Casting-rolling process and equipment for magnesium alloy slab

A magnesium alloy, casting and rolling technology, applied in metal processing equipment, metal rolling, metal rolling, etc., can solve the problems of high chemical activity of magnesium alloy solution, unsuitable production of magnesium alloy plate, reaction of magnesium alloy liquid, etc., and achieve improvement Plasticity, improvement of solidification state, and effect of improving the quality of molten magnesium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

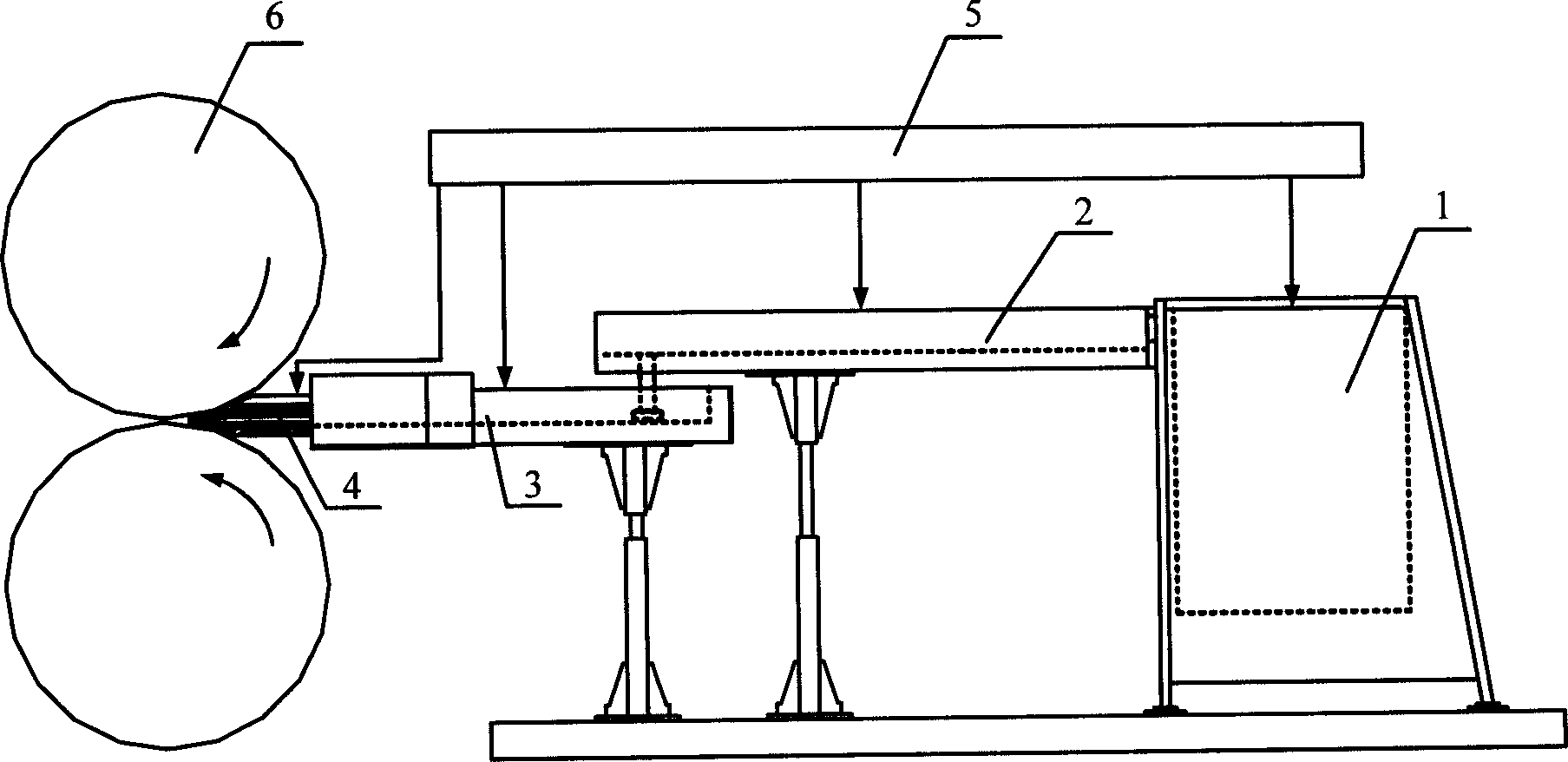

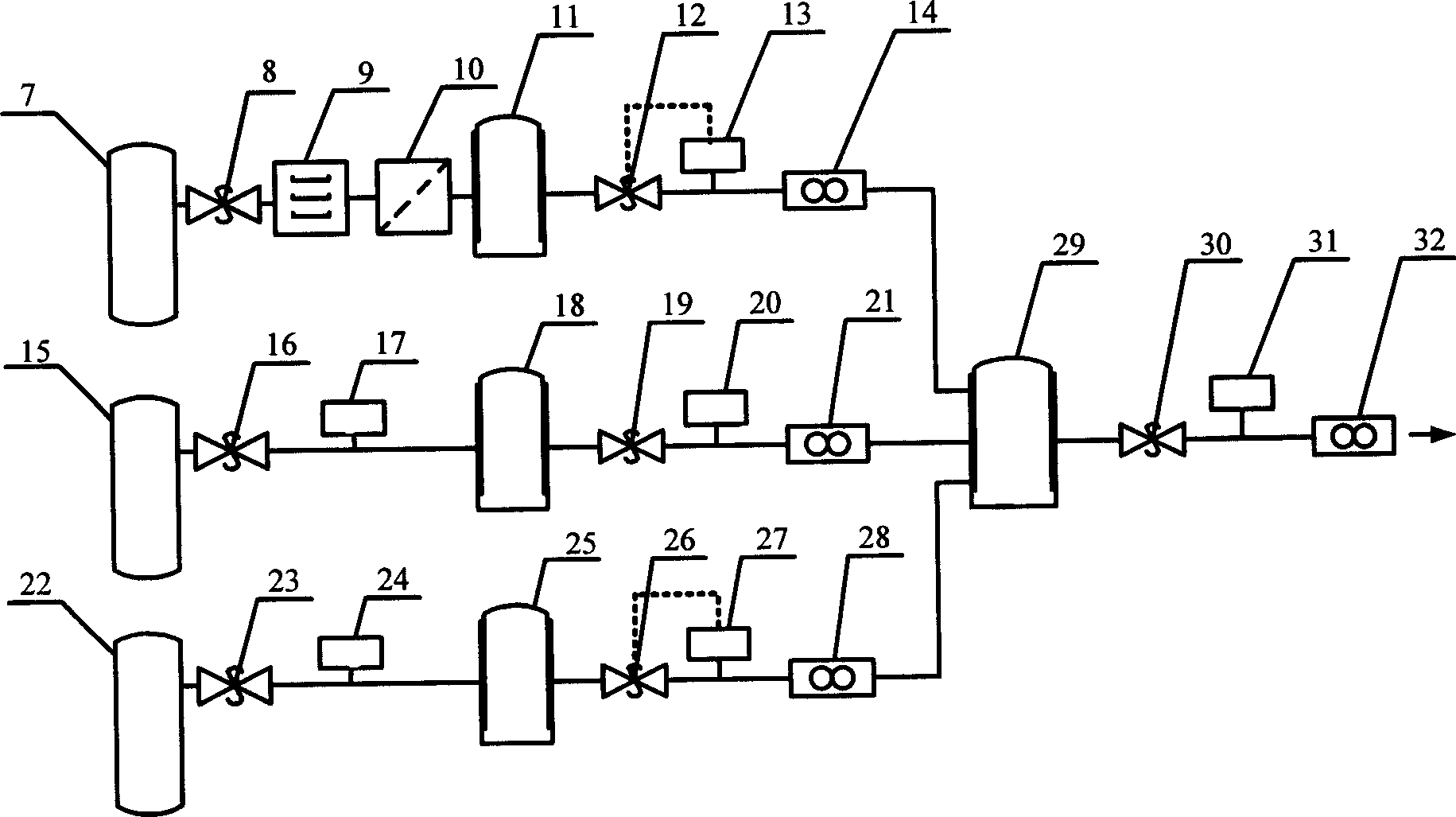

Embodiment 1

[0030] After the AZ31 magnesium alloy ingot is preheated, it is put into the 100kg resistance melting furnace 1, and when the temperature reaches 300°C, the mixed gas (SF 6 +CO 2 + air, proportional to SF 6 : 0.1%, CO 2 : 4.9%, dry air: 95%;). When the temperature reaches 500°C, carry out stirring and refining, ventilate and blow slag and let it stand for 10 minutes. Under the protective gas, the magnesium alloy liquid is then transported to the front box 3 through the launder 2, and the front box 3 keeps the magnesium alloy liquid at a constant temperature of 600°C to control the inflow. The magnesium alloy liquid of the casting roll has a relatively constant liquid level, which is 2cm higher than the center line. The magnesium alloy liquid passes through the nozzle 5 at the same temperature and enters the casting machine 6 at a uniform flow rate. The casting temperature is controlled at 500°C under the protective gas , The diameter of the 6 rolls of the casting and rolling m

Embodiment 2

[0032] After the AZ31 magnesium alloy ingot is preheated, it is put into the 550kg resistance melting furnace 1, and when the temperature reaches 400°C, the mixed gas (SF 6 +CO 2 + air, proportional to SF 6 : 0.4%, CO 2 : 20%, dry air: 79.6%;). When the temperature reaches 600°C, carry out stirring and refining, ventilate and blow slag, and let it stand for 20 minutes. Under the protective gas, the magnesium alloy liquid is then transported to the front box 3 through the launder 2, and the front box 3 keeps the magnesium alloy liquid at a constant temperature of 700°C to control the inflow. The magnesium alloy liquid of the casting roll has a relatively constant liquid level, which is 4cm higher than the center line. The magnesium alloy liquid passes through the nozzle 5 at the same temperature and enters the casting machine 6 at a uniform flow rate. The casting temperature is controlled at 600°C under the protective gas , the roll diameter of the cast-rolling machine is 600mm

Embodiment 3

[0034] After the AZ31 magnesium alloy ingot is preheated, it is put into the 1000kg resistance melting furnace 1, and when the temperature reaches 500°C, the mixed gas (SF 6 +CO 2 + air, proportional to SF 6 : 1%, CO 2 : 49%, dry air: 50% ;). When the temperature reaches 700°C, carry out stirring and refining, ventilate and blow slag, and let it stand for 30 minutes. Under the protective atmosphere, the magnesium alloy liquid is then transported to the front box 3 through the launder 2, and the front box 3 keeps the magnesium alloy liquid at a constant temperature of 800°C to control the inflow. The magnesium alloy liquid of the casting roll has a relatively constant liquid level, which is 6cm higher than the center line. The magnesium alloy liquid passes through the nozzle 5 at the same temperature and enters the casting machine 6 at a uniform flow rate. The casting temperature is controlled at 700°C under the protective gas , the roll diameter of the casting and rolling mach

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap