Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22 results about "Magnesium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloys are mixtures of magnesium with other metals (called an alloy), often aluminum, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium is the lightest structural metal. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

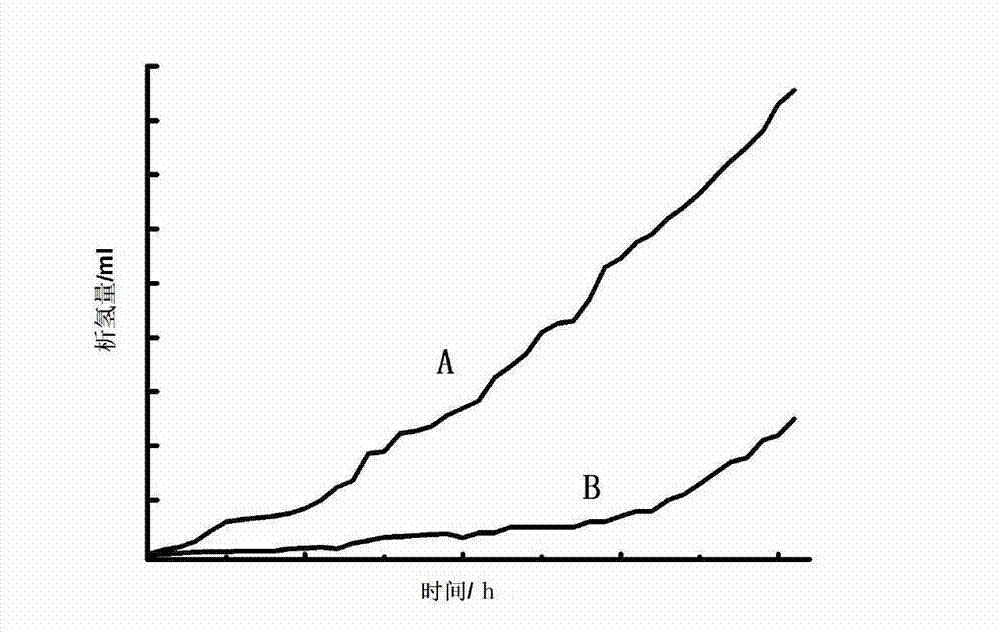

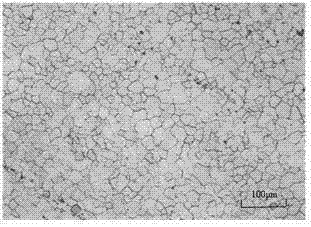

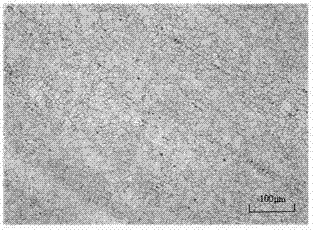

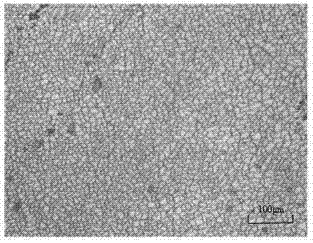

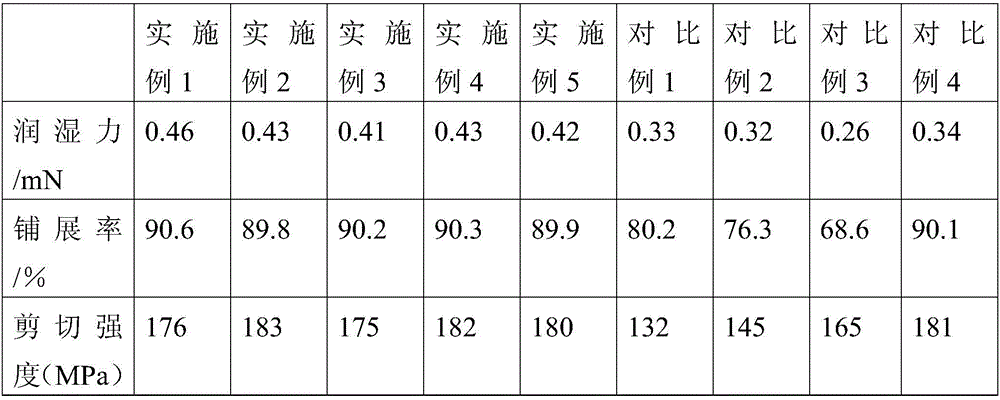

Biodegradable medical magnesium alloy as well as preparation method thereof

The invention discloses a biodegradable medical magnesium alloy which consists of the following matters in percentage by weight: 1.0-3.0% of Zn, 0.20-1.50% of Y, 0.40-1.50% of Nd, 0.30-0.50% of Zr and the balance of Mg and inevitable impurity elements. Meanwhile, the invention discloses a preparation method of the alloy. The magnesium alloy is smelted to prepare common magnesium alloy. The use level of Zn, Y and Nd in furnace burden is 1.2-1.4 times the content of Zn, Y and Nd in the magnesium alloy, and the use level of Zr is 2-2.5 times the content of Zr in the magnesium alloy. According to the invention, the magnesium alloy overcomes the problems of cytotoxicity, excessively high corrosion rate and the like by adding rare earth elements Y, Nd and Zr into a magnesium-zinc alloy, and the potential difference with a matrix is reduced due to a lot of uniformly dispersed and distributed nano MgZn particle phases in the matrix by extrusion and processing, so that the corrosion resistance of the alloy is greatly improved, and the alloy has better mechanical properties.

Owner:ZHENGZHOU UNIV

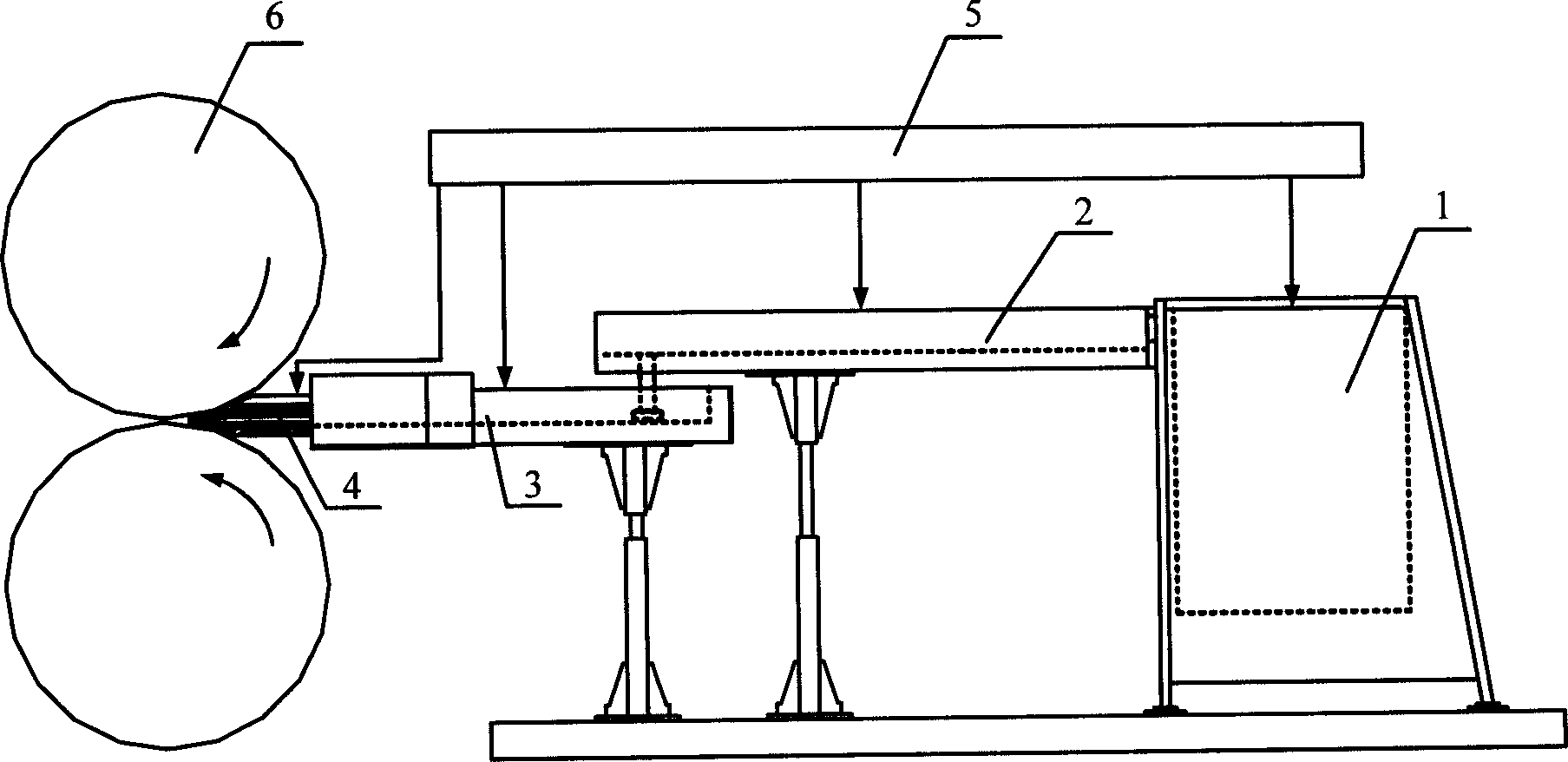

Casting-rolling process and equipment for magnesium alloy slab

InactiveCN1850378AOmit flaw detectionSave on sawingMetal rolling stand detailsRollsShielding gasIngot

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Flux for removing iron from Mg alloy and its preparing process

Owner:SHANGHAI JIAO TONG UNIV

Antirust oil and preparation method thereof

InactiveCN107653045AWork fasterImprove rust resistanceLubricant compositionAntioxidantRoom temperature

The invention relates to antirust oil and a preparation method thereof. The antirust oil is prepared from the following components by weight percent: 20 to 35 percent of film forming agent, 5 to 15 percent of antirust agent, 0.1 to 5 percent of co-solvent, 0.1 to 2 percent of antioxidant and 40 to 75 percent of basic oil. The preparation method comprises the following steps: preparing all raw materials according to the components and the weight ratio, adding the basic oil into a reactor, heating and stirring, when the temperature is increased to 90 to 120 DEG C, adding the antirust agent, theco-solvent and the antioxidant, sufficiently stirring, completely dissolving, lowering the temperature in the reactor to 50 to 80 DEG C, then slowly adding the film forming agent and the residual basic oil, sufficiently stirring, completely dissolving, cooling to the room temperature, detecting, discharging the material, thus obtaining the antirust oil. The antirust oil of the invention is high inactually completely drying speed and has good antirust effects for the long-term storage and transportation of various metals such as iron, copper, aluminum, magnesium alloy and the like.

Owner:SHANGHAI YOUDAO NEW ENERGY TECH CO LTD +1

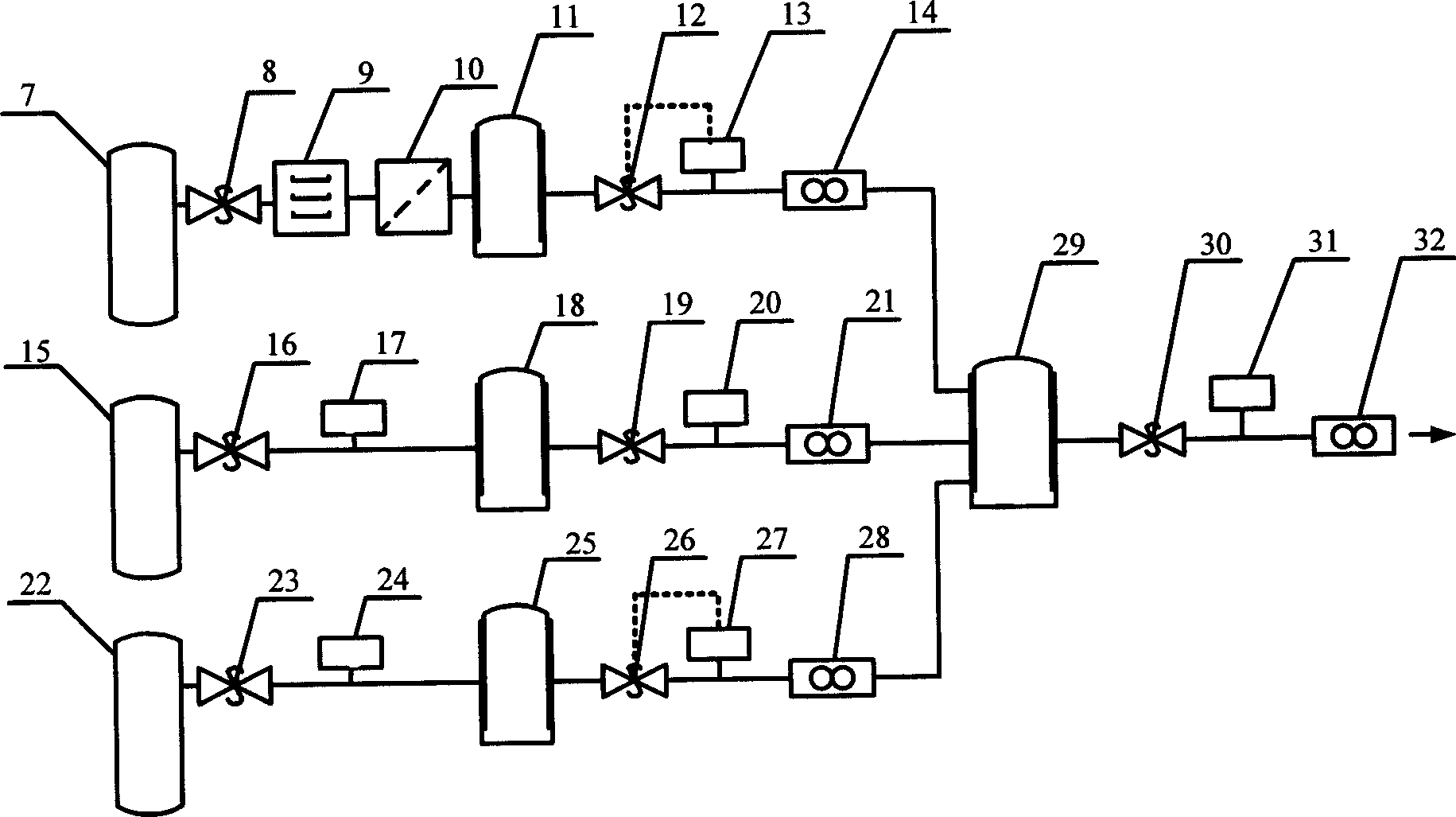

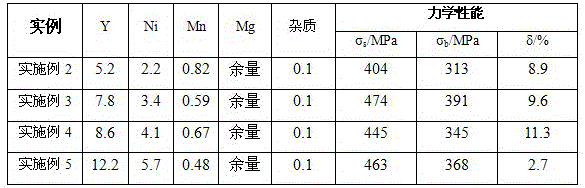

High-strength Mg-Y-Ni-Mn alloy and manufacturing method thereof

ActiveCN105543605ASignificant diffusion strengthening effectImprove acceleration performanceIngot castingRoom temperature

Owner:CHONGQING UNIV

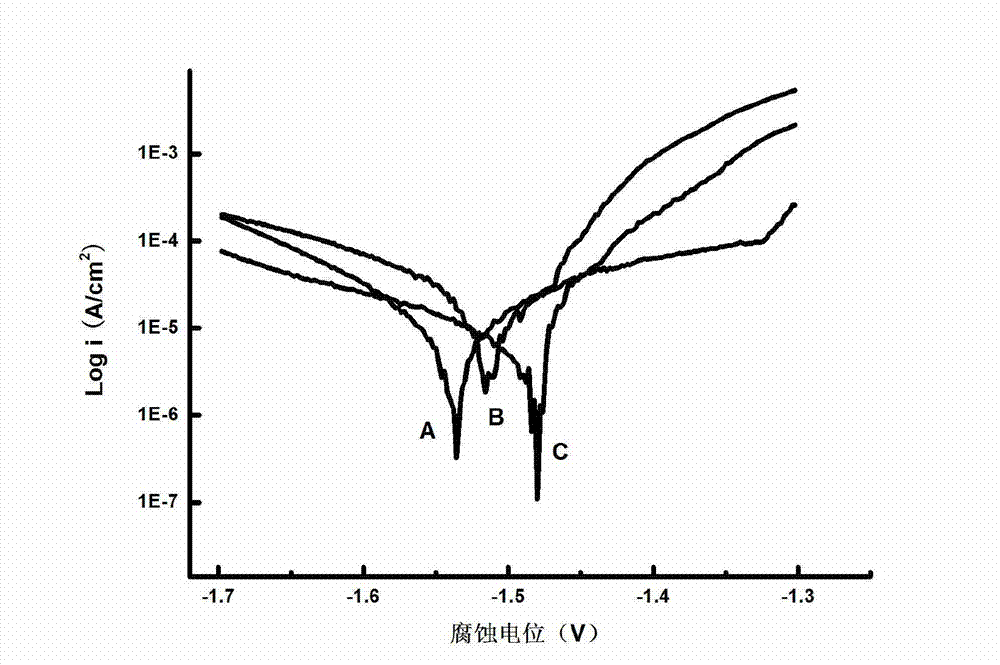

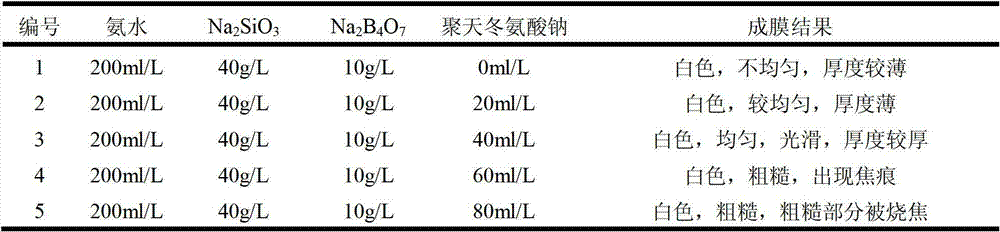

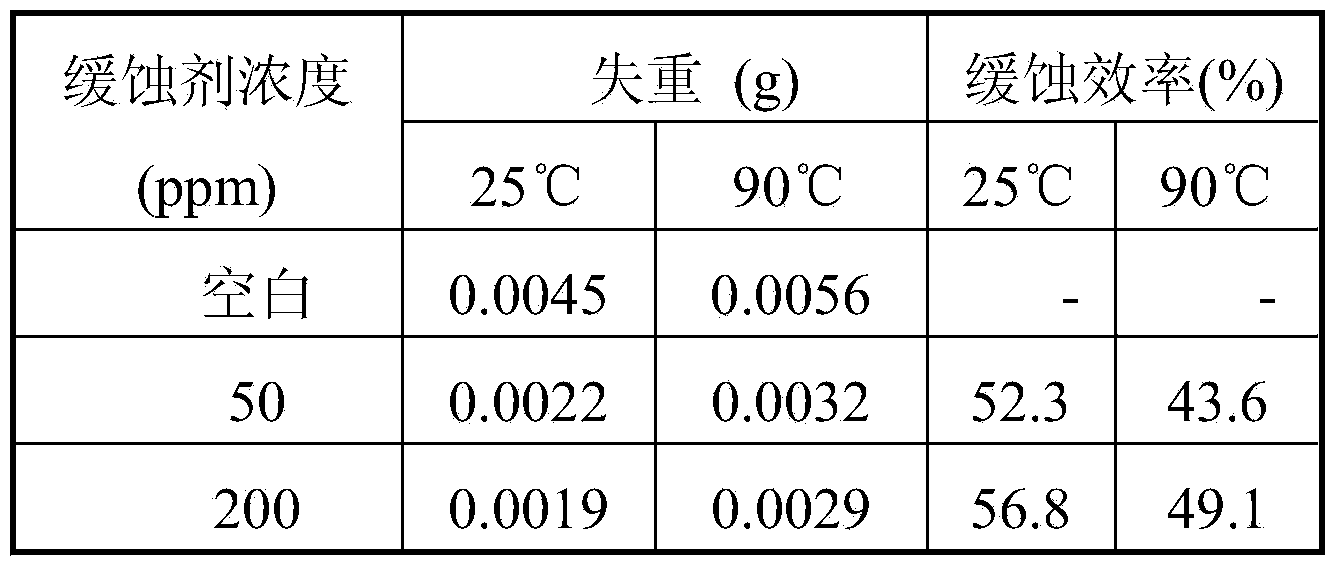

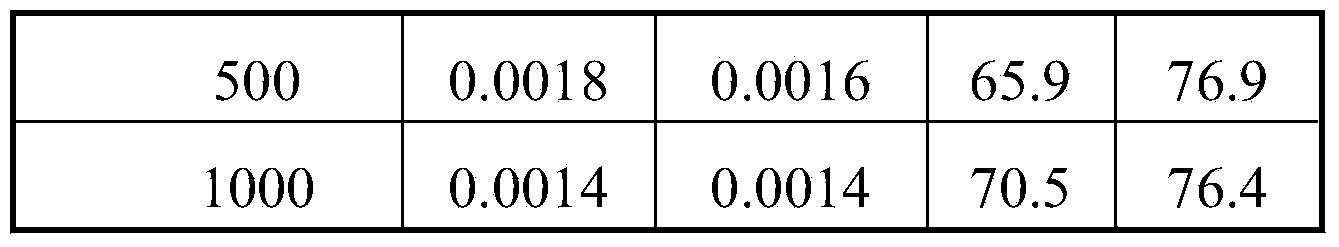

Electrolyte used for magnesium alloy anode oxidation treatment and treatment method

ActiveCN102828218AImprove corrosion resistanceStable temperatureAnodisationElectrolytic agentOxidative treatment

Owner:戚威臣

High-strength high-conductivity rare earth copper-magnesium alloy contact wire and manufacturing method thereof

InactiveCN106555073AMeet performance requirementsHigh elongationSingle bars/rods/wires/strips conductorsConductive materialRare-earth elementCerium

Owner:HENAN UNIV OF SCI & TECH

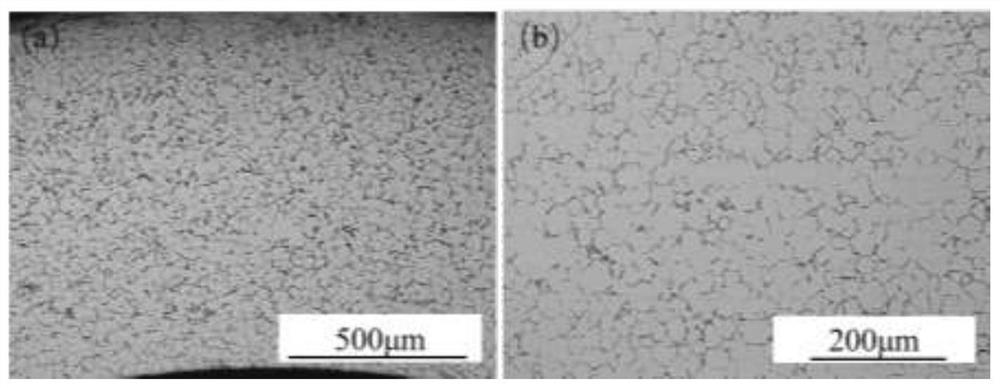

Method for characterizing oxidation phase of solid-phase regenerated AZ31B magnesium alloy

InactiveCN106908577AIncrease the number ofSmall sizePreparing sample for investigationTesting metalsAir atmosphereElectron microscope

Owner:JIAMUSI UNIVERSITY

Phosphorus-containing indoor-temperature high-plastic-deformation magnesium alloy

InactiveCN103924141AReduce the c/a valueImprove plastic forming abilitySmelting processPlastic property

Owner:NORTHEASTERN UNIV +1

Aluminum magnesium alloy welding flux and preparation method thereof

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

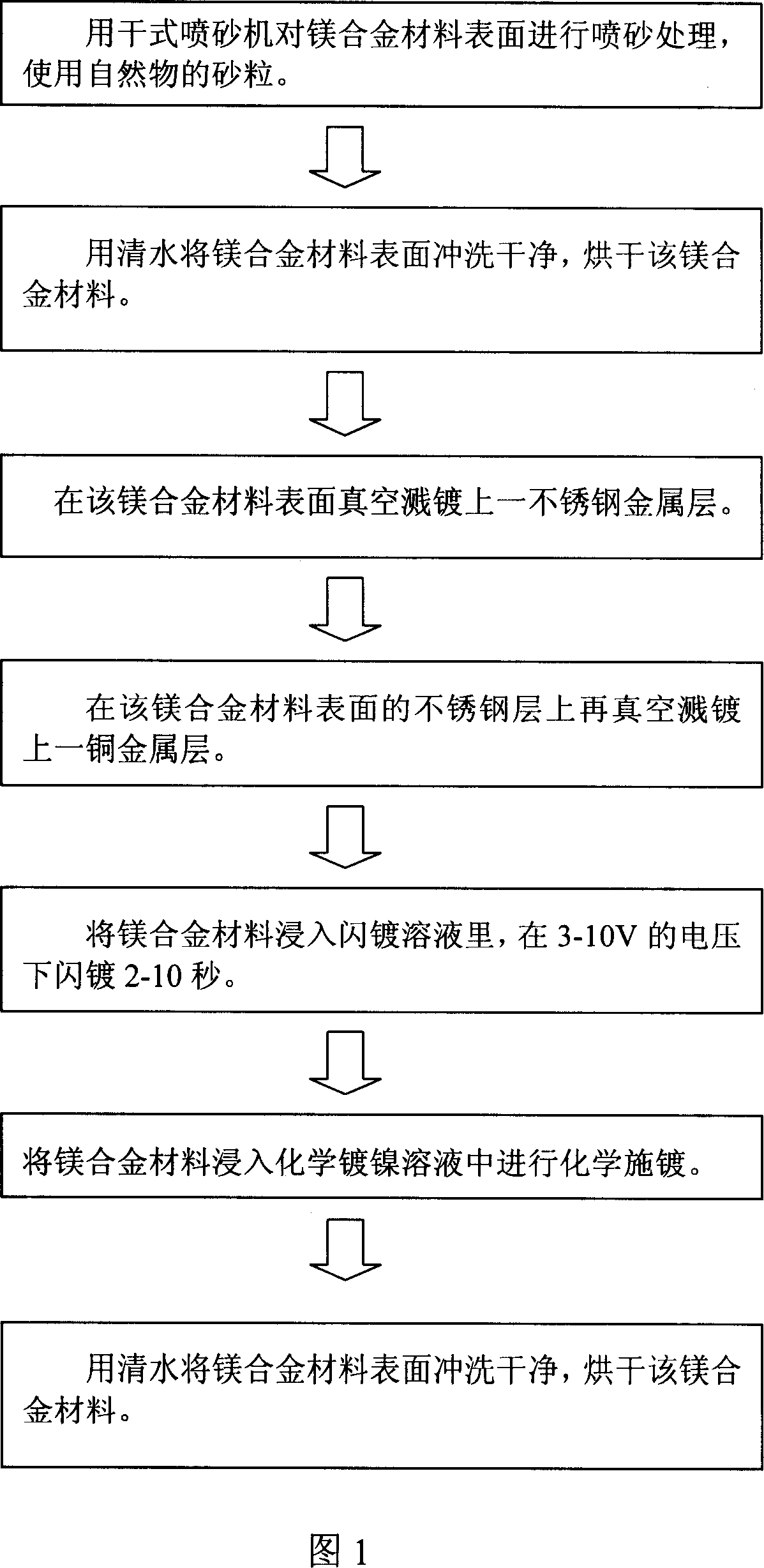

Magnesium-alloy surface treatment

InactiveCN1940136AImprove corrosion resistanceImprove wear resistanceSuperimposed coating processElectroless nickelSputtering

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Metal surface micro-patterning method

ActiveCN109175708AAvoid rapid degradationImprove heat dissipationLaser beam welding apparatusMicro nanoLiquid medium

The invention discloses a metal surface micro-patterning method. A transparent liquid medium not reacted with metal is adopted as protecting liquid; and in particular, when sodium hydroxide solution is adopted, the quick degradation of magnesium in water is prevented, and the machining of a magnesium alloy material by femtosecond laser filamentation in water is realized. When a flowing liquid filmis adopted, the heat dissipation condition of the periphery of a machined part can be prominently improved; and meanwhile, bubbles generated in machining are taken away to prevent accumulation of chips, so that the self-cleaning in the machining process is realized. In addition, compared with high-energy femtosecond laser filamentation in air, on the basis of guaranteeing the machining quality ofa metal surface micro-nano structure, the machining precision can be prominently improved to reach about 10 microns, and meanwhile, the production equipment cost is reduced. More importantly, an active oxidation atmosphere formed by femtosecond laser in the air is prevented, and oxides in machined products are prominently reduced, so that the metal surface and the microcosmic substance forms in machined grooves are not changed to the greatest extent.

Owner:BEIHANG UNIV

Method for treating or pretreating containers

InactiveUS7344757B2Simpler and cost-effective processIncrease chanceHot-dipping/immersion processesPretreated surfacesBottleAluminium alloy

Owner:CHEMETALLGMBH

Special magnesium alloy material for vehicle crankshaft and preparation method thereof

The invention discloses a special magnesium alloy material for a vehicle crankshaft and a preparation method thereof. The special magnesium alloy material for the vehicle crankshaft comprises the following components in percentage by weight: 4.0-7.0% of silicon, 3.7-5.8% of copper, 2.5-4.0% of lithium, 0.4-0.6% of tungsten, 0.5-0.9% of chromium, 0.04-0.07% of titanium, 0.02-0.07% of boron, 0.001-0.004% of nickel, 0.001-0.003% of vitriol, 0.001-0.003% of zirconium, and the balance of magnesium. The high-performance magnesium alloy material with higher strength and hardness is prepared through selecting the specific formula, has the advantages of lightness and wear resistance, is excellent in heat dissipating capacity, and can satisfy the quality requirement of the vehicle crankshaft.

Owner:YUYAO WANZHEN HARDWARE FACTORY

Aluminum-magnesium alloy electroplating solution

Owner:常熟市伟达电镀有限责任公司

Electronic balance with voice reading function

InactiveCN105509847ASimple structureLight in massWeighing apparatus using counterbalanceWeighing indication devicesEngineeringLoad cell

The invention discloses an electronic balance with a voice reading function. The electronic balance comprises an electronic balance body which is made of high-quality titanium magnesium alloy. The electronic balance body comprises a weighing loading table, a weighing control device and a weighing display screen. The weighing loading table is arranged at the upper end of the electronic balance body. The weighing display screen is arranged at the front end of the electronic balance body. The weighing control device is arranged in the electronic balance body. The weighing control device comprises a master control chip, and a control circuit, a weighing sensor, a storage module, an input module, a display module and a voice output module which are electrically connected with the master control chip. The input module is electrically connected with a braille keyboard. With application of the mode, the electronic balance has the voice output module and can be externally connected with the braille keyboard so that use is facilitated for the blind.

Owner:CHANGSHU JIAHENG BALANCE INSTR CO LTD

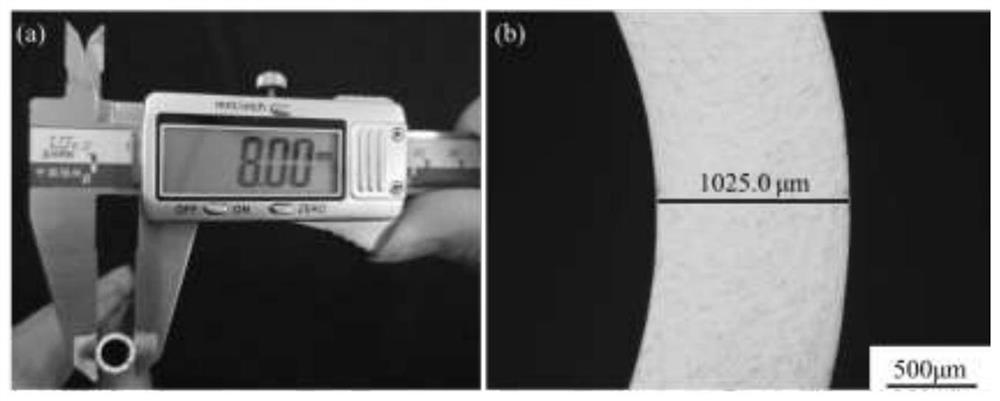

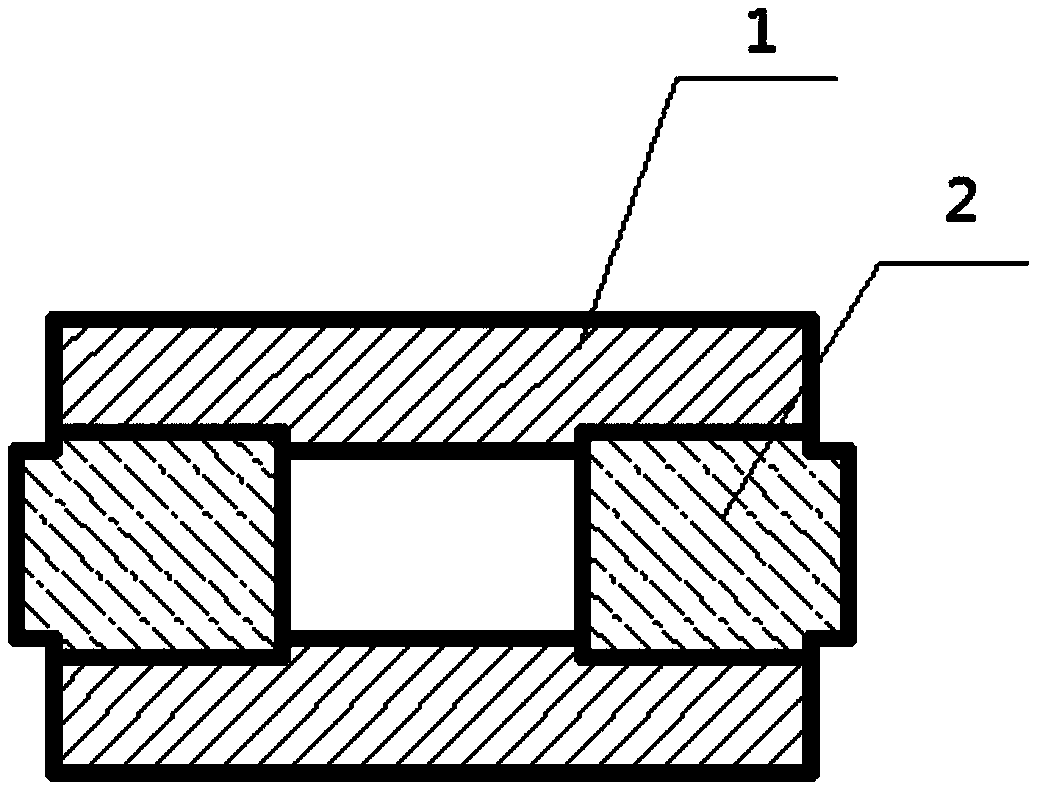

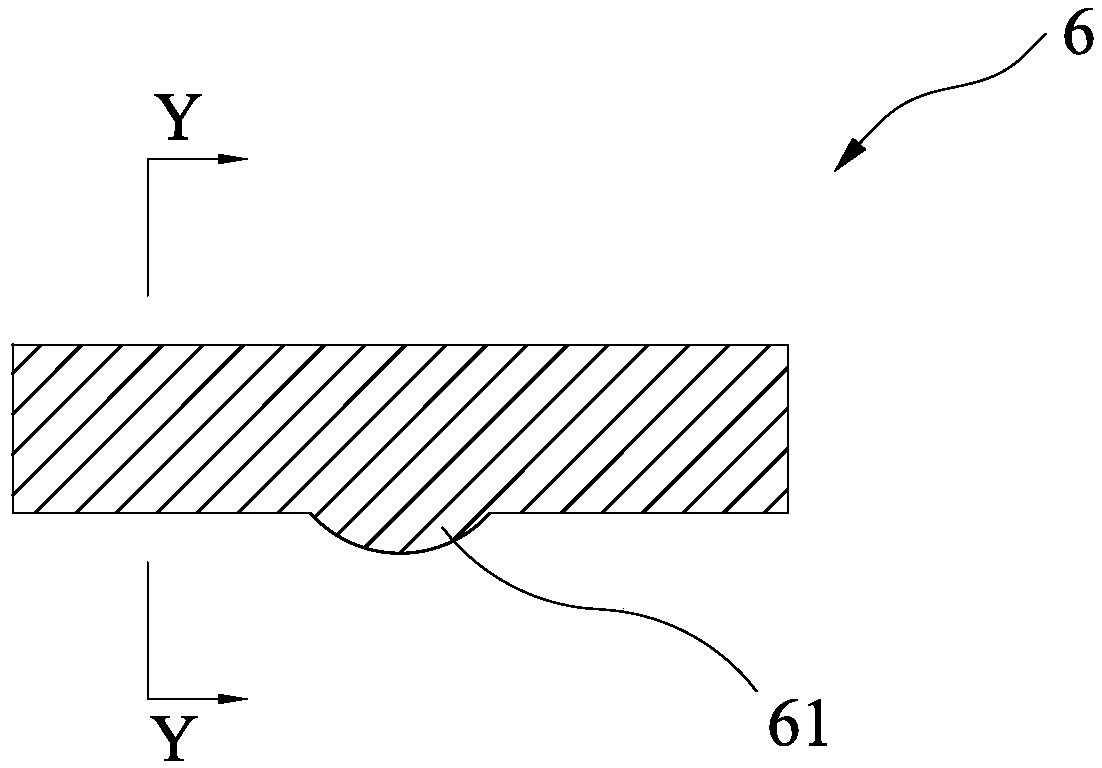

Rod-needle separated magnesium alloy slim tube preparation device and method

InactiveCN112246903AEasy to demouldSimple structureExtrusion diesExtrusion mandrelsMetallic materialsMechanical property

Owner:BEIJING UNIV OF TECH

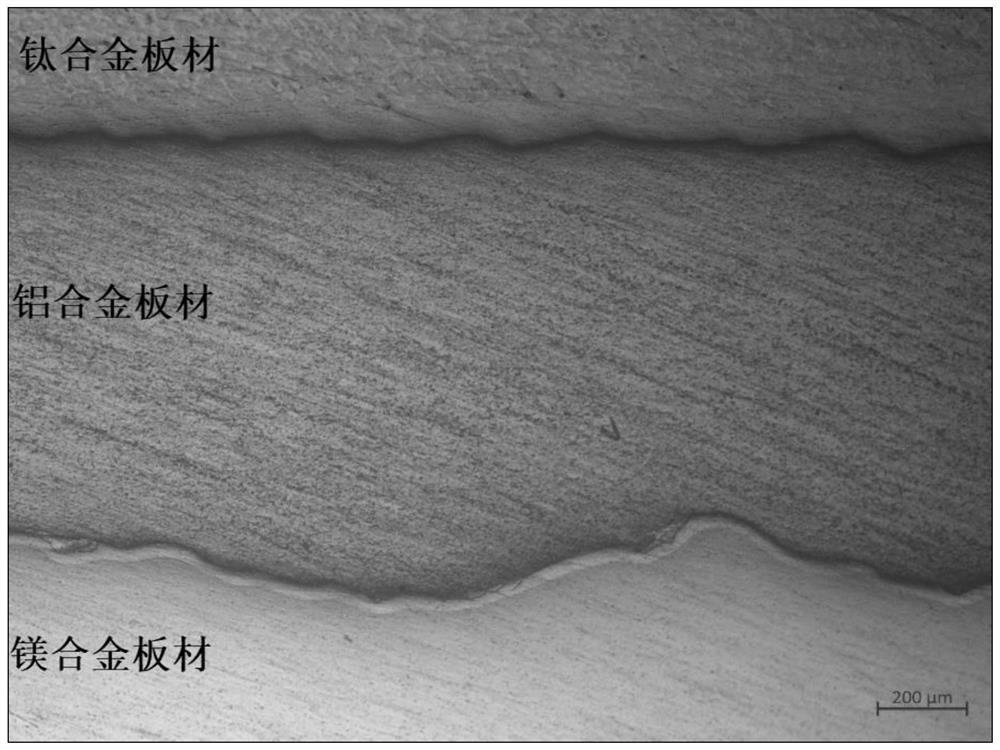

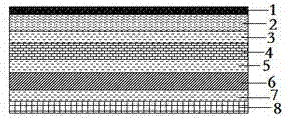

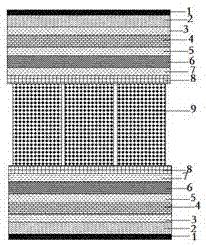

Preparation method of titanium/aluminum/magnesium composite plate

PendingCN113953642AImprove mechanical propertiesWell formedNon-electric welding apparatusDetonatorTitanium

Owner:XIAN TIANLI CLAD METAL MATERIALS

Heat dissipation plate of electric automobile battery pack and battery pack of electric automobile

ActiveCN107394309AImprove cooling effectExtended service lifeSynthetic resin layered productsSecondary cellsPolyesterElectrical battery

Owner:NANTONG NAIWEITE POWER SUPPLY CO LTD

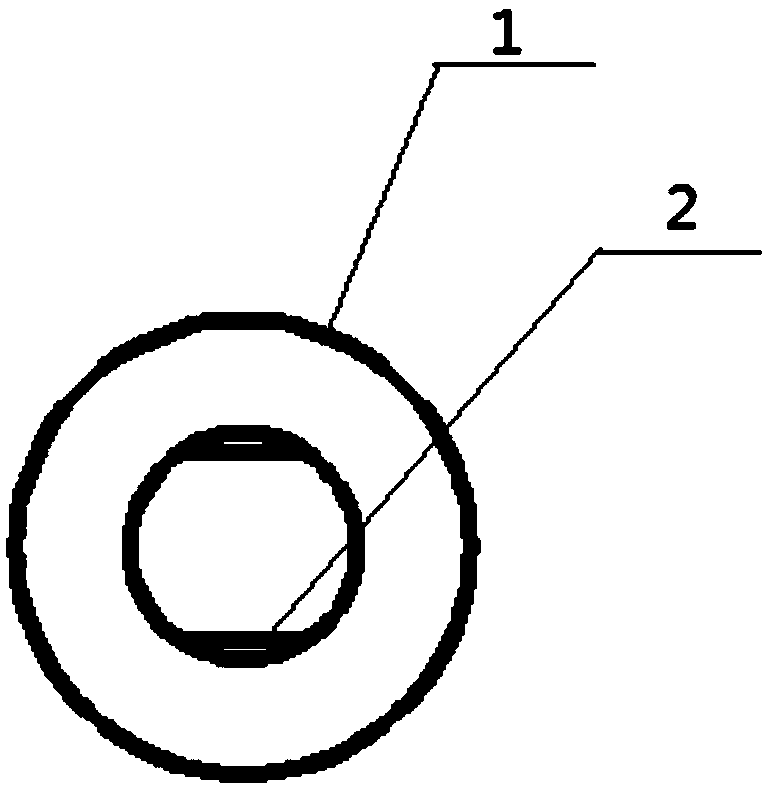

Extrusion processing method of magnesium alloy AZ91D internal threads

ActiveCN109604488ASolve prone to rotten teethSolve the \"slip button\"Thread cutting machinesScrew-threads articlesEmulsionIngot

Owner:HARBIN UNIV OF SCI & TECH +1

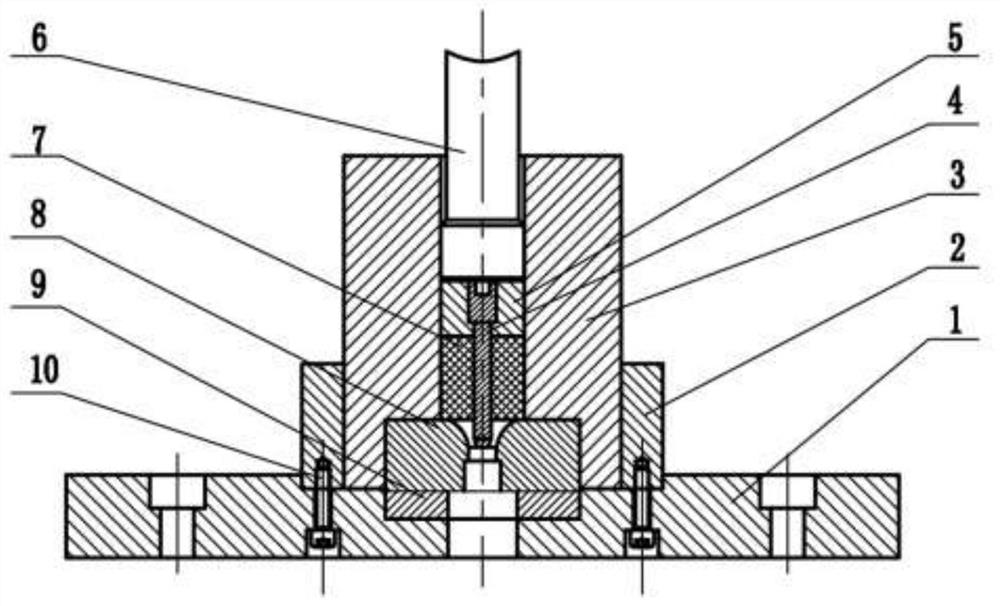

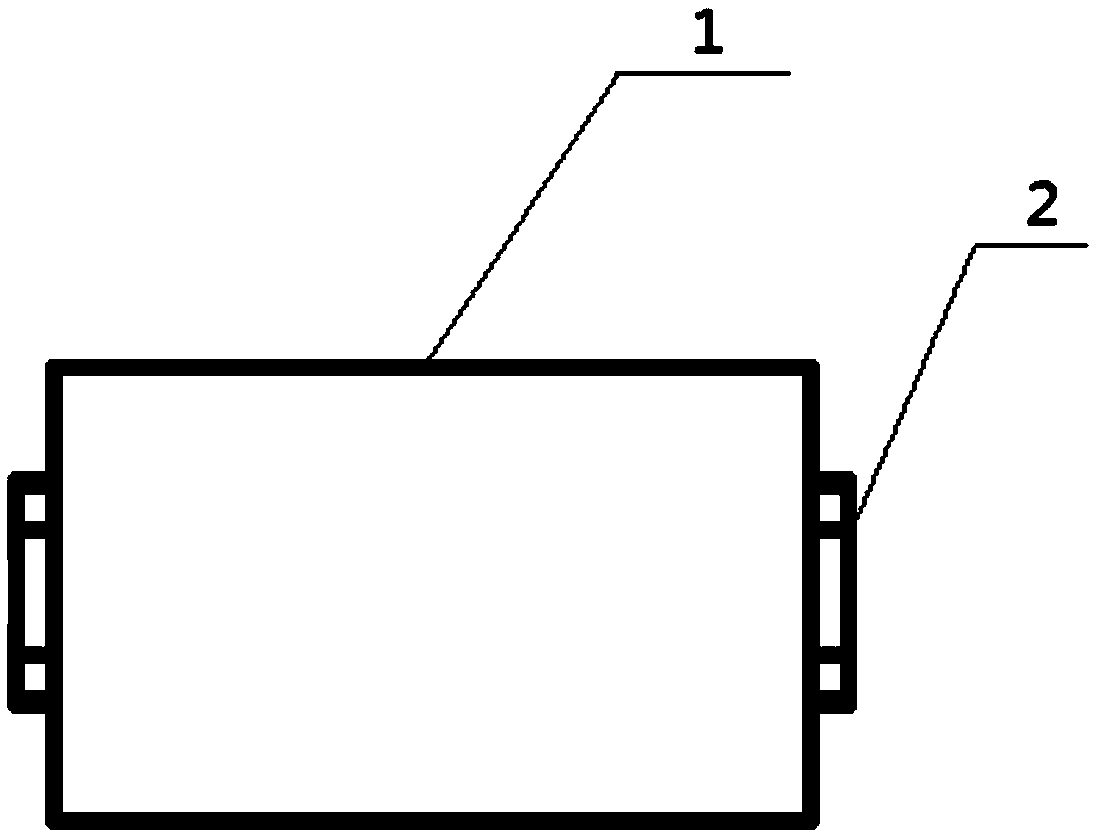

Forming die of Mg-Gd-Y-Zn-Zr magnesium alloy bidirectional expansion equal channel extrusion blank forming

InactiveCN109604364AAchieving shear stress deformationImprove uniformityExtrusion diesShearing deformationMechanical property

Owner:ZHONGBEI UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap