Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Polylactic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polylactic acid or polylactide (PLA) is a thermoplastic aliphatic polyester derived from renewable resources. In 2010, PLA had the second highest consumption volume of any bioplastic of the world, although it is still not a commodity polymer. Its widespread application has been hindered by numerous physical and processing shortcomings.

Preparation method of polylactic acid strand filtering rod capable of lowering flue-gas temperature and reducing suction resistance

ActiveCN108523216AImprove the taste of smokingReduce the temperatureTobacco treatmentCigar manufactureFlue gasEngineering

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

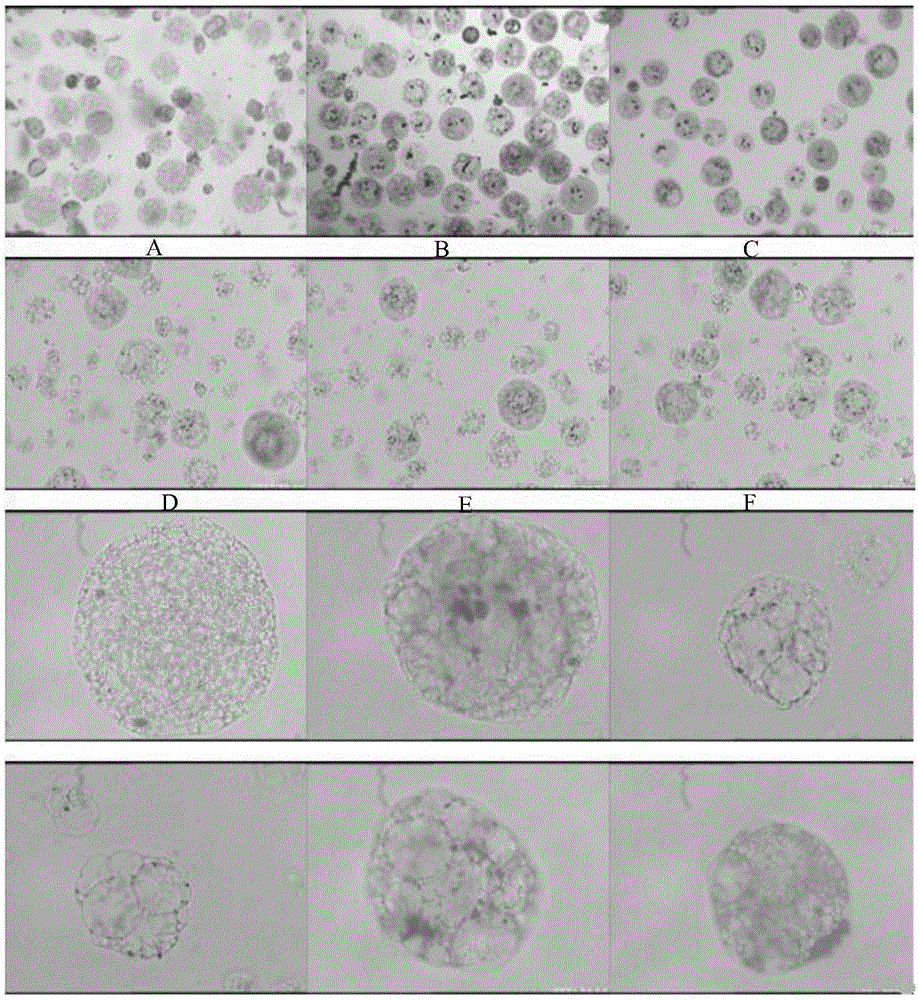

Three-dimensional wrinkle polylactic acid microballoons and preparation method and uses thereof

InactiveCN105273216AAchieve transformationLarge specific surface areaTissue cultureLiquid separationCell adhesionMicrosphere

Owner:JIANGSU UNIV

Environmental-friendly foaming plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

PE (polyethylene) plastic wrap and preparation method thereof

Owner:LUOYANG MINGLI TECH DEV

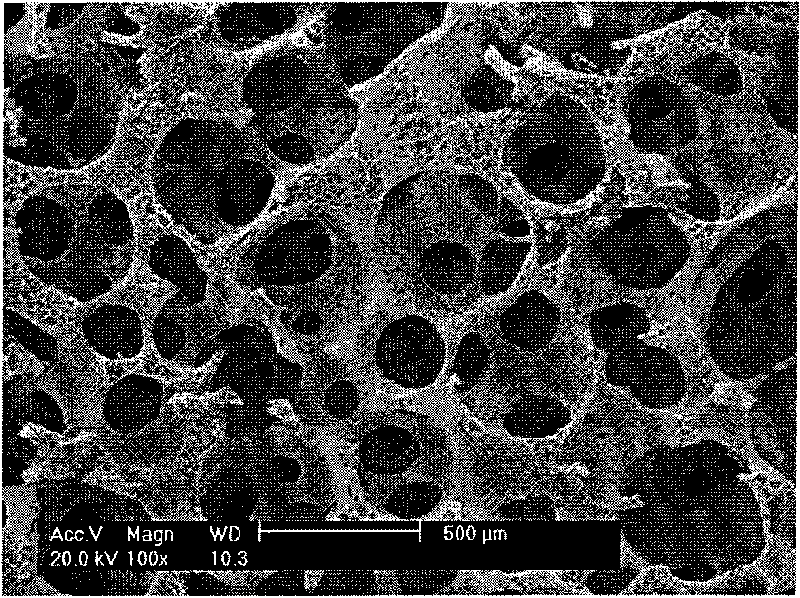

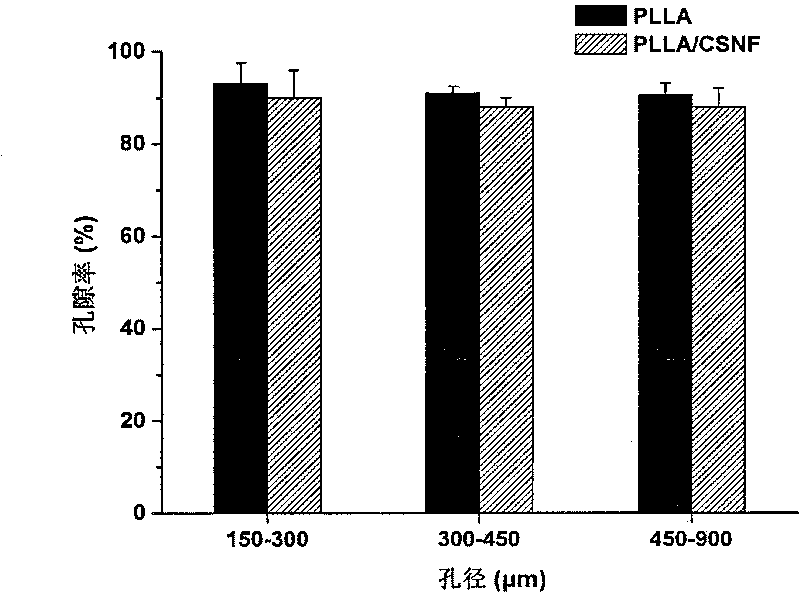

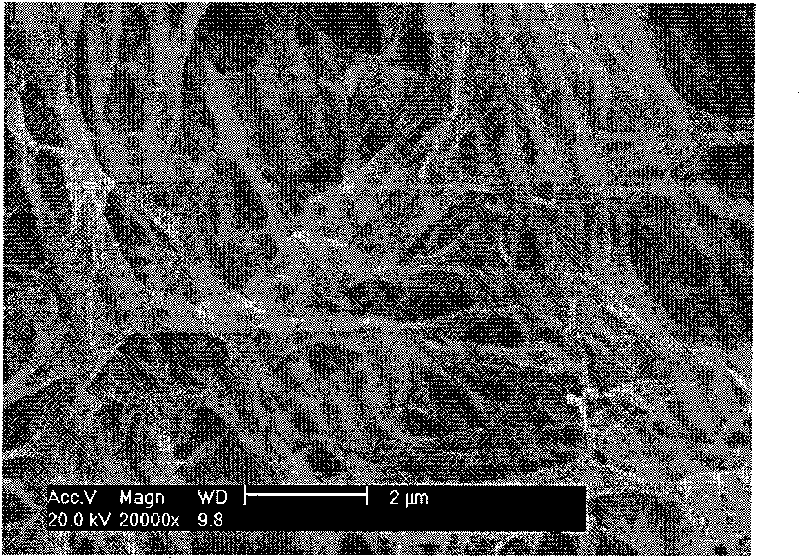

Polylactic acid/chitosan composite nano fiber scaffold, preparation method and application thereof

Owner:JINAN UNIVERSITY

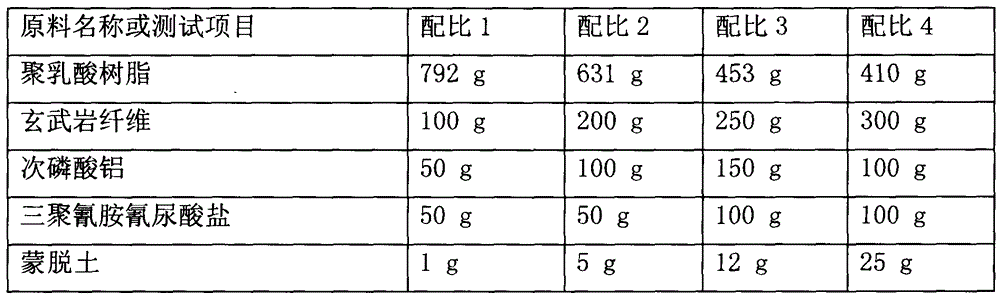

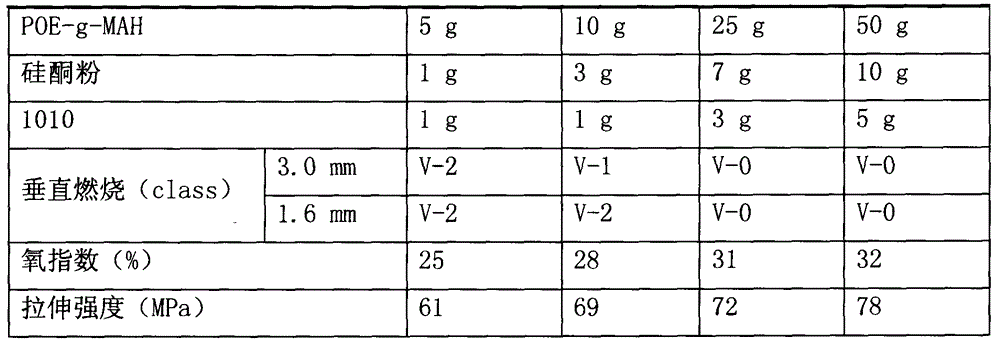

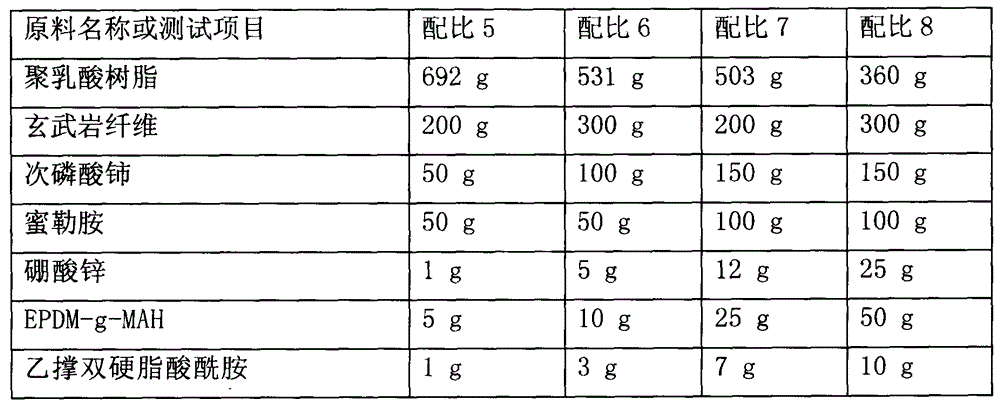

Halogen-free flame-retardant basalt fiber reinforced polylactic acid composite material and preparation method thereof

InactiveCN104312118AImprove flame retardant performanceImprove heat resistancePolymer scienceNitrogen

Owner:HEFEI UNIV

Polylactic acid/starch whole biological-base composite material and preparation method of composite material

The invention discloses polylactic acid / starch whole biological-base composite material and a preparation method of the composite material. Based on 100 parts by weight of total raw materials, the composite material is prepared from the raw materials: 40-85 parts by weight of polylactic acid, 5-25 parts by weight of dextral polylactic acid-polyurethane and 7-50 parts of starch. The composite material is safe, non-toxic, and biodegradable, and has excellent mechanical properties. The preparation method comprises the following steps: uniformly mixing the raw material components, then adding themixed materials into a double-screw extruder for melting and blending, then performing pulling and pelletizing to obtain granular mixed resin, and performing drying to obtain the polylactic acid / starch whole biological-base composite material. The preparation method is simple and is easy to control; the operability is high; the implementation is easy; the production cost is low; the preparation method is easy for industrial large-scale production; and the prepared composite material can be applied to the fields of foaming materials, thin films, fibers, other special-shaped materials and the like.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

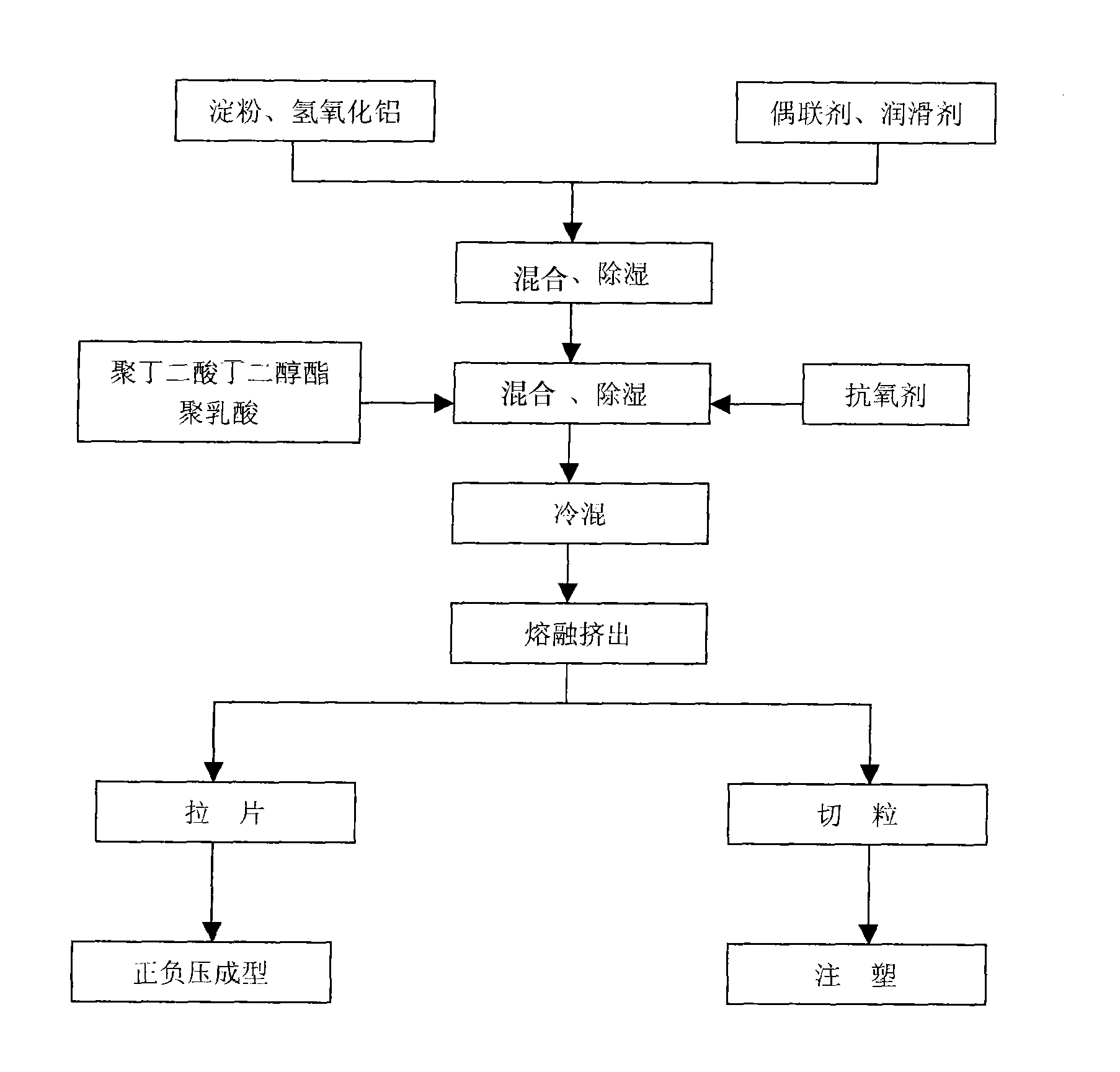

Hydroted alumina-poly-succinic acid butanediol ester composite degradation material and preparation technique

Owner:浙江华发生态科技有限公司

Biodegradable 3D printing toughened material and preparation method thereof

InactiveCN106893279AImprove the shortcomings of low impact performanceHigh impact strengthAdditive manufacturing apparatusPolymer scienceGlycidyl methacrylate

Owner:四川鑫达企业集团有限公司

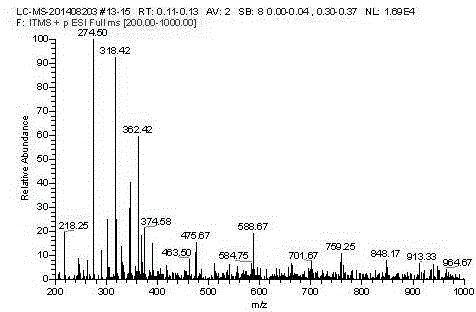

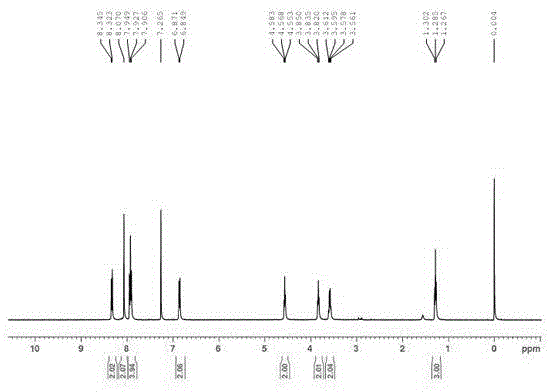

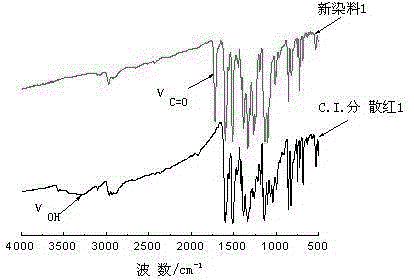

Disperse dye compound as well as preparation method and application thereof

Owner:SHAOXING UNIVERSITY

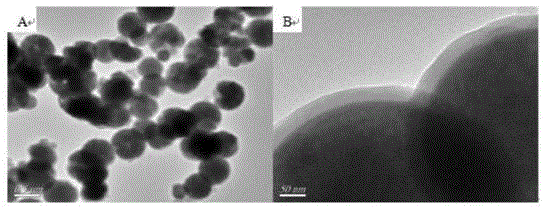

Water-soluble hypocrellin PLGA nanoparticle and preparation method thereof

InactiveCN103933568AGood biocompatibilitySmall particlesPowder deliveryEnergy modified materialsSolubilitySide effect

The invention relates to the technical field of medicines, and particularly relates to a water-soluble hypocrellin PLGAnanoparticle and a preparation method thereof. The preparation method comprises the following steps: by taking poly(lactic-co-glycolic acid) (PLGA) as a carrier, dissolving PLGA and hypocrellin into an organic solvent to prepare an oil phase, adding into freeze-drying excipient-containing water phase under high-speed stirring, and finally obtaining the hypocrellin nanoparticle by adopting an emulsification freeze-drying method. By using a biodegradable medical polymer material PLGA used in the preparation method and approved by the food and drug administration (FDA) of the United States, the toxic and side effects of a common drug-carrying material can be reduced, the water solubility of the drug can be improved, the particle size of the prepared nanoparticle ranges from 20-200nm, the drug has red shift, the absorption of the nanoparticle in a phototherapy window (600-900nm) can be increased, and the dark toxicity of the drug can be reduced. The preparation method is simple in raw materials and easy to operate.

Owner:NANJING NORMAL UNIVERSITY

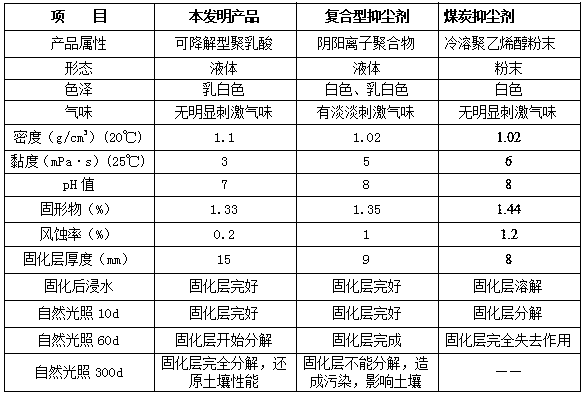

Degradable environment-friendly efficient dust suppressant and preparation method and use method thereof

Owner:喜跃发国际环保新材料股份有限公司

Wood-plastic composite material for 3D printing and preparing method thereof

InactiveCN106280330AImprove the lubrication effectImprove liquidityAdditive manufacturing apparatusMicrosphereUltrahigh molecular weight polyethylene

The invention discloses a wood-plastic composite material for 3D printing and a preparing method thereof. The wood-plastic composite material is prepared from, by weight, 55-65 parts of polylactic acid, 25-35 parts of rice hull powder, 15-25 parts of paper pulp, 8-12 parts of ultrahigh molecular weight polyethylene, 6-8 parts of sodium methallyl sulfonate, 4-6 parts of disodium glycyrrhizate, 4-6 parts of hollow microspheres, 1-3 parts of coupling agent, 1-3 parts of lubricating agent, 1-3 parts of toughening agent and 1-2 parts of anti-oxidant. The wood-plastic composite material has excellent lubricity and mobility, is good for smooth proceeding of 3D printing, can not block a nozzle of printing equipment, and improves the working efficiency of the equipment and the qualified rate of products. The preparing method can be implemented with conventional equipment without strict requirements for conditions, and is easy to popularize.

Owner:DONGGUAN JINGGU NEW MATERIAL TECH CO LTD

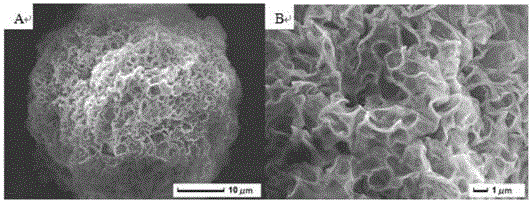

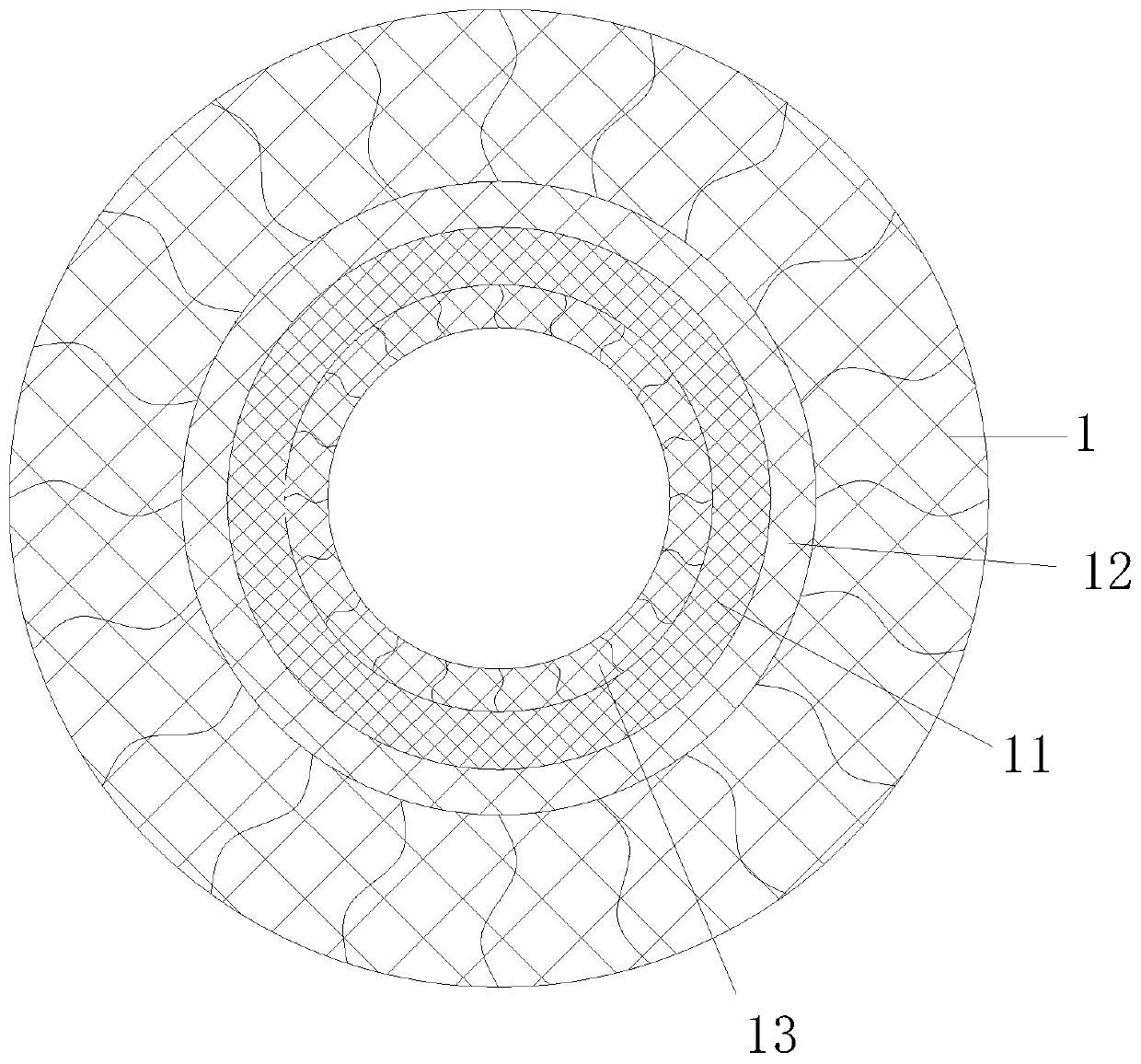

High-adsorption polylactic acid composite biofilm carrier material and preparation method thereof

InactiveCN107841037ALarge surface activation areaImprove liquiditySustainable biological treatmentConjugated synthetic polymer artificial filamentsSodium BentoniteWater quality

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Stock-solution-coloring high-melting-point polylactic acid fibers and preparation method thereof

InactiveCN108070914AOvercoming the disadvantage of difficulty in dyeing dark colorsOvercome the disadvantage of reduced performanceArtificial filament heat treatmentMelt spinning methodsFiberState of art

Owner:SHANGHAI DEFULUN CHEM FIBER

High-strength wear-resistant environmental-friendly plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

Block copolymer modified amphipathy polylactic acid composite membrane and preparation method

Owner:上海理振工业技术有限公司

Preparation method of non-woven fabric

InactiveCN108517621AImprove toughnessImprove wear resistanceBiochemical fibre treatmentNon-woven fabricsCardingPyrophosphate

Owner:徐冬

Attractive, elegant and high-impact-resistance automobile trim material

InactiveCN105543999AImprove interface compatibilityImprove wear resistancePhysical treatmentSpinning head liquid feederFiberPolyvinyl alcohol

Owner:芜湖跃飞新型吸音材料股份有限公司

Thermal-dye-transfer receiver element with polylactic-acid-based sheet material

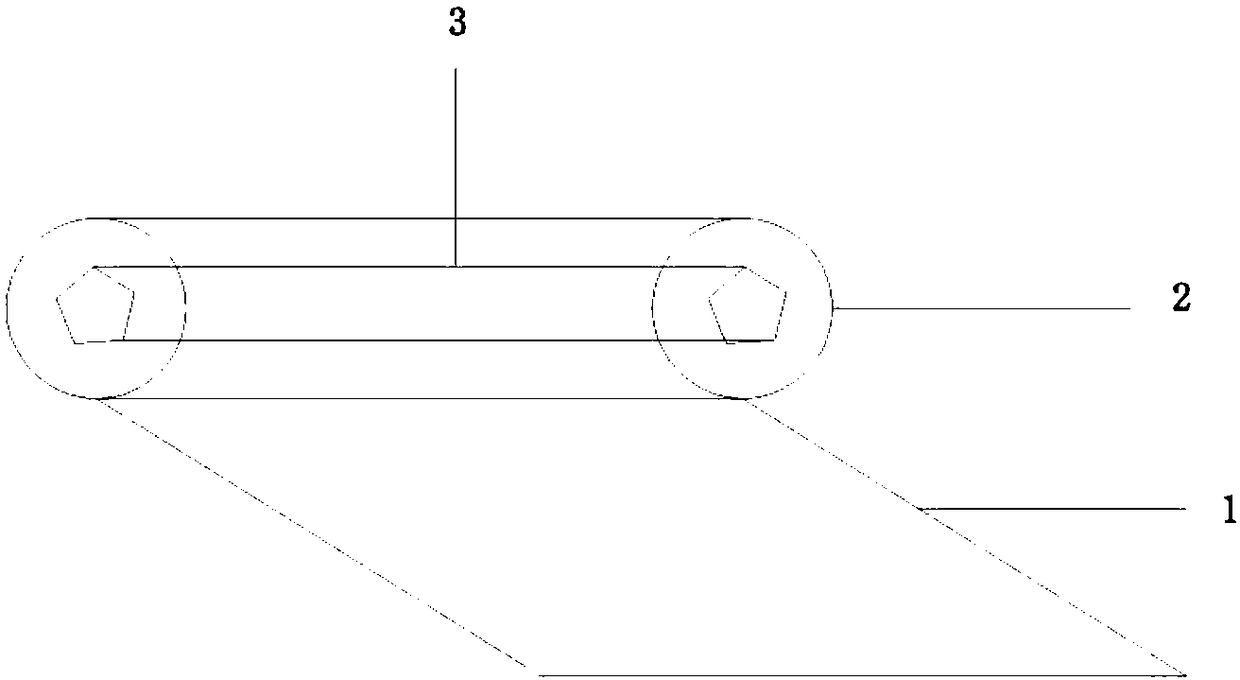

Disclosed is a thermal dye-transfer dye-image receiving element comprising a thermal dye-transfer receiver element comprising a dye-receiving layer 1; beneath layer 1, a substrate layer 2 containing a microvoided layer 2 comprising, in a continuous phase, a polylactic-acid-based material, wherein microvoids in said microvoided layer provide a void volume of at least 25% by volume, and wherein at least about half of the microvoids are formed from void initiating particles less than 1.5 micrometer in average diameter; and beneath layer 2, an optional support layer 3.

Owner:EASTMAN KODAK CO

Application of porous polymer film with regular pores to preparation of artificial periosteum

ActiveCN114656678AGood mechanical propertiesArranged in orderPharmaceutical delivery mechanismTissue regenerationPolymer sciencePolymer thin films

Owner:CHONGQING UNIV

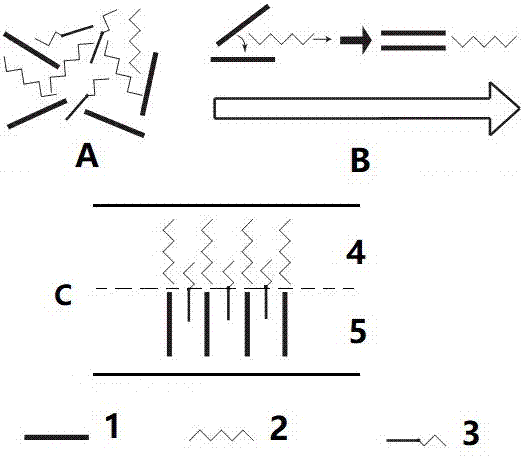

Method for preparing medical polylactic acid melt-spun fiber porous ordered scaffold

The invention discloses a method for preparing a medical polymer melt-spun fiber porous ordered scaffold. The method comprises the following steps: sequentially spinning and winding polylactic acid slices into fiber assemblies in parallel arrangement; forming the loose and parallel polylactic acid fiber assemblies into a stable structure by adopting the solvent cementing method; and performing vacuum drying. The medical polymer melt-spun fiber ordered scaffold prepared by the method is relatively small in thickness and relatively good in aperture and degree of order and can be applied to the aspects of bone tissue engineering and the like.

Owner:ZHEJIANG UNIV

Medical cotton swab capable of adhering to wound surface to promote healing

InactiveCN106730296AAddress inherent flawsReduce manufacturing costMedical applicatorsSwabsWound healingFiber

Owner:阜阳市汇康医疗器械有限公司

High-strength durable polylactic acid and preparation method thereof

The invention relates to high-strength durable polylactic acid and a preparation method thereof, belongs to the technical field of composite materials, and aims to solve the technical problems of lowmechanical strength and poor durability of polylactic acid in the prior art. The high-strength durable polylactic acid is prepared from 100 parts by weight of polylactic acid, 5 to 8 parts by weight of poly(butylene adipate-co-terephthalate) resin, 3 to 5 parts by weight of 2-(3,4-dihydroxyphenyl)ethylamine, 4.5 to 7.5 parts by weight of polycarbonate, 1 to 2 parts by weight of wood flour, 2 to 4parts by weight of silane coupling agent, 1 to 3 parts by weight of antioxidant, 1.5 to 3 parts by weight of polyethylene wax, 2.5 to 3 parts by weight of ethylene-vinyl acetate copolymer, 1 to 2 parts by weight of wollastonite powder, 0.5 to 1.5 parts by weight of ultraviolet light absorber, 1 to 3 parts by weight of sodium phosphite and 0.5 to 1 part by weight of heat stabilizer. The high-strength durable polylactic acid has high mechanical performance and high durability.

Owner:CHANGCHUN YUNCHUANG SPACE TECH CO LTD

Preparation method of microcapsules

InactiveCN108096215AGood film formingGood biocompatibilityNervous disorderAnthropod material medical ingredientsWaxBiocompatibility Testing

Owner:重庆岚灏科技有限责任公司

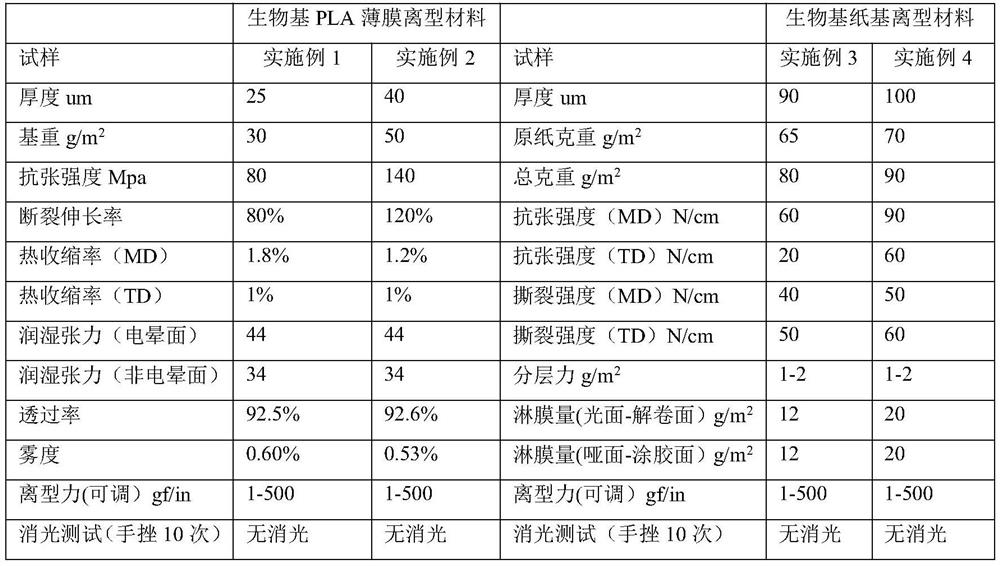

Recyclable and degradable release material and preparation method thereof

Owner:CROWN TAICANG ADHESIVE PROD CO LTD

Antibacterial nanofiber

PendingCN111286811APrevent outflowAvoid pollutionHollow filament manufactureConjugated synthetic polymer artificial filamentsPolyesterTextile technology

Owner:王康辉

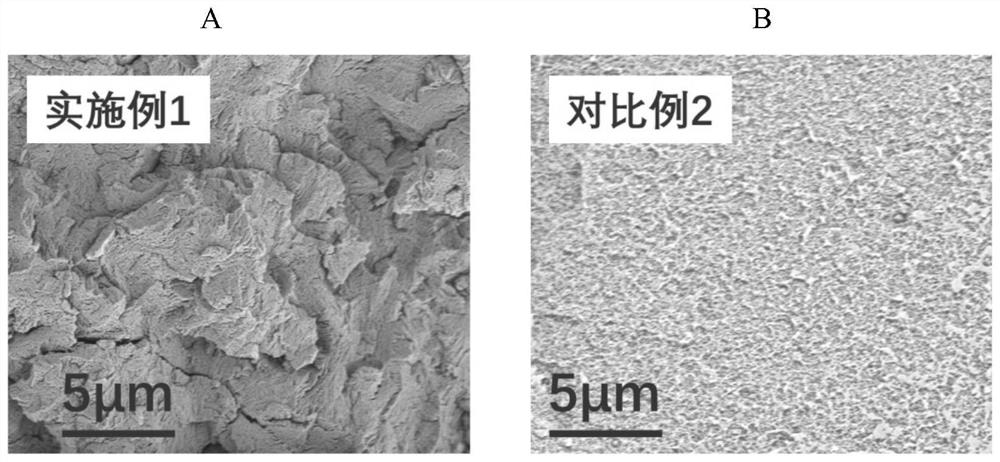

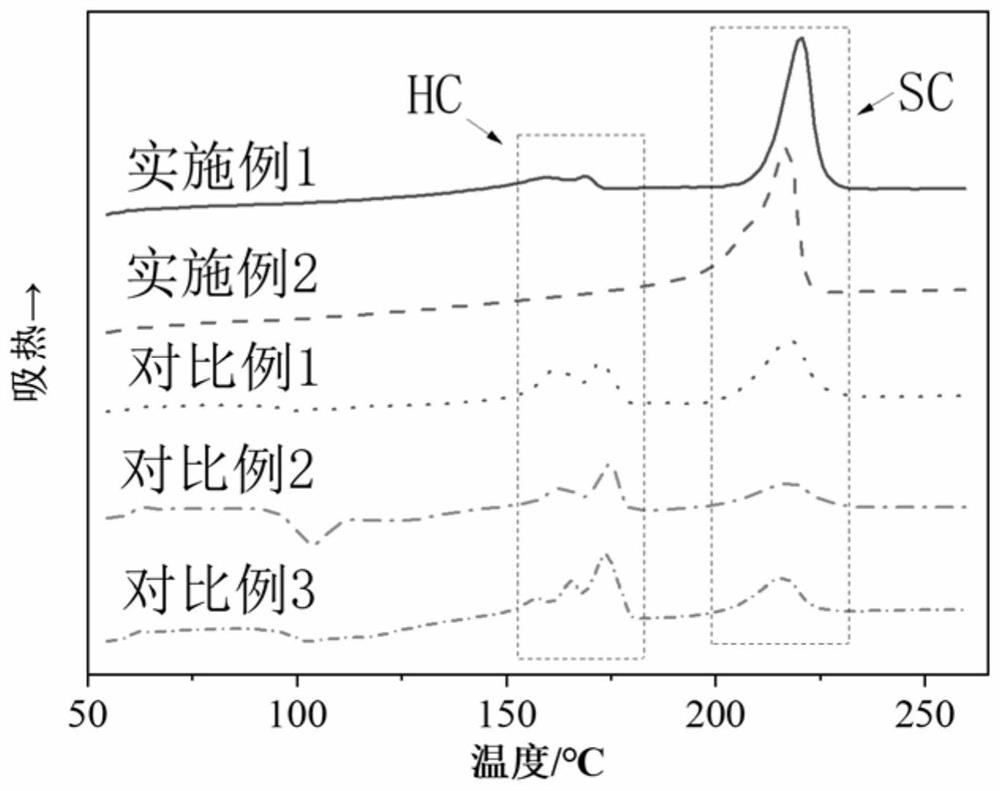

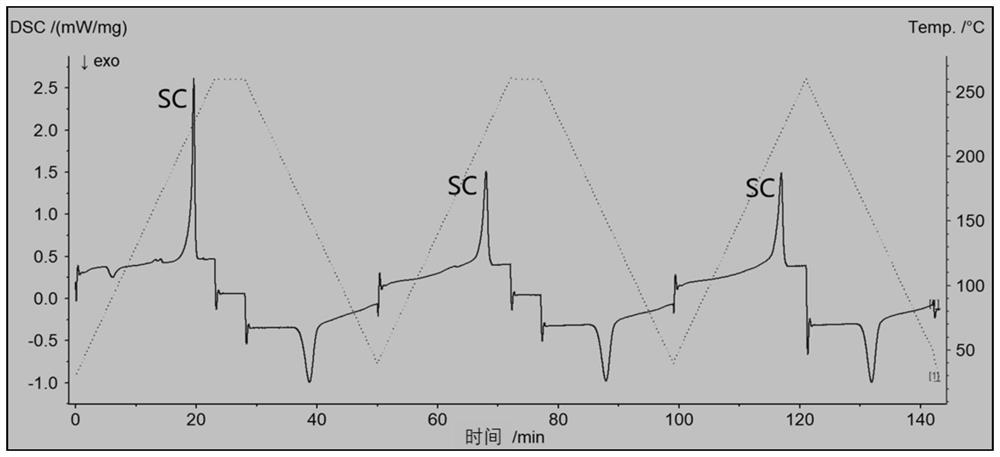

Stereocomplex polylactic acid and preparation method thereof

ActiveCN113980443AImprove conversion rateSuitable for industrial productionPolymer scienceVacuum drying

Owner:XIAMEN UNIV OF TECH

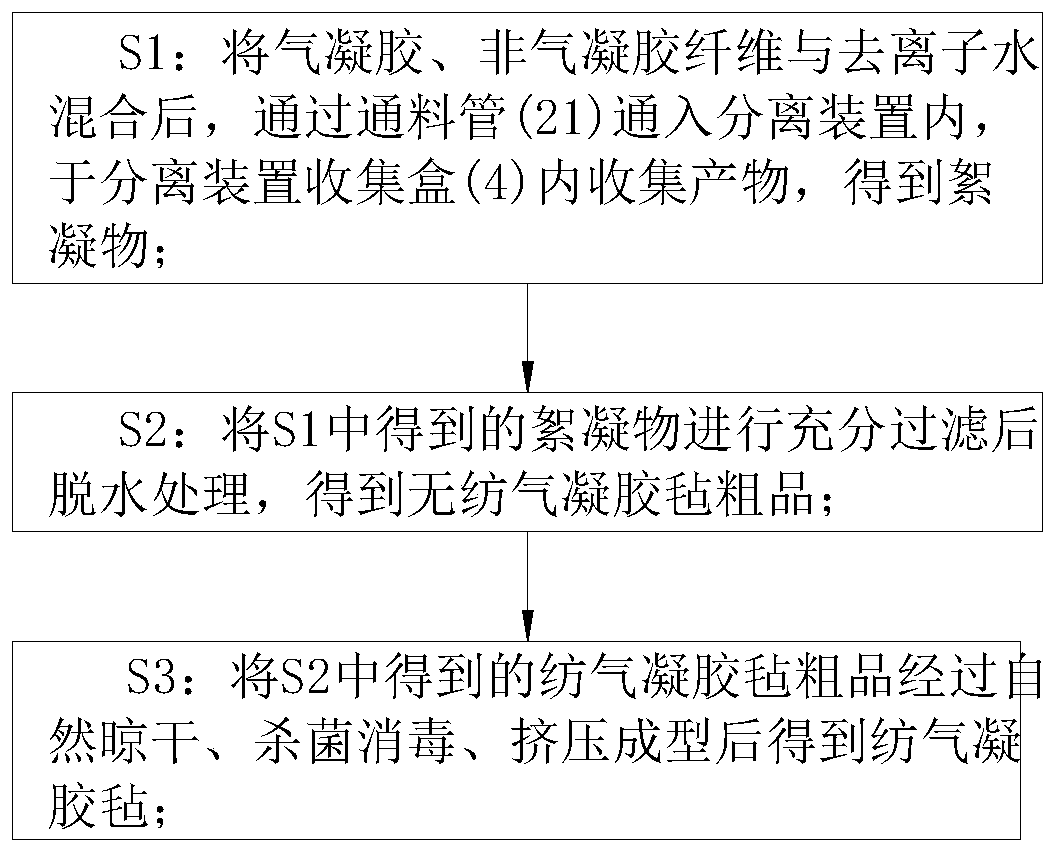

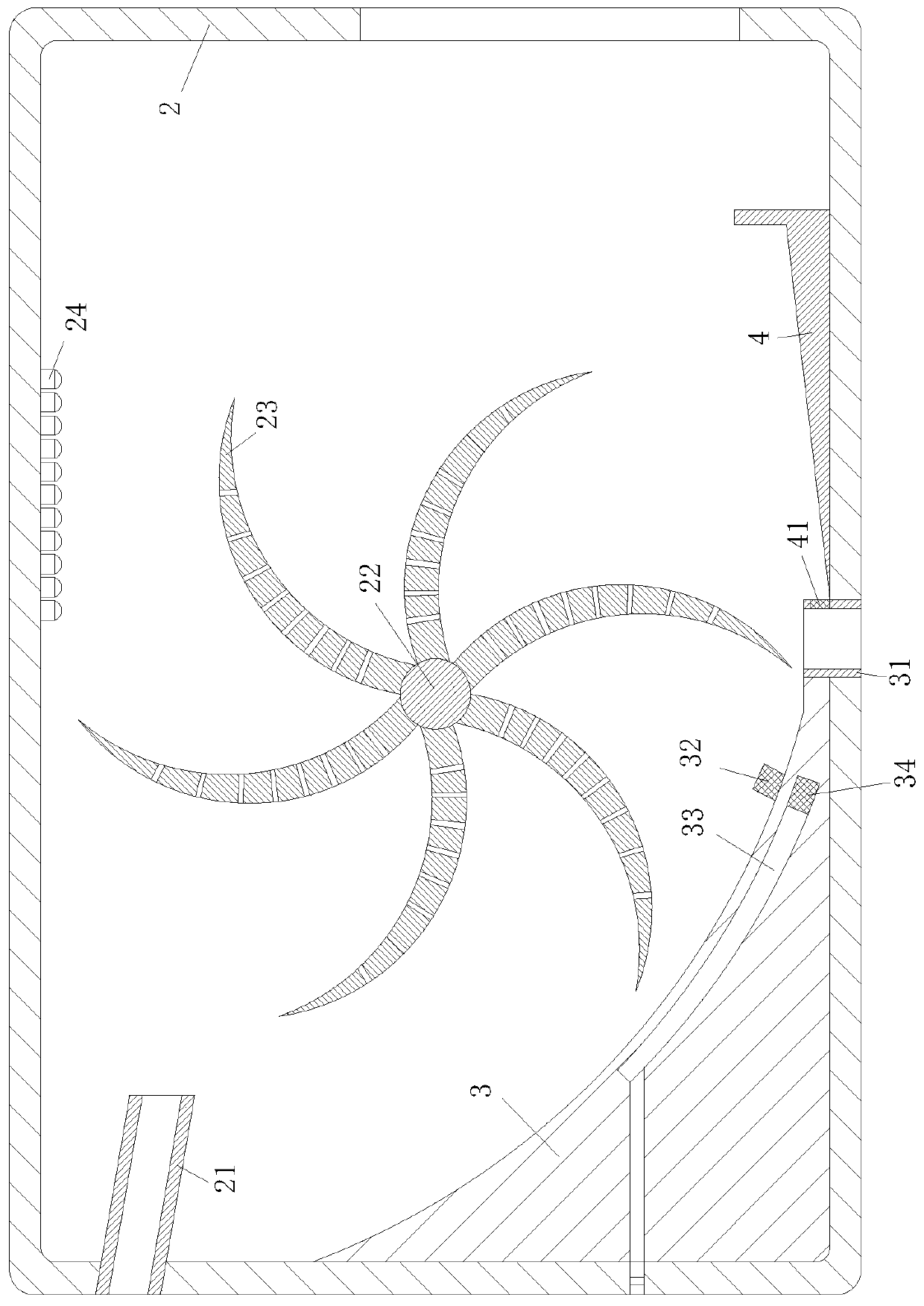

Manufacturing method of biodegradable cast film paper

PendingCN113956520ASolve non-degradable problemsImprove water vapor permeabilityFiberPolyethylene glycol

Owner:XIONGXIAN HENGTONG IND & TRADE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap