Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Improve wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Boron-containing semi-high speed steel cold roller and manufacturing method thereof

InactiveCN101407891AReduce manufacturing costReduce the amount addedProcess efficiency improvementElectric furnaceIngotMolten steel

The invention relates to a boron-containing semi high-speed steel cold roller and a manufacturing method thereof and belongs to the field of steel rolling technology. The existing cold rollers have the problems of poor wear-resistance, high production cost and the like. The invention obtains the boron-containing semi high-speed steel cold roller by pouring the molten steel with the compositions of the following weight percentages of 0.30 to 0.45 of C, 3.8 to 4.2 of Cr, 0.2 to 0.6 of Si, 0.2 to 0.6 of Mn, 0.5 to 0.8 of Mo, 0.2 to 0.4 of Ni, 0.3 to 0.6 of Cu, 0.6 to 1.0 of B, 0.3 to 0.7 of V, 0.6 to 0.8 of Ti, 0.1 to 0.3 of Nb, 0.03 to 0.10 of N, 0.25 to 0.45 of Al, less than 0.03 of S, less than 0.04 of P and the residual quantity of Fe into an outer layer of the cold roller and adopting ductile cast iron as a core part or directly pouring the molten steel into ingots. The roller has the advantages of high hardness and intensity, good toughness and wear-resistance, simple production process, low cost, etc.

Owner:BEIJING UNIV OF TECH

Method for preparing diamond-like composite coating on surface of piston ring

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ceramics particle strengthened composite material lining metal tube and manufacturing method thereof

InactiveCN101900227AExtended service lifeImprove wear resistanceCorrosion preventionPipe protection against corrosion/incrustationPolyesterManufacturing technology

The invention discloses a ceramics particle strengthened composite material lining metal tube and a manufacturing method thereof, belonging to the field of composite wear-resistant tubes. 4,4-Diphenylmethane diisocyanate (MDI), polyester glycol, 1,4-butanediol (BD), ceramics particles and the like serve as raw materials to prepare composite material liquid castables, and a centrifugal casting technology is adopted to cast polyurethane base ceramics particle strengthened composite material lining layers on the inner wall of an outer thimble. The invention has the beneficial effect that the prepared ceramics particle strengthened composite material lining metal tube has excellent abrasive resistance and corrosion-resistance and greatly improves service life. The raw materials of the invention are easy to be obtained, manufacturing technology is simple, cost is low and economic benefit is obvious and practical application and mass production are beneficial for factories.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

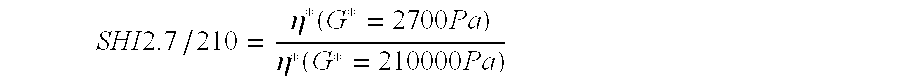

Lldpe Pressure Pipe

InactiveUS20070273066A1Low densityImprove mechanical propertiesElectric/magnetic/electromagnetic heatingLow-density polyethyleneEngineering

The present invention relates to a multimodal linear low density polyethylene composition for the preparation of a pressure pipe. The invention further relates to a pressure pipe, comprising said composition, a process for the manufacturing of a pipe made of the composition and to a process for the recycling of pipe material consisting of the composition according to the invention. Furthermore the invention relates to the use of the pressure pipe as an irrigation pipe, especially a drip irrigation pipe.

Owner:BOREALIS TECH OY

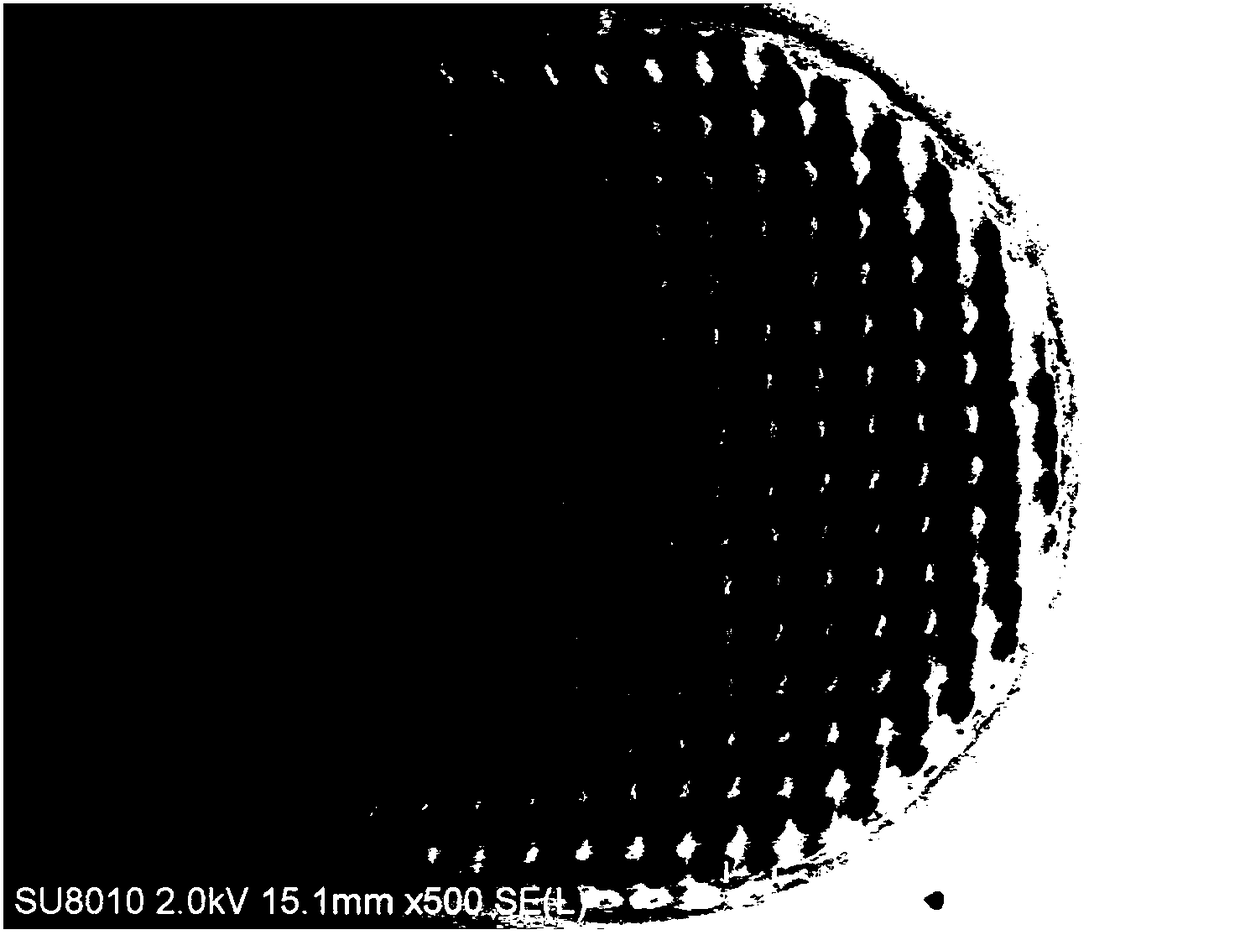

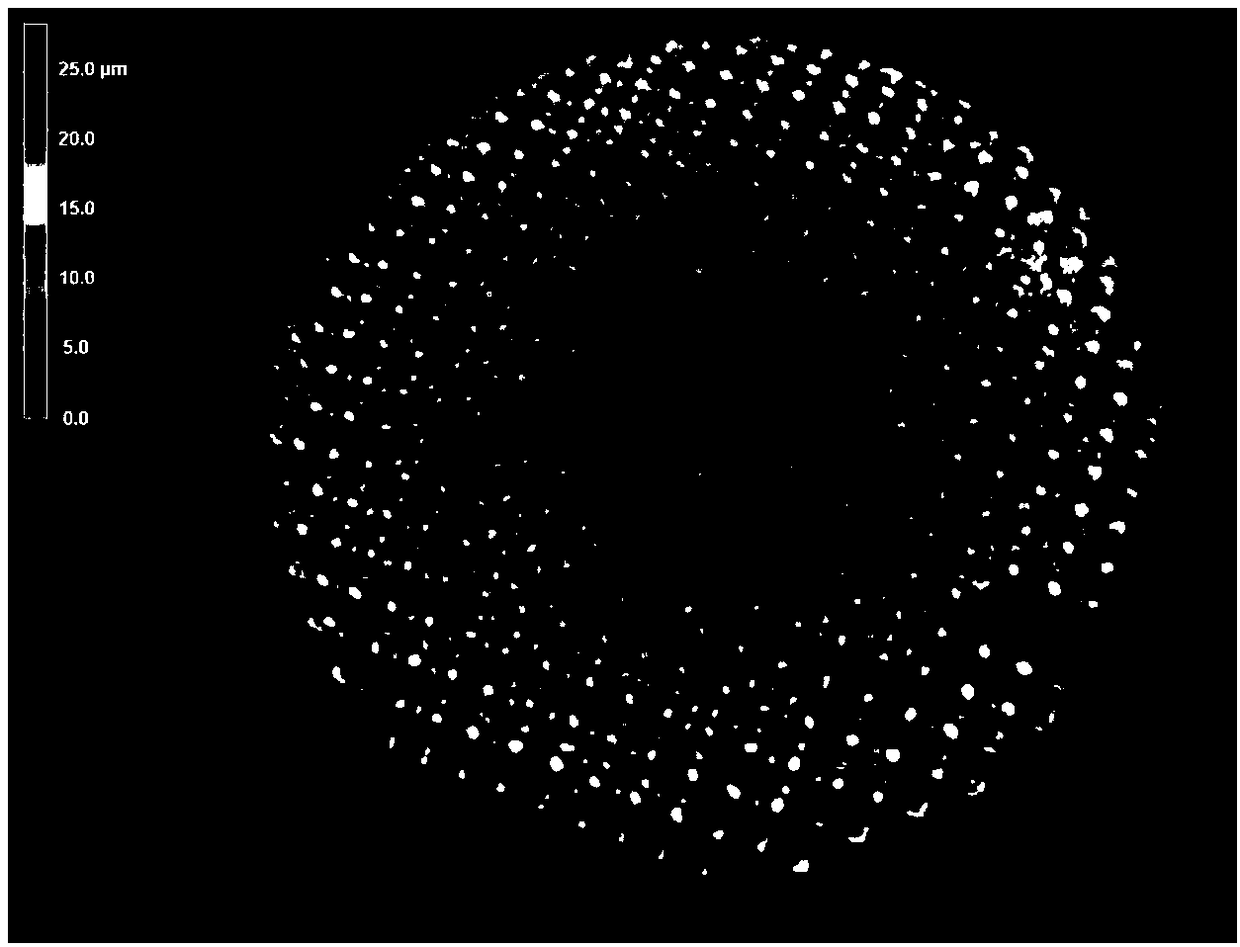

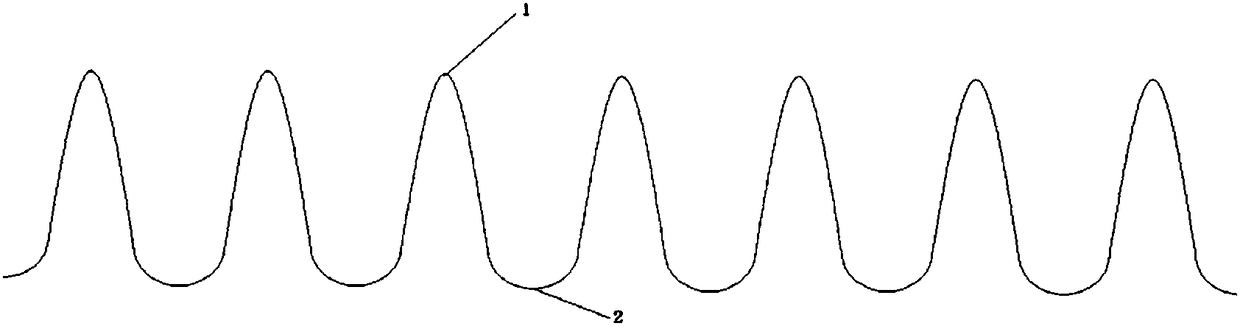

Chopper for improving bonding strength of lead

ActiveCN108389806AImprove bonding performanceImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingWear resistantEngineering

The invention discloses a chopper for improving bonding strength of a lead. The chopper is a welding ceramic chopper and comprises a body, a welding nozzle and a hole, wherein the welding nozzle is arranged at one end of the body, the hole extends along a longitudinal axis of the body and the welding nozzle, and a tip surface of the welding nozzle comprises convex parts and concave parts which arealternatively distributed. By the design of a chopper surface structure, the wear-resistant region of the surface can be expanded, the hardness of the tip surface is improved, the roughness of the surface is improved, and the service lifetime is prolonged; compared with a traditional polishing and thermal processing chopper, the chopper has the advantages of better bonding effect and higher stability; on one hand, the gold reservation degree of a tip is effectively reduced by the design; and on the other hand, the wear-resistant degree of a porcelain nozzle is improved, and thus, the servicelifetime of the porcelain nozzle is prolonged.

Owner:CHAOZHOU THREE CIRCLE GRP

Solar photoelectric photo-thermal integrated assembly and solar combined heat and power generation system thereof

InactiveCN103594538AEliminates the effects of thermal contact resistanceEliminate the effects ofPV power plantsEnergy industryCells panelMetal sheet

The invention relates to a solar photoelectric photo-thermal integrated assembly and a solar combined heat and power generation system of the solar photoelectric photo-thermal integrated assembly. The solar photoelectric photo-thermal integrated assembly is characterized by comprising a photovoltaic cell panel provided with a metal outer frame, a metal sheet type heat exchanger and a heat-preservation material layer, wherein the metal sheet type heat exchanger and the heat-preservation material layer are sequentially arranged on the back surface of the photovoltaic cell panel in parallel and in an overlapped mode, and are rapidly fixed in the metal outer frame of the photovoltaic cell panel through a metal fixing clamp, and the standard photovoltaic cell panel can be rapidly modified into the photoelectric photo-thermal integrated assembly. The photoelectric photo-thermal integrated assembly has the advantages of being compact in structure, high in efficiency, small in pressure loss, light in weight, flexible to install, high in pressure bearing performance, resistant to corrosion, low in cost and the like, further reduces the initial investment and installation space of a medium and low temperature solar thermoelectric system, lowers the operation expenses of the system, and is suitable for civil and industrial occasions requiring for both heat and power.

Owner:SHANGHAI LVJIAN ENERGY TECH

High-toughness wear-resistant polyformaldehyde composition and preparation method thereof

ActiveCN101885896AHigh toughness and wear resistanceImprove wear resistanceCompound sEngineering plastic

Owner:BEIJING UNIV OF CHEM TECH

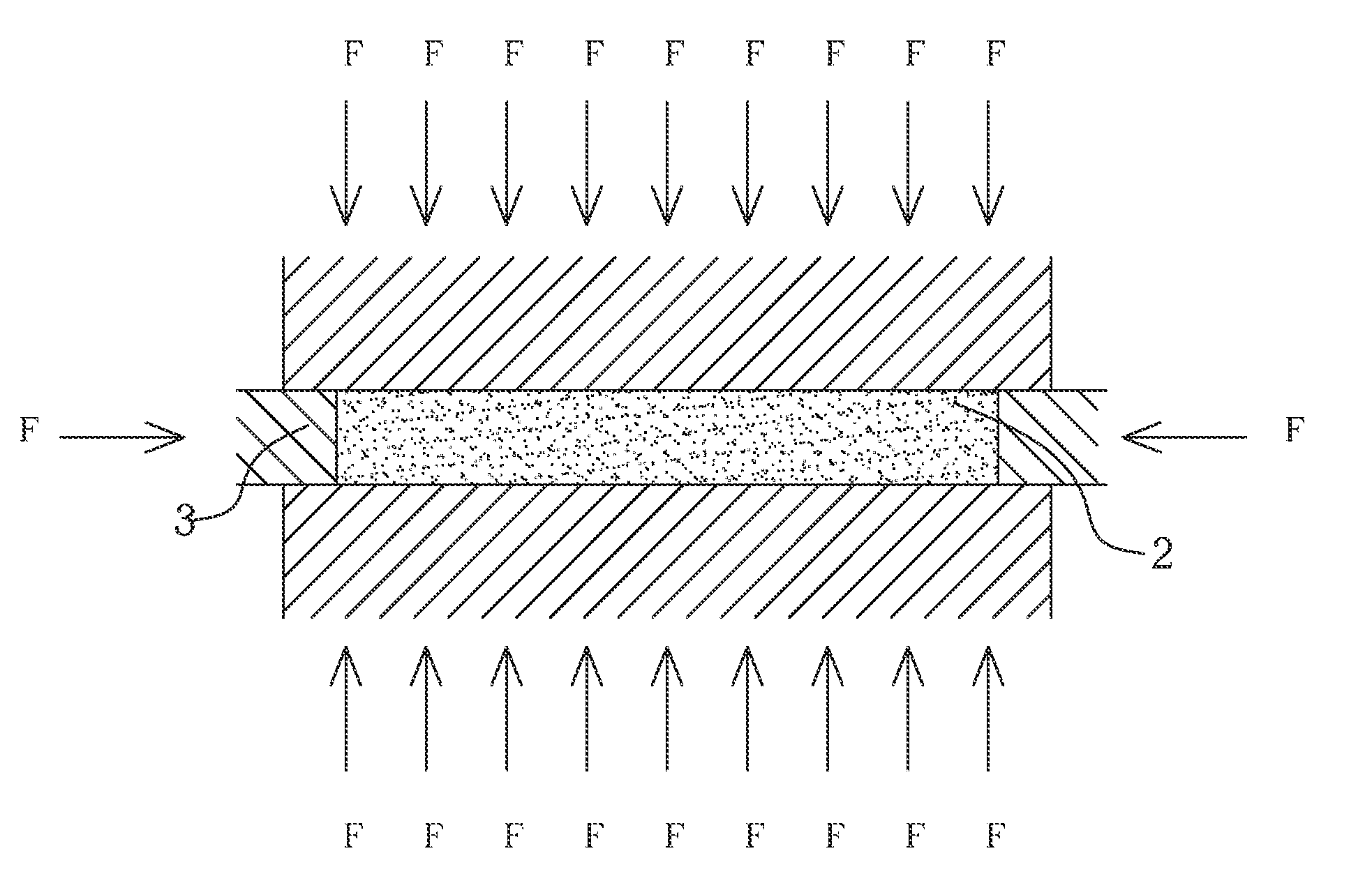

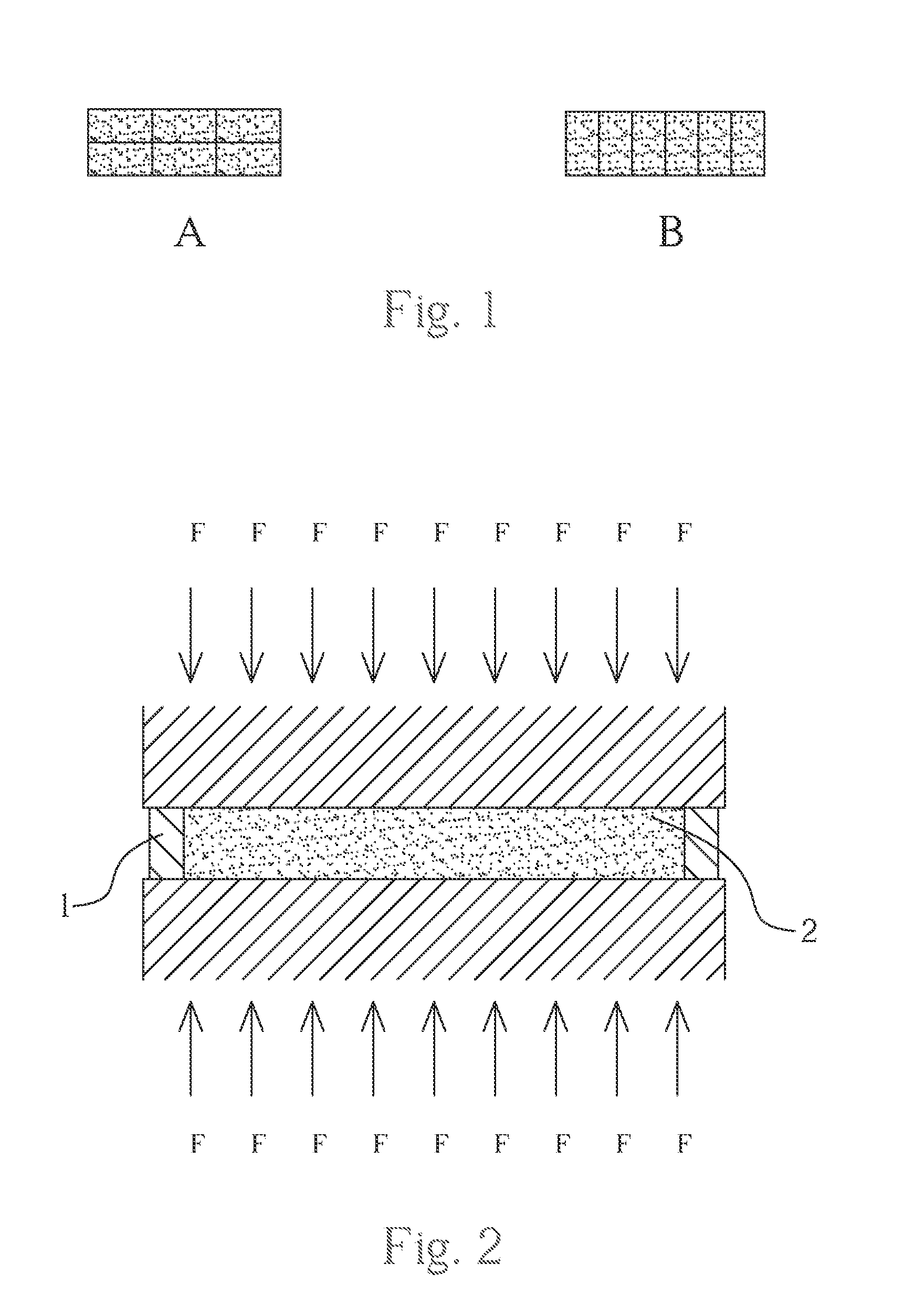

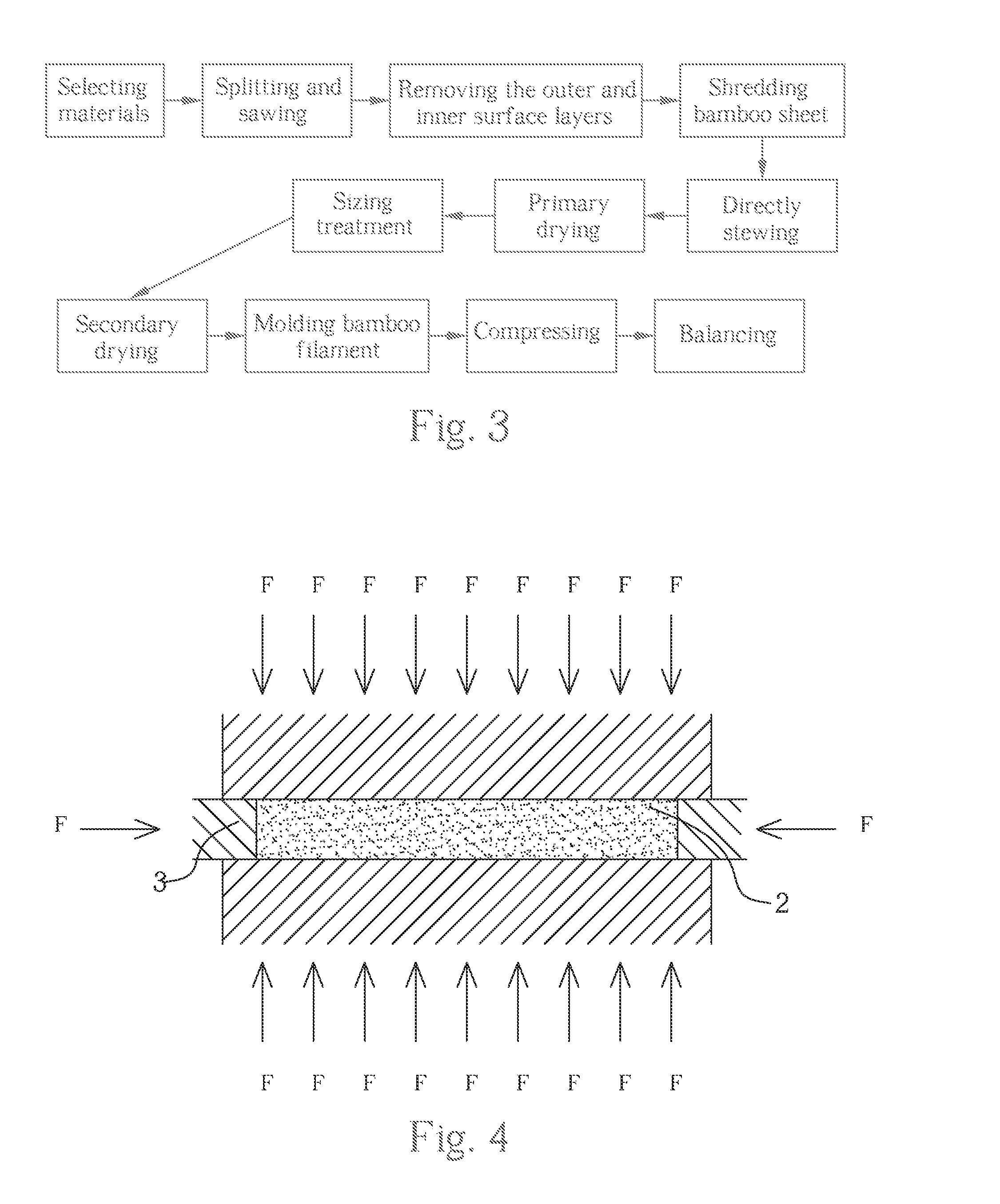

Process for Making a Bamboo Filament Slab Floor by Opposite Directional Hot Pressing

The present invention relates to bamboo manufacturing field, in particular, to a process for making a bamboo filament slab floor by opposite directional hot pressing. Aiming to overcome the defects that, while compressing, the existing bamboo filament slab floor at normal temperature under cold pressing is easy to rebound and expand, has low strength and weak resistance to abrasion and is easy to mildew while using for a long time, the present invention adopts shredding bamboo sheet, sizing treatment, moulding bamboo filament and etc. procedures, characterized in that, a secondary drying procedure should be inserted between said sizing treatment and bamboo filament moulding procedure; said sizing treatment should be implemented by soak sizing bamboo filament; said compressing includes opposite directional hot pressing of positive pressing and side pressing. The present invention adopts specific manufacturing technology, thus the floor can avoid the occurrence of holes and gaps inside bamboo filament slab floor and discharge formaldehyde and has stable quality, and will be not prone to mildew and deform while using for a long time. It can be widely used and suitable for indoor and outdoor flooring and various boards used in decoration and furniture.

Owner:WANG ZHENGFENG

Copper/cerium-containing antimicrobial stainless steel and preparation method thereof

The invention discloses a copper / cerium-containing antimicrobial stainless steel and a preparation method thereof. The copper / cerium-containing antimicrobial stainless steel comprises the following chemical components in percentage by weight: at most 0.08% of C, at most 1% of Si, at most 2.00% of Mn, less than 0.045% of P, less than 0.030% of S, 17.5-20.0% of Cr, 8-11% of Ni, 0.5-2.8% of Cu, 0.01-0.45% of Ce, and the balance of Fe and inevitable impurities. The stainless steel is molten in an induction furnace after smelting, and is subjected to aging high-temperature diffusion heat treatment composed of 20-minute 1180 DEG C solid solution and 1-hour 685 DEG C thermal insulation so as to precipitate the antimicrobial phase epsilon-Cu and Ce, thereby endowing the stainless steel with antimicrobial property. The steel grade has stainless steel performance and broad-spectrum antibacterial property; the corrosion resistance, wear resistance, strength, toughness, oxidation resistance and other comprehensive properties of the stainless steel are improved; and the production technique is simple, has great utilization value in industry, and is suitable for industrial production.

Owner:SHANGHAI UNIV

Working roll for rolling medium-thickness plate with high grade and high strength and manufacture method thereof

ActiveCN101954378AImprove wear resistanceImproved roll shape retentionRollsMetal rolling arrangementsChemical compositionWork roll

The invention discloses a working roll for rolling a medium-thickness plate with high grade and high strength and a manufacture method thereof. The working roll is applied to a medium-thickness plate rolling mill of a rolling steel industry. A working layer comprises the following alloy components in percentage by weight: 3.00-3.50 percent of C, 0.40-1.20 percent of Si, 0.50-1.20 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 1.30-2.50 percent of Cr, 3.20-4.50 percent of Ni, 0.20-1.00 percent of Mo, 0.20-2.00 percent of W and 1.00-1.50 percent of V. A roll core comprises the following chemical components in percentage by weight: 2.80-3.50 percent of C, 2.00-2.50 percent of Si, 0.50-1.00 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 0.20-0.50 percent of Cr, 0.20-0.60 percent of Ni, not more than 0.20 percent of Mo and not more than 0.30 percent of Re. The working roll manufactured by adopting a centrifugal composite casting process and two-section tempering production at 400-550 DEG C for 25-30 hours is the working roll for rolling the medium-thickness plate with high grade and high strength, which has the advantages of high abrasion resistance and less hardness reduction.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Wear resistant sole material

InactiveCN103483677ADoes not affect elasticityDoes not affect resilienceSolesEnvironmental resistanceFoaming agent

The invention relates to a wear resistant sole material. The wear resistant sole material comprises, by weight, 35-45 parts of EVA, 4-8 parts of styrene butadiene rubber, 1-8 parts of butadiene rubber, 1-4 parts of a vulcanizing agent, 2-5 parts of a reinforcing agent, 1-4 parts of an activator, 1-4 parts of an accelerant and 0.5-3 parts of a foaming agent. The wear resistant material greatly improves the wear resistance of a sole without influencing the elasticity, the resilience, the portability or the like of the sole, and also has the advantages of non-toxicity, no pollution, safety and environmental protection.

Owner:KUNSHAN CHUNBAI PRECISE HARDWARE CO LTD

Glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and preparation method thereof

The invention provides glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and a preparation method thereof. The glass ceramics use the tailings obtained by nickel-molybdenum ore dressing and smelting as main raw materials and silica or quartz sand (SiO2), limestone or calcite (CaCO3), sodium carbonate (Na2CO3), alumina (Al2O3), potassium carbonate (K2CO3), magnesium oxide (MgO) and calcium fluoride (CaF2) as auxiliary raw materials. The preparation method comprises the steps of grinding the tailings obtained by nickel-molybdenum ore dressing and smelting and the auxiliary raw materials, sieving the powder with a 20-mesh sieve, and mixing the powder uniformly in a mixer to obtain a base batch; melting the base batch at the temperature of 1450-1550 DEG C, homogenizing and clarifying the melt to obtain qualified molten glass, and then forming a base glass plate or granules through moulding by casting or water quenching of the molten glass; finally filling the base glass plate or the granules into a mould, and then carrying out crystallization thermal treatment, thus obtaining the glass ceramics prepared from the tailings obtained by nickel-molybdenum ore dressing and smelting. The preparation process is simple in operation course and has the effects of not only expanding the way of resource comprehensive utilization of the tailings obtained by nickel-molybdenum ore dressing and smelting but also reducing the environmental pollution of the tailings.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

SMC molding compound with high wear resistance and preparation method thereof

Owner:常熟市华邦汽车复合材料有限公司

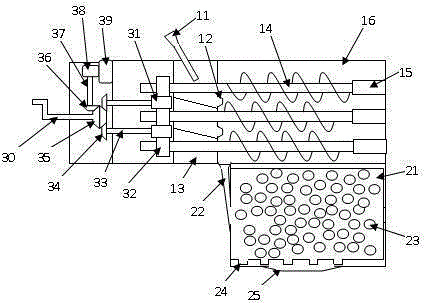

Drug breaking and grinding device

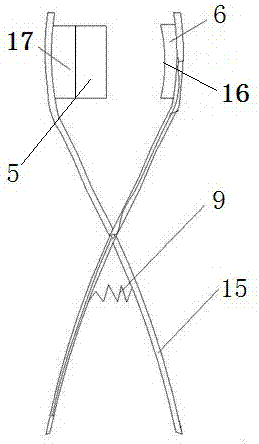

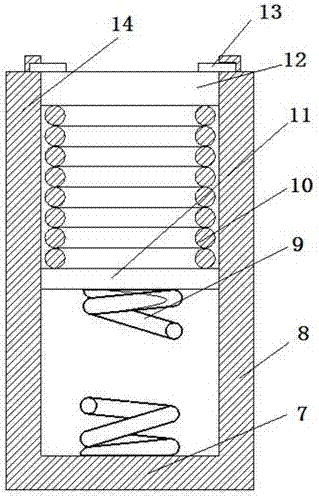

InactiveCN106733109AIncrease grinding rateImprove grinding effectFurnace typesGrain treatmentsDrugTransmission system

The invention relates to a drug breaking and grinding device which comprises a breaking system, a grinding system and a power and transmission system. Through the improvement and reasonable arrangement of the various components, breaking and grinding are separated, so that the working efficiency is improved. In addition, with the creative adoption of the grinding system in which grinding balls are matched with a grinding internal barrel and a grinding external barrel, the grinding efficiency and the product quality are improved.

Owner:王宝林

Halogen-free flame-retardant copper-plastic composite belt and preparation thereof

InactiveCN103165237AHas an ultra-thin structureReduce manufacturing costConductive layers on insulating-supportsLaminationPolyesterEngineering

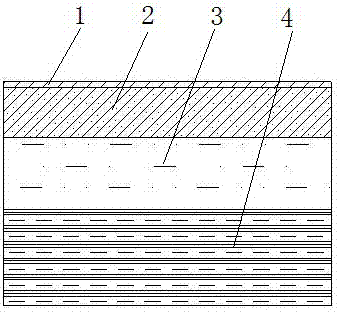

The invention relates to the field of cable belts, in particular to a copper-plastic composite belt suitable for a communication cable and an optical cable and preparation thereof. The copper-plastic composite belt is coated on the outer surface of the communication cable or the optical cable and sequentially comprises a red copper layer (1), an adhesive layer (2) and a polyester film layer (3), wherein the red copper layer (1), the adhesive layer (2) and the polyester film layer (3) are bonded and heated to form a composite structure. The tensile strength of the copper-plastic composite belt is larger than or equal to 180MPa, the elongation at break of the copper-plastic composite belt is larger than or equal to 15%, the interlayer peeling strength between a copper belt and a plastic layer is larger than or equal to 15N / cm, the conductivity of the copper-plastic composite belt is larger than or equal to 90% IACS, and no punchthrough happens on the single side of the copper-plastic composite belt 1 kvd.c,1min.

Owner:JIUXING HLDG GRP

Double metal alloy barrel material and producing technology thereof

InactiveCN107312962AModerate hardnessImprove high temperature performanceChromium carbideMetal alloy

The invention discloses a double metal alloy barrel material. Raw material powder of the double metal alloy barrel material comprises, by mass, 25-50% of molybdenum, 2-10% of boron, 5-15% of chromium, 2-10% of nickel, 1-5 %of manganese, 0.1-1% of carbon, 0.8-3% of chromium carbide and the balance ferrum. The producing technology of the double metal alloy barrel material comprises the following steps of 1), raw powder ball-milling, 2), powder mixing and drying, 3), powder pressing for forming a green body, 4) green body machining and shaping, 5), vacuum degreasing and sintering, 6) semi-finished product shaping and machining, 7) green body heat covering treatment, and 8), inner hole machining treatment. A double metal alloy barrel produced by the above materials is moderate in rigidity, excellent in high temperature performance, good in bending strength, close to density of steel substrate, high in breaking tenacity, excellent in wear-resisting property and excellent in decay resistance, plastic molding can be more stable by using the producing technology, and the service life of the alloy barrel is greatly improved.

Owner:DONGGUAN JIEYU MASCH CO

Novel anti-wear device of port loading and unloading hopper and hopper

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

Nickel-based alloy powder material for repairing crystallizer foot roller and repairing method

ActiveCN112680634AImprove antioxidant capacityImprove thermal shock resistanceIncreasing energy efficiencyMetallic material coating processesOxidation resistantWear resistance

The invention discloses a nickel-based alloy powder material for repairing a crystallizer foot roller. The nickel-based alloy powder material comprises the following chemical components in percentage by mass of 22-28% of Cr, 8-12% of Mo, 3-4% of Nb, 1.0-2.5% of Si, 0.8-1.6% of B, 0.8-2% of V, 0.05-0.08% of C and the balance of Ni. The invention further discloses a repairing method of the crystallizer foot roller. The method comprises the following steps of 1, rough turning; 2, pre-flaw detection; 3, laser cladding, wherein a cladding layer comprises two layers, a base coat is iron-based alloy powder, a functional layer is cladded on the base coat, and the functional layer is made of nickel-based alloy powder; 4, finish turning; 5, grinding; and 6, post-flaw detection. The crystallizer foot roller repaired by using the material and the method provided by the invention has the advantages that the properties such as high-temperature oxidation resistance, cold and hot fatigue resistance and wear resistance are obviously improved, and the corresponding service life is also greatly prolonged.

Owner:TAIER (ANHUI) IND TECH SERVICE CO LTD

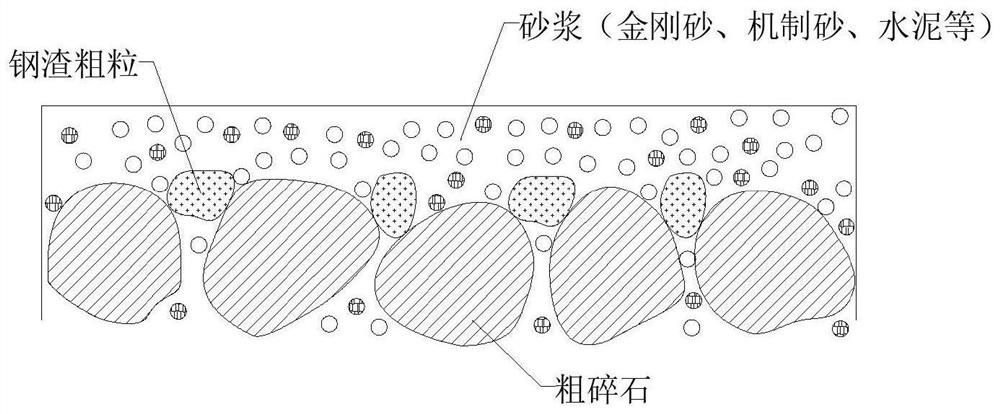

Special cementing material for preparing wear-resistant ultra-high performance concrete

ActiveCN113321433AImprove bonding performanceImprove wear resistanceSolid waste managementAluminateBelite

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Construction method for carborundum wear-resisting floor of large spinning workshop

Owner:CHINA CHEM ENG SECOND CONSTR

Heavy duty pneumatic tire

PendingUS20210023887A1Improve wear resistanceHeavy duty tyresHeavy duty vehicleHeavy dutyShoulder surface

Owner:SUMITOMO RUBBER IND LTD

Waterborne polyester resin and preparation method thereof

InactiveCN106893087AImprove hydrolysis resistanceGood dispersionPolyester coatingsWater dispersibleAdipic acid

The invention discloses waterborne polyester resin, comprising polyols and polyacids; the polyols include 8-12% of trimethylol propane, 12-24% of neopentyl glycol, 6-12% of ethylene glycol, and 8-12% of propylene glycol; the polyacids include 5-15% of purified terephthalic acid, 12-24% of isophthalic acid, 6-12% of phthalic acid, 10-18% of trimellitic anhydride, 6-12% of hexahydro-phthalic acid, 10-20% of maleic anhydride, and 5-10% of adipic acid; the waterborne polyester resin also comprises 0.1-0.3% of p-methoxyphenol, 6-24% of ethylene glycol butyl ether, 8-16% of dimethylethanolamine, and 60-100% of deionized water. The waterborne polyester resin can gain improved hydrolysis resistance, water dispersibility and storage stability, has improved stability of polyester main chain hydrolysis and is widely applicable to waterborne insulating devices, the defects of the prior art can be overcome, and the requirement on actual use can be met.

Owner:CHUZHOU QUAN FENG MATERIALS CO LTD

Wear-resistant stainless steel wire

Owner:江苏金基特钢有限公司

Water pump

ActiveCN106246603AImprove wear resistanceImprove corrosion resistancePump componentsEngine fuctionsEngineeringCorrosion

The invention discloses a water pump. The water pump comprises a volute, a pump shell and a bearing seat, wherein the volute, the pump shell and the bearing seat are sequentially connected. A wear-proof pump shaft and a mechanical seal cavity of a reasonable structure are applied to the water pump, and a reasonable locating structure and a reasonable jackscrew structure are designed. In this way, the wear resisting capacity and the corrosion resisting capacity of the water pump are improved; and besides, detachment is convenient, installation and detachment can be simplified, the production cost and the installation cost can be reduced, and the production efficiency and the maintenance efficiency can be improved.

Owner:QINGMUCHUAN ENVIRONMENTAL PROTECTION TECH (GUANGZHOU) CO LTD

Plastics products and preparation method thereof

InactiveCN101396890AImprove wear resistanceFeel goodVacuum evaporation coatingSynthetic resin layered productsCopper coatingCeramic coating

The invention relates to a plastic product, comprising plastic substrate. The plastic product is characterized in that the product also comprises a copper coating, a nickel coating, a chrome coating and a ceramic coating from the surface of the plastic substrate to the outside in sequence; the ceramic coating is one or more layer of titanium nitride, titanium carbide and titanium carbonitride. The plastic product made by the invention has excellent wearing resistance, the film formed on the surface of the plastic product has excellent adhesiveness, and the plastic product that is obtained finally also has ceramic texture and good handfeel.

Owner:BYD CO LTD

Nano-modified PET engineering plastic and preparation method thereof

The invention discloses a nano-modified PET engineering plastic and a preparation method thereof. The nano-modified PET engineering plastic comprises 40%-60% of polyester (PET), 20%-40% of glass fibers, 0.4% of lubricant, 0.6% of antioxidant, 2.5% of flexibilizer, 13% of fire retardant, 2.5% of synergistic-effect fire retardant, and 1% of nano-nucleating agent; according to the proportions of the materials, the nano-modified PET engineering plastic has the advantages of good tenacity, good mechanical properties and good fire resistance, is greatly improved in the aspects of tenacity, wear resistance, high temperature resistance and ageing resistance, and is capable of well satisfying the use requirements and the use environments. In addition, the preparation method comprises the step of weighing materials, the step of mixing and stirring and the step of extruding and granulating by use of a twin-screw extruder; and due to the design of the process steps, the preparation method of the nano-modified PET engineering plastic is simple and low in cost.

Owner:广东壹豪新材料科技股份有限公司

Ceramic for Decorative Part and Decorative Part Comprising the Same

InactiveUS20110104404A1High compressive stressImprove wear resistanceBraceletsCeramic layered productsCeramicCrystal

Owner:KYOCERA CORP

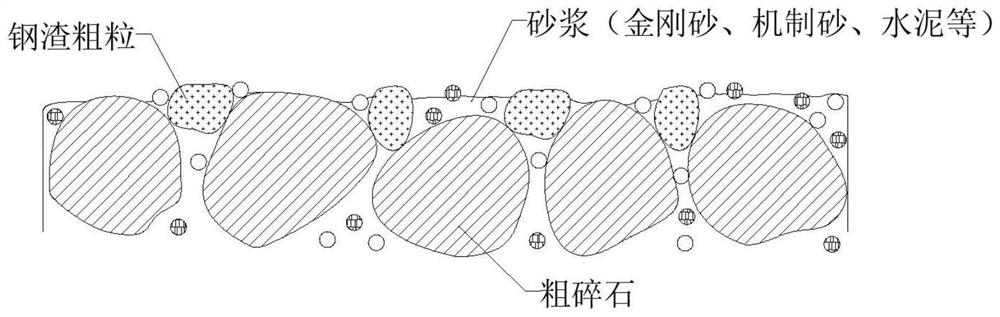

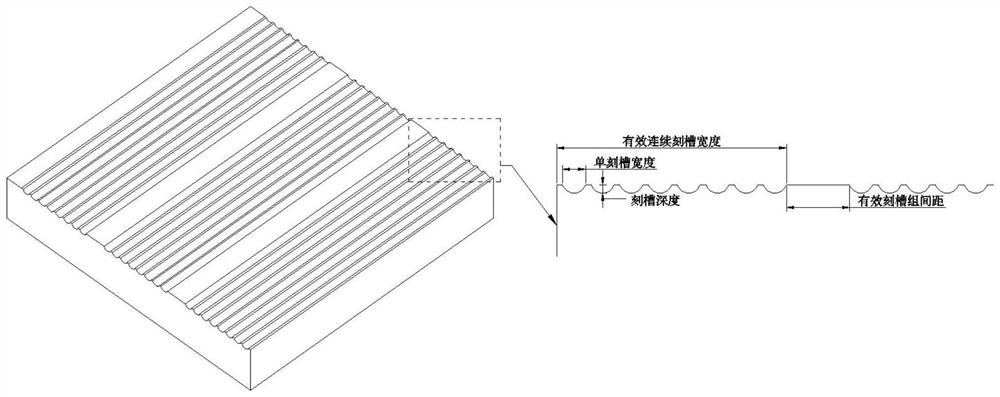

Implementation method of wear-resistant and skid-resistant tunnel cement concrete pavement

PendingCN114775356AImprove wear resistanceIncrease frictional resistanceIn situ pavingsRoads maintainenceCementDriving safety

Owner:ROAD & BRIDGE INT +1

Black phosphorus modified polyimide composite material, and preparation method and application thereof

ActiveCN109880365AExcellent performanceImprove wear resistanceOther chemical processesBlack phosphorusCarbon fibers

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap