Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Carbon nanotube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon nanotubes (CNTs) are tubes made of carbon with diameters typically measured in nanometers. Carbon nanotubes often refers to single-wall carbon nanotubes (SWCNTs) with diameters in the range of a nanometer. They were discovered independently by Iijima and Ichihashi and Bethune et al. In carbon arc chambers similar to those used to produce fullerenes. Single-wall carbon nanotubes are one of the allotropes of carbon, intermediate between fullerene cages and flat graphene.

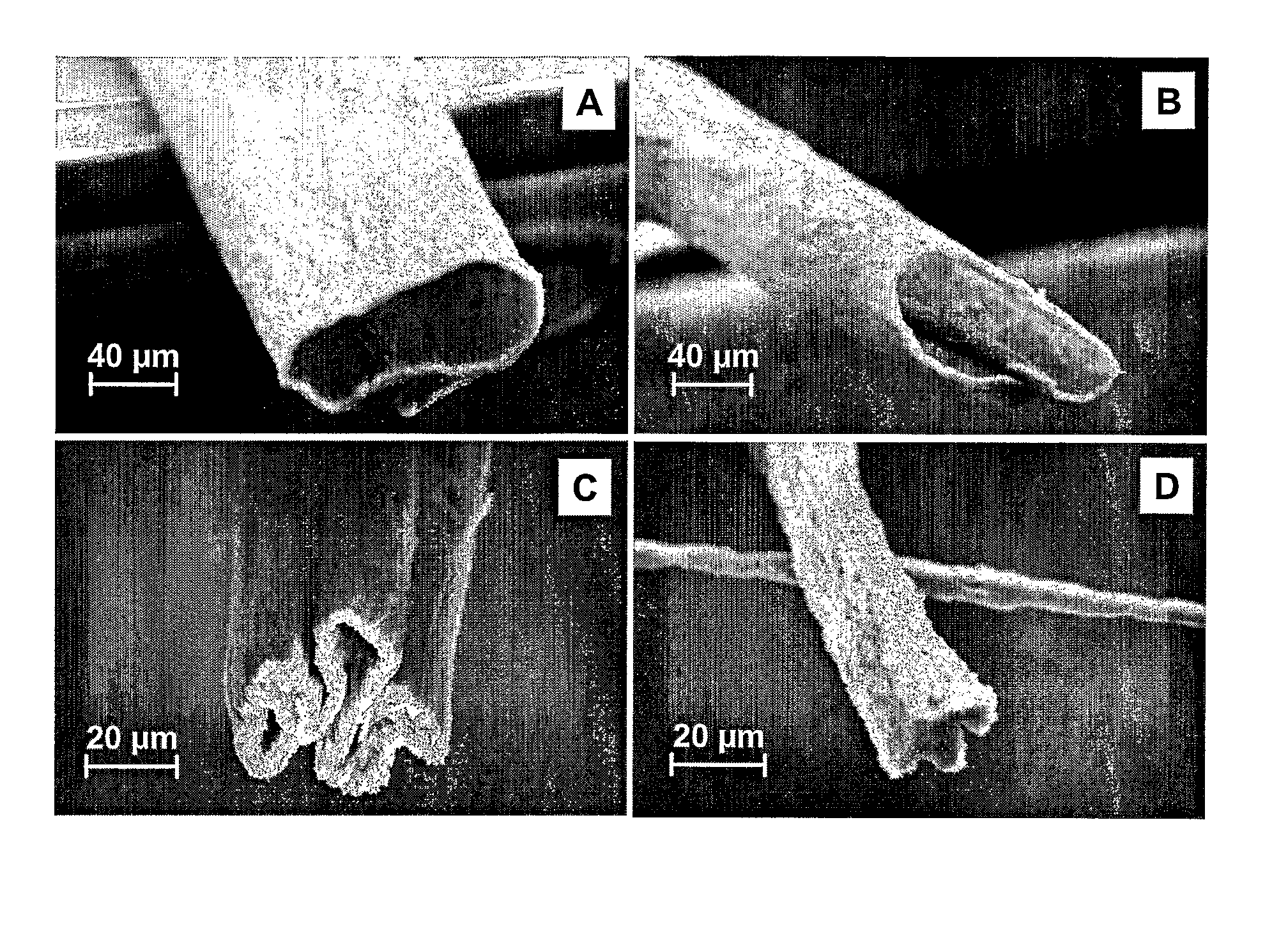

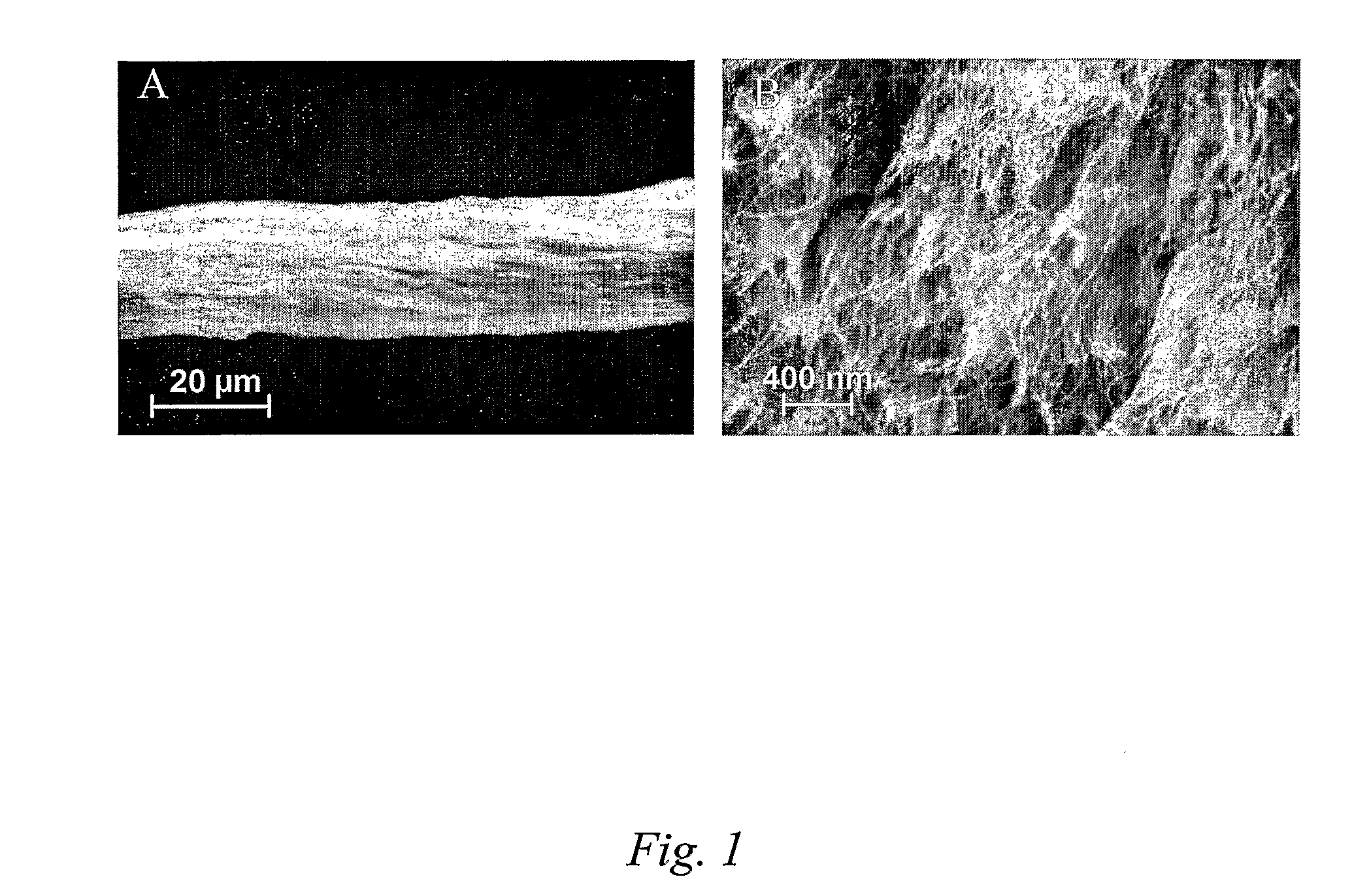

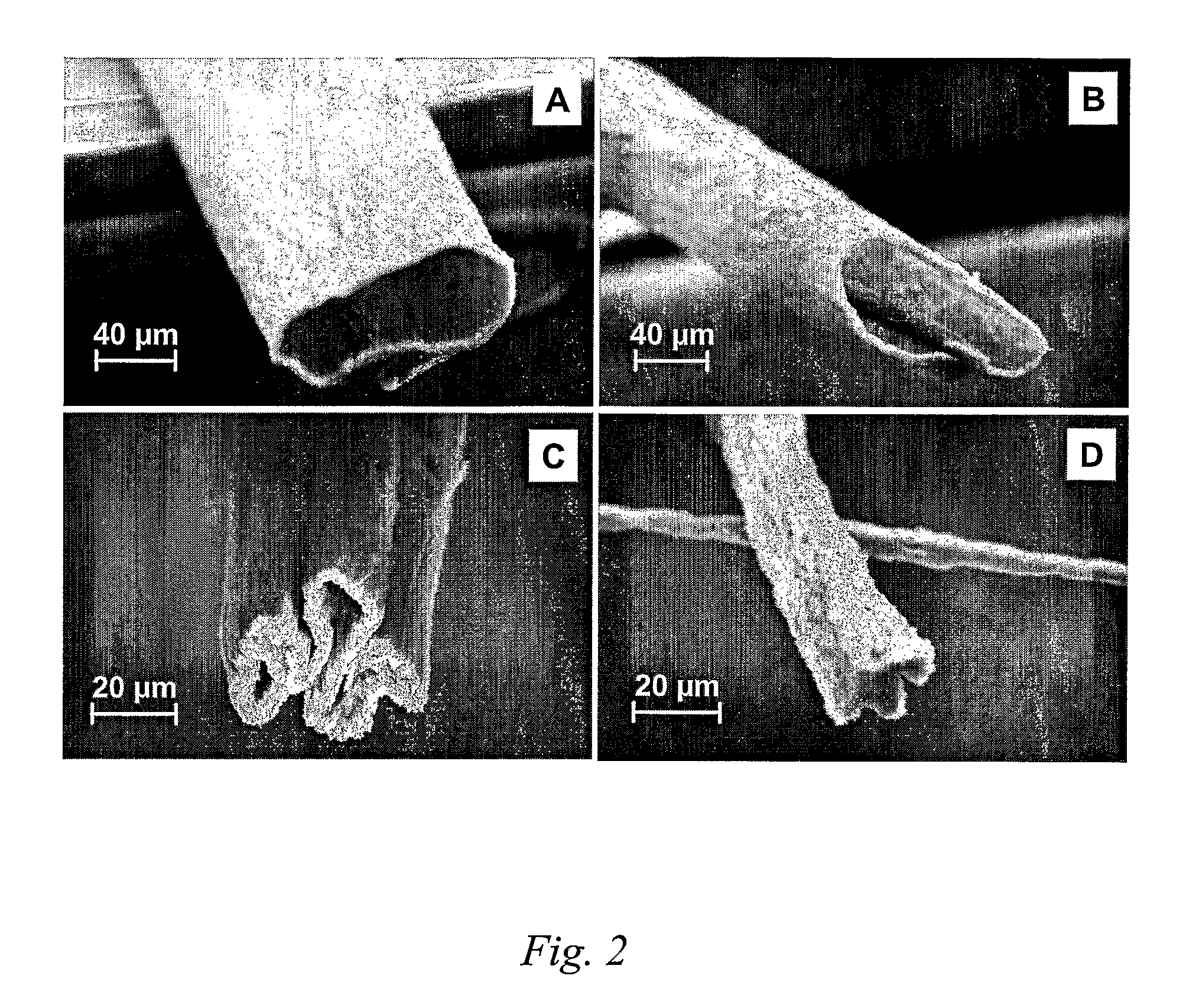

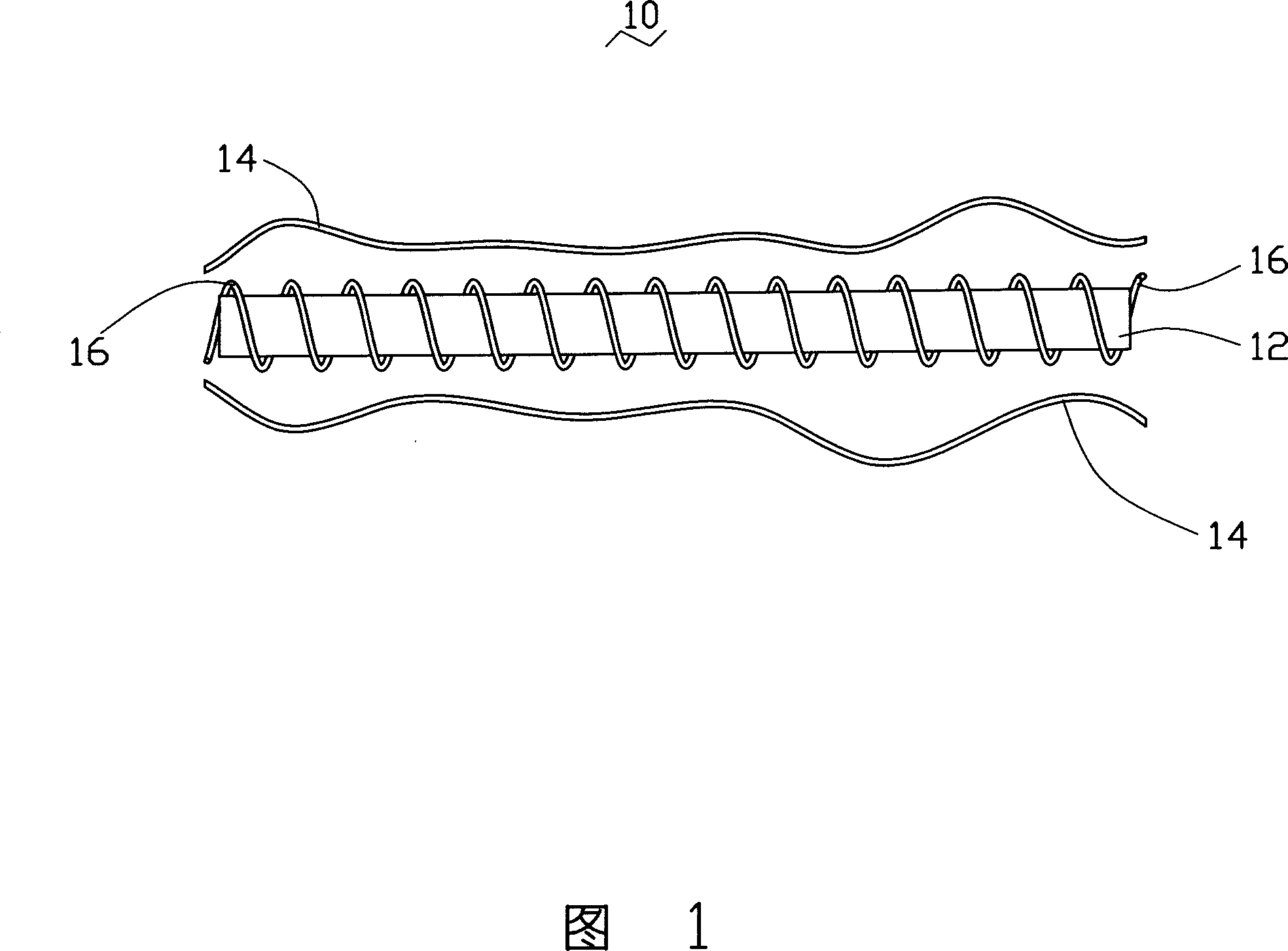

Polymer-Free Carbon Nanotube Assemblies (Fibers, Ropes, Ribbons, Films)

InactiveUS20070243124A1Pigmenting treatmentMaterial nanotechnologyCarbon nanotubeElectromechanical actuator

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

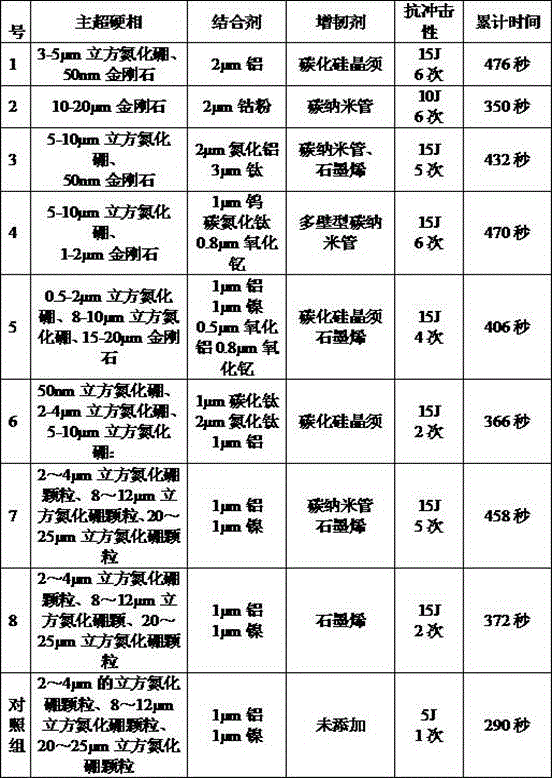

High-tenacity polycrystalline composite material, high-tenacity polycrystalline blade and preparation method of high-tenacity polycrystalline blade

InactiveCN105908041AImprove fracture toughnessImprove impact resistanceTurbinesOther manufacturing equipments/toolsCarbide siliconCarbon nanotube

Owner:FUNIK ULTRAHARD MATERIAL

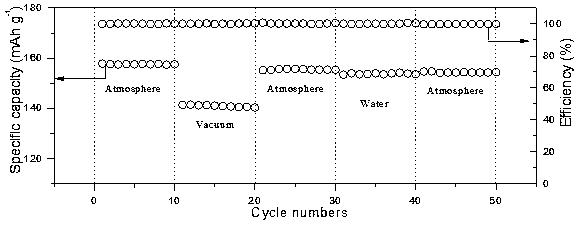

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

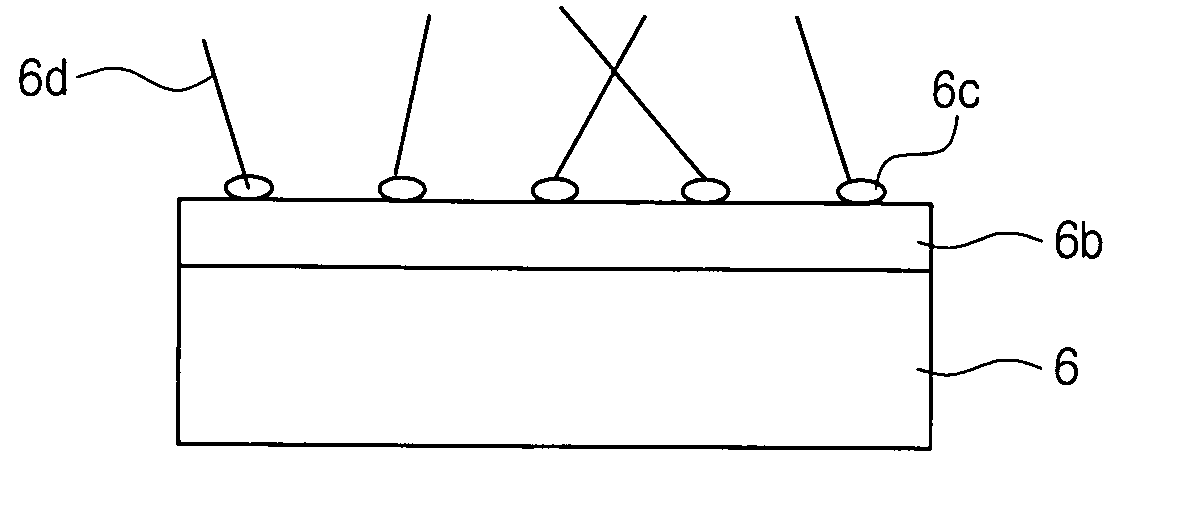

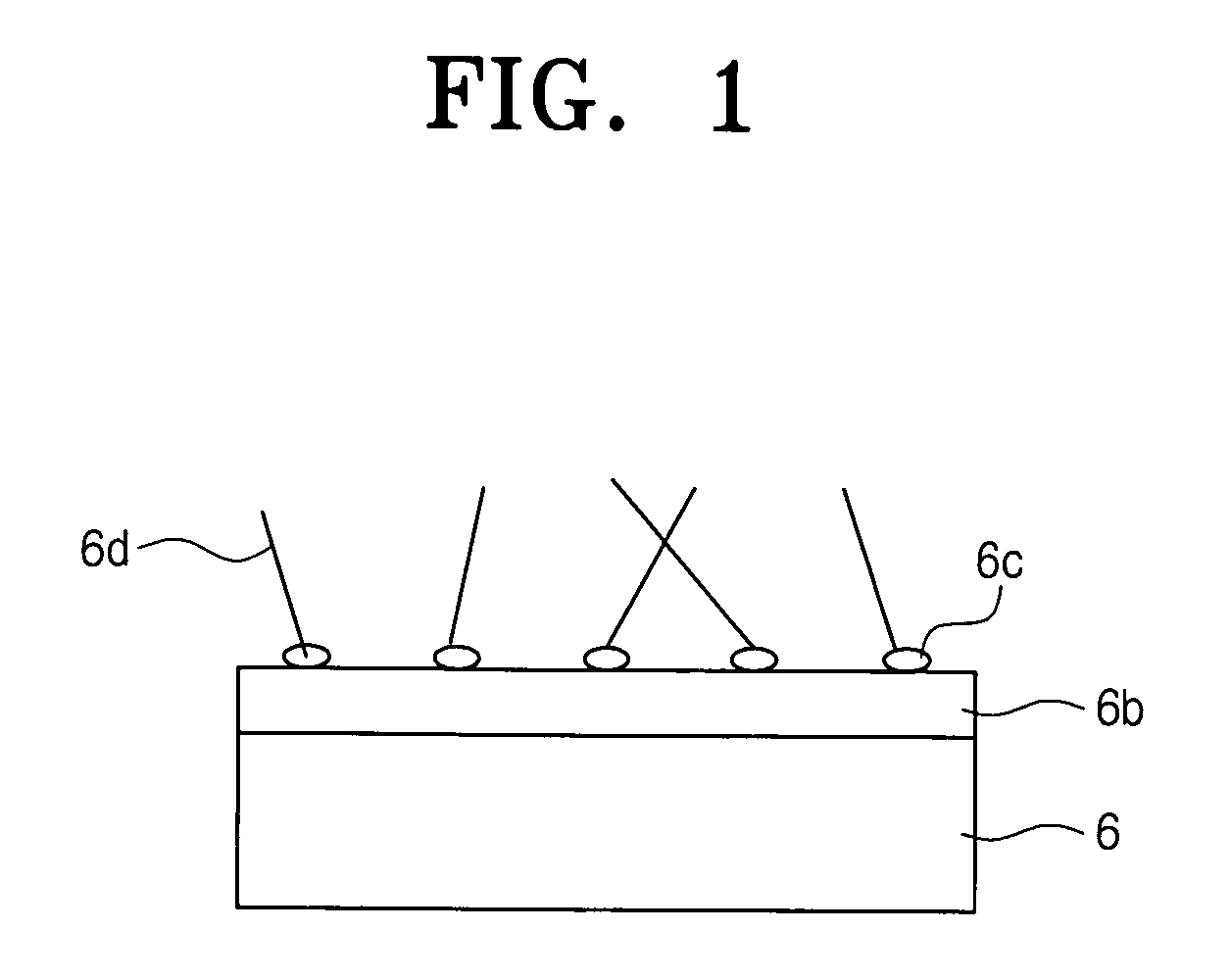

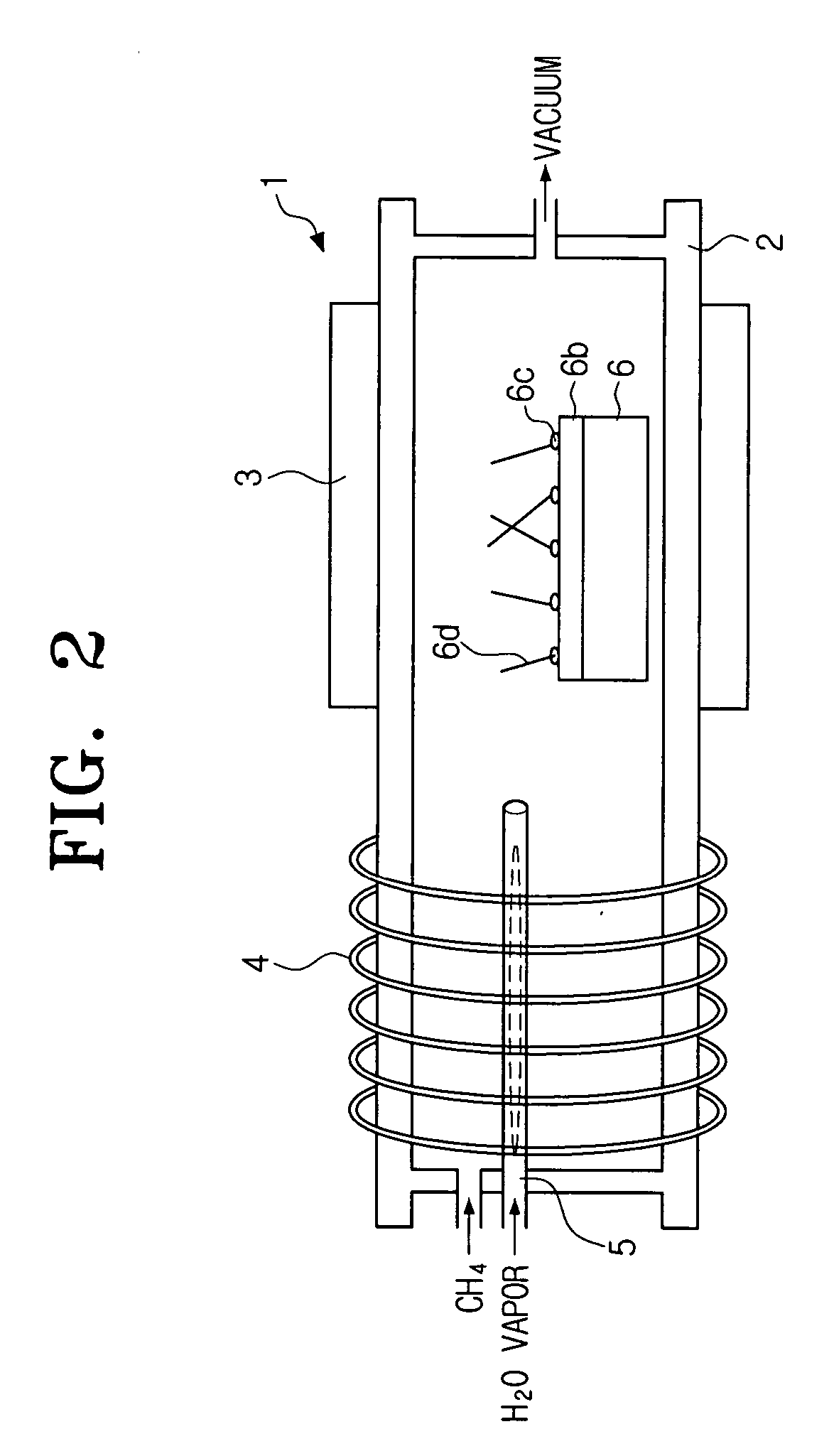

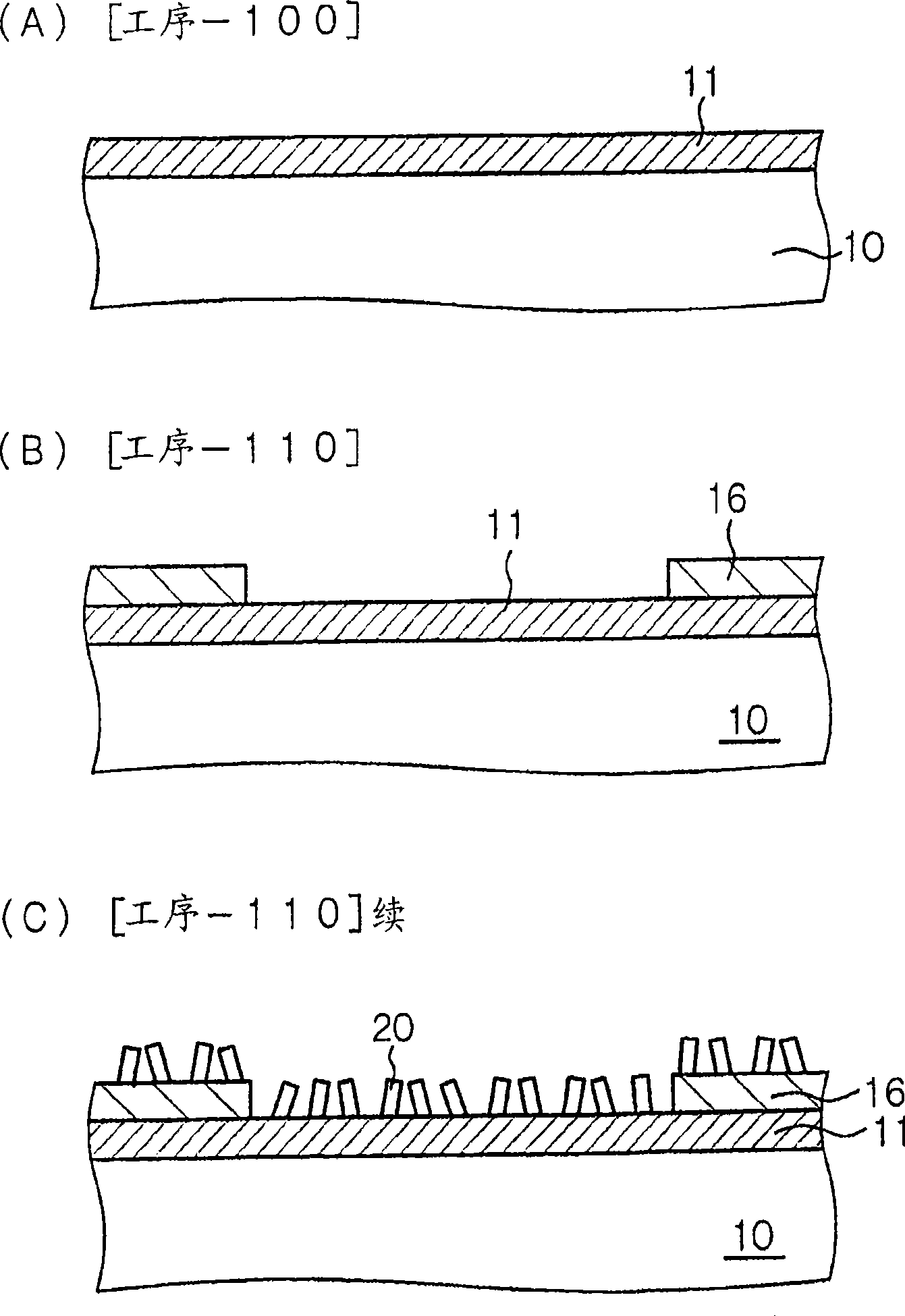

Method for manufacturing single-walled carbon nanotube on glass

InactiveUS20070154623A1Reduce the temperatureSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeMaterials science

Owner:SAMSUNG ELECTRONICS CO LTD

Castable for blast-furnace tapping channel and preparation method thereof

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

Transparent anti-static polyvinylidene fluoride piezoelectric material and preparation method thereof

InactiveCN103102623AImprove antistatic performanceExcellent piezoelectric propertiesCarbon nanotubePolyvinylidene difluoride

The invention relates to a transparent anti-static polyvinylidene fluoride piezoelectric material and a preparation method thereof. The filler is very difficult to uniformly disperse by adding carbon nano-tubes, graphene or zinc oxide to PVDF (Polyvinylidene Fluoride) material in the prior art; and the material is directly transmitted to be conductive from insulating, and is not attractive. The polyvinylidene fluoride piezoelectric material is a mixture of polyvinylidene fluoride and ionic liquid. The preparation method of the transparent anti-static polyvinylidene fluoride piezoelectric material comprises the following steps of: drying the polyvinylidene fluoride and the ionic liquid for 24 hours to 48 hours at 80 DEG C to 110 DEG C in a vacuum environment; adding the dried polyvinylidene fluoride and ionic liquid in a mass ratio of 100:(0.5-40) to a fusion smelting device for melting-blending at 180 DEG C to 200 DEG C to obtain a mixture; and discharging the mixture from the melting-blending device, cooling the mixture to normal temperature and crystallizing the cooled mixture to obtain the polyvinylidene fluoride piezoelectric material. The polyvinylidene fluoride piezoelectric material disclosed by the invention has good antistatic property, good piezoelectricity and excellent transparency. According to the preparation method of the polyvinylidene fluoride piezoelectric material disclosed by the invention, the normal melting-blending device is only needed to be used, and the industrial preparation is simple.

Owner:HANGZHOU NORMAL UNIVERSITY

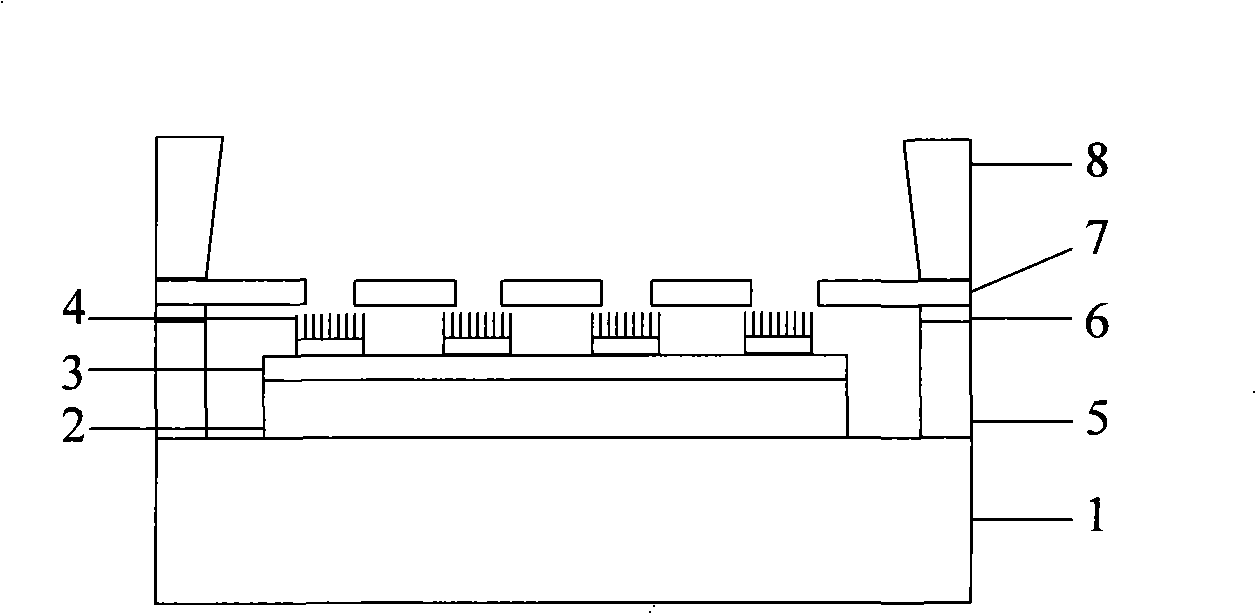

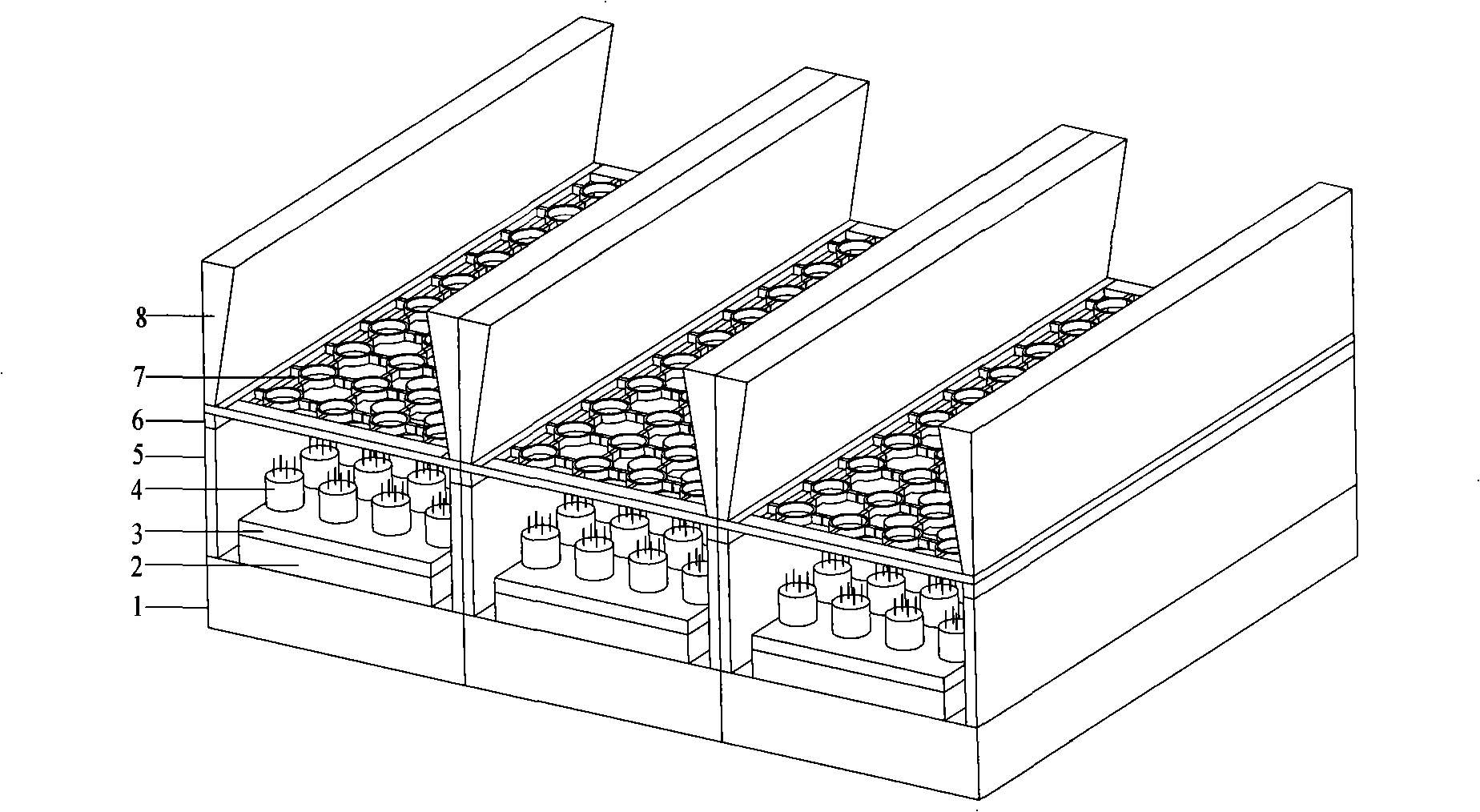

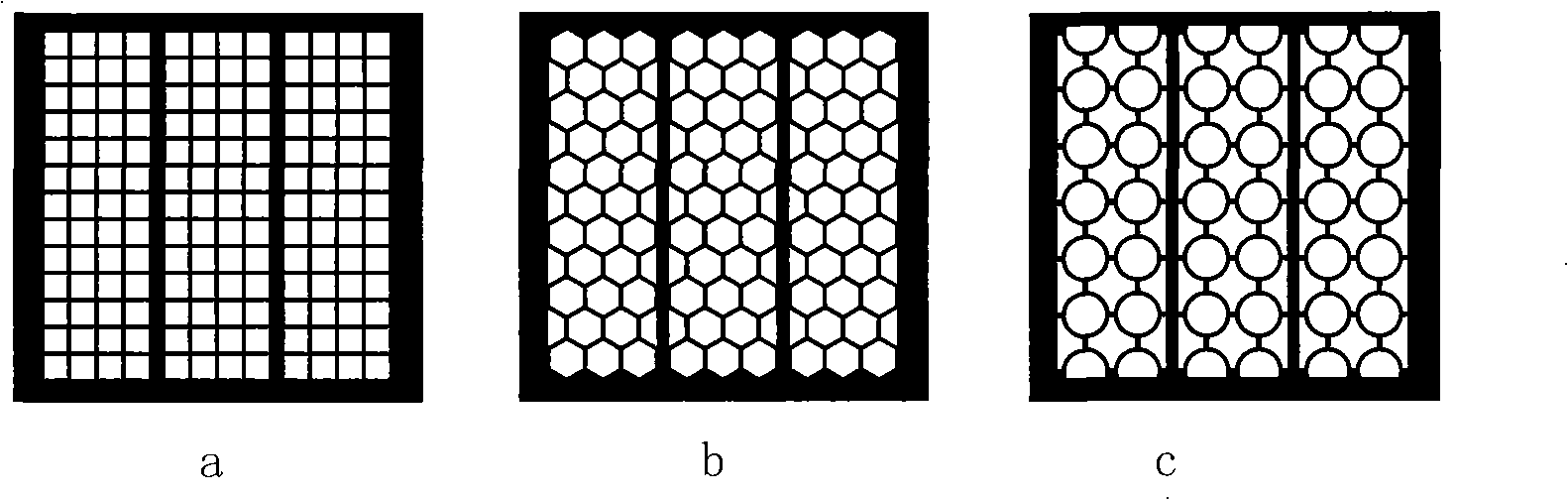

Metal and carbon nanotube or carbon fiber film emission array cathode as well as preparation method thereof

InactiveCN101355001AEasy to implementSimple processCathode ray tubes/electron beam tubesDischarge tube/lamp detailsFiberCarbon fibers

Owner:SHANGHAI JIAO TONG UNIV

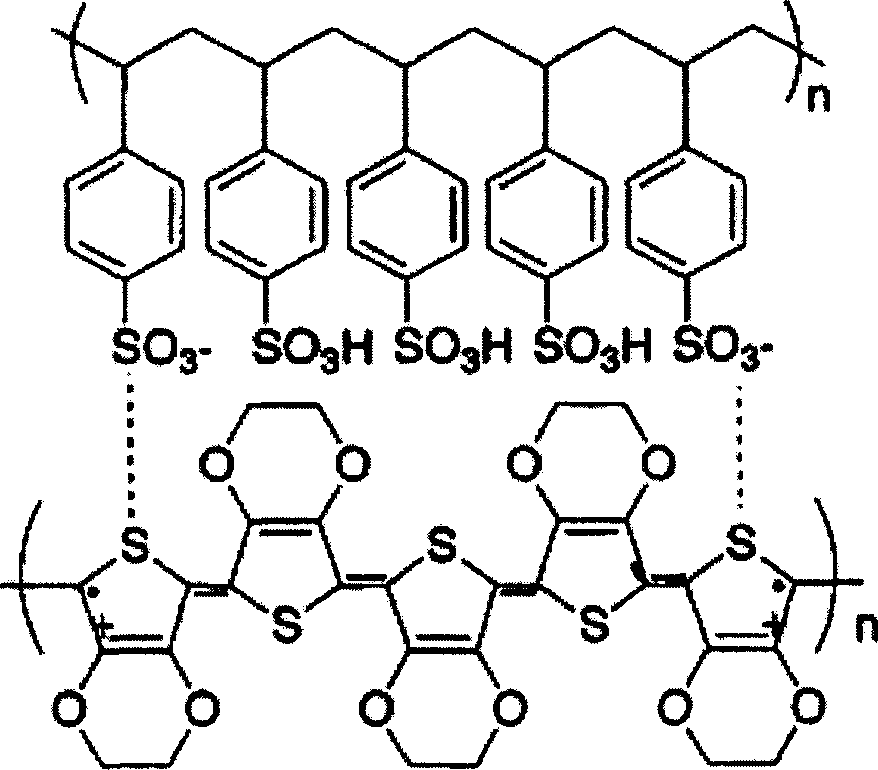

Carbon nanotube filled polycarbonate Anti-curl back coating with improved electrical and mechanical properties

Transparent or semi-transparent, electrically conductive anti-curl back coating composite for electrophotographic imaging member comprising a carbon nanotube complex and a polycarbonate binder are described along with processes for preparing them.

Owner:XEROX CORP

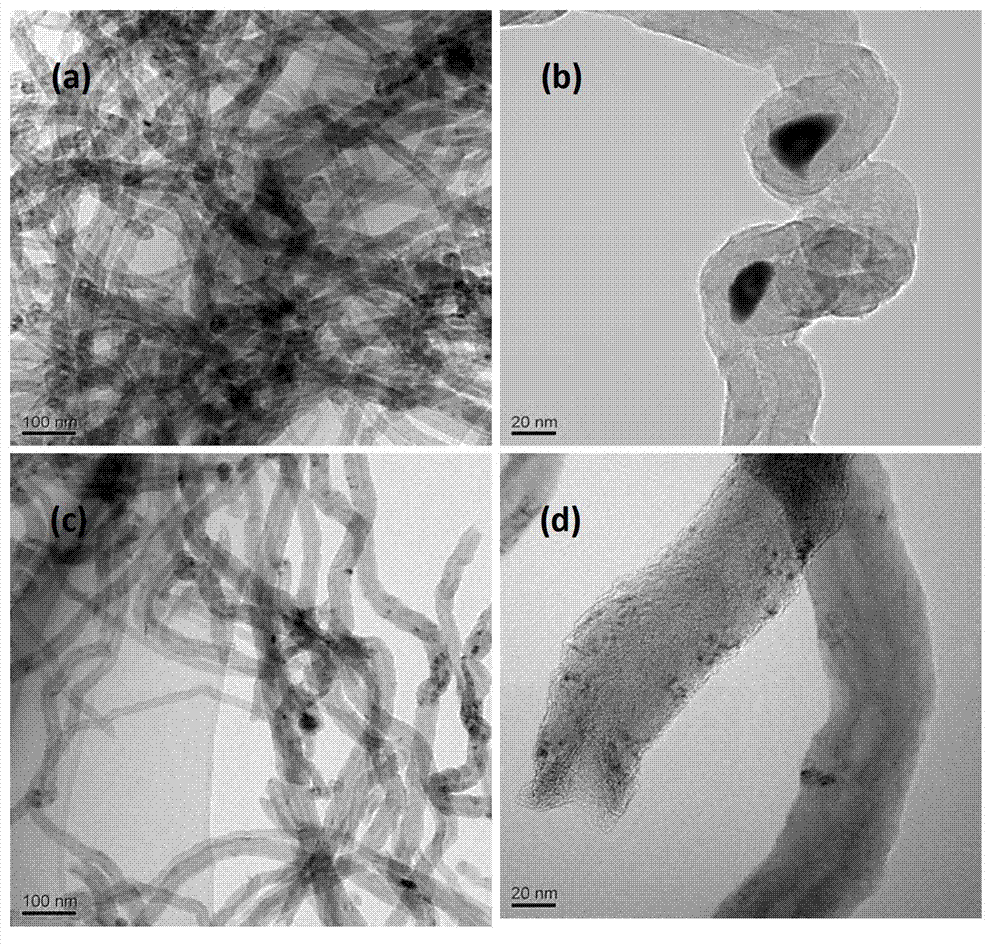

Carbon nanotube powder, carbon nanotubes, and processes for their production

InactiveUS8398949B2High purityImprove liquidityMaterial nanotechnologyBiocideCarbon nanotubeMaterials science

Owner:COVESTRO DEUTSCHLAND AG

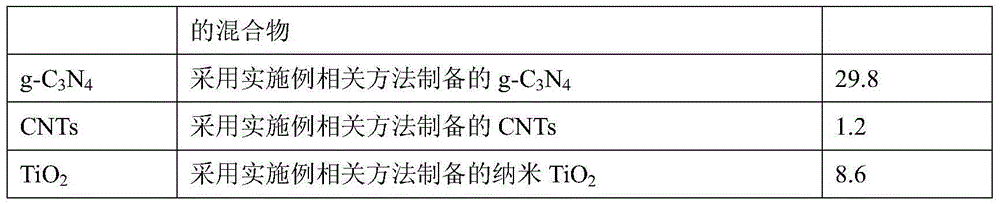

Photocatalyst composite structure and preparation method thereof

InactiveCN104801325AImprove adsorption capacityLarge specific surface areaPhysical/chemical process catalystsHydrogen productionDecompositionCarbon nanotube

Owner:EAST CHINA UNIV OF SCI & TECH +1

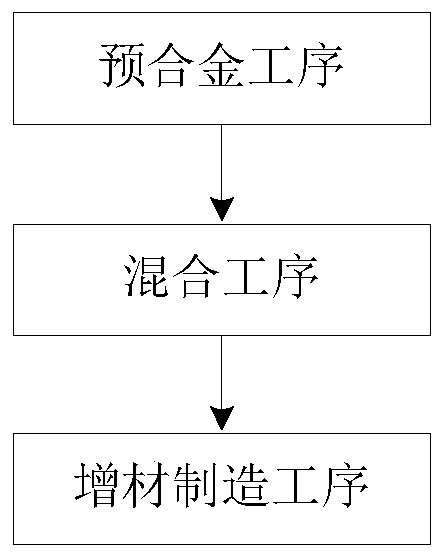

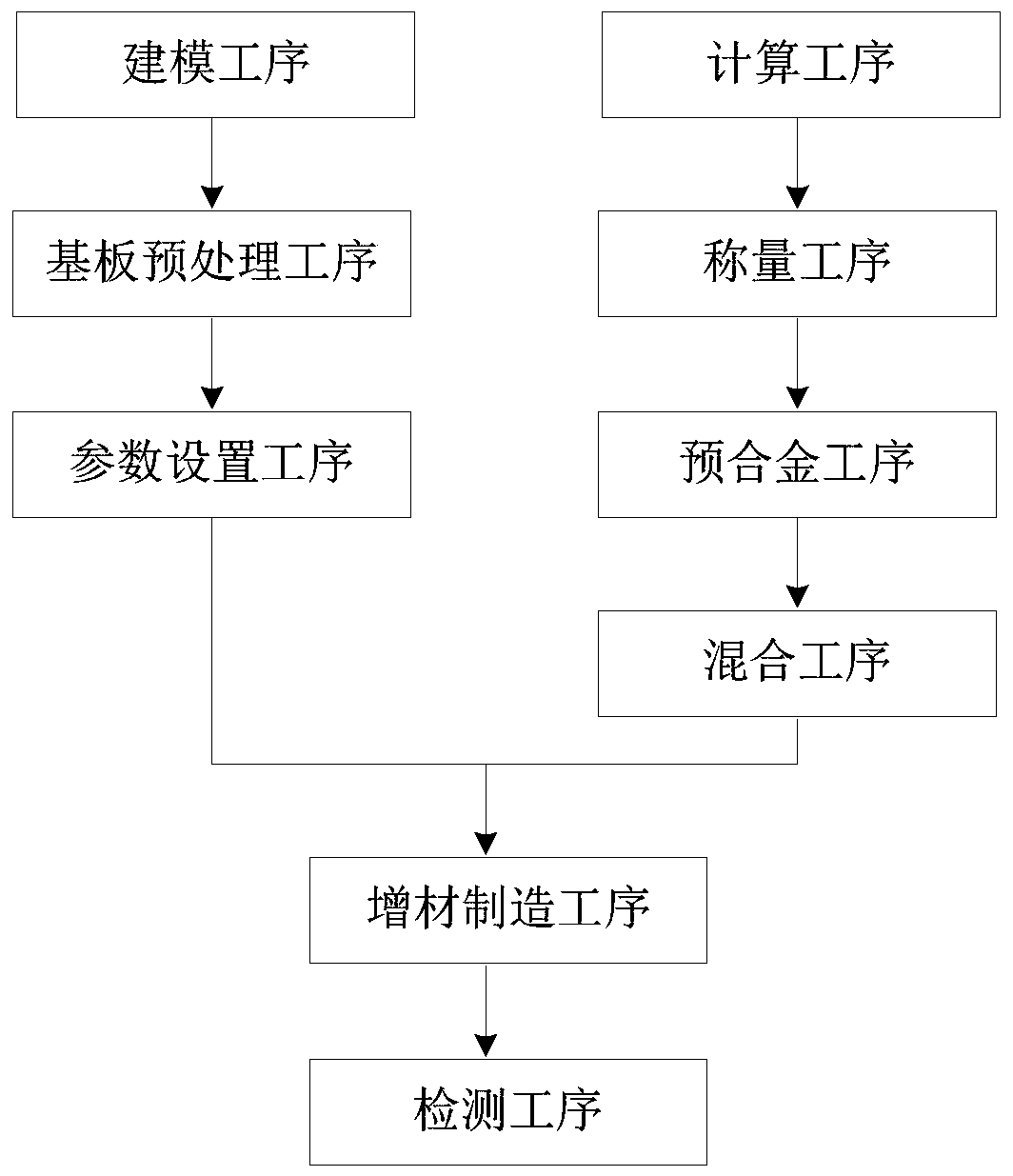

Alloying component and preparation method thereof

ActiveCN110592411AImprove distributionFull play formAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysCarbon nanotube

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

Nanometer carbon tube modification process

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation method of carbon nano-tube/amorphous carbon/epoxy resin composite material

Owner:HARBIN INST OF TECH

Method for removing phenol-based substances from water by using iron-sulfur supported multi-walled carbon nano-tube reinforced persulfate

InactiveCN107487832ALow costEasy to operateWater contaminantsWater/sewage treatment by sorptionPersulfateSulfur

Owner:SICHUAN UNIV

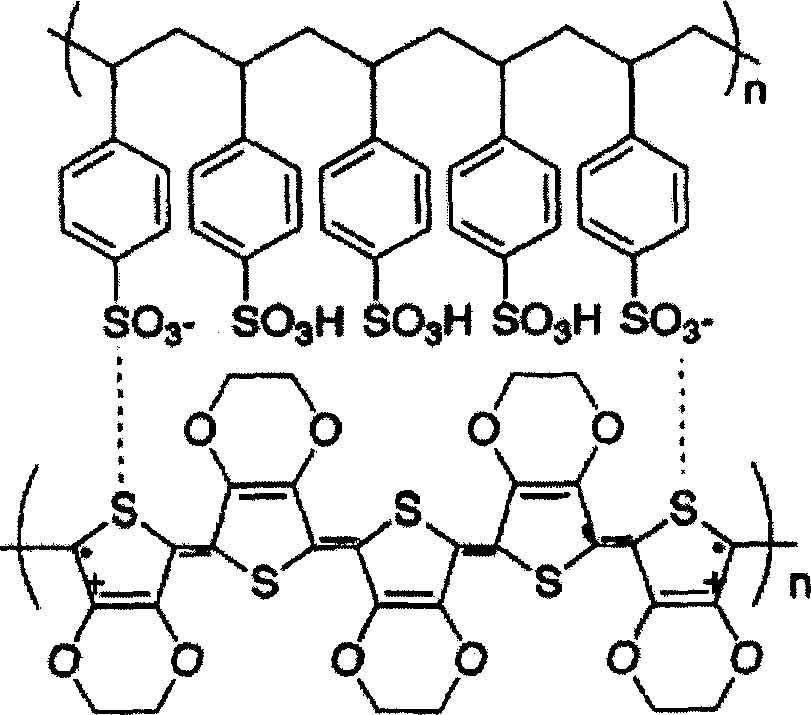

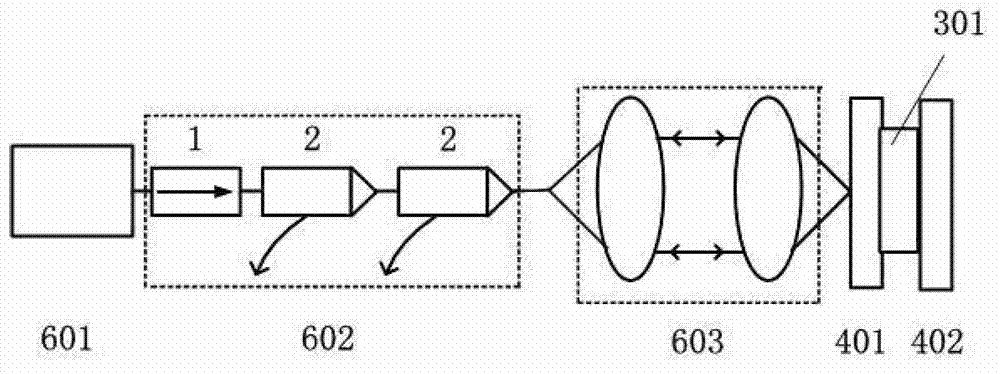

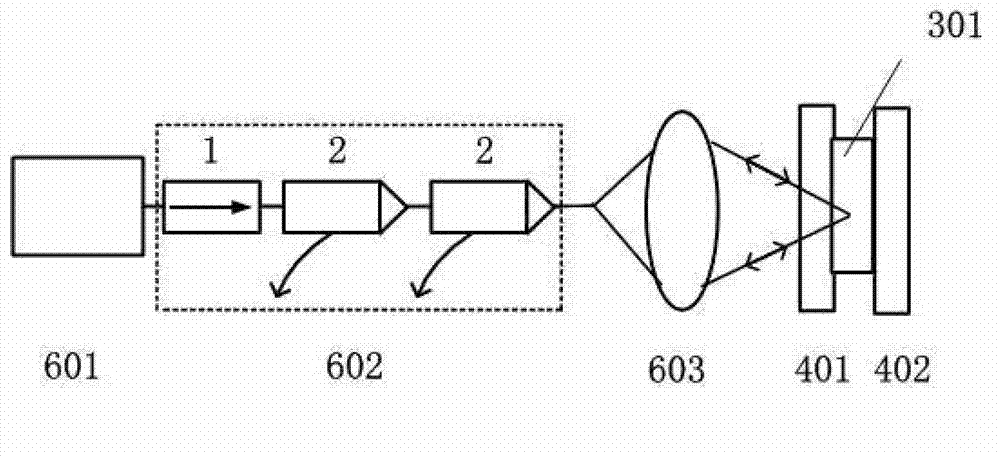

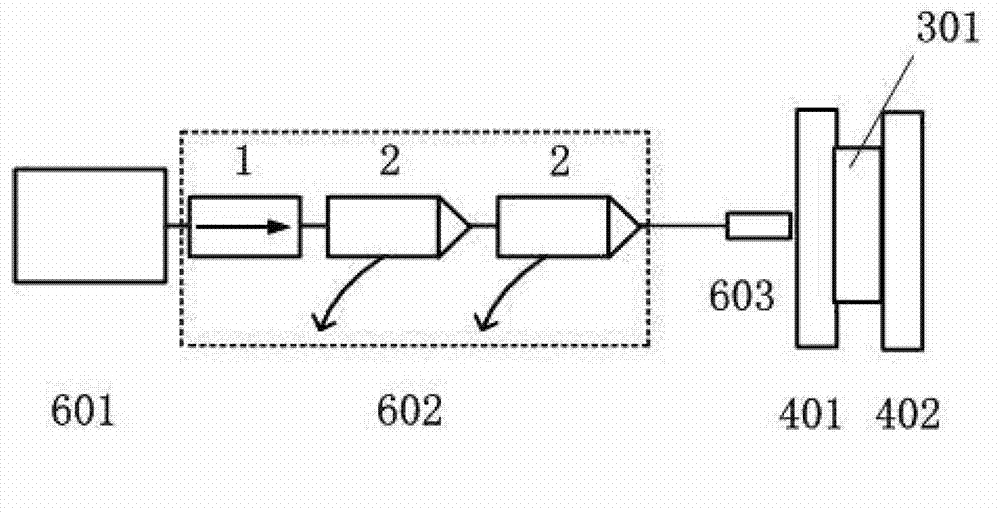

Novel microchip laser supporting optical fiber output

ActiveCN103050870AStable outputStable single frequency outputOptical resonator shape and constructionActive medium materialCarbon nanotubeMicrochip laser

Owner:BEIJING UNIV OF TECH

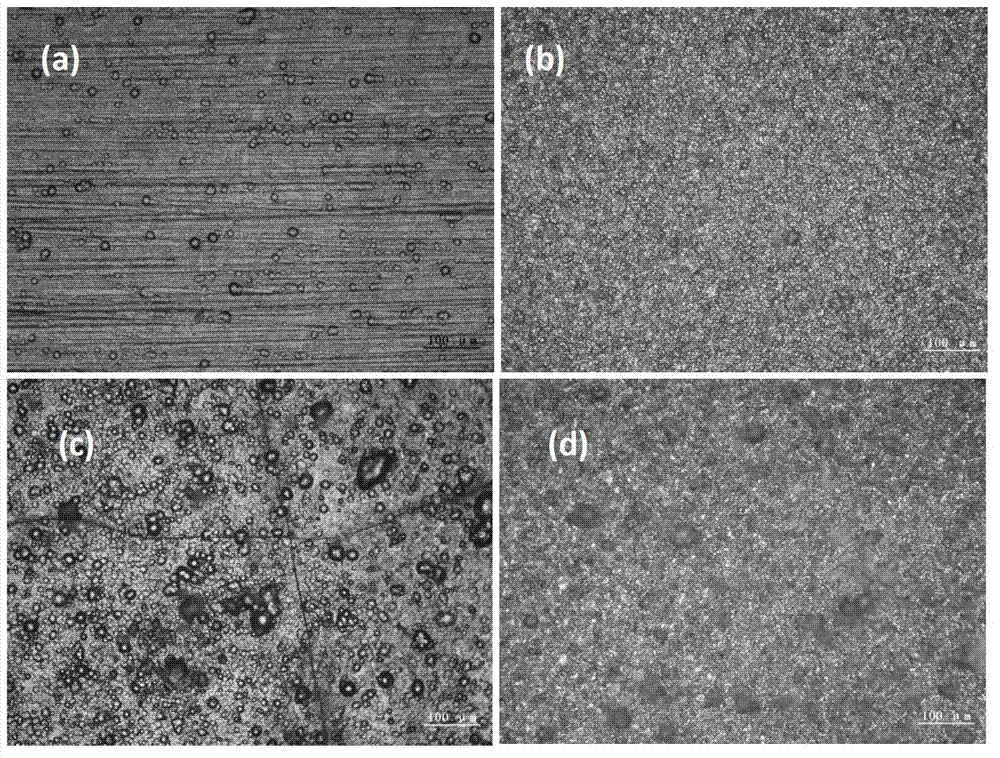

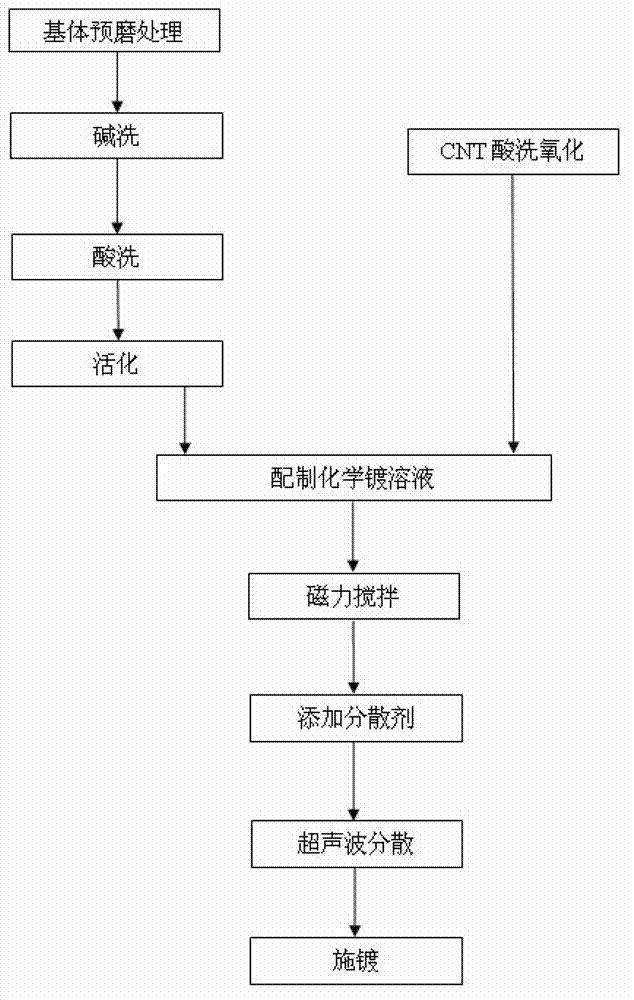

Method for preparing Ni-P-CNT (Carbon nanotube) nano composite coating

Owner:XIAN UNIV OF SCI & TECH

Novel metal-organic framework material separation membrane based on carbon nanotube substrate and preparation method thereof

InactiveCN105771685AHigh selectivityImprove permeabilitySemi-permeable membranesSurface layerFiltration

Owner:BEIJING FORESTRY UNIVERSITY

Flexible lithium-ion battery capable of working around clock and preparation method thereof

ActiveCN108649230AHigh degree of orderImprove electrochemical performanceFinal product manufactureElectrode carriers/collectorsCarbon nanotubeEngineering

Owner:JIANGXI UNIV OF SCI & TECH

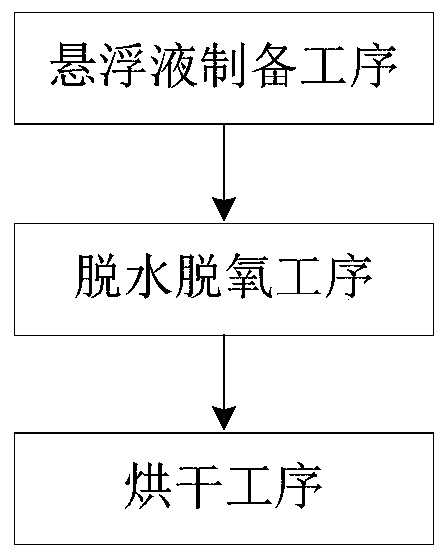

Water-based carbon nanotube dye, composition thereof and method for preparing conductive fiber

Owner:MATERIAL & IND TECH RES INST BEIJING

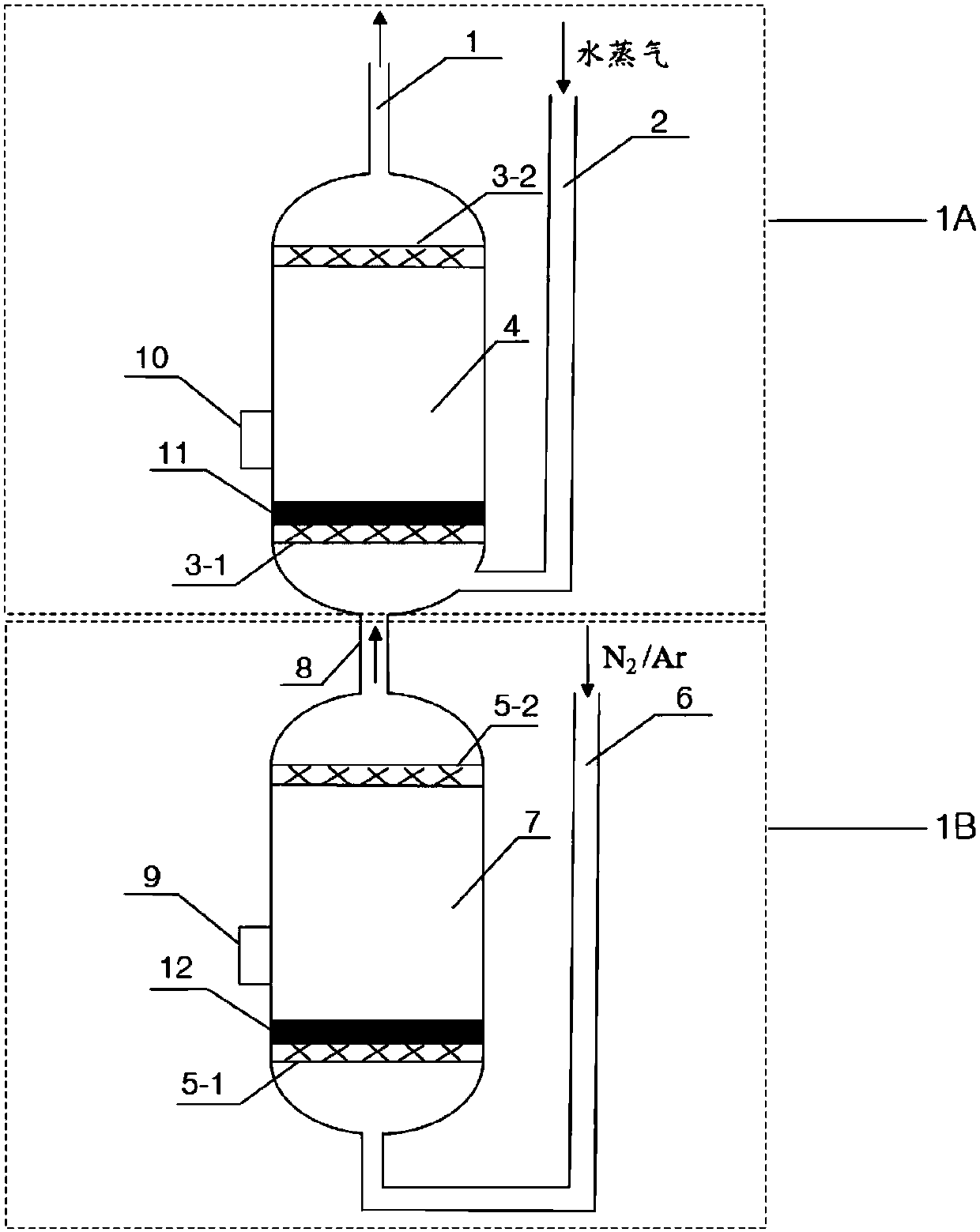

Two-section system and method for coproducing coal-based graphite and carbon nano-tubes

Owner:HUAZHONG UNIV OF SCI & TECH

Graphene coated carbon-sulfur composite material

InactiveCN104201354AImprove adsorption capacityBound to dissolveCell electrodesSecondary cellsEnvironmental resistanceCompound a

Owner:NANJING ZHONGCHU NEW ENERGY

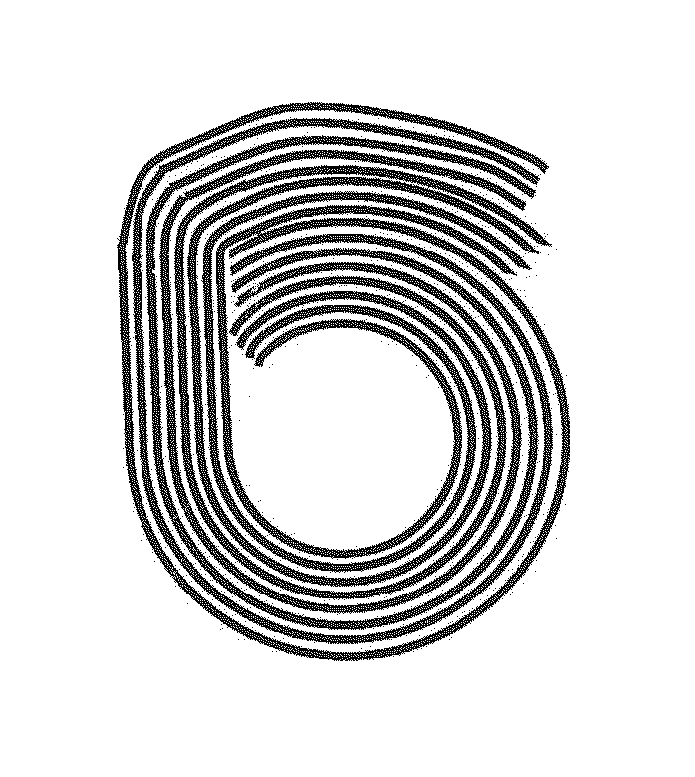

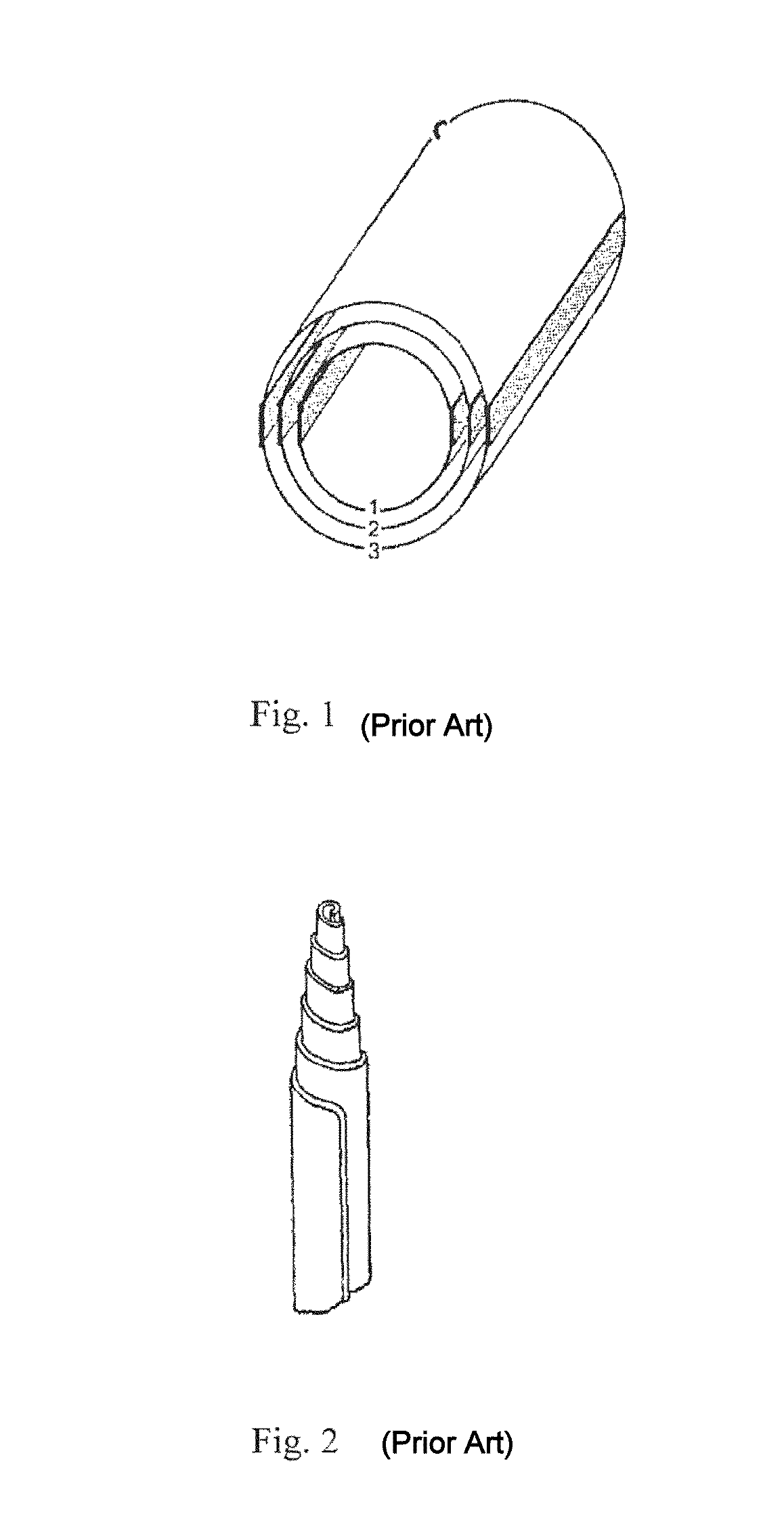

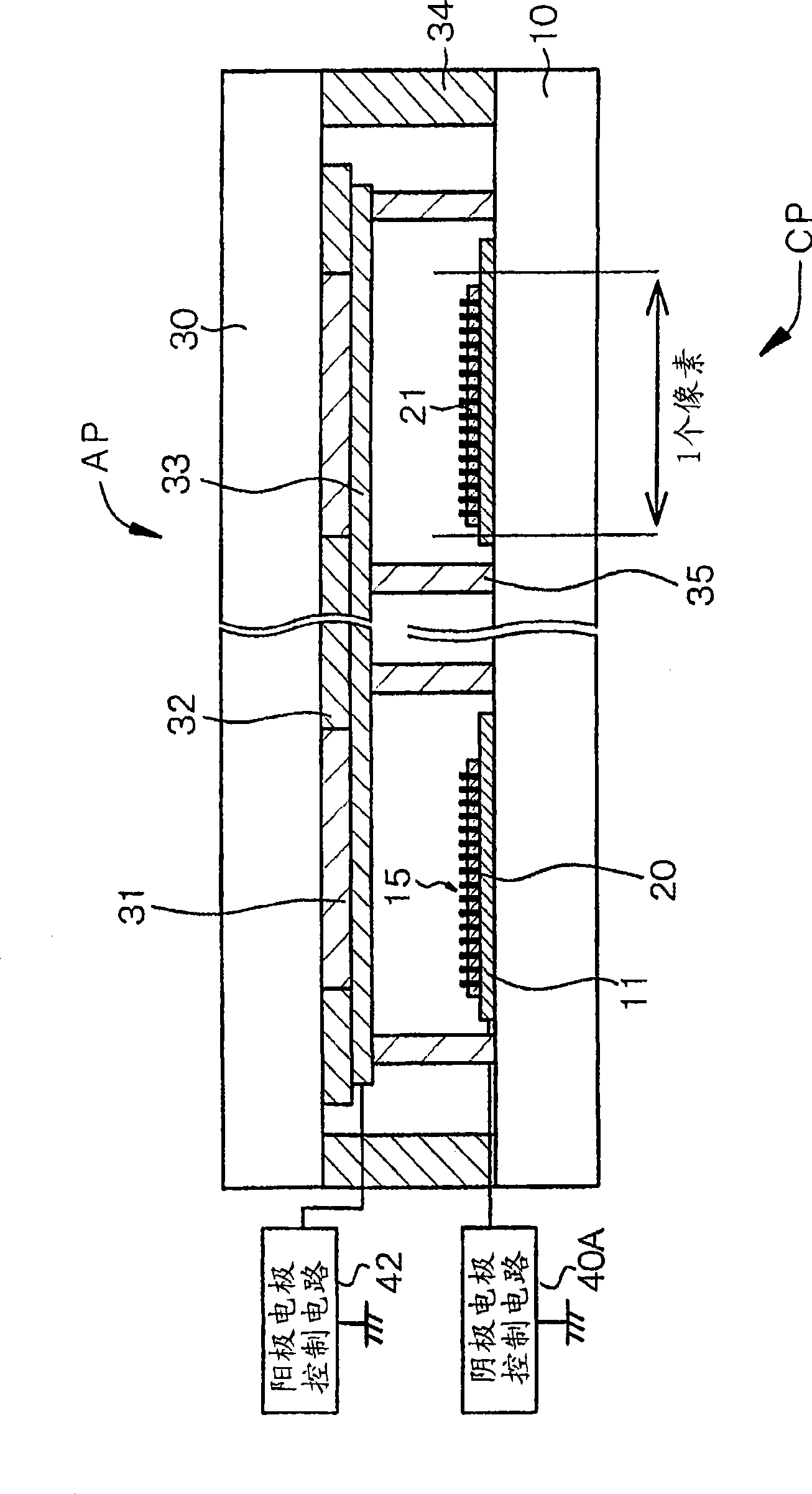

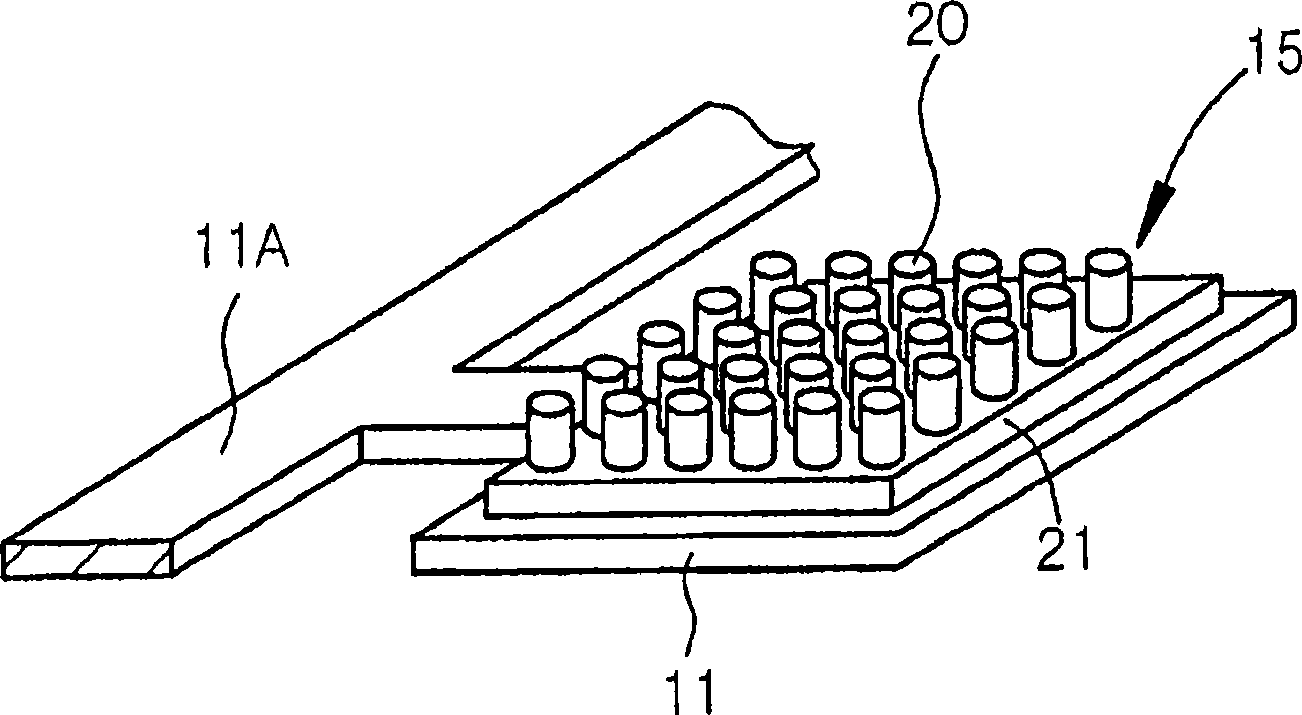

Electron emitter, cold-cathode field electron emitter, and method for manufacturing cold-cathode field electron emission display

Owner:SONY CORP

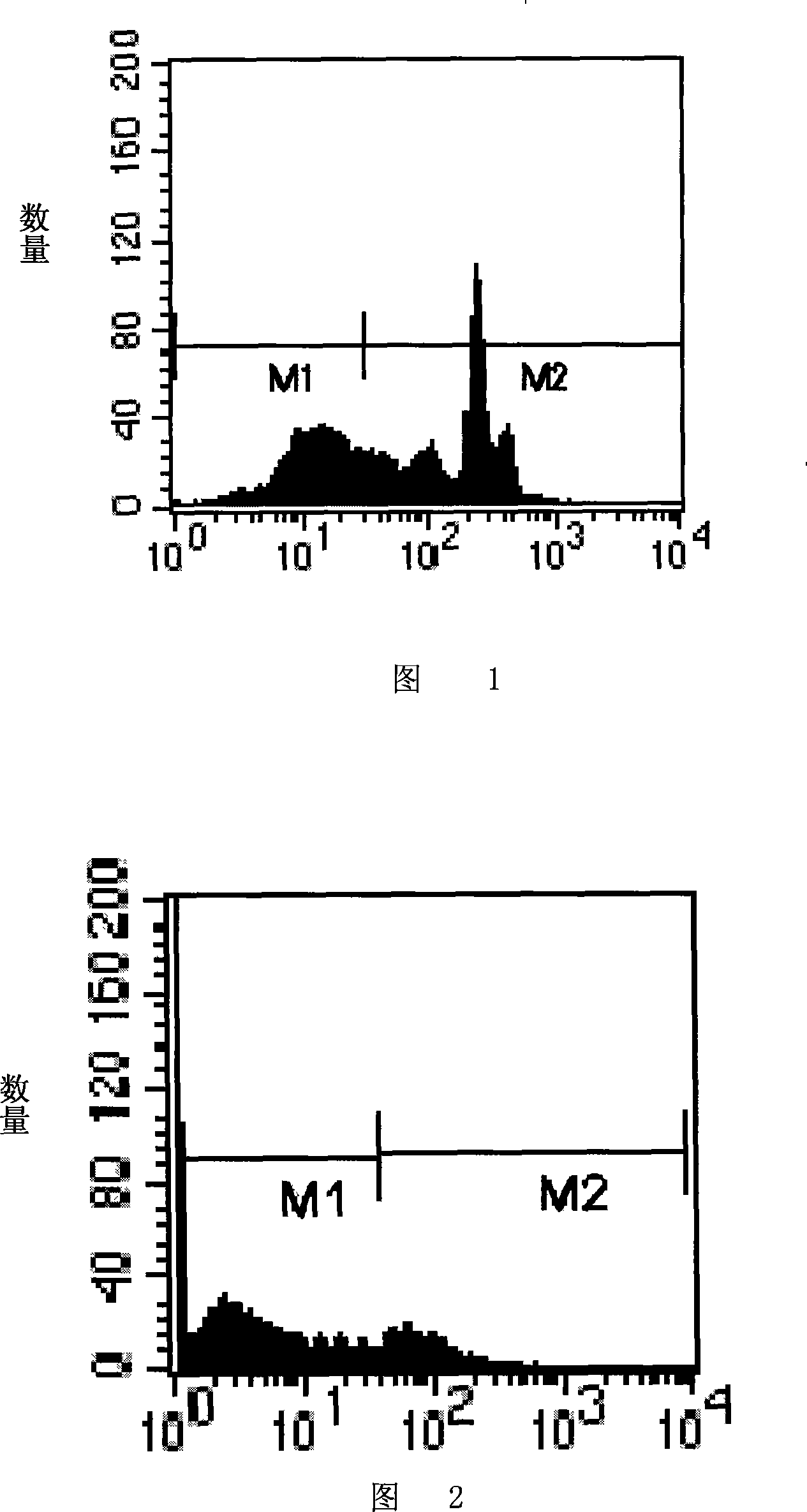

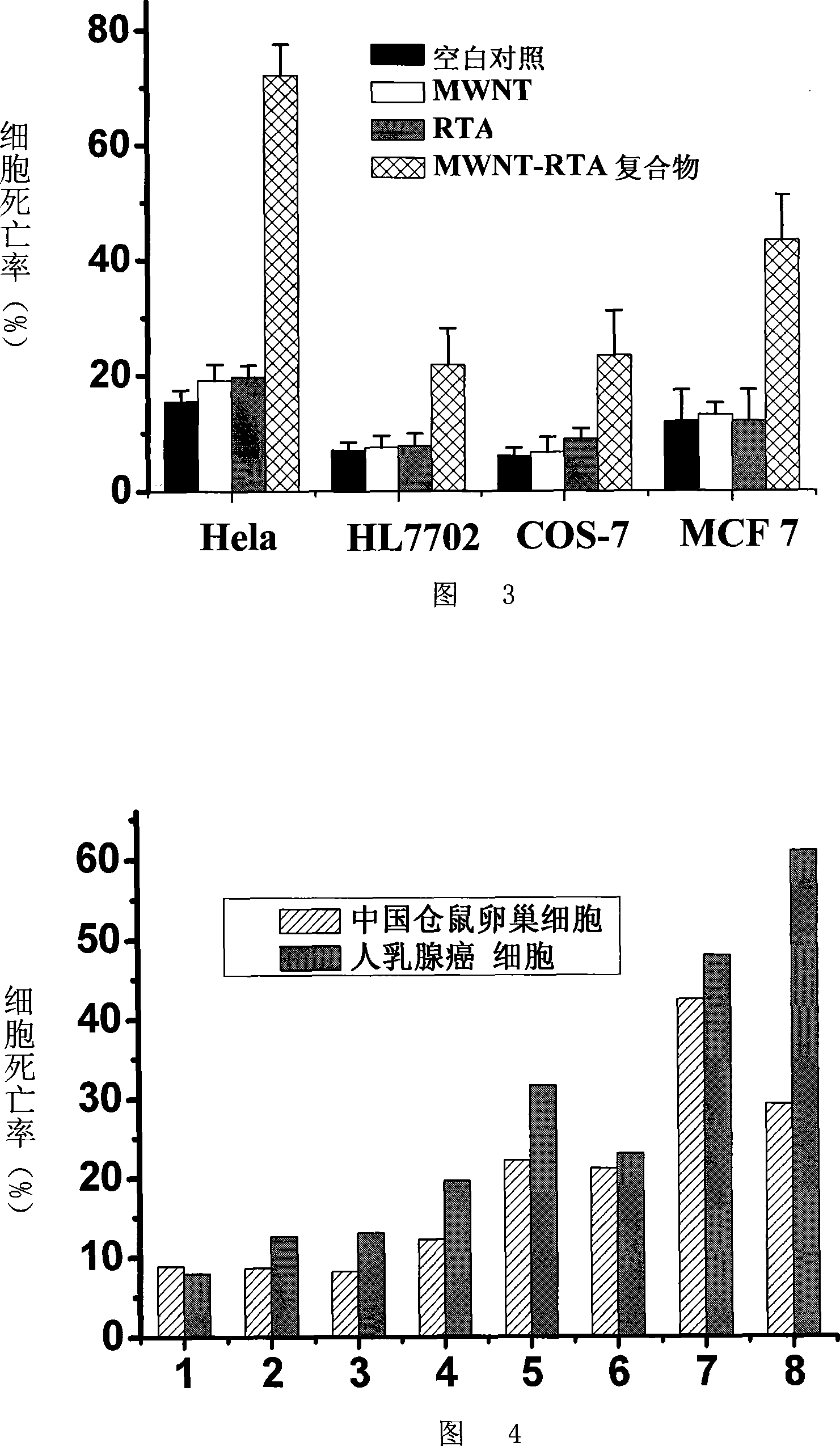

Complexes for target killing tumor cell, preparation and application thereof

InactiveCN101239180AGood dispersion in water phaseIncrease loadPeptide/protein ingredientsPharmaceutical non-active ingredientsProtein targetCarbon nanotube

Owner:FUDAN UNIV

Tomato fertilizer containing rich nucleic acid and preparation method of tomato fertilizer

InactiveCN106007932AImprove water holding capacityImprove stabilityCalcareous fertilisersAlkali orthophosphate fertiliserHeavy metal chelationPolyvinyl alcohol

The invention discloses a tomato fertilizer containing rich nucleic acid. The tomato fertilizer is prepared from raw materials in parts by weight as follows: 200-210 parts of rice straw, 20-21 parts of kaoline, 10-11 parts of urea, 10-11 parts of furnace dust, 5-6 parts of hawthorn seeds, 7-8 parts of nucleic acid wastewater, 0.3-0.4 parts of ammonium polyphosphate, 0.1-0.2 parts of a urease inhibitor, 1-2 parts of gypsum powder, 1-2 parts of amino acid powder, 15-16 parts of polyvinyl alcohol, 1-1.1 parts of tea polyphenol, 1-1.1 parts of carbon nanotubes, 1.2-1.3 parts of beta-cyclodextrine and 800-810 parts of 28% ammonia water. Amino groups are introduced to biomass charcoal prepared from the rice straw and can be chelated with heavy metal, the heavy metal adsorption capability is improved, and the pollution influence of the heavy metal on soil and the environment is reduced. The carbon nanotubes are added to a film coating liquid, the mechanical strength of a film can be improved, and added tea polyphenol can improve the slow-release property of the film; besides, the tomato fertilizer contains rich nucleic acid, the activity of tomatoes can be enhanced, decaying of the tomatoes is delayed, and the yield is increased.

Owner:ANHUI YONGGUAN AGRI TECH CO LTD

Full-frequency wave-absorbing high-temperature heat-insulating stealth integrated paint and preparation method thereof

InactiveCN111393989AImprove reflective absorption performanceIncrease autonomyFireproof paintsRadiation-absorbing paintsFiberFrequency wave

Owner:QINGDAO AIR NEW MATERIALS

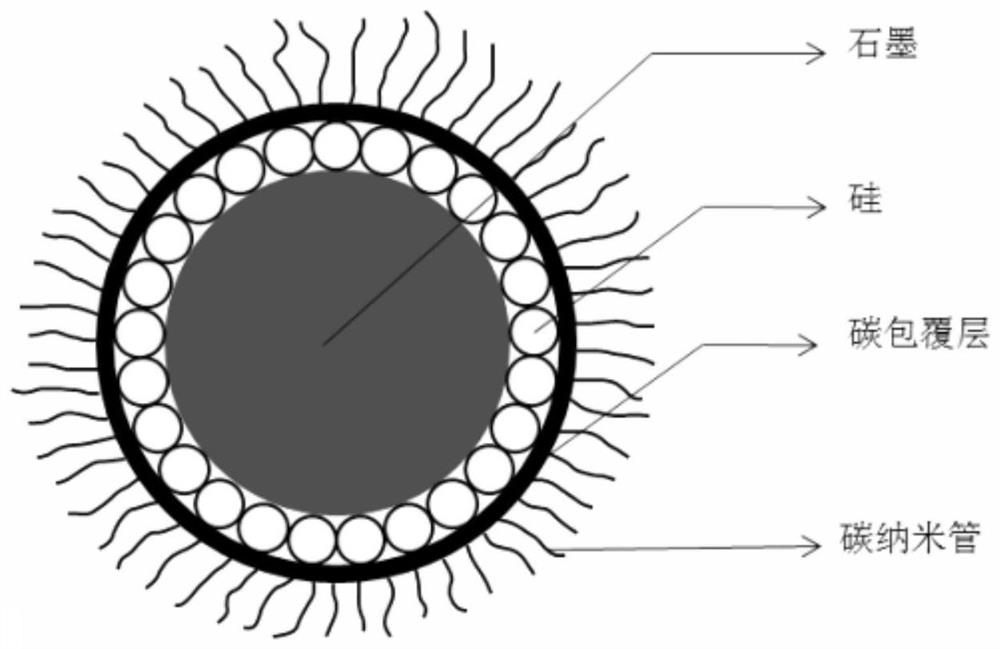

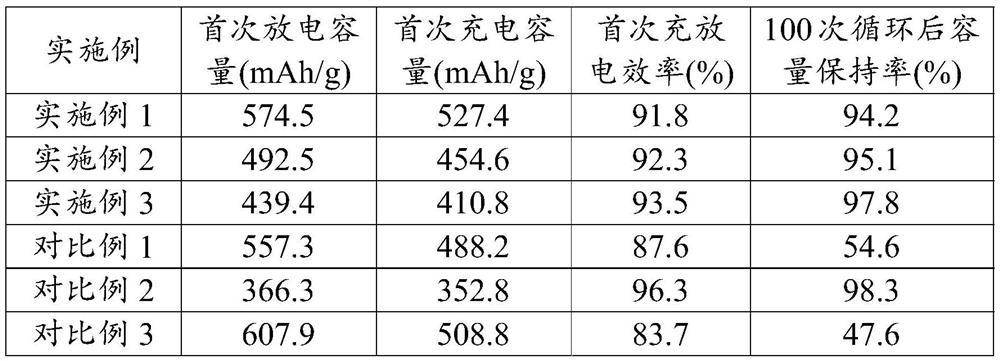

Negative electrode material and preparation method thereof and secondary battery

Owner:SHENZHEN DYNANONIC

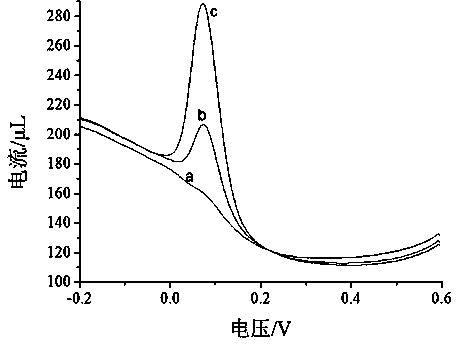

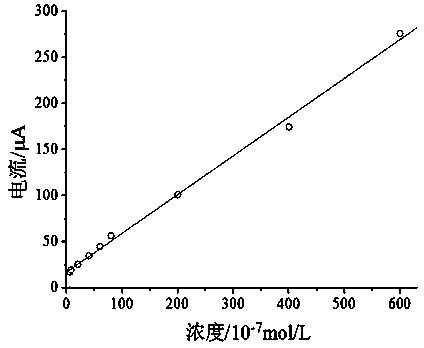

Method for detecting trace hydroquinone by using graphene/carbon nano tube modified electrode

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

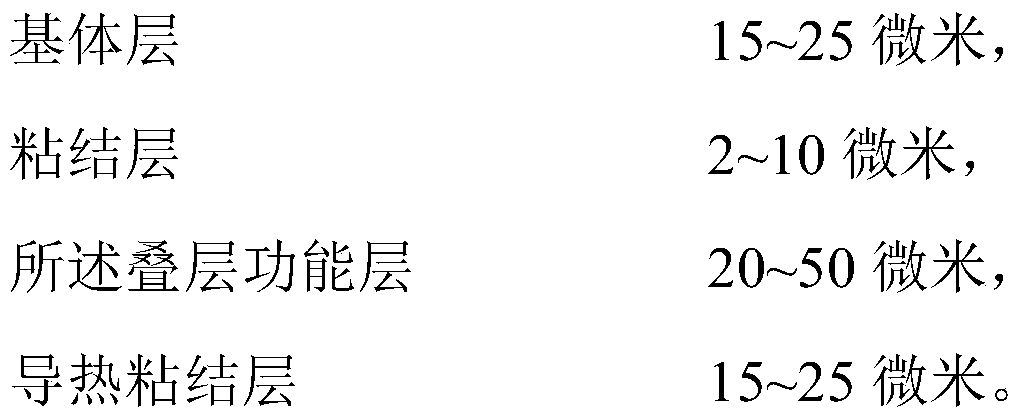

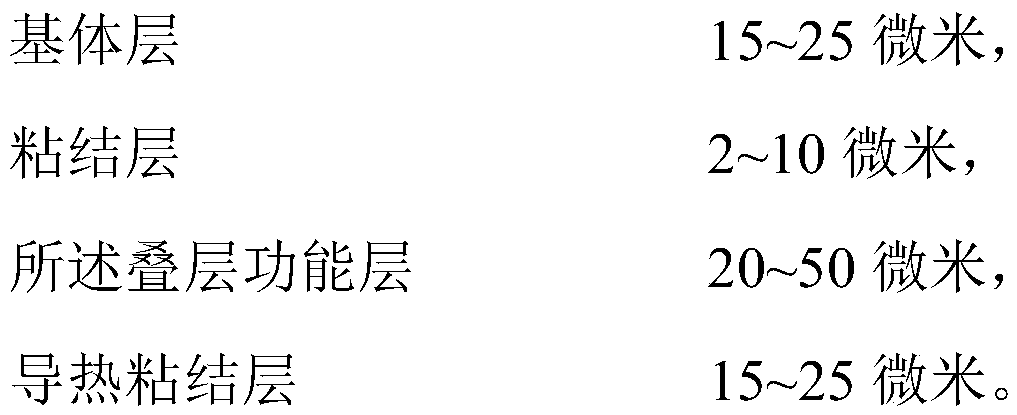

Electromagnetic shielding heat dissipation film and preparation method and application thereof

InactiveCN110602934AHigh thermal conductivityImprove conductivityMagnetic/electric field screeningSynthetic resin layered productsAdhesiveCarbon nanotube

Owner:SHENZHEN XIWAN TECH CO LTD

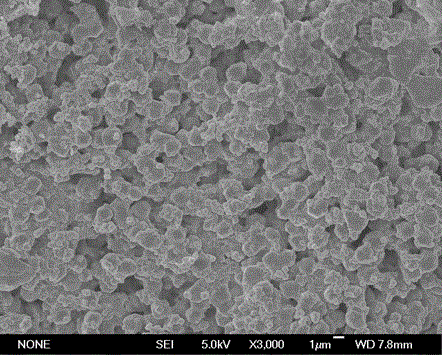

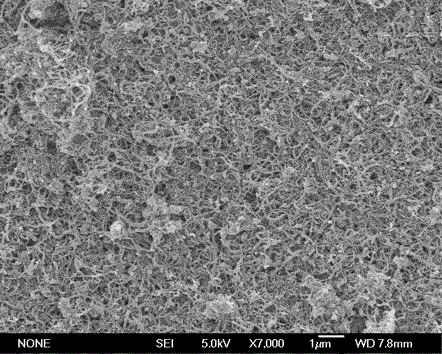

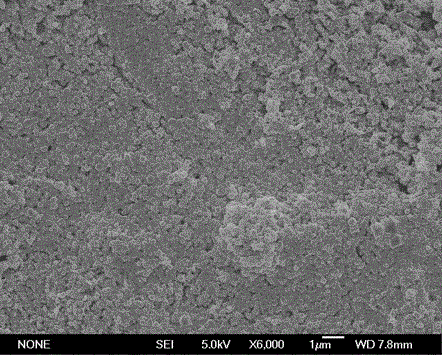

Multiwall carbon nanotube cement-based composite material and preparation method thereof

The invention relates to a multiwall carbon nanotube cement-based composite material and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 0.4 to 0.7 part of surfactant, 10 to 20 parts of ethanol, 0.05 to 0.15 part of multiwall carbon nanotubes, 1.5 to 1.8 parts of nano silicon dioxide, 100 parts of cement gelling material, 10 to20 parts of silica fume, 300 to 400 parts of standard sand, and 40 to 60 parts of water. The multiwall carbon nanotube is added into the cement-based composite material, so that the composite materialis low in porosity, small in average aperture, and compact in structure, thereby improving the mechanical performance of the material. By virtue of determination, the pressure resistant strength is increased by 11.6 to 20.99 percent, so that the service life of a building is effectively prolonged. The method disclosed by the invention is simple and easy in operation, controllable in cost, capableof solving the agglomeration problem of the multiwall carbon nanotube, and capable of preventing the secondary agglomeration of the multiwall carbon nanotube in the cement-based composite material. In the current construction process of smart cities and green cities, the multiwall carbon nanotube cement-based composite material have wide market prospect and application value.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap