Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Fatigue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fatigue resistance is one of the most important mechanical characteristics of structural biomaterials, because biomaterials are generally used under cyclic loading conditions.

High-performance bridge steel with yield strength not smaller than 500 MPa and preparation method and application of high-performance bridge steel

The invention belongs to the technical field of metallurgy, and particularly relates to high-performance bridge steel with the yield strength not smaller than 500 MPa and a preparation method and application of the high-performance bridge steel. The bridge steel is prepared from the following components: 0.03% to 0.06% of C, 0.10% to 0.25% of Si, 1.30% to 1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.010% to 0.040% of Als, 0.25% to 0.45% of Cr, 0.05% to 0.20% of Mo, 0.20% to 0.30% of Cu, 0.25% to 0.40% of Ni, 0.030% to 0.040% of Nb, 0.010% to 0.040% of Ti and the balance Fe and impurities. According to the high-performance bridge steel with the yield strength not smaller than 500 MPa and the preparation method and application of the high-performance bridge steel, microalloying design is adopted, a TMCP technology is matched, precious elements are reduced, the structure is fine and uniform, and a prepared steel plate has high toughness, a low yield ratio, weather resistance, weldability and the anti-fatigue performance.

Owner:SD STEEL RIZHAO CO LTD

Nickel-based alloy powder material for repairing crystallizer foot roller and repairing method

ActiveCN112680634AImprove antioxidant capacityImprove thermal shock resistanceIncreasing energy efficiencyMetallic material coating processesOxidation resistantWear resistance

The invention discloses a nickel-based alloy powder material for repairing a crystallizer foot roller. The nickel-based alloy powder material comprises the following chemical components in percentage by mass of 22-28% of Cr, 8-12% of Mo, 3-4% of Nb, 1.0-2.5% of Si, 0.8-1.6% of B, 0.8-2% of V, 0.05-0.08% of C and the balance of Ni. The invention further discloses a repairing method of the crystallizer foot roller. The method comprises the following steps of 1, rough turning; 2, pre-flaw detection; 3, laser cladding, wherein a cladding layer comprises two layers, a base coat is iron-based alloy powder, a functional layer is cladded on the base coat, and the functional layer is made of nickel-based alloy powder; 4, finish turning; 5, grinding; and 6, post-flaw detection. The crystallizer foot roller repaired by using the material and the method provided by the invention has the advantages that the properties such as high-temperature oxidation resistance, cold and hot fatigue resistance and wear resistance are obviously improved, and the corresponding service life is also greatly prolonged.

Owner:TAIER (ANHUI) IND TECH SERVICE CO LTD

Weather-resistant impact-resistant waterproof plugging material with stable quality and its preparation method

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

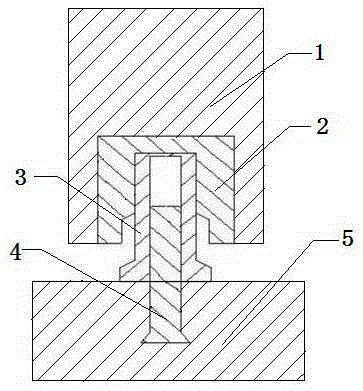

Production process for rubber of spherical hinge

InactiveCN108084513AImprove anti-aging propertiesImprove fatigue resistanceCoatingsAfter treatmentVulcanization

Owner:南通市弘达轨道交通配件有限公司

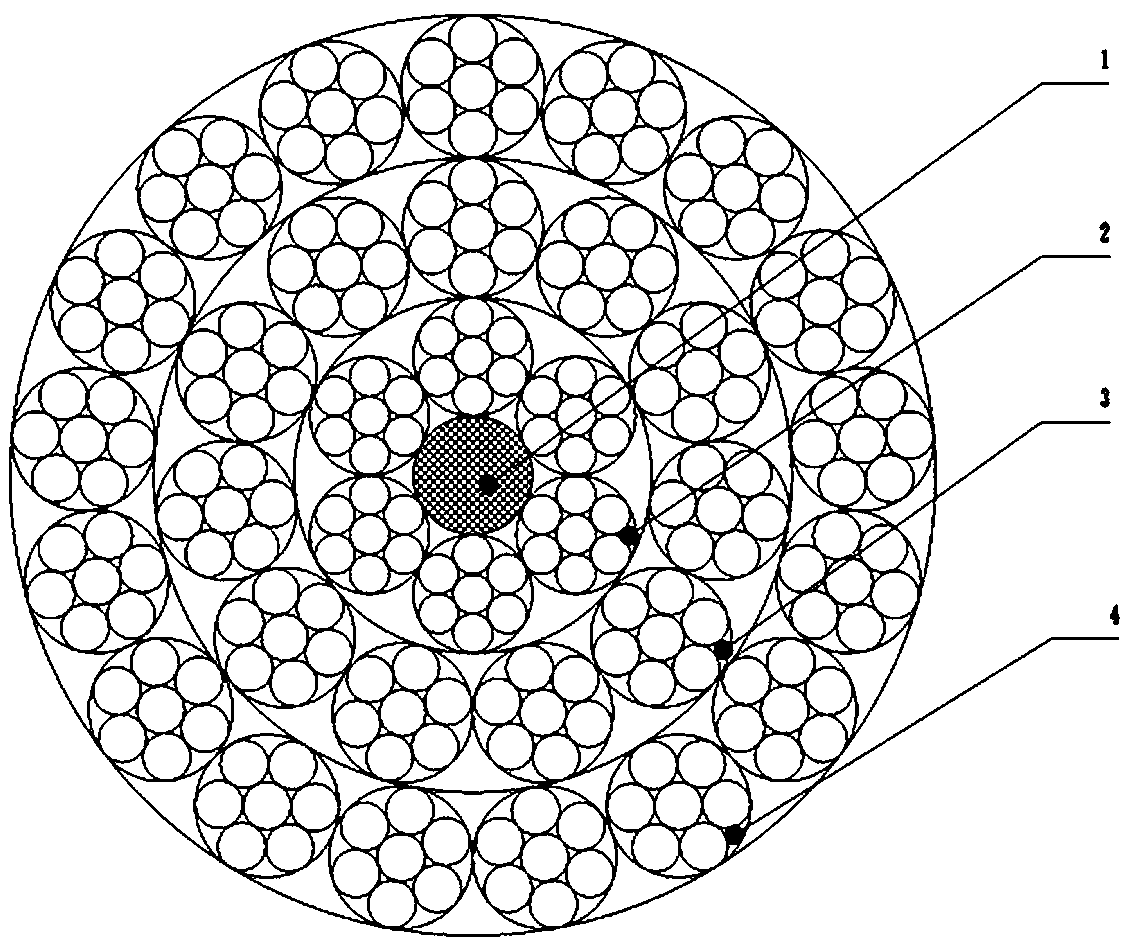

Structure design method of strand compacted non-rotating steel wire rope with diameter of 45mm

PendingCN110055781ACompact structureImprove fatigue resistanceRope making machinesFiberCarrying capacity

Owner:GUIZHOU WIRE ROPE

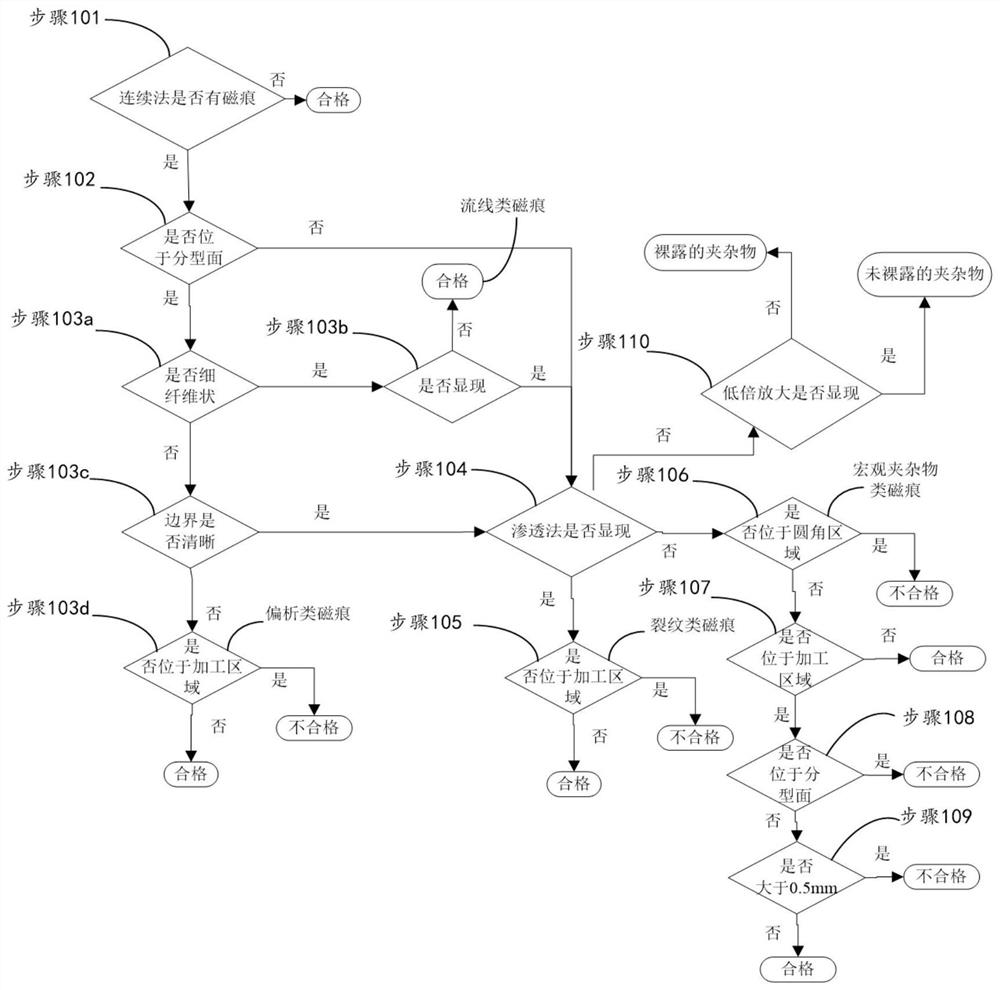

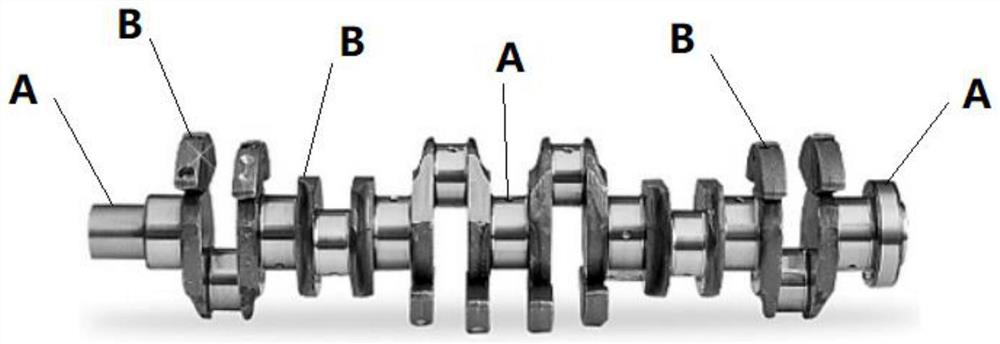

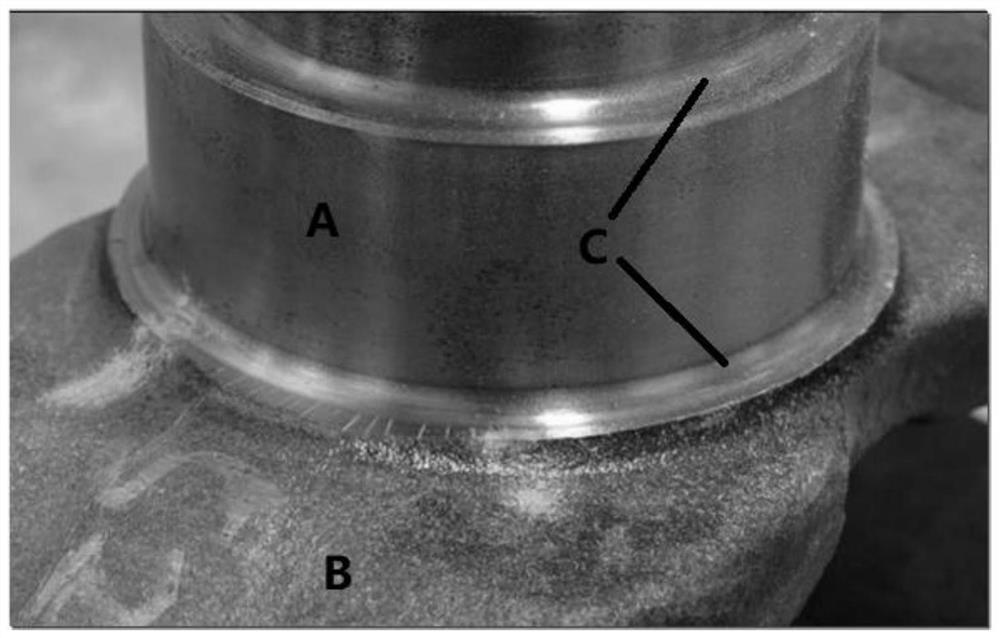

Engine crankshaft inspection method

ActiveCN113740416AAvoid misjudgmentImprove reliabilityInternal combustion piston enginesOptically investigating flaws/contaminationMechanical engineeringCrankshaft

Owner:DONGFENG COMML VEHICLE CO LTD

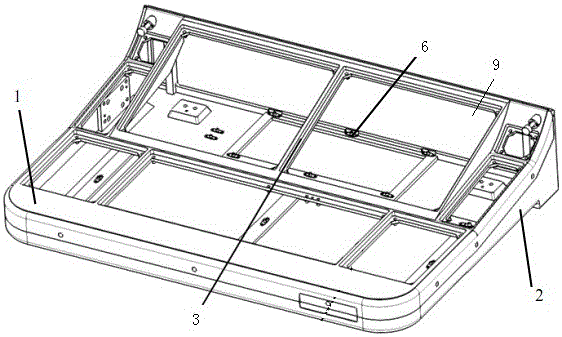

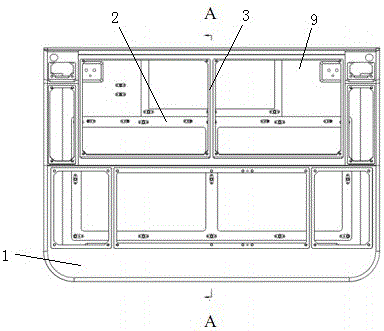

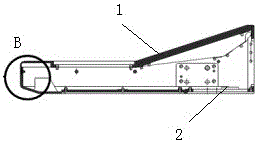

Carbon fiber composite operation skeleton of display and control console

InactiveCN106548810AMeet structural strengthMeet the stiffnessInstrument housingAdhesiveComputer module

Owner:HENGSHEN

Ion filling and depositing combined treatment method of rolling bearing ring raceways

ActiveCN104018115AIncreased working surface hardnessImprove wear resistanceSolid state diffusion coatingEngineeringHardness

Owner:HUANGSHAN MINGMINGDE BEARING

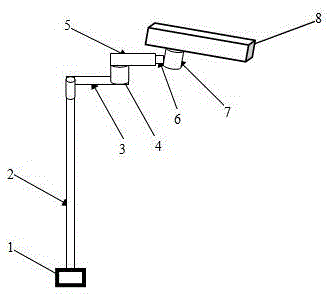

Information collection device bracket applied to information tracing system

Owner:万信方达科技发展(北京)有限责任公司

Efficient and material-saving metal processing fixture

InactiveCN106670307AIncrease grain size gradeImprove fatigue resistanceShaping toolsMetalworkingGranularity

Owner:秦世林

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap