Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Weldability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The weldability, also known as joinability, of a material refers to its ability to be welded. Many metals and thermoplastics can be welded, but some are easier to weld than others (see Rheological weldability). A material's weldability is used to determine the welding process and to compare the final weld quality to other materials.

Hot-rolled steel strip for high strength electric resistance welding pipe and manufacturing method thereof

InactiveUS7501030B2Low costIncreasing costFurnace typesWelding/cutting media/materialsElectrical resistance and conductanceSolderability

A hot-rolled steel strip having superior low temperature toughness and weldability, which is suitably used as a starting material for high strength electric resistance welding pipe, is provided at a low cost without constructing new production facilities and increasing cost. The hot-rolled steel strip is low carbon steel containing at least one of about 0.5.% or less of Cu, about 0.5% or less of Ni, and about 0.5% or less of Mo, wherein Pcm represented by the following equation (1) is 0.17 or less:Pcm=(% C)+(% Si) / 30+((% Mn)+(% Cu)) / 20+(% Ni) / 60+(% Mo) / 7+(% V) / 10 Equation (1),(where (% M) indicates the content of element M on a mass percent basis), and the balance includes Fe and incidental impurities. In addition, in the entire microstructure, the ratio of bainitic ferrite, which is a primary phase, is controlled to be about 95 percent by volume or more.

Owner:JFE STEEL CORP

High-performance bridge steel with yield strength not smaller than 500 MPa and preparation method and application of high-performance bridge steel

The invention belongs to the technical field of metallurgy, and particularly relates to high-performance bridge steel with the yield strength not smaller than 500 MPa and a preparation method and application of the high-performance bridge steel. The bridge steel is prepared from the following components: 0.03% to 0.06% of C, 0.10% to 0.25% of Si, 1.30% to 1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.010% to 0.040% of Als, 0.25% to 0.45% of Cr, 0.05% to 0.20% of Mo, 0.20% to 0.30% of Cu, 0.25% to 0.40% of Ni, 0.030% to 0.040% of Nb, 0.010% to 0.040% of Ti and the balance Fe and impurities. According to the high-performance bridge steel with the yield strength not smaller than 500 MPa and the preparation method and application of the high-performance bridge steel, microalloying design is adopted, a TMCP technology is matched, precious elements are reduced, the structure is fine and uniform, and a prepared steel plate has high toughness, a low yield ratio, weather resistance, weldability and the anti-fatigue performance.

Owner:SD STEEL RIZHAO CO LTD

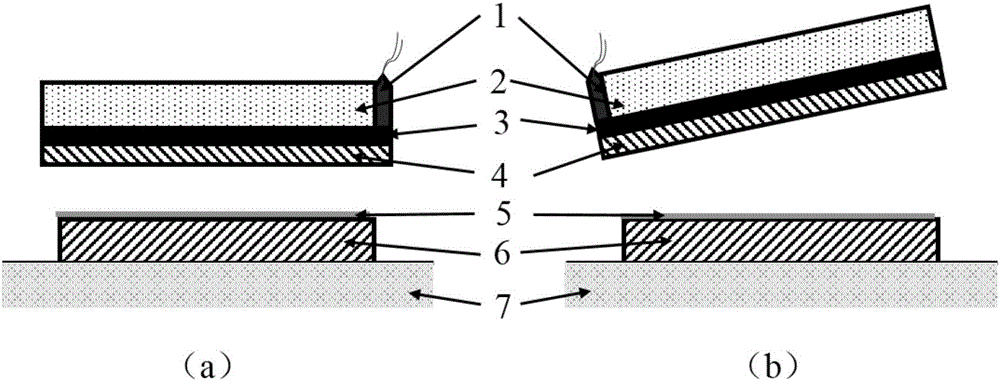

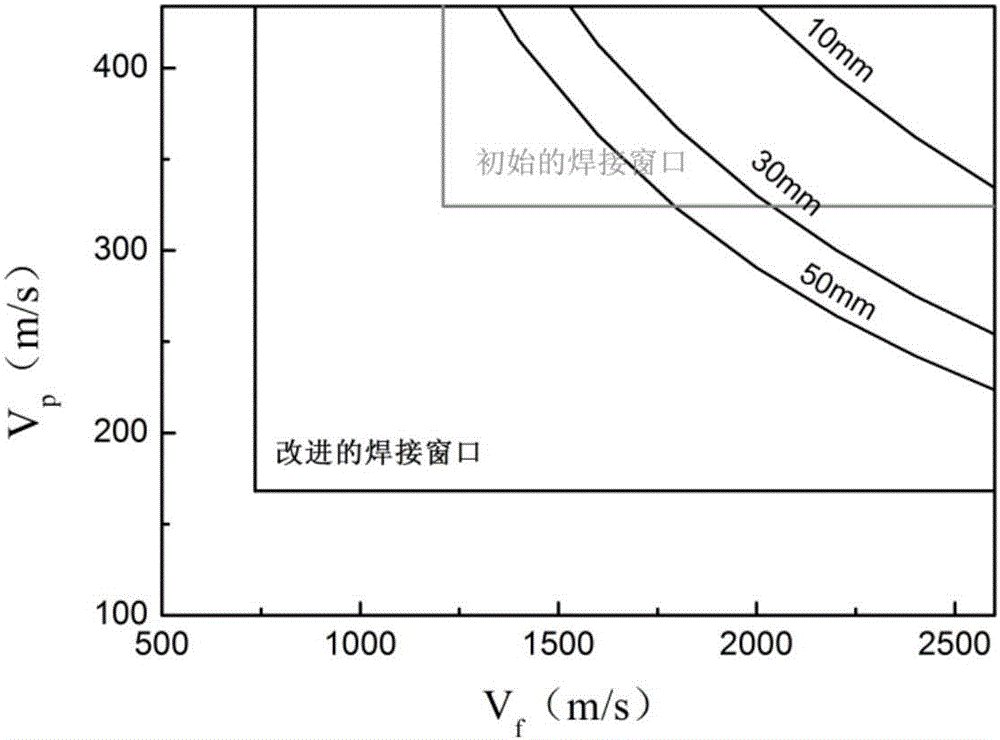

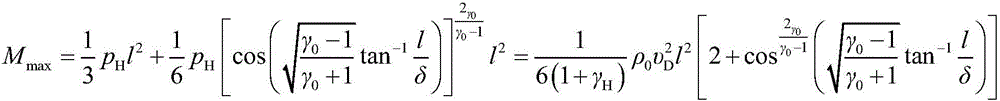

Method capable of improving explosive welding weldability of large-thickness high-strength alloy

Owner:XI AN JIAOTONG UNIV

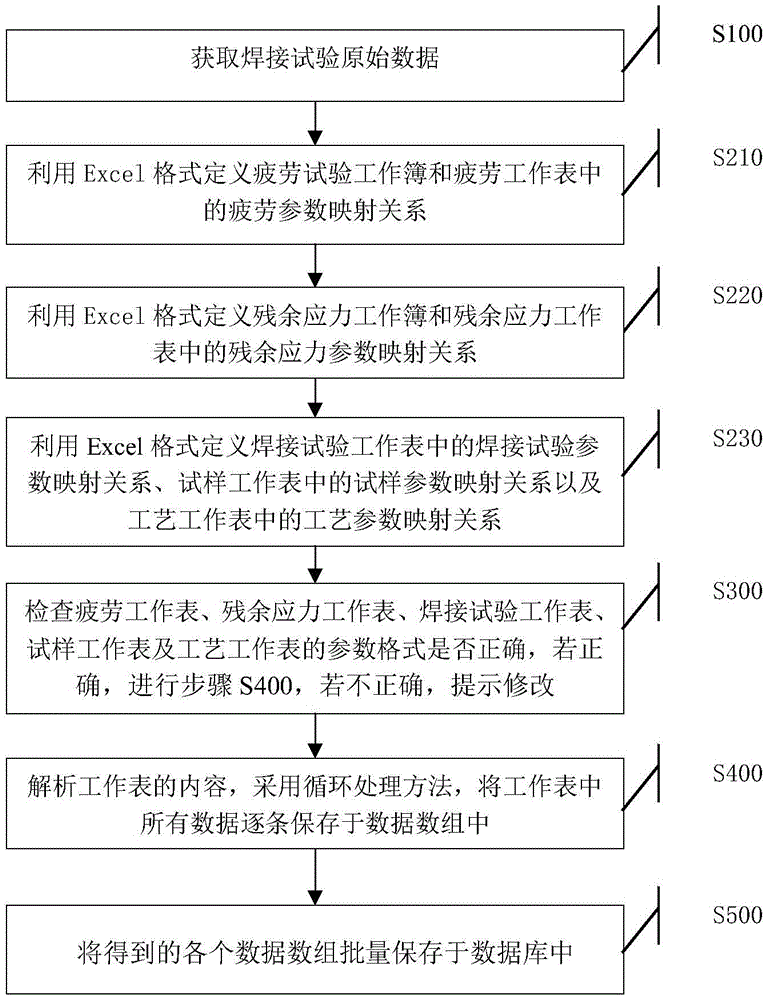

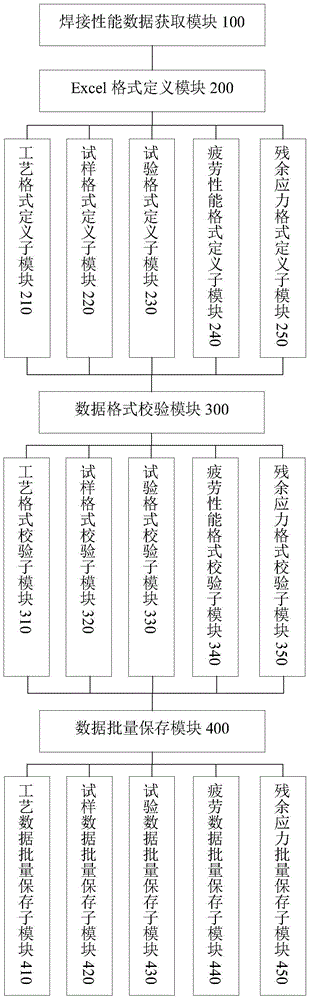

Method and system utilizing Excel format data to process welding performance data

ActiveCN105550267AConvenient and quick organization of recordsEasy to useObject oriented databasesNatural language data processingArray data structureData processing

The invention discloses a method and system utilizing Excel format data to process welding performance data. The method comprises the following steps: acquiring original welding data; utilizing the Excel format to define a fatigue test workbook and a residual stress workbook, and utilizing the Excel format to define the mapping relations of performance parameters in a fatigue worksheet, a residual stress worksheet, welding test worksheets, sample worksheets and process worksheets in the workbooks; examining whether the parameter format in each worksheet is correct or not; analyzing the contents of each worksheet, and saving item by item the data from each worksheet in a data array through the circular processing method; and according to the obtained data array, saving in batches fatigue performance parameter information, residual stress parameter information, welding test parameter information, sample parameter information and process parameter information in a database. The method and system provided by the invention have the advantages that the Excel format data is utilized to integrate and describe welding performances, so that the data complexity is greatly reduced, and the data is clearer and more intuitive to be conveniently read and processed for use.

Owner:SOUTHWEST JIAOTONG UNIV

High heat input welding resistant building steel and production method thereof

ActiveCN114150228AImprove welding effectGood anti-fatigueHeat treatment process controlProcess efficiency improvementNiobiumHeat cycling

Owner:NORTHEASTERN UNIV

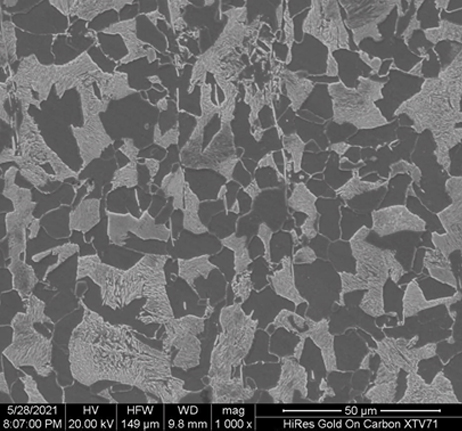

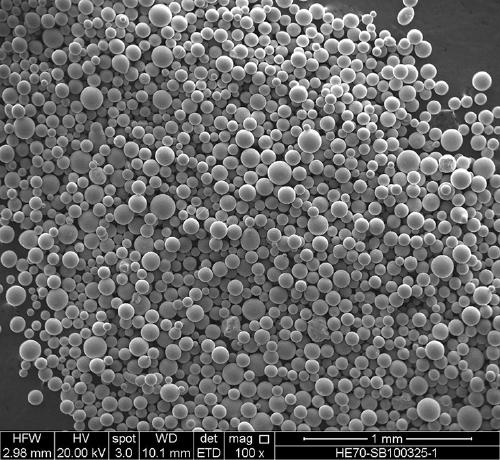

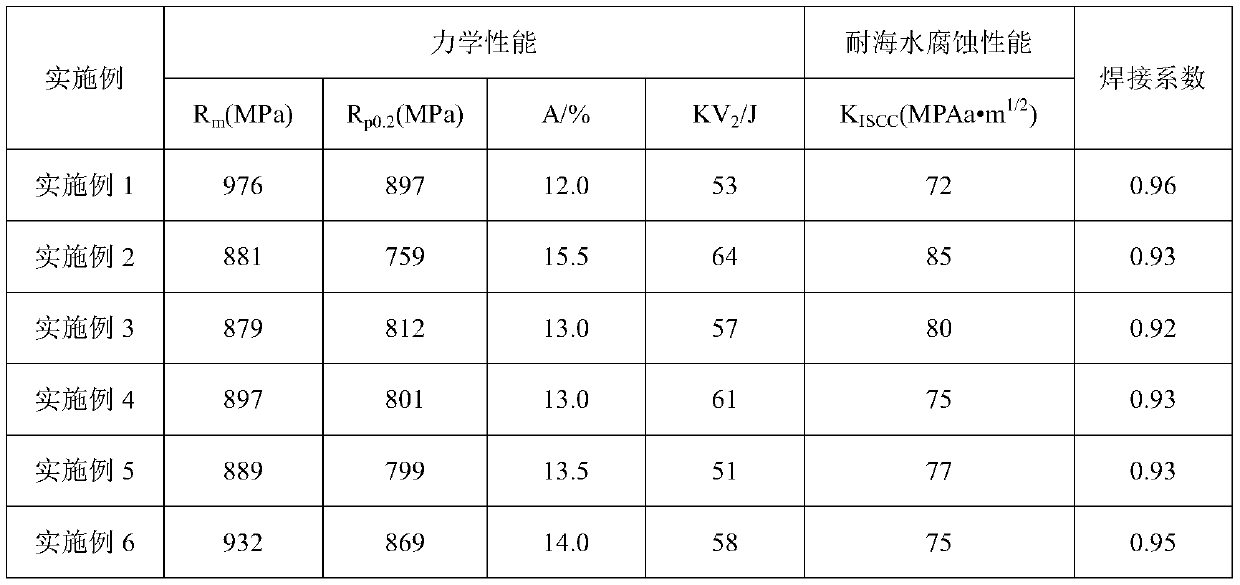

Titanium alloy for 3D printing ship and preparation method

ActiveCN111411260AGood mechanical propertiesHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyIngotTitanium alloy

Owner:XINXIANG UNIV

Coated steel sheet and painted member

ActiveUS20190330478A1Improve corrosion resistanceHot-dipping/immersion processesLiquid surface applicatorsNon oxide ceramicsZinc

Owner:NIPPON STEEL CORP

Manufacturing method of titanium-steel composite board and titanium-steel inner container cup

PendingCN112705570AReduce usageCorrosion resistanceFurnace typesMetal rolling arrangementsExplosive claddingComposite slab

Owner:沈州

Copper surface treating agent and surface treatment method

InactiveCN101668883ASoldering apparatusMetallic material coating processesHeat resistanceSolderability

Disclosed is a copper surface treating agent satisfying both heat resistance and solderability. Also disclosed is a surface treatment method. Specifically disclosed is a copper surface treating agentcontaining an acid, a benzimidazole compound and water, which is characterized in that at least a first benzimidazole compound and a second benzimidazole compound having a melting point lower than that of the first benzimidazole compound by 70 DEG C or more are contained as the benzimidazole compound.

Owner:MEC CO LTD

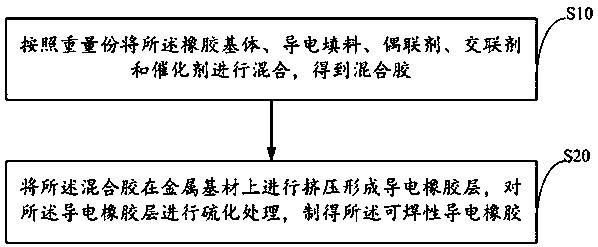

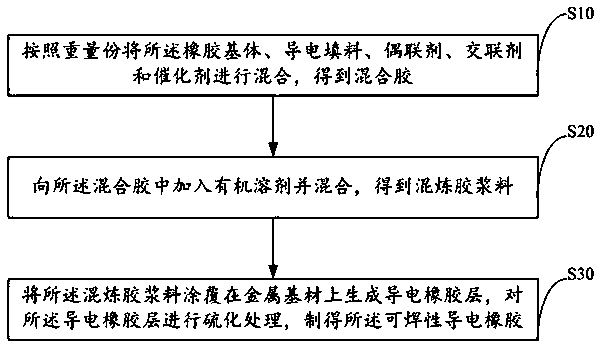

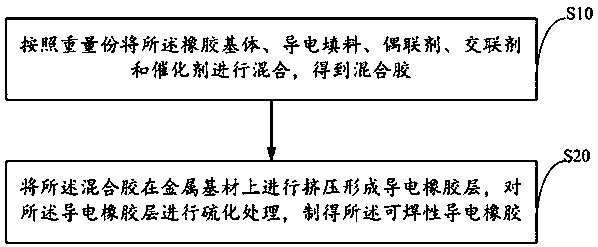

Weldable electroconductive rubber and preparation method thereof

InactiveCN110016230AGood electrical propertiesImprove mechanical propertiesLiquid surface applicatorsCoatingsPolymer scienceMechanical property

Owner:深圳市腾顺电子材料有限公司 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap