Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Continuous annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous annealing. Annealing is a process in which metals, glass and other materials are treated to render them less brittle and more workable. Continuous steel annealing subjects rolled strip product to a sequence of furnaces to elevate and profile the strip temperature according to grade and dimension.

Control method for cold-rolled product size precision

ActiveCN107442576AHigh dimensional accuracyHigh yieldMetal rolling stand detailsRoll mill control devicesRegression analysisContinuous annealing

The invention relates to the field of cold rolling, in particular to a control method for the cold-rolled product size precision. The control method comprises the steps that regression analysis is conducted on relevant parameters of the raw material texture, an acid pickling and cold rolling technology of an acid pickling and cold rolling unit and a continuous annealing technology of a continuous annealing unit by adopting a five-stand six-roll UCM rolling mill, and a final reasonable regression equation and main influence factors are determined through multiple times of analysis and selection. According to the control method, the improving direction is provided for size precision control of various cold-rolled varieties, main points of new variety size precision control and size precision control of all unit products obtained after technology optimization are adjusted, and the good guiding significance is achieved. In addition, reference is provided for galvanized product size precision control according to analysis on the factors influencing the product size precision.

Owner:BENGANG STEEL PLATES

High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

ActiveCN106868403AImprove performanceGood coating performanceHot-dipping/immersion processesFurnace typesSteelmakingHigh surface

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Continuous spheroidizing annealing method for high-carbon chromium bearing steel round steel

PendingCN114107626AImprove uniformityPromote the transformation of globularizationBrinellingHeat conservation

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

Energy-saving and consumption-reducing cable conductor manufacturing method

InactiveCN109698048AReduce gapQuality improvementCable/conductor manufactureWinding machineElectrical conductor

The invention provides an energy-saving and consumption-reducing cable conductor manufacturing method. The cable conductor manufacturing method includes the following steps: round copper rods are drawn into copper wires, the copper wires are continuously annealed into soft copper wires by using a continuous annealing copper wire drawing machine, and the soften copper wires are wound by an I-shapedwheel; a stranding machine can adjust pitch, rotation direction, PLC man-machine interface control, and polycrystalline drawing die on each segment; the copper wires on the I-shaped wheel wound wiresare on the frame type stranding machine, the pitch diameter ratio of each outer layer is not greater than the pitch diameter ratio of the inner layer, and the cable conductors are twisted into a strand; and the cable conductors twisted into a strand are stored in a cable tool disk by a tractor and a winding machine. The advantages of the energy-saving and consumption-reducing cable conductor manufacturing method are that the cable conductor is of a special-shaped single-filament stranded structure and has the advantages of reduced gaps between filaments, smooth, bright and round appearance, reduced diameter, improved density, more stable resistance and improved cable quality, and the method reduces the consumption of materials and increases the economic benefit of an enterprise.

Owner:SHANDONG JINYUAN COPPER CO LTD

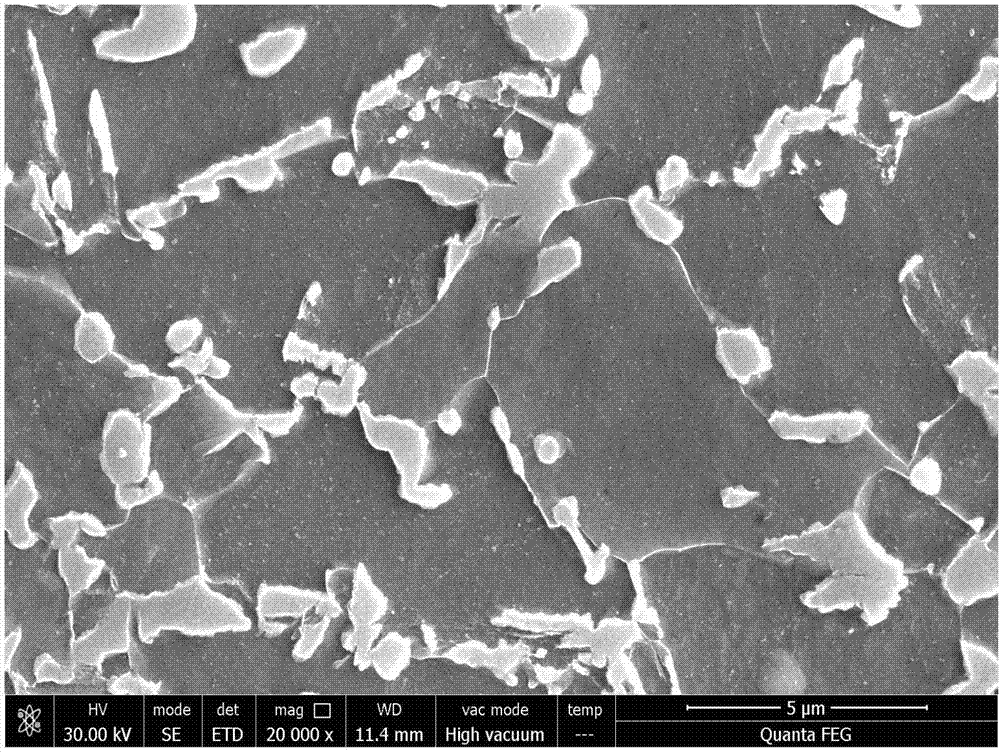

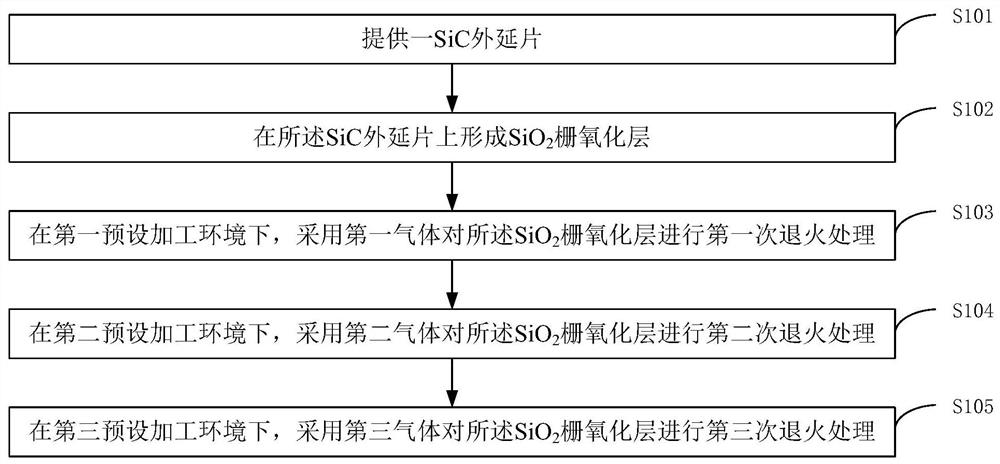

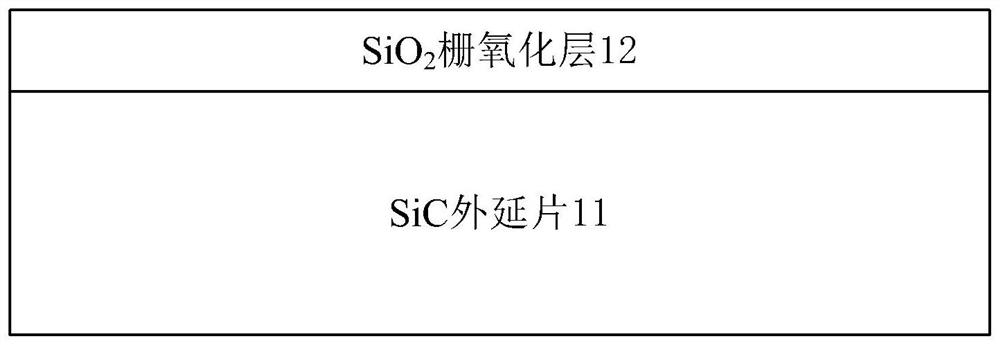

Method for improving reliability of gate oxide layer in SiC field effect transistor

PendingCN114783862AImprove performanceReduce C-related defectsSemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryEngineering

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap