Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Feldspar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feldspars (KAlSi₃O₈ – NaAlSi₃O₈ – CaAl₂Si₂O₈) are a group of rock-forming tectosilicate minerals that make up about 41% of the Earth's continental crust by weight. Feldspars crystallize from magma as veins in both intrusive and extrusive igneous rocks and are also present in many types of metamorphic rock. Rock formed almost entirely of calcic plagioclase feldspar is known as anorthosite. Feldspars are also found in many types of sedimentary rocks.

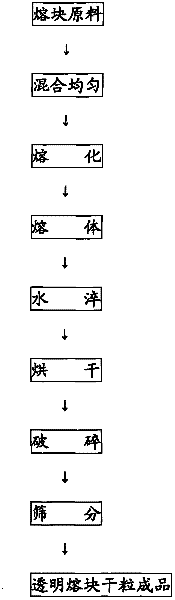

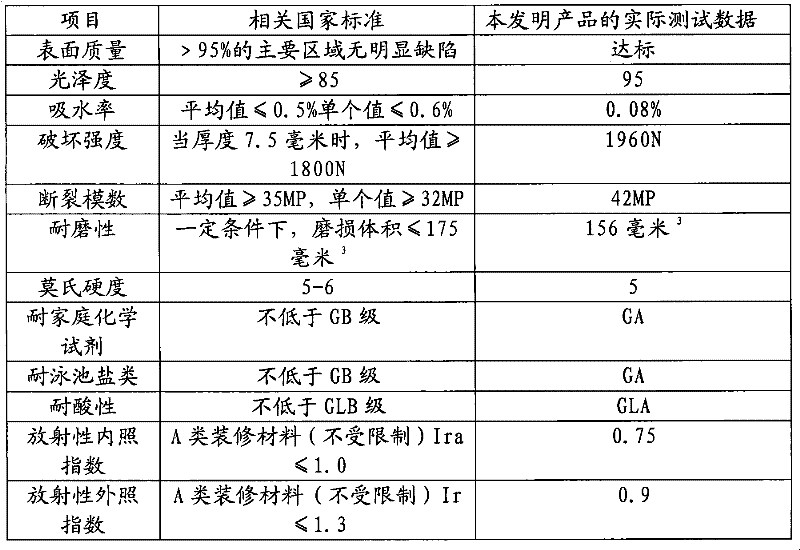

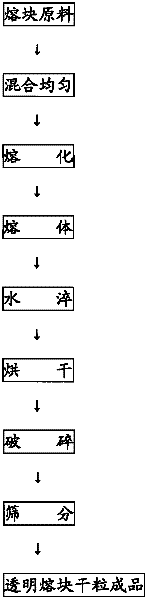

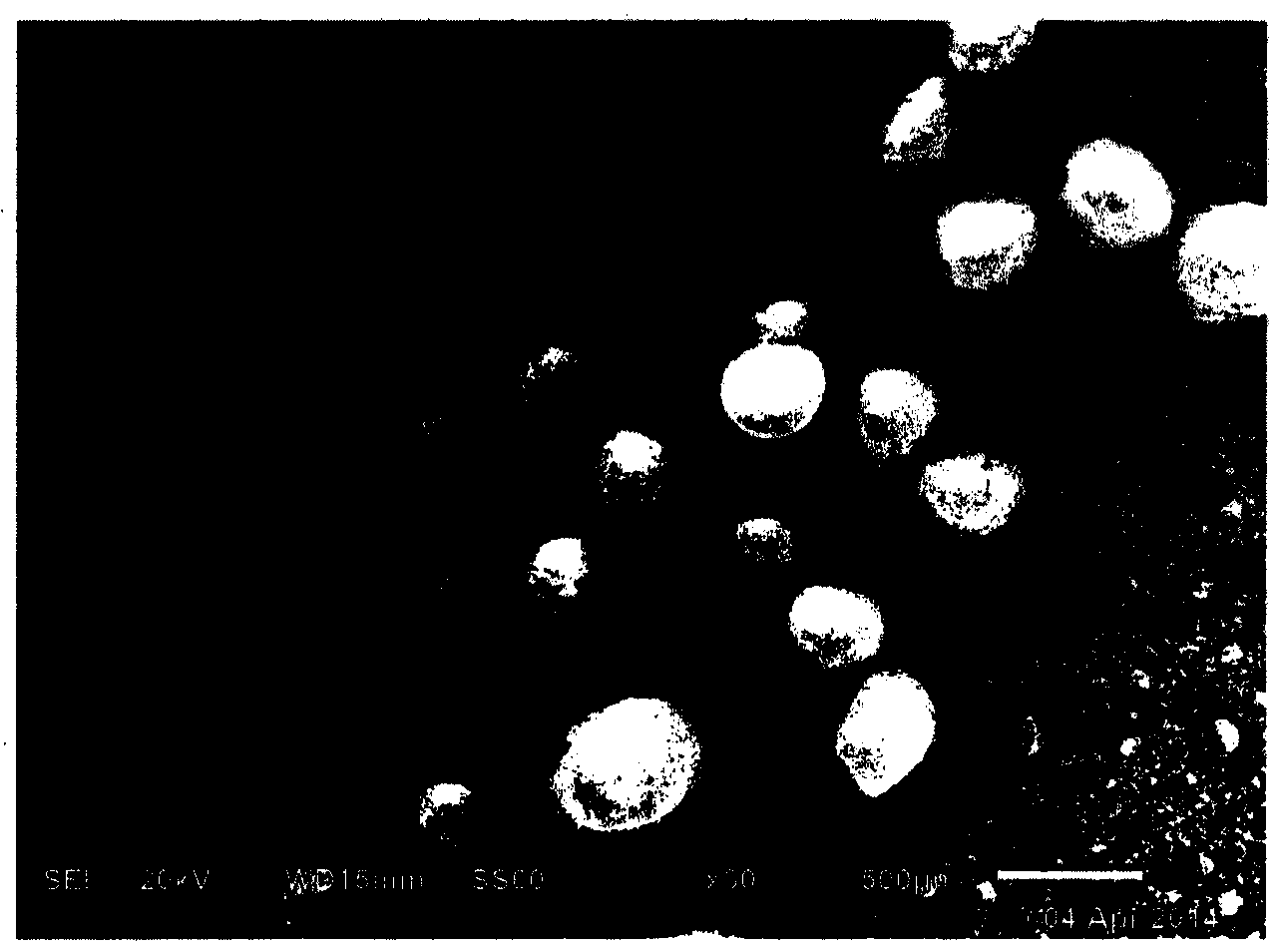

Method for producing transparent clinker capable of being compounded with colored glaze ceramic blank

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

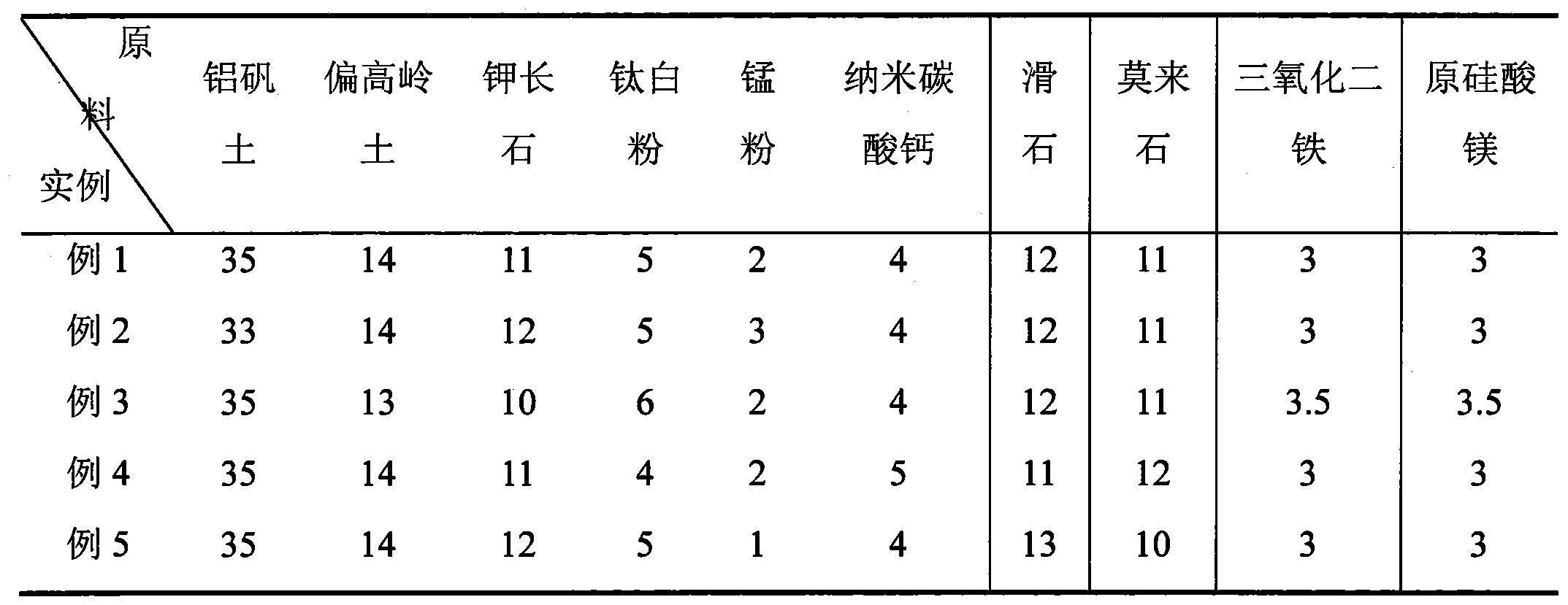

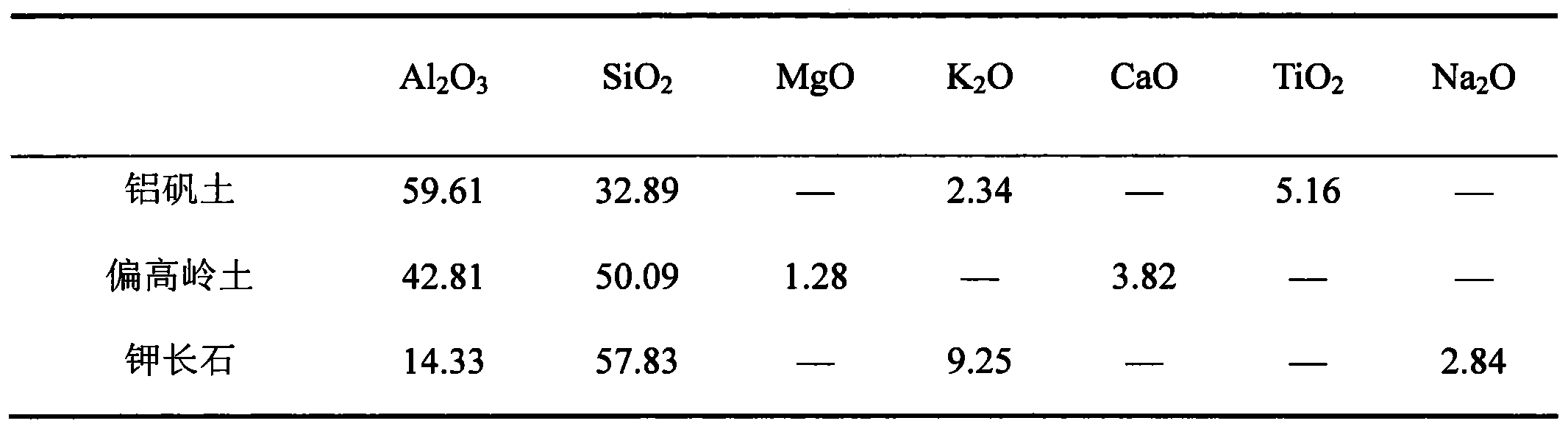

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Ceramic floor tile with diatom mud and method for manufacturing ceramic floor tile

InactiveCN105298081AReduce processing difficultyNice appearanceCeramic shaping apparatusFlooringSurface layerEthylic acid

Owner:佛山市高明区生产力促进中心

Foaming-ceramic heat insulating board and preparing method thereof

InactiveCN105503238ALow thermal conductivityHigh compressive and flexural strengthCeramicwarePorosityPotassium

Owner:韩功篑

High-strength crack-resistant concrete and producing method thereof

Owner:南京加豪新型建筑材料有限公司

Wear-resistant composite microcrystalline sheet material

Owner:HENAN JINGXIANG ABRASION PROOF MATERIAL

Ultrawhite stoneware and production process

Owner:SHENYANG SHUNXIN CERAMIC

Alkali-free glass fiber yarn

Owner:安徽省绩溪县华宇防火滤料有限公司

Antibacterial ceramic glaze and preparation method thereof

PendingCN109399933AImprove antibacterial propertiesGuaranteed glaze effectMontmorilloniteSodium silicate

The invention discloses an antibacterial ceramic glaze and a preparation method thereof. The glaze includes 30-50 parts of montmorillonite, 30-50 parts of talc, 10-30 parts of quartz, 5-10 parts of barium carbonate, 5-15 parts of manganese dioxide, 10-25 parts of sodium silicate, 20-50 parts of feldspar, 5-10 parts of titanium dioxide, and 2-10 parts of silver nitrate. The antibacterial performance of the glaze can be enhanced while the glaze effect is ensured, and the antibacterial ceramic glaze can keep a stable and sustained antibacterial effect at high temperatures.

Owner:FOSHAN UNIVERSITY

Ceramic glaze and preparation method thereof

The invention discloses a ceramic glaze. The ceramic glaze is characterized by being prepared from the following raw materials in parts by weight: 35-50 parts of nano-silica, 55-75 parts of kaolin, 15-30 parts of albite, 5-15 parts of magnesium oxide, 5-15 parts of sodium oxide, 25-50 parts of dolomite, 25-40 parts of limestone, 3-8 parts of pigment and filler, 15-20 parts of property-modifying additive, and 55-70 parts of deionized water. The invention further discloses a preparation method of the ceramic glaze. The ceramic glaze disclosed in the invention has good brightness and glossiness,and the prepared pigment and filler are present in a nanometer-grade form, have a good coloring effect and are not easy to agglomerate; the ceramic glaze prepared from the activated kaolin, the pigment and filler and the property-modifying additive has not only good mechanical properties, but also good chemical stability and wear resistance, and can effectively protect a ceramic body and allow theceramic to have a better appearance.

Owner:CHANGSHA JIZHI INNOVATION IND DESIGN CO LTD

Celadon blank making technology through overweight pressure one-time moulding

InactiveCN106187077AHigh refractorinessWith natural lusterCeramic shaping apparatusClaywaresPotassiumHigh intensity

The invention provides a celadon blank making technology through overweight pressure one-time moulding. The celadon blank making technology comprises the following steps of (1) preparing raw material powder; (2) performing compression moulding; (3) performing sintering on compressed blanks, wherein the sintering temperature is controlled to 1190-1300 DEG C; and (4) trimming the blanks so as to obtain the celadon blank. Raw materials for preparing the raw material powder comprise 35-45% of Longyan kaolin, 15-20% of celadon blank clay powder, 8-20% of potassium feldspar, 7-12% of quartz, 3-8% of hematite, 5-10% of Zijin clay, 6-10% of bone ash, 9-15% of nanometer alpha-Al2O3 powder, and 5-10% of filler. According to the celadon blank making technology disclosed by the invention, the refractoriness of blanks is greatly improved, besides, the made blank has the advantages of being high in strength, natural in glossiness, and fine in texture, and the celadon blank can be produced in batches, and the production cost is reduced.

Owner:LONGQUAN HONGXIN PORCELAIN CO LTD

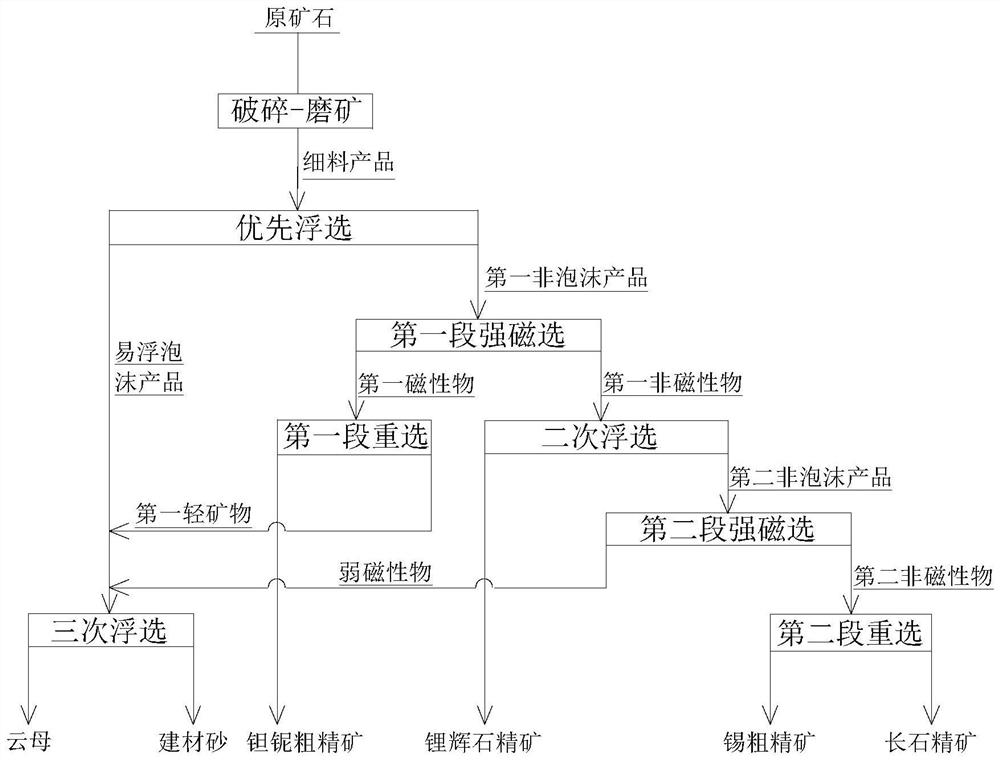

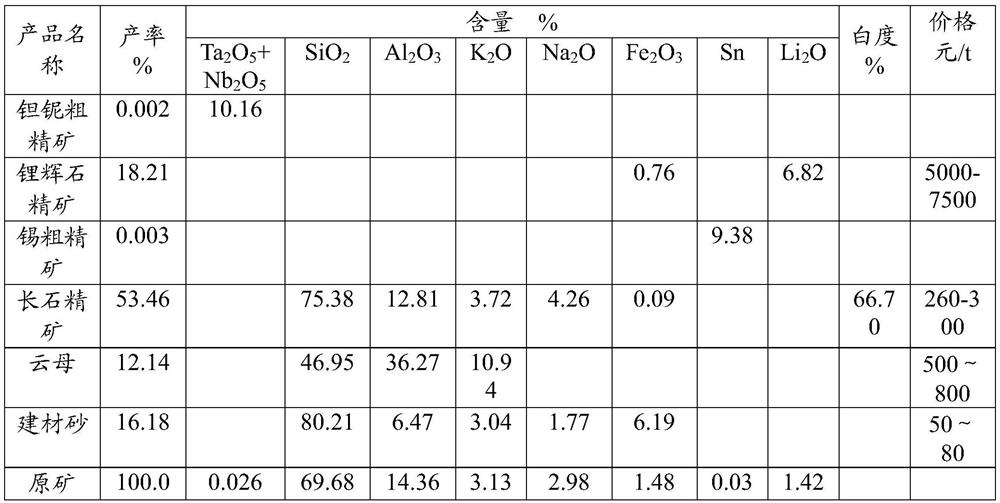

Comprehensive utilization method of pegmatite containing tantalum niobium, cassiterite, feldspar and spodumene

PendingCN114588998AImprove recycling ratesTake advantage ofHigh gradient magnetic separationFlotationNiobiumMagnetic separation

Owner:SHANDONG HUATE MAGNET TECH

Glassware cup body material

Owner:宜兴市帝洲新能源科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap