System and method for preparing ammonium metavanadate crystals

A technology of ammonium metavanadate and crystal, which is applied in the field of vanadium chemical industry, can solve the problems of clogged filter devices and ammonium metavanadate precipitation, etc., and achieve the effect of solving the problem of material blocking, speeding up the filtration speed and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0050] Example 1

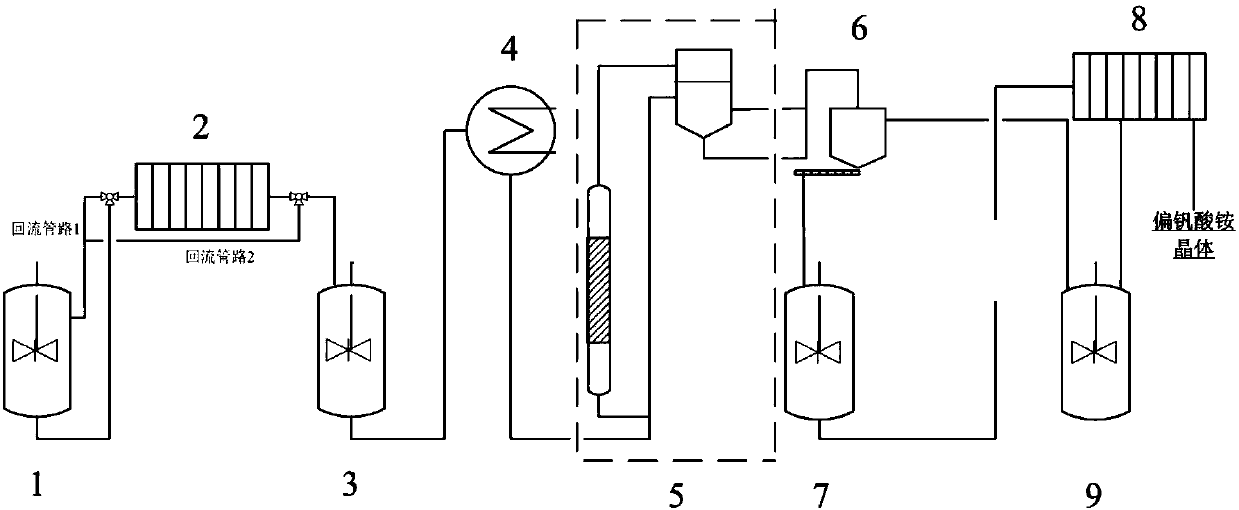

[0051] The structural schematic diagram of the system for preparing ammonium metavanadate of this embodiment is as figure 1 Shown.

[0052] The system includes the following units connected in sequence: a conversion reaction tank 1, a horizontal filter press 2, a filtrate buffer tank 3, a heat exchanger 4, a crystallizer 5, a thickener 6, a crystal slurry storage tank 7 and a horizontal A filter press 8, wherein a mother liquor storage tank 9 is provided between the thickener 6 and the horizontal filter press 8 for collecting supernatant;

[0053] The discharge port at the bottom of the conversion reaction tank 1 is connected to the horizontal filter press 2 through a feed pipe, and the upper discharge port of the conversion reaction tank 1 is formed with the feed pipe through a first return line Circulation loop

[0054] A second return line is provided between the horizontal filter press 2 and the first return line;

[0055] The pore size of the filter cloth of the

Example Embodiment

[0063] Example 2

[0064] In this example, the system described in Example 1 is used to prepare ammonium metavanadate, and the specific steps are:

[0065] 1) Circulate the mixture of calcium vanadate conversion solution and ammonium metavanadate solution in the conversion reaction tank 1 at a temperature of 95°C in the first return line for 3 minutes, close the first return line, and open the second return line Keep the slurry in the horizontal filter press 2 with a pore size of 15 μm for 2 minutes to form a filter cake layer, close the second return line, and collect the filtrate into the filtrate buffer tank 3;

[0066] 2) The obtained filtrate is transferred from the filtrate buffer tank 3 to the tube heat exchanger 4 at a temperature of 55°C by a transfer pump. After the first cooling, it is transferred to the continuous crystallizer 5 at a temperature of 35°C for the second Cool down twice to obtain crystal slurry;

[0067] 3) Transport the crystal slurry described in step 2) to t

Example Embodiment

[0070] Example 3

[0071] In this example, the system described in Example 1 is used to prepare ammonium metavanadate, and the specific steps are:

[0072] 1) Circulate the calcium vanadate conversion solution with a temperature of 90℃ in the conversion reaction tank 1 in the first return line for 5 minutes, close the first return line, and open the second return line so that the slurry has a diameter of 5μm. The horizontal filter press 2 is maintained for 3 minutes to form a filter cake layer, the second return line is closed, and the filtrate is collected in the filtrate buffer tank 3;

[0073] 2) The obtained filtrate is transferred from the filtrate buffer tank 3 to the tube heat exchanger 4 at a temperature of 50°C by a transfer pump. After the first cooling, it is transferred to the continuous crystallizer 5 at a temperature of 40°C for the second Cool down twice to obtain crystal slurry;

[0074] 3) Transport the crystal slurry described in step 2) to the thickener 6, the solid c

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap