High-tensile steel sheet, steel sheet joining process and high-strength automotive part

a technology of high-tensile steel and steel sheets, applied in the field of high-tensile steel sheets, can solve the problems of steel sheets deteriorating in hardenability, and achieve the effects of no deterioration in hardenability, and no deterioration in resistance welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]A high-tensile steel sheet according to the present invention will be described in detail below. In the following description, all percentages are by mass unless otherwise specified.

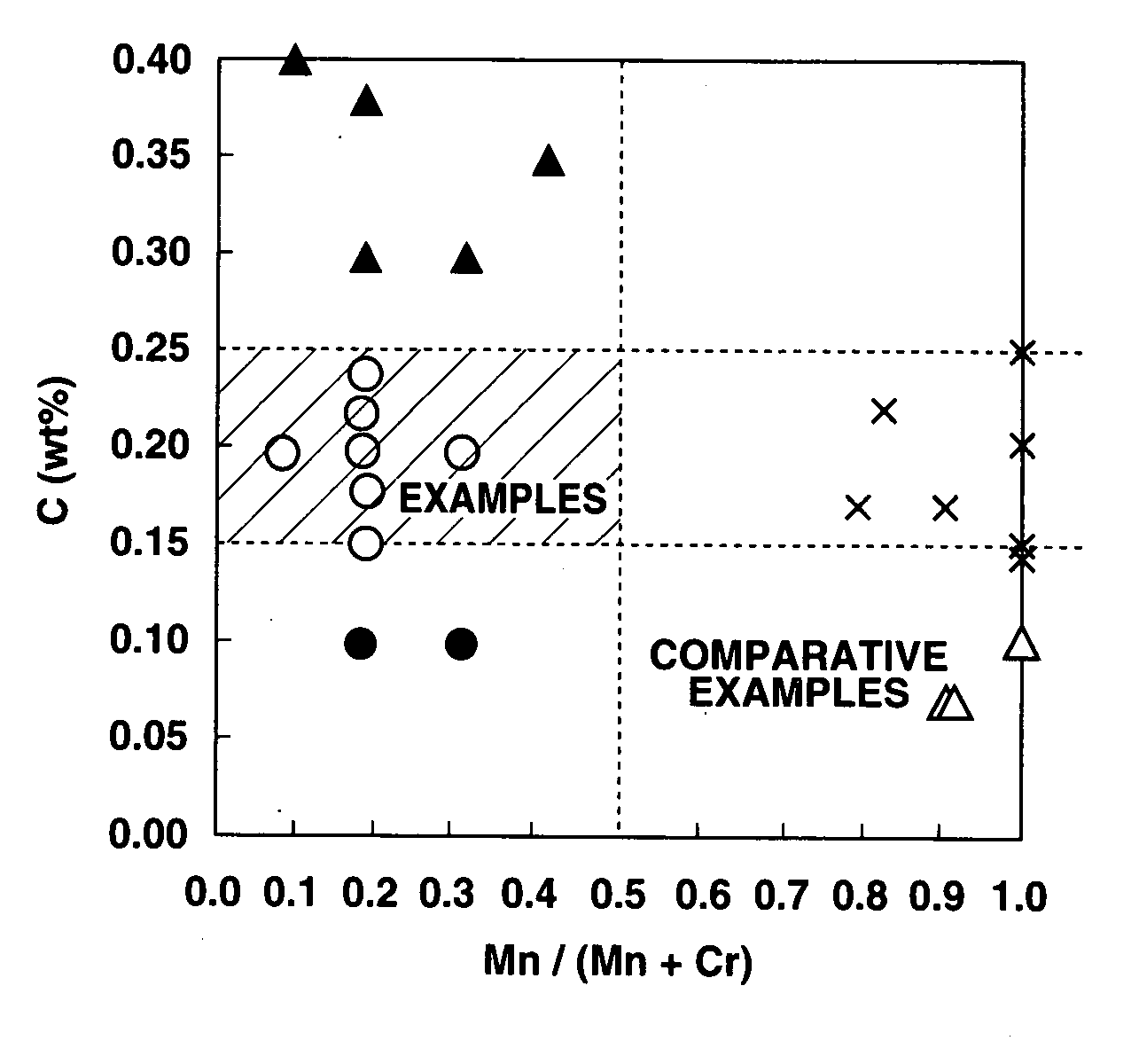

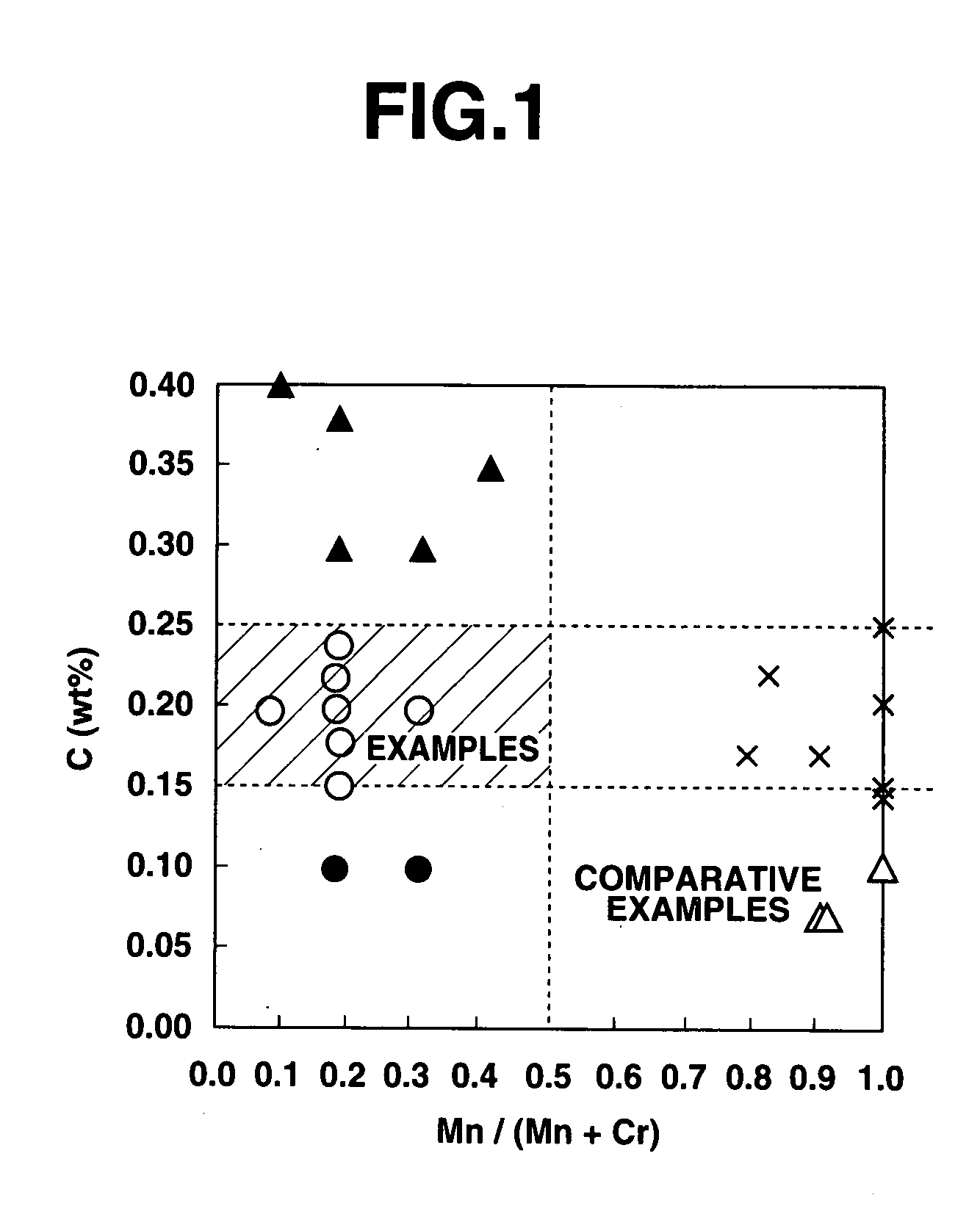

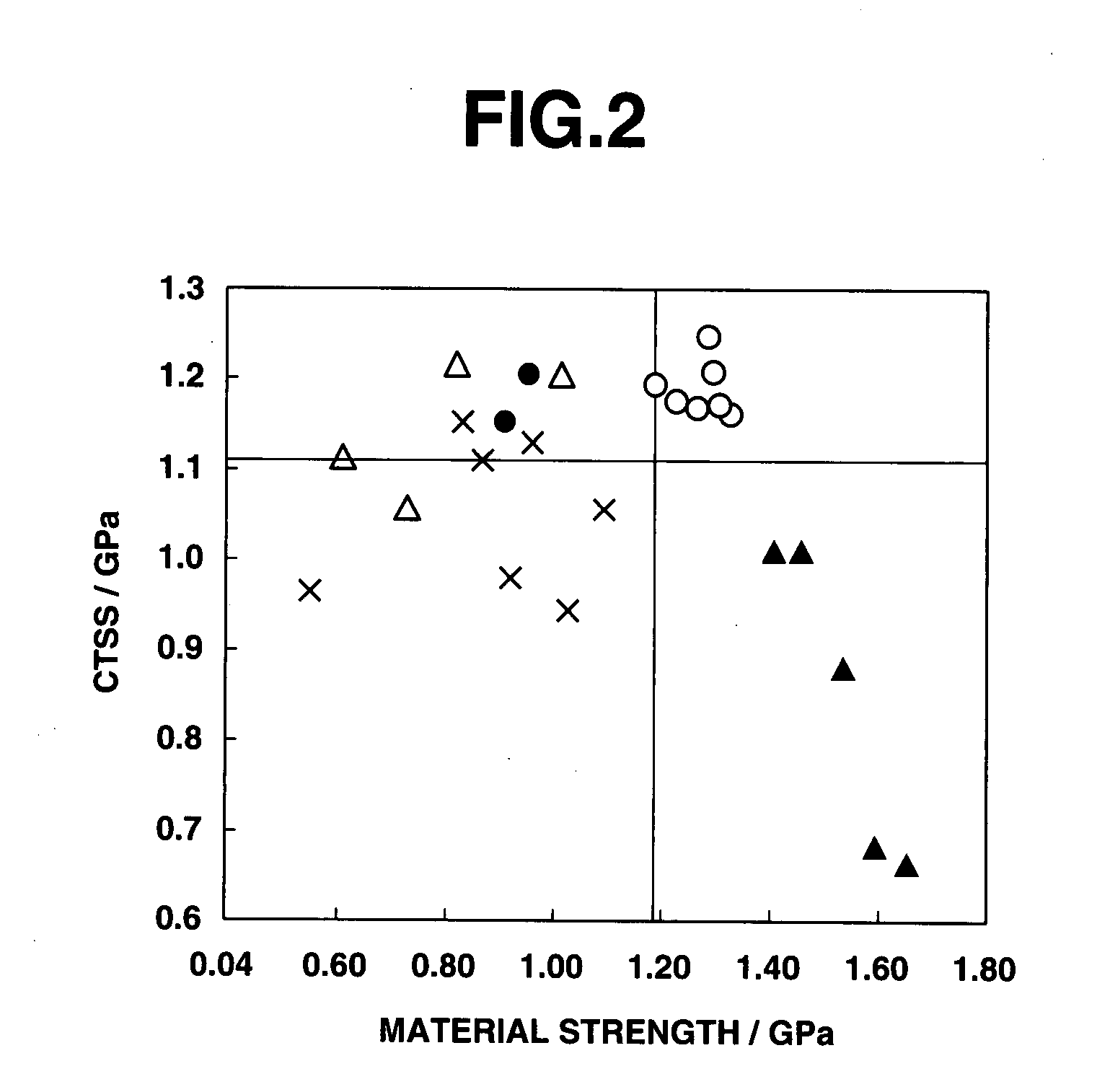

[0016]The high-tensile steel sheet of the present invention comprises 0.15 to 0.25% of C, 0.1 to 2.0% of Si, 0.10 to 1.0% of Mn, 0.5 to 3.5% of Cr and the balance being Fe and unavoidable impurities based on the total mass of the steel sheet and satisfies a content ratio of Mn / (Mn+Cr)<0.50. Preferably, the high-tensile steel sheet of the present invention may further comprise 0.1 to 3.0% of Ni, 0.01 to 3.0% of Cu and 0.001 to 0.1% of Al based on the total mass of the steel sheet.

[0017]C (carbon) is particularly effective in increasing the strength of the high-tensile steel sheet. If the C content of the high-tensile steel sheet is less than 0.15%, the high-tensile steel sheet fails to secure desired strength. If the C content of the high-tensile steel sheet exceeds 0.25%, the high-tensile steel shee

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap