Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "POLYOXYETHYLENE ETHER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyethylene glycol (PEG) is a polyether compound with many applications from industrial manufacturing to medicine. PEG is also known as polyethylene oxide (PEO) or polyoxyethylene (POE), depending on its molecular weight.

Calcium carbonate compound type flame-retardant foaming agent

Owner:新建特阔漂整(南通)有限公司

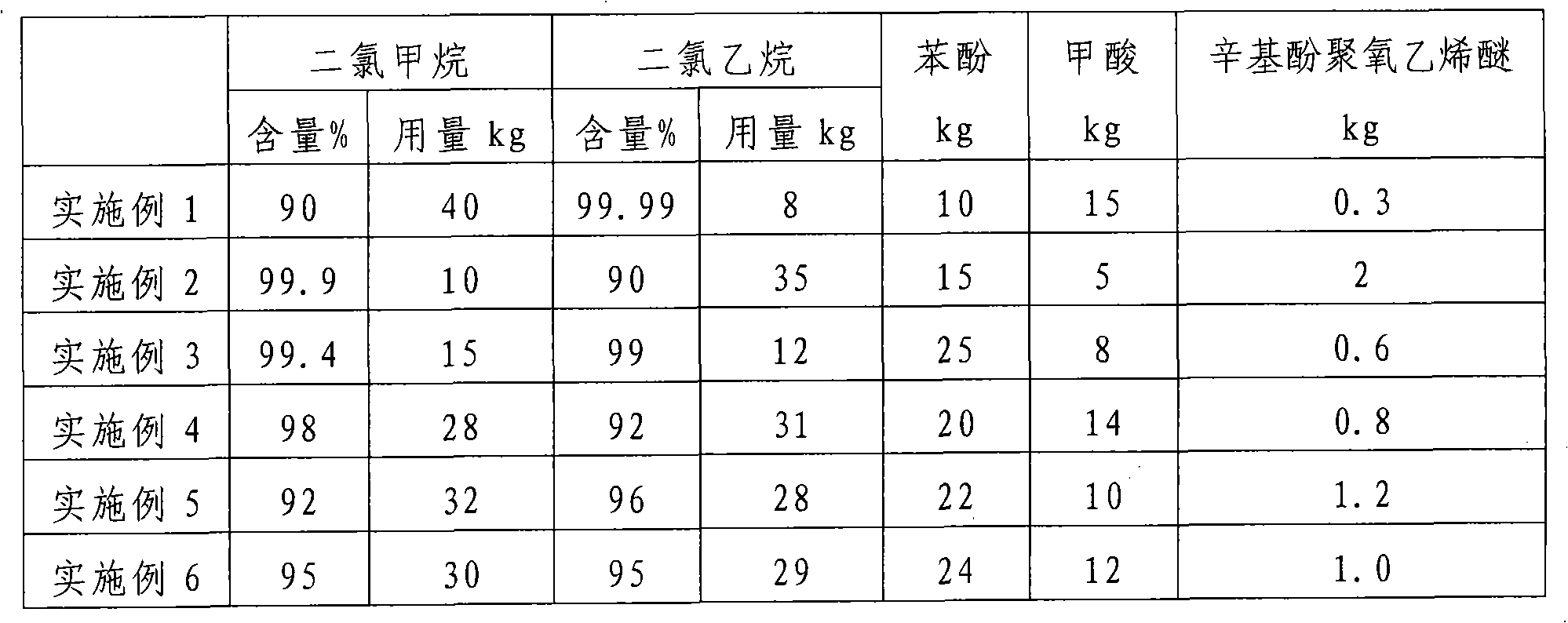

Metal paint remover and method for preparing same

InactiveCN101284961AFast paint removalGood paint removal effectChemical paints/ink removersMethylene DichlorideEthane Dichloride

Owner:JIANGSU DEMEI TECH

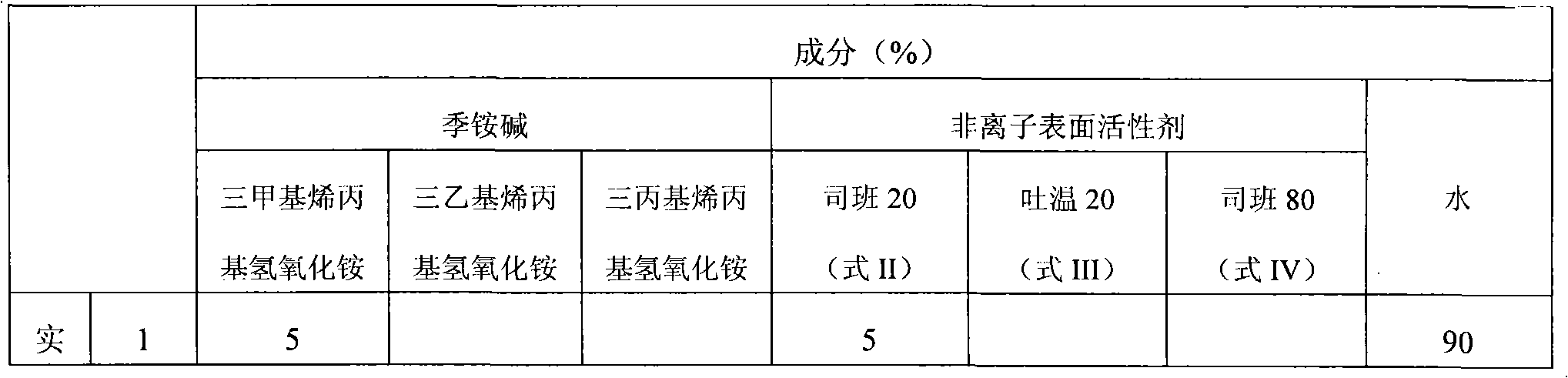

Environment-friendly concentrated liquid detergent for clothing materials

InactiveCN106047529AEasy to rinseConserve waterInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlkaneSodium bicarbonate

The invention provides an environment-friendly concentrated liquid detergent for clothing materials. The liquid detergent is environmentally friendly and easily degradable, does not stimulate the human body and has multiple functions of purifying, softening, fragrance depositing and the like. The environment-friendly concentrated liquid detergent comprises the following components in percentage by weight: 10%-15% of fatty alcohol-polyoxyethylene ether, 15%-20% of alkyl glycoside, 10%-12% of dodecyl dimethyl betaine, 6%-8% of seconary alkane sulphonate sodium, 3%-6% of fatty acid alkanol amide, 0-2% of citric acid, 0-2% of sodium carbonate, 0-2% of sodium bicarbonate, 0-1% of a flavoring agent and the balance of softened water.

Owner:ANHUI TAILONG CHENGYA GRP CO LTD

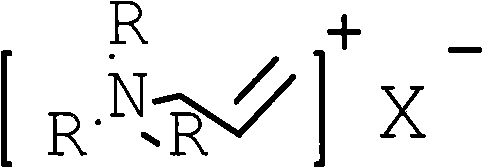

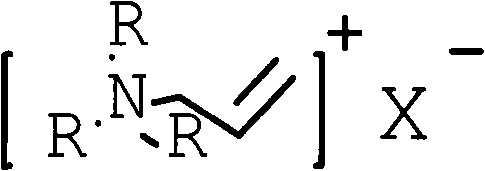

Developing agent for flat-panel display

InactiveCN101566804AGood miscibilityExcellent developabilityPhotosensitive material processingPhotosensitive materials for photomechanical apparatusFlat panel displayStructural formula

Owner:绵阳艾萨斯电子材料有限公司

Method for dyeing polyester fiber type material by using oligomer removing agent

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Ink cleaning agent with no damage to equipment and preparation method thereof

InactiveCN103613978AImprove craftsmanshipReduce pollutionChemical paints/ink removersLimoneneCleansing Agents

Owner:东莞梵拓熙实业有限公司

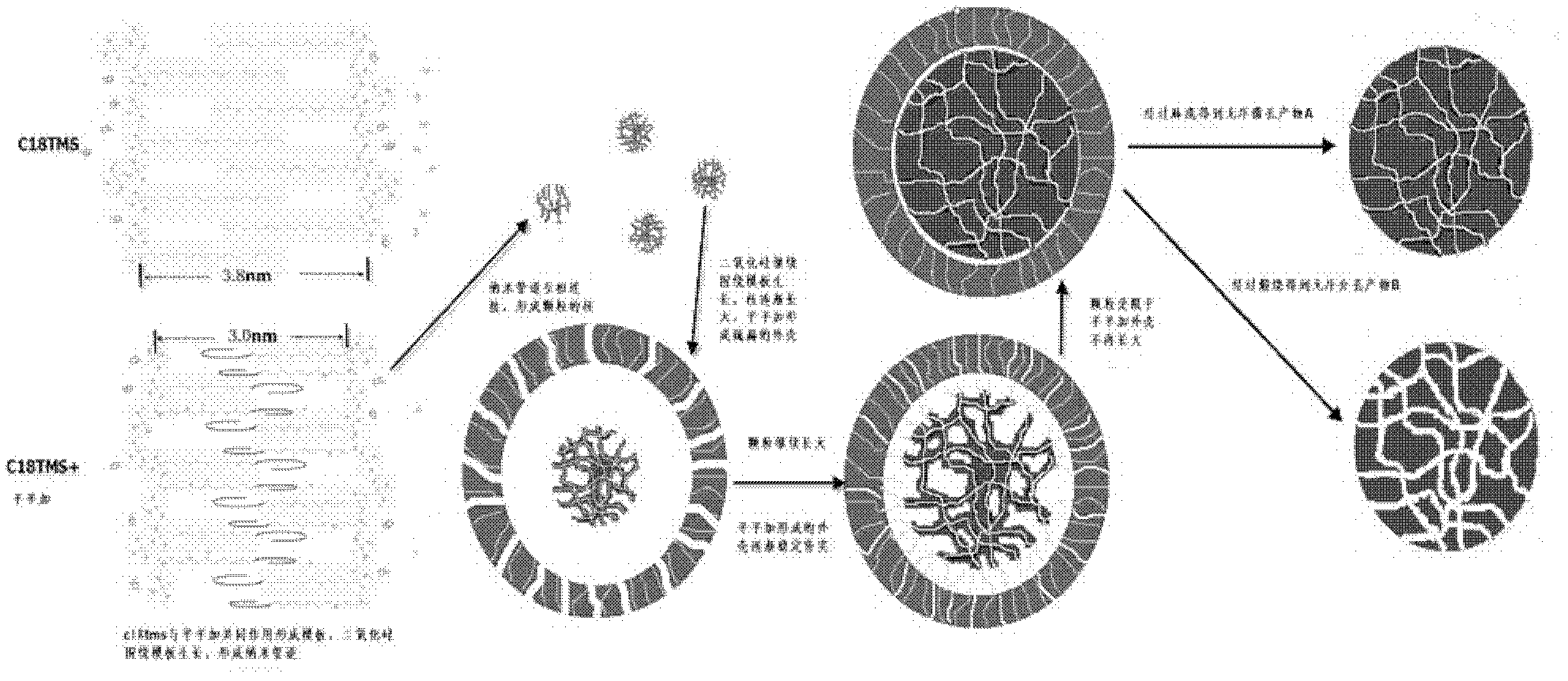

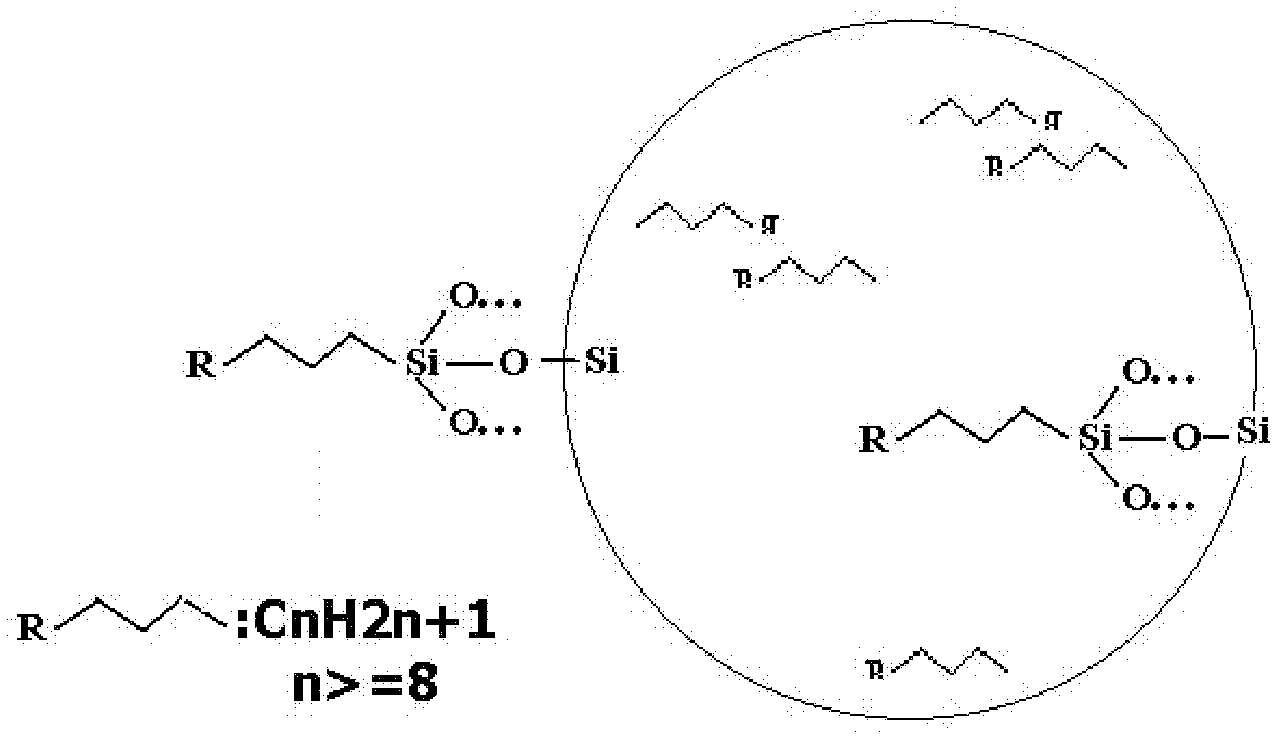

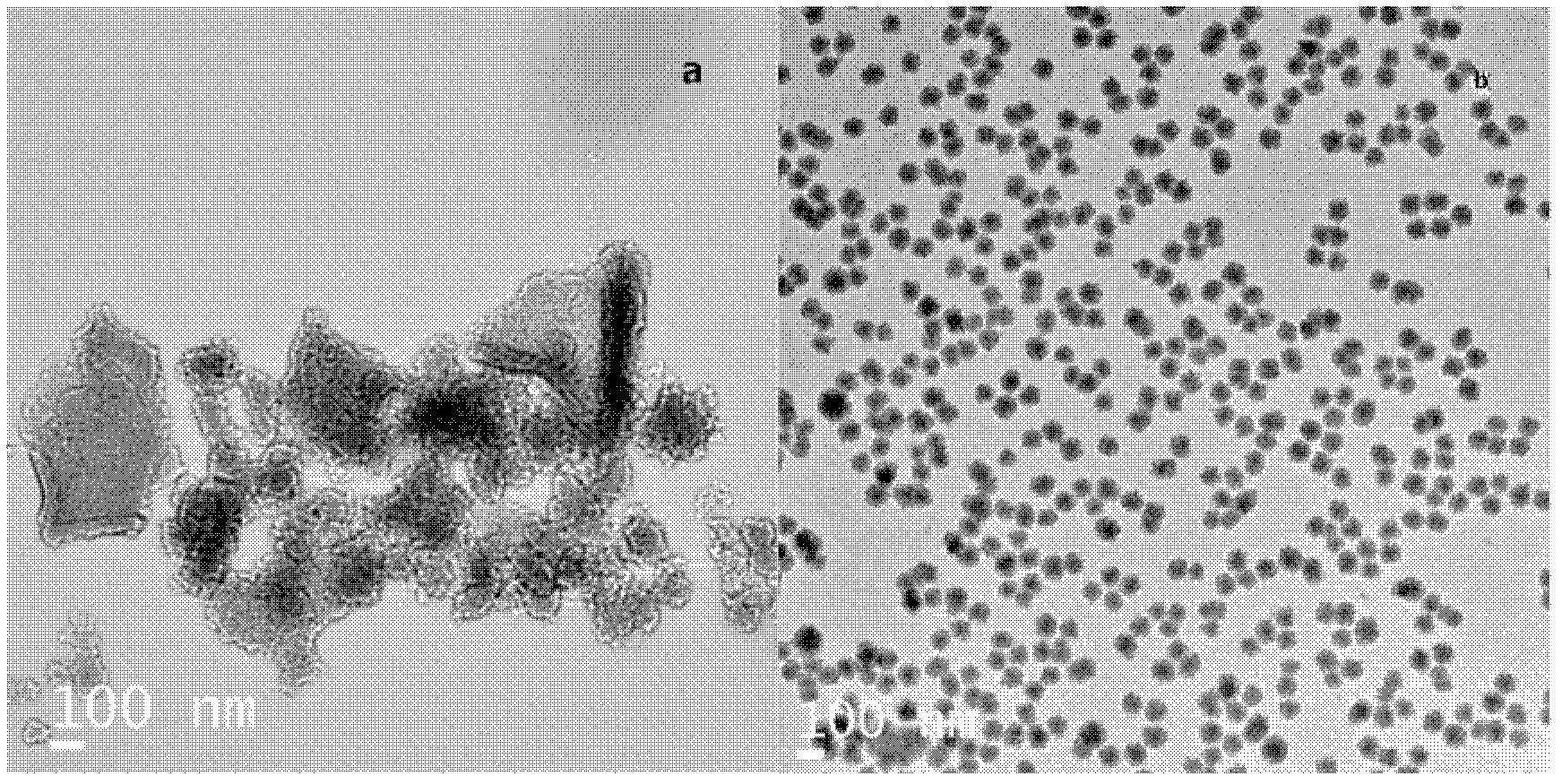

Preparation of disordered porous silicon dioxide material and application of fatty alcohol-polyoxyethylene ether to preparation of disordered porous silicon dioxide material

InactiveCN102807225AGood dispersionStrong level dyeingSilicon organic compoundsSilicaPlatinumPhysical chemistry

Owner:GUANGZHOU NACOMES NEW MATERIAL CORP

Treatment method of circulating water with leaking wax oil

ActiveCN102730866AEasy to controlAvoid re-adhesionFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWaxCarboxylic acid

The invention provides a treatment method of circulating water with leaking wax oil. The method comprises the following steps: a) adding an oxidation-type bactericide; b) adding a corrosion and scale inhibitor containing at least one organic phosphonic acid, at least one organic carboxylic acid polymer, an optional copper corrosion inhibitor agent and an optional zinc salt; and c) adding at least one polysorbate as a wax oil emulsifier; and d ) adding at least one polyoxyethylene nonionic surfactant. The method of the invention can carry out oil removal and microbial slime stripping on equipment in a circulating water system by one time, without mass pollution discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-flaming thermal-insulation environmentally-friendly polymeric foaming material and method for producing the same

InactiveCN102516710ALow thermal conductivityImprove insulation effectPolymer sciencePolyvinyl alcohol

The invention discloses an anti-flaming thermal-insulation environmentally friendly polymeric foaming material and a method for producing the material. The method comprises the following steps: preparing a urea resin foam adhesive by successively adding 37 % of formaldehyde, polyvinyl alcohol and glycerin in a reaction kettle and stirring to heat up and then adding urea, hexamethylene tetramine, stabilizer and thiourea, preparing a foaming agent by firstly adding water in a stirring tank, successively adding nekal and nonylphenol polyoxylethylene ether with stirring, heating up for completely dissolving, and then adding phosphoric acid, glycerin and sodium phosphate, uniformly stirring until completely dissolving, and discharging and packaging, and preparing a foamed product by taking the urea resin adhesive, urea and the foaming agent, mixing and stirring uniformly, putting in a foaming machine to foam, and carrying out foaming, extrusion molding, drying and packaging. The invention can be widely applied in thermal insulation of building facilities, thermal insulation of venue decoration, shock absorption, replacement of benzene plate flexible package without anti-flaming property, and the like.

Owner:王喆

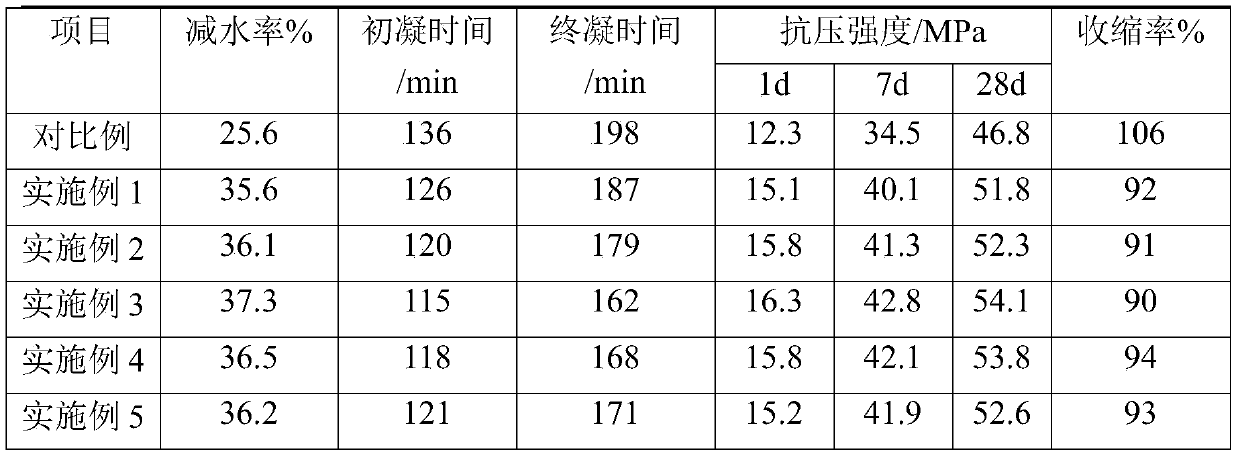

Concrete high-efficiency water reducer and preparation method thereof

Owner:KUNMING ANXIA NEW MATERIAL SCI & TECH CO LTD

Impact-resistant composite insulating material and preparing method thereof

The invention discloses an impact-resistant composite insulating material and a preparing method thereof. The insulating material is prepared from 4-10 parts of polyimide resin, 3-6 parts of glass fibers, 5-12 parts of bisphenol-S epoxy resin, 5-15 parts of polycarbonate, 4-8 parts of dodecyl acrylate, 3-7 parts of dodecanol polyethenoxy ether, 2-5 parts of ethylene bis-oleamide, 3-6 parts of styrylphenol polyoxyethylene ether, 4-10 parts of phenolic epoxy vinyl ester resin and 2-5 parts of polyvinyl cinnamate. The preparing method includes the following steps that 1, the components are thrown into a high-speed mixer to be mixed; 2, the insulating material mixture mixed evenly is taken out of the high-speed mixer and extruded through a double-screw extruder; 3, the material extruded in the step 2 is granulated, and the impact-resistant composite insulating material is obtained after the granulated material is cooled to normal temperature.

Owner:SUZHOU YIXINYUAN PHOTOELECTRIC TECH

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

High-activity multifunctional laundry bead and preparation method thereof

InactiveCN111234967AIncrease contentImprove solubilityOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentHigh activity

Owner:JIANGNAN UNIV

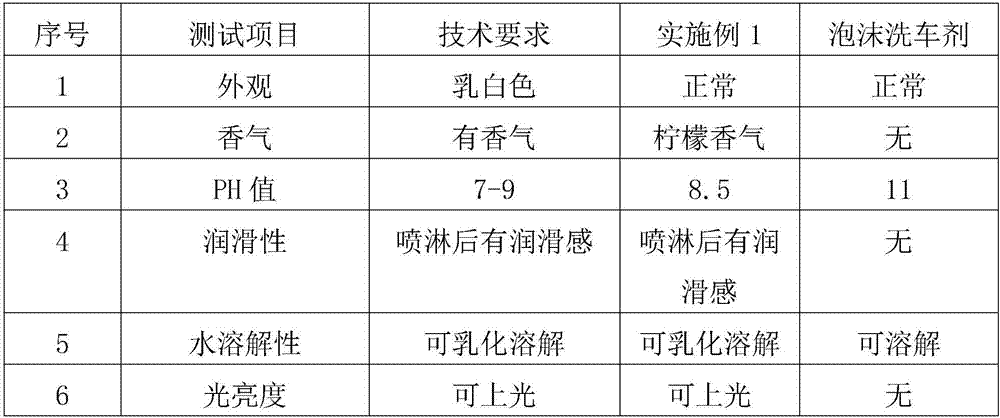

Ultraviolet-proof anhydrous automobile-washing agent and preparation method thereof

InactiveCN106929200AEfficient removalExcellent decontaminationInorganic/elemental detergent compounding agentsCationic surface-active compoundsUltravioletSalicylic acid

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

Bamboo plywood and preparing method thereof

ActiveCN107310001AEasy to spreadImprove permeabilityWood treatment detailsReed/straw treatmentPolyvinyl alcoholDiluent

Owner:SHENZHEN ART DECORATION ENG CO LTD

Preparation method of composite acrylate emulsion

ActiveCN109369842AImproved rheological propertiesSmall size effectWater bathsSodium bicarbonate

Owner:XUZHOU NORMAL UNIVERSITY

Method of applying nontoxic deforming agent to liquid edible fungus fermentation tank

InactiveCN104073446ALight weightHigh market priceFungiFoam dispersion/preventionManufacturing cost reductionBiotechnology

The invention discloses a method of applying a nontoxic deforming agent to a liquid edible fungus fermentation tank; the liquid edible fungus fermentation tank must be cleaned thoroughly and inspected after every use or before reuse; the method comprises the following steps: boiling the tank to disinfect; adding sucrose, bean flour and a monopotassium phosphate main ingredient to the liquid edible fungus fermentation tank; adding water and stirring; injecting a deforming agent; selecting a proper cultivating process, wherein soybean oil serves as the defoaming agent, and is added and adjusted depending on a volume of 3-8%; the soybean oil, which is lower than polyoxypropylene-polyoxyethylene glycerol ether in specific gravity, is easier to float on surface in a cultivating environment that the fermentation tank is strenuous and is longer to act on an effective area of foam; scientific name of the polyoxypropylene-polyoxyethylene glycerol ether is polyether, and has low toxicity although being under edible grade, while the soybean oil, as edible oil, contains a great amount of linoleic acid which is fatty acid essential to body, free from toxicity and harm and is more suitable for massive use of food-grade fermentation tank products; and market price of the soybean oil is lower than that of the polyoxypropylene-polyoxyethylene glycerol ether, so as to reduce manufacturing cost.

Owner:XUZHOU LVWEI MODERN AGRI TECH CO LTD

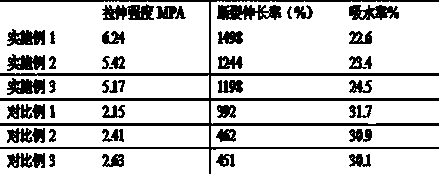

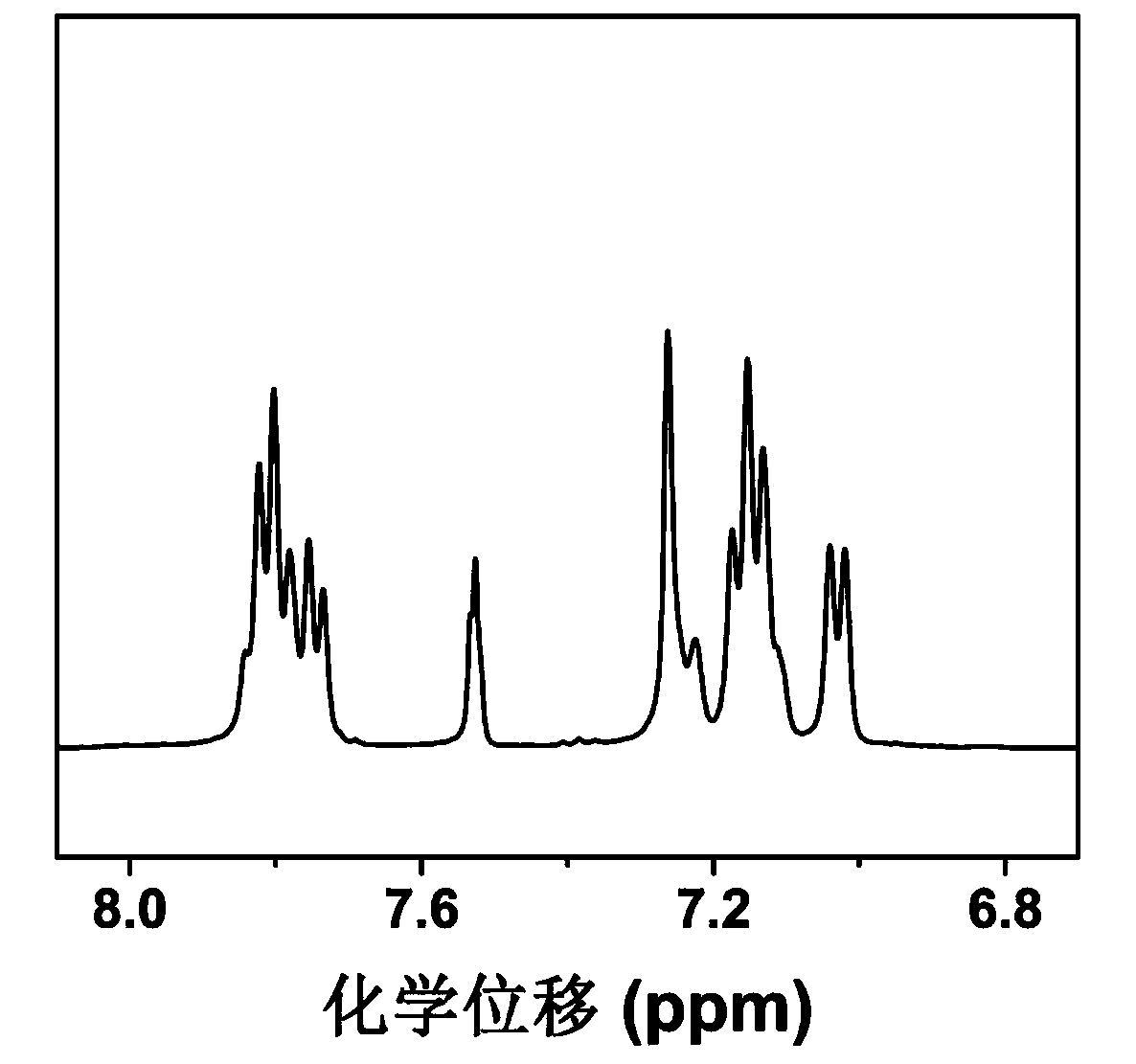

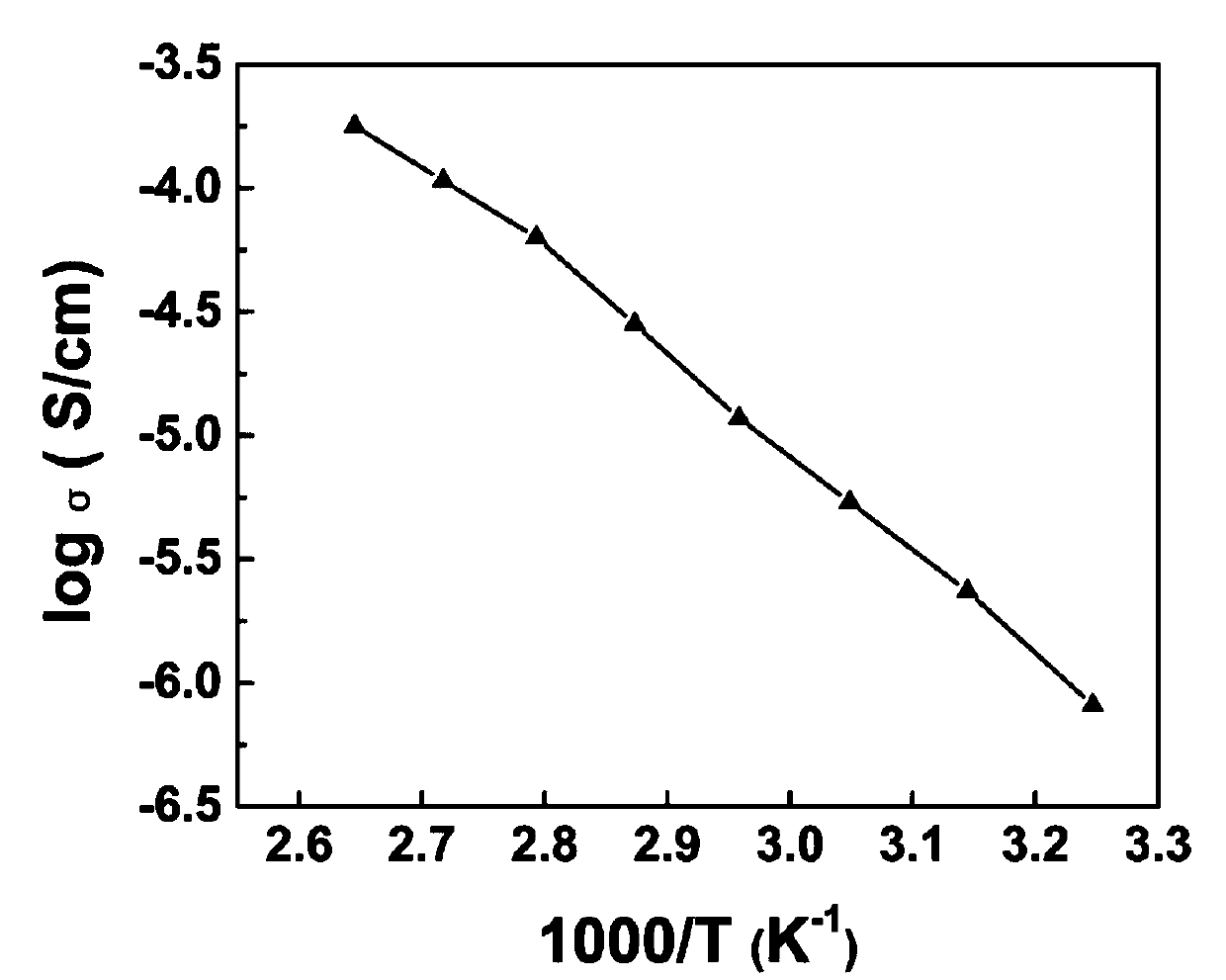

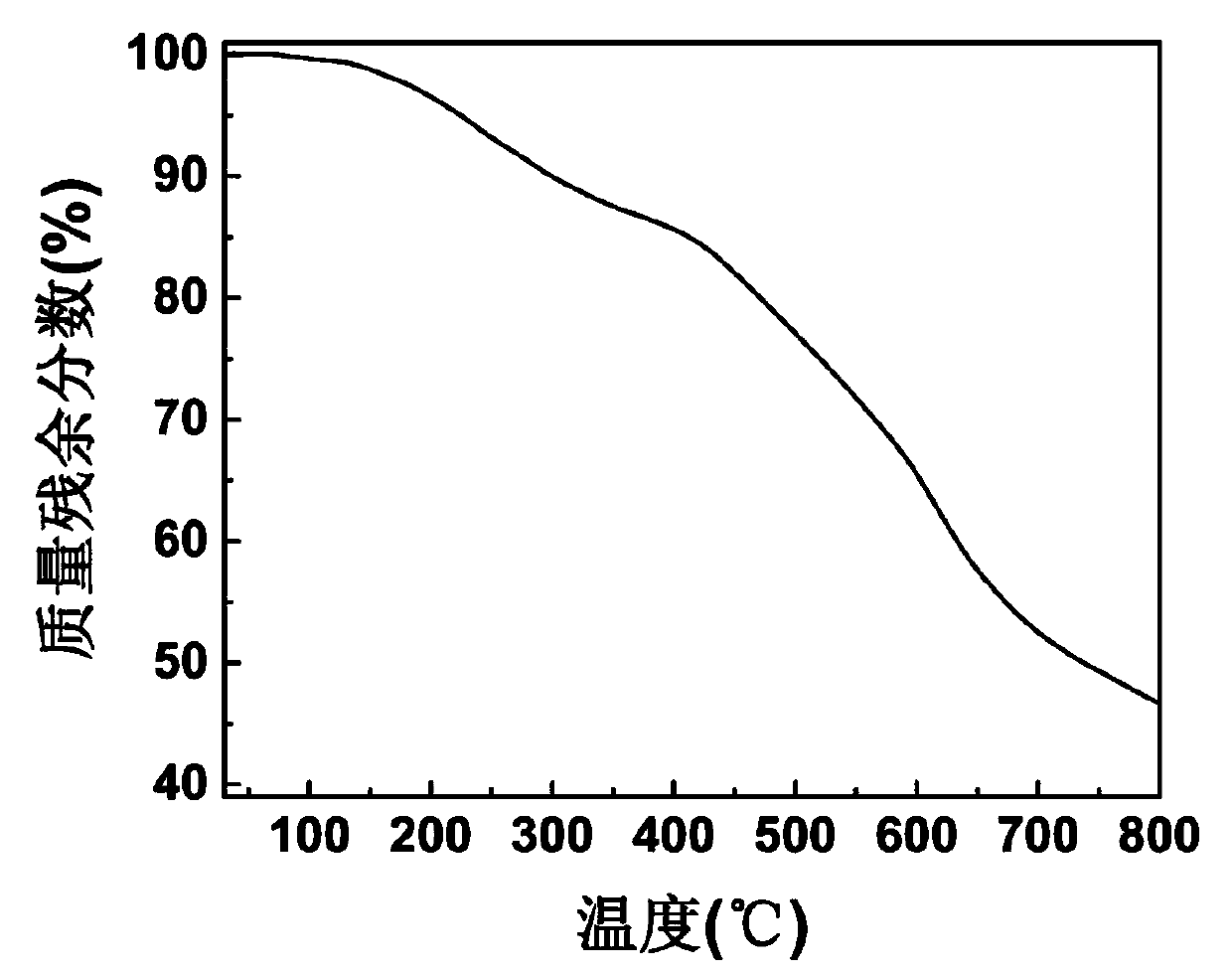

Comb polymer electrolyte and preparation and application thereof

ActiveCN107658501AImprove mechanical propertiesHigh thermodynamic stabilityFinal product manufactureElectrolyte accumulators manufactureLithiumPolymer electrolytes

Owner:HUAZHONG UNIV OF SCI & TECH

Avermectin.triazophos emulsifiable concentrate

InactiveCN102246816AImprove the effect of prevention and controlDelay drug resistanceBiocideAnimal repellantsSulfonateAvermectin

Owner:王海林

High-temperature-resistant special water-retaining admixture for concrete as well as preparation process and application of admixture

ActiveCN109867486AImprove water retentionGood and lasting water-locking effectCarboxylic acidTartrate

The invention discloses a high-temperature-resistant special water-retaining admixture for concrete as well as a preparation process and application of the admixture. The admixture comprises the following components: 1-5 parts of a sustained-release polycarboxylic acid, 5-20 parts of a comprehensive polycarboxylic acid, 1-10 parts of a retarder, 0.1-2 parts of a biomass glue, 0.1-5 parts of an airentraining agent, 0.1-5 parts of a defoaming agent, and 63.8-92.97 parts of water, wherein the sustained-release polycarboxylic acid is composed of isopentenyl polyoxyethylene ether, water, acrylic acid, hydroxyethyl acrylate, sodium methallyl sulfonate and ammonium persulfate, and the comprehensive polycarboxylic acid is composed of isobutylene polyoxyethylene ether, water, acrylic acid, tartrate acrylate, ascorbic acid and mercaptopropionic acid. The water-retaining admixture provided by the invention has a better water-retaining effect, and the preparation process provided by the inventionmakes the obtained admixture less prone to overpolymerization; and according to the application of the water-retaining admixture, the concrete can maintain a better water lock effect for a long timein a high-temperature environment in summer, so that the phenomenon of blocking of a pumping pipe when the concrete is pumped is not easy to cause.

Owner:HANGZHOU JIANSHE NEW MATERIALS CO LTD

Filter paper with high filtering efficiency, and preparation method thereof

InactiveCN103437249AEvenly distributedFacilitate cross-linkingSynthetic cellulose/non-cellulose material pulp/paperFiltration separationFiberFiltration

The invention relates to filter paper with high filtering efficiency, and a preparation method thereof. The filter paper with high filtering efficiency disclosed by the invention is composed of the following raw materials by weight: 50-60 parts of jute pulp, 45-50 parts of wood pulp, 20-25 parts of polystyrene fibers, 3-5 parts of sodium carboxymethyl cellulose, 3-4 parts of a nano carbon powder, 1-2 parts of feldspar powder, 1-2 parts of alum powder, 1-2 parts of 4,4'-diphenylmethane diisocyanate, 2-3 parts of diethylene triamine, 2-3 parts of polyamide wax micropowder, 0.8-1 part of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 0.4-0.6 part of an antioxidant DSTP, 0.5-0.6 part of sodium persulfate, 2-3 parts of ethylene glycol, 6-7 parts of rosin, 15-20 parts of absolute ethyl alcohol, 3-4 parts of nano diatomite, 0.8-1 part of polyoxyethylene octyphenyl ether, 0.3-0.4 part of Gamma-(2,3-epoxypropoxy)propyl trimethoxysilane and a proper amount of water. The filter paper produced by the invention has high filtration precision, high filtration efficiency, small air resistance and strong pollutant-holding capacity, and is environment-friendly.

Owner:BENGBU PIONEER FILTER

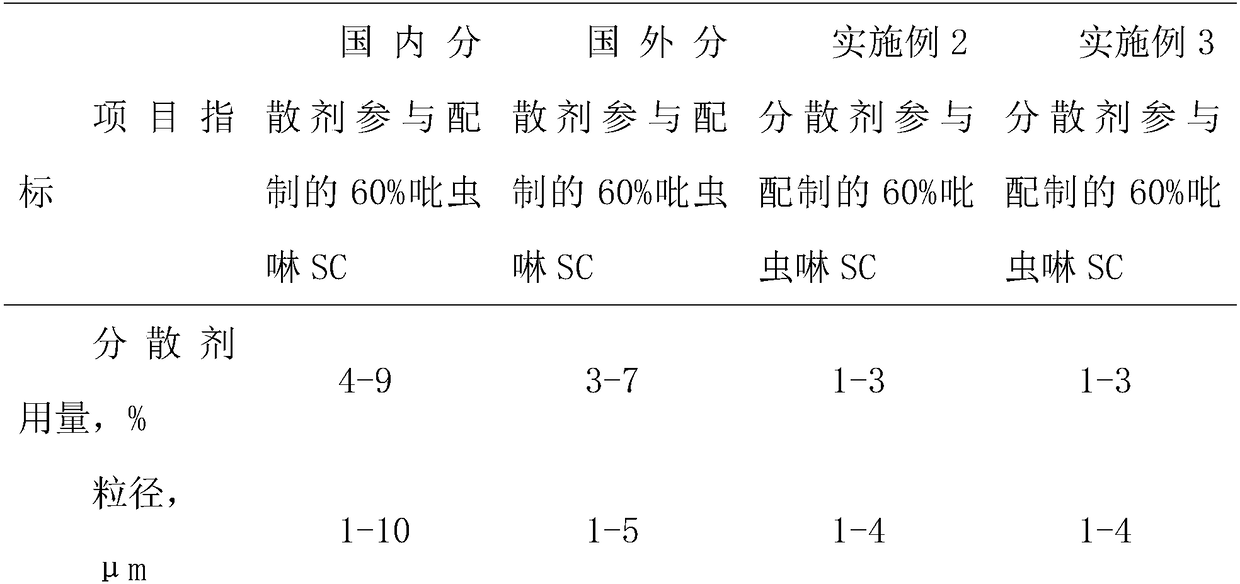

Preparation method and application of efficient agricultural water suspension and dispersion agent

InactiveCN109042634AGood dispersionHigh suspension rateBiocideAnimal repellantsFunctional monomerPhosphate

Owner:南京拓际生物科技有限公司

Weeding composition as well as use method and application thereof

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Novel biological material for plant disease and pest control

InactiveCN108184878AIncrease the fragranceImprove durabilityBiocidePest attractantsDehydroacetic acidDisease

Owner:陈益德

Lubricating liquid for food transporting equipment and preparation method of lubricating liquid

InactiveCN106167731ADifficult to volatileHigh specific heat capacityLubricant compositionPhosphateWater soluble chitosan

The invention relates to the field of lubricating liquid, in particular to lubricating liquid for food transporting equipment. The lubricating liquid is prepared from the following raw materials in parts by weight: 2-3 parts of water-soluble chitosan, 2-3 parts of triethanolamine citrate, 0.5-1 part of polyvinylpyrrolidone, 10-14 parts of mint extract, 8-14 parts of carboxylic acid, 2-4 parts of polyalkylene glycol, 3-5 parts of sodium octadecyl polyoxyethylene ether phosphate, 0.3-0.5 part of medical rust, 2-3 parts of a silicone defoamer, 1-2 parts of ethoxylated pentaerythritol tetra (methyl) acrylate, 1-2 parts of ethylparaben, 4-8 parts of sedoheptulose 7-phosphoric acid, and 20-26 parts of simethicone. The lubricating liquid disclosed by the invention is free from toxins, difficult to volatilize, and high in specific heat capacity, has certain heat-conducting properties for heat produced by equipment abrasion, has certain attraction capacity on bacteria and pests, has excellent capacity of killing the bacteria and the pests, has quite significant antirust capacity, and does not have crystal deposition, and the kinematic viscosity of the lubricating liquid is 10-20% higher than that of general lubricating liquid.

Owner:BENGBU ZHONGZHENG INDAL

Modification treatment method for coal ash for concrete

InactiveCN108467213AGood dispersionImprove stabilitySolid waste managementSodium phosphatesCarboxylic salt

Owner:广西高企科技有限公司

Diacetyl tartaric acid ester of mono(di)glyceride fried bread stick bulking agents

InactiveCN103891813ARaw materials are easy to getLow costDough treatmentBakery productsSodium bicarbonatePhosphate

Owner:韦谷林

Rapid-sterilizing tableware disinfectant

InactiveCN104920489ARapid sterilizationEasy to cleanBiocideDisinfectantsBiotechnologyHypericum perforatum

Owner:QINGDAO DONGCHANGRUI TEXTILE

Medicament for increasing fruit setting rate and yield of Torreya grandis and using method

Owner:ZHEJIANG UNIV

Preparation method of polyacrylamide reverse-phase emulsion

Owner:SHANDONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap