Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74 results about "High intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

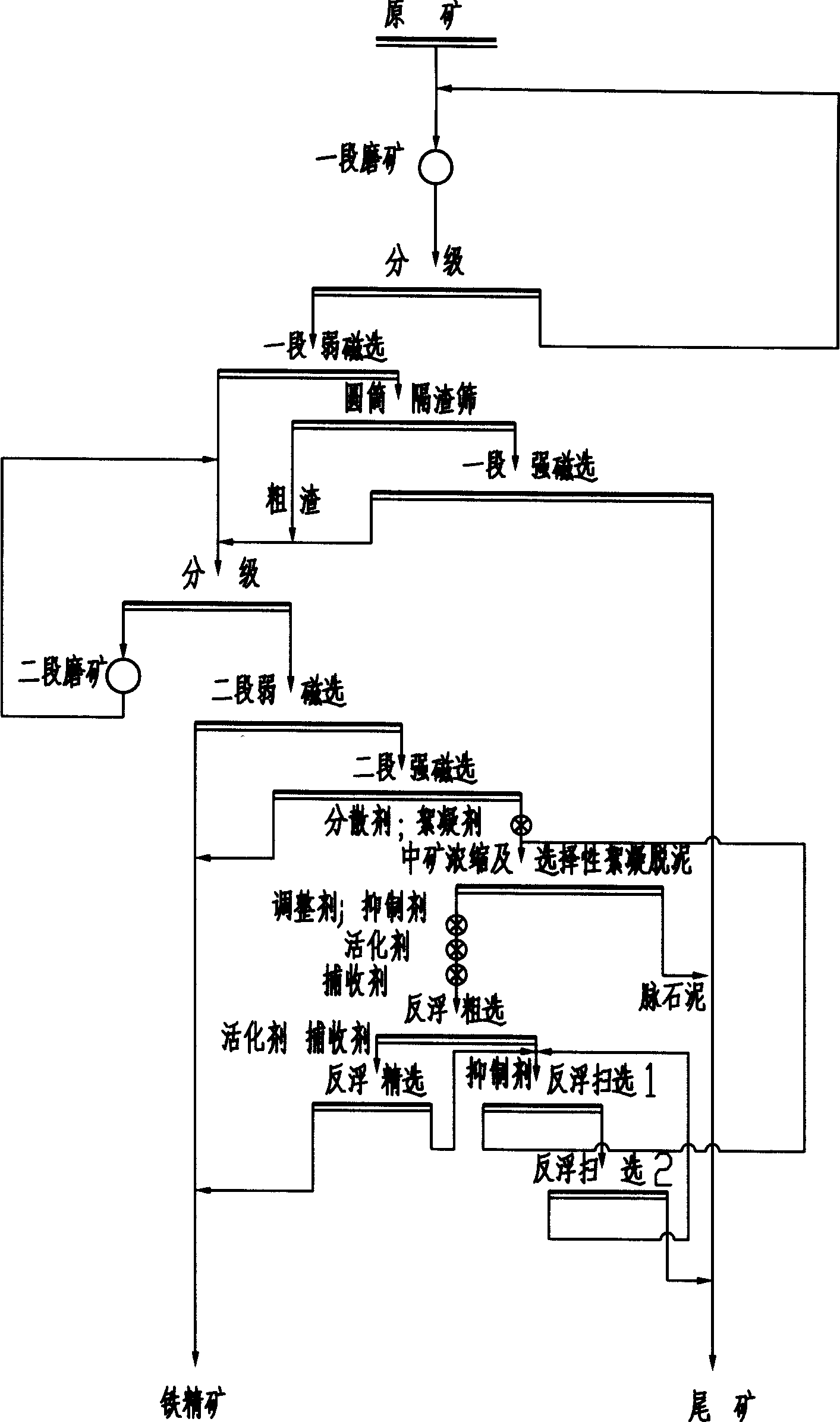

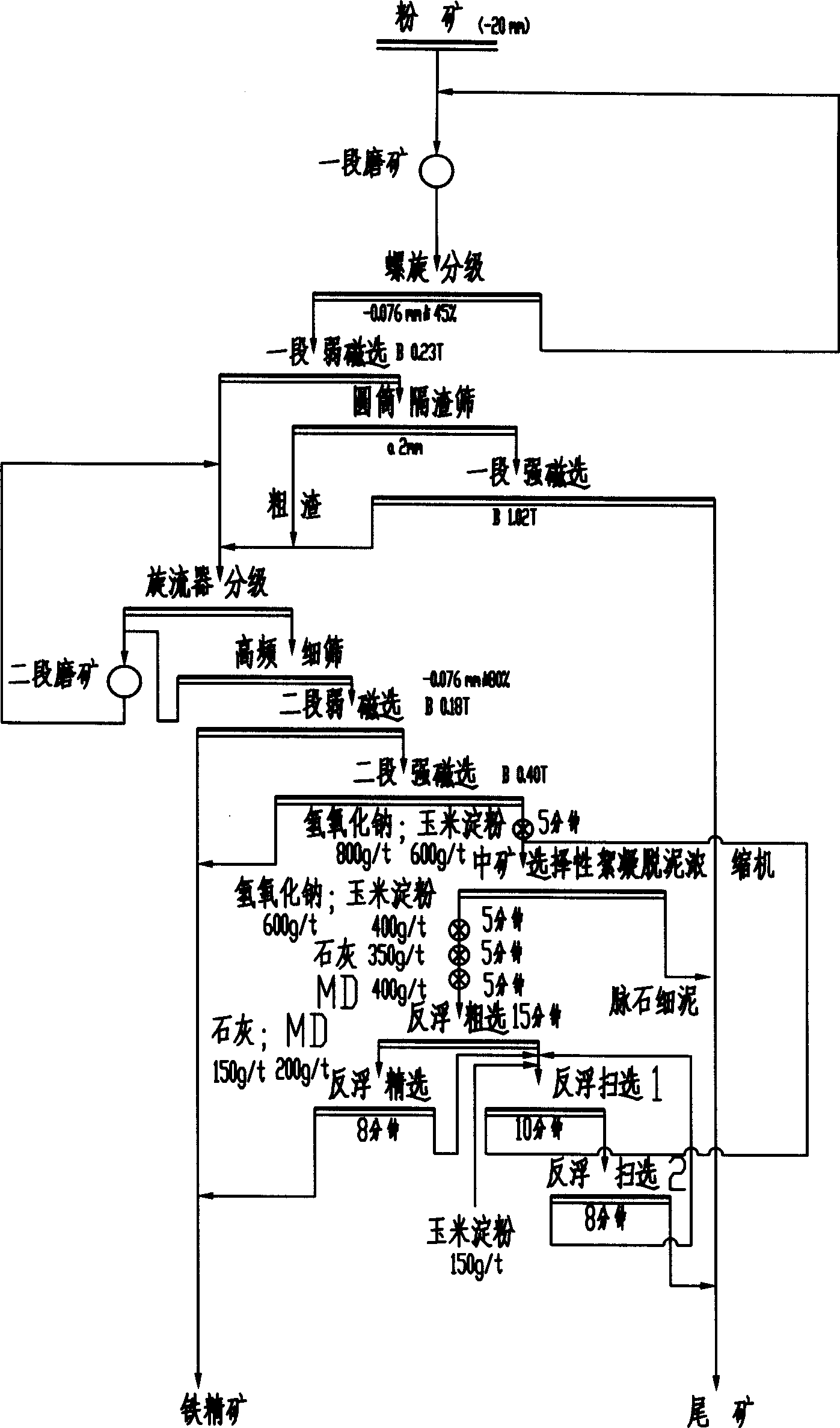

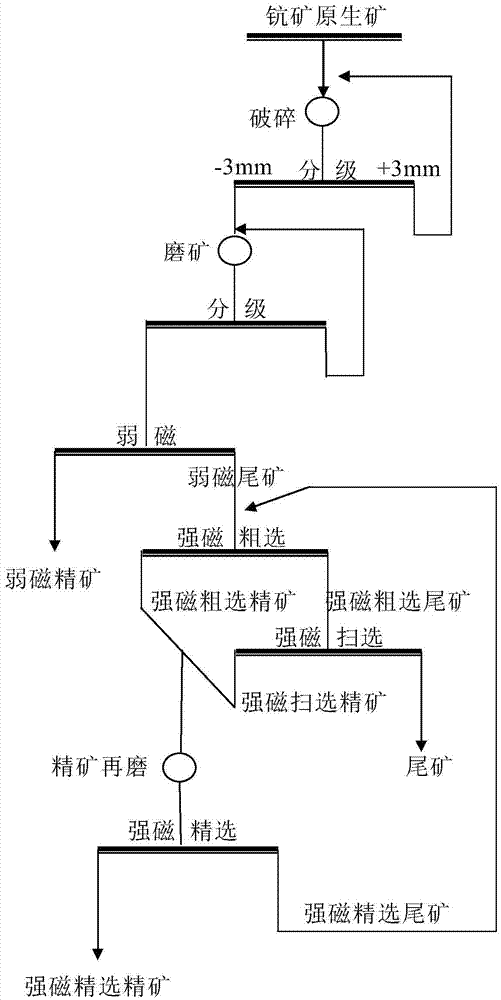

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

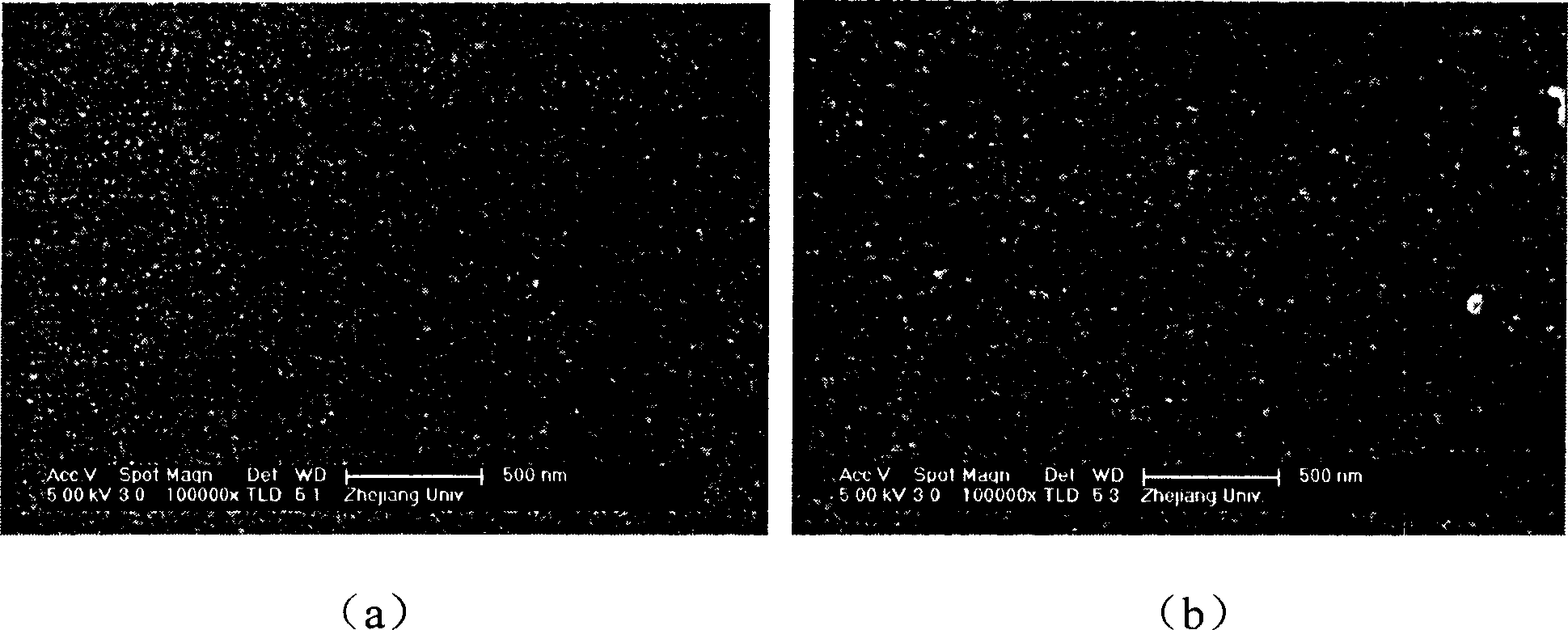

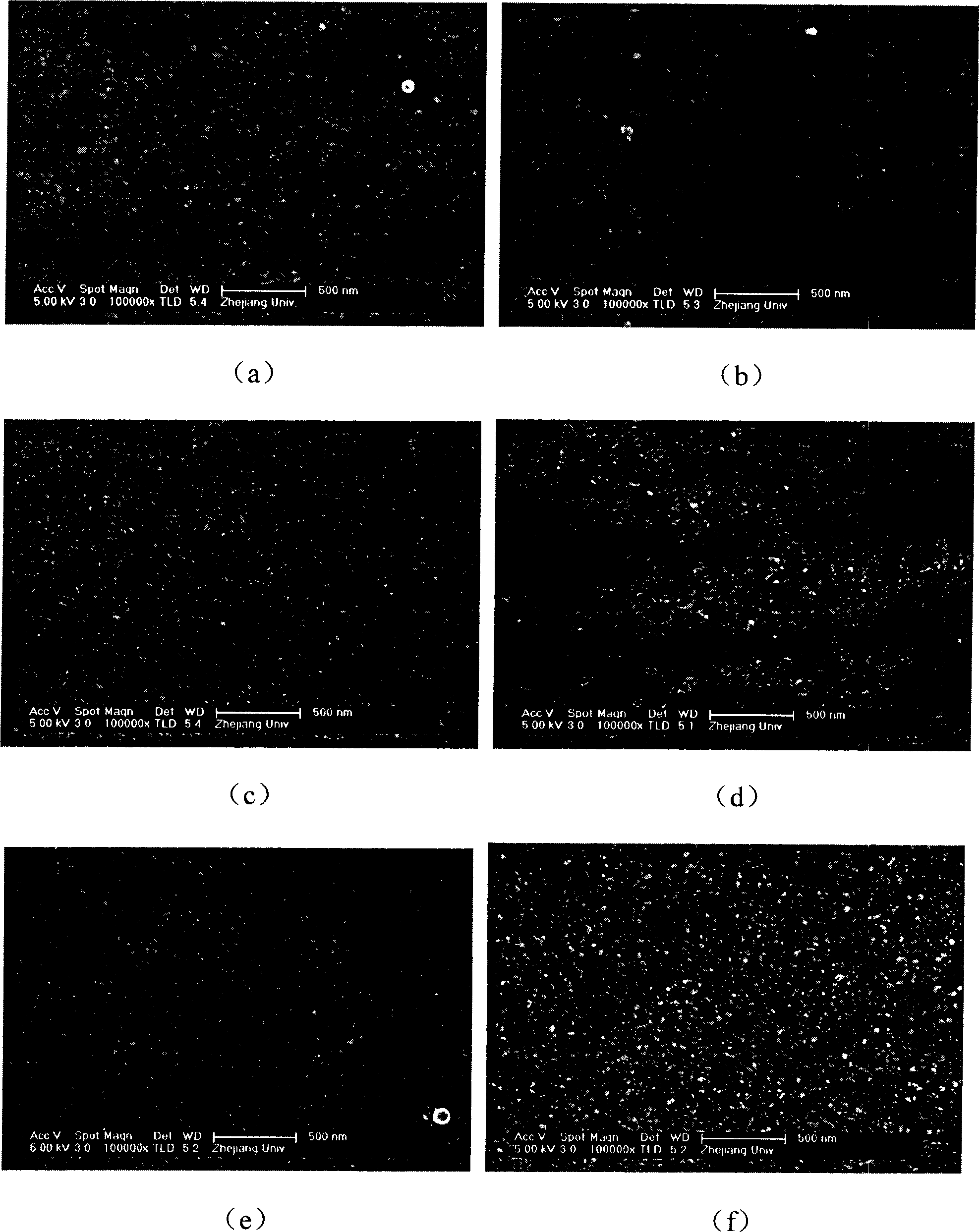

Process for preparing co-mixed polyethersulfone platform complex film

Owner:ZHEJIANG UNIV

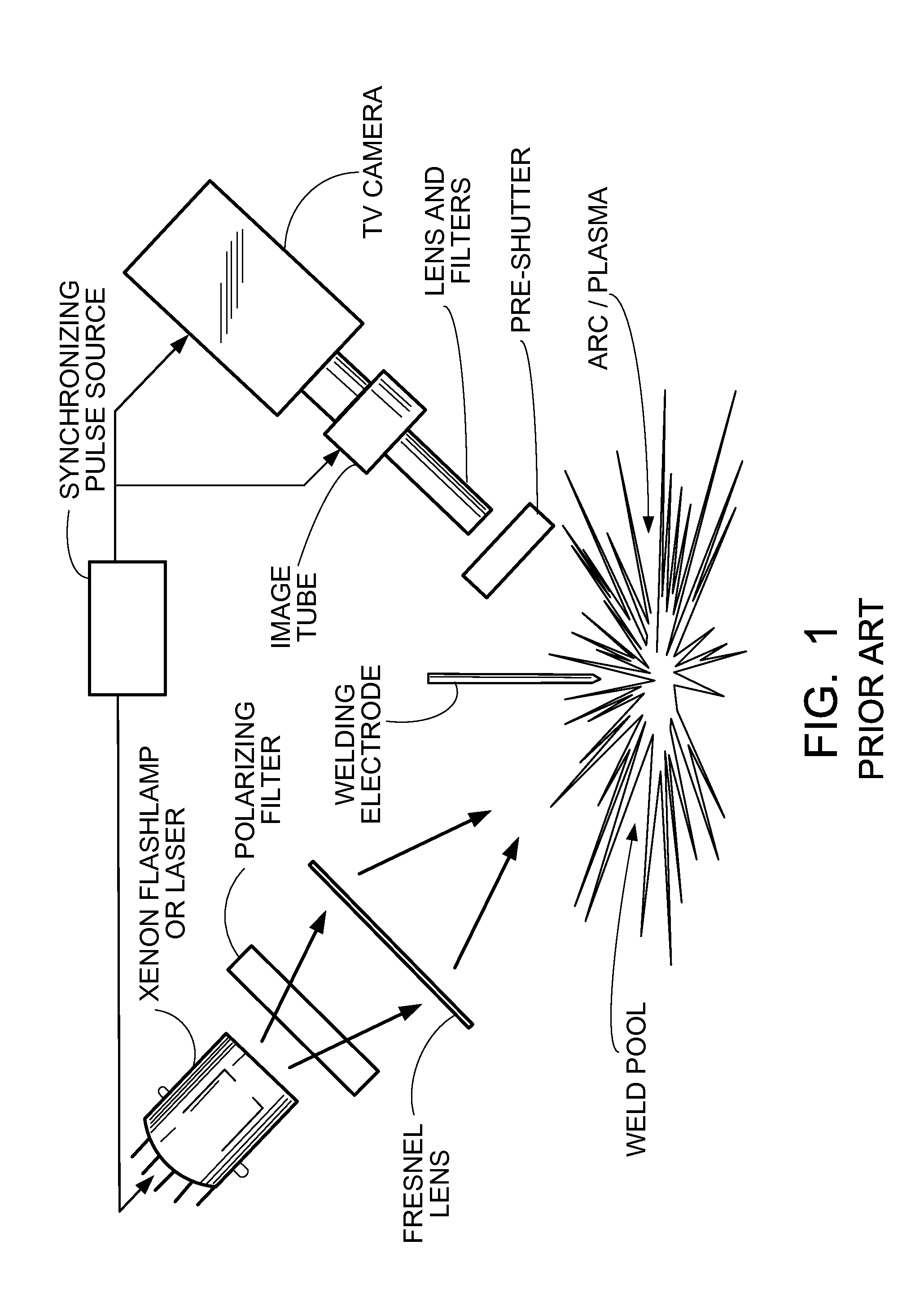

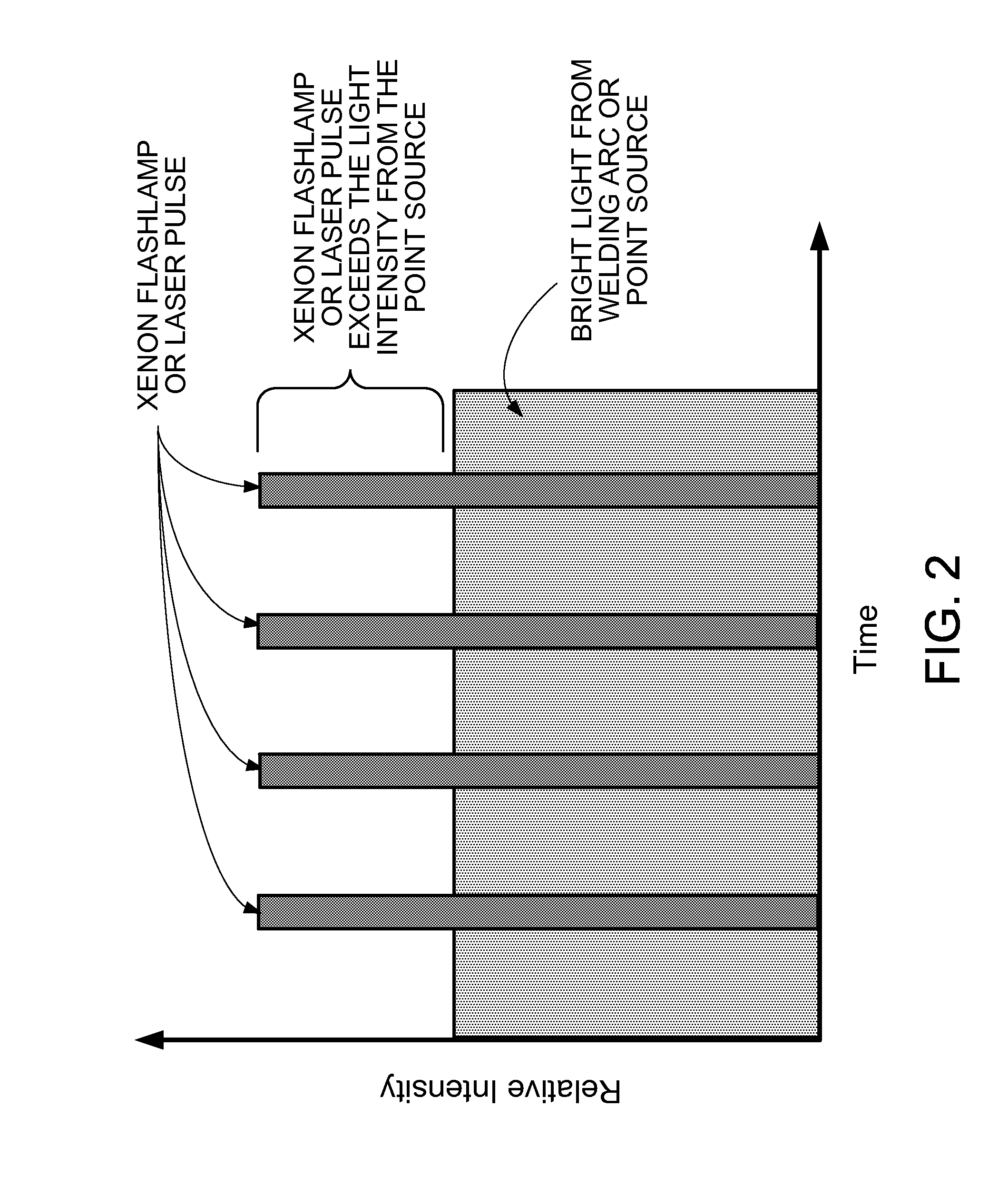

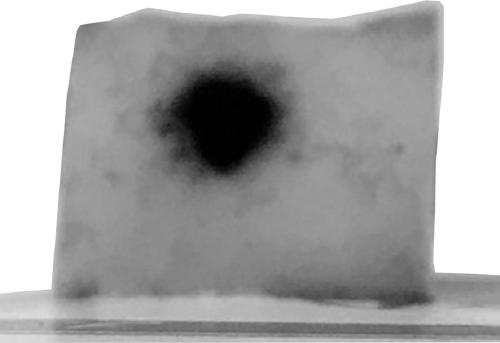

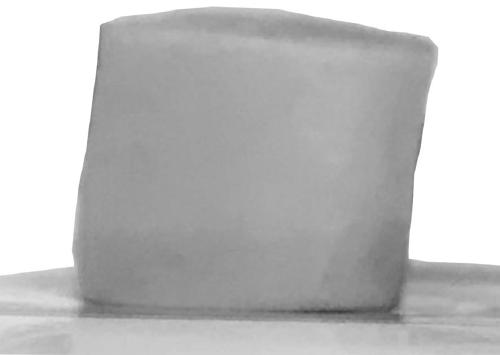

Visual monitoring, or imaging, system and method for using same

Owner:BWXT NUCLEAR OPERATIONS GRP

Preparation method and application of high-strength oriented polyvinyl alcohol hydrogel

ActiveCN110229374AGuaranteed biocompatibilityReduce usageTissue regenerationProsthesisFreeze thawingPolymer science

Owner:BEIFANG UNIV OF NATITIES

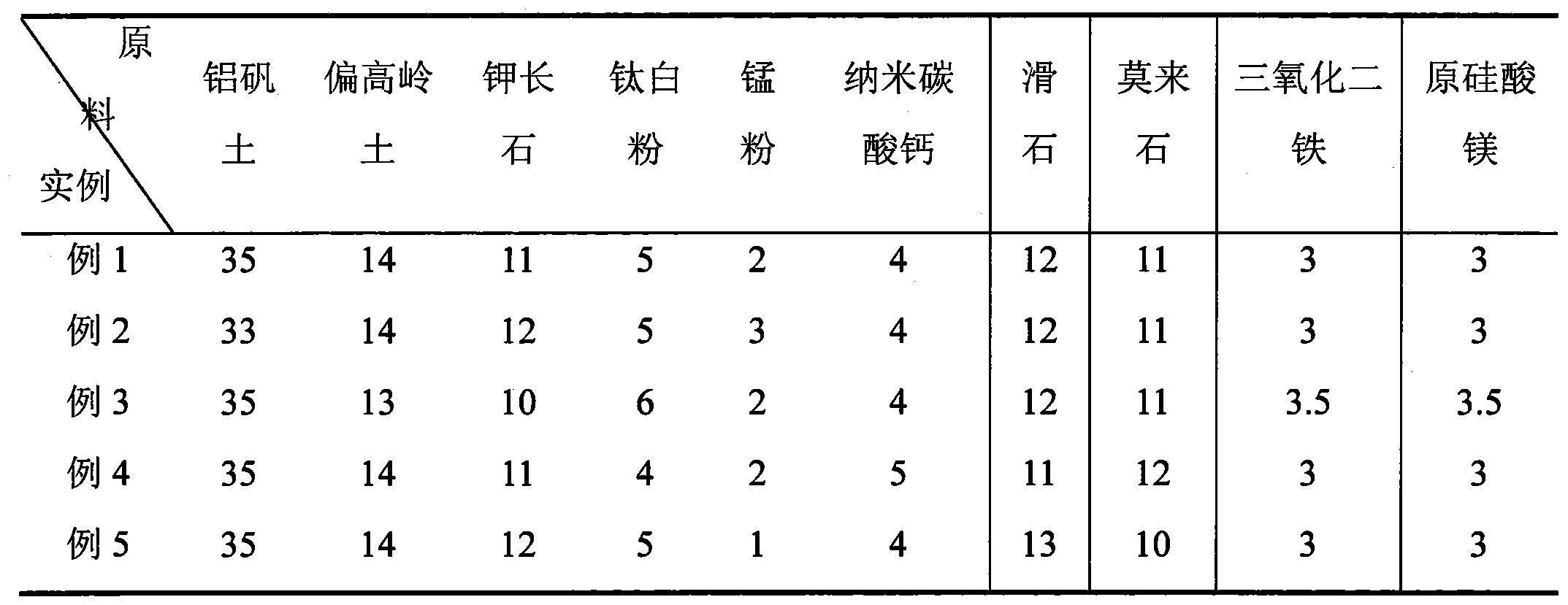

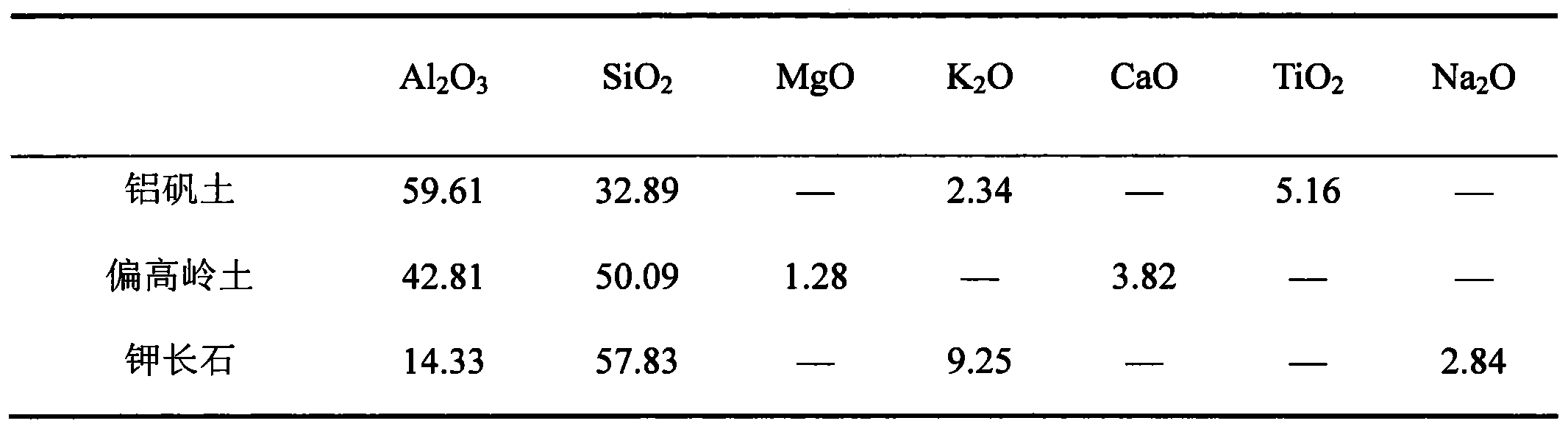

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

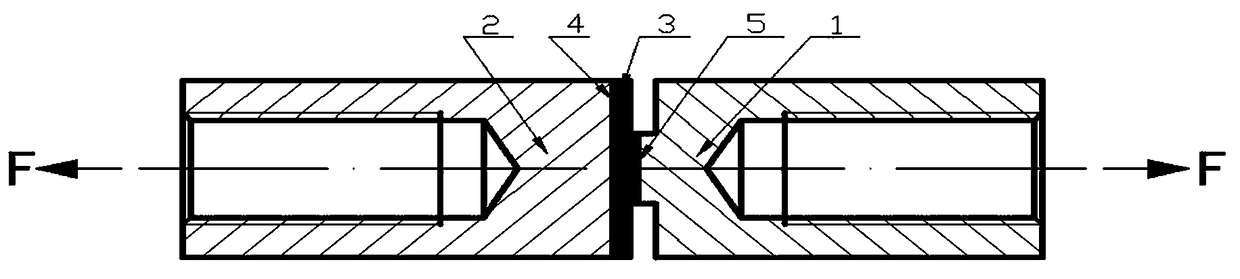

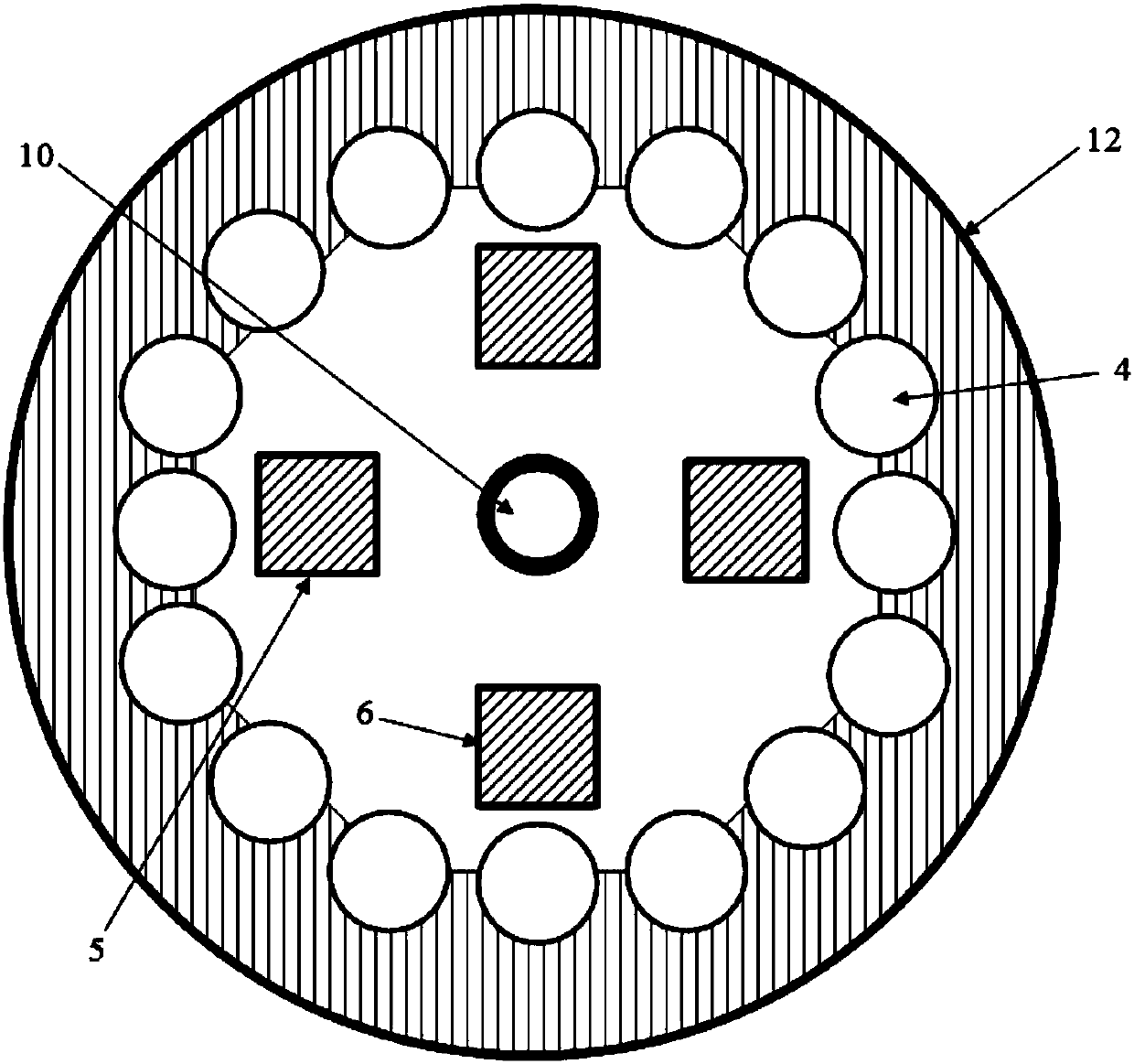

Annular super-hard abrasive wire and method for manufacturing same

ActiveCN102873401AUniform particle distributionHigh tensile strengthMetal sawing tool makingElectrical conductorHigh intensity

The invention discloses an annular super-hard abrasive wire and a method for manufacturing the same. The annular super-hard abrasive wire comprises a rope, super-hard abrasive particles and a coating, wherein the size of the rope ranges from 0.1mm to 6mm, the super-hard abrasive particles are solidified on the surface of the rope, and the coating is used for solidifying the super-hard abrasive particles. The method for manufacturing the annular super-hard abrasive wire includes braiding the thin rope to form a ring with an optional perimeter; and then solidifying the super-hard abrasive particles on the surface of the annular rope by means of coating to form the high-strength annular super-hard abrasive wire with the uniform outer diameter and a long service life. The annular super-hard abrasive wire is low in cost, high in fatigue strength, long in service life, good in cutting quality and high in cutting efficiency, and a cutting machine with the annular wire can be used for cutting conductors, semiconductors and non-conductor materials.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

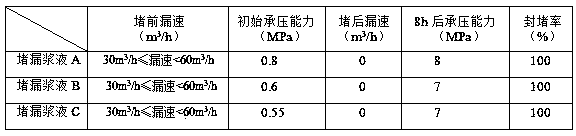

Anti-pressure anti-torsion high-strength V-groove self-cleaning sand-proof screen pipe

The invention discloses a pressure and torsion resistance high-strength V groove self-cleaning anti-sand sieve tube which belongs to a petroleum exploitation mechanical anti-sand device. A coupling is connected with a base tube; the base tube is provided with a round through hole along the axial direction; a filter component is fixed in the round through hole on the base tube; the outer diameter of the base tube is provided with a protective tube. The filter component of the invention is welded on the base tube, and then a protective cover is welded on the filter component; next, the filter component is connected with the coupling and access to the lower end of a petroleum pipe to produce the petroleum. In the anti-sand sieve tube of the invention, the filter component with a V groove filter element consisting of a plurality of circular rings with V-shaped gaps is fixed on the tube wall of the base tube, so as to overcome the defects of low strength, high processing difficulty, high cost, etc. Fine sand can be discharged as the petroleum through elastic and vermicular filtering crack and spacing, so that the sand filtering procedure keeps self-cleaning; in this way, the gap size can mostly meet the petroleum production requirements.

Owner:詹其国

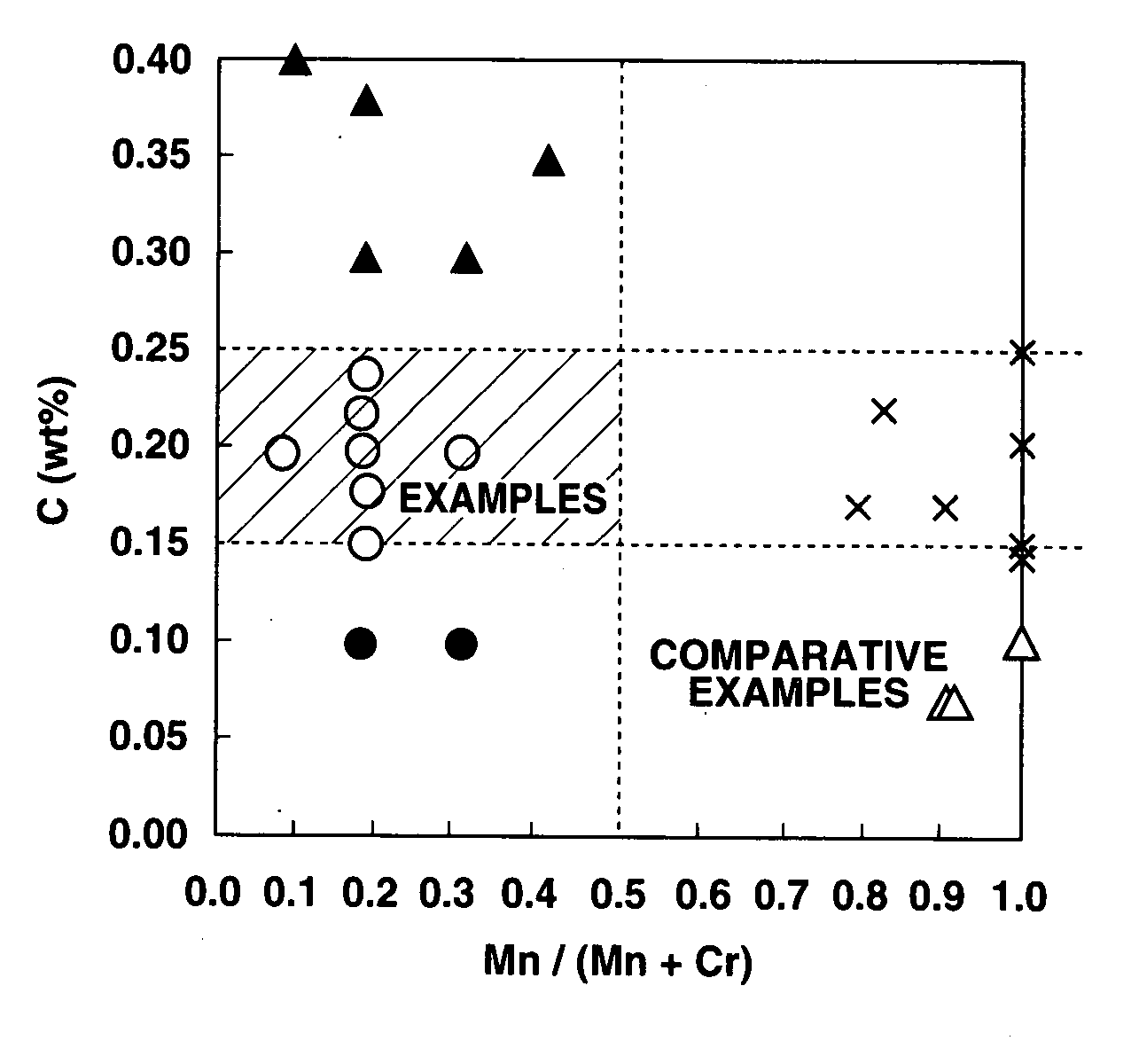

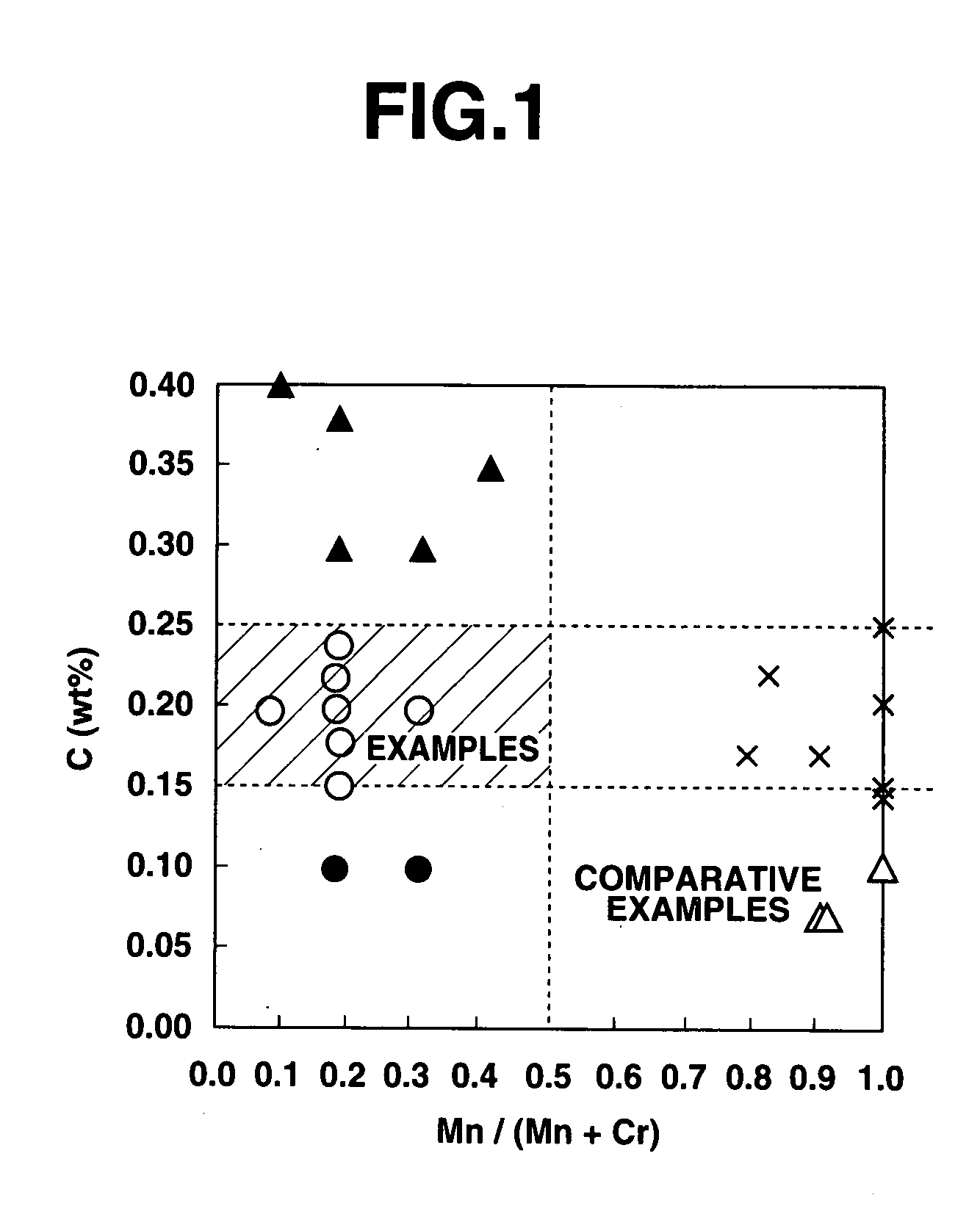

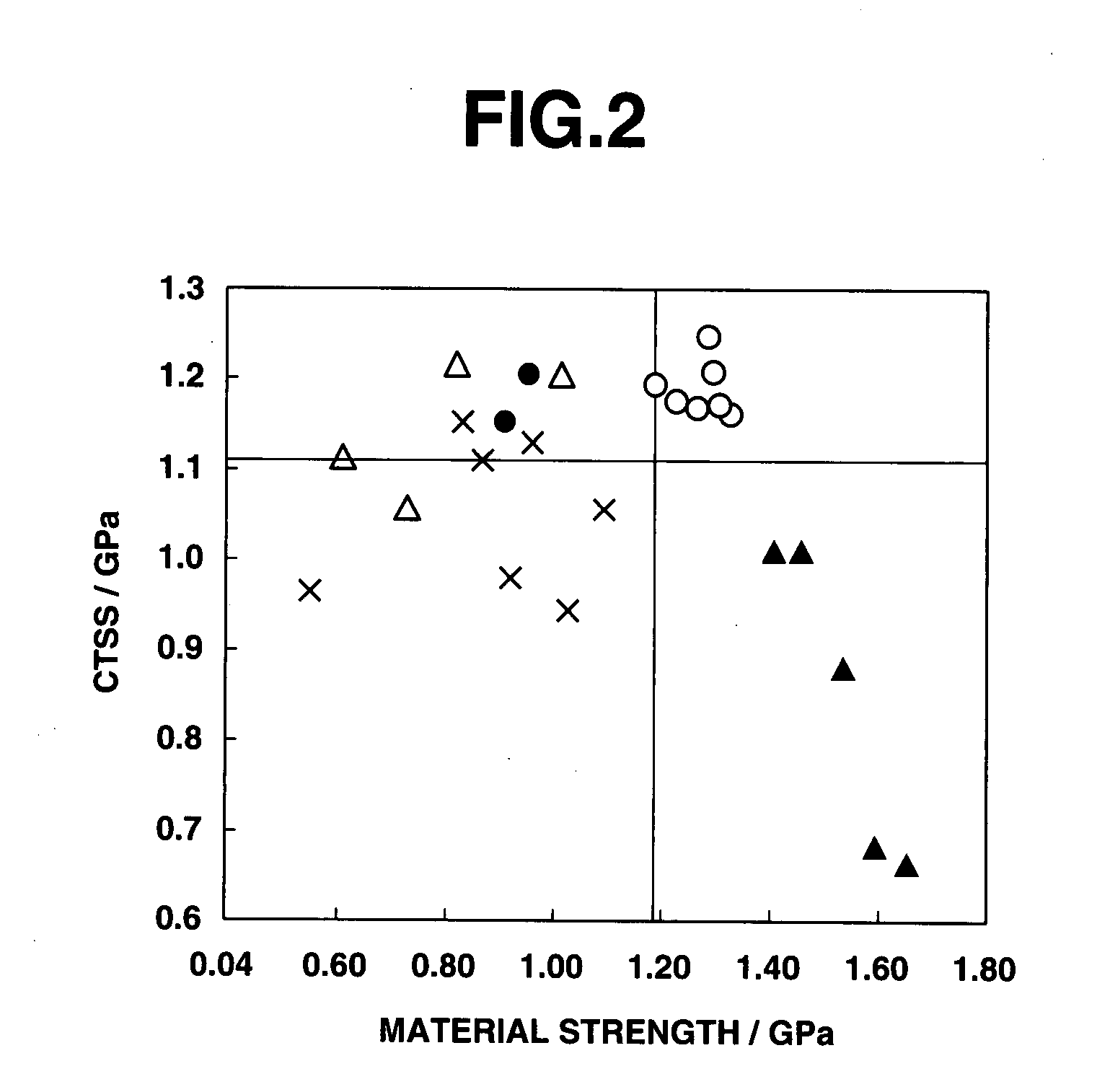

High-tensile steel sheet, steel sheet joining process and high-strength automotive part

InactiveUS20070269678A1No deterioration in resistance welding strengthDeteriorating hardenabilityFurnace typesThin material handlingMetallurgyHigh intensity

Owner:NISSAN MOTOR CO LTD

Sulfur erosion resisting steel and smelting method thereof

Owner:攀钢集团成都钢铁有限责任公司

Corrosion fatigue life prediction method based on BP neural network and application

InactiveCN106442291AEasy to operatePromote engineering applicationWeather/light/corrosion resistanceDesign optimisation/simulationNonlinear approximationNervous system

The invention relates to a corrosion fatigue life prediction method based on a BP neural network and application. The prediction method comprises the following steps: selecting maximum stress, stress ratio, loading frequency and pH value of a solution as main factors influencing corrosion fatigue life; designing and processing a corrosion solution circulating device matched with a corrosion fatigue test, and carrying out a corrosion fatigue circulation failure series experiments on a high-strength sucker rod sample in a specific production environment, collecting and neatening experiment data and dividing the experiment data into training samples and prediction samples; setting artificial neuron network parameters, and establishing nonlinear mapping between the influencing factors and the corrosion fatigue life; training and testing a nervous system; and predicting the corrosion fatigue life of a new sample. The corrosion fatigue life prediction method based on the BP neural network has the beneficial effects that the corrosion fatigue life of a high-strength sucker rod is predicted by high non-linear approximation capability of the BP neural network model, and operation is simple; and the prediction method is high in generalization performance, and engineering application is facilitated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

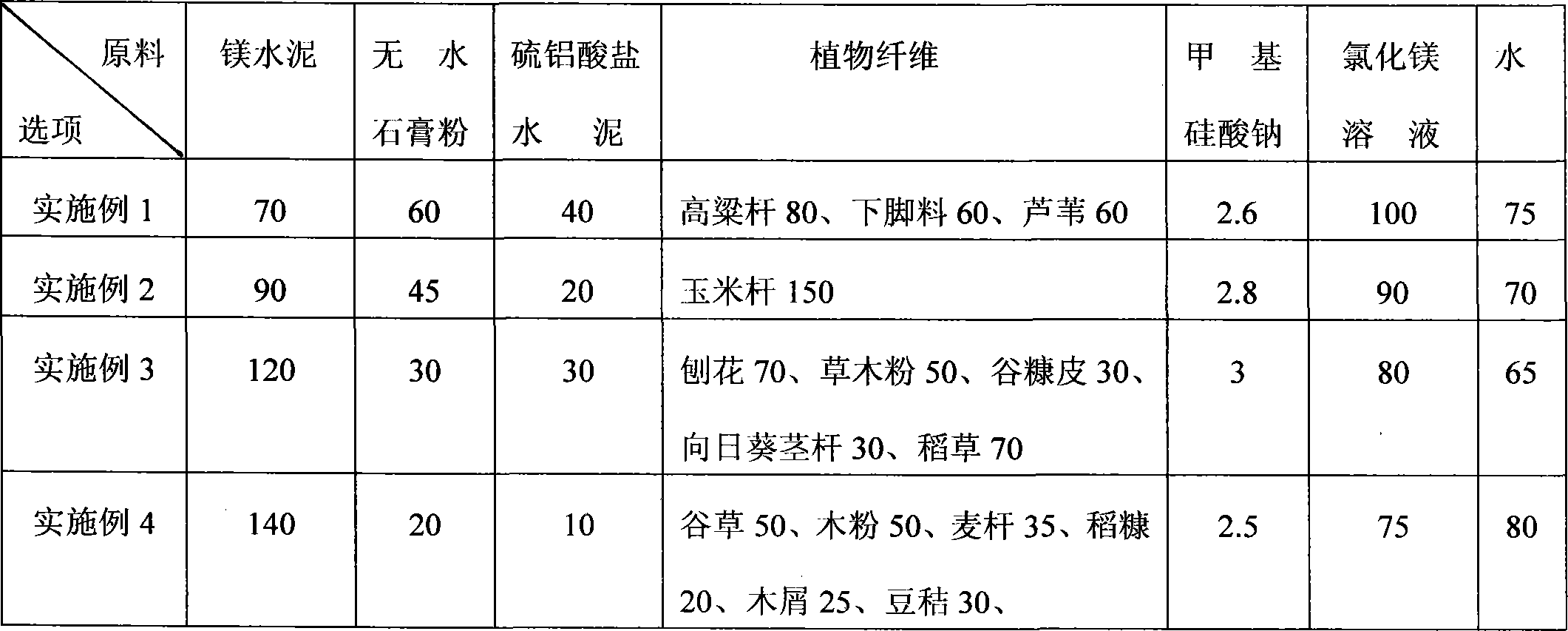

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

Hot-rolled steel strip for high strength electric resistance welding pipe and manufacturing method thereof

InactiveUS7501030B2Low costIncreasing costFurnace typesWelding/cutting media/materialsElectrical resistance and conductanceSolderability

A hot-rolled steel strip having superior low temperature toughness and weldability, which is suitably used as a starting material for high strength electric resistance welding pipe, is provided at a low cost without constructing new production facilities and increasing cost. The hot-rolled steel strip is low carbon steel containing at least one of about 0.5.% or less of Cu, about 0.5% or less of Ni, and about 0.5% or less of Mo, wherein Pcm represented by the following equation (1) is 0.17 or less:Pcm=(% C)+(% Si) / 30+((% Mn)+(% Cu)) / 20+(% Ni) / 60+(% Mo) / 7+(% V) / 10 Equation (1),(where (% M) indicates the content of element M on a mass percent basis), and the balance includes Fe and incidental impurities. In addition, in the entire microstructure, the ratio of bainitic ferrite, which is a primary phase, is controlled to be about 95 percent by volume or more.

Owner:JFE STEEL CORP

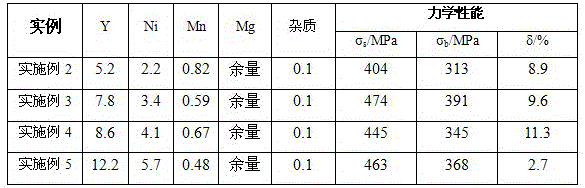

High-strength Mg-Y-Ni-Mn alloy and manufacturing method thereof

ActiveCN105543605ASignificant diffusion strengthening effectImprove acceleration performanceIngot castingRoom temperature

Owner:CHONGQING UNIV

High-strength environment-friendly composite board and preparation method thereof

InactiveCN104690805AHigh strengthImprove toughnessNon-macromolecular adhesive additivesProtein adhesivesEnvironmental resistanceFiber

Owner:安徽忠盛新型装饰材料有限公司

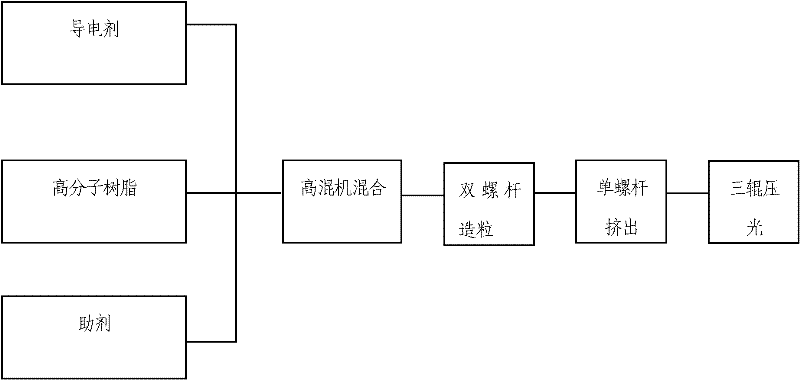

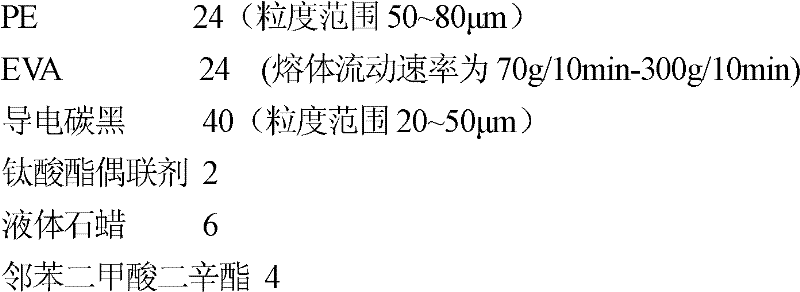

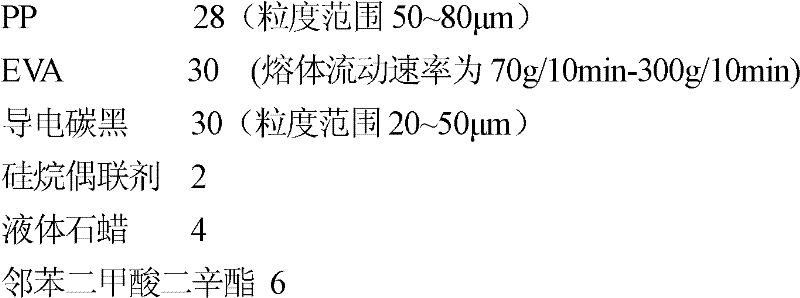

Method for manufacturing high-conductivity conductive plastic bipolar plate for vanadium cell

InactiveCN102683723ASimple processStrong continuous processingCell electrodesEngineeringHigh intensity

The invention relates to the field of manufacturing vanadium cells, in particular to a method for manufacturing a high-conductivity conductive plastic bipolar plate for the vanadium cell. The method comprises the steps of: uniformly mixing a conductive plastic raw material in a high-speed mixing machine, mixing through a double-screw extruder to manufacture master batches, adding the manufactured master batches to a single-screw extruder, and carrying out extrusion molding through the single-screw extruder to manufacture a conductive high-molecular-material collector plate. According to a bipolar plate meeting technique requirements, temperature-resistant resin and a conductive filler are selected, pelletized by the double-screw extruder, and extruded by the single-screw extruder to manufacture a high-strength, anti-corrosion and high-temperature-resistant plastic bipolar plate; and the resistivity of the manufactured high-strength, anti-corrosion and high-temperature-resistant plastic bipolar plate can reach 0.1-0.5 omega per centimeter so as to meet an application index of the vanadium cell. The bipolar plate manufactured by the method disclosed by the invention can be rather thin, has the advantages of large area, good continuity and low cost, and also has the advantages of being capable of reducing the cost of the vanadium cell, ensuring stable operation in cells without releasing chemical groups, and maintaining stability and reliability of an electric pile of the vanadium cell.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Drilling water based plugging agent and using method thereof

InactiveCN107603574ADehydration fastHigh fluid lossDrilling compositionSealing/packingWater basedSolubility

Owner:成都瑞吉星化工有限责任公司

Low-temperature photo-irradiation preparation method for rare earth doped bismuth titanate ferro-electricity membrane

InactiveCN101269957APromoting solidification and densificationImprove ferroelectric propertiesElectricityPhoto irradiation

Owner:HARBIN INST OF TECH

High-strength and high-apparent high glass fiber reinforced nylon material and preparation method thereof

Owner:5ELEM HI TECH CORP

Preparation method for Nb-Zr alloy/Cu multi-core composite wire

ActiveCN105855316AOrganizational structure is stableHigh strengthCable/conductor manufactureOxidation resistantHigh intensity

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-strength curb and manufacturing method thereof

InactiveCN101817695AHigh compressive strengthLow costPaving gutters/kerbsTraffic signalsWater basedHigh intensity

The invention discloses a high-strength curb and a manufacturing method thereof. The surface of the curb is treated by the following method in turn: firstly, curing the surface of the demoulded curb for 5 to 10 days by using a concrete nano curing agent; secondly, performing surface solidification on the cured curb surface by using a concrete sealer; and finally, polishing the consolidated surface by using a water-based permeating brightener. The high--strength curb with the unique formula, and the manufacturing method have the advantages of high strength, low cost and environmental protection and the like.

Owner:SHENZHEN HUILI DEBANG ENVIRONMENTAL PROTECTION TECH CO LTD

High-strength concrete formula and preparation method of high-strength concrete formula

InactiveCN102690126AHigh strengthImprove penetration resistanceCeramicwareHigh strength concreteLevel structure

The invention discloses a high-strength concrete formula. The high-strength concrete formula is characterized by comprising the following constituents by weight: 20-40% of cement, 3-5% of pulverized coal ash, 30-50% of fine aggregate, 20-40% of coarse aggregate, 3-5% of plant protein foaming agent, 1-10% of water reducer and 1-10% of water. Above materials are mixed and uniformly stirred to obtain the concrete. The concrete disclosed by the invention has the advantages of fewer holes in interior of the concrete, compact microstructure and meso-level structure and excellent anti-permeability performance by mutual interaction of various ingredients, so that the high-performance concrete is good in durability, and the strength can be up to over 280MPa.

Owner:LANGFANG RONGSHENG CONCRETE

High-strength high-elongation antibacterial soft graphene rubber latex

Owner:镇江华扬乳胶制品有限公司

Testing method for ultra-high bonding strength of coating

InactiveCN109238958AReduce contact areaReduce areaPreparing sample for investigationUsing mechanical meansAbrasive blastingEpoxy

Owner:广东省工业分析检测中心 +1

Rolling-cut type bilateral scissors and manufacturing method thereof

ActiveCN104233101AMeet normal cutting needsFurnace typesHeat treatment furnacesThick plateIngot casting

Owner:TAIER HEAVY IND

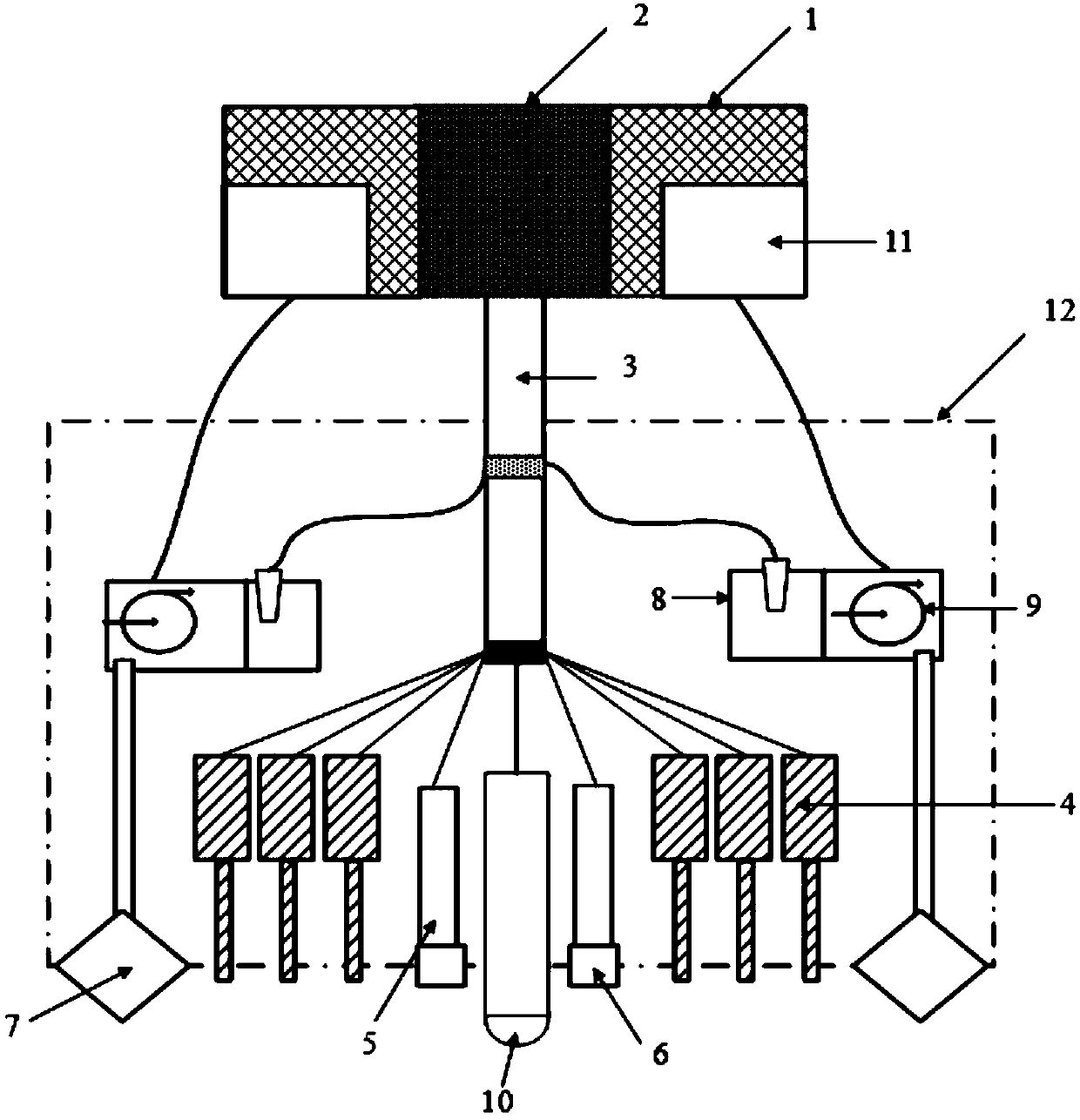

Mineral separation and enrichment method for primary scandium ore

ActiveCN105435958ASimple processEconomically reasonableMagnetic separationWet separationChemical industryEnrichment methods

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

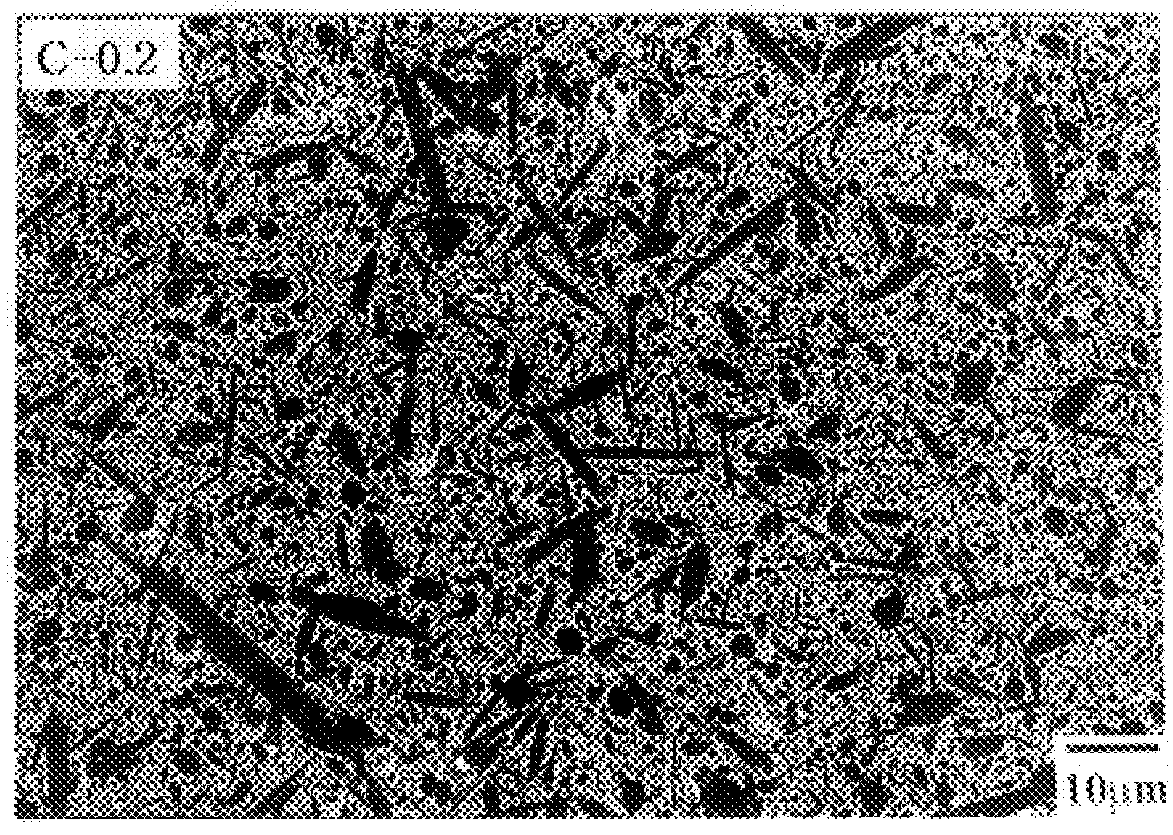

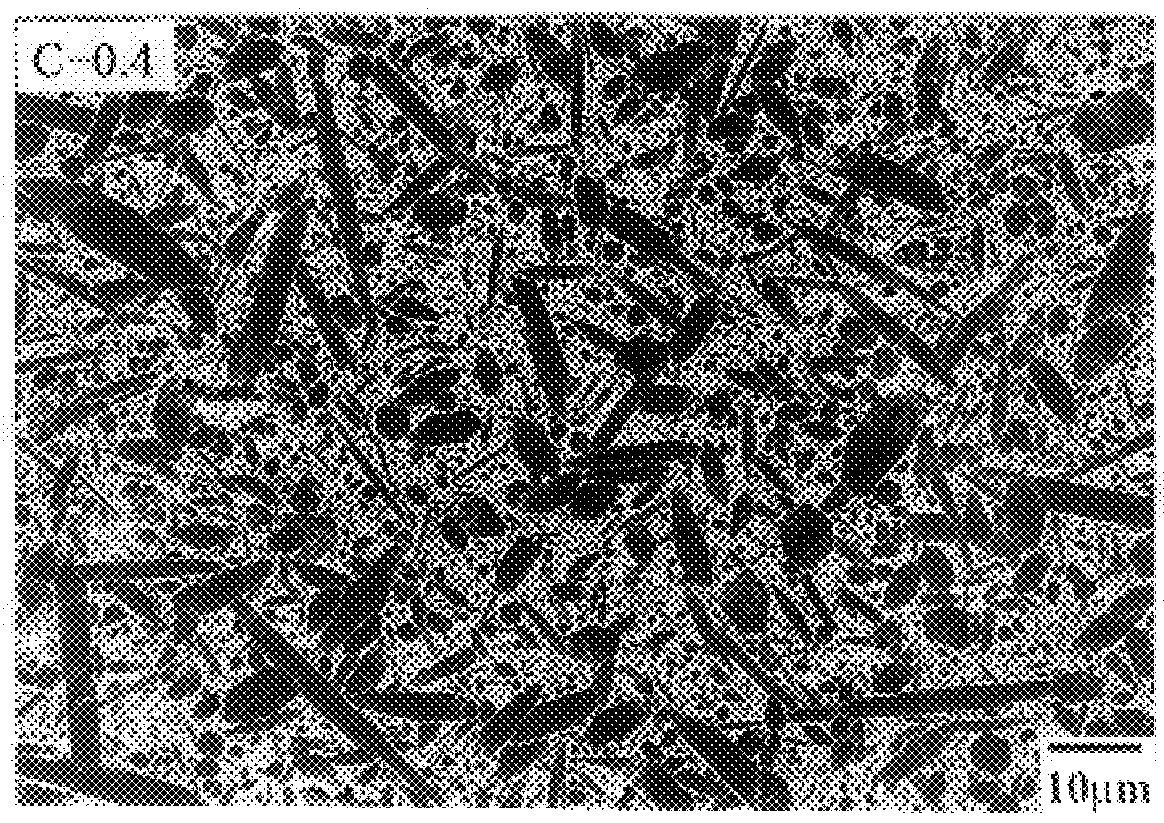

Method for preparing silicon nitride ceramic with high strength and toughness

InactiveUS6232252B1High strengthImprove toughnessCeramic shaping apparatusClaywaresHigh intensityReduction treatment

Provided with a method for preparing a silicon nitride ceramic with high strength and toughness including: mixing 0.2-0.9 wt % of carbon (C) powder with silicon nitride powder containing 5.0-6.0 wt % of yttria (Y2O3) and 1.0-2.0 wt % of alumina (Al2O3) added thereto as a sintering agent, and preparing a molding; subjecting the molding to a carbothermal reduction treatment at 1400-1500° C.; and gas pressure sintering the molding at a temperature above 1850° C. after the carbothermal reduction treatment.

Owner:KOREA INST OF MASCH & MATERIALS

Ultrasonic laser drilling device

ActiveCN107620566ARock breaking drillingGood effectDrilling machines and methodsLaser arrayWater circulation

Owner:CHINA WEAPON EQUIP RES INST

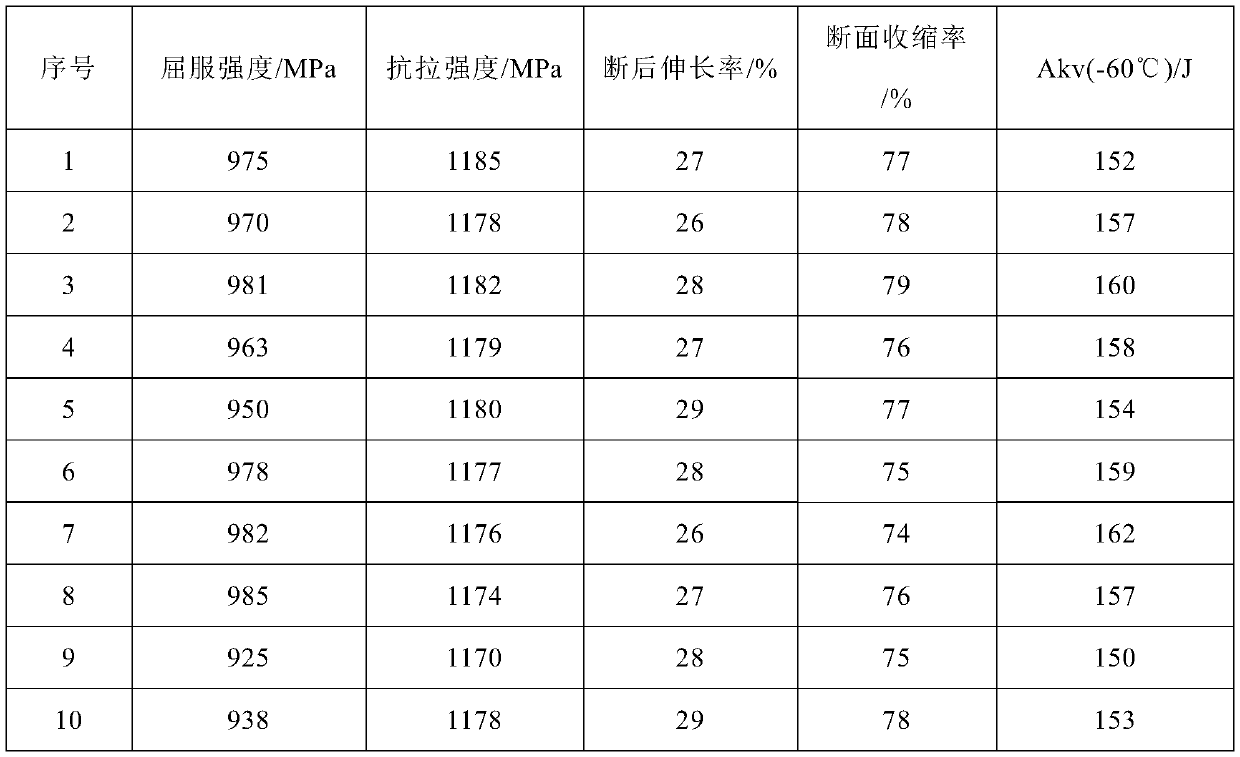

High-strength 23Mn2CrNiMnVERA steel for railway train connection and preparation method thereof

Owner:SHANDONG XIWANG SPECIAL STEEL

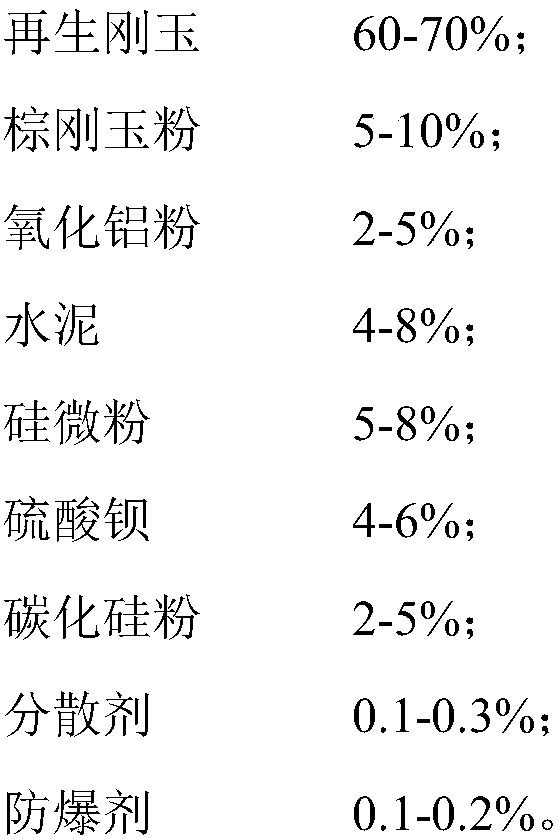

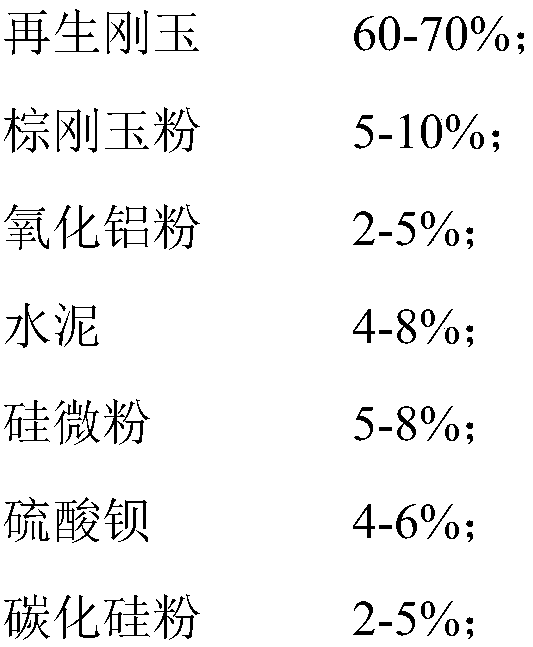

High-strength aluminum-resisting permeable castable as well as preparation method and application thereof

Owner:BAOJIUHE REFRACTORY

High-strength composite acrylic material

Owner:SUZHOU CITY XIANGCHENG DISTRICT MINGDA COMPOSITE MATERIAL FACTORY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap