Cold source device for welding

A technology of cold source device and coolant, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of welding seam defects, polluted molten pool, welding seam oxidation, etc., to achieve low cost, improve welding quality and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

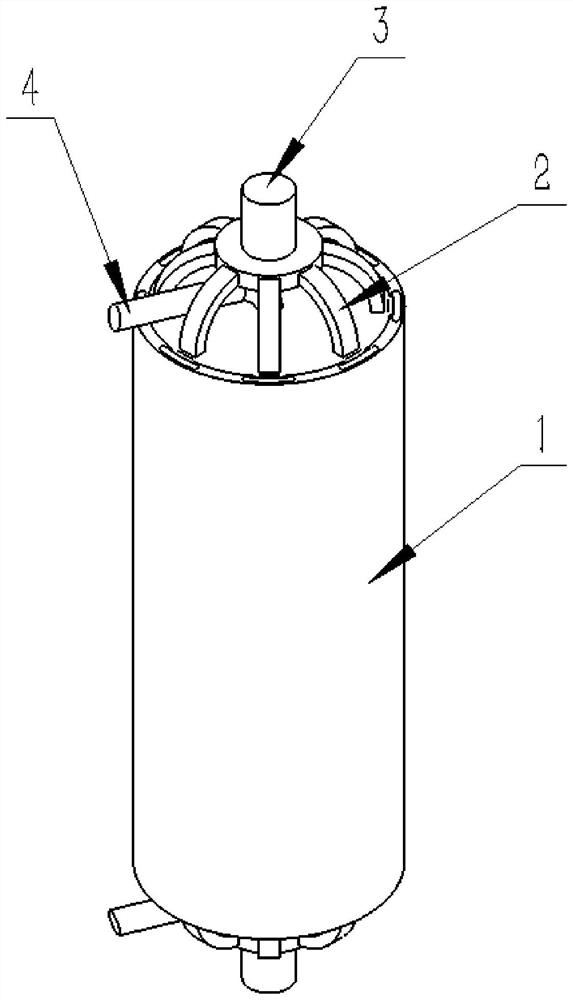

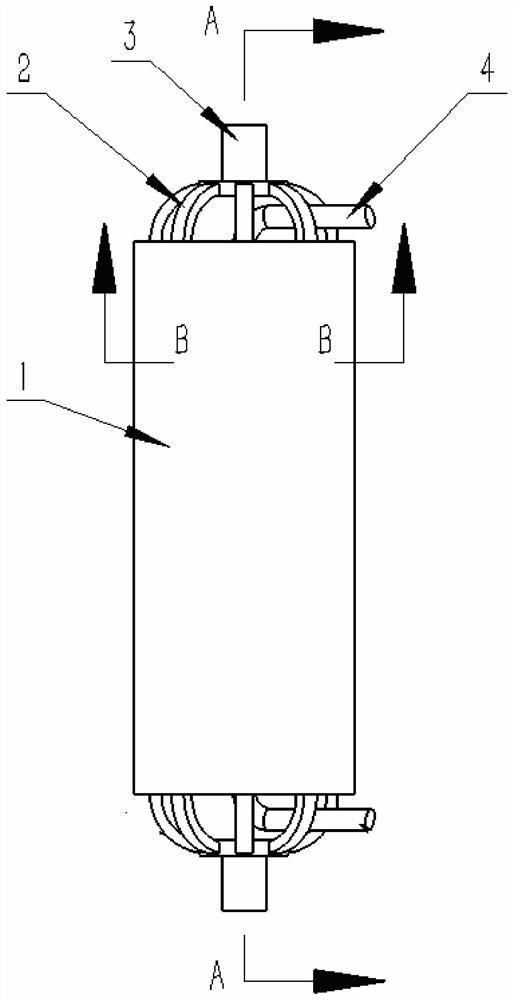

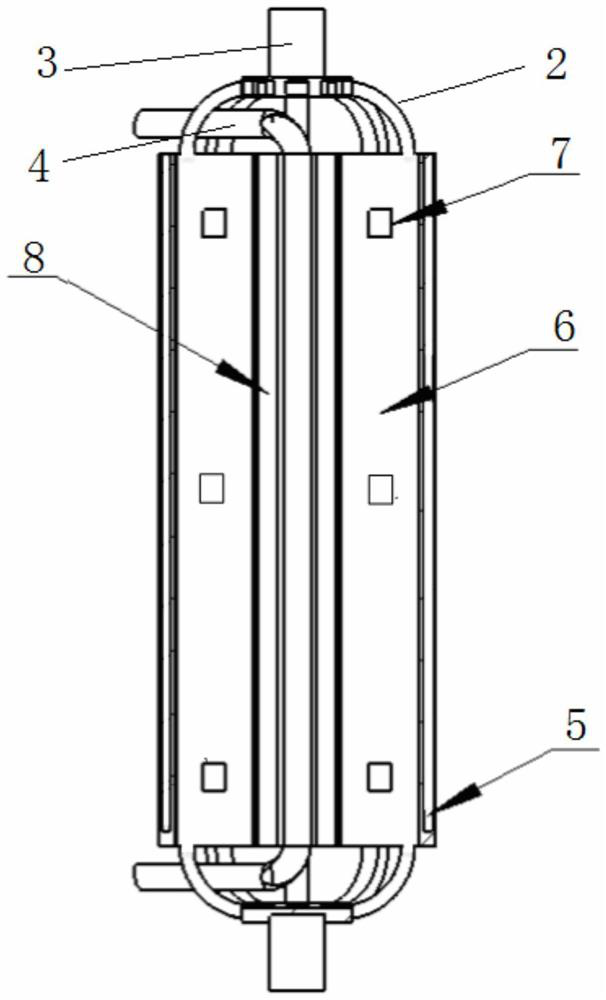

[0019] Such as Figure 1~5 As shown, the present invention includes a casing 1, and the casing 1 is a cylindrical structure with end caps sealed at both ends. A number of protective gas passages 6 are provided on the inner wall of the housing 1, and the protective gas passages 6 are arranged along the axis of the housing (the protective gas passages 6 can also be arranged in the housing 1 without contacting the side wall of the housing 1, and the two The end is fixed on the end cover at the end of the housing 1.), and three guide impellers 7 are respectively installed in each shielding gas channel 6 . The side wall of the housing 1 and the shielding gas passage 6 enclose a cooling liquid passage 8 . An air pipe 3 and a cooling liquid pipe 4 are arranged on the end cover; the air pipe 3 communicates with a plurality of protective gas passages through a plurality of br...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap