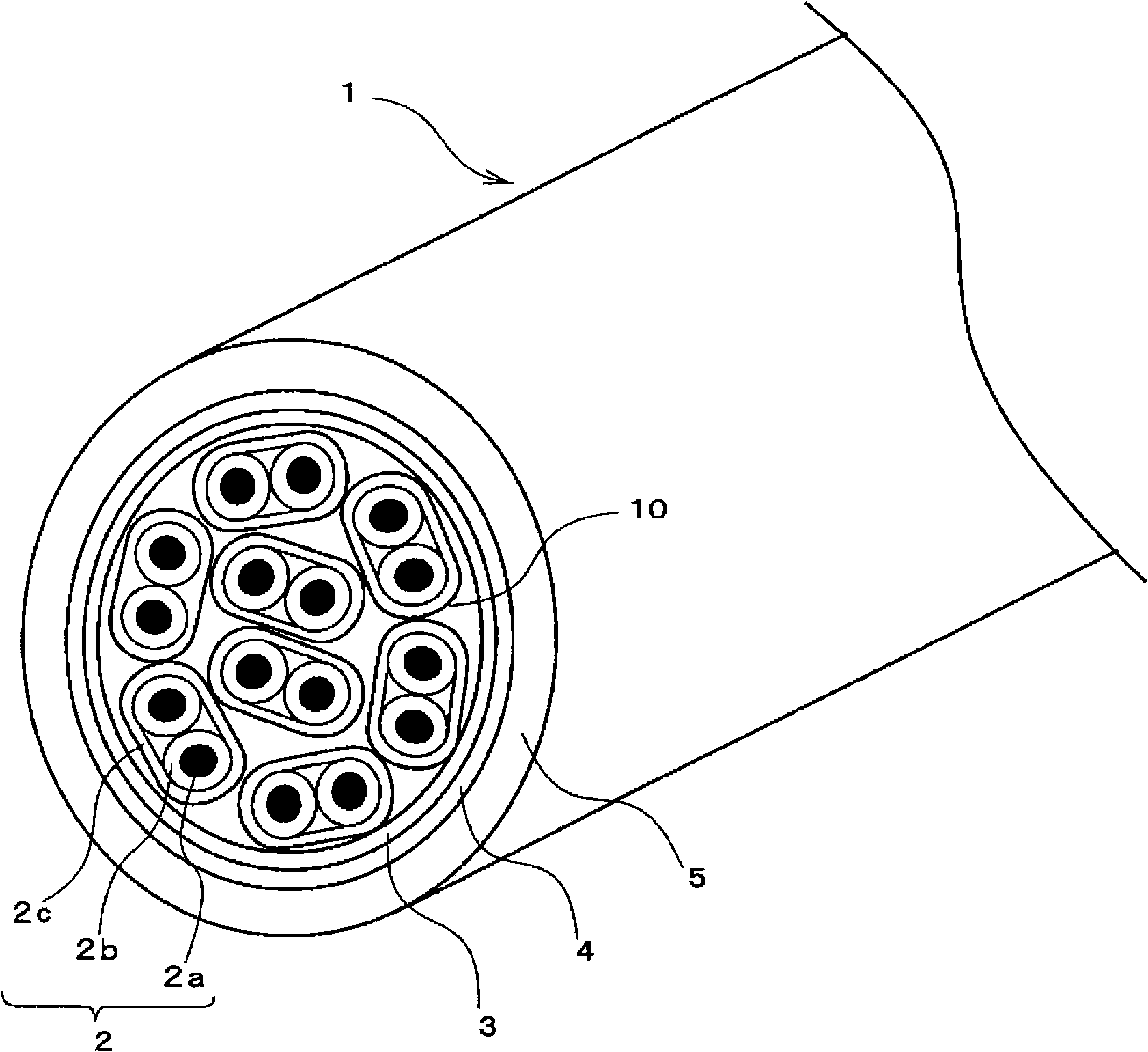

Multi-core cable

A multi-core cable and cable technology, which is applied in the direction of communication cables, cables, cable/conductor manufacturing, etc., can solve the problems of not mentioning the winding direction of insulating tape or metal foil tape, not mentioning multi-core cables, etc., and achieve reduction The effect of small incidence rate, reduced skew, and reduced difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

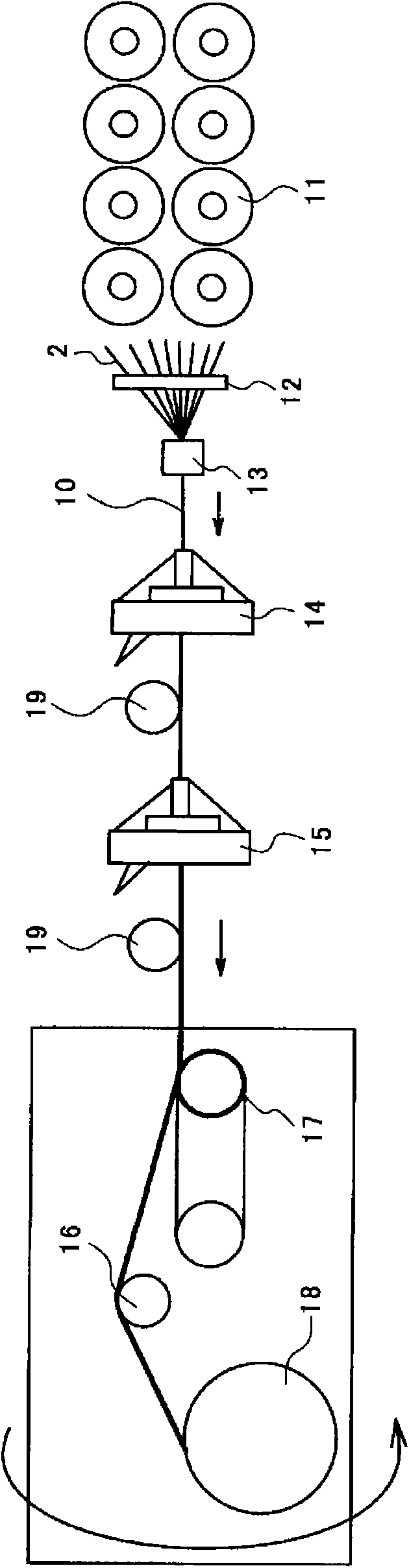

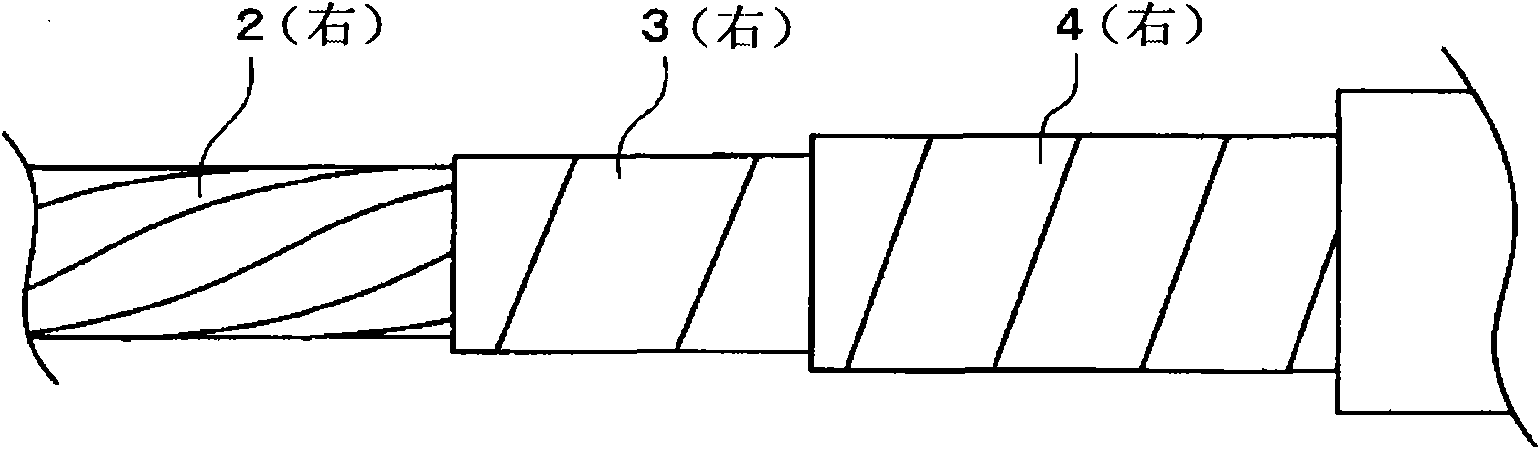

[0012] Hereinafter, preferred embodiments of the present invention will be described based on the accompanying drawings. The drawings are provided for the purpose of explaining the embodiments and are not intended to limit the scope of the invention. In the drawings, the same symbols denote the same elements, so that repeated explanations may be omitted. The dimensional ratios in the drawings are not always accurate.

[0013] In the multi-core cable described in Patent Document 1, a twisted-pair cable is used as a core cable, and the cross-sectional shape of a core unit formed of the core cable is close to a circle. Thus, the metal foil tape can be wound with relatively uniform force. However, when two signal conductors arranged in parallel are used as a core cable without being twisted to reduce the incidence of skew, the core unit formed by the core cable will have a profile that changes in the longitudinal direction. In this case, when the insulating tape and the metal foil

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap