Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Disodium hydrogen phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloy surface zinc-calcium series phosphating solution and conversion treatment process thereof

InactiveCN101671824AImprove corrosion resistanceStrong adhesionMetallic material coating processesMg alloysPhosphate

The invention discloses magnesium alloy surface zinc-calcium series phosphating solution and a conversion treatment process thereof; the magnesium alloy surface phosphating solution is aqueous solution formed by the following constituents, namely, every liter solution contains: 10-30g of disodium hydrogen phosphate, 4-6g of zinc nitrate, 2-4g of sodium nitrite, s0.5-2g of sodium fluoride, and 0.-2g of calcium nitrate; the process for carrying out surface conversion treatment to the phosphating solution comprises the following process flows: alkaline washing and degreasing->rinsing->acidity activation->rinsing->surface activation->rinsing->phosphating->rinsing->drying; the working temperature is 40-70 DEG C, and the time is 5-60 minutes. The conversion treatment process can obtain phosphateconversion coating on the surface of the magnesium alloy, wherein the conversion coating has good protectiveness, is fine and uniform and stable, and has strong adhesive force, and can improve the corrosion-resisting property of magnesium alloy parts; the conversion treatment process is stable and easy to control, and has low cost.

Owner:CHONGQING UNIV OF TECH

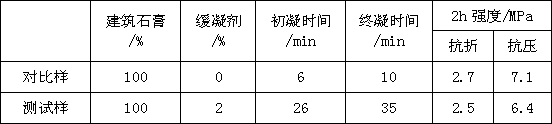

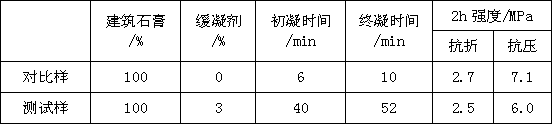

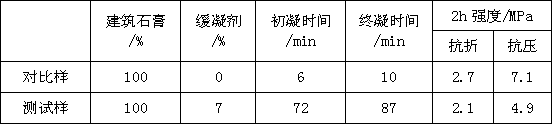

Novel gypsum retarder and preparation method thereof

The invention relates to a novel gypsum retarder and a preparation method thereof. The novel gypsum retarder consists of the following components in parts by weight: 150-180 parts of penicillin mycelium, 0.2-0.4 part of disodium hydrogen phosphate, 0.3-0.6 part of sodium hydroxide, 0.05-0.08 part of polydimethylsiloxane, 0.04-0.06 part of potassium sorbate, 10-20 parts of alkaline calcium bentonite, 0.01-0.03 part of beta-phenethyl alcohol and 350-450 parts of water. Modification condition: modification is performed at the temperature of 40-50 DEG C for 3-5 hours; and a modified material is prepared into a solid gypsum retarder by spray drying. The retarder has the characteristics of low cost, good retarding effect and small strength loss.

Owner:邯郸市潘仁新能源科技有限公司

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Method for preparing mercury-free ammonium detection test paper

InactiveCN101887055AEasy to makeEasy to carryAnalysis using chemical indicatorsNitrosoSodium phosphates

The invention relates to a method for preparing mercury-free ammonium detection test paper, and belongs to the field of analytical chemistry. Based on filter paper of 1 square centimeter, the ammonium test paper consists of 0.5 to 5.6 milligrams of soaked phenol, 0 to 0.1 milligram of sodium nitroprusside, 0.35 to 4.5 milligrams of disodium hydrogen phosphate, 3.0 to 10 milligrams of sodium phosphate, 0.3 to 4.6 milligrams of sodium hypochlorite and 0.15 to 0.5 milligram of sodium hydroxide. The reagent content of the ammonium test paper is only one percent of that in other ammonium ion test methods. The test paper of the invention has the advantages of simple manufacturing, convenience to carry, simple, convenient and rapid operation, vivid detection, high selectivity and capability of judging the ammonium ion content of a sample by visually comparing the color of the developing test paper with that of a standard color card. Reagents used by the method are ordinary chemical reagents which are non-toxic, safe and reliable and can be used for testing the ammonium content of various nitrogen fertilizers, soil, crop hydroponics nutrient solution, different kinds of ammonium-containing solution and sewage.

Owner:UNIV OF JINAN

Novel sewage treatment agent and preparation method thereof

InactiveCN106219622AWide range of processingGood effectWater treatment parameter controlWater/sewage treatment by flocculation/precipitationPhosphoric acidWater quality

The invention belongs to the field of sewage treatment and discloses a novel sewage treatment agent and a preparation method thereof. The novel sewage treatment agent is prepared from, by weight, 4-10 parts of coal ash, 4-10 parts of sodium silicide, 4-10 parts of sodium polyacrylate, 5-10 parts of polymeric iron phosphate, 2-6 parts of adsorption substances, 3-9 parts of polymeric aluminum calcium chloride, 4-10 parts of ammonium persulfate, 3-9 parts of disodium hydrogen phosphate, 4-12 parts of zeolite and 80-100 parts of water. The novel sewage treatment agent is wide in pollutant treatment range, effective, extensive in material source, low in cost and widely applicable to treatment of municipal sewage and various types of industrial wastewater and treatment of polluted water of rivers and lakes, and treated water can be recycled.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of anti-mildew agent for feeds

InactiveCN108371238AIncrease feed intakePromotes decreased feed intake, growthAccessory food factorsFreeze-dryingFiltration

Owner:汪逸凡

Preparation method of composite efficient coagulant for treatment of textile printing and dyeing wastewater

InactiveCN110980909AEasy to reuseReduce processing costsWater treatment parameter controlWaste water treatment from textile industryTextile printerDyeing wastewater

Owner:安徽子延科技有限公司

Accumulator case material for new energy automobiles

Owner:HUANGSHAN ANDAER PLASTIC IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap