Amphoteric polyurethane and application thereof serving as retanning agent for reducing free formaldehyde in leather

A technology of polyurethane and retanning agent, applied in the field of polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

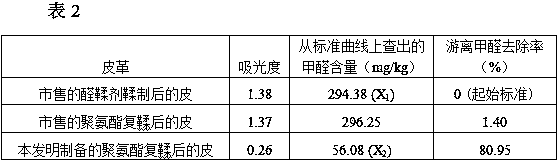

Embodiment 1

[0044]1) React isophorone diisocyanate (IPDI), polypropylene glycol (PPG), N-methyldiethanolamine (MDEA), acetone and dibutyltin dilaurate (DBTDL) at 60°C for 4 hours to obtain a polyurethane prepolymer , then pour chromic acid (1, 8-dihydroxynaphthalene-3, 6-disulfonic acid) into a three-necked flask and raise the temperature to 80°C. After 3h, lower the temperature to 40°C and add ethanol to react for 1h. Then add triethylamine for neutralization, and finally place it in distilled water for emulsification, remove the solvent acetone with a rotary evaporator, and remove unreacted small molecules with a dialysis bag to obtain a milky white amphoteric polyurethane emulsion;

[0045] Wherein, the substance ratio of isophorone diisocyanate (IPDI) and polypropylene glycol (PPG) is 1.0:0.25;

[0046] The amount of N-methyldiethanolamine (MDEA) substance is 10% of the amount of isophorone diisocyanate (IPDI) substance;

[0047] Acetone and dibutyltin dilaurate account for 10% and 0.01

Embodiment 2

[0053] 1) React toluene diisocyanate (TDI), polycarbonate diol, N-methyldiethanolamine (MDEA), dimethylformamide and dibutyltin dilaurate (DBTDL) at 90°C for 8 hours to obtain polyurethane prepolymerization body, and then pour the chromic acid (1, 8-dihydroxynaphthalene-3, 6-disulfonic acid) into a three-necked flask and raise the temperature to 100°C. After 6 hours, lower the temperature to 50°C and add propanol to react 3h, then add ammonia water for neutralization, and finally emulsify it in distilled water, remove the solvent dimethylformamide with a rotary evaporator, remove unreacted small molecules with a dialysis bag, and obtain a milky white amphoteric polyurethane emulsion;

[0054] Wherein, the substance ratio of toluene diisocyanate (TDI) and polycarbonate diol is 1.0:0.5;

[0055] The amount of substance of N-methyldiethanolamine (MDEA) is 15% of the amount of substance of toluene diisocyanate (TDI);

[0056] Dimethylformamide and dibutyltin dilaurate account for 15

Embodiment 3

[0062] 1) React hexamethylene diisocyanate (HDI), polyoxypropylene ether diol, N-methyldiethanolamine (MDEA), dimethylformamide and dibutyltin dilaurate (DBTDL) at 80°C for 6 hours to obtain polyurethane pre- polymer, then pour chromic acid (1, 8-dihydroxynaphthalene-3, 6-disulfonic acid) into a three-necked flask and raise the temperature to 90°C. After 4 hours, lower the temperature to 55°C and add propanol React for 2 hours, then add ammonia water for neutralization, and finally place it in distilled water for emulsification, remove the solvent dimethylformamide with a rotary evaporator, and remove unreacted small molecules with a dialysis bag to obtain a milky white amphoteric polyurethane emulsion;

[0063] Wherein, the mass ratio of hexamethylene diisocyanate (HDI) and polyoxypropylene ether glycol is 1.0:0.3;

[0064] The amount of N-methyldiethanolamine (MDEA) substance is 20% of the amount of hexamethylene diisocyanate (HDI) substance;

[0065] Dimethylformamide and dib

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap