Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about "Cable/conductor manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

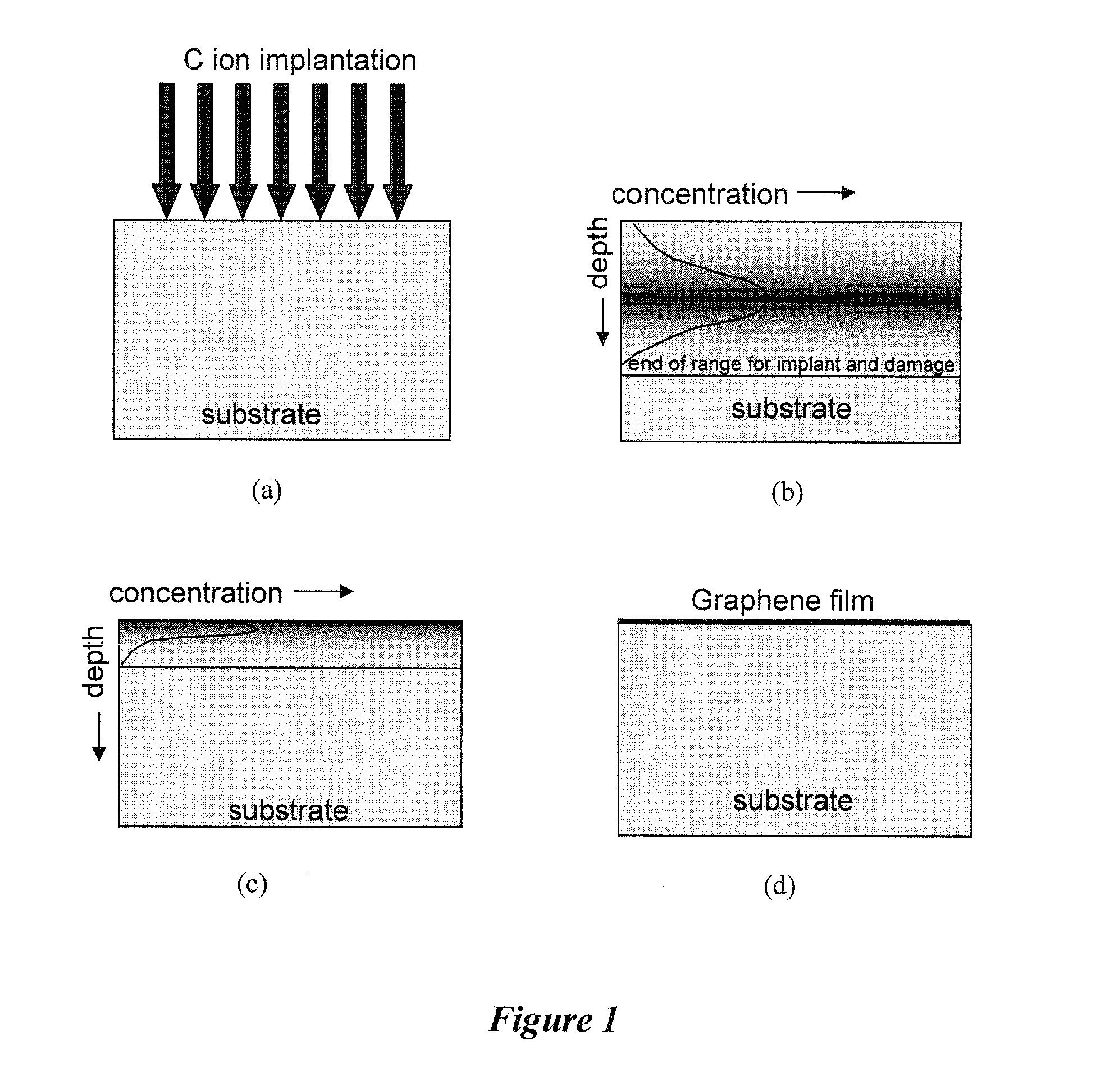

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

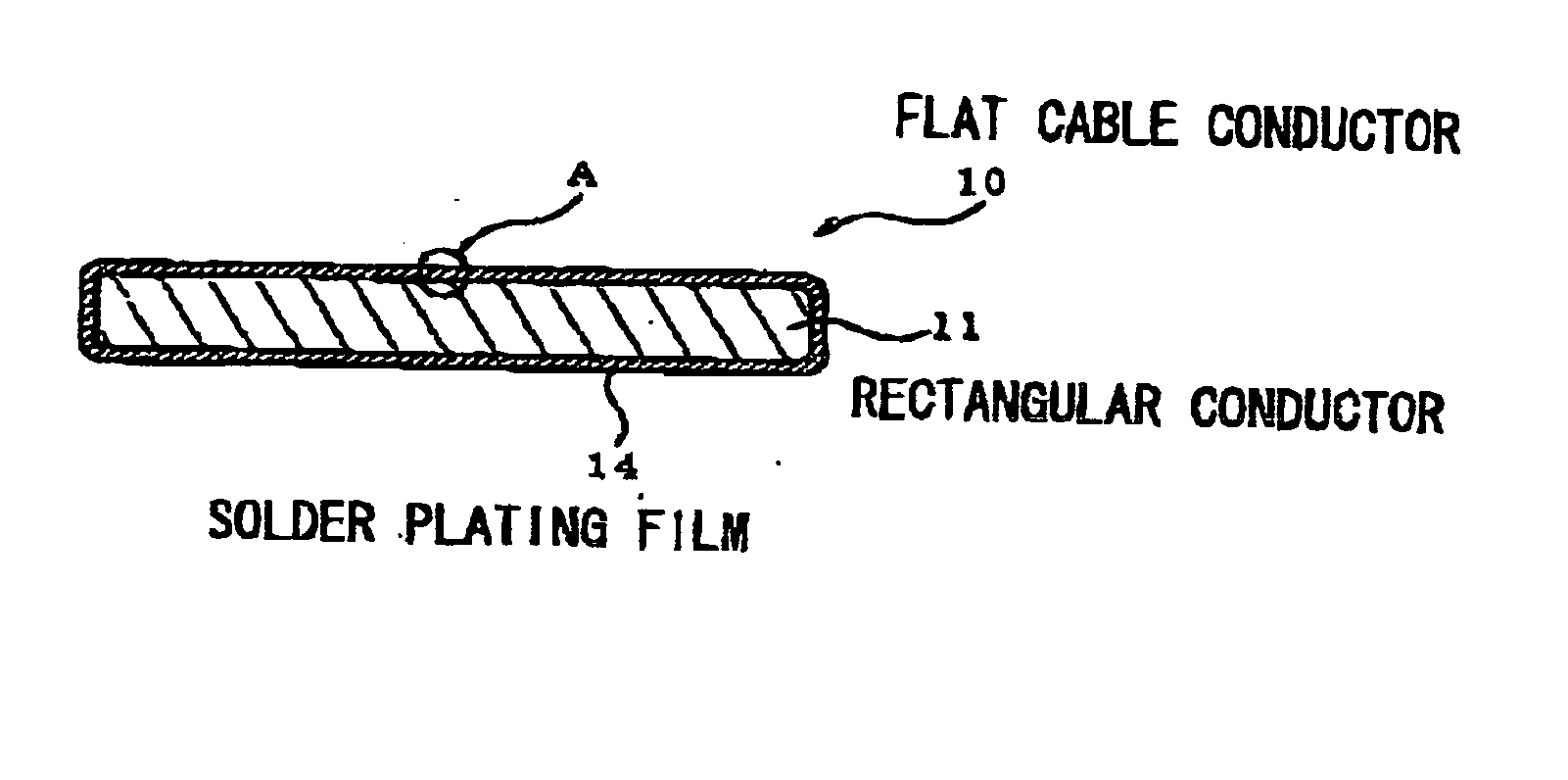

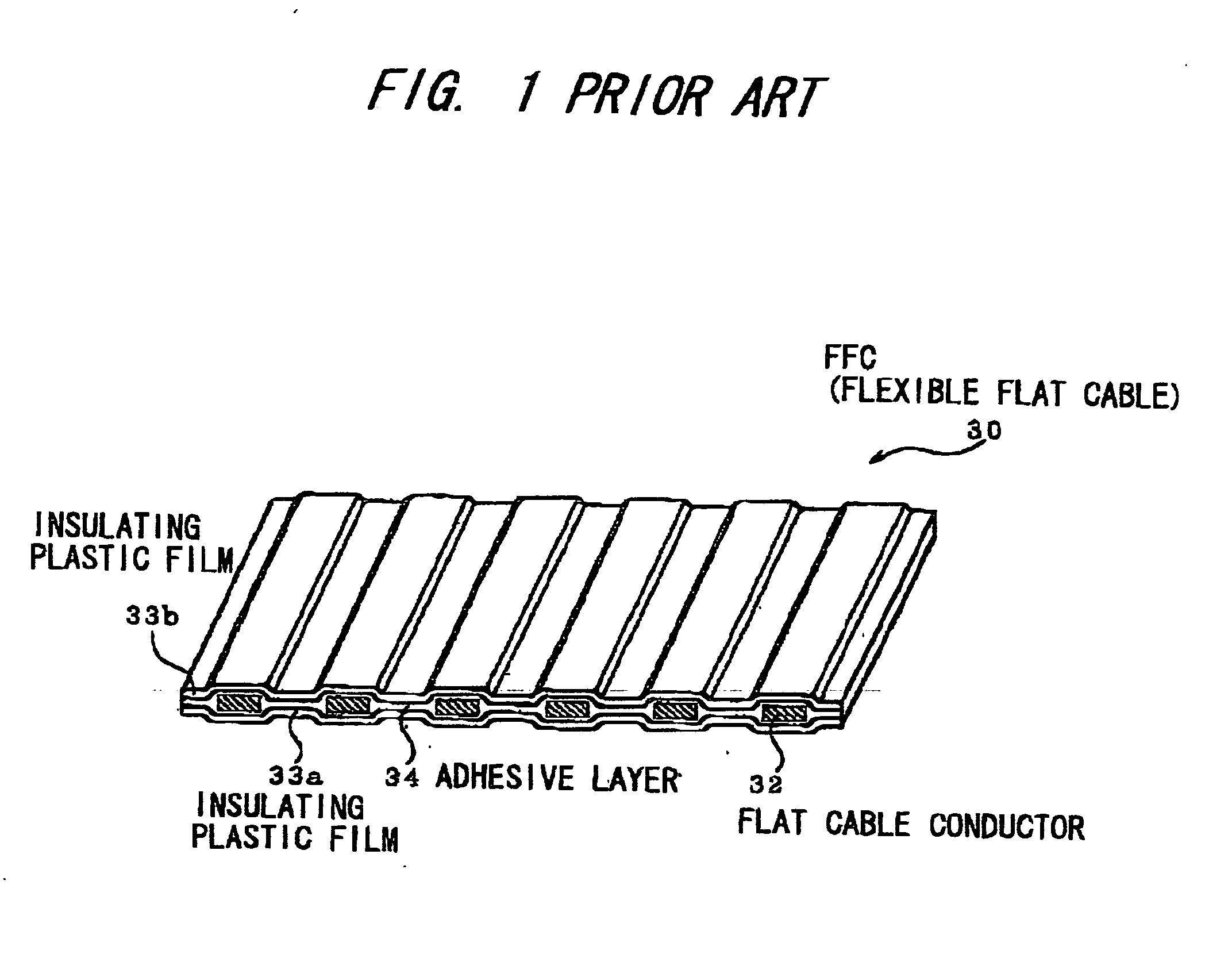

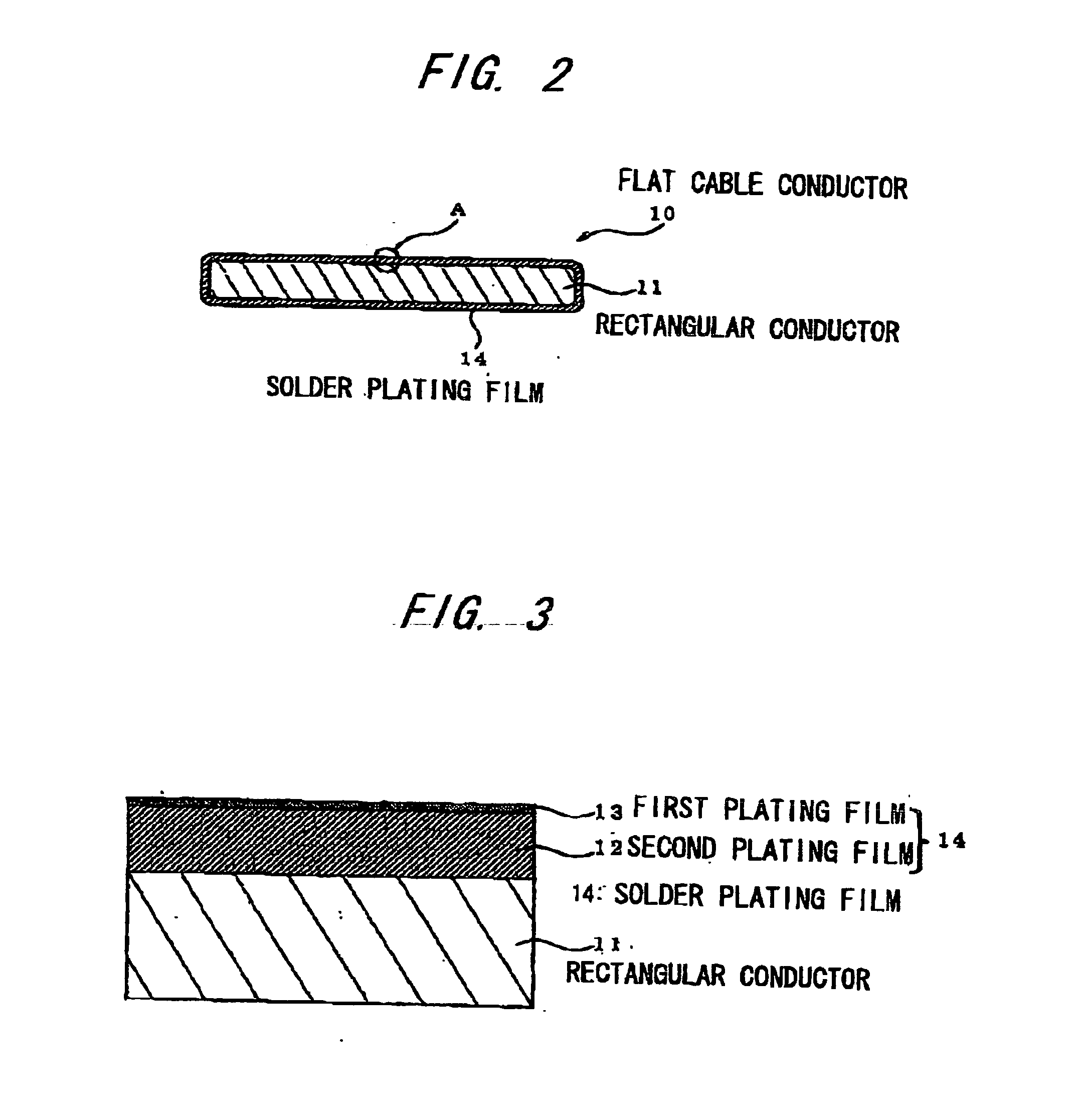

Flat cable conductor, method of making the same and flat cable using the same

ActiveUS20050211461A1Increase manufacturing costHot-dipping/immersion processesInsulating substrate metal adhesion improvementElectrical conductorElectric cables

Owner:HITACHI CABLE

A production method for copper-coated aluminum material

InactiveCN101123129AAvoid high temperature oxidationAvoid lubricationCable/conductor manufactureCelsius DegreeMaterials science

Owner:丹阳市中信化工电器设备有限公司

Highly conductive heat-resistant aluminum conductor and production process thereof

InactiveCN102103896ANon-insulated conductorsCable/conductor manufactureTransmission lineHigh conductivity

Owner:江苏通光强能输电线科技有限公司

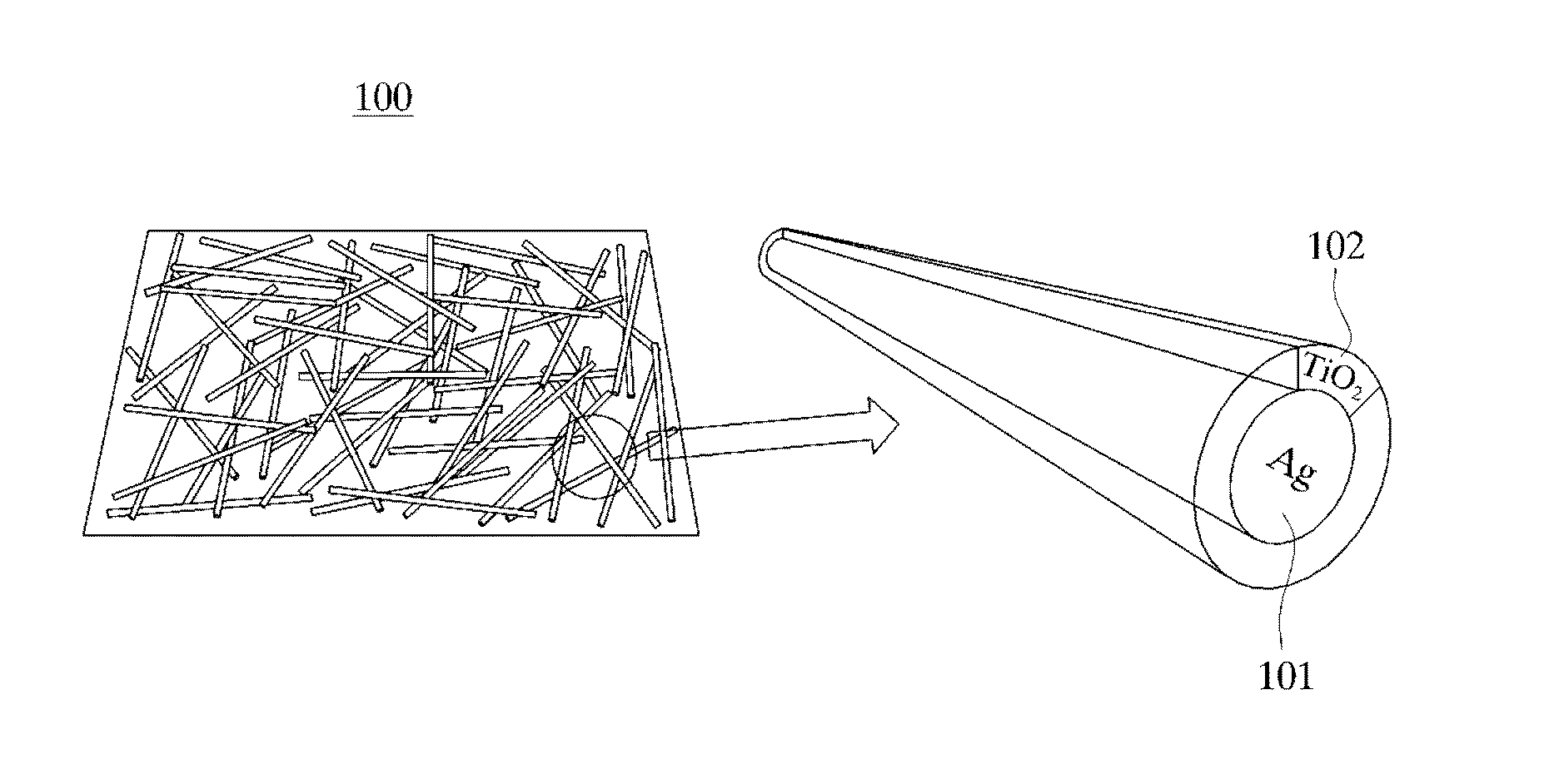

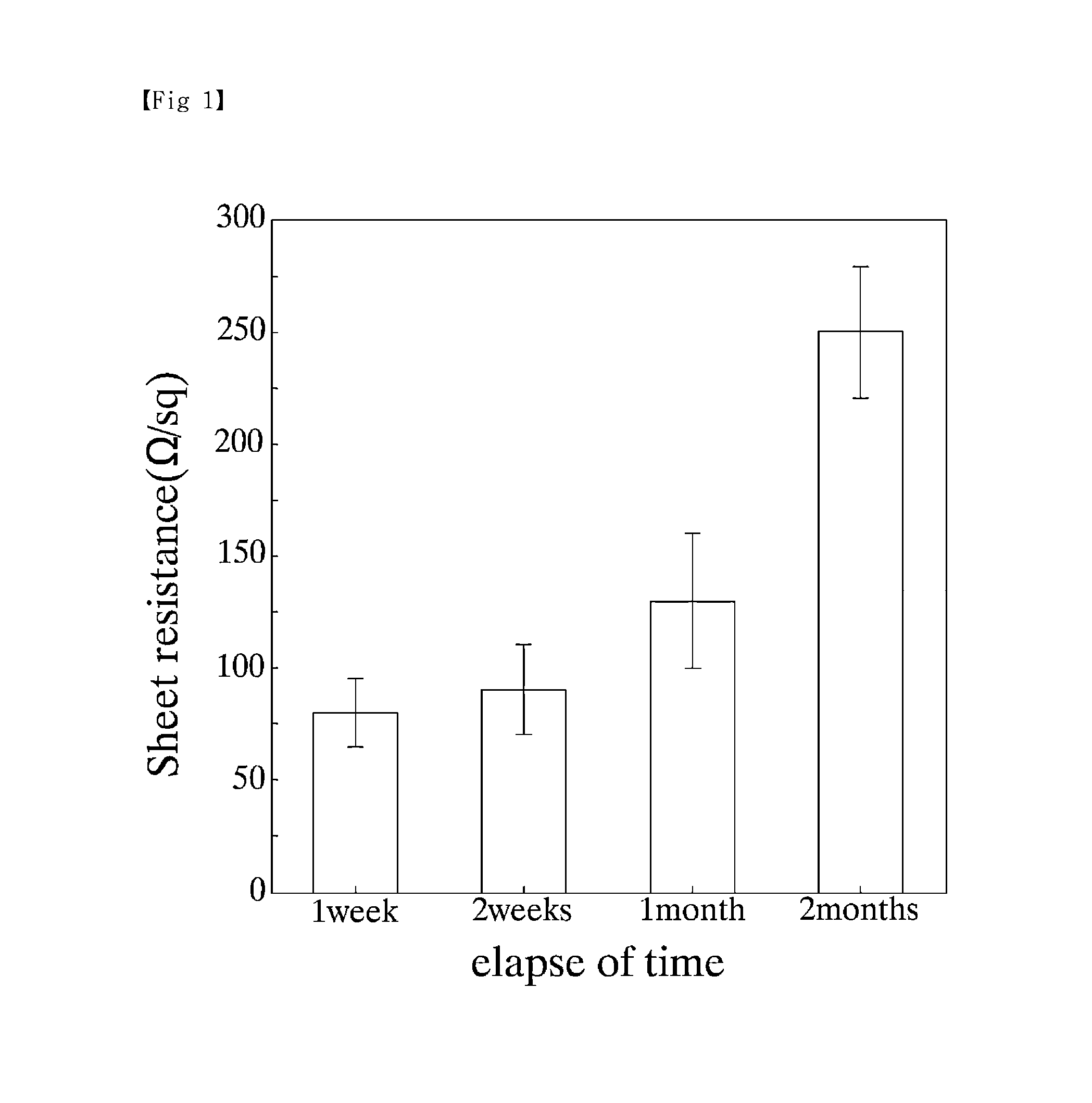

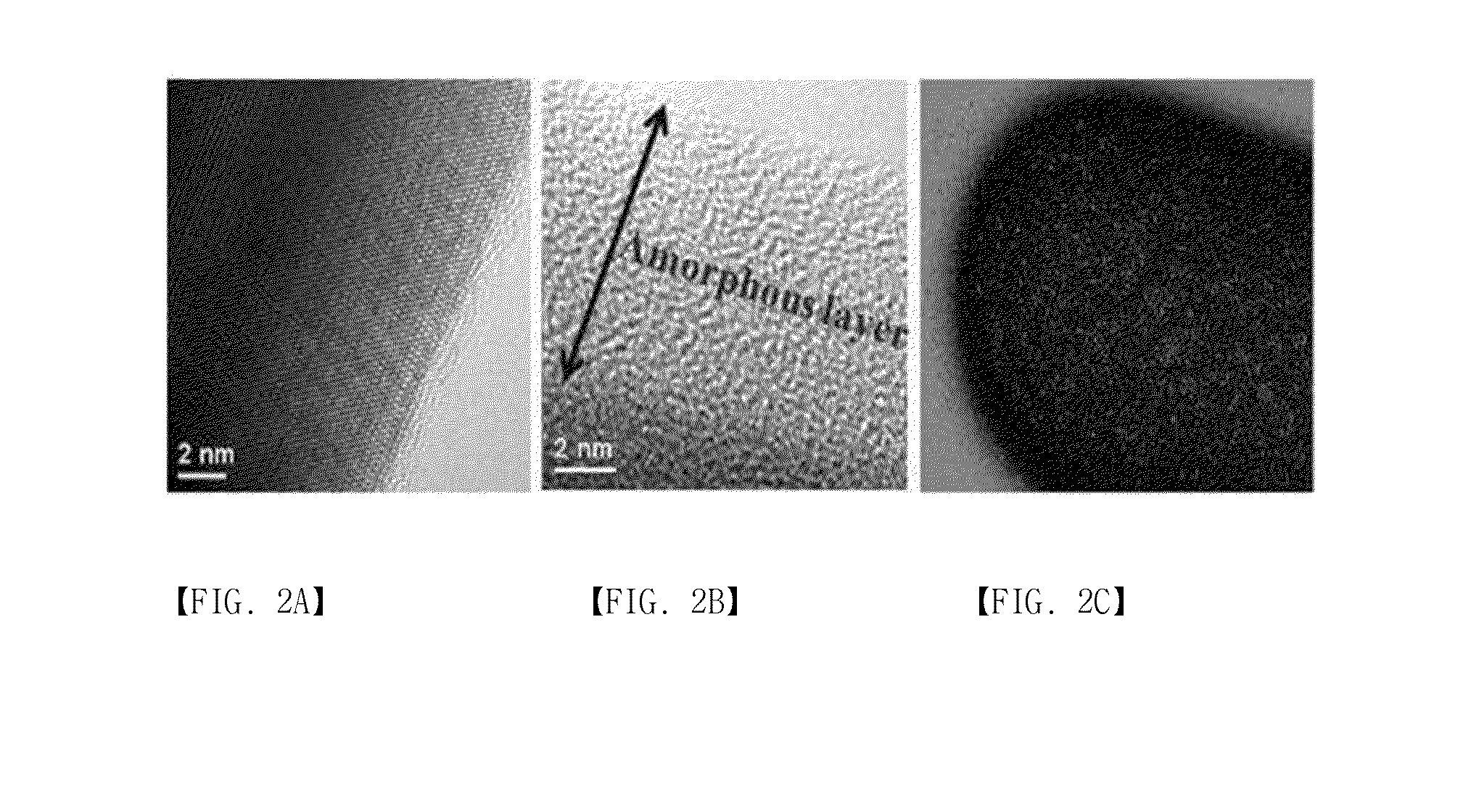

Silver nanowire conductive film and method of fabricating the same

ActiveUS20140020737A1Conductive layers on insulating-supportsSynthetic resin layered productsProtection layerSilver nanowires

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

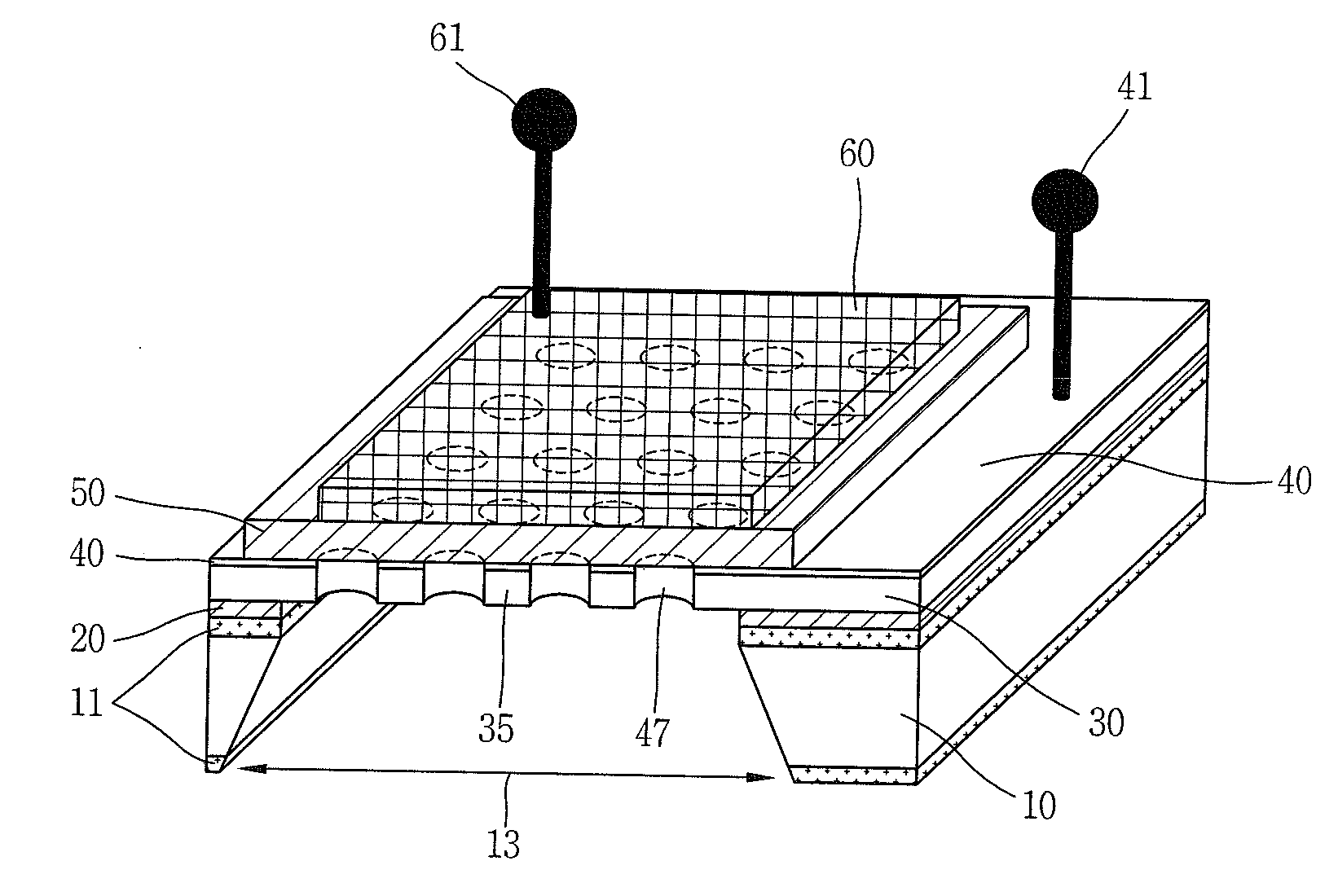

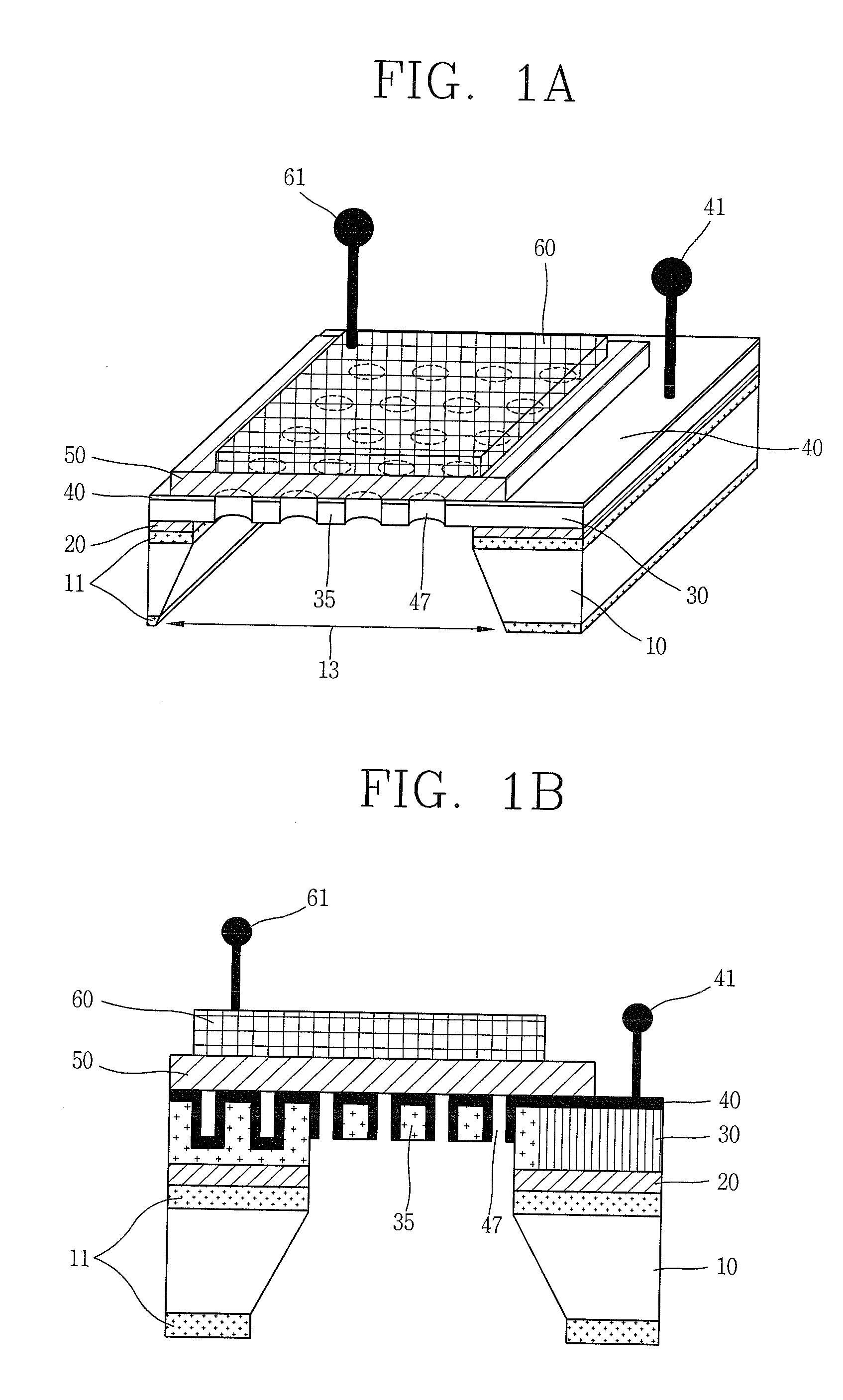

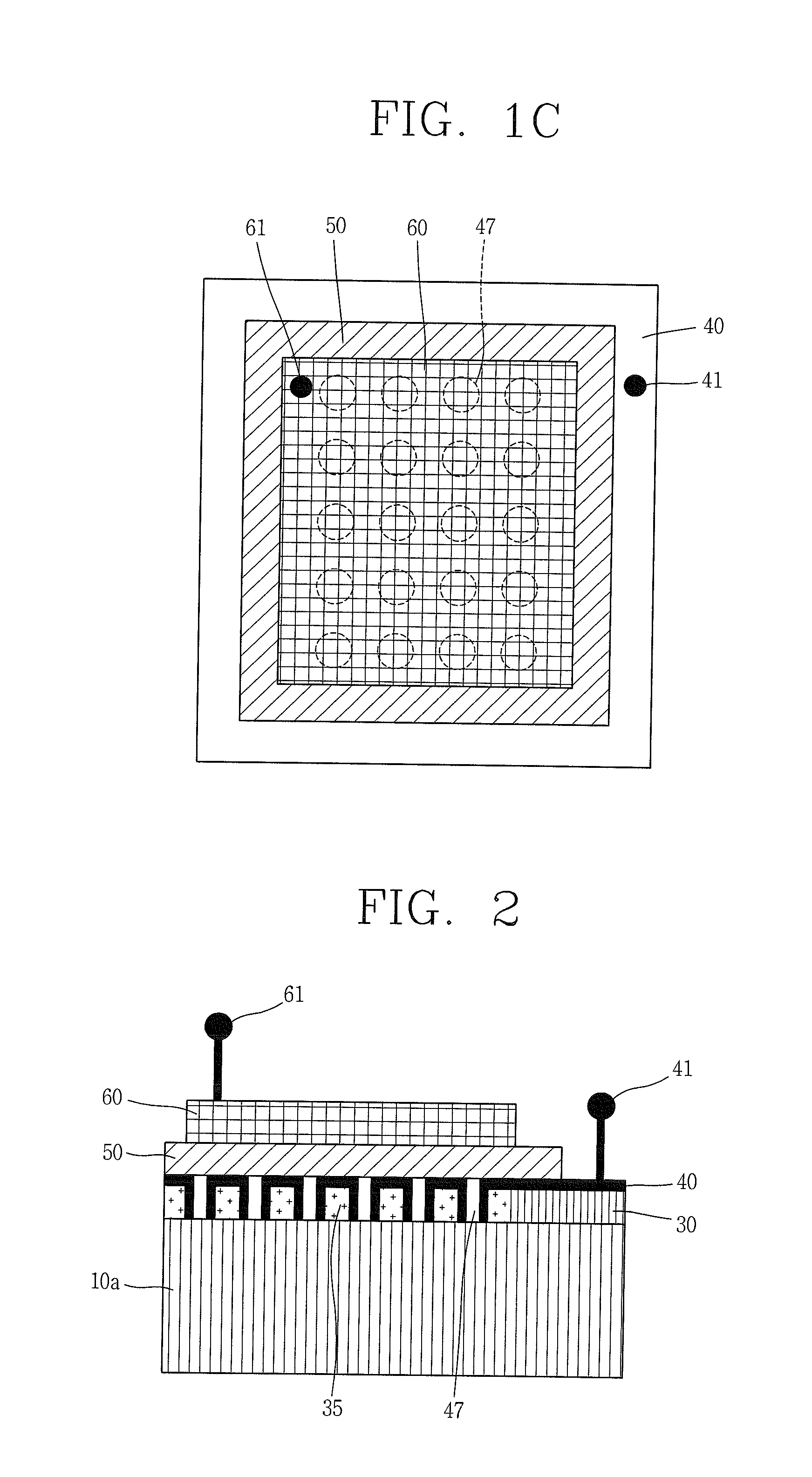

Micro fuel cell, fabrication method thereof, and micro fuel cell stack using the same

InactiveUS20090181278A1Keep the structure stablePrevent coagulationAnodisationMaterial nanotechnologyAnodizingMicro cell

Owner:KOREA INST OF SCI & TECH

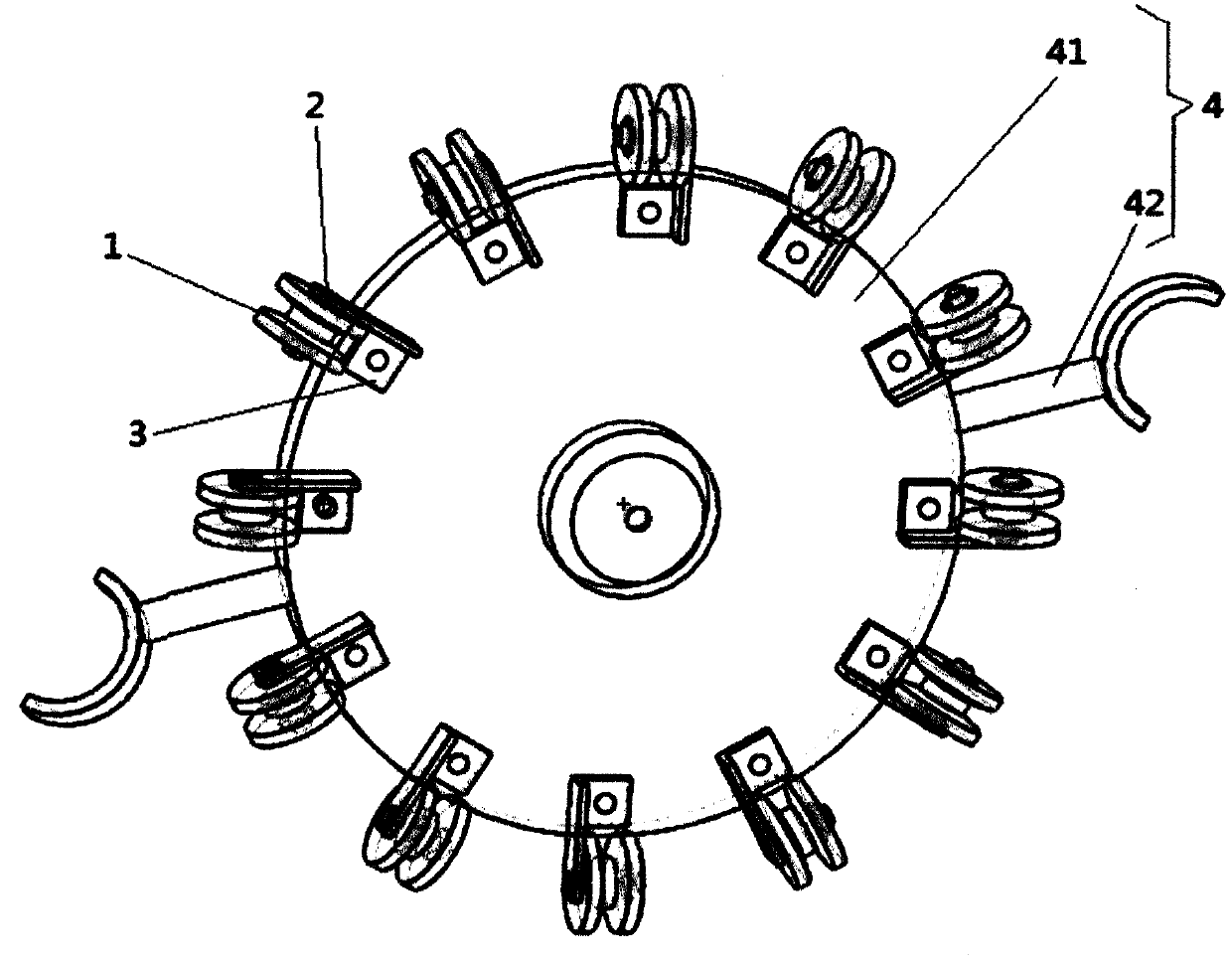

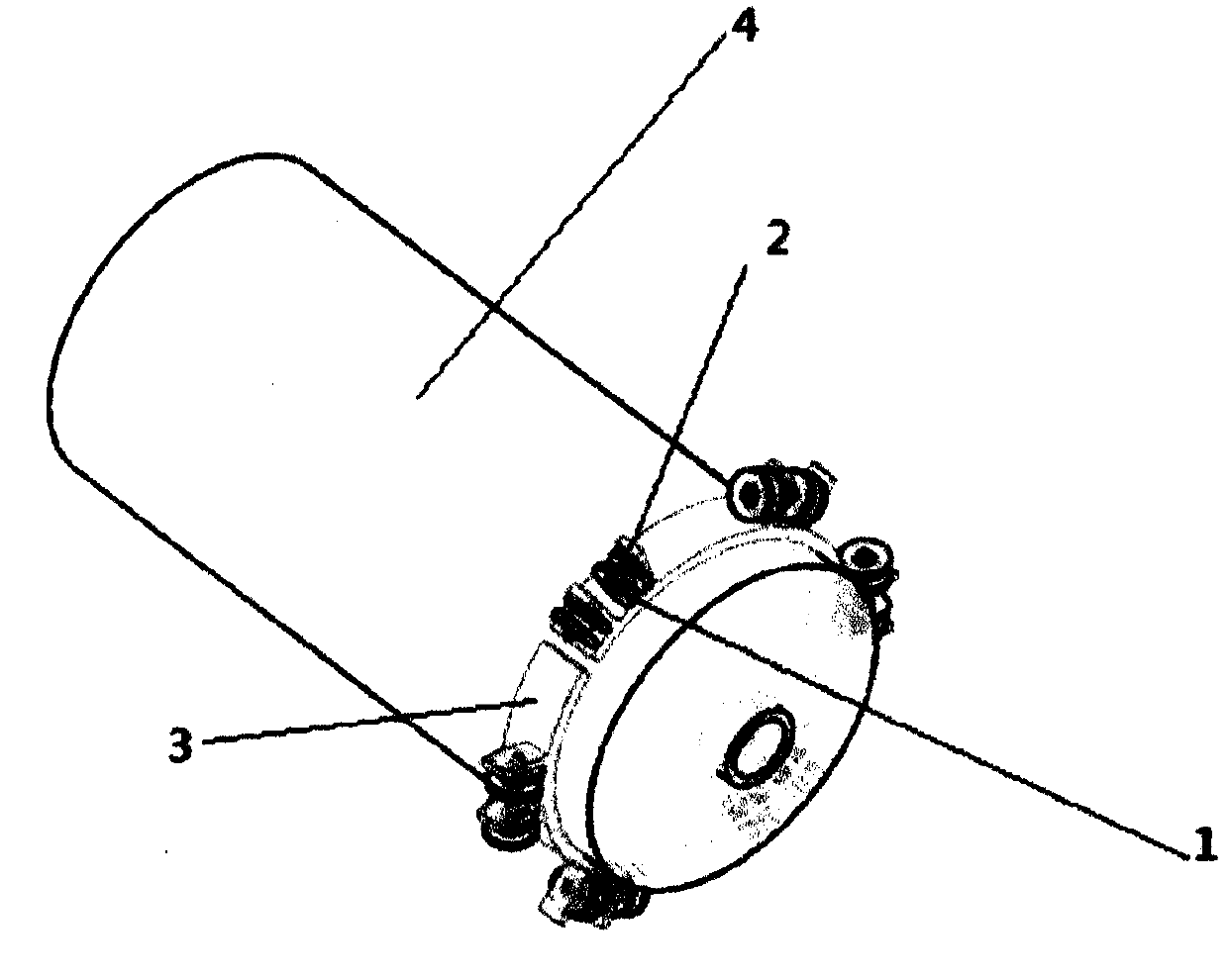

Movable clamping device for enameled wires

ActiveCN104658702AImprove efficiencyReduce labor costsCable/conductor manufactureCopper wireCoupling

Owner:苏州华盛电工材料有限公司

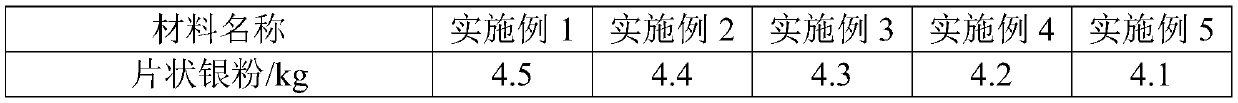

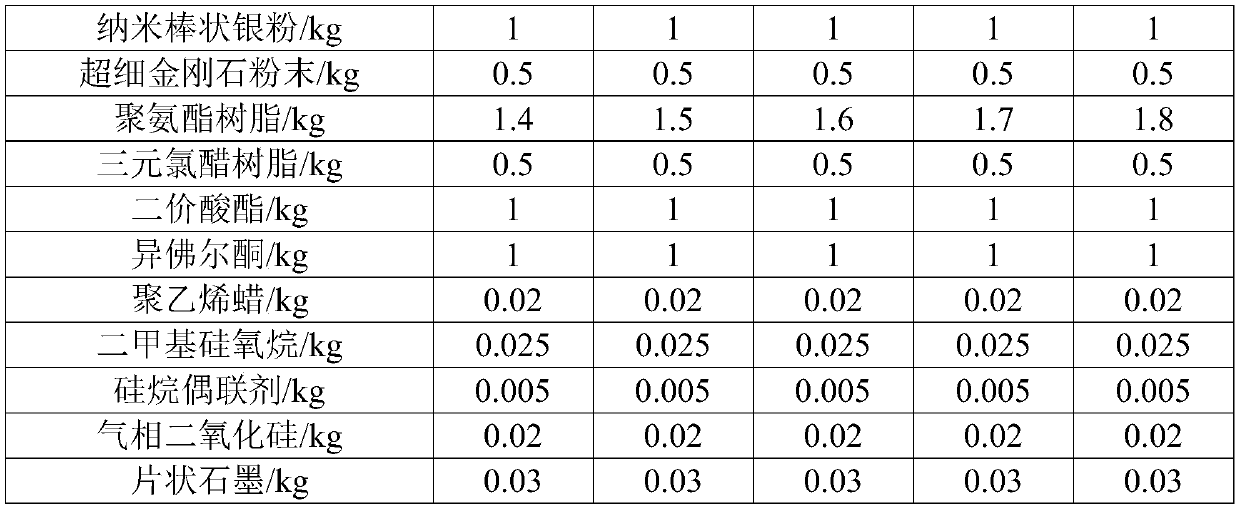

Low-silver-content composite conductive silver paste and preparation method thereof

InactiveCN104282356AImprove conductivityReduce silver contentNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteScreen printing

The invention relates to a low-silver-content composite conductive silver paste and a preparation method thereof, and belongs to the technical field of electroconductive slurry. The low-silver-content composite conductive silver paste can be used for screen printing. At present, the conductive silver paste preparation technology in China is high in production cost, complex in preparation technology and the like. According to the low-silver-content composite conductive silver paste, silver-plated copper powder and silver-plated glass powder are adopted to replace pure silver powder, so that the production cost of the silver paste is effectively reduced; the mode that spherical particles and platy particles are combined is selected, so that the conductivity of the silver paste is improved; the silver-plated glass powder with the low specific density is adopted, so that the stability of the conductive silver paste is improved, and the storage life of the silver paste is prolonged. The problems existing in silver paste production at present in China are well solved, the sliver paste preparation technology is simple, the silver paste is good in conductivity and impressionability (including automatic and semi-automatic screen printing and the like), and high in adhesion capacity with various substrates such as a PET film, and has significant application value.

Owner:肖淑勇

Manufacturing process of graphene transparent conductive film

Owner:苏州瑞邦塑胶有限公司

Preparation method for Nb-Zr alloy/Cu multi-core composite wire

ActiveCN105855316AOrganizational structure is stableHigh strengthCable/conductor manufactureOxidation resistantHigh intensity

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

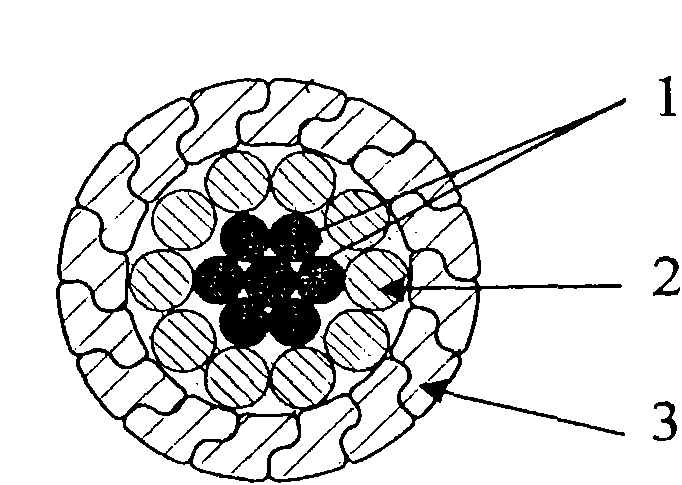

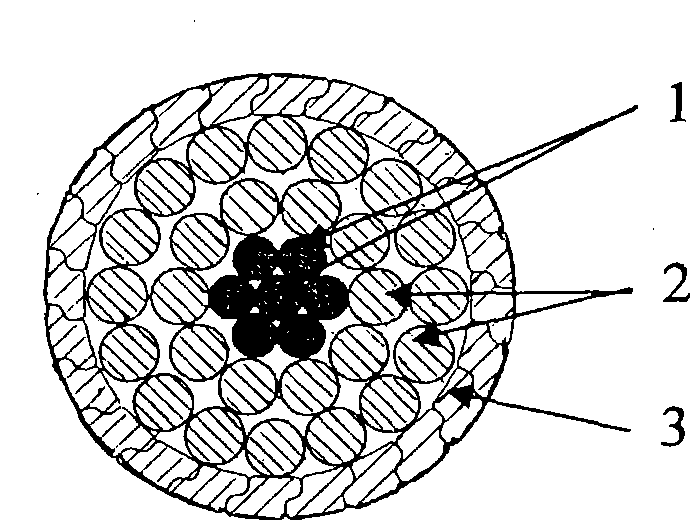

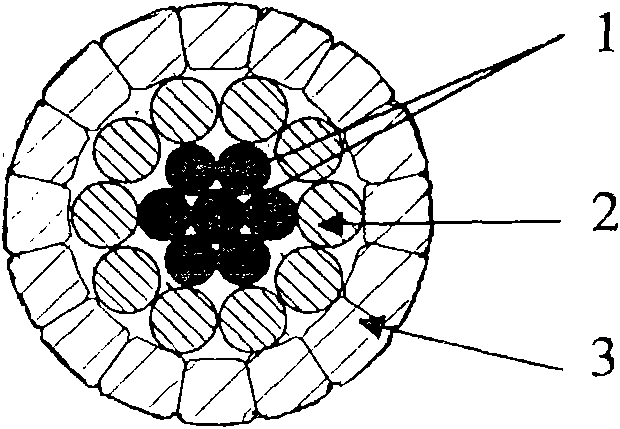

Halogen-free flame-retardant copper-plastic composite belt and preparation thereof

InactiveCN103165237AHas an ultra-thin structureReduce manufacturing costConductive layers on insulating-supportsLaminationPolyesterEngineering

The invention relates to the field of cable belts, in particular to a copper-plastic composite belt suitable for a communication cable and an optical cable and preparation thereof. The copper-plastic composite belt is coated on the outer surface of the communication cable or the optical cable and sequentially comprises a red copper layer (1), an adhesive layer (2) and a polyester film layer (3), wherein the red copper layer (1), the adhesive layer (2) and the polyester film layer (3) are bonded and heated to form a composite structure. The tensile strength of the copper-plastic composite belt is larger than or equal to 180MPa, the elongation at break of the copper-plastic composite belt is larger than or equal to 15%, the interlayer peeling strength between a copper belt and a plastic layer is larger than or equal to 15N / cm, the conductivity of the copper-plastic composite belt is larger than or equal to 90% IACS, and no punchthrough happens on the single side of the copper-plastic composite belt 1 kvd.c,1min.

Owner:JIUXING HLDG GRP

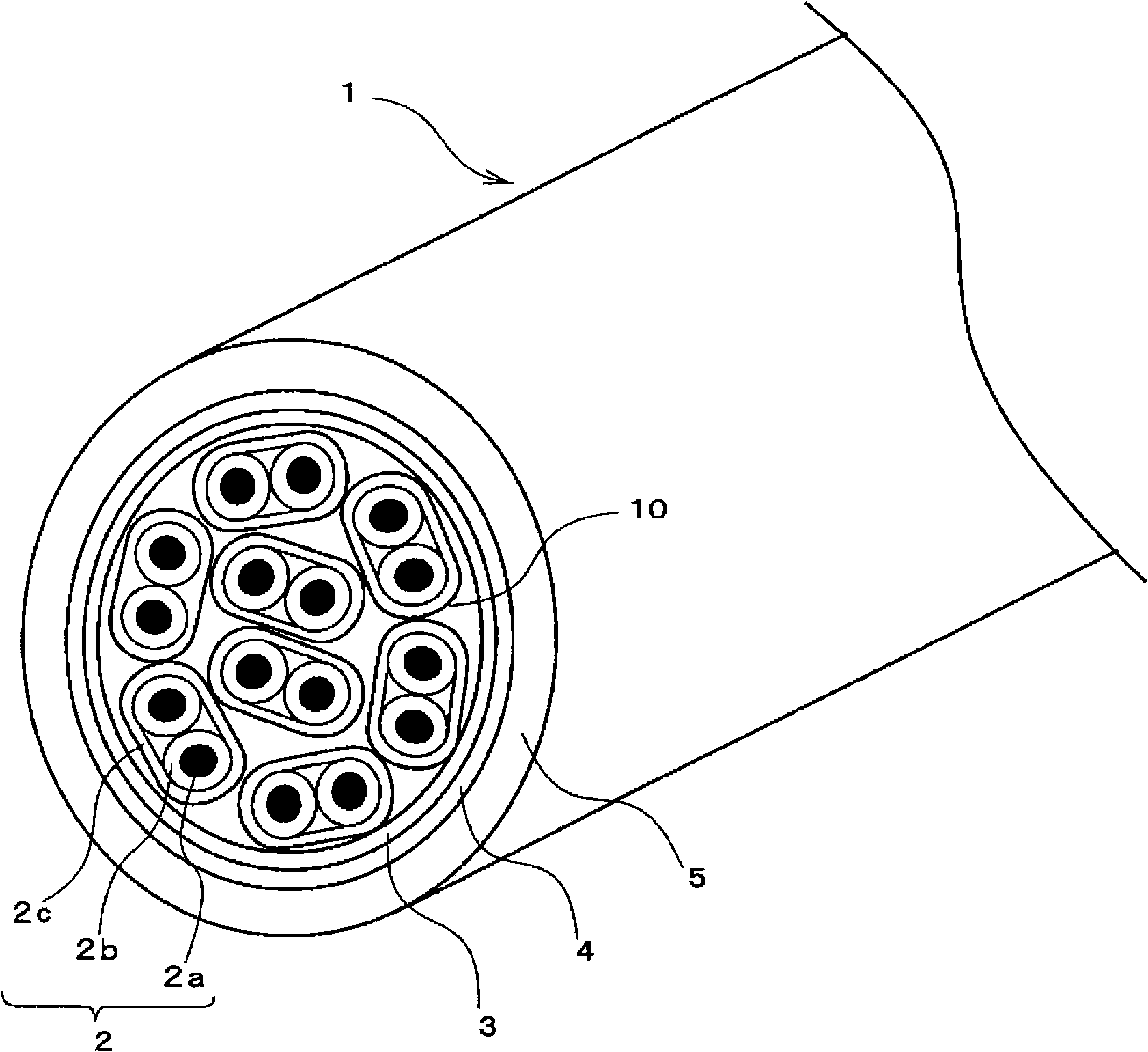

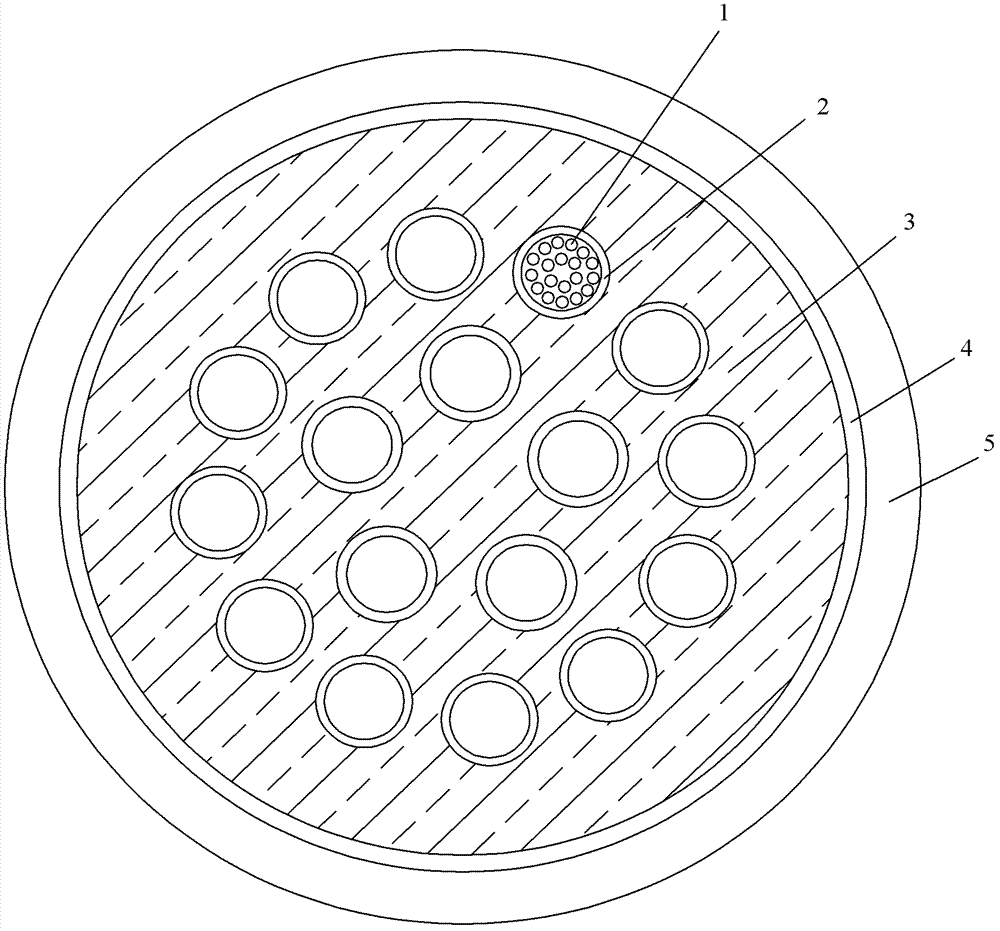

Multi-core cable

Owner:SUMITOMO ELECTRIC IND LTD

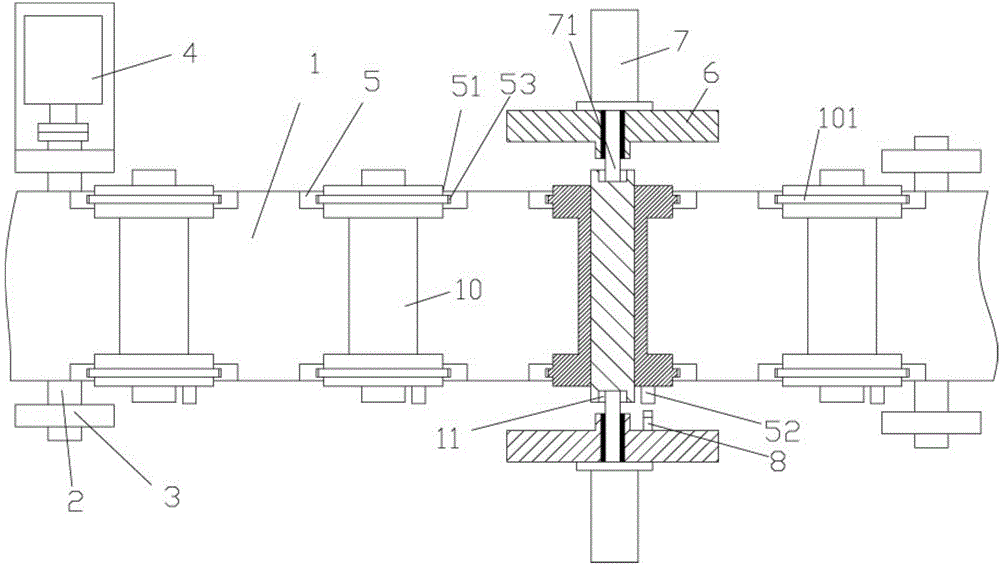

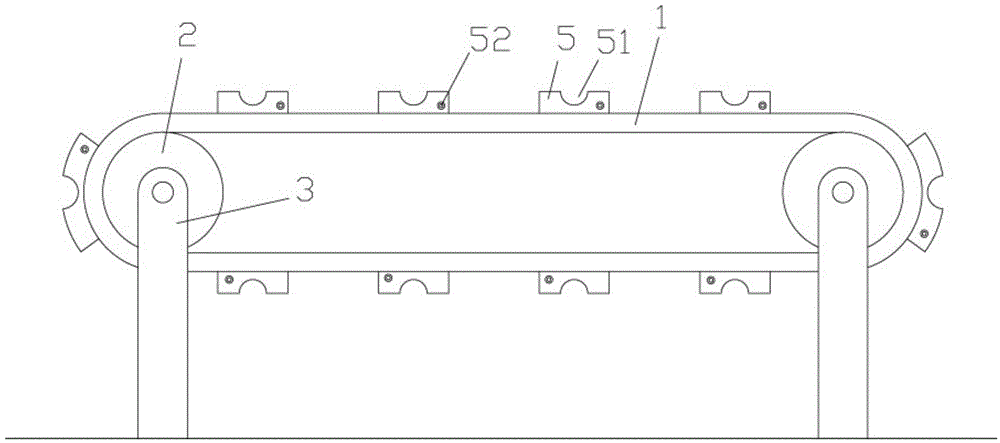

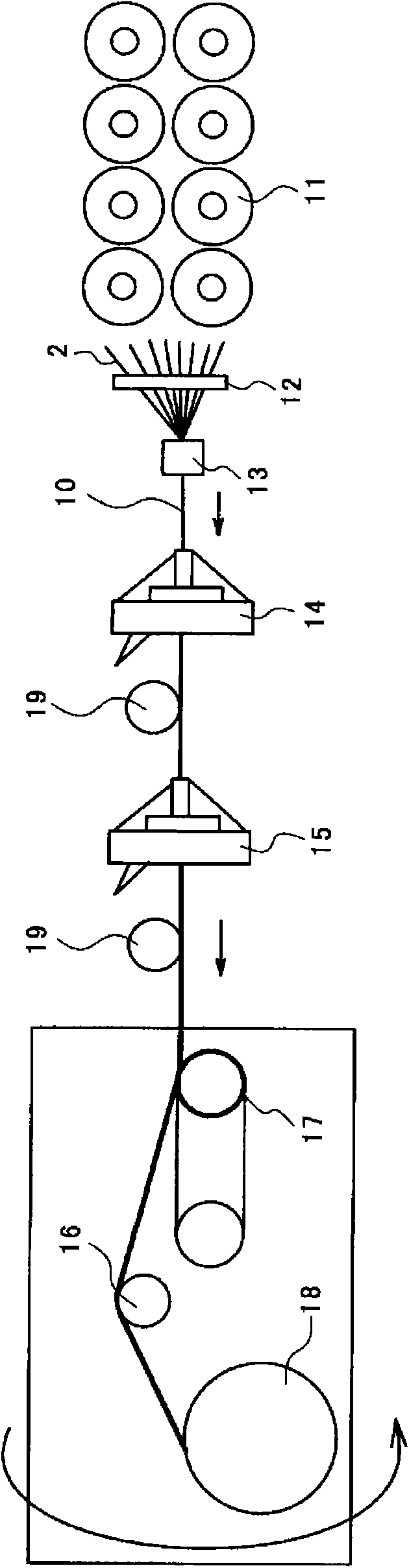

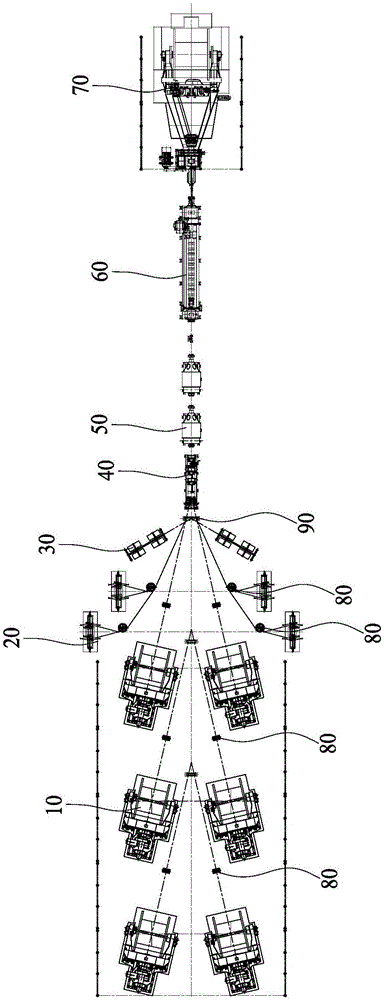

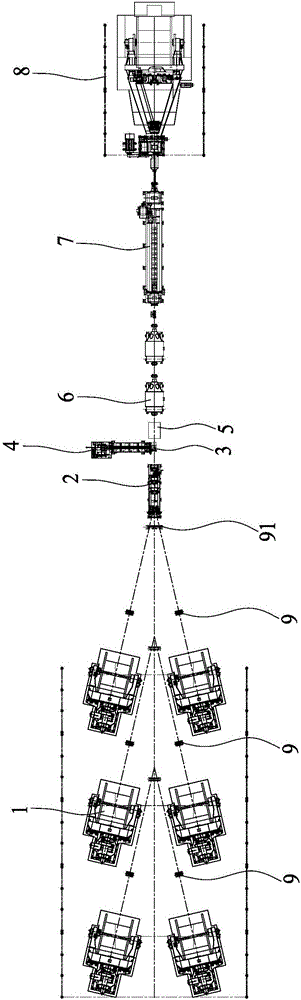

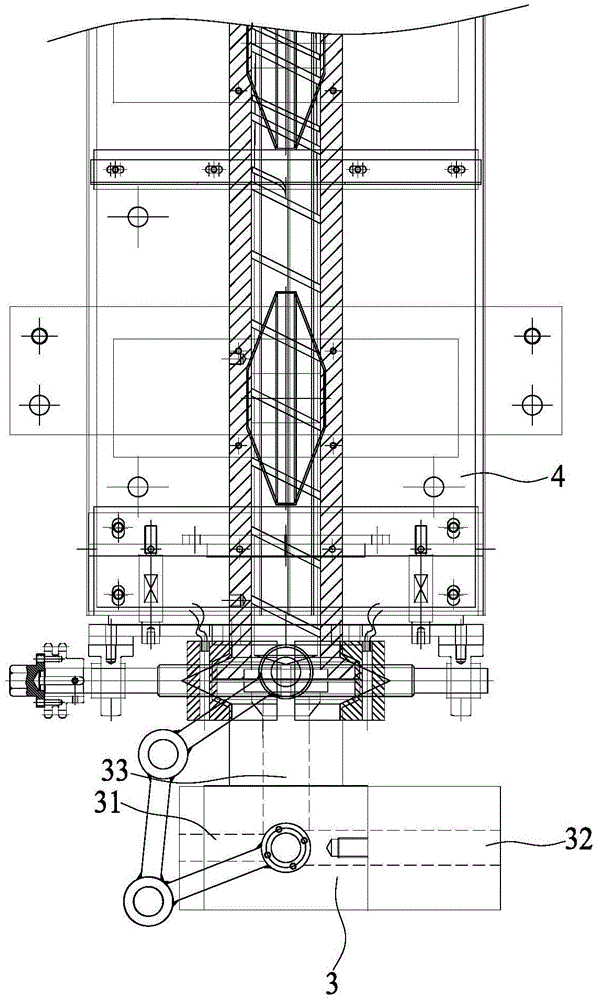

Pressure filling type cable former and cable forming process

ActiveCN106448940AFilled tightlyStable structureCable/conductor manufactureEngineeringMechanical engineering

Owner:FUJIAN NANPING SUN CABLE +1

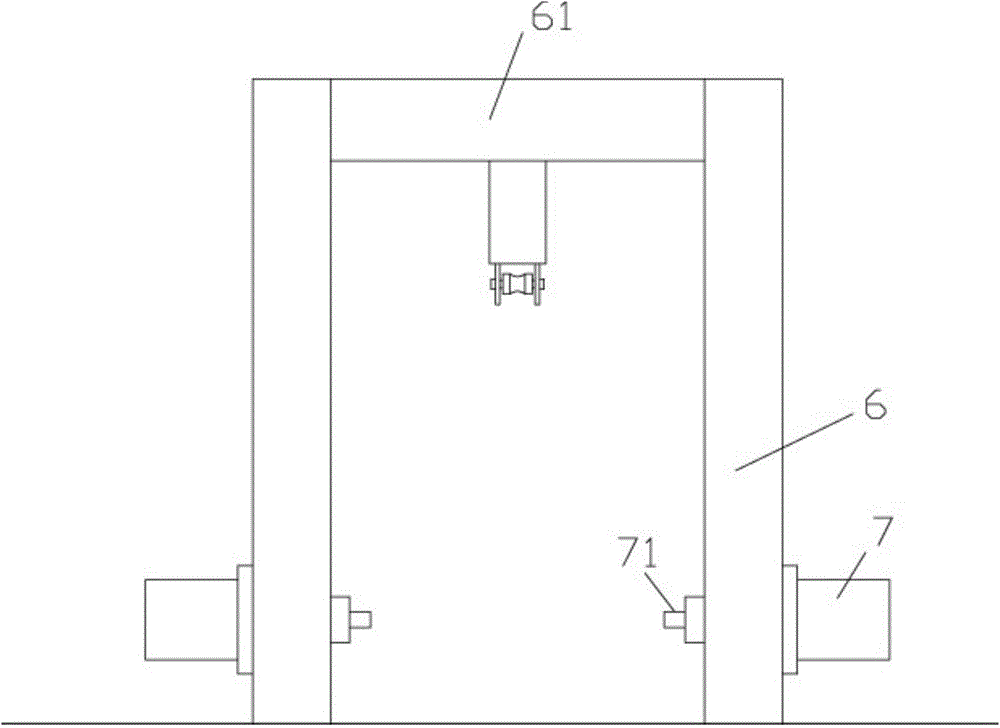

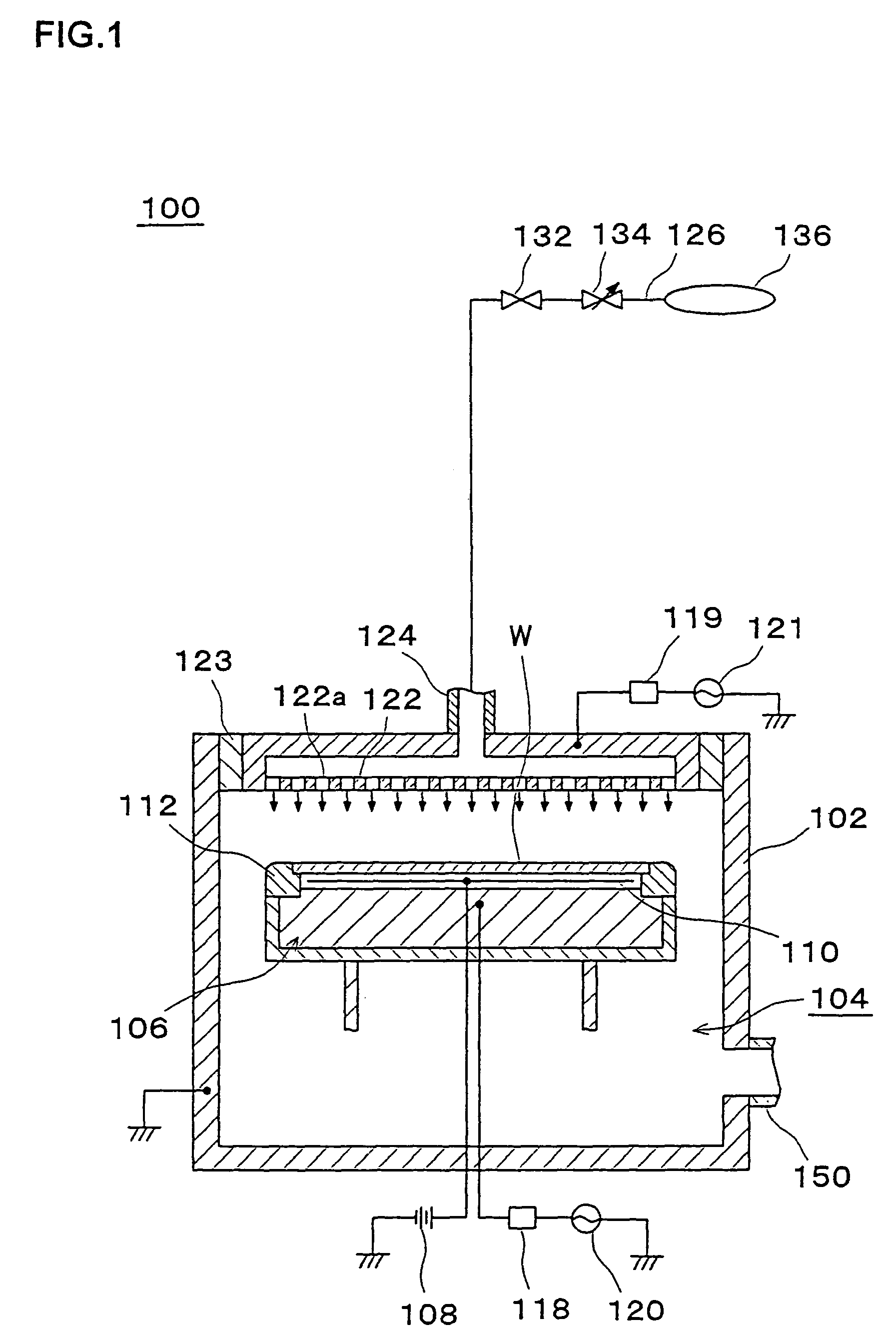

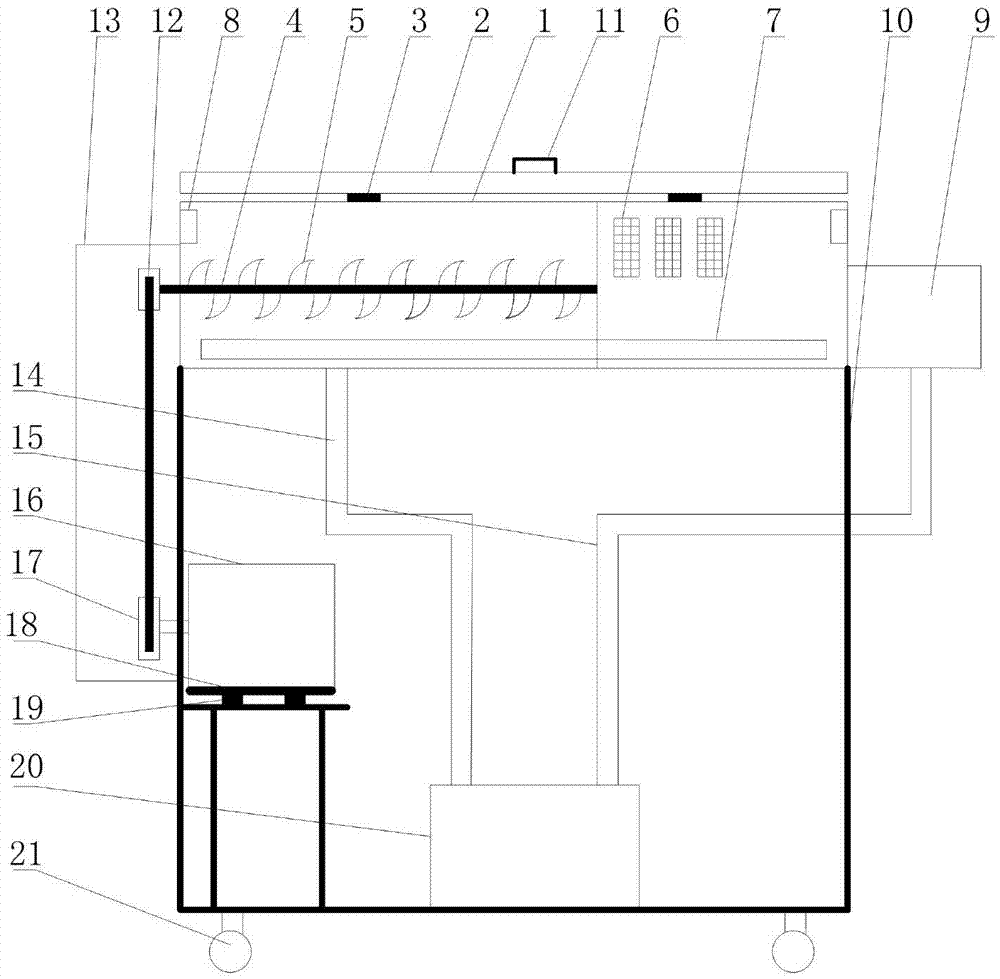

Temperature-controllable electric field induction platform

ActiveCN106816226ARealize the processing effectRealization of process conditionsCable/conductor manufactureSilicon-controlled rectifierEngineering

The invention provides a temperature-controllable electric field induction platform. The temperature-controllable electric field induction platform comprises a clamping portion, a temperature keeping portion and an electric field generation portion, wherein the clamping portion is arranged on a work platform (16) in the temperature keeping portion, temperature of a temperature control box of the temperature keeping portion is controlled through a temperature control heating system composed of a PID silicon controlled rectifier temperature control component (21), thermocouples (19) and (20) and ten sets of resistor heating components (18), and the electric field generation portion can generate a 50kV-voltage power frequency AC electric field and a DC electric field. The platform mainly satisfies requirements of a complete sulfuration process of preformed liquid state silicone rubber while being applied to electric field induction processing manufacturing, ordered arrangement is realized under the orientation induction action of the electric field, conductive particles of the conductive rubber are made to form a more effective flow path, the heating portion can provide a heat source for rubber sulfuration, and the platform can provide an external high-field-intensity field for the conductive rubber when influence of the external electric field on conductive performance of materials is tested.

Owner:BEIJING UNIV OF TECH +4

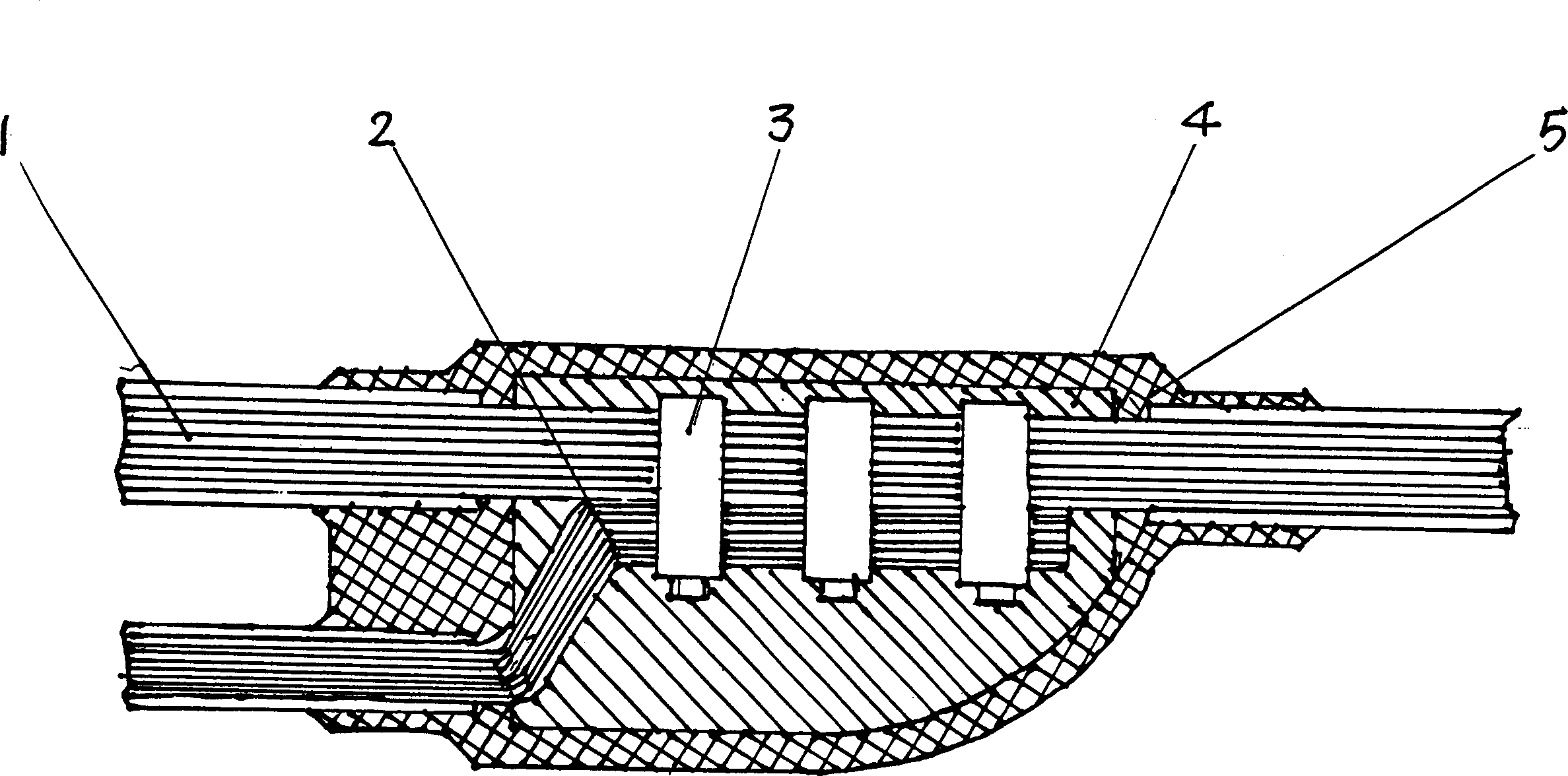

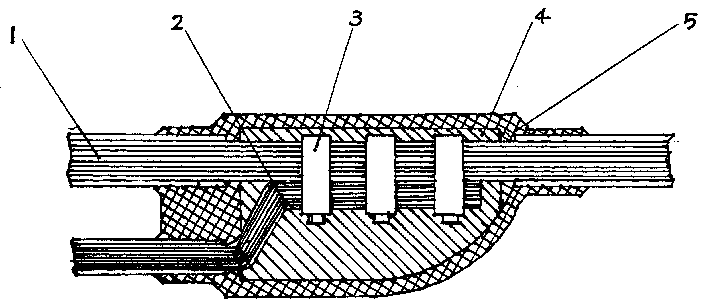

Metal cable connector welding machine

InactiveCN104779508AMeet welding requirementsReasonable designLine/current collector detailsCable/conductor manufactureCopper conductorEngineering

A metal cable connector welding machine comprises a fixed copper conductor (1), a sliding copper conductor (2), bolts (3), push rods (4), slide rods (5), a cable slot I (6), a handle (7), a connecting rod (8), a power regulator (9) and a work bench (10), and is characterized in that the other ends of the slide rods (5) are connected with the handle (7) through the connecting rod (8); ends of two metal cables requiring welding are placed in the cable slot I (6) and a cable slot II (11) respectively and tightened by bolts (3), the handle (7) pushes the slide rods (5) on the push rods (4) through the connecting rod (8), two ends of each cable are contacted and powered on, the cables are molten, and welding is completed. The metal cable connector welding machine is reasonable in design, simple in structure, reliable in action and convenient to operate and can feasibly meet the cable welding requirement, and the product quality is ensured.

Owner:JIANGSU GANGHONG WIRE & CABLE CO LTD

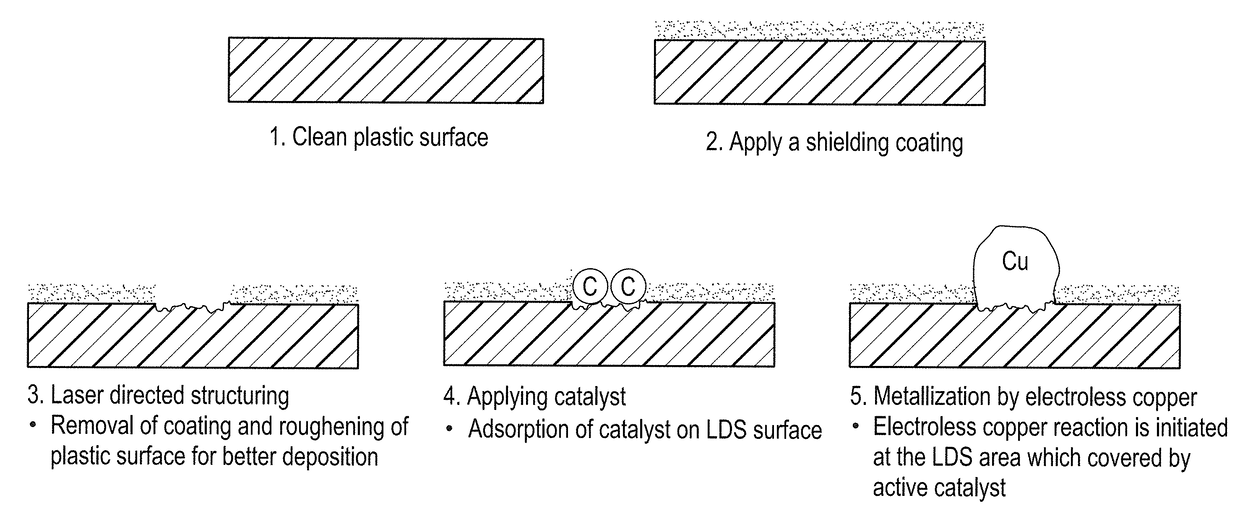

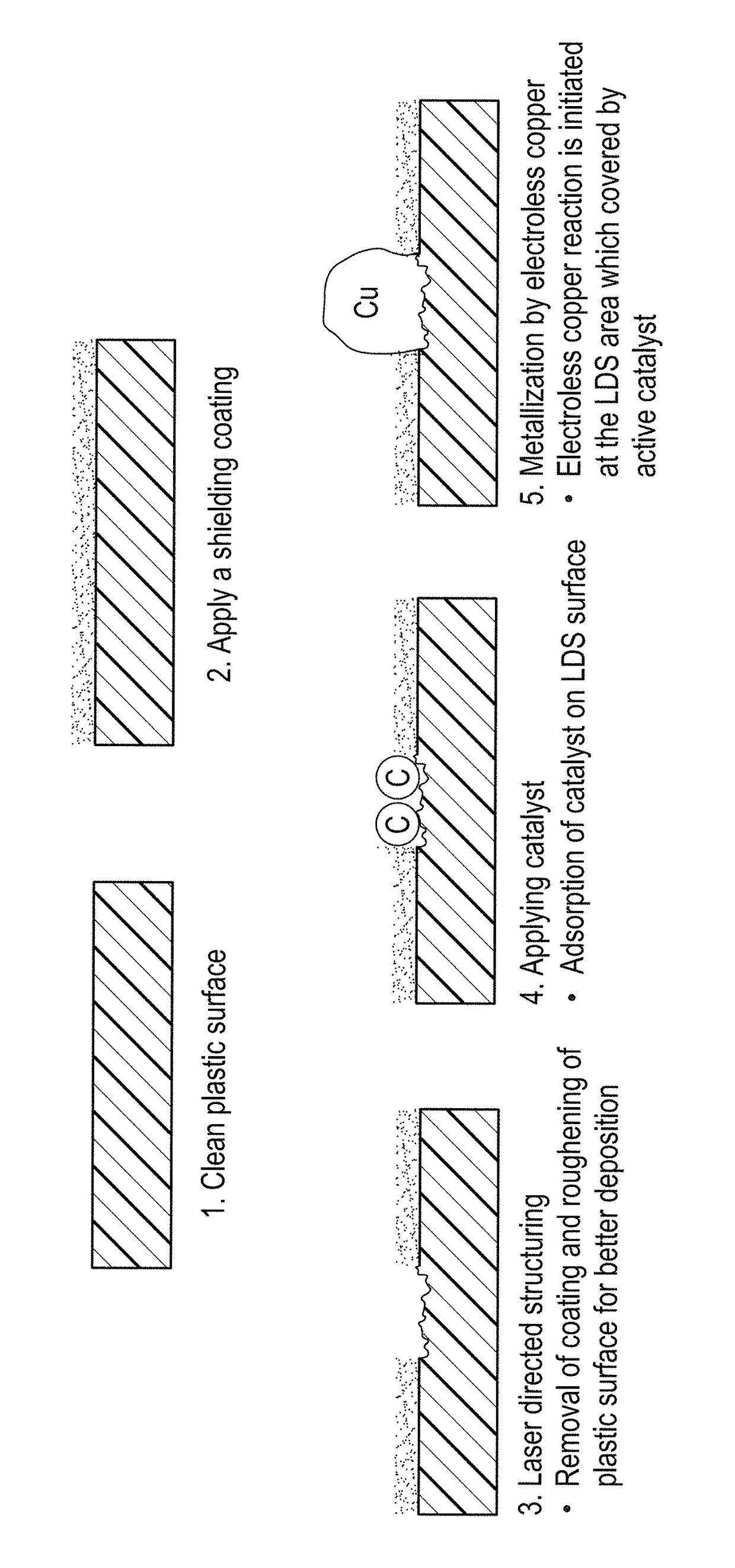

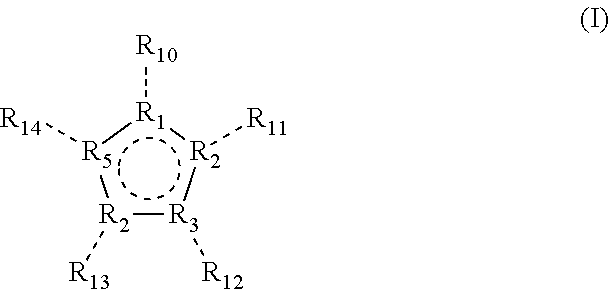

Shielding coating for selective metallization

InactiveUS9797043B1Avoid adsorptionLiquid/solution decomposition chemical coatingCable/conductor manufacturePolymer substrateOrganic compound

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

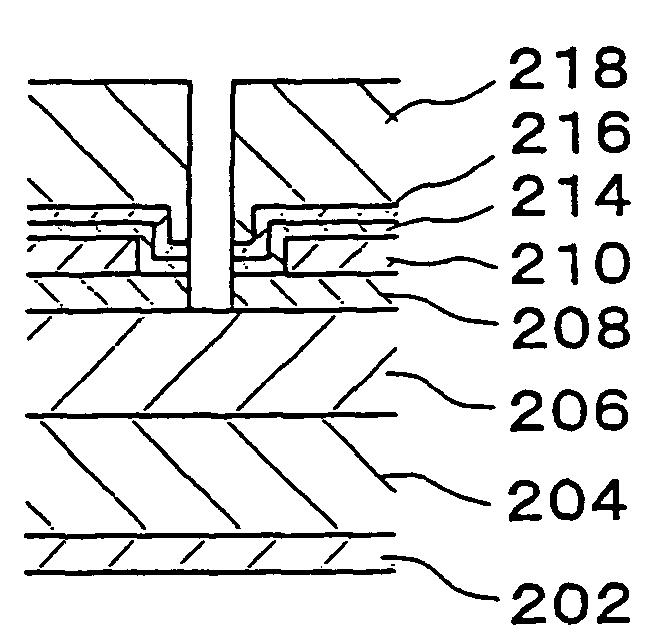

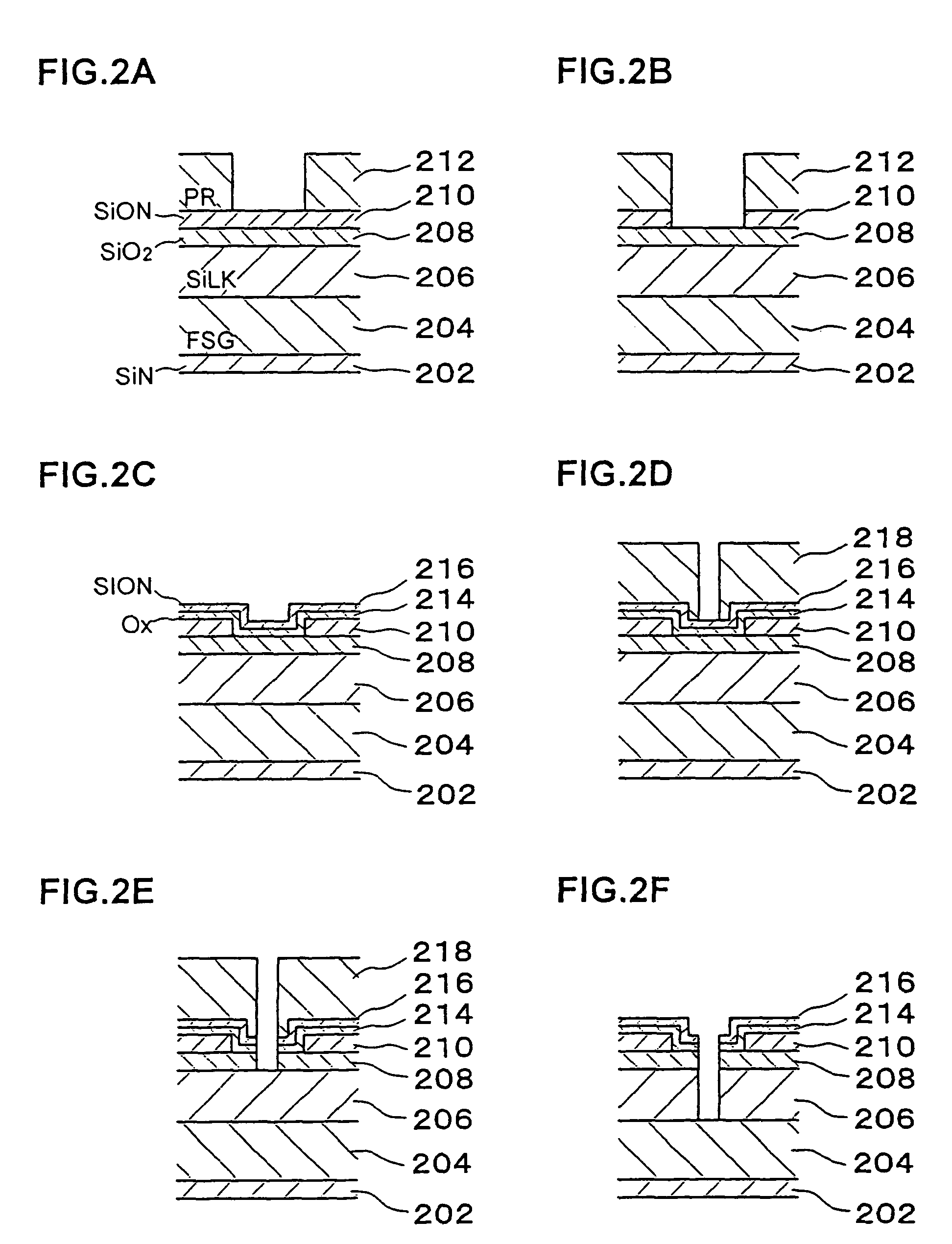

Method of etching dual damascene structure

InactiveUS7326650B2Maintain dimensional stabilityDecorative surface effectsSemiconductor/solid-state device manufacturingHard maskPhysics

Owner:TOKYO ELECTRON LTD

Thermoplastic Elastomer Compositions Comprising Intumescent Flame Retardants and Non-Phosphorous-Based Flame Retardant Synergists

ActiveUS20120125657A1Plastic/resin/waxes insulatorsInsulated cablesThermoplastic elastomerPolyphosphate

Owner:UNION CARBIDE CORP

Solar energy electrical conduction slurry and preparation method thereof

InactiveCN102938260ANon-conductive material with dispersed conductive materialCable/conductor manufactureWeather resistanceSilane coupling

Owner:DONGFANG ELECTRIC YIXING MAGI SOLAR POWER TECH

Insulation water retaining aerial cable and manufacture method thereof

InactiveCN102982883APower cables with screens/conductive layersCable/conductor manufactureOuter coreCorrosion

Owner:JING FENG GRP

High-strength high-conductivity rare earth copper-magnesium alloy contact wire and manufacturing method thereof

InactiveCN106555073AMeet performance requirementsHigh elongationSingle bars/rods/wires/strips conductorsConductive materialRare-earth elementCerium

Owner:HENAN UNIV OF SCI & TECH

Powder-passing apparatus for cable

InactiveCN106920596AApply evenlyGuaranteed application qualityCable/conductor manufactureHelical bladeEngineering

Owner:ANHUI JIUHUA KIMRUN COPPER IND

Method for crimping high-pressure cross-linking three-layer co-extrusion continuous produced disc-exchanging conductor

InactiveCN102945710ANo drop in tensile strengthLow technical requirementsConnections effected by permanent deformationCable/conductor manufactureCross-linkElectrical resistance and conductance

Owner:HENGYANG HENGFEI CABLE CO LTD

Energy-saving and consumption-reducing cable conductor manufacturing method

InactiveCN109698048AReduce gapQuality improvementCable/conductor manufactureWinding machineElectrical conductor

The invention provides an energy-saving and consumption-reducing cable conductor manufacturing method. The cable conductor manufacturing method includes the following steps: round copper rods are drawn into copper wires, the copper wires are continuously annealed into soft copper wires by using a continuous annealing copper wire drawing machine, and the soften copper wires are wound by an I-shapedwheel; a stranding machine can adjust pitch, rotation direction, PLC man-machine interface control, and polycrystalline drawing die on each segment; the copper wires on the I-shaped wheel wound wiresare on the frame type stranding machine, the pitch diameter ratio of each outer layer is not greater than the pitch diameter ratio of the inner layer, and the cable conductors are twisted into a strand; and the cable conductors twisted into a strand are stored in a cable tool disk by a tractor and a winding machine. The advantages of the energy-saving and consumption-reducing cable conductor manufacturing method are that the cable conductor is of a special-shaped single-filament stranded structure and has the advantages of reduced gaps between filaments, smooth, bright and round appearance, reduced diameter, improved density, more stable resistance and improved cable quality, and the method reduces the consumption of materials and increases the economic benefit of an enterprise.

Owner:SHANDONG JINYUAN COPPER CO LTD

Cable cleaning device

ActiveCN108405441ACleaning using toolsDrying machines with progressive movementsLiquid wasteEngineering

The invention provides a cable cleaning device which comprises a cleaning tank, a cleaning part in the cleaning tank, a liquid waste pool located below the cleaning tank, and a cable inlet formed in the side face of the cleaning tank. The cleaning part comprises cleaning devices arranged in the cleaning tank and spraying devices connected with a water tank. The cleaning devices comprise mounting seats arranged on the inner walls of the side faces of the cleaning tank and connected with a cleaning liquid tank, supporting devices and cleaning wheels. Cleaning grooves sunken towards the centers of the cleaning wheels are formed in the cleaning wheels, and cleaning sponge layers are arranged on the cleaning grooves. According to the cable cleaning device, a cable is cooled through the sprayingdevices, the cable is wetted preliminarily, the mounting seats connected with the cleaning liquid tank provide cleaning liquid for cable cleaning when the cable passes through the cleaning wheels, the cable is sufficiently cleaned when passing through the cleaning grooves with the cleaning sponge layers, the service life of the cable is prolonged, and the manpower cost is reduced.

Owner:LONGYOU COUNTY POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD

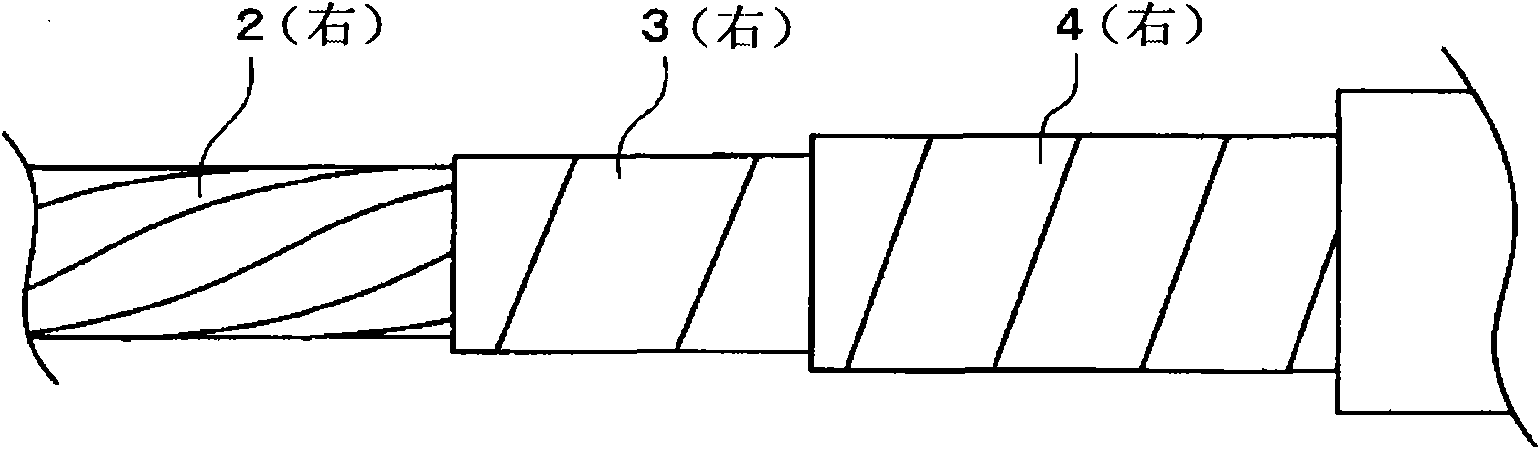

Controlling cable and manufacturing method thereof

InactiveCN102820082AGood flexibilityLarge curvatureNon-insulated conductorsFlexible cablesElectrical conductorCopper

Owner:SHANGHAI FEIHANG ELECTRIC WIRE & CABLE

Low-temperature conductive silver paste for automobile safety belt alarming and preparation method thereof

InactiveCN111489847AEffective defoamingEffective simulation of printing effectsNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteAutomobile safety

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Preparation method for solar cell conductive mixed paste containing polyethylene vinyl acetate

ActiveCN103117130AImprove photoelectric conversion efficiencyImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufacturePolyethylene vinyl acetateEpoxy

Owner:重庆新锐科技服务有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap