Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Compositermes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

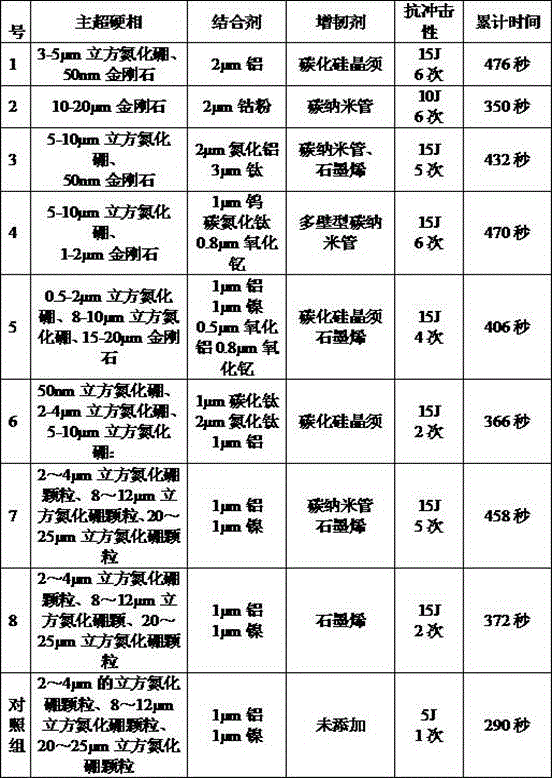

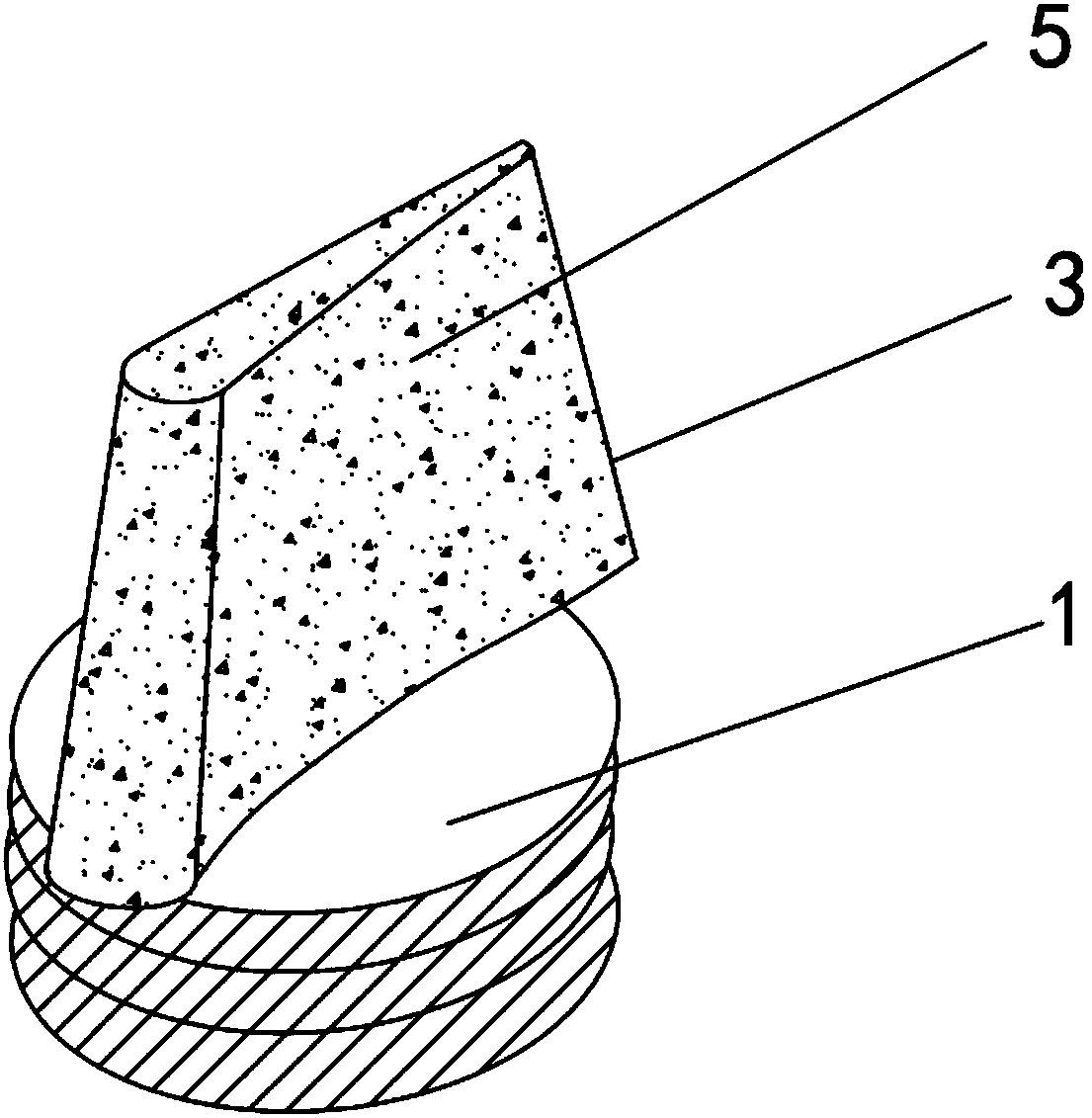

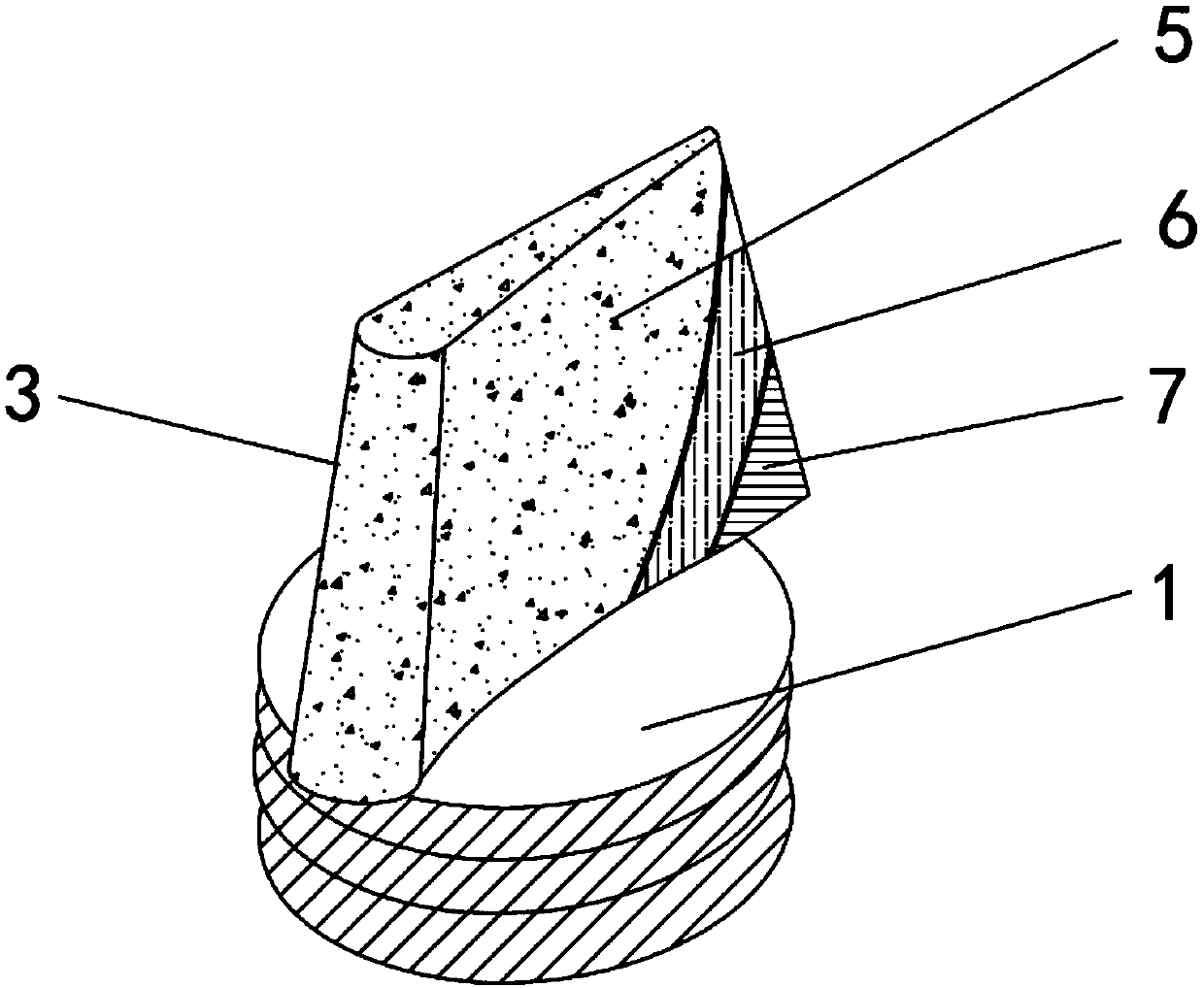

High-tenacity polycrystalline composite material, high-tenacity polycrystalline blade and preparation method of high-tenacity polycrystalline blade

InactiveCN105908041AImprove fracture toughnessImprove impact resistanceTurbinesOther manufacturing equipments/toolsCarbide siliconCarbon nanotube

Owner:FUNIK ULTRAHARD MATERIAL

Phase change energy storage thermoplastic composite material and preparation method thereof

ActiveCN102070845AHas processing propertiesHigh elongation at breakHeat-exchange elementsPolymer scienceVulcanization

Owner:KINGFA SCI & TECH CO LTD +2

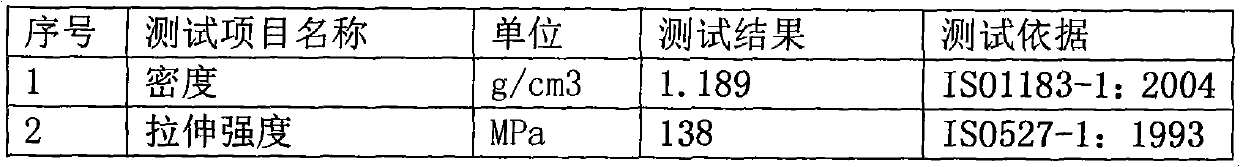

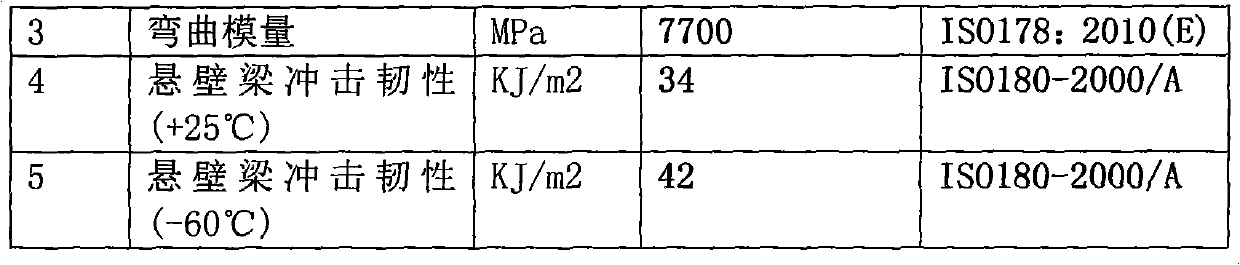

Long-fiber enhanced thermoplastic composite material vane used for wind energy generator

InactiveCN102675740ALow shrinkageLow temperature impact resistanceFinal product manufactureMachines/enginesGlass fiberPhoto aging

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

Multi additive multifunctional composite for use in a non-metallic fuel conveyance system

A multifunctional composite material may include a polymer matrix, at least one nano-additive, micro-additive, and / or a spherical nano-additive. The non-metallic composite material may be used to make non-metallic parts for fuel conveyance systems for use in aircraft.

Owner:EATON INTELLIGENT POWER LTD

MoS2@C composite anode material for lithium ion battery and preparation method thereof

ActiveCN111900408AImproved magnification performanceLimit volume expansionNegative electrodesSecondary cellsCarbon layerBattery cell

The invention discloses a MoS2@C composite anode material for a lithium ion battery and a preparation method thereof, MoS2 sheets in the composite anode material are stacked disorderly and intertwinedto form a wormlike microsphere structure, and the MoS2@C composite anode material comprises 38-43% of Mo, 47-53% of S and the balance of C. According to the invention, MoS2 and a carbon material arecompounded; the prepared anode material has a wormlike structure; the diffusion path of Li<+> can be shortened; the composite material has excellent rate capability; and the carbon layer coated on thesurface of the MoS2 sheet can limit the further growth of the MoS2 nanosheet and can inhibit the problem of easy volume expansion of the MoS2 composite material in the cycle process, thereby effectively enhancing the rate capability and cycle stability of the lithium ion battery anode material.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Preparation method of mesoporous silica in situ doped acrylic resin bone cement composite for enhancing durable release capacity of medicines

Owner:NANJING DRUM TOWER HOSPITAL

High-thermal-conductivity pure porous silicon carbide material, preparation method and application thereof

ActiveCN110746192AImprove thermal conductivityAdjustable volumeCeramicwareElectromagnetic shieldingGrain boundary

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Coating material for sealing coal wall of gob-side coal roadway

Owner:SHANDONG UNIV OF SCI & TECH

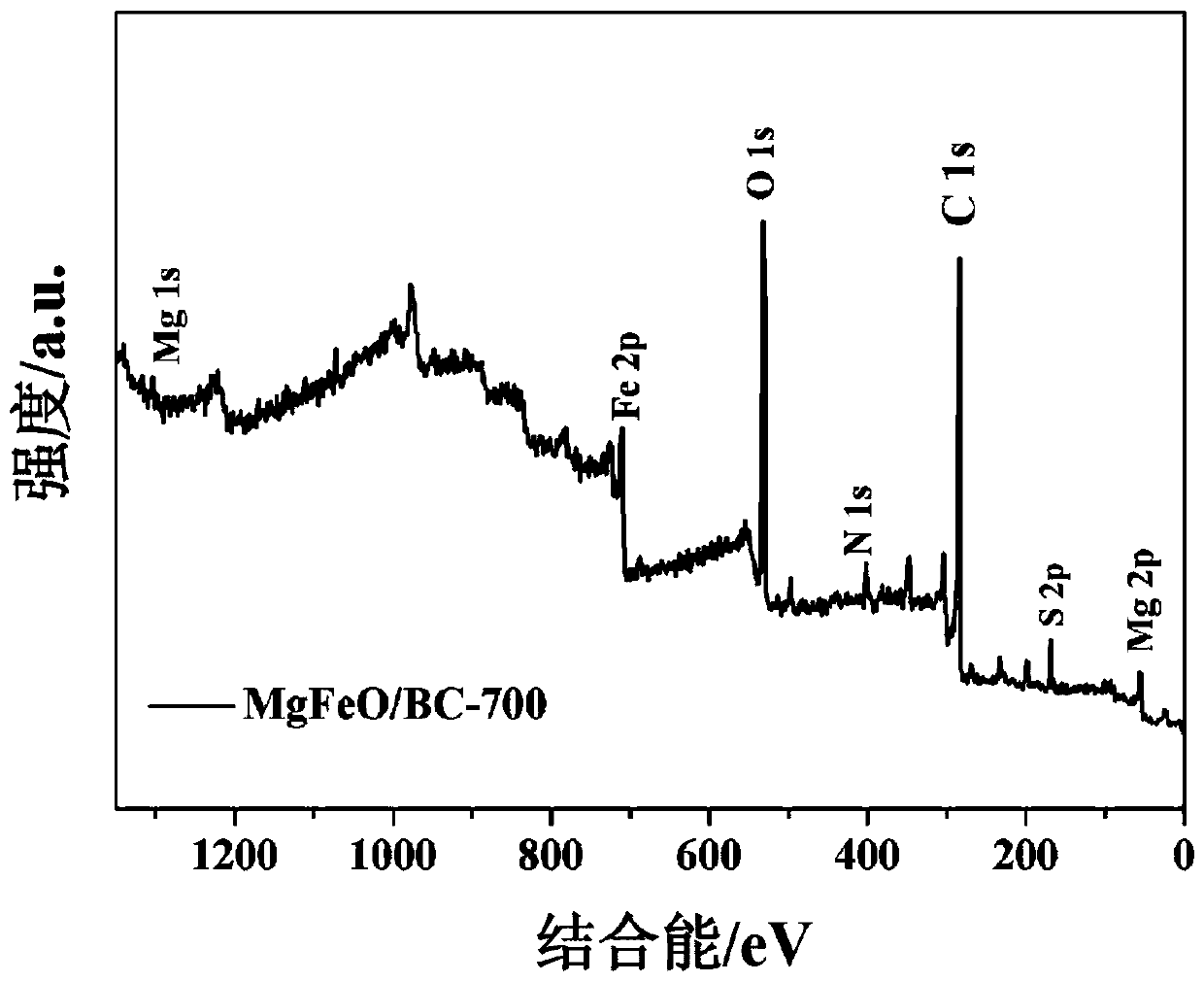

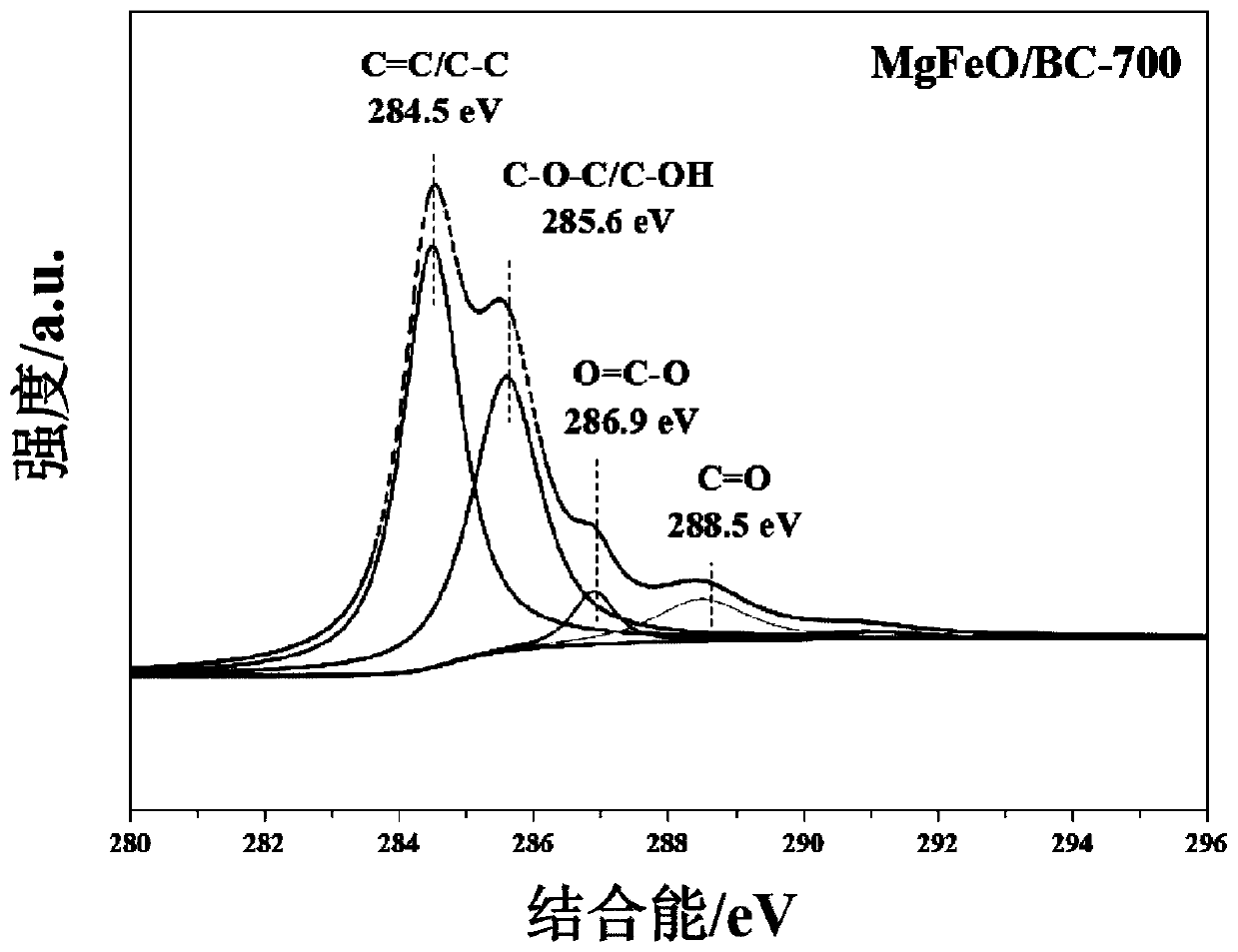

Application of Mg/Fe oxide modified biochar nano composite material in removing antibiotics

ActiveCN110813237AIncrease the number of active sitesImprove catalytic performanceOther chemical processesWater contaminantsEngineeringAntibiotic drug

Owner:HUNAN UNIV

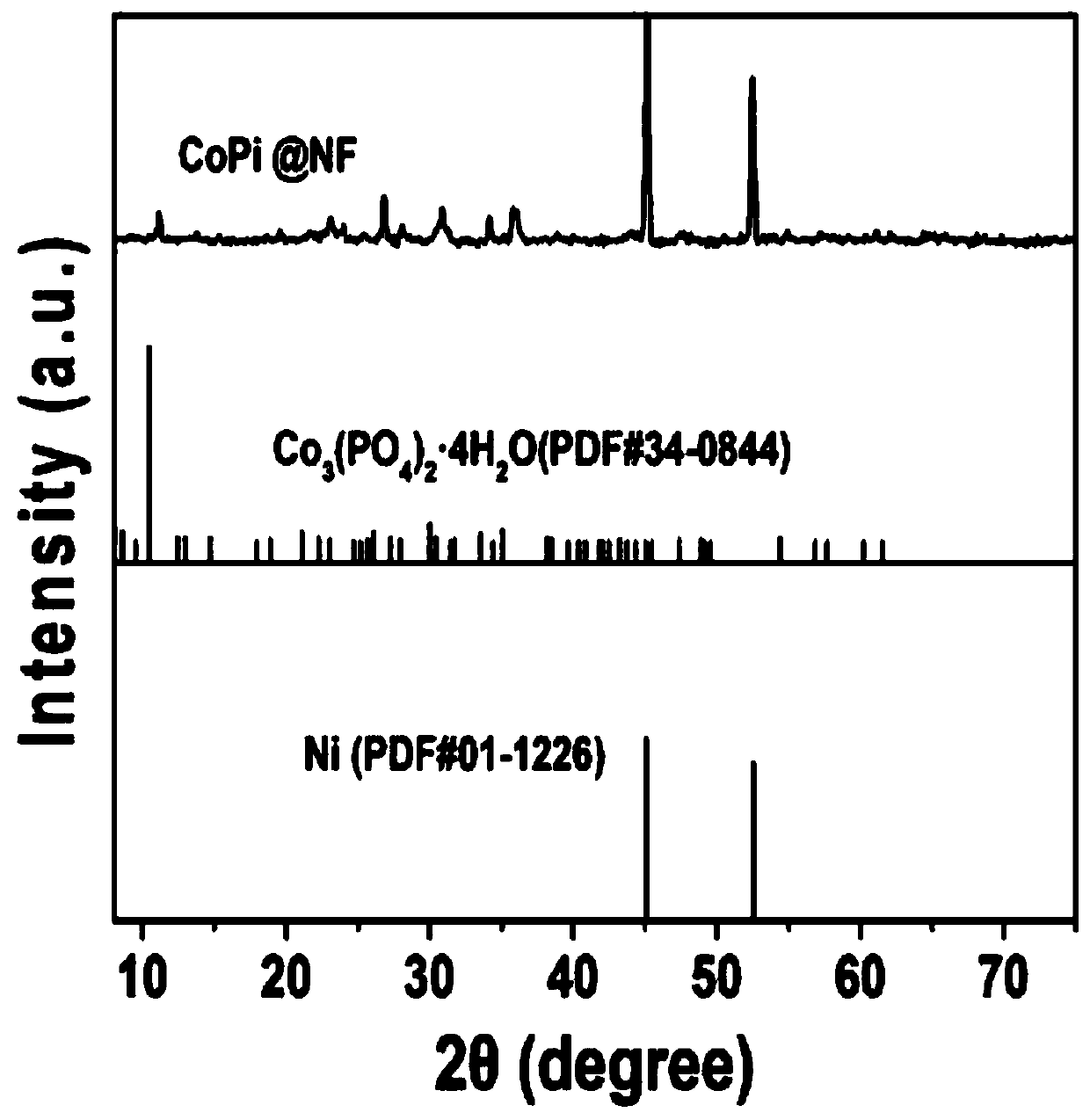

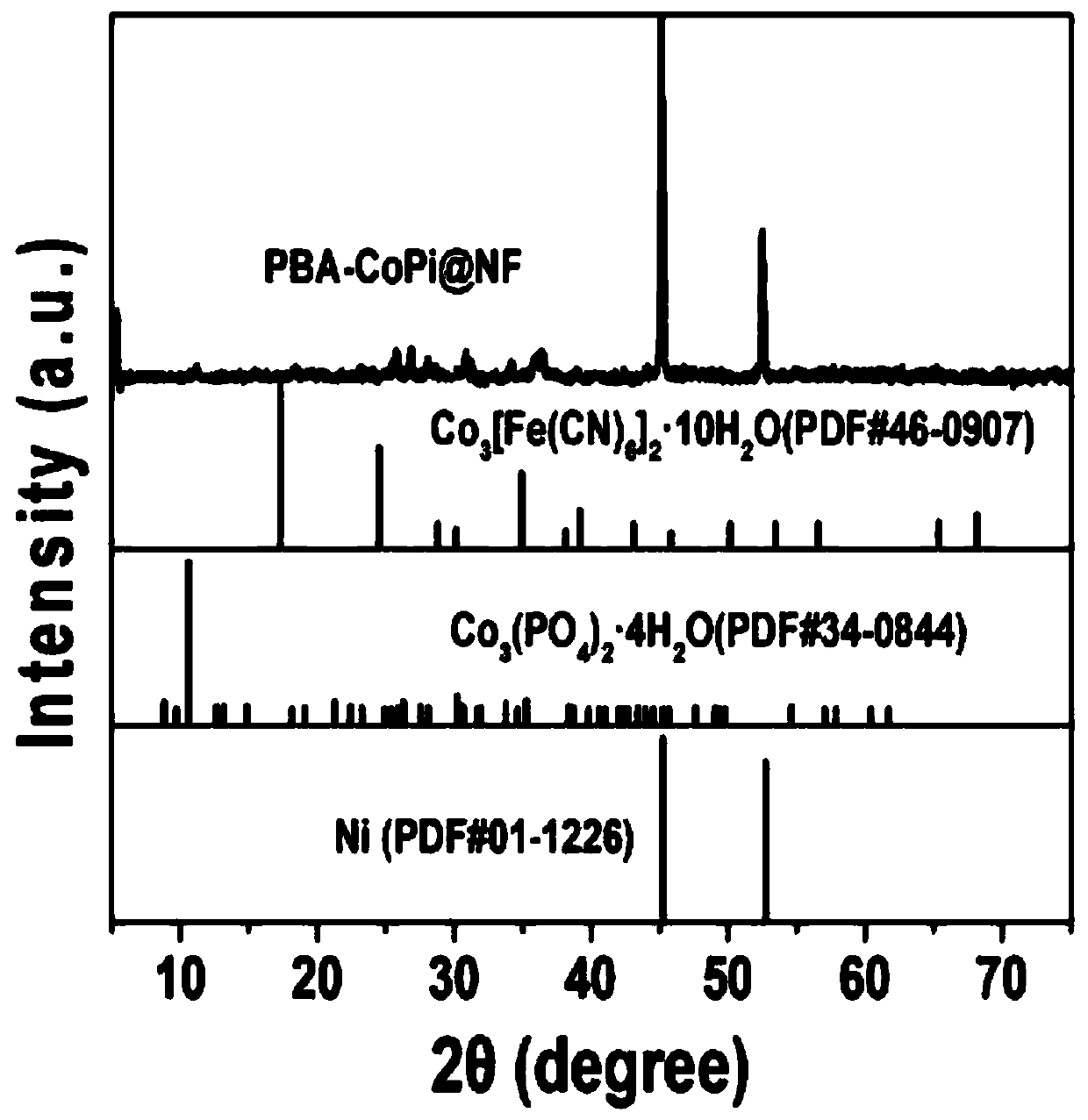

Cobalt iron oxide-cobalt phosphate electrocatalytic oxygen evolution composite material, and preparation method and application thereof

ActiveCN111036247AShape is easy to controlImprove performanceMetal/metal-oxides/metal-hydroxide catalystsElectrodesAir atmosphereMaterial synthesis

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Ceramic composite, light source apparatus, and projector

A ceramic composite according to the present disclosure has a phosphor phase containing an activator and a phosphor and a matrix phase containing MgO as a light transmissive ceramic material. The ceramic composite is made of an inorganic material, and the content of the phosphor phase is so set that the volume ratio of the phosphor phase to the entire phase including the matrix phase and the phosphor phase is lower than or equal to 20 vol %.

Owner:SEIKO EPSON CORP

Photocatalytic self-cleaning coating as well as preparation method and application thereof

InactiveCN114196241ASimple manufacturing processAvoid reunionPhotovoltaicsEnergy based wastewater treatmentSilicic acidPhosphoric acid

Owner:TIANJIN VOCATIONAL INST

Wood-plastic composite material for 3D printing and preparing method thereof

InactiveCN106280330AImprove the lubrication effectImprove liquidityAdditive manufacturing apparatusMicrosphereUltrahigh molecular weight polyethylene

The invention discloses a wood-plastic composite material for 3D printing and a preparing method thereof. The wood-plastic composite material is prepared from, by weight, 55-65 parts of polylactic acid, 25-35 parts of rice hull powder, 15-25 parts of paper pulp, 8-12 parts of ultrahigh molecular weight polyethylene, 6-8 parts of sodium methallyl sulfonate, 4-6 parts of disodium glycyrrhizate, 4-6 parts of hollow microspheres, 1-3 parts of coupling agent, 1-3 parts of lubricating agent, 1-3 parts of toughening agent and 1-2 parts of anti-oxidant. The wood-plastic composite material has excellent lubricity and mobility, is good for smooth proceeding of 3D printing, can not block a nozzle of printing equipment, and improves the working efficiency of the equipment and the qualified rate of products. The preparing method can be implemented with conventional equipment without strict requirements for conditions, and is easy to popularize.

Owner:DONGGUAN JINGGU NEW MATERIAL TECH CO LTD

Silicon-based negative electrode material and preparation method thereof, lithium ion battery and electric appliance

InactiveCN112820847AImprove cycle stabilityHigh reversible capacityElectrode thermal treatmentNegative electrodesElectrical batteryCopper foil

The invention discloses a silicon-based negative electrode material and a preparation method thereof, a lithium ion battery and an electric appliance and relates to the technical field of battery electrode material preparation. The preparation method of the silicon-based negative electrode material comprises the following steps: annealing a primary negative electrode material which is obtained by cold spraying and is loaded with a Si-Cu coating on the surface in an inert gas atmosphere at the temperature of 500-800 DEG C, and preserving heat for 7-9 hours. The silicon-based negative electrode material is prepared by the preparation method. The lithium ion battery adopts the silicon-based negative electrode material as a negative electrode. The electric appliance takes the lithium ion battery as a power supply. After the primary negative electrode material of the Si-Cu coating is obtained through cold spraying on the copper foil, the Si-Cu3Si-Cu composite material obtained through annealing treatment at the proper temperature and the proper heat preservation time is used as the negative electrode material of the lithium ion battery and has good cycle stability and reversible capacity.

Owner:GUANGDONG INST OF NEW MATERIALS

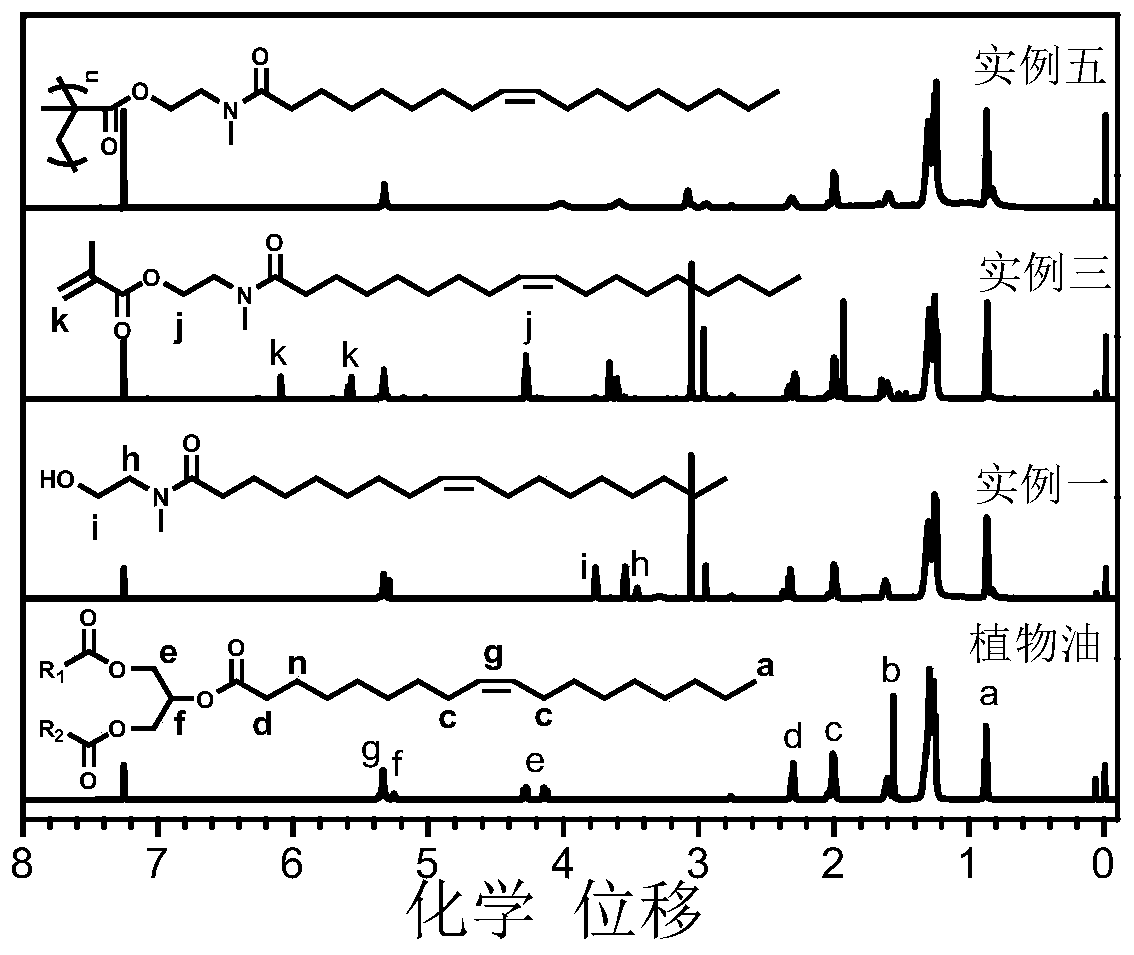

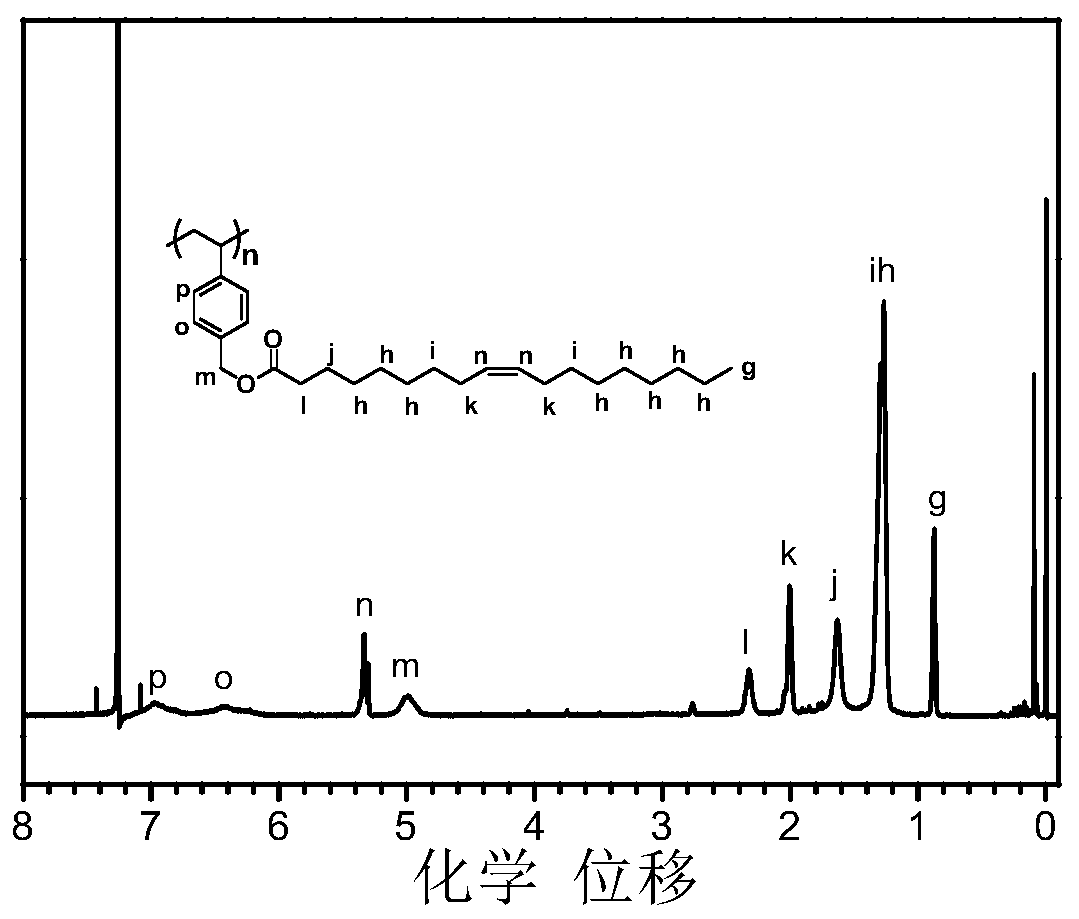

Grease-based epoxy polymer and epoxy copolymer, and preparation methods thereof

InactiveCN110804109AImprove mechanical propertiesIn line with the theme of sustainable developmentEpoxyPolymer science

Owner:ANHUI AGRICULTURAL UNIVERSITY

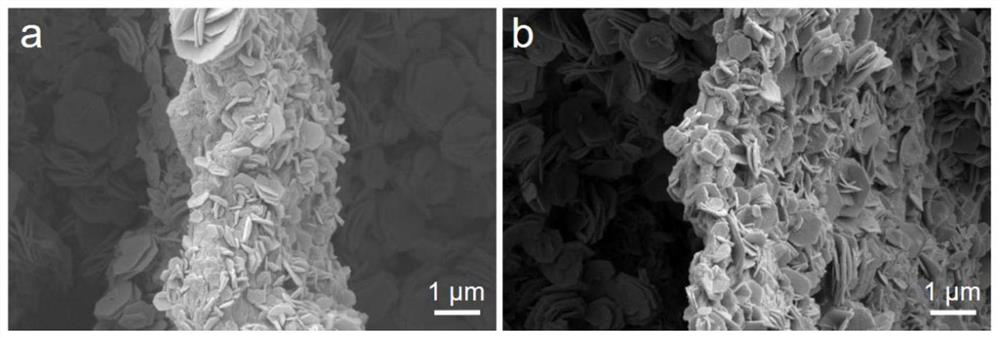

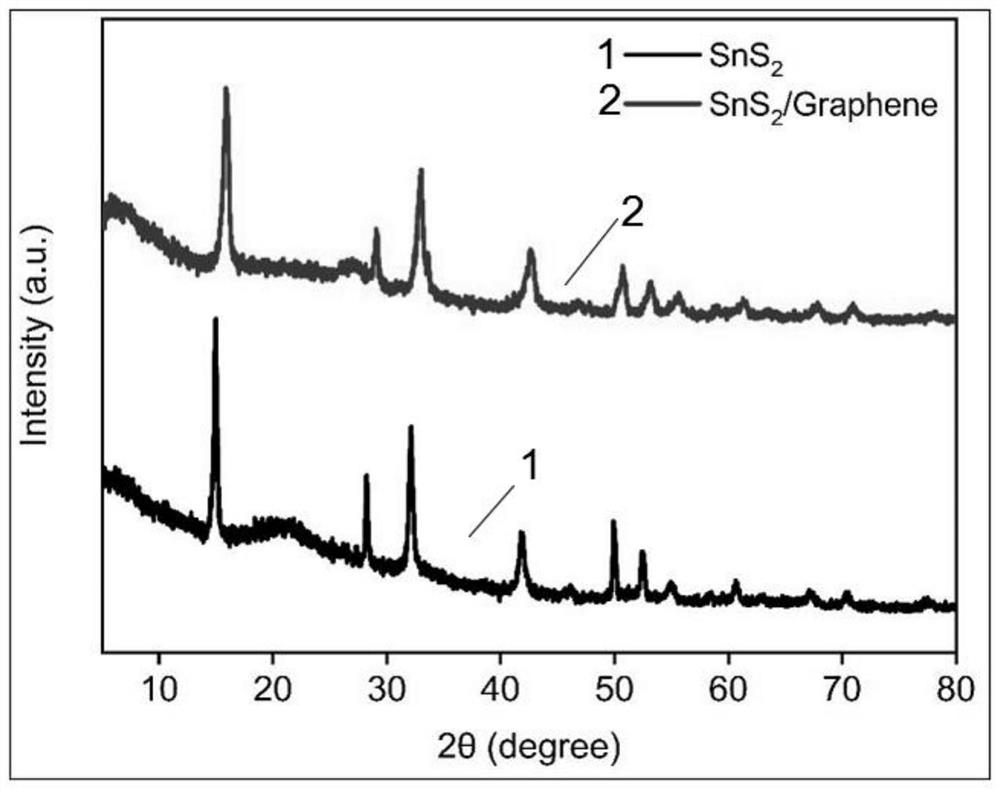

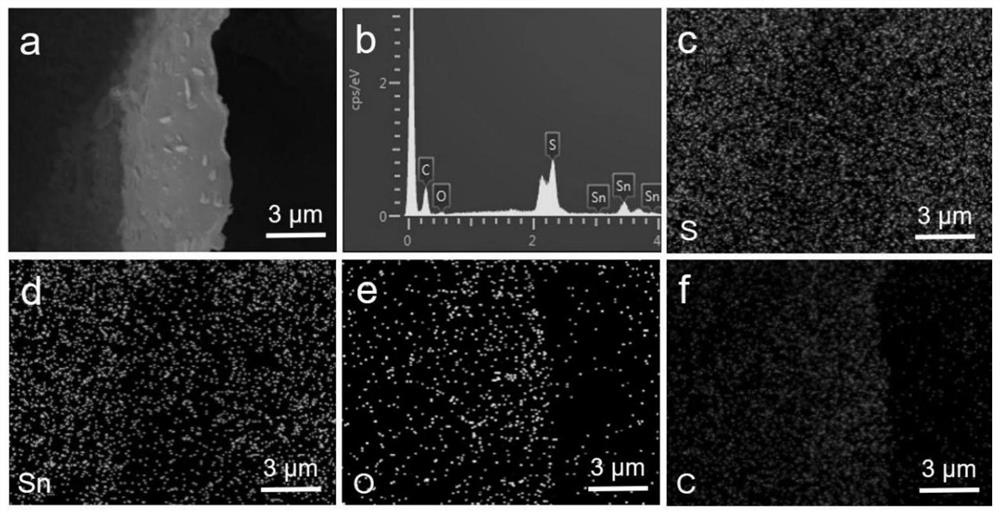

Preparation method of SnS2 nanosheet loaded graphene-based nanocomposite

Owner:安徽光特新材料科技有限公司

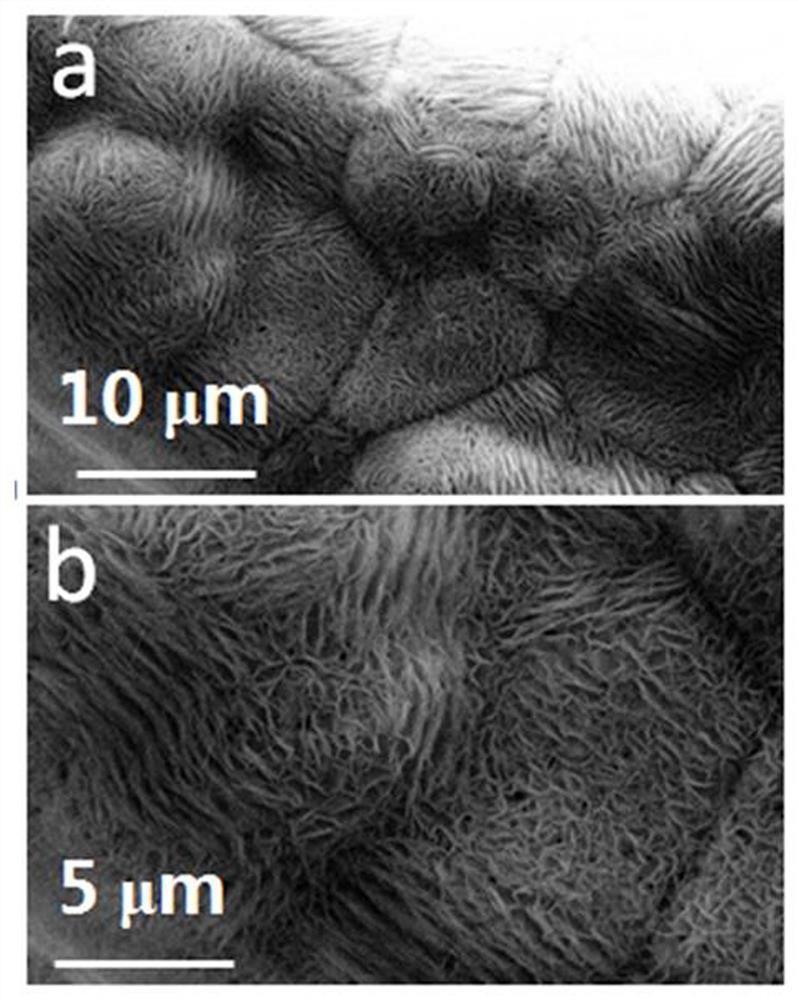

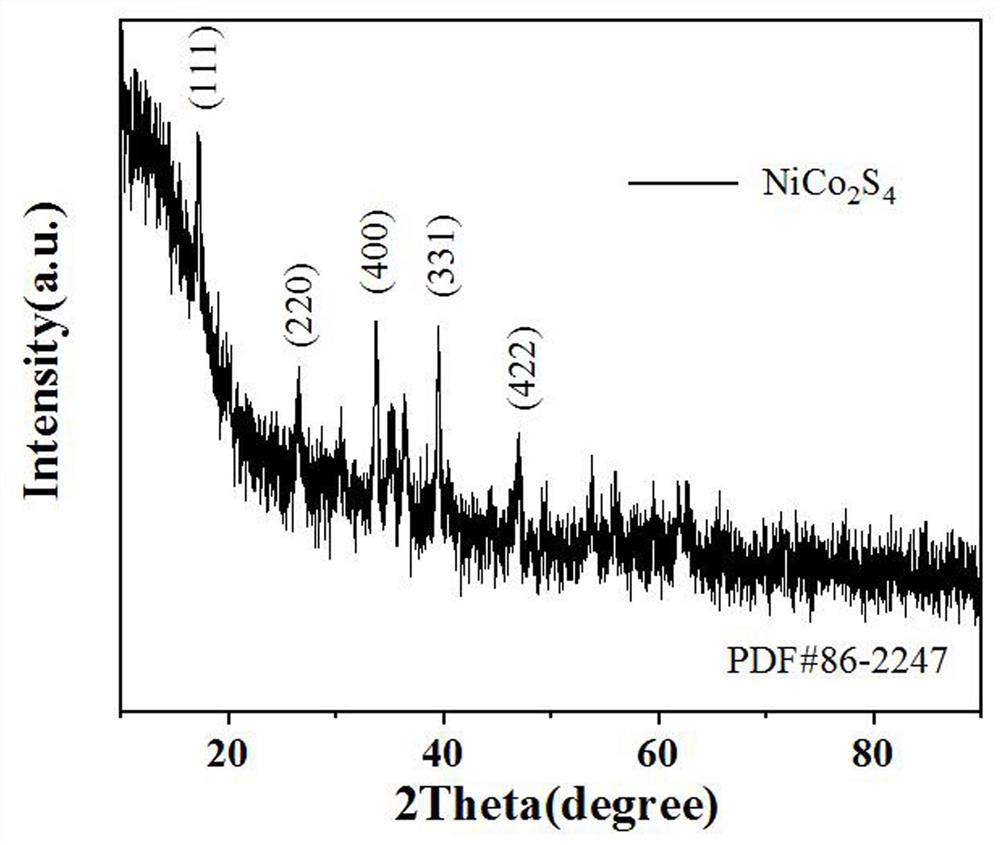

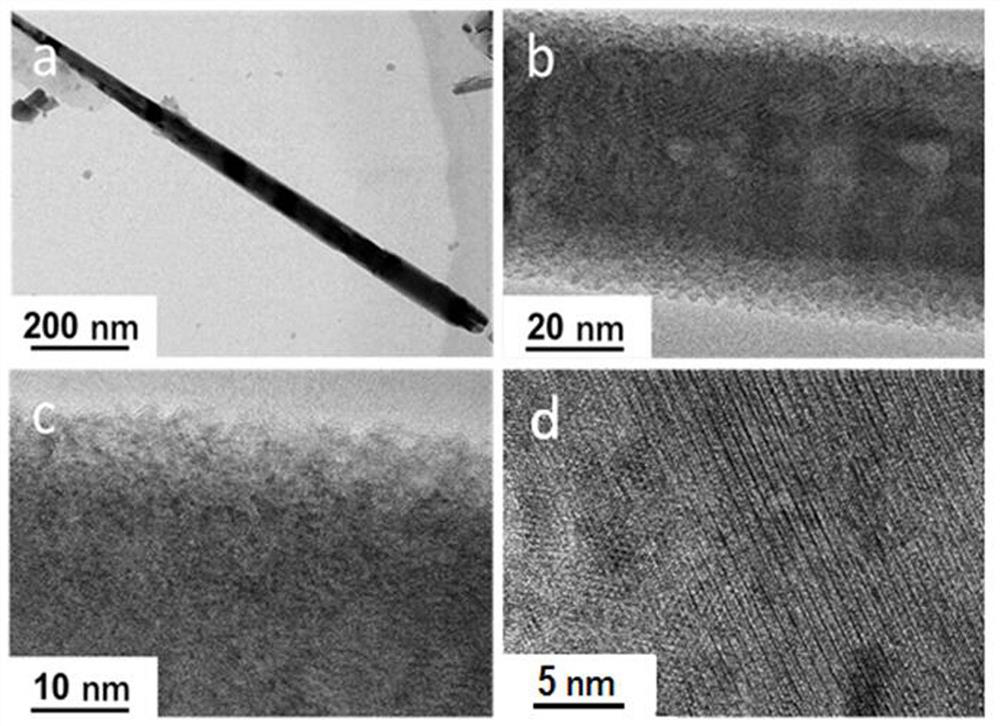

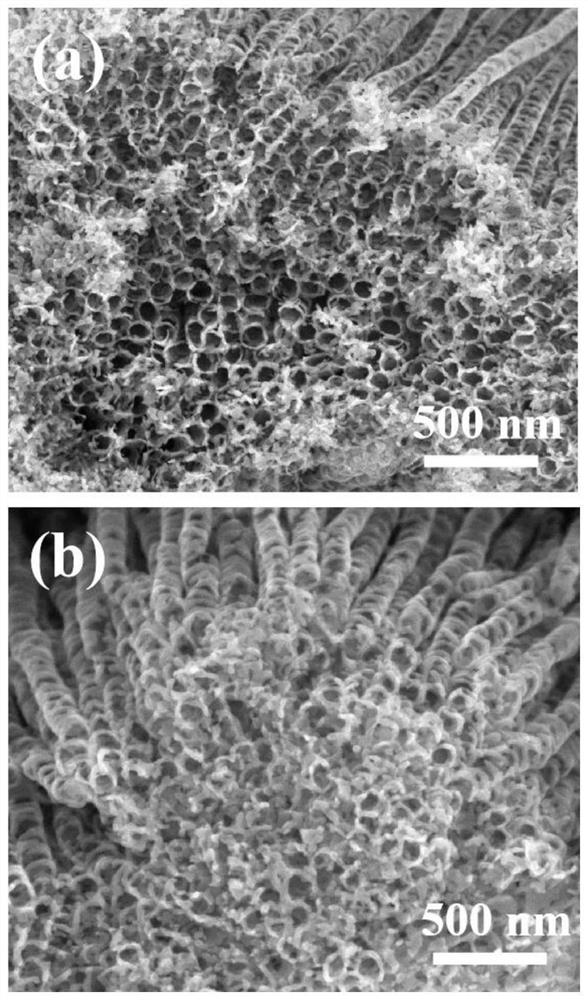

Polypyrrole coated Ni-Co-S nanoneedle array composite material and preparation method and application thereof

ActiveCN111785526AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceConductive polymer

Owner:GUILIN UNIV OF ELECTRONIC TECH

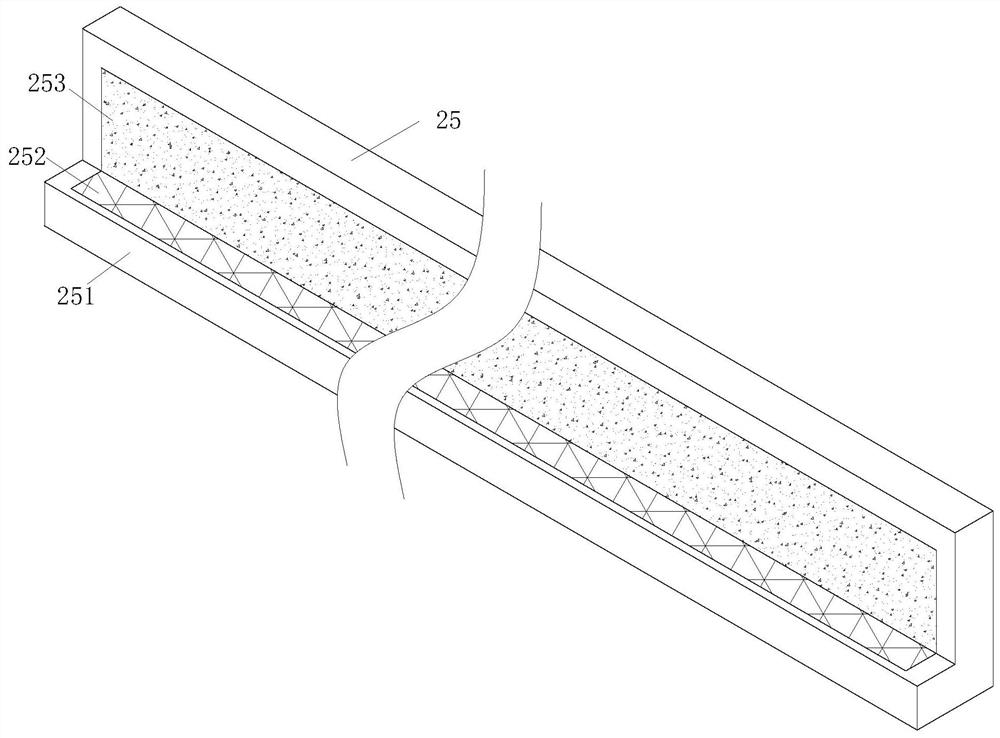

High-drawing-resistance aerogel composite material and preparation method thereof

PendingCN113478930AHigh tensile strengthSolve the problem of small pulling forceFibre treatmentSynthetic resin layered productsFiber compositionAerogel

Owner:浙江圣润纳米科技有限公司

Multicolor adjustable light-emitting organic eutectic heterojunction composite material as well as preparation and application thereof

ActiveCN111909687AEasy to operateMild preparation conditionsLuminescent compositionsHeterojunctionHemt circuits

The invention discloses a multicolor adjustable light-emitting organic eutectic heterojunction composite material and preparation and application thereof. The preparation method comprises the steps that a DMATFP mixed solution and a DMATCNB mixed solution are mixed, then the mixed solution is dropwise added to a substrate and placed in an anti-solvent atmosphere; then a solvent volatilizes slowly,and organic eutectic materials are combined together through a liquid-phase self-assembly method and a co-crystallization strategy; therefore, the organic eutectic materials are combined together, and the multicolor adjustable light-emitting organic eutectic heterojunction is prepared by adjusting the proportion of organic eutectic. The preparation method provided by the invention is simple in process, convenient to operate and mild in preparation condition, and blindness of a heterojunction preparation process is avoided to a great extent. Laser is used for respectively exciting the middle part and the two end parts of the heterojunction, good waveguide performance is shown, and resonance energy transfer is also accompanied. The organic eutectic heterojunction can be applied to optical logic operation by utilizing the light-emitting performance of the organic eutectic heterojunction, so that the technical scheme has a good application prospect in an integrated photonic circuit.

Owner:HUNAN NORMAL UNIVERSITY

Green heat-preservation, heat-insulation and sound-absorption composite material and preparation method thereof

The invention belongs to the field of aerogel technology and organic fiber sound-absorbing composite materials, and relates to a green heat-preservation, heat-insulation and sound-absorbing composite material and a preparation method thereof. The green heat-preservation, heat-insulation and sound-absorbing composite material comprises an organic fiber felt and an aerogel material, the aerogel material is an aerogel material containing silicon aluminum or silicon aluminum titanium, and the mass ratio of the organic fiber felt to the aerogel material is 1: (2-12). The preparation method comprises the following steps of preparing a hydrophilic solvent with the surfactant concentration of 0.1-10%, spraying the hydrophilic solvent on the surface of the organic fiber felt, and drying the hydrophilic modified organic fiber felt at 80-150 DEG C after the hydrophilic solvent completely permeates into the organic fiber felt, and compounding a glass aqueous solution containing silicon-aluminum or silicon-aluminum-titanium components with the dried organic fiber felt to obtain a wet gel composite material, further putting the wet gel composite material into an ethanol solution for extraction and replacement, and drying the wet gel composite material after extraction and replacement to obtain a target product.

Owner:ZHEJIANG UGOO TECH CO LTD

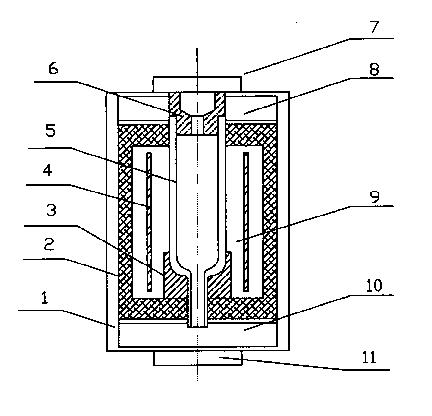

Solid oxide electrolytic cell and preparation method thereof

ActiveCN114016063AAvoid harmful reactionsSuppress internal leakage problemsCellsElectrodesElectron blocking layerMaterials science

The invention discloses a low-temperature solid oxide electrolytic cell and a preparation method thereof. The electrolytic cell comprises a hydrogen electrode layer, an electrolyte layer, an electron barrier layer, an interlayer and an oxygen electrode layer, wherein the hydrogen electrode layer is a composite material composed of NiO and doped cerium oxide LnxCe<1-x>O2, the electrolyte layer is a doped cerium oxide-based material LnxCe<1-x>O2, Ln is one or more of La, Gd, Sm, Pr and Er, x is greater than or equal to 0.1 and less than or equal to 0.5, the electron barrier layer is a doped zirconia-based material MyZr<1-y>O2, M is one or more of Y, Sc, Ce, Yb, La, Gd and Sm, y is greater than or equal to 0 and less than or equal to 0.5, the interlayer is doped cerium oxide LnxCe<1-x>O2, Ln is one or more of La, Gd, Sm, Y, Pr and Er, x is greater than or equal to 0.1 and less than or equal to 0.5, and the oxygen electrode is a composite material composed of a perovskite oxide, a perovskite-like oxide or a perovskite oxide and doped cerium oxide or a perovskite-like oxide and doped cerium oxide. The electrolytic cell disclosed by the invention has excellent performance of producing hydrogen by electrolyzing water at low temperature and supplying electrolytic water and carbon dioxide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

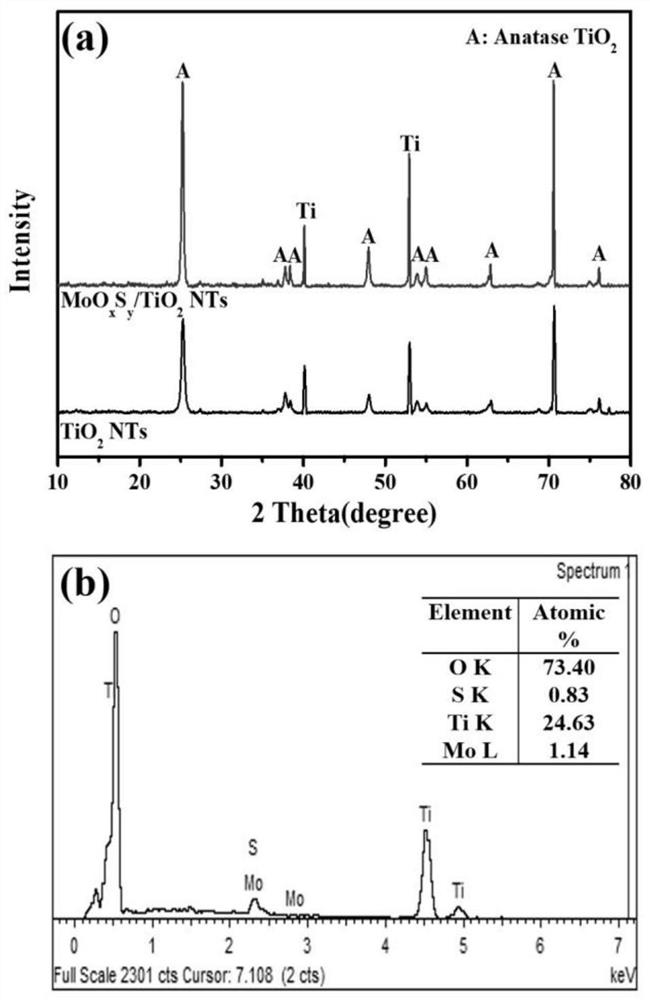

Preparation method and application of nano composite material oxygen-doped molybdenum disulfide/titanium dioxide nanotube array

InactiveCN112811523AEasy to operateMild conditionsMaterial nanotechnologyWater/sewage treatment by irradiationTio2 nanotubeSodium dithionite

Owner:NANCHANG HANGKONG UNIVERSITY

FG-coated MOF composite material, coating containing composite material, and preparation methods and application of coating

InactiveCN112442187ARegulatory loadModulation of crosslink densityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceWater methanol

The invention belongs to the technical field of anticorrosive materials in a marine environment, and particularly relates to an FG-coated MOF composite material, a coating containing the composite material, and preparation methods and application of the composite material and coating. The preparation method of the coating comprises the following steps: dispersing FG in absolute methanol, carryingout ultrasonic oscillation, adding a metal salt and an imidazole ligand into an FG methanol dispersion liquid, conducting stirring to obtain a turbid liquid, carrying out centrifugal separation to obtain a solid, alternately conducting washing with methanol and deionized water, and carrying out vacuum drying to obtain an FG-coated MOF composite material; and mixing epoxy resin, the FG-coated MOF composite material and a diluent, carrying out ball-milling stirring, adding a curing agent, and conducting uniform mixing to obtain a composite coating. A composite coating layer is obtained by coating the surface of a pretreated metal matrix with the composite coating, and conducting drying and curing. The epoxy resin is modified by the FG-coated MOF composite material, so that an imidazole ringin the composite material is chemically bonded with the epoxy resin, the problem of interfacial compatibility between the FG and the epoxy resin is solved, and the corrosion resistance and the mechanical property of an epoxy resin coating are improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

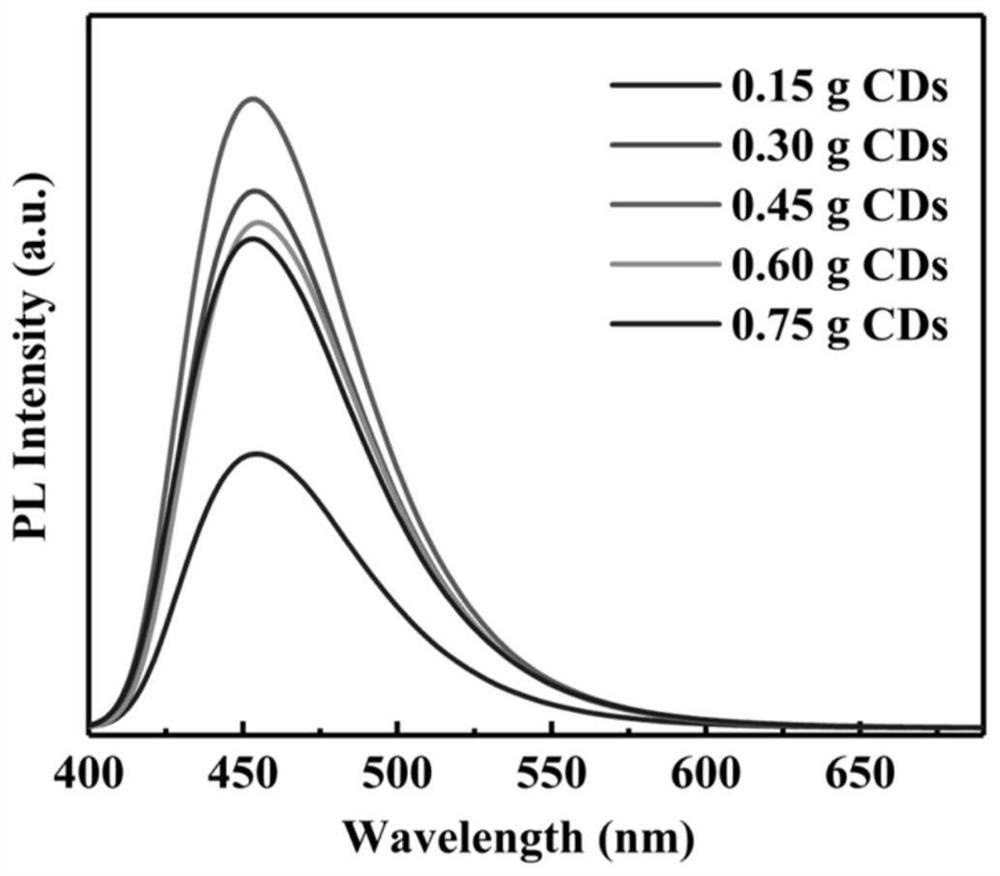

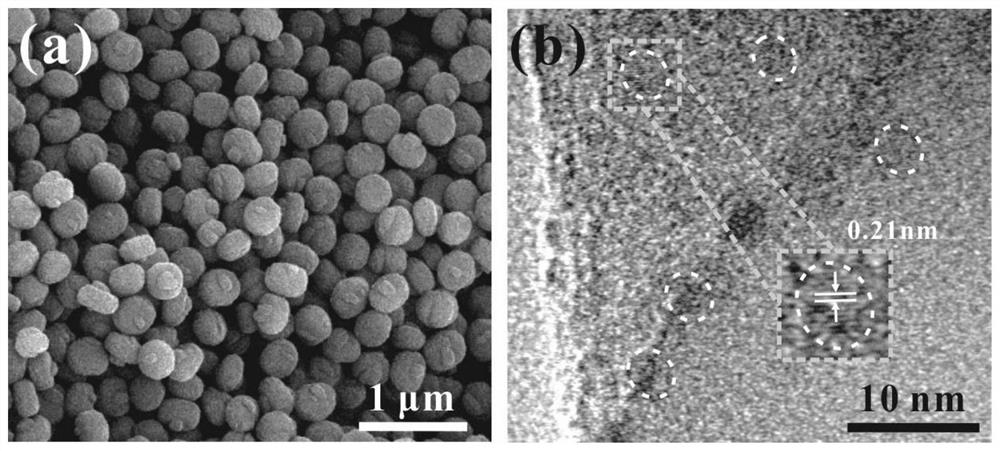

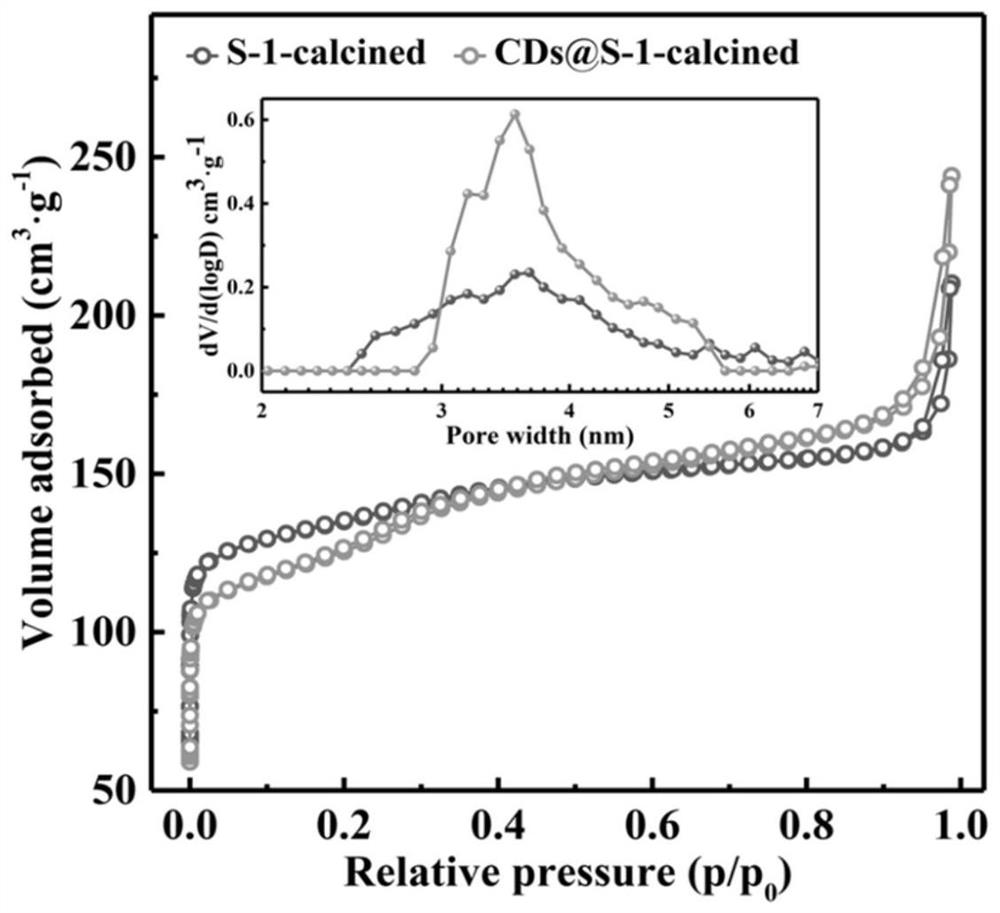

Solid carbon dot zeolite composite material fingerprint developing powder and preparation method thereof

PendingCN113930232AAddressing Aggregation-Induced Quenching EffectsSimple processMaterial nanotechnologyNanoopticsSolid carbonSilicic acid

Owner:FUDAN UNIV +1

Column insulator and manufacturing method thereof

ActiveCN114496424AImprove corrosion resistanceImprove wear resistanceSupporting insulatorsOrganic insulatorsEpoxyPolyvinyl alcohol

The invention discloses a column type insulator and a manufacturing method thereof, and relates to the technical field of insulators, the column type insulator comprises an insulator base body, and a first protective layer and a second protective layer which sequentially cover the surface of the insulator base body, the first protective layer is prepared from the following raw materials: silicon carbide, polyvinyl alcohol, fraxinus mandshurica clay / glass fiber composite material, wollastonite and diatomite / nano calcium carbonate composite material; the second protective layer is prepared from the following raw materials: a modified epoxy resin / montmorillonite composite material, modified hydrophobic silicon dioxide, polyacrylate and silicone acrylic emulsion. The invention has the beneficial effects that the first protection layer and the second protection layer are formed on the surface of the insulator substrate, so that the corrosion resistance, the wear resistance, the weather resistance and the anti-pollution flashover performance of the insulator can be improved.

Owner:PINGXIANG HUACHUANG ELECTRIC CO LTD

Novel method for preparing recyclable graphene composite titanium dioxide nano material

InactiveCN111821979AEasy to operateReaction conditions are easy to controlHeterogenous catalyst chemical elementsCatalyst activation/preparationPhoto catalysisCalcination

Owner:江苏康德龙环保有限公司

Flexible liquid metal pattern based on laser activation selective metallization and preparation method thereof

ActiveCN113727531AGood production flexibilityEasy to operateConductive pattern formationPhysical chemistryLiquid metal

Owner:SICHUAN UNIV

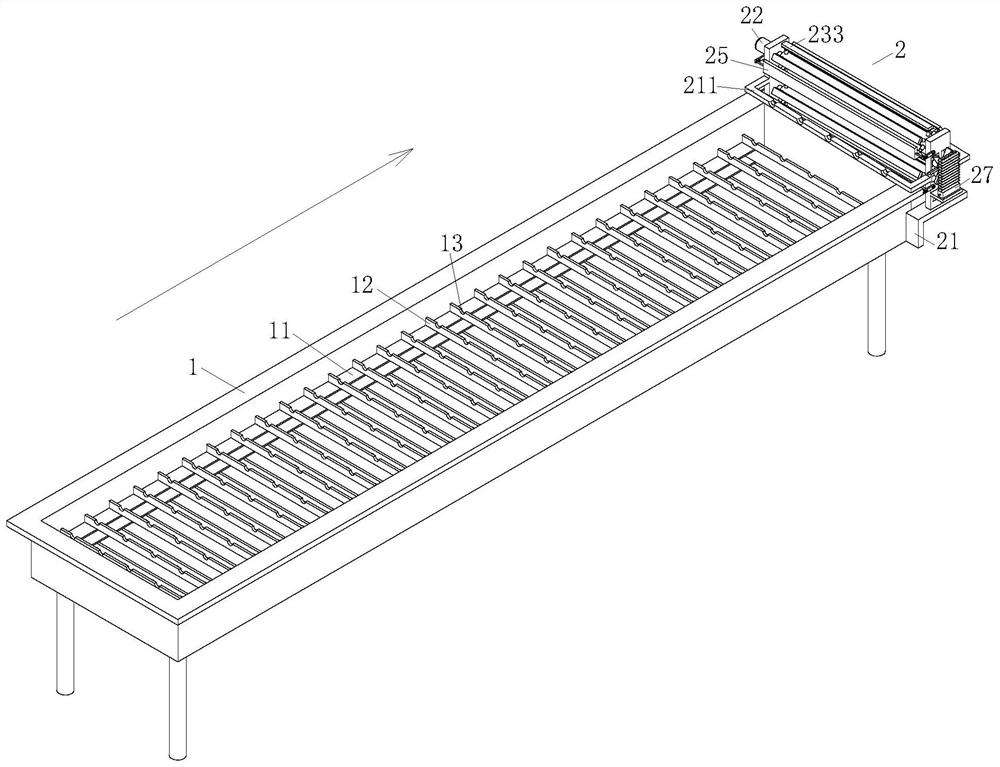

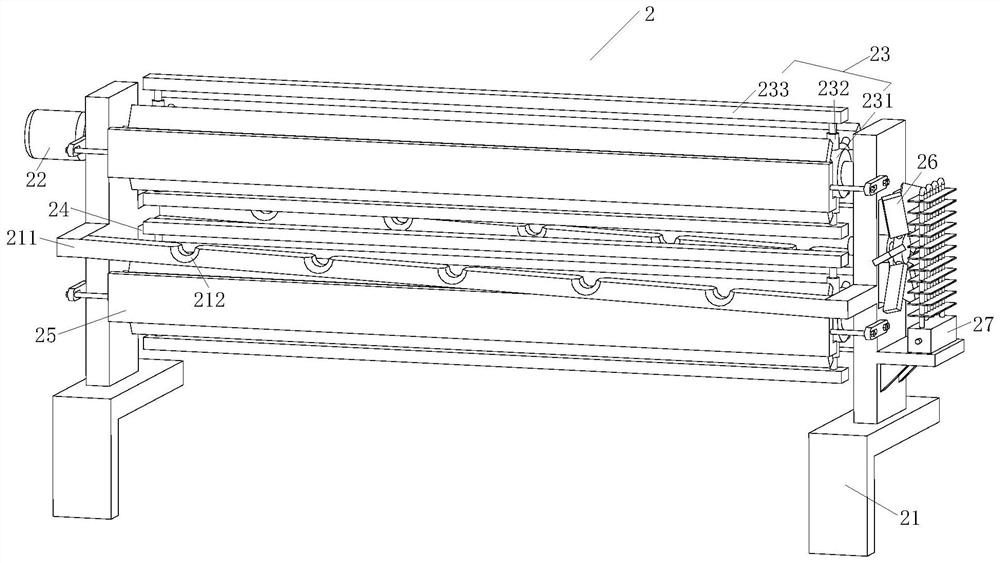

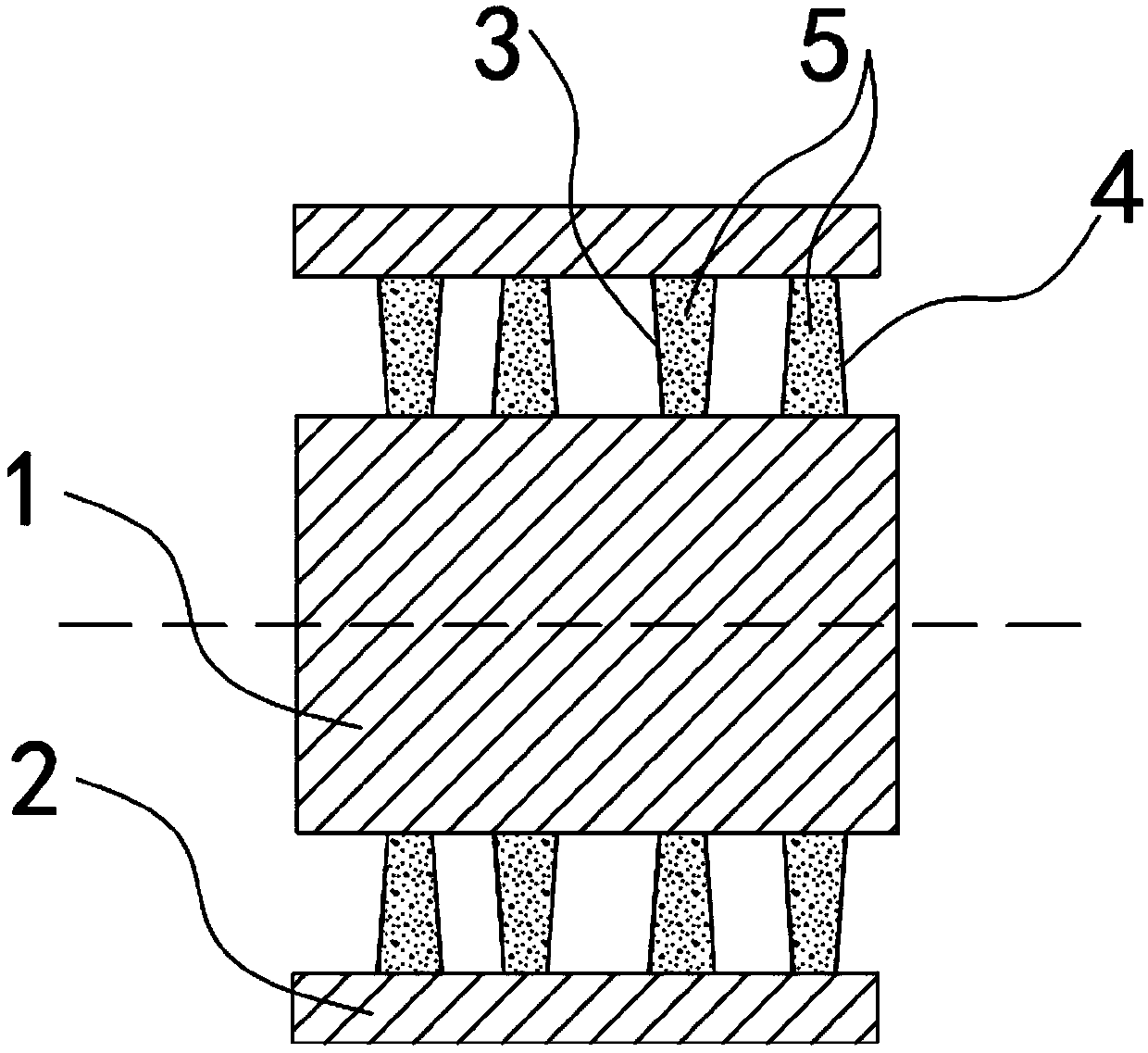

Preparation system of biodegradable composite material

PendingCN113478674ADry fastFully contactedDrying gas arrangementsDrying machines with progressive movementsSurface cleaningWater resources

Owner:李文干

Method for preparing feeding nozzle for continuous high-purity alumina melting furnace and continuous melting furnace

Owner:SHANDONG UNIV OF TECH

TRT turbine with abrasion-resistant corrosion-resistant nano coating

PendingCN107725116AIncrease power generationImprove work efficiencyMolten spray coatingEngine fuctionsCorrosion resistantStator

The invention discloses a TRT turbine with an abrasion-resistant corrosion-resistant nano coating. The TRT turbine includes a TRT turbine movable blade and a static blade. The outer surfaces of both the TRT turbine movable blade and the static blade each is provided with a nano protection layer. According to the TRT turbine with the abrasion-resistant corrosion-resistant nano coating, the surfacesof the movable blade and the static blade of the TRT turbine each are provided with the protection layer made of a nanometer material. The nano coating is a functional coating which is of a nano structure, is prepared from a nanometer ceramic composite material and is resistant to abrasion, acid-base corrosion, high temperature and cavitation, the shortcomings in the prior art are overcome, the service life is prolonged from 7-10 months to 36 months or over, and the service life and a use effect of a TRT turbine in the prior art are greatly improved. The TRT turbine can work continuously fora long time, the production cost and overhaul coat are reduced, and the working efficiency is improved.

Owner:上海英佛曼纳米科技股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap