Graphene processing for device and sensor applications

a technology of graphene and sensor, applied in the direction of instruments, transportation and packaging, coatings, etc., can solve the problems of difficult control of the number of graphene layers and grain sizes, limited to the tedious fabrication of devices for research purposes, and the difficulty inherent in the method of dispersing graphene in solution separation of layers without breaking layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

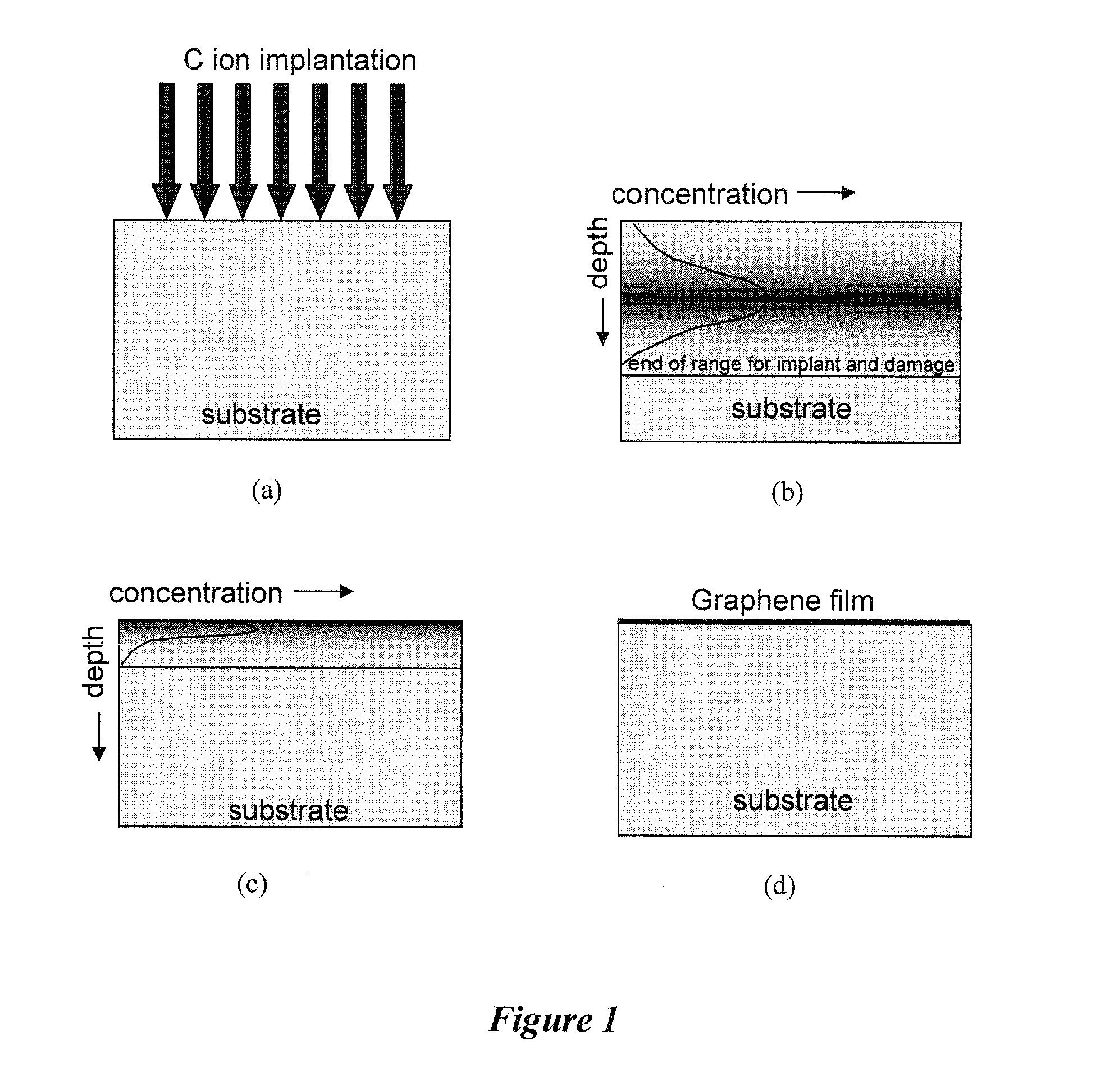

[0010]One embodiments of the invention is directed to methods for fabricating graphene layers of a controlled-thickness over large areas on a substrate. Another embodiment of the invention is directed to methods for fabricated patterned graphene layers of a controlled-thickness. Other embodiments of the invention are directed to devices useful for sensor or other applications that are formed by these methods of forming graphene layers. The devices can be fabricated using conventional semiconductor technologies or ion beam processing methods, see for example Ion Implantation and Beam Processing, J. S. Williams et al., ed., Academic Press 1984, where the graphene layers form single device features or integrated circuits.

[0011]In one embodiment of the invention, solid phase epitaxy (SPE) is employed on a substrate that has ion implanted carbon. By heating a single crystalline carbon implanted silicon or germanium in the volume near the surface to elevated temperatures, for example 500° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap