for preparing the same, medical uses therefor and dispensing systems for the same

InactiveUS20090191145A1Broaden applicationSurgical adhesivesPolyureas/polyurethane adhesivesPolyolHydrogen

Owner:BAYER MATERIALSCIENCE AG

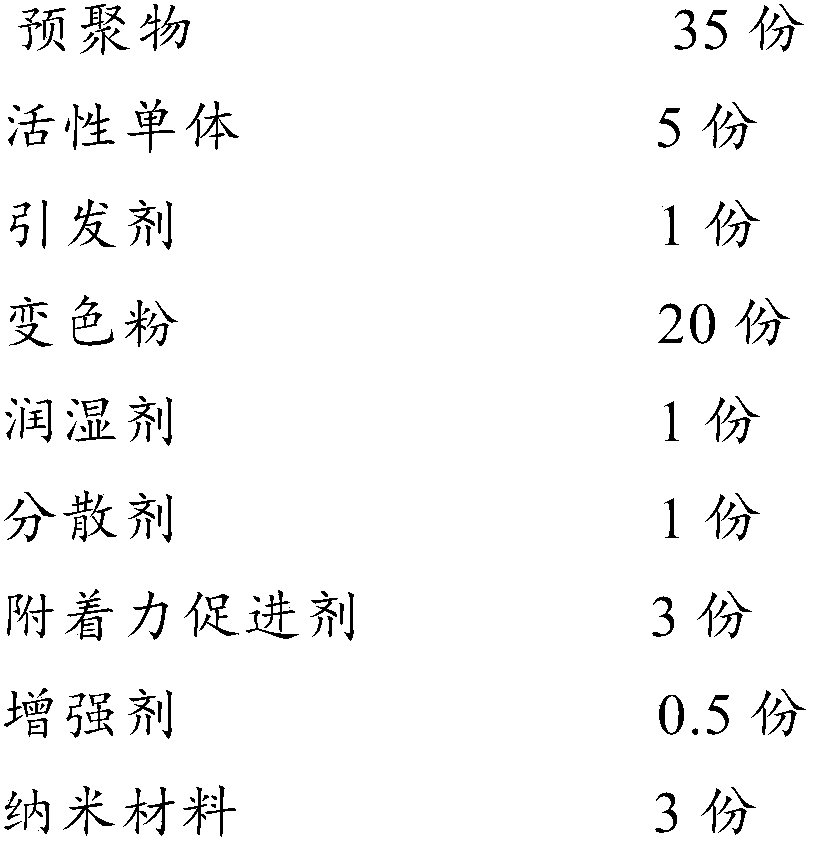

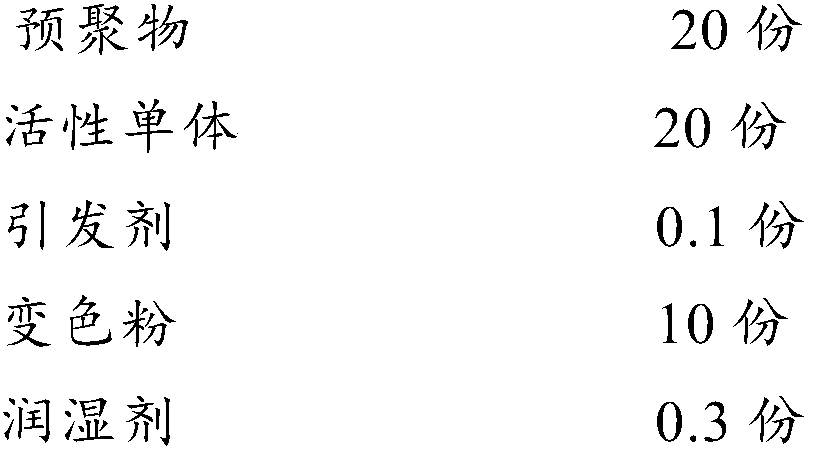

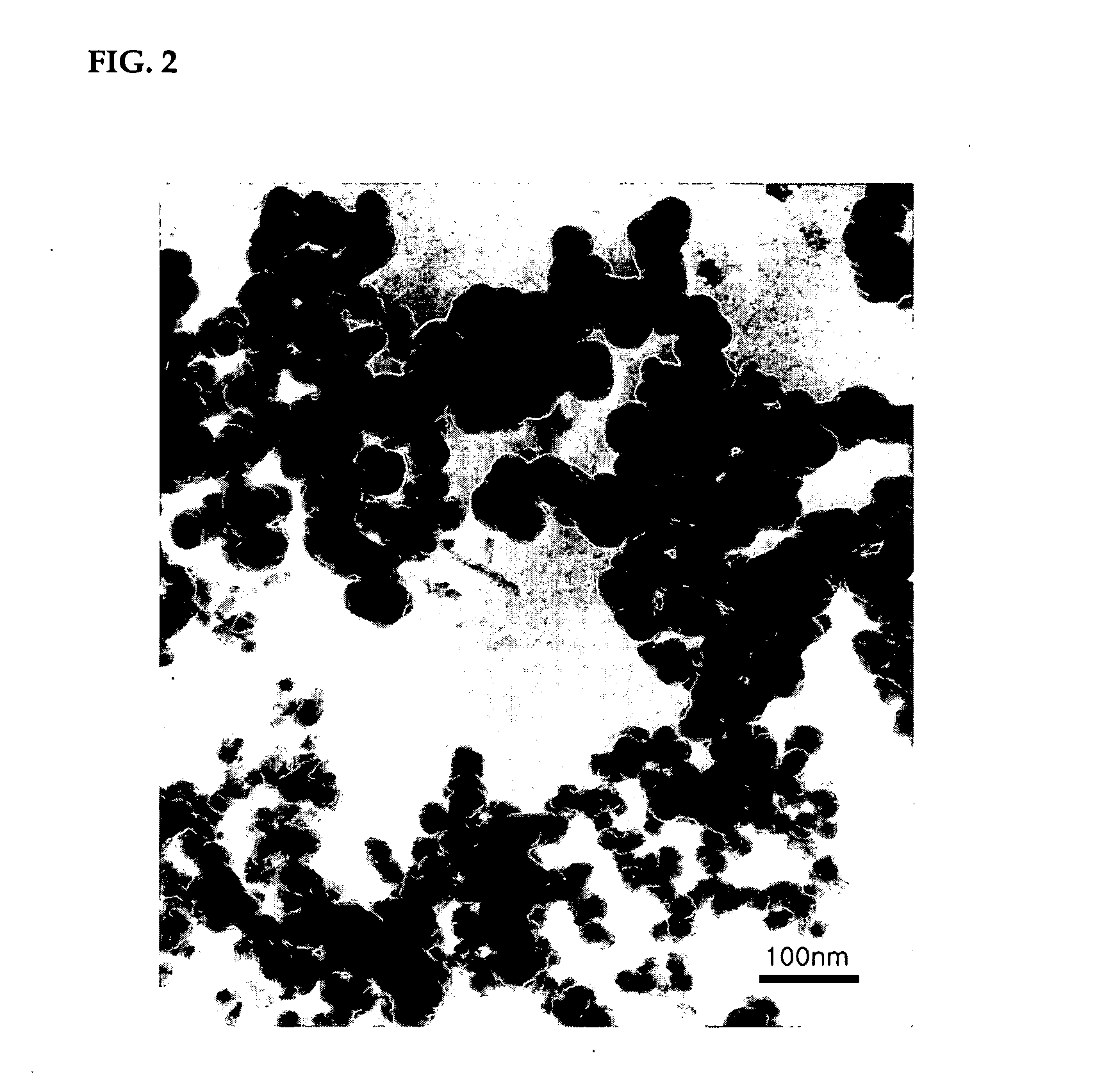

Photochromic glass paint and preparation method thereof

Owner:北京首创纳米科技有限公司

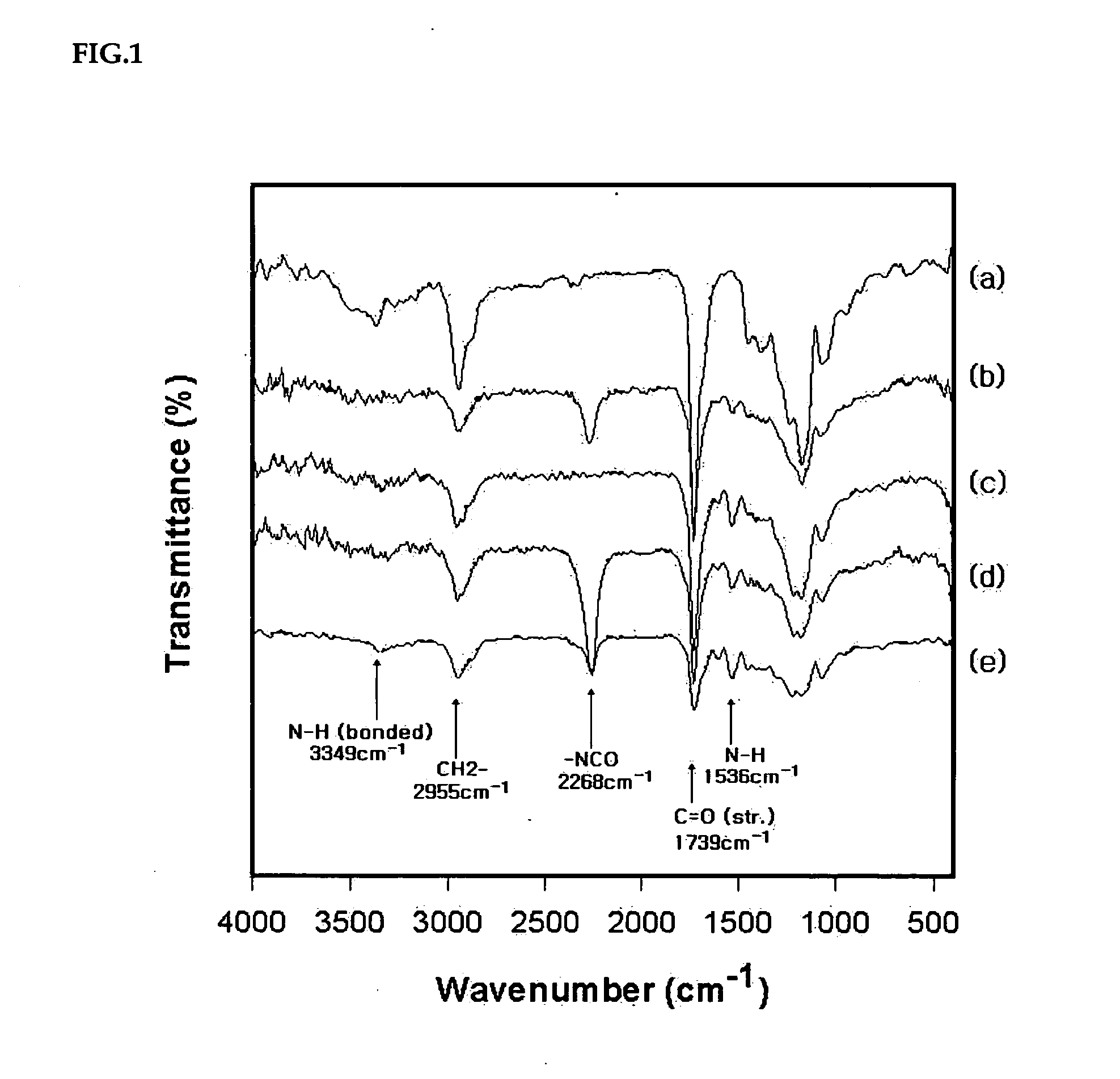

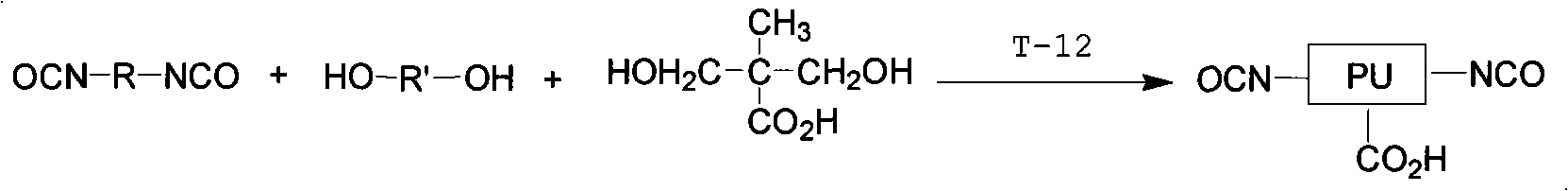

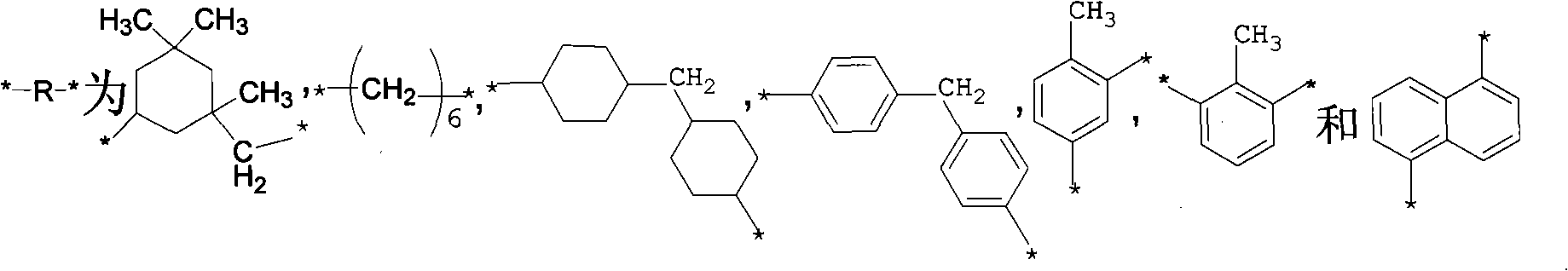

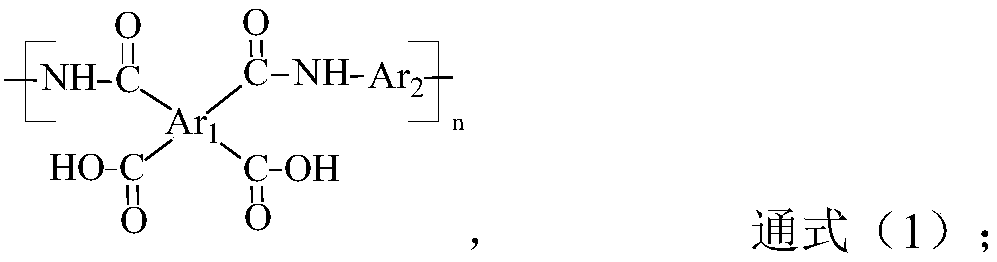

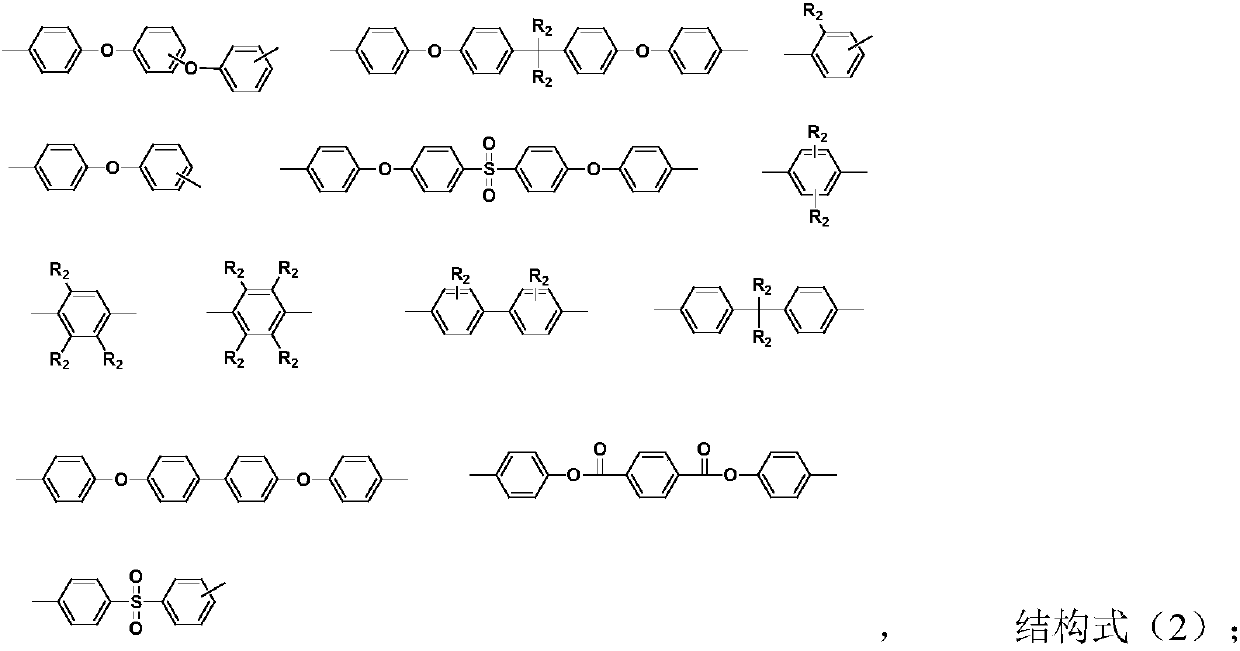

Method of preparing water-dispersible poly (urethane-urea) having aromatic-aliphatic isocyanate

Owner:YONSEI UNIVERSITY

Preparation method of waterborne polyurethane emulsion and waterborne polyurethane emulsion prepared by preparation method

InactiveCN104211902AImprove waterproof performanceGood solvent resistanceHydroxybutyric acidPolymer science

Owner:内蒙古源创绿能节能环保产业创业投资合伙企业(有限合伙)

Solvent-free isocyanate prepolymer, preparartion method of solvent-free isocyanate prepolymer and isocyanate composition

InactiveCN103755920ALow viscosityAdjustable performancePolyurea/polyurethane coatingsPolymer scienceAlcohol

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Photocurable polyester oligomer for 3D printing as well as preparation method and application thereof

Owner:BMF NANO MATERIAL TECH CO LTD

Polyurethane resin,water polyurethane resin,hydrophilic modifier,moisture resin and process for producing polyurethaneresin

Owner:MITSUI CHEMICALS POLYURETHANES INC

Preparation method of glass/polymethyl methacrylate (PMMA) micro-nano interface structure laminated material

Owner:NANCHANG HANGKONG UNIVERSITY

Weather-resistant impact-resistant waterproof plugging material with stable quality and its preparation method

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

High-fidelity durable lightfast UV/UVLED curing coating for note and preparation method thereof

InactiveCN107325691ALow VOC/NOVOCWith transparentWax coatingsPaper coatingMethacrylateVinyl ether

Owner:XIAN BANKNOTE PRINTING +1

Ultraviolet-curing composition for LED packaging

InactiveCN104031591AImprove bonding performanceGood high and low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerLed packaging

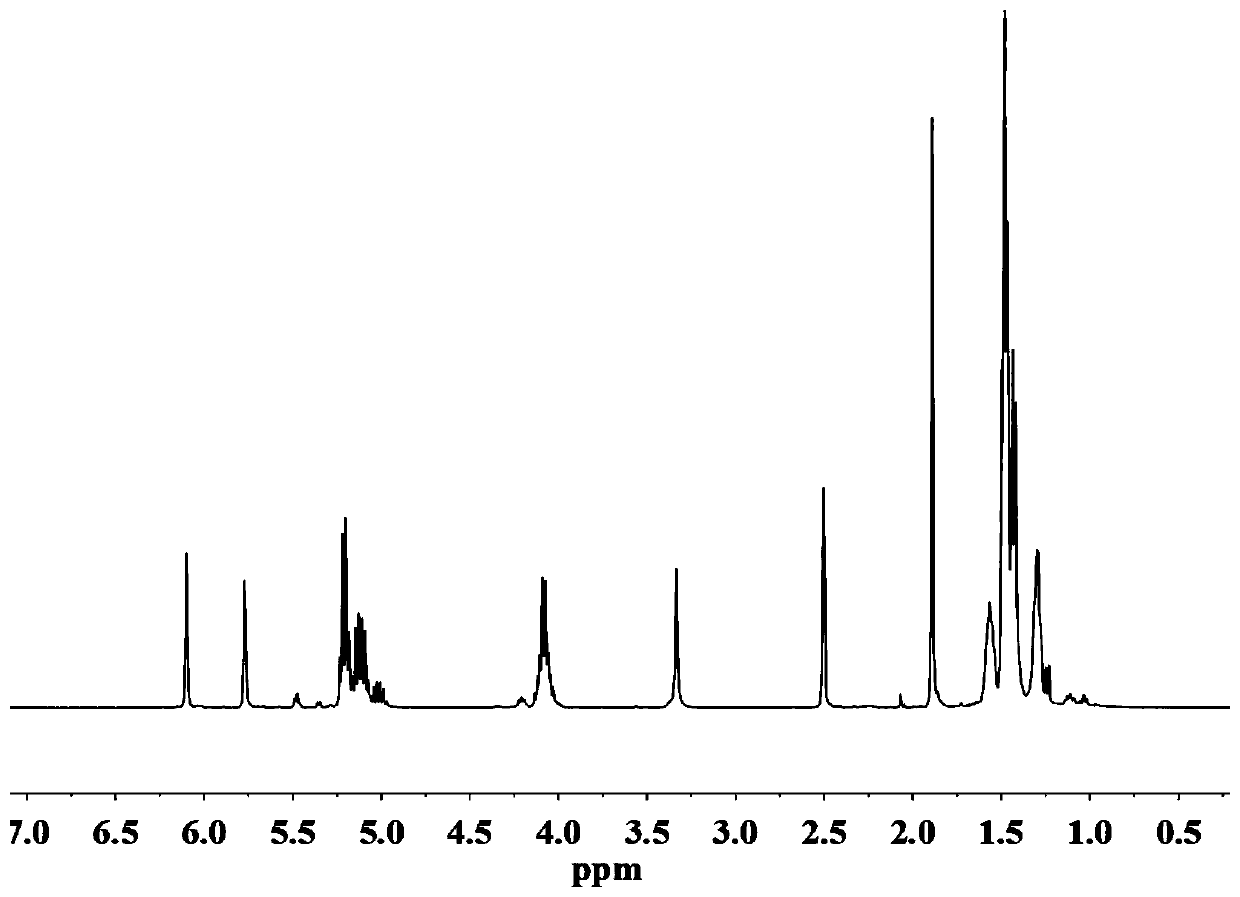

The invention relates to the technical field of LED packaging, and particularly relates to an ultraviolet-curing composition for LED packaging. The ultraviolet-curing composition comprises the following components: a polyurethane-acrylate-epoxy resin photosensitive prepolymer, epoxy resin acrylate, a light initiator, a flatting agent and an active diluent. According to the ultraviolet-curing composition for LED packaging disclosed by the invention, a certain amount of epoxy resin acrylate is added in the composition, so that the adhesive property of the composition after being cured is effectively improved; the adhesive has the advantages of excellent high and low-temperature resistance, high aging resistance and transparency, good formability, good bonding property, mild curing conditions, and the like.

Owner:江苏华程光电科技有限公司

Novel fire retardant microencapsulated red phosphorus and preparation method thereof

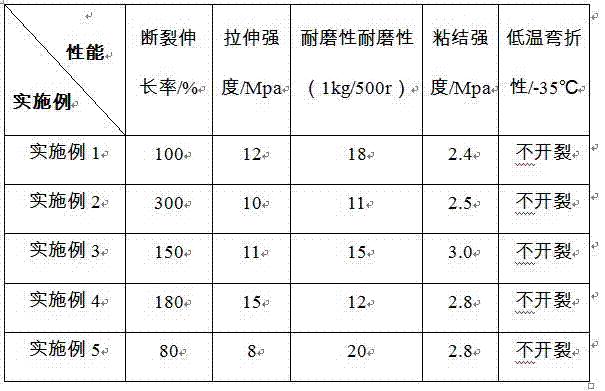

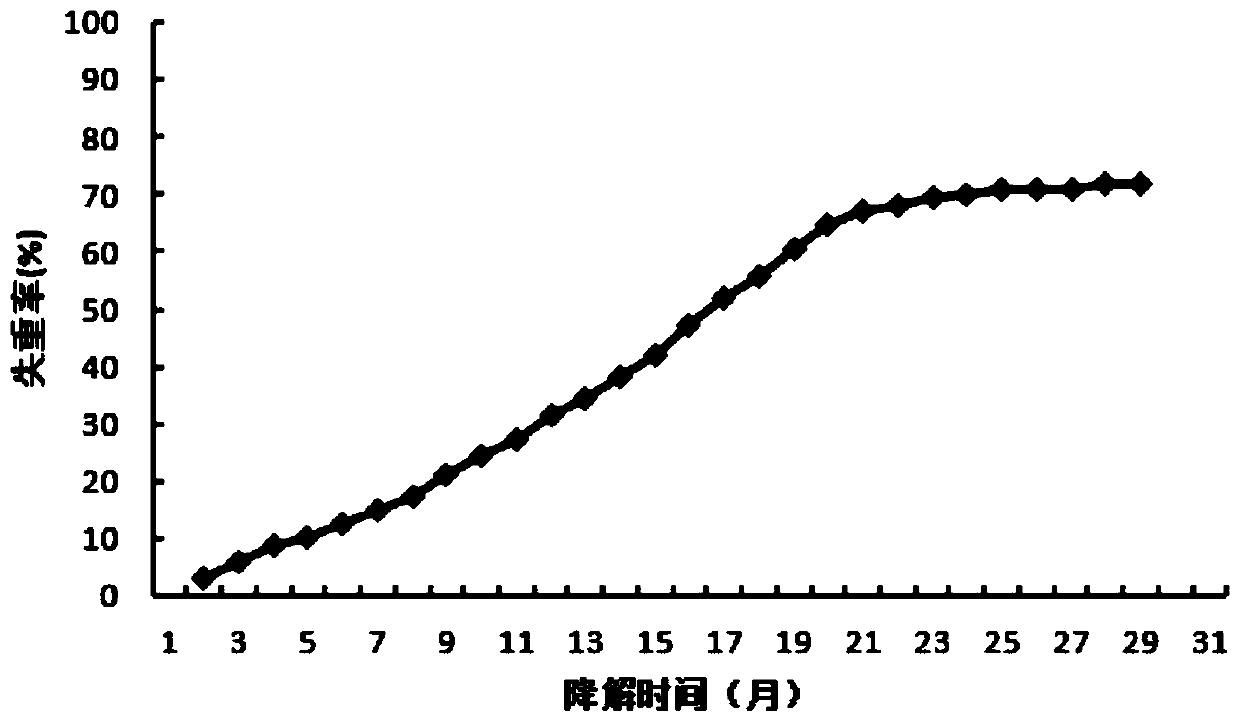

The invention discloses a novel fire retardant microencapsulated red phosphorus which is formed by wrapping phenol-formaldehyde prepolymer (PFP) on the surface of superfine red phosphorus powder. Due to addition of a high-efficient catalyst in the preparation process, the surface activity of the red phosphorus is improved, the surface of the red phosphorus is tightly wrapped with a PFP layer, and meanwhile as methanol is added to prevent formaldehyde auto-agglutination and the pH value of a reaction solution in the wrapping process is controlled to be 1-6, the stability and the resistivity of the red phosphorus are improved, the machining property is improved, and meanwhile the moisture absorption rate and the PH3 release amount are greatly reduced.

Owner:NANJING UNIV OF SCI & TECH

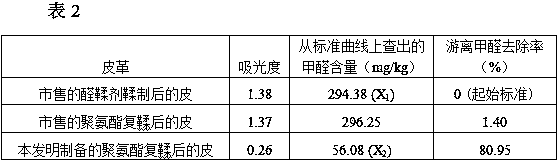

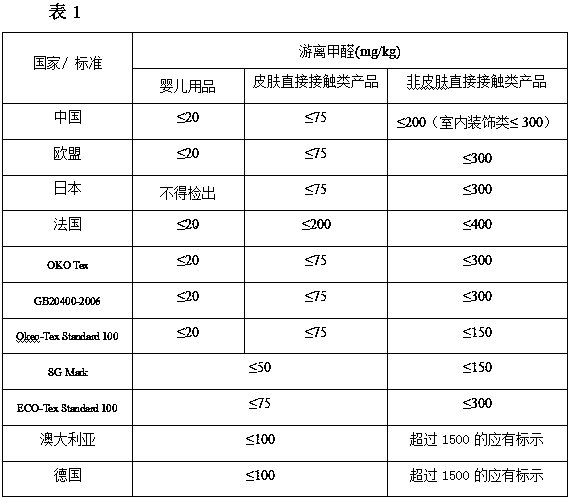

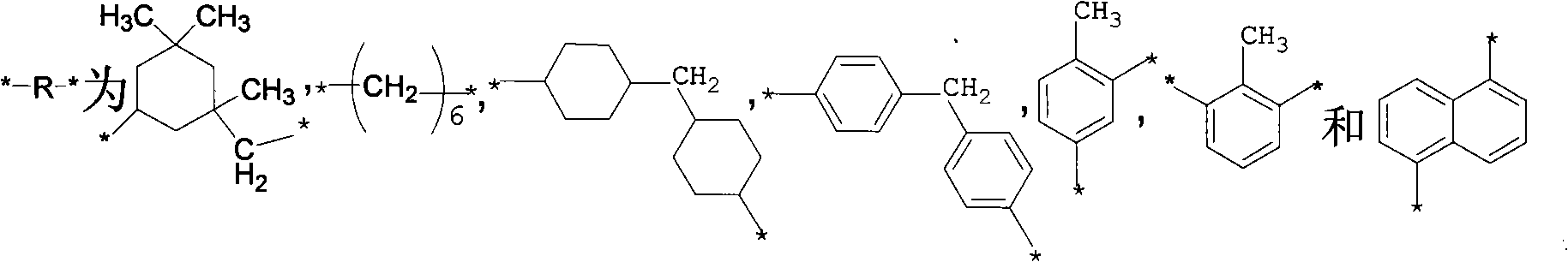

Amphoteric polyurethane and application thereof serving as retanning agent for reducing free formaldehyde in leather

Owner:SHAANXI UNIV OF SCI & TECH

Room-temperature self-crosslinking fluorine-containing water-based PU dispersion, preparation method and application thereof

Owner:江苏裕廊石油化工有限公司

Hydrophobicity-enhanced heat-vulcanized silicone rubber and preparation method thereof

InactiveCN107286671AEnhance internal bondingImprove mechanical propertiesVulcanizationPolymer science

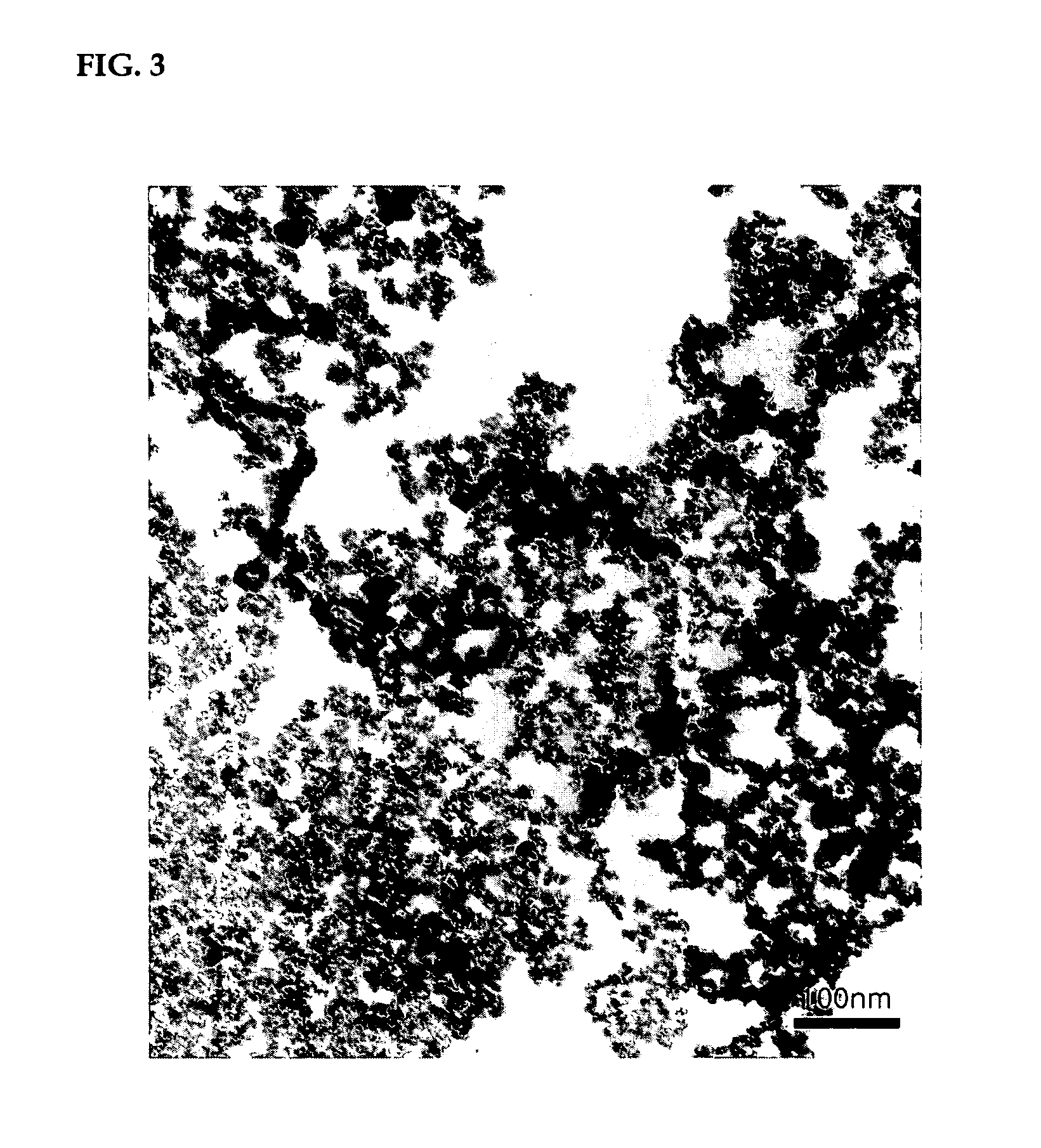

The invention provides hydrophobicity-enhanced heat-vulcanized silicone rubber and a preparation method thereof. The specific preparation method of the silicone rubber comprises steps as follows: divinyltetramethyldisiloxane is mixed with a mixed solution of concentrated hydrochloric acid, deionized water and ethanol, the mixture is mechanically stirred, ethyl orthosilicate is dropwise added, the mixture is subjected to hydrolytic condensation, methylbenzene is added for extraction and layering, methyl vinyl silicone resin is obtained, crosslinked polyethylene particles are added to the methyl vinyl silicone resin, the mixture is stirred uniformly and subjected to molding curing and vacuum heat treatment, and the polyethylene particle crosslinked methyl vinyl silicone resin is obtained; nano-montmorillonite, amorphous alumina and titanium dioxide are added to a polydimethylsiloxane prepolymer, the mixture is mixed and subjected to crosslinking and curing, and a reinforced material coated with organic silicone rubber is obtained; the polyethylene particle crosslinked methyl vinyl silicone resin, the reinforced material coated with organic silicone rubber, 2,4-dichlorobenzoyl peroxide, diphenyl silanediol and octamethylcyclotetrasiloxane are mixed uniformly, left to stand, subjected to open milling and secondary vulcanization, and the hydrophobicity-enhanced heat-vulcanized silicone rubber is obtained.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Polyamic acid solution, preparation method and applications thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Environmentally-friendly color pavement coating material and paving method of road markings

Owner:SICHUAN JUNSHANG ACRYLIC MFG CO LTD

UV photocuring product

Owner:成都迪泰化工有限公司

Emulsion acrylic pressure-sensitive adhesive and preparation method thereof

Owner:QINGDAO PENGHAI SOFT CO LTD

Reactive permeable tack coat material special for water permeable pavement

InactiveCN108949087ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerRosin

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

Method for synthesizing heat-resistant polyurethane based on soybean oil

Owner:JIANGSU SHUANGBAO TECH

Adhesive, preparation method thereof and skin

ActiveCN110499134AImprove wettabilityHigh tear strengthLayered productsPolyureas/polyurethane adhesivesEpoxyAdhesive

Owner:SHENZHEN KUANG CHI HIGH END EQUIP TECH DEV LTD +1

Novel moisture-curing flame-retardant polyurethane hot melt adhesive and preparation method thereof

InactiveCN109679562AImprove performanceImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterMethacrylate

Owner:SHUNDE POLYTECHNIC

Method for mfg. single sheet pneumatic gel mini valve

InactiveCN1693183AOperating means/releasing devices for valvesDecorative surface effectsIonPrepolymer

Owner:SHANGHAI JIAO TONG UNIV

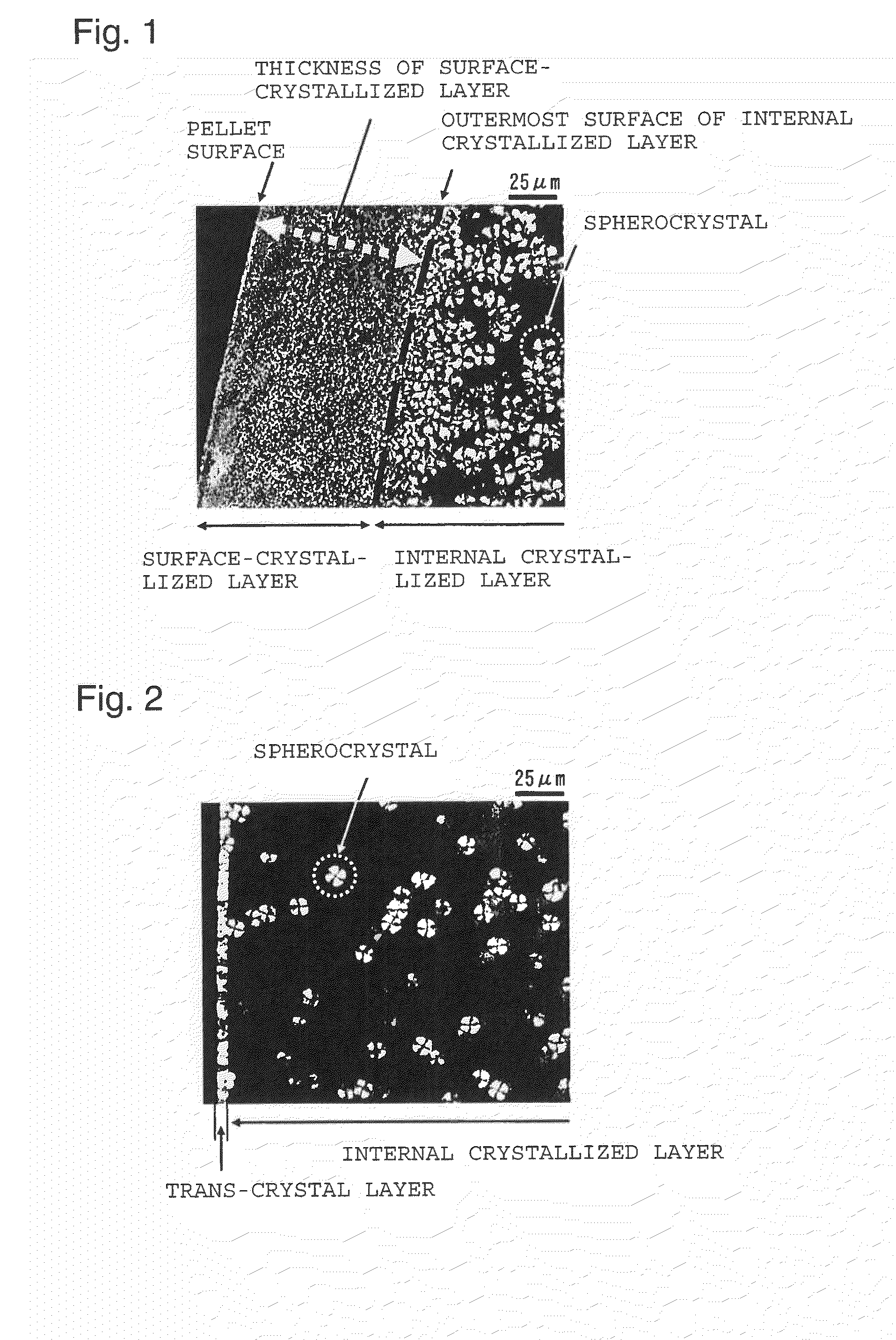

Polyester resin particle and method for producing the same

ActiveUS20090263661A1Synthetic resin layered productsCellulosic plastic layered productsPrepolymerSolid phases

Owner:MITSUBISHI CHEM CORP

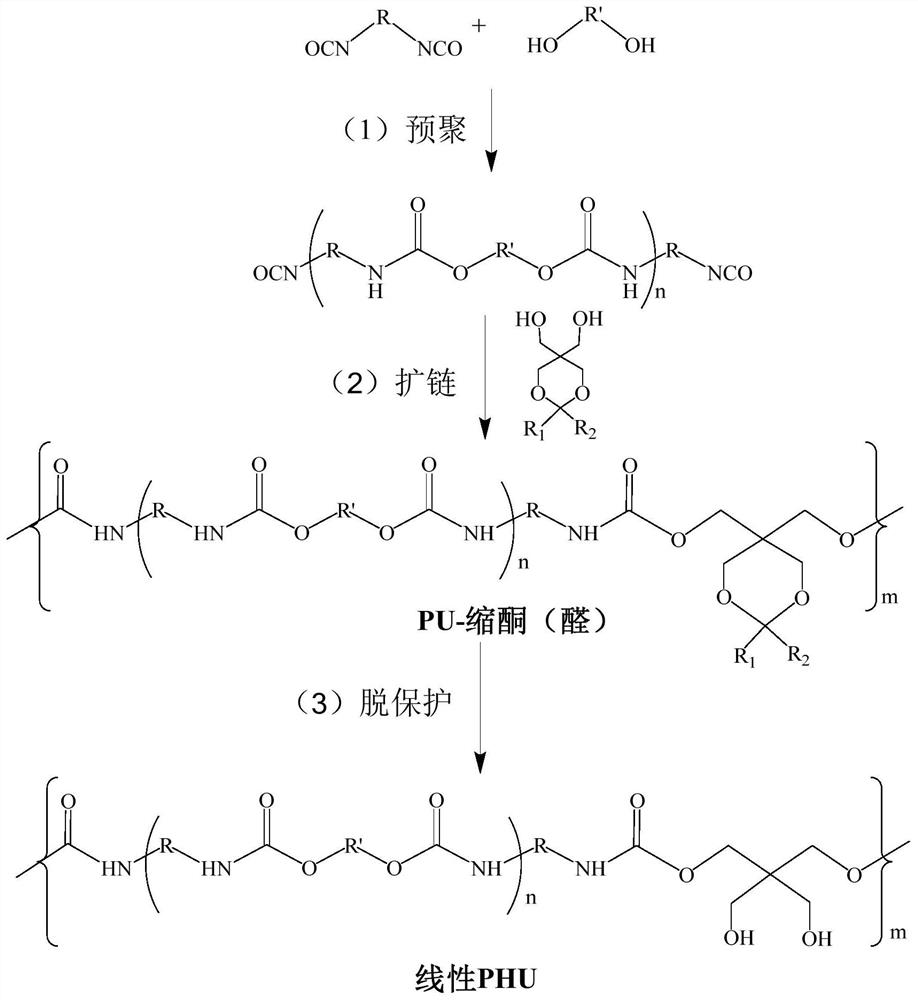

Preparation method of hydroxyl polyurethane

Owner:SHANGHAI JIAO TONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap