Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Corrosion resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion resistance. noun. The definition of corrosion resistance refers to how well a substance (especially a metal) can withstand damage caused by oxidization or other chemical reactions. An example of corrosion resistance is when a boat is treated to prevent rust and is thus able to withstand damage.

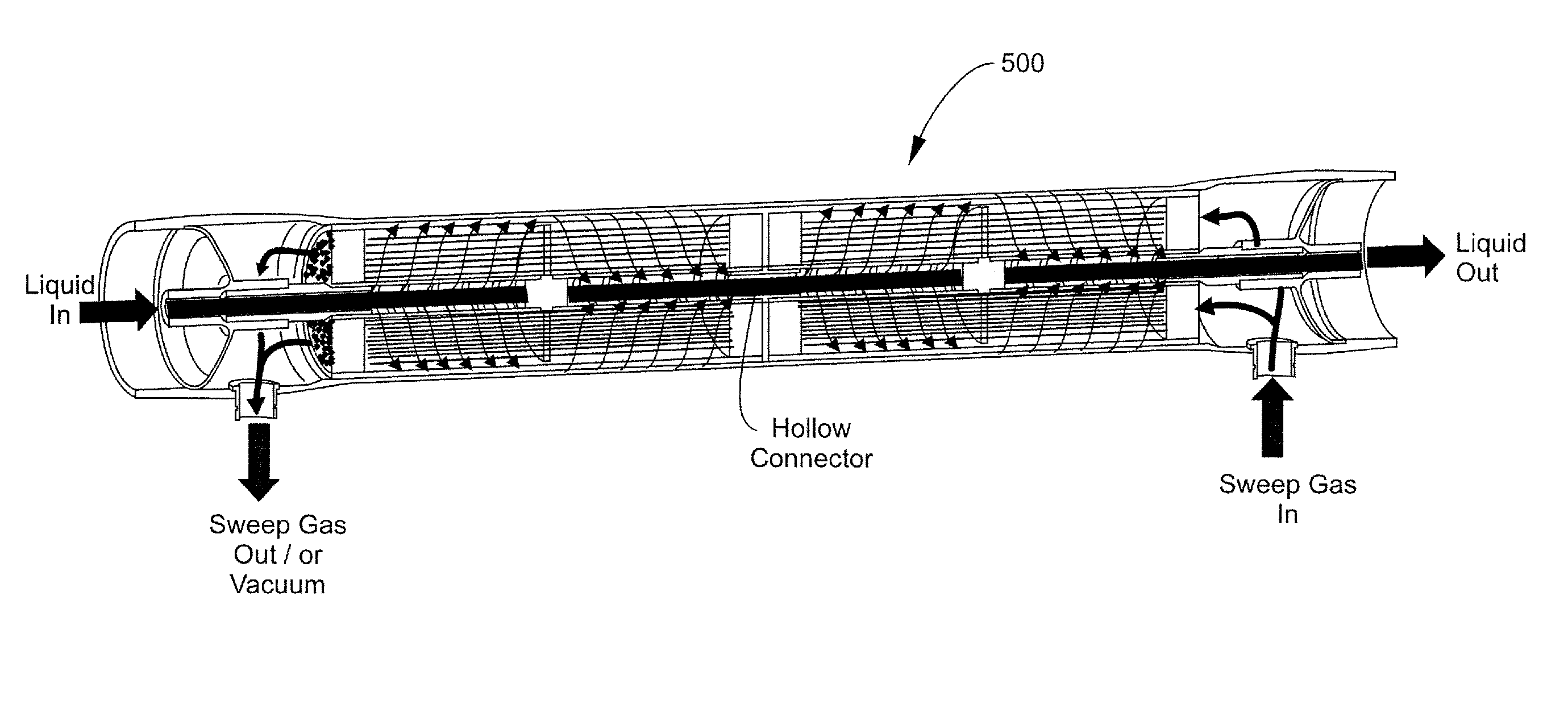

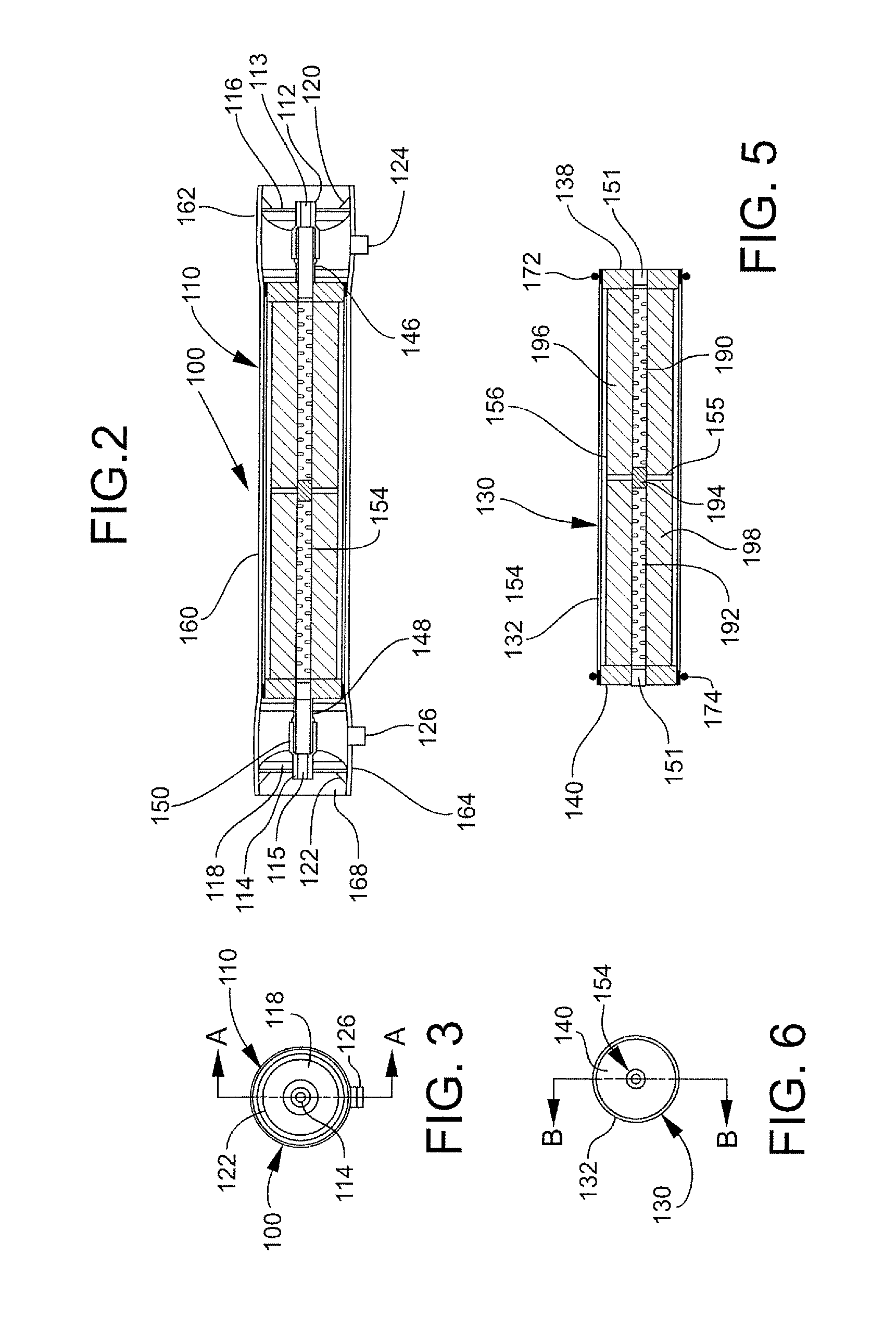

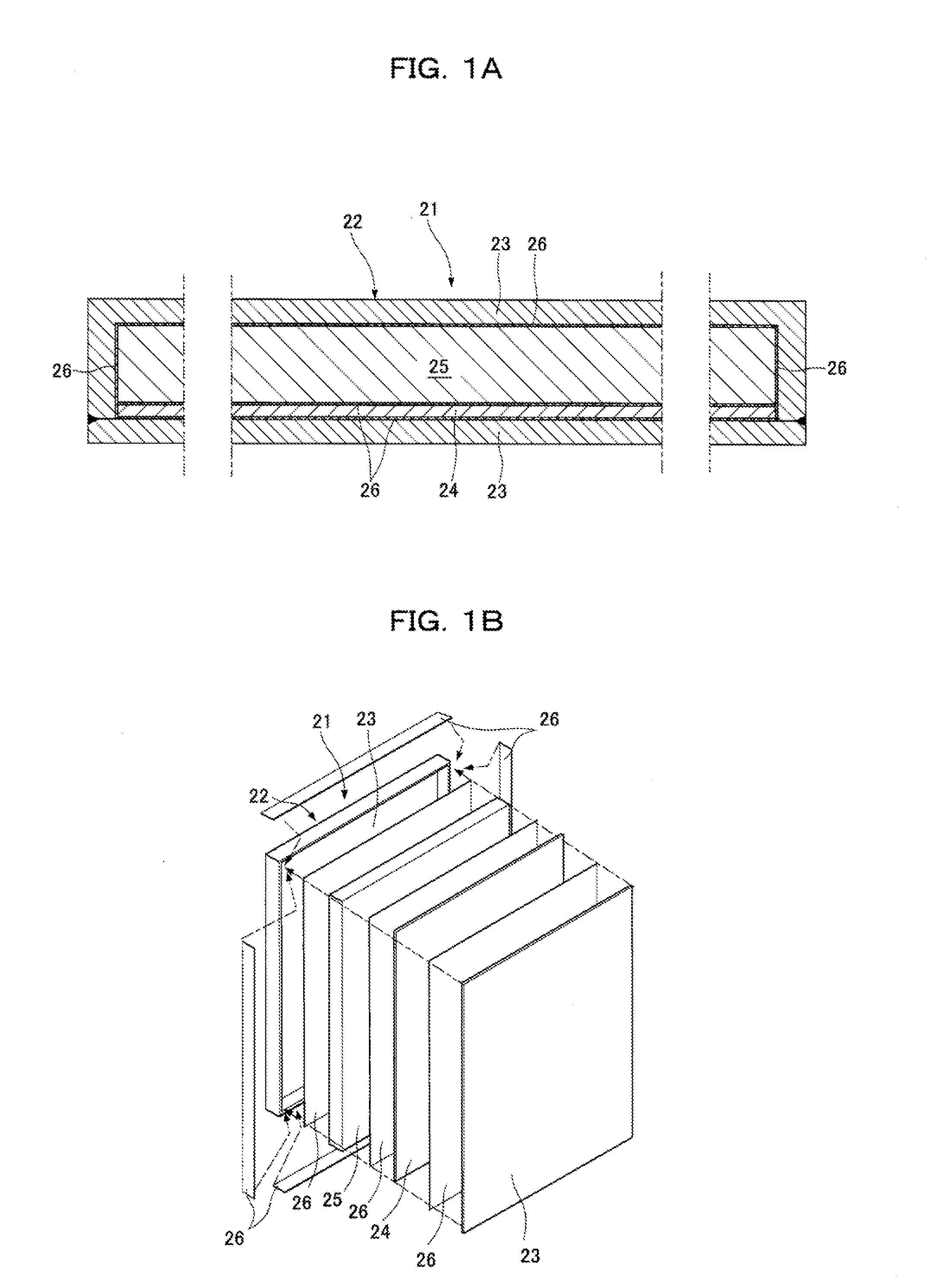

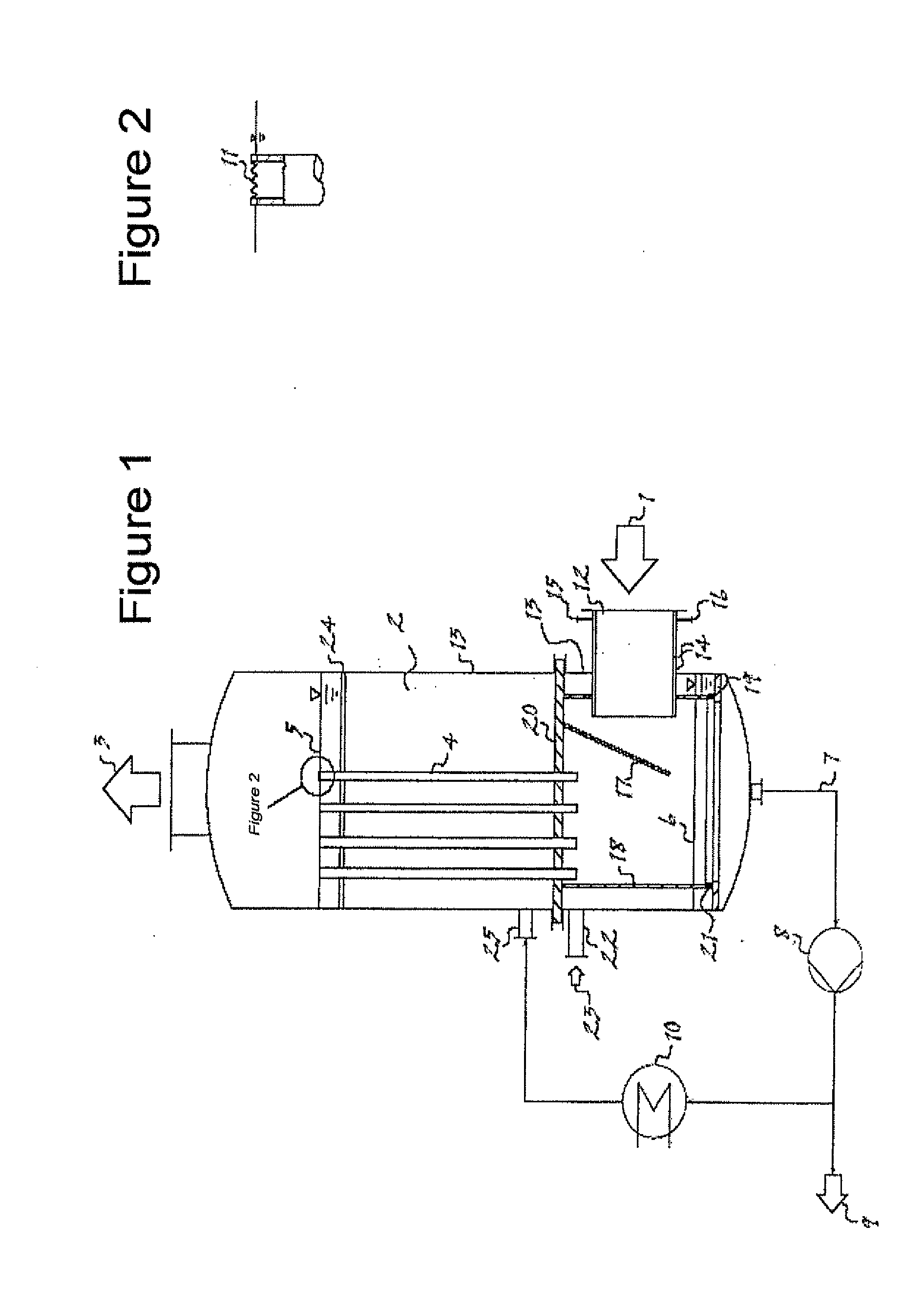

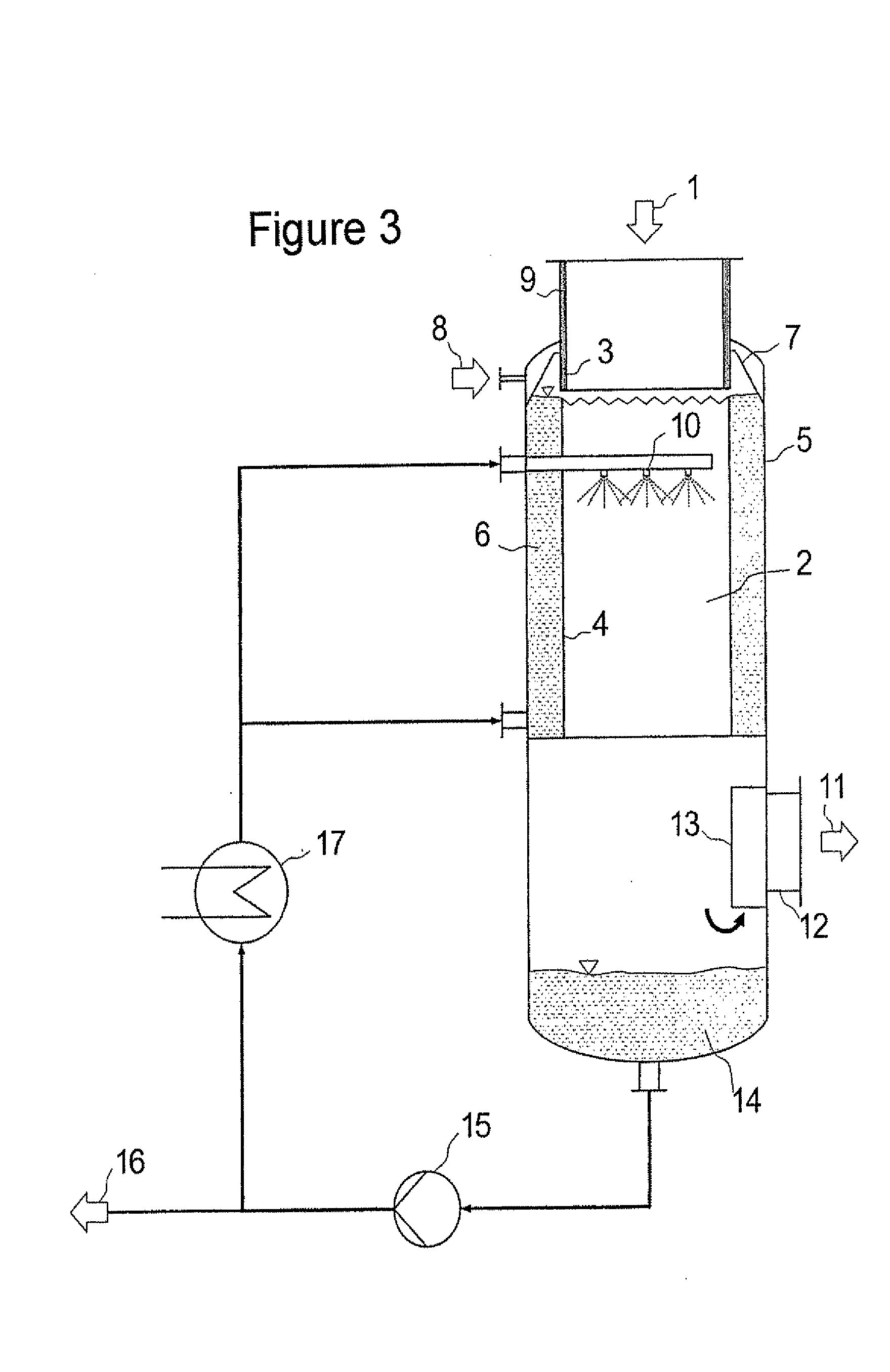

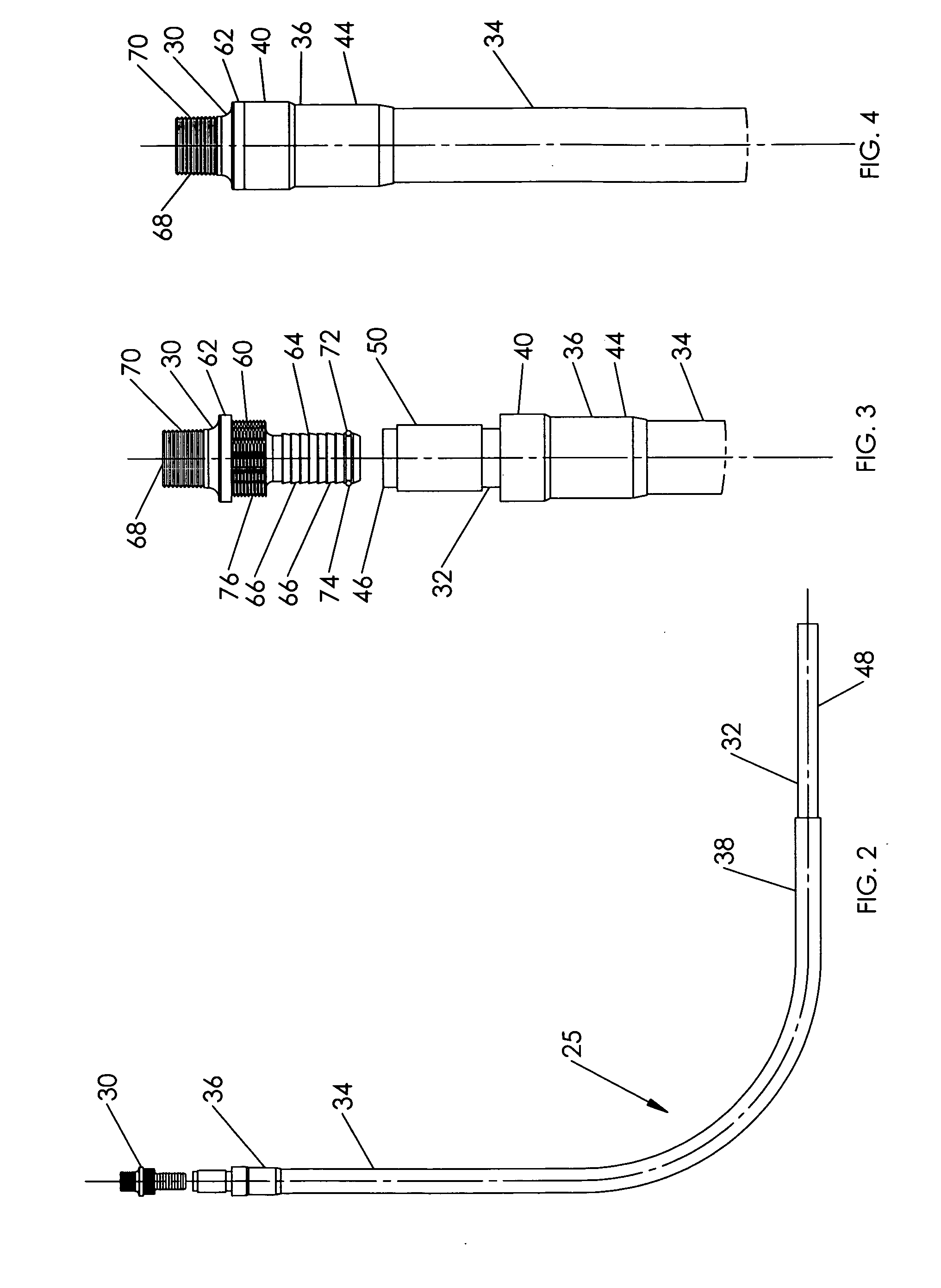

High pressure liquid degassing membrane contactors and methods of manufacturing and use

ActiveUS20110036240A1Fast displacementCost-effectiveMembranesIsotope separationPolypropyleneCorrosion resistant

Owner:3M INNOVATIVE PROPERTIES CO

Rare earth aluminum alloy wire for thermal spraying

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

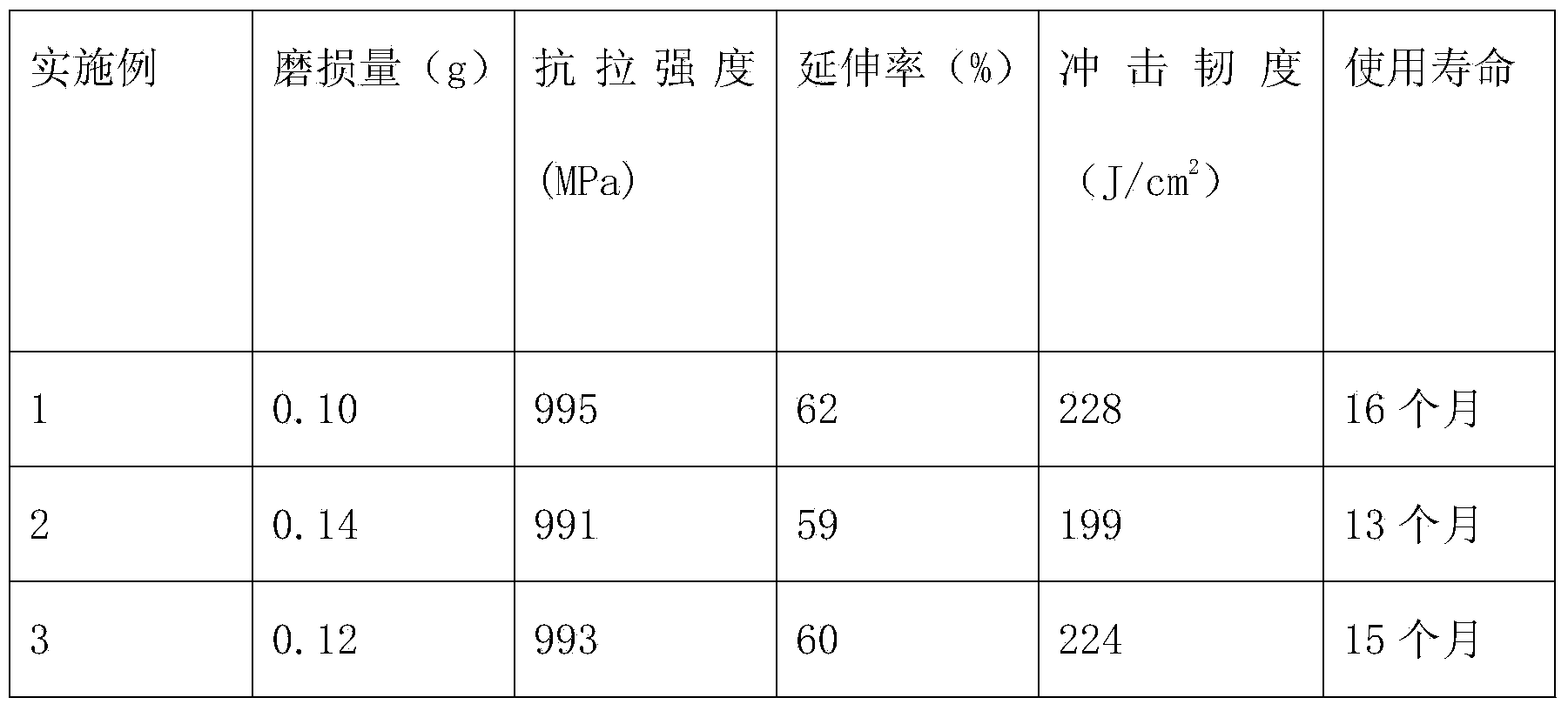

Biodegradable medical magnesium alloy as well as preparation method thereof

The invention discloses a biodegradable medical magnesium alloy which consists of the following matters in percentage by weight: 1.0-3.0% of Zn, 0.20-1.50% of Y, 0.40-1.50% of Nd, 0.30-0.50% of Zr and the balance of Mg and inevitable impurity elements. Meanwhile, the invention discloses a preparation method of the alloy. The magnesium alloy is smelted to prepare common magnesium alloy. The use level of Zn, Y and Nd in furnace burden is 1.2-1.4 times the content of Zn, Y and Nd in the magnesium alloy, and the use level of Zr is 2-2.5 times the content of Zr in the magnesium alloy. According to the invention, the magnesium alloy overcomes the problems of cytotoxicity, excessively high corrosion rate and the like by adding rare earth elements Y, Nd and Zr into a magnesium-zinc alloy, and the potential difference with a matrix is reduced due to a lot of uniformly dispersed and distributed nano MgZn particle phases in the matrix by extrusion and processing, so that the corrosion resistance of the alloy is greatly improved, and the alloy has better mechanical properties.

Owner:ZHENGZHOU UNIV

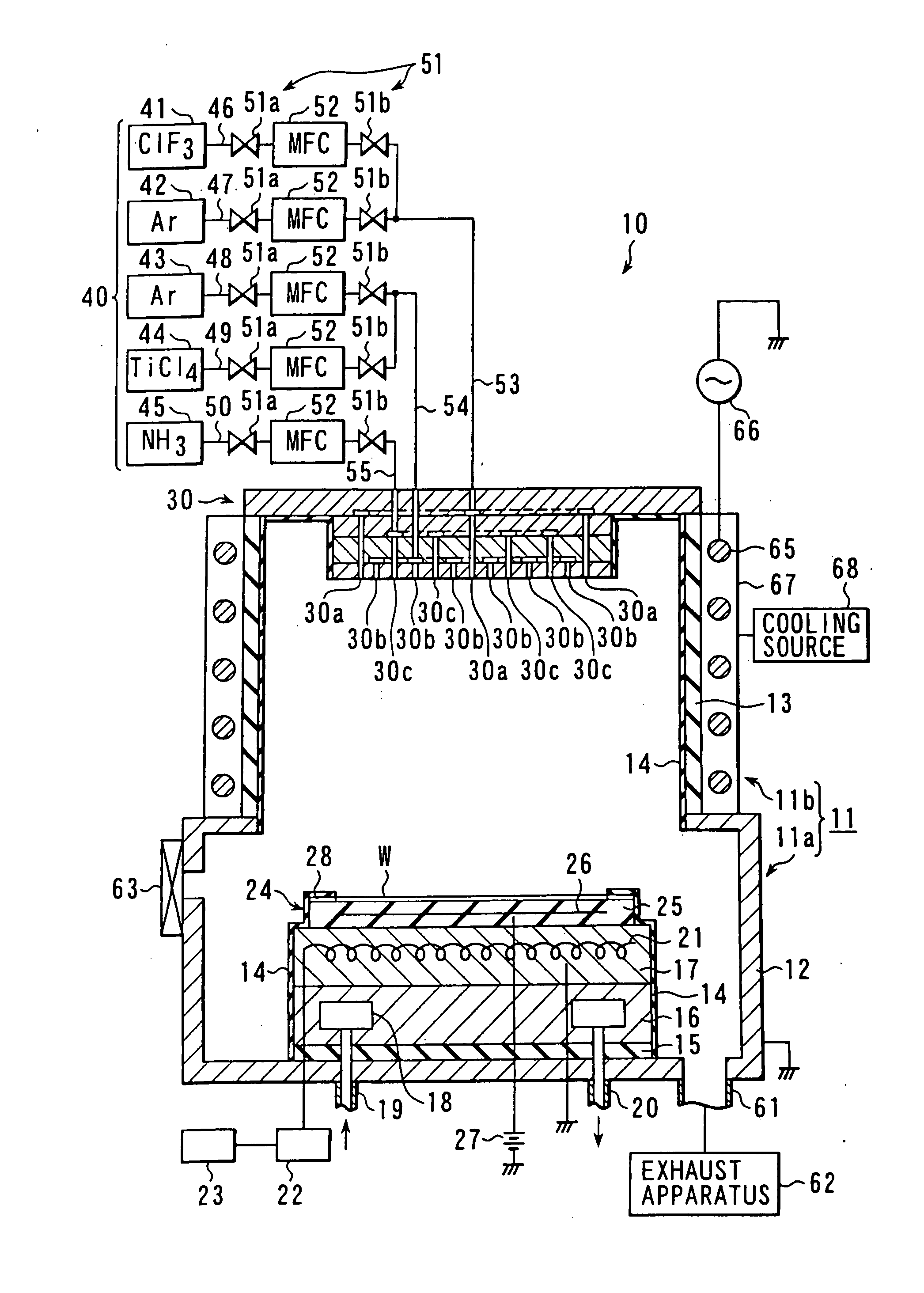

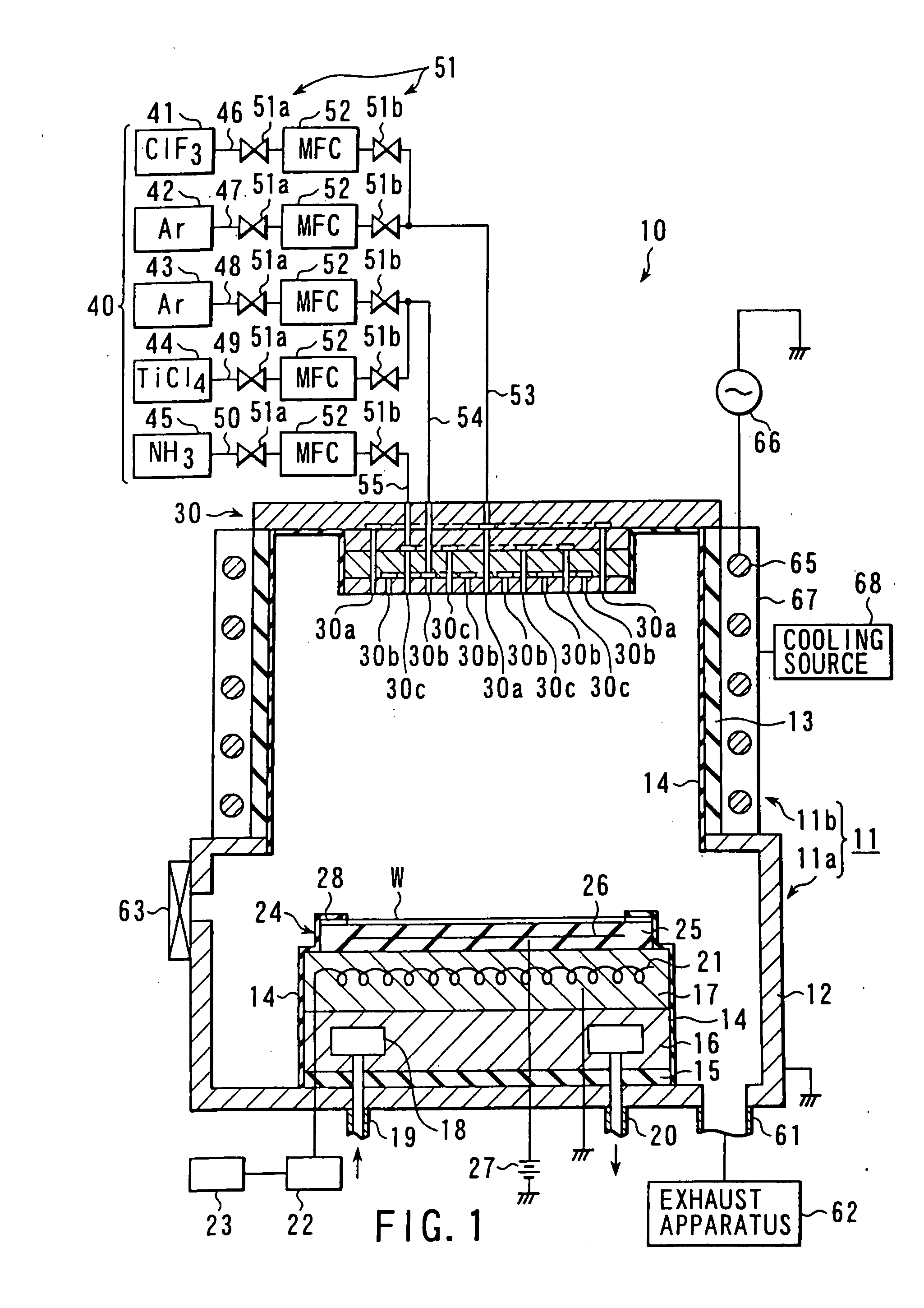

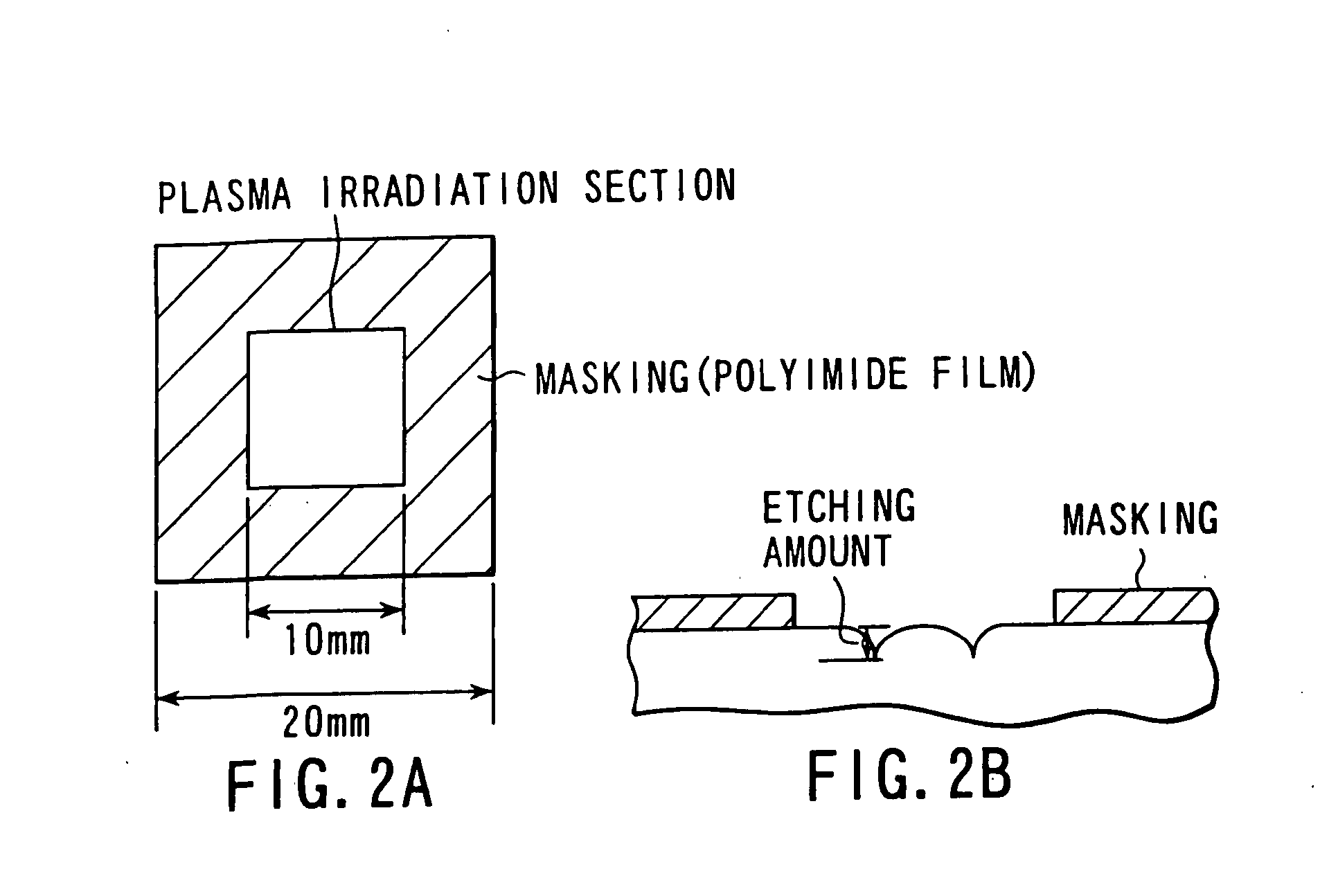

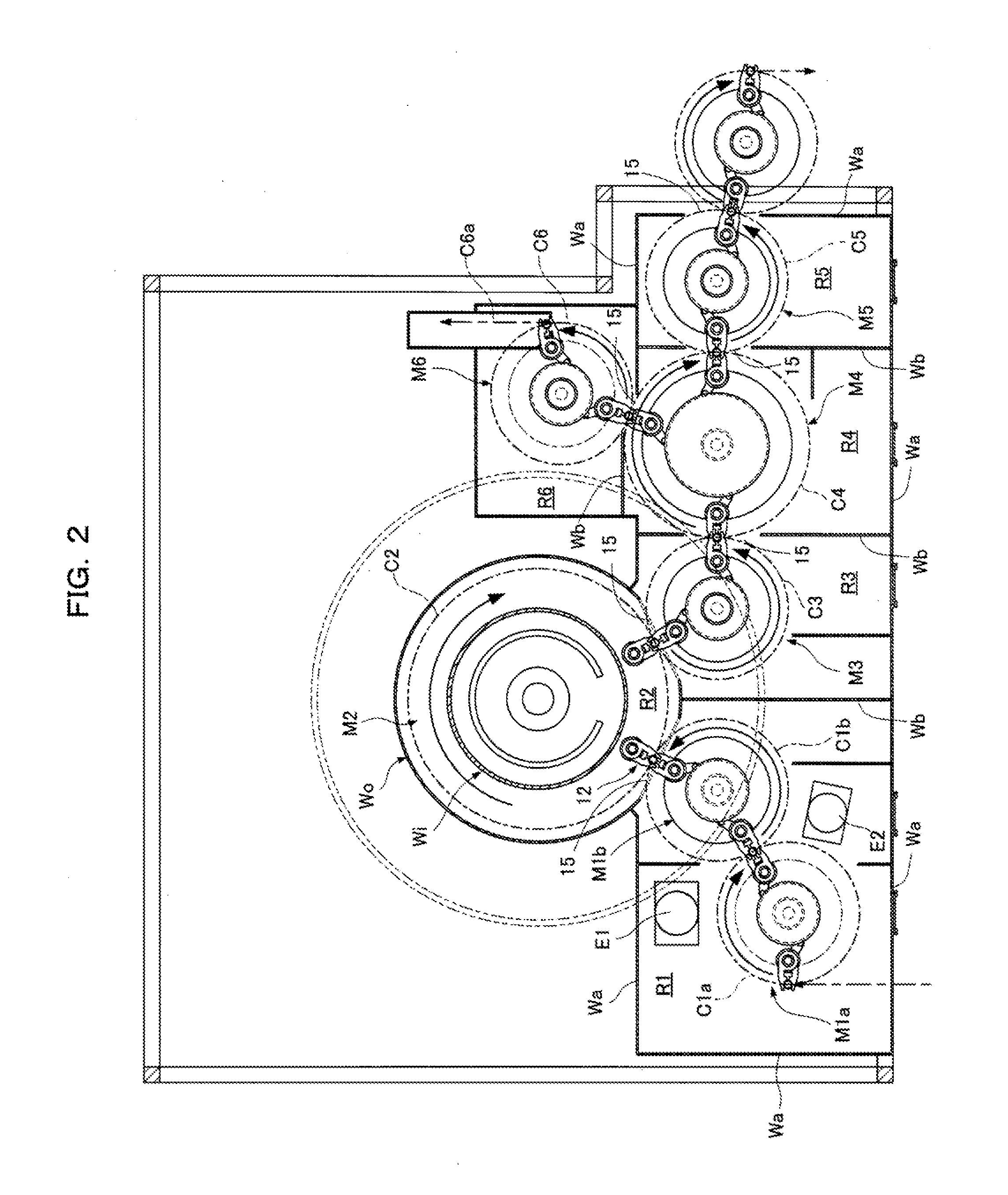

Processing apparatus with a chamber having therein a high-corrosion-resistant sprayed film

InactiveUS20080070032A1High-corrosion-resistant propertyLess depositionLiquid surface applicatorsMolten spray coatingCorrosion resistantEngineering

A processing apparatus of the present invention has a mounted chamber holding a semiconductor wafer and having members for work-processing the substrate under any of heating, plasma and process gas or a combination of them, in which a film of Al2O3 and Y2O3 is formed on an inner wall surface of the chamber and on those exposed surface of the members within the chamber and has a high-corrosion resistance and insulating property and, when the process gas is introduced onto a processing surface of a semiconductor wafer and diffused into it, any product is less liable to be deposited on a plasma generation area and on those members held within the chamber.

Owner:TOKYO ELECTRON LTD

Magnesium alloy surface zinc-calcium series phosphating solution and conversion treatment process thereof

InactiveCN101671824AImprove corrosion resistanceStrong adhesionMetallic material coating processesMg alloysPhosphate

The invention discloses magnesium alloy surface zinc-calcium series phosphating solution and a conversion treatment process thereof; the magnesium alloy surface phosphating solution is aqueous solution formed by the following constituents, namely, every liter solution contains: 10-30g of disodium hydrogen phosphate, 4-6g of zinc nitrate, 2-4g of sodium nitrite, s0.5-2g of sodium fluoride, and 0.-2g of calcium nitrate; the process for carrying out surface conversion treatment to the phosphating solution comprises the following process flows: alkaline washing and degreasing->rinsing->acidity activation->rinsing->surface activation->rinsing->phosphating->rinsing->drying; the working temperature is 40-70 DEG C, and the time is 5-60 minutes. The conversion treatment process can obtain phosphateconversion coating on the surface of the magnesium alloy, wherein the conversion coating has good protectiveness, is fine and uniform and stable, and has strong adhesive force, and can improve the corrosion-resisting property of magnesium alloy parts; the conversion treatment process is stable and easy to control, and has low cost.

Owner:CHONGQING UNIV OF TECH

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

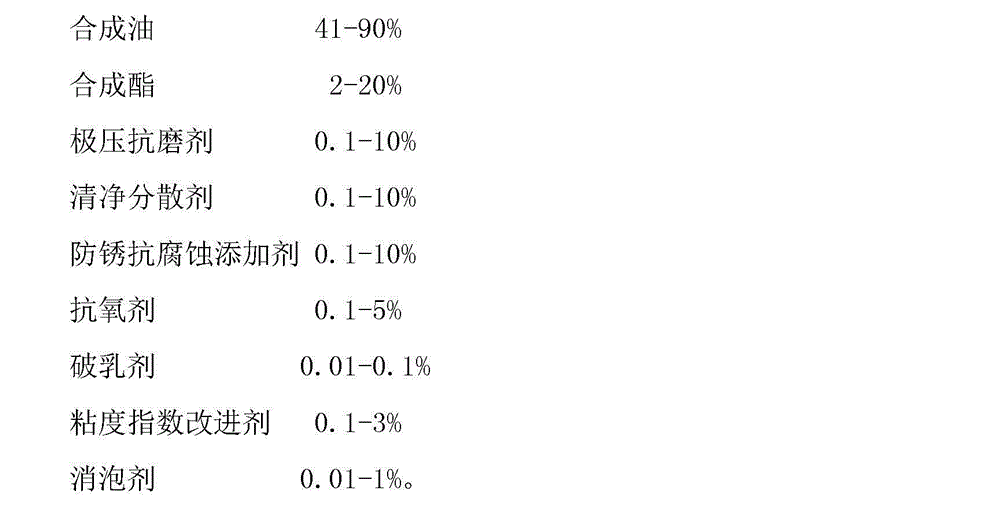

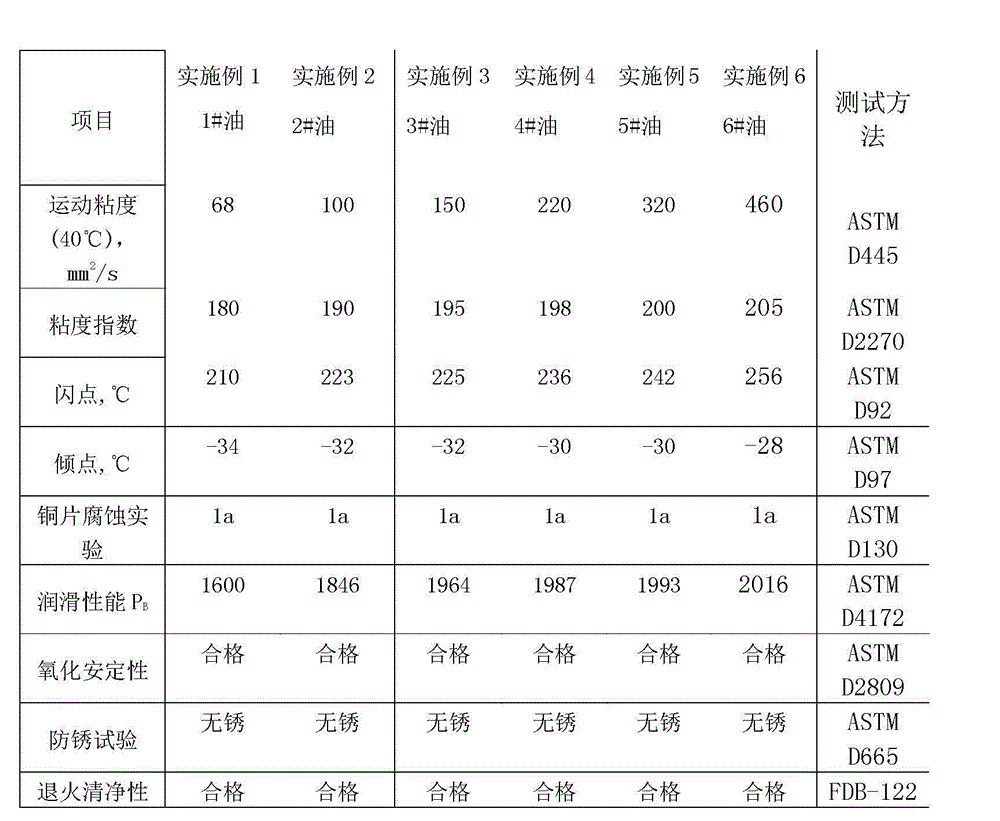

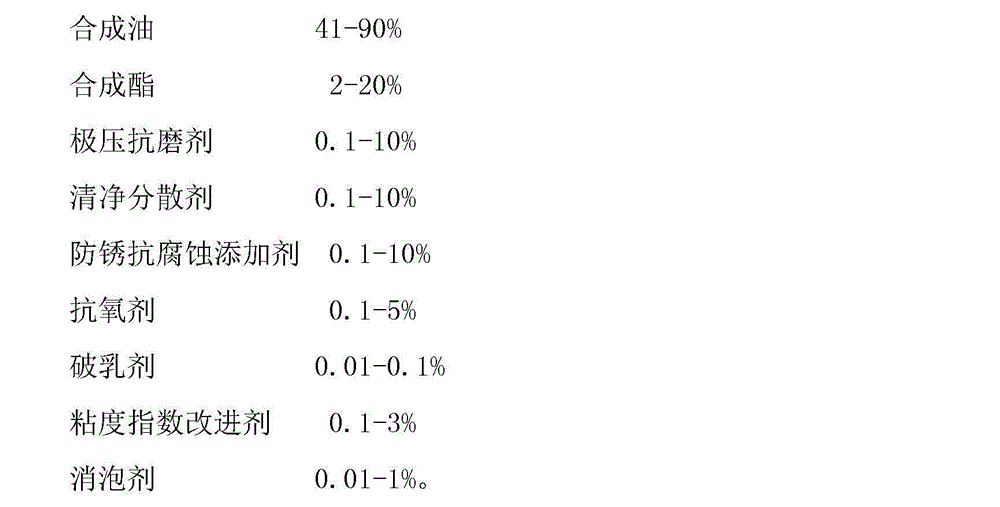

Totally synthetic non-staining bearing oil

InactiveCN102719305AReduce the temperatureImprove surface qualityLubricant compositionAntioxidantEngineering

Owner:上海福岛新材料科技有限公司

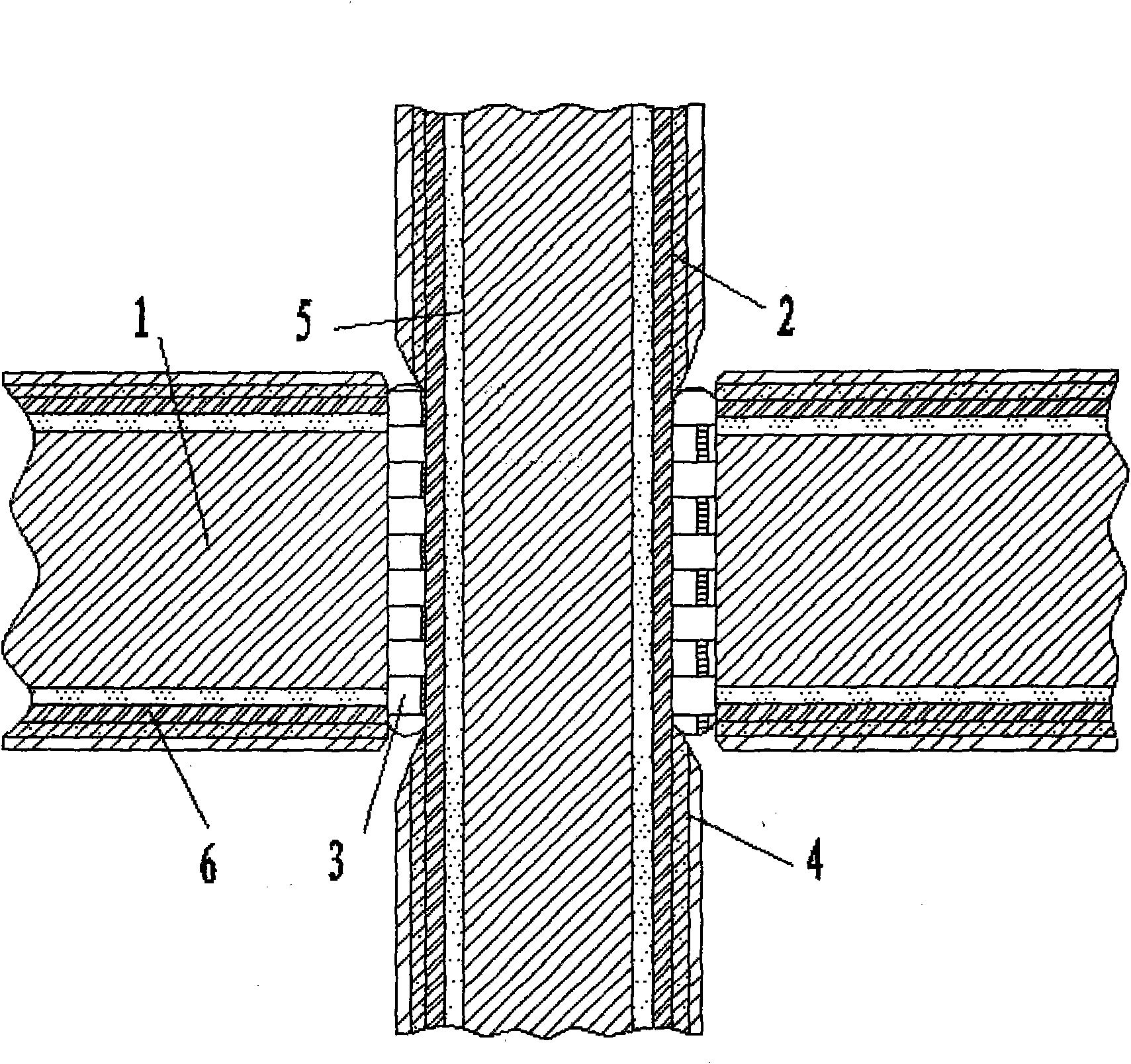

Mineral methane gas drainage pipe and production method thereof

ActiveCN103195988AReduce weightImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationHigh pressureMethane gas

Owner:河北拓安管业有限公司

A microwave-absorbing corrosion-resistant powder material and a preparation method thereof

InactiveCN108889939AReduce self-healing abilityMaintain electromagnetic propertiesOther chemical processesTransportation and packagingMesoporous silicaMetal particle

The invention discloses a corrosion-resistant powder material capable of absorbing microwave and a preparation method thereof, wherein the powder material is a core-shell structure, the core-shell structure comprises a shell and a core, the shell is a mesoporous silicon dioxide layer, the core is magnetic metal particles, a corrosion inhibitor is filled between the shell and the core, and the particle size of the magnetic metal particles is 0.6 1 micron, is iron carbonyl and nickel carbonyl, or a composite of iron carbonyl and cobalt carbonyl, the weight ratio of iron carbonyl to nickel or cobalt is 8: 1 4: 1. The invention can effectively solve the problems of insufficient microwave absorption and deterioration of corrosion resistance of conventional coatings.

Owner:SHANDONG GEWU NEW MATERIAL TECH CO LTD

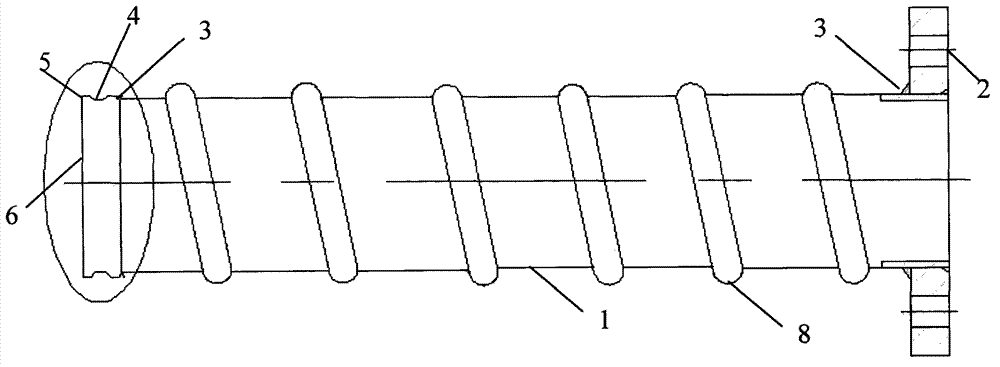

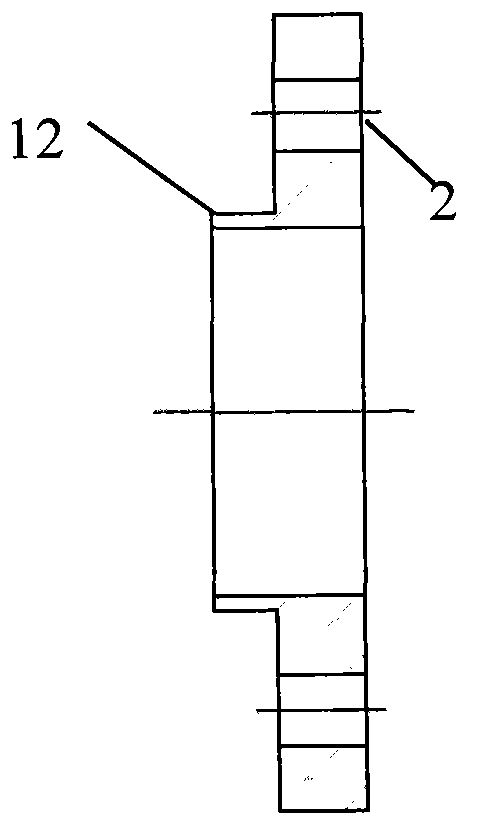

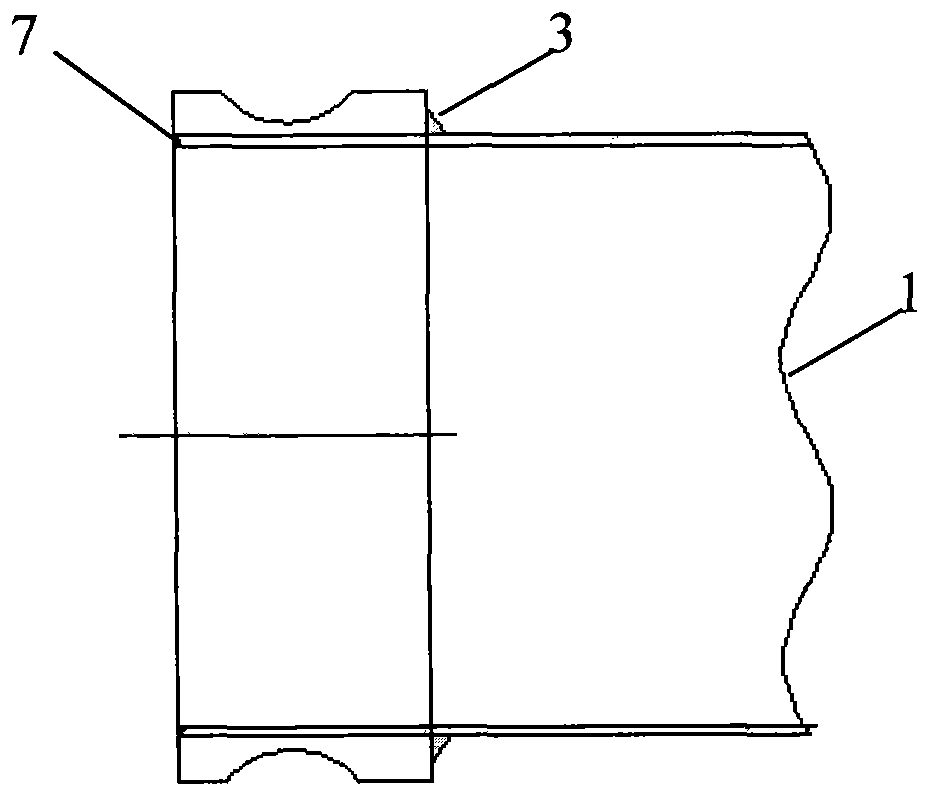

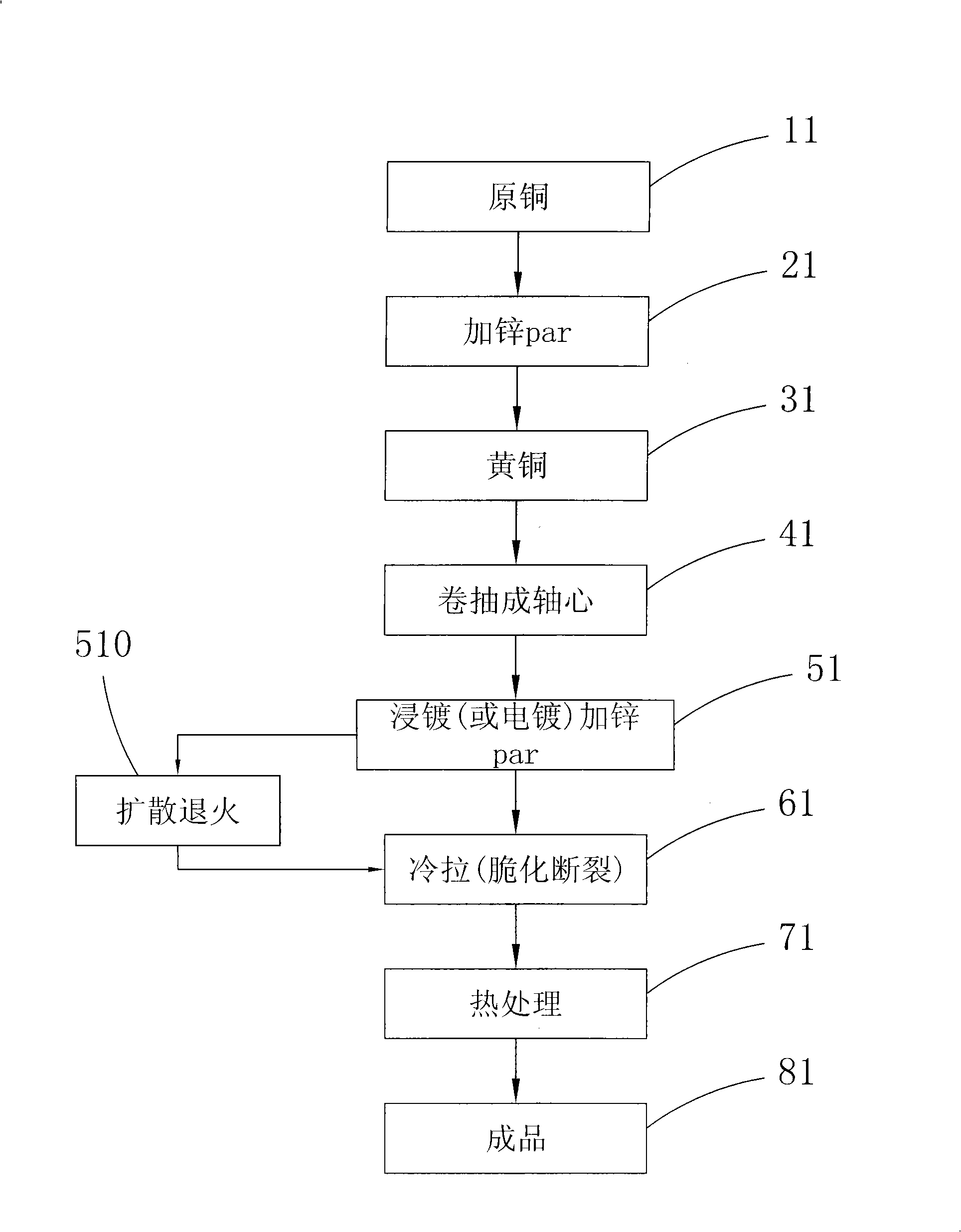

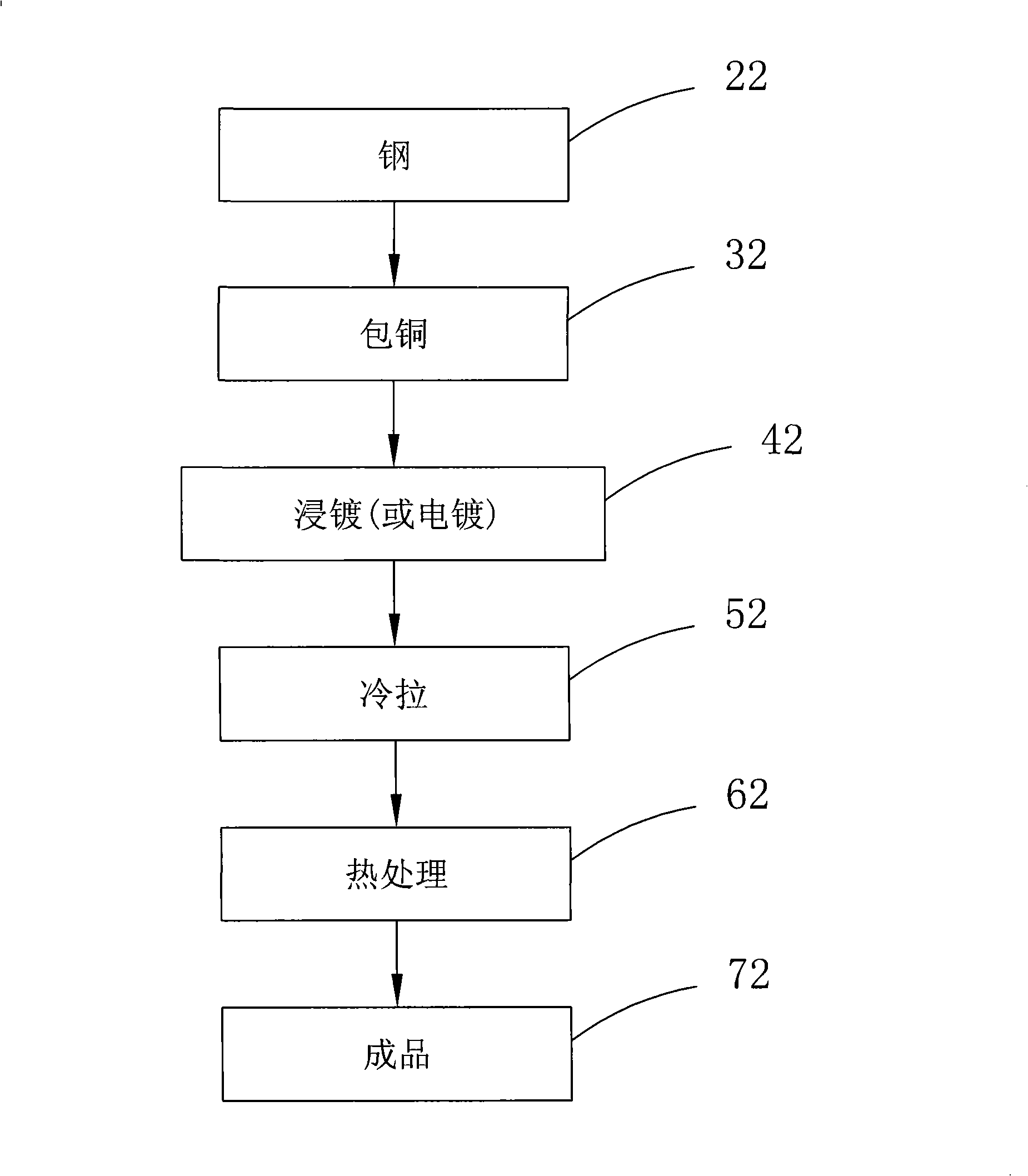

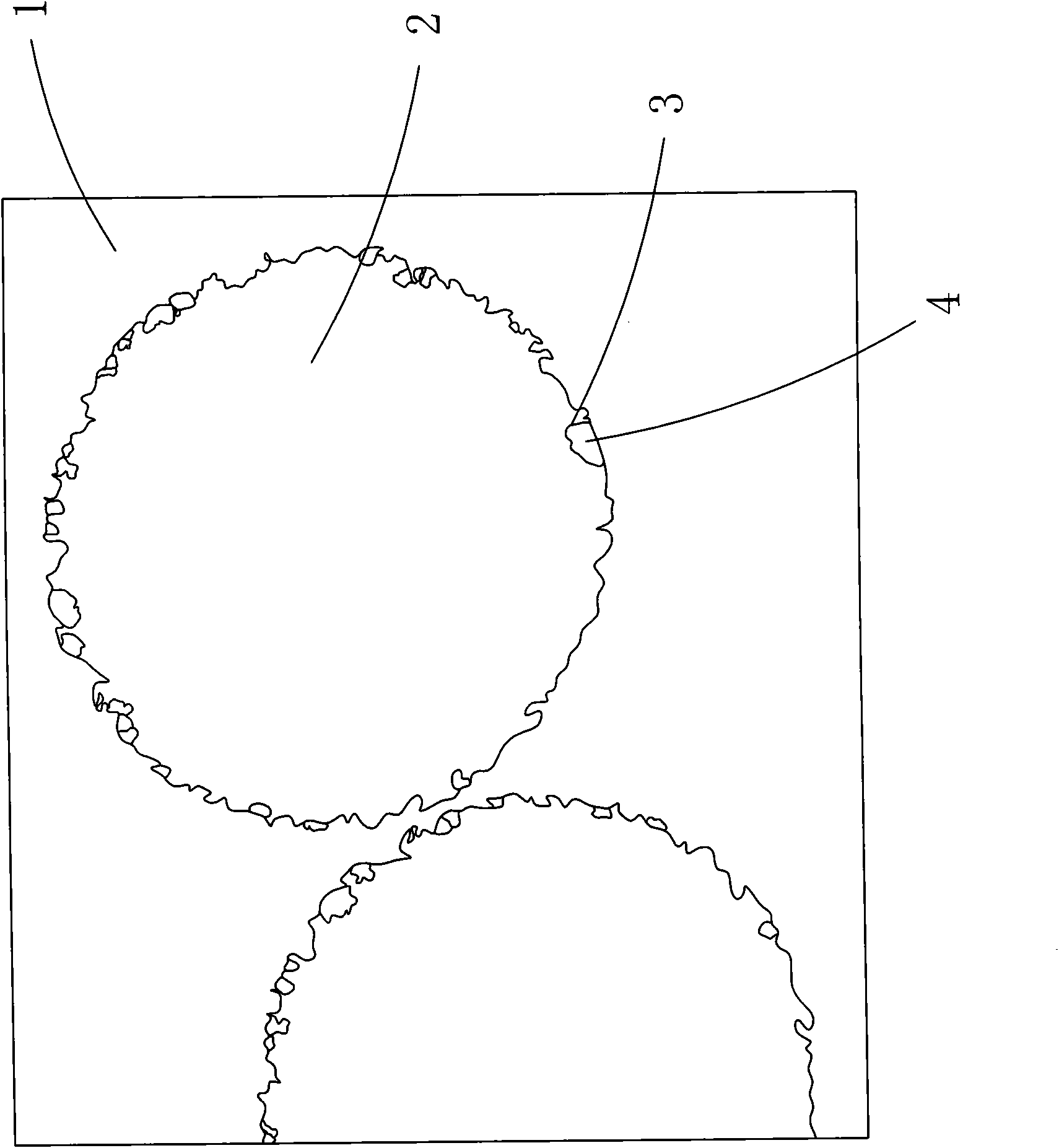

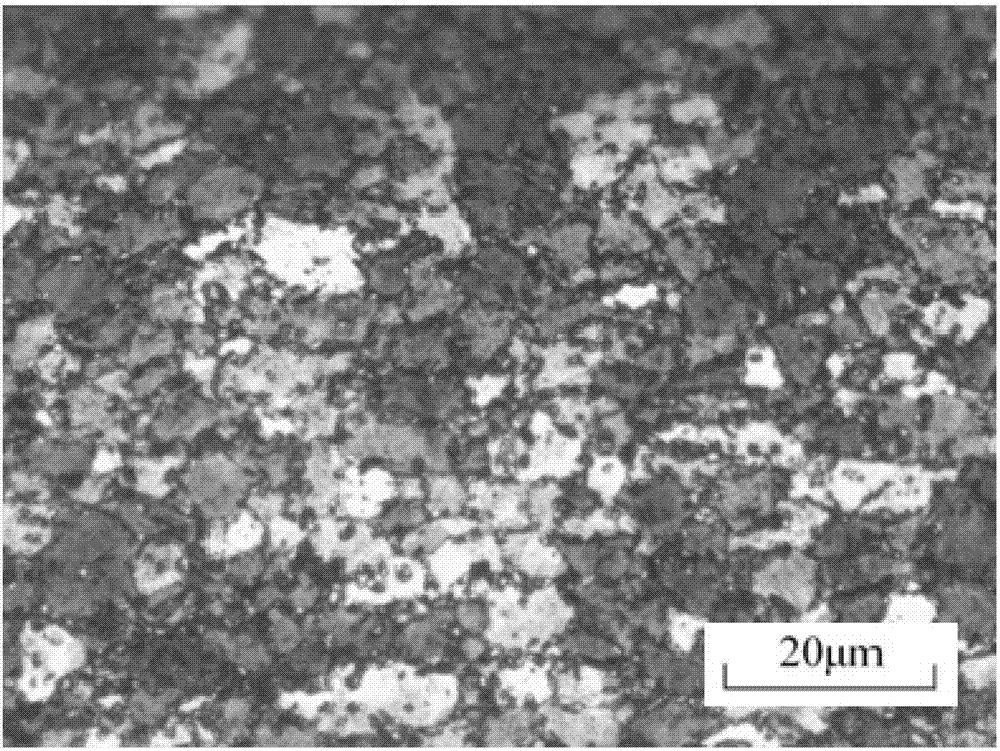

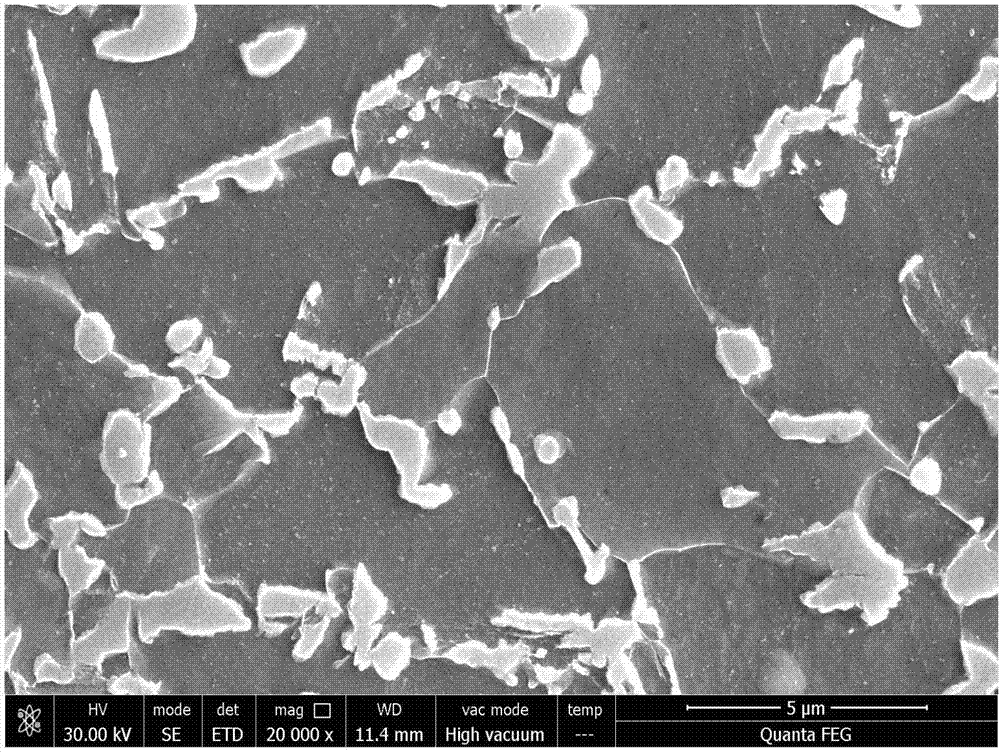

Method for manufacturing cutting line of electrical discharge machine

InactiveCN101537519AMachining electrodesElectrical-based machining electrodesCorrosion resistantMetal alloy

Owner:张国大

High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

ActiveCN106868403AImprove performanceGood coating performanceHot-dipping/immersion processesFurnace typesSteelmakingHigh surface

Owner:MAGANG (GROUP) HOLDING CO LTD +1

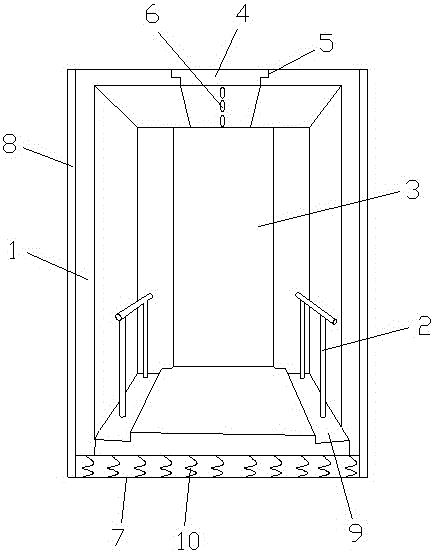

Elevator car

InactiveCN106467265ACorrosion-resistantKeep the structure corrosion resistantBuilding liftsEngineeringLED lamp

Owner:成都聚立汇信科技有限公司

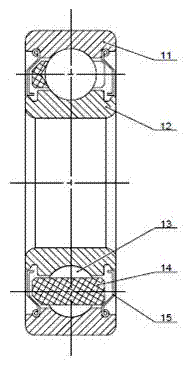

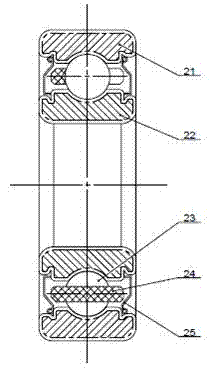

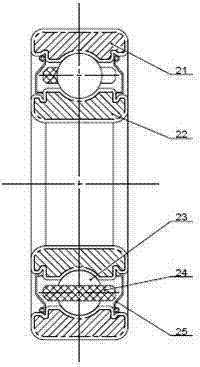

Carbon-graphite keeper rolling bearing used for performing protection and antifriction treatment and manufacturing method of carbon-graphite keeper rolling bearing

InactiveCN102562813ANo corrosionImprove operational reliabilityBearing componentsRolling-element bearingCarbon graphite

Owner:SHANGHAI F&S BEARING TECH

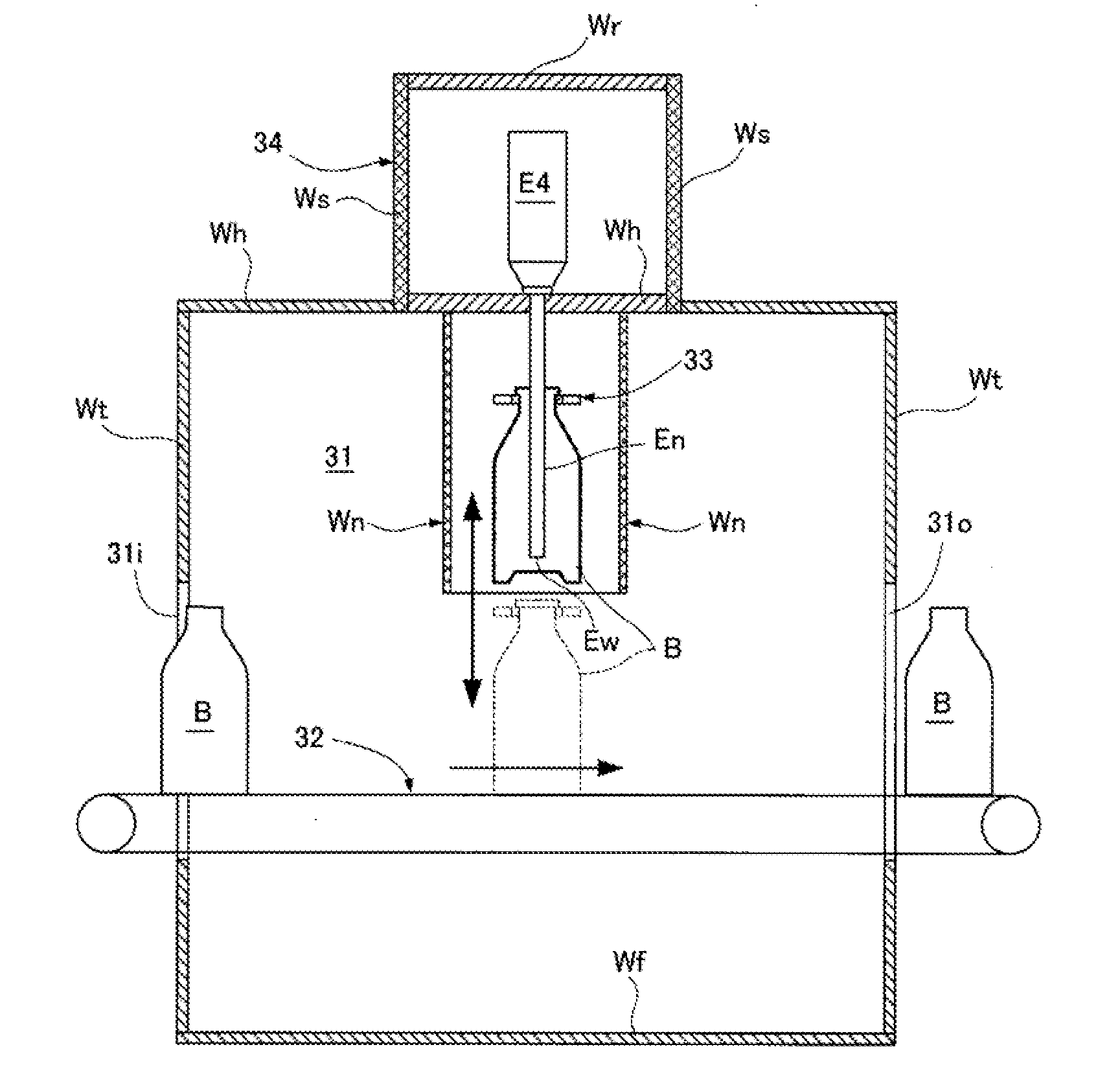

Shield and electron beam container sterilization equipment

ActiveUS20160083131A1Avoid corrosionEasy to manufacturePackage sterilisationMaterial analysis by optical meansCorrosion resistantEngineering

Owner:HITACHI ZOSEN CORP

Nickel-chromium-molybdenum-niobium corrosion resistant welded alloy and manufacturing method thereof

Owner:DANYANG XINHANG SPECIAL ALLOY

Method for preparing cobalt-based wear-resistant and corrosion-resistant coating layer by adopting ultra-high speed laser cladding

InactiveCN108118334ASmall amount of deformationNot easily oxidizedMetallic material coating processesUltra high speedWear resistant

The invention relates to a method for preparing cobalt-based wear-resistant and corrosion-resistant coating layer by adopting ultra-high speed laser cladding and belongs to the technical field of surface treatment. Through methods of selecting appropriate cobalt-based alloy powder, adjusting the positions of a powder convergence point and a laser focus, adjusting process parameters and the like, the cobalt-based wear-resistant and corrosion-resistant coating layer with good surface evenness and small thickness and without defect can be quickly and accurately produced, so that the ultra-high speed laser cladding is realized, and the purposes of improving the production efficiency and reducing the production cost are achieved.

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD

Preparation method for tungsten-nickel alloy with abrasion-resistant and corrosion-resistant coating

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

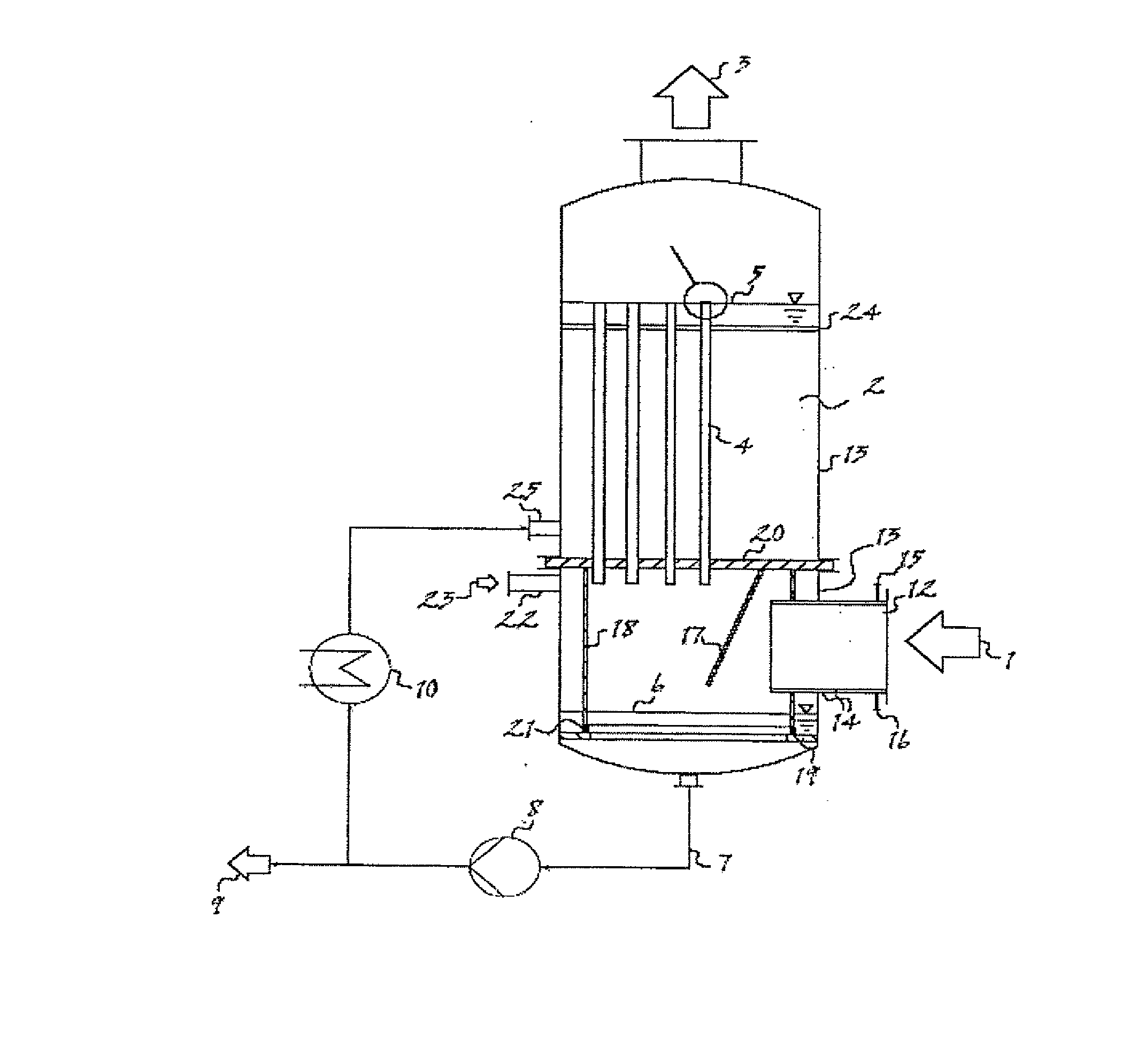

Devices for cooling gases which form a corrosive condensation product upon cooling

Owner:BAYER MATERIALSCIENCE AG

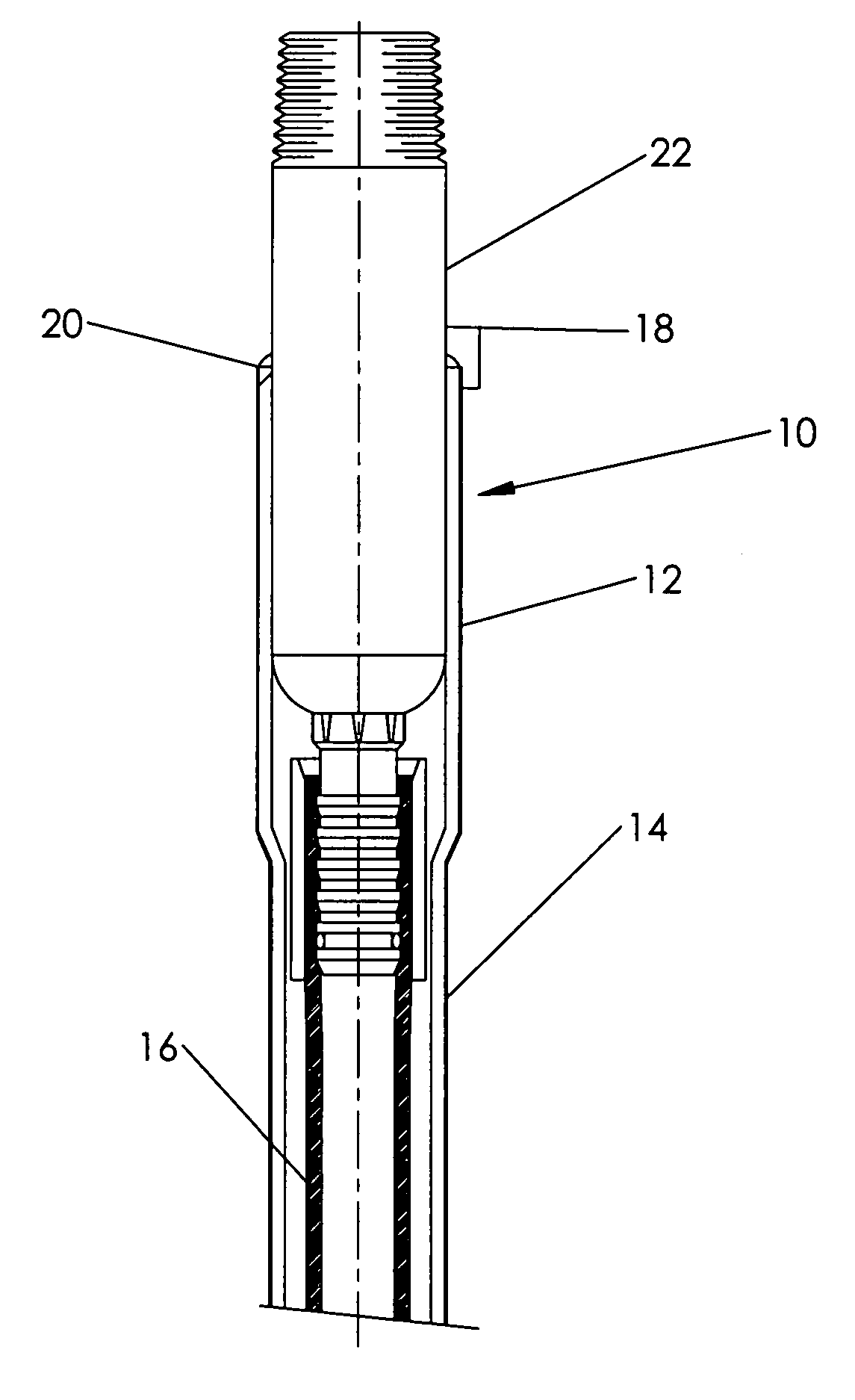

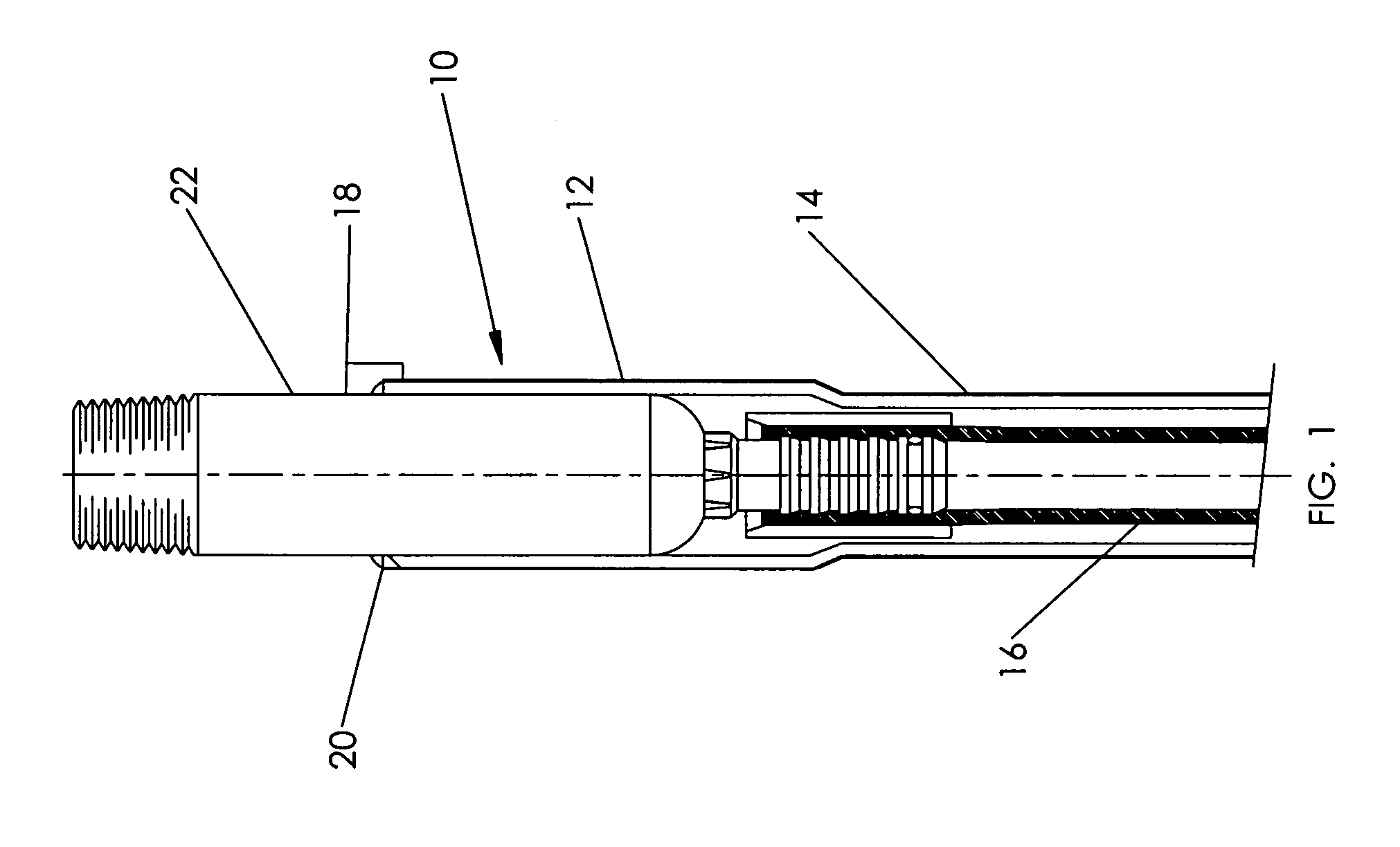

Corrosion resistant gas service riser assembly

Owner:GEORG FISCHER CENT PLASTICS

Surface treatment method of coal mine machinery parts

Owner:CHANGZHI TONGCHENG MACHINERY

Plating layer for electrochemistry corrosion resistant electronic encapsulation shell

InactiveCN101649456ASemiconductor/solid-state device manufacturingMetallic material coating processesCorrosion resistantNickel

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Anti-corrosion and anti-wear high manganese steel and preparation method thereof

Owner:江苏久华环保科技股份有限公司

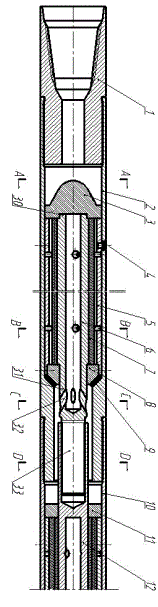

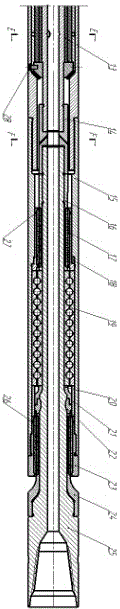

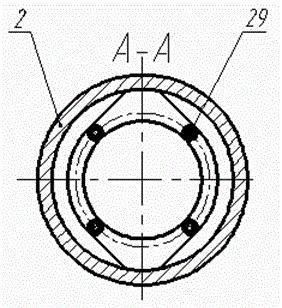

Coaxial all-metal cam stator and rotor underground dynamical drilling tool

Owner:XI'AN PETROLEUM UNIVERSITY

Full-inorganic interior and exterior wall coating and preparation method thereof

InactiveCN111393881AImprove corrosion resistanceStrong hardnessAlkali metal silicate coatingsAnti-corrosive paintsBarium solutionBarium dichloride

Owner:国鼎(苏州)材料科技有限公司

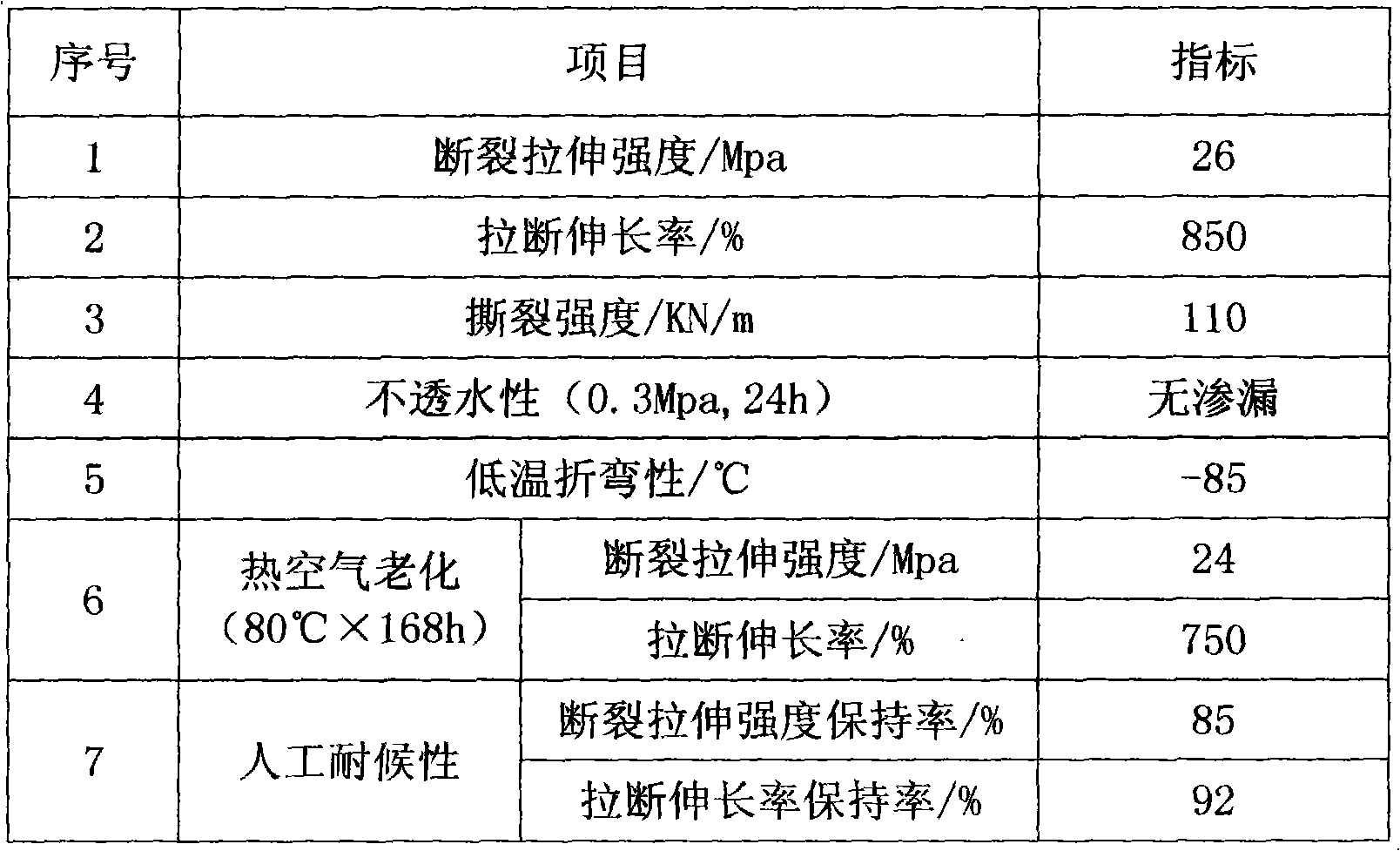

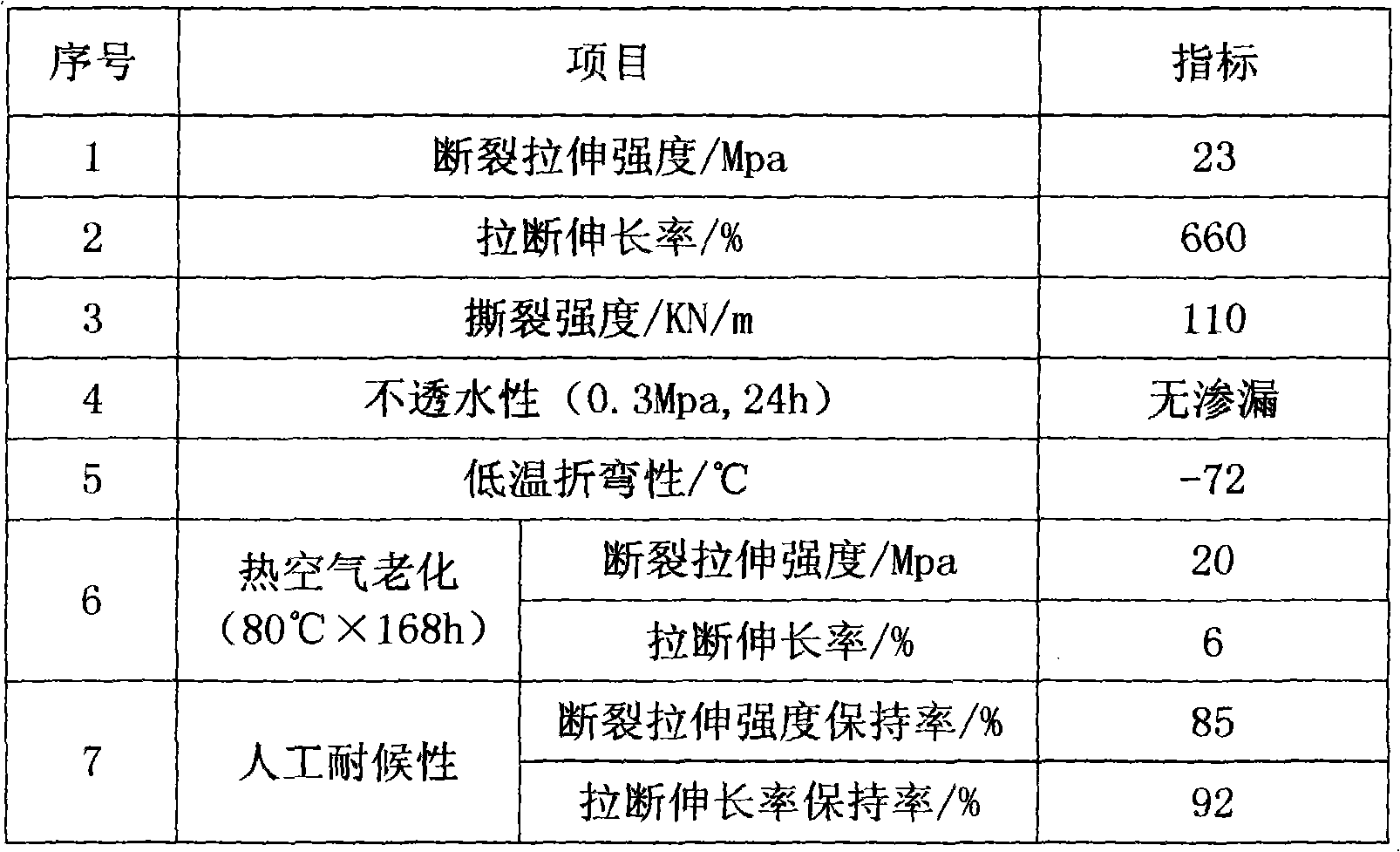

High-temperature-resistant and corrosion-resistant waterproof board for tunnels and production process thereof

ActiveCN103541745AEasy to useImprove toughnessUnderground chambersSynthetic resin layered productsGround temperatureAntioxidant

Owner:HONGXIANG NEW GEO MATERIAL

Wear-resistant composite microcrystalline sheet material

Owner:HENAN JINGXIANG ABRASION PROOF MATERIAL

Plate material for inner container of refrigerator and preparation method thereof

Owner:HEFEI HUALING CO LTD +2

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap