Polyurethane resin,water polyurethane resin,hydrophilic modifier,moisture resin and process for producing polyurethaneresin

A technology of polyurethane resin and water-based polyurethane, which is applied in the field of manufacturing polyurethane resin, water-based polyurethane resin, hydrophilic modifier, moisture-permeable resin and polyurethane resin. Endows problems such as hydrophilicity and poor compatibility, and achieves excellent compatibility, excellent water swelling, and moisture-permeable and water-repellent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

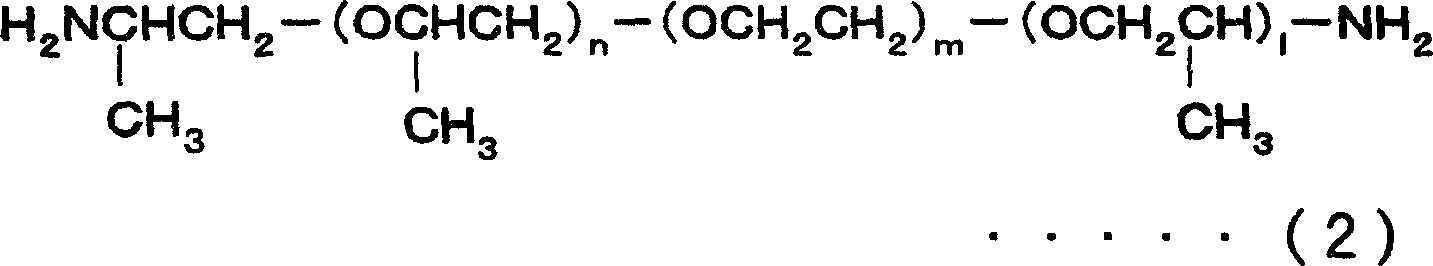

Method used

Image

Examples

Embodiment 1

[0113] Preparation of polyurethane prepolymer

[0114] 8.3 parts by weight of 1,3-bis(isocyanatomethyl)cyclohexane (1,3-bis(isocyanatomethyl)cyclohexane) (trade name: タケネ-ト 600, Mitsui Takeda) are charged into the stirred reactor. Chemikar Corporation), 1.2 parts by weight ethylene glycol, 0.7 parts by weight dimethylolpropionic acid (trade name: Nichikama-PA, manufactured by Nippon Chemical Corporation), 2.5 parts by weight acetonitrile, and the reaction temperature is adjusted at 70 to 75 °C, react until the reaction rate is greater than or equal to 99%, and obtain a polyurethane prepolymer having anionic groups in the molecular side chains and free isocyanate groups in the molecular terminals. The carboxylic acid was 49 milliequivalents per 100 g of the polyurethane prepolymer.

[0115] Preparation of waterborne polyurethane resin

[0116] The polyurethane prepolymer obtained above was cooled to 30° C., 0.5 parts by weight of triethylamine was added, and the mixture was suff

Embodiment 2~5

[0118] According to the formula shown in Table 1, through the same operation as Example 1, waterborne polyurethane resin was obtained.

Synthetic example 1

[0150] Synthesis of Waterborne Resins

[0151]11.75 parts by weight of 4,4'-methylene bis(cyclohexyl isocyanate), 31.39 parts by weight of polyoxytetramethylene ethylene glycol with a molecular weight of 2000 (number average molecular weight) are charged into the stirred reactor. Diol (trade name: PTG2000SN, manufactured by Hodo Ke Valley Chemical Co.), 2.37 parts by weight dimethylol butyric acid (trade name: ニッカマ-BA, manufactured by Nippon Chemical Corporation) and 20.4 parts by weight acetone, the temperature of the reaction solution is adjusted at 53 ~55°C, as a reaction catalyst, add a small amount of stannous octoate (trade name: スタノクト, manufactured by Co., Ltd. API コ-ポレ-ション), and the reaction is carried out until the reaction rate is greater than or equal to 99%. Polyurethane prepolymers with free isocyanate groups at molecular ends.

[0152] This polyurethane prepolymer was cooled to 30° C., 1.46 parts by weight of triethylamine (carboxylic acid neutralization ratio: 0.9

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap