Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Non-woven fabrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

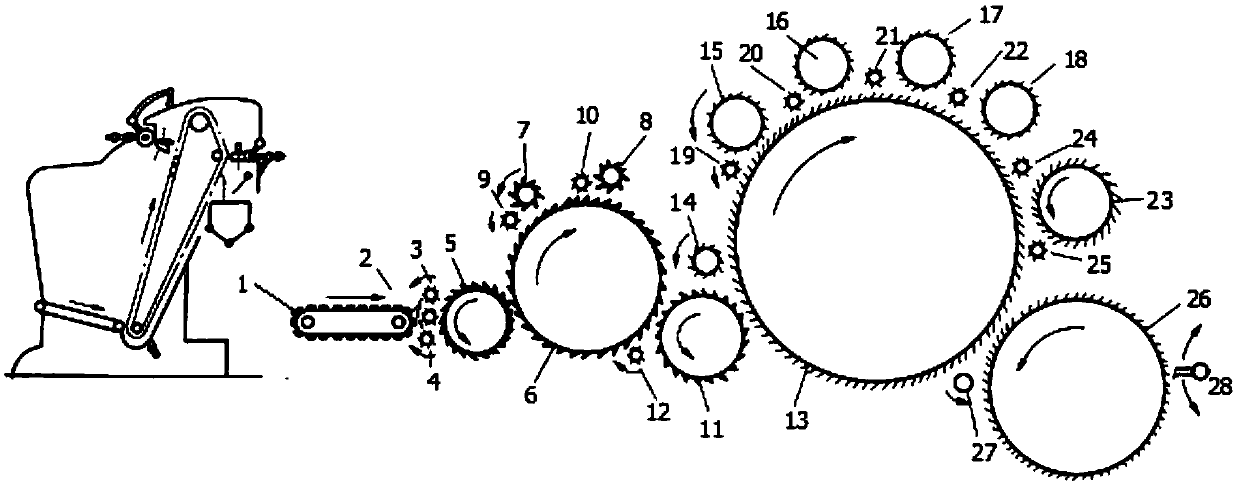

Flocked multi-colored adhesive article with bright lustered flock and methods for making the same

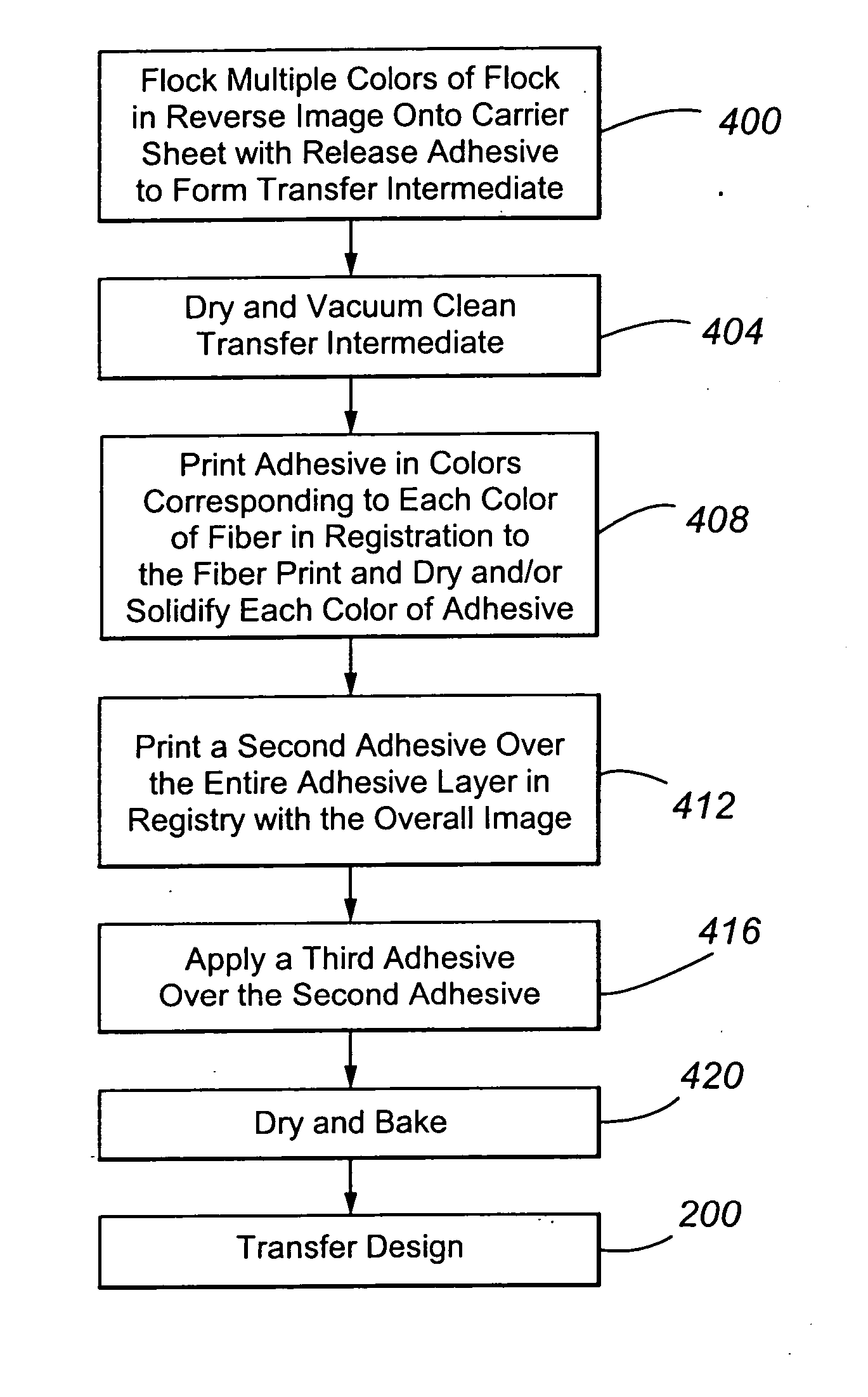

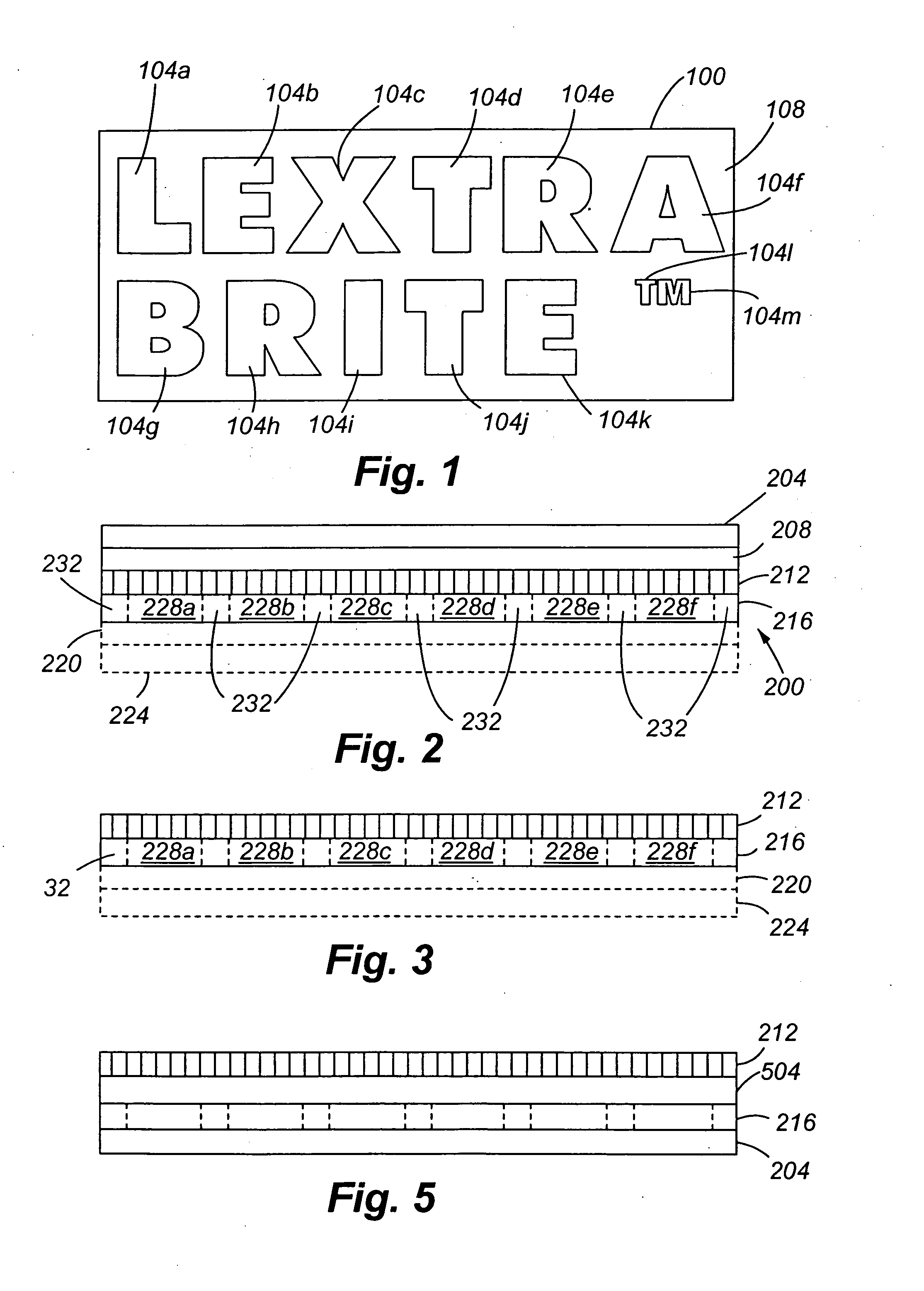

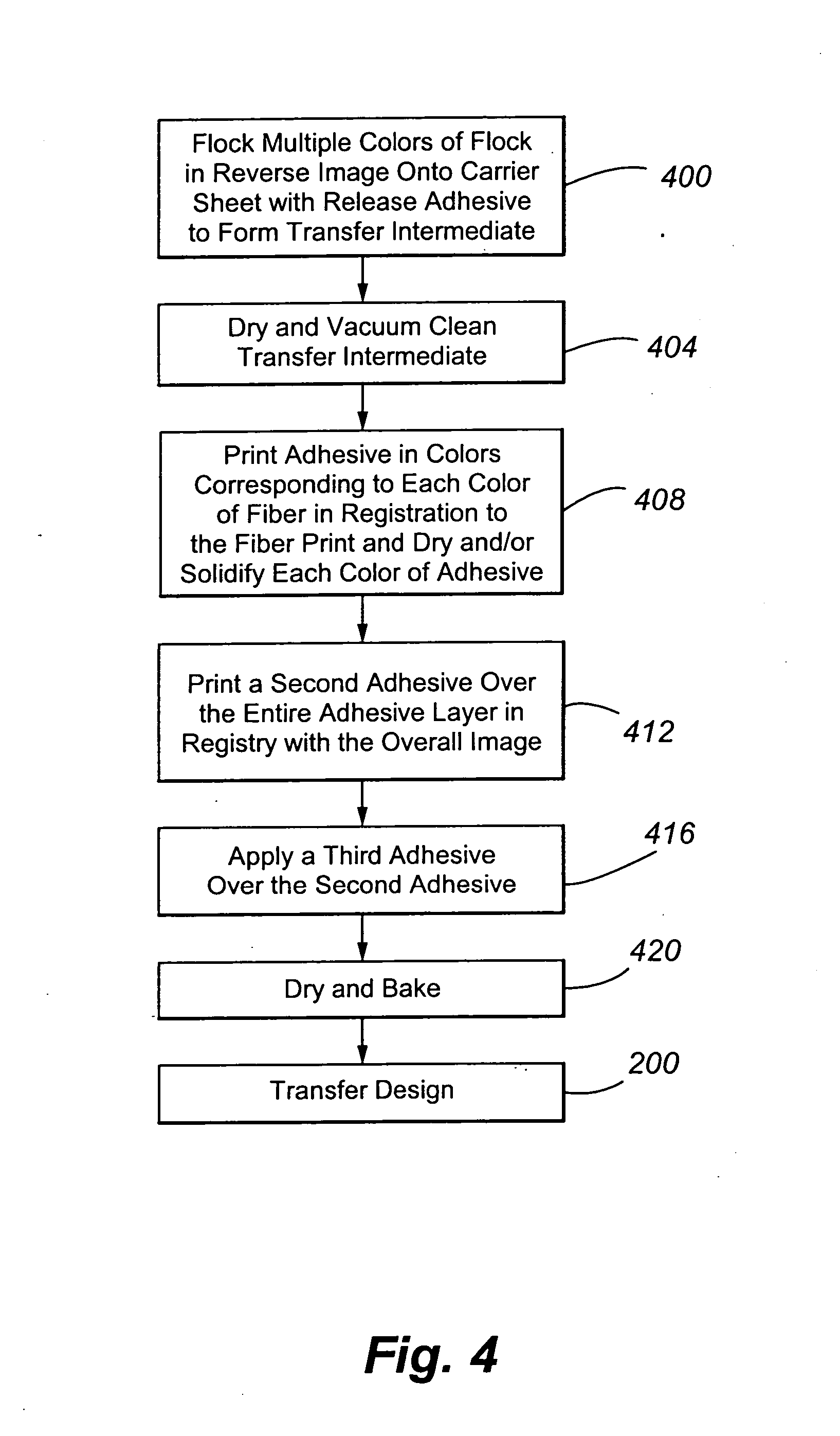

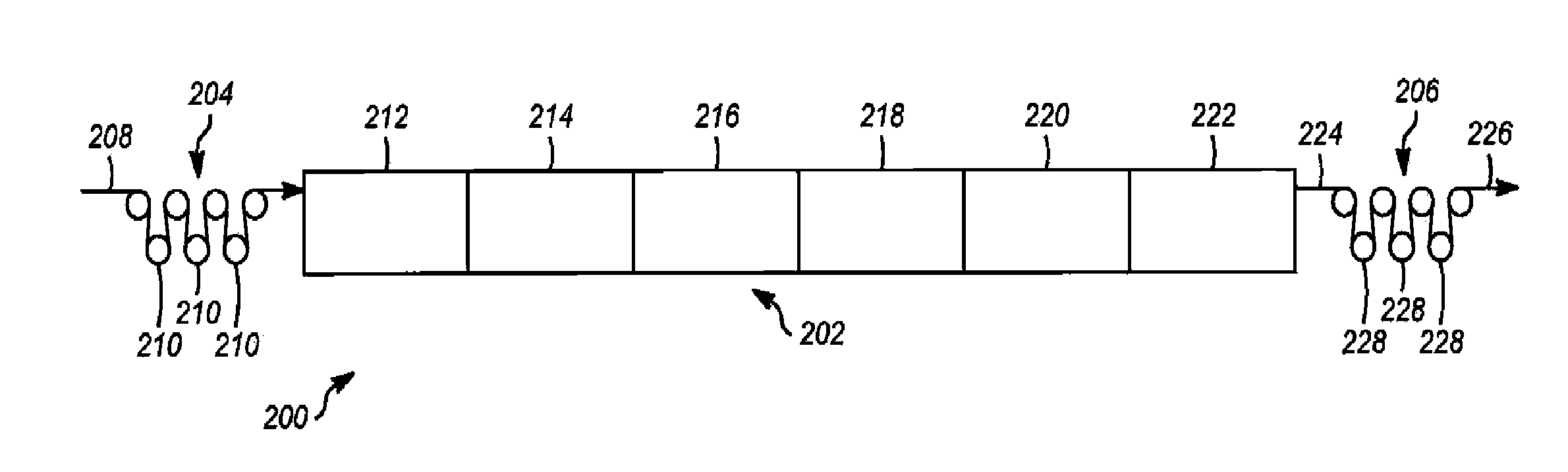

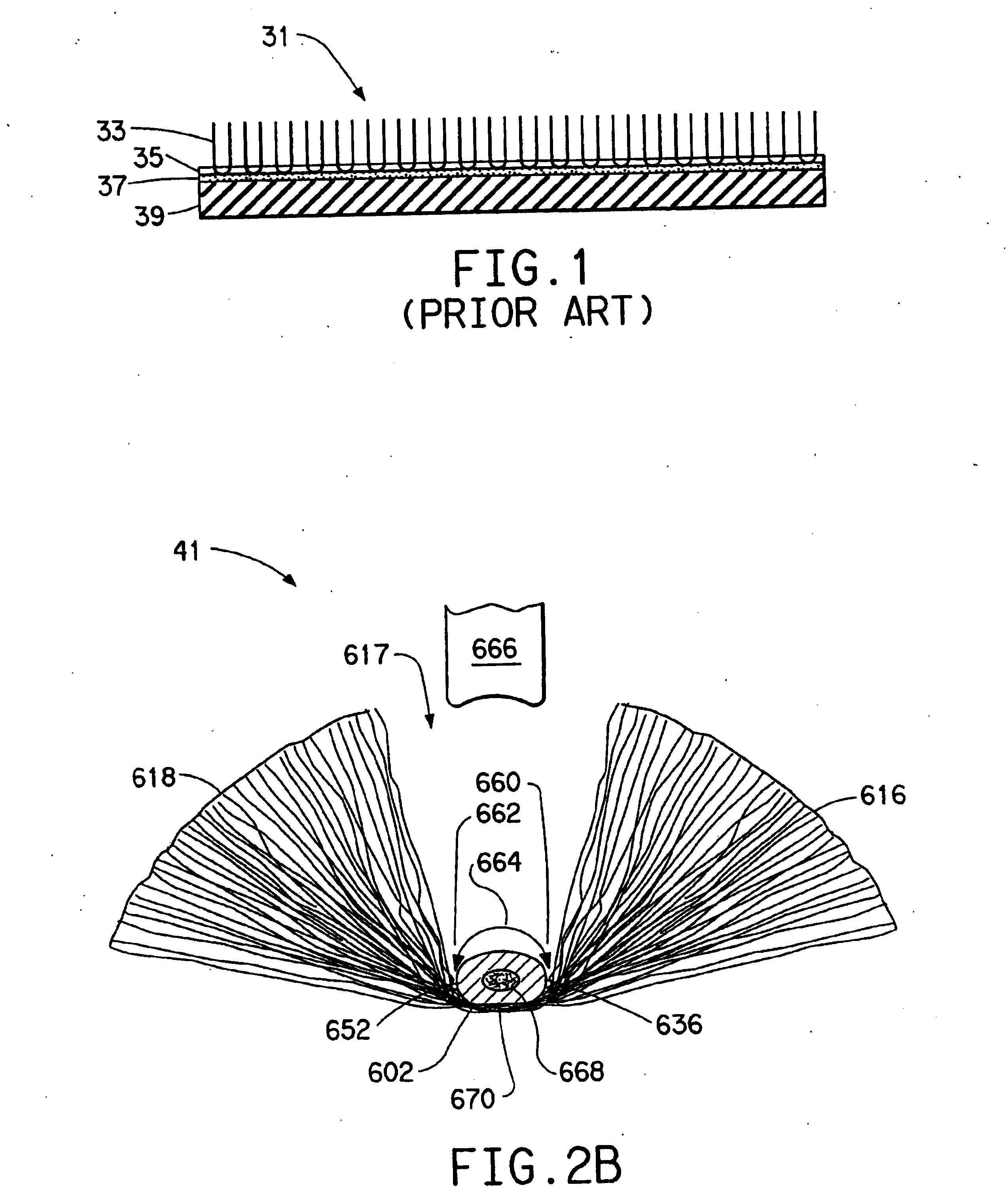

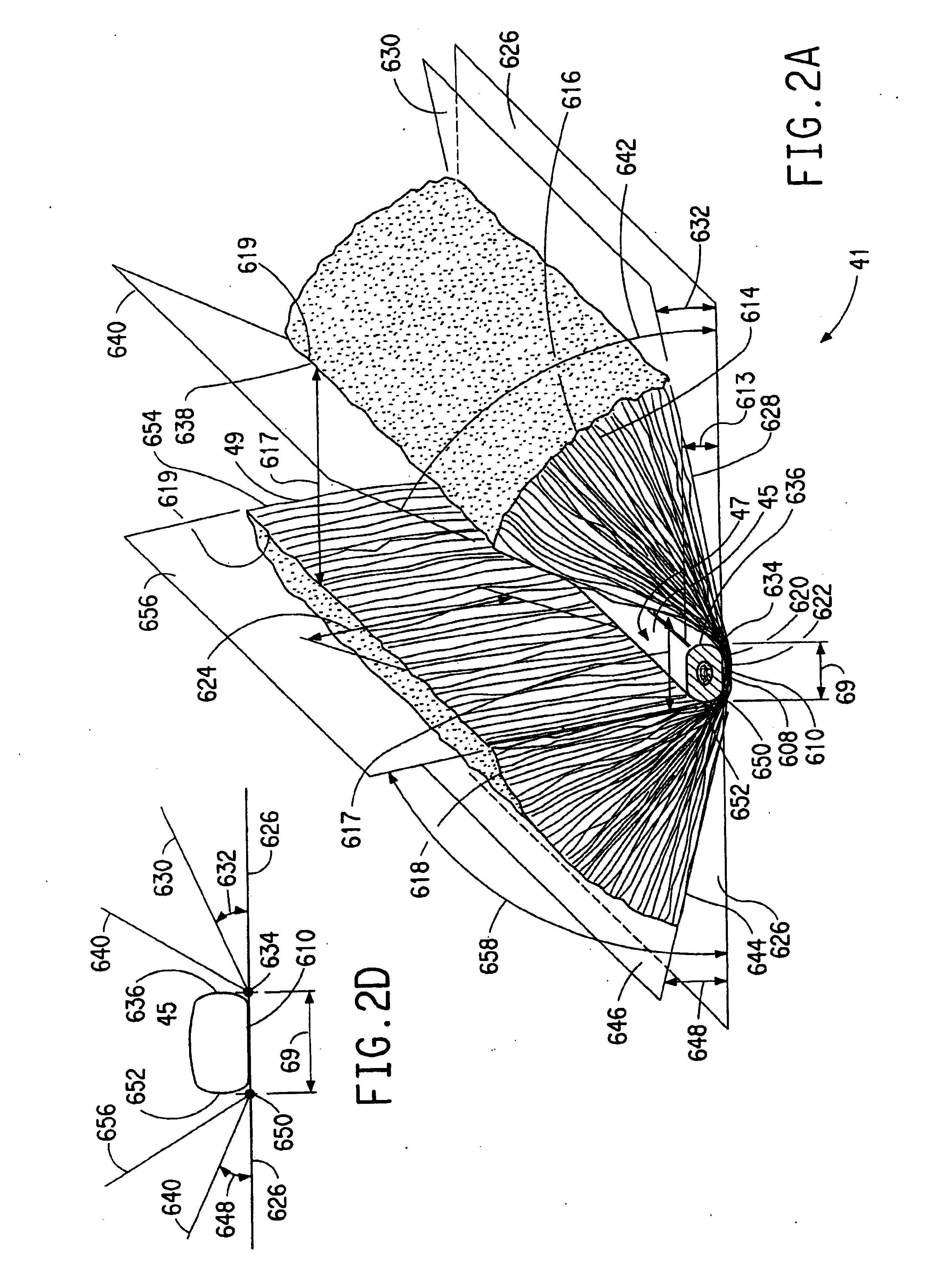

InactiveUS20060251852A1Reduce shadowing effectFlock densityLayered productsOrnamental structuresFiberEngineering

Owner:HIGH VOLTAGE GRAPHICS

Novel uhmwpe fiber and method to produce

Owner:HONEYWELL INT INC

Reinforced coatings and methods of making the same

Owner:GENERAL ELECTRIC CO

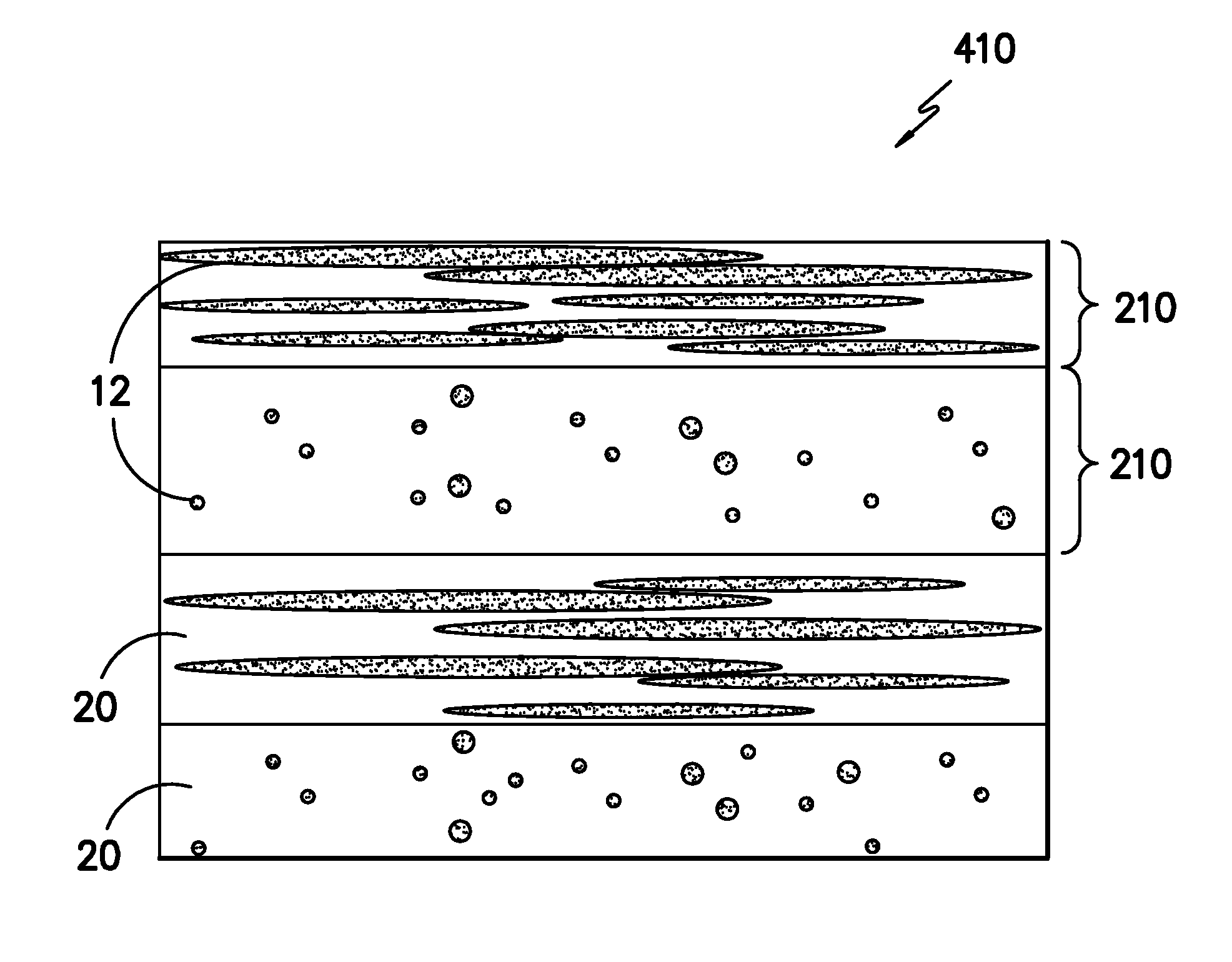

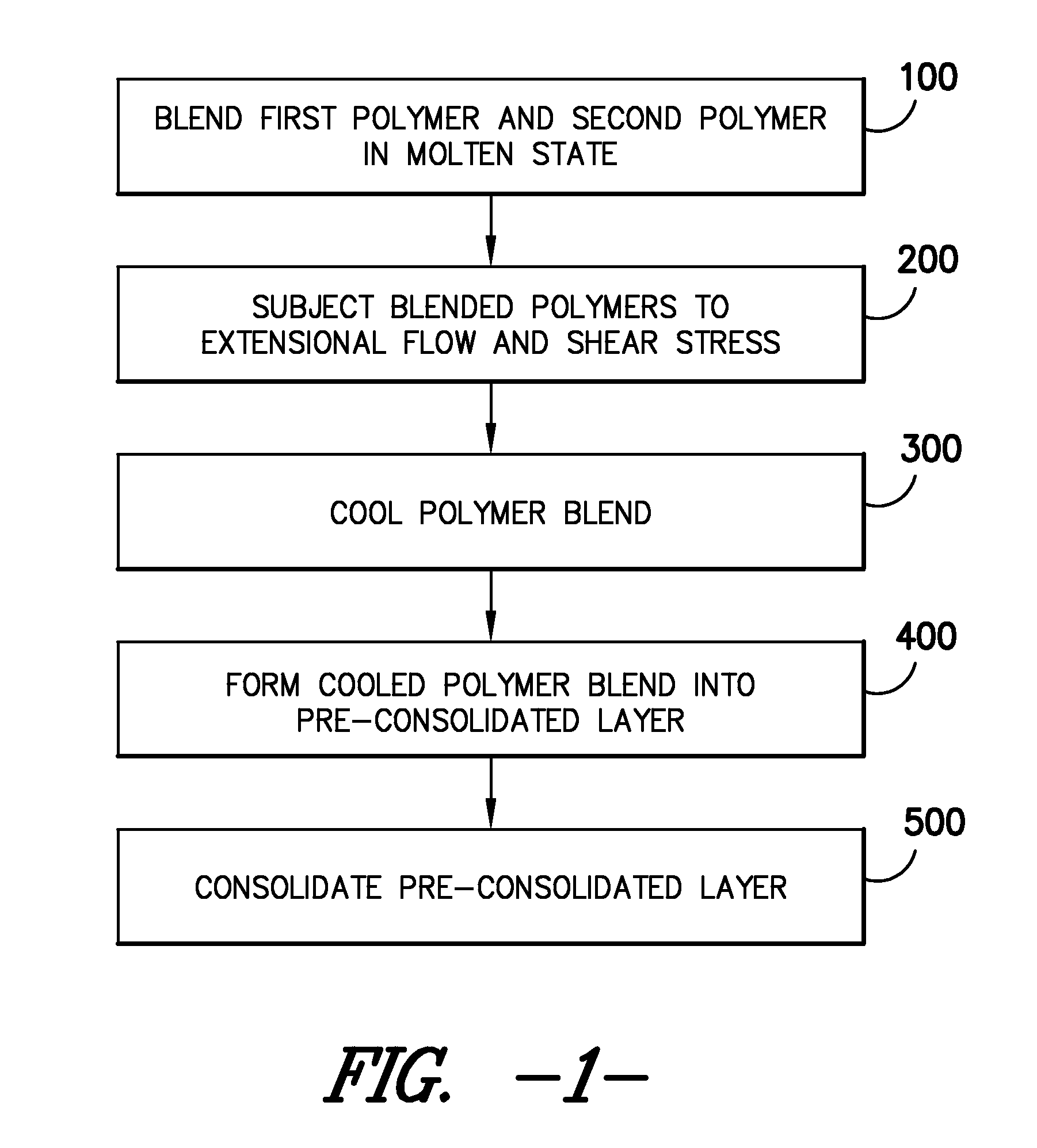

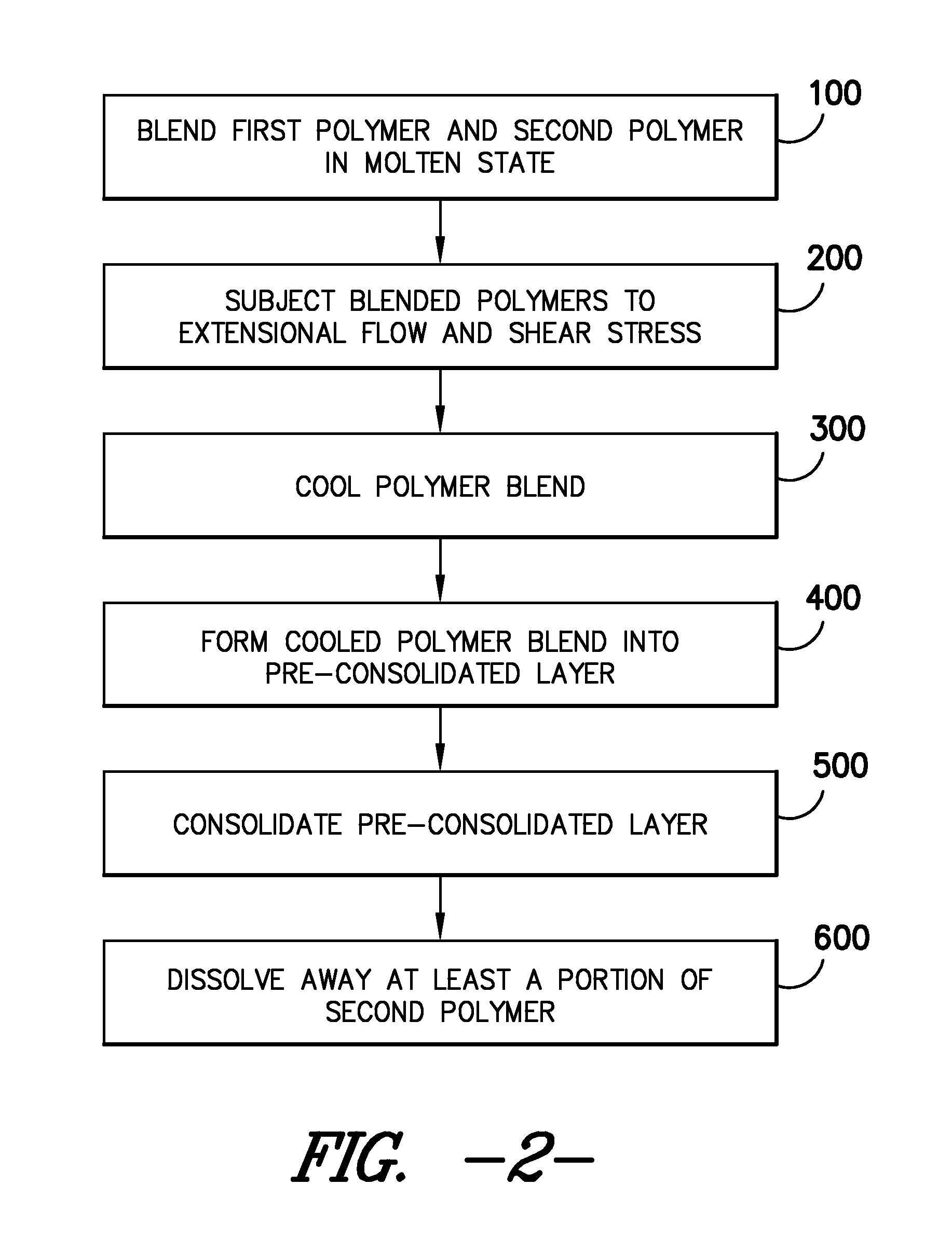

Process of Forming Nano-Composites and Nano-Porous Non-Wovens

Owner:MILLIKEN & CO

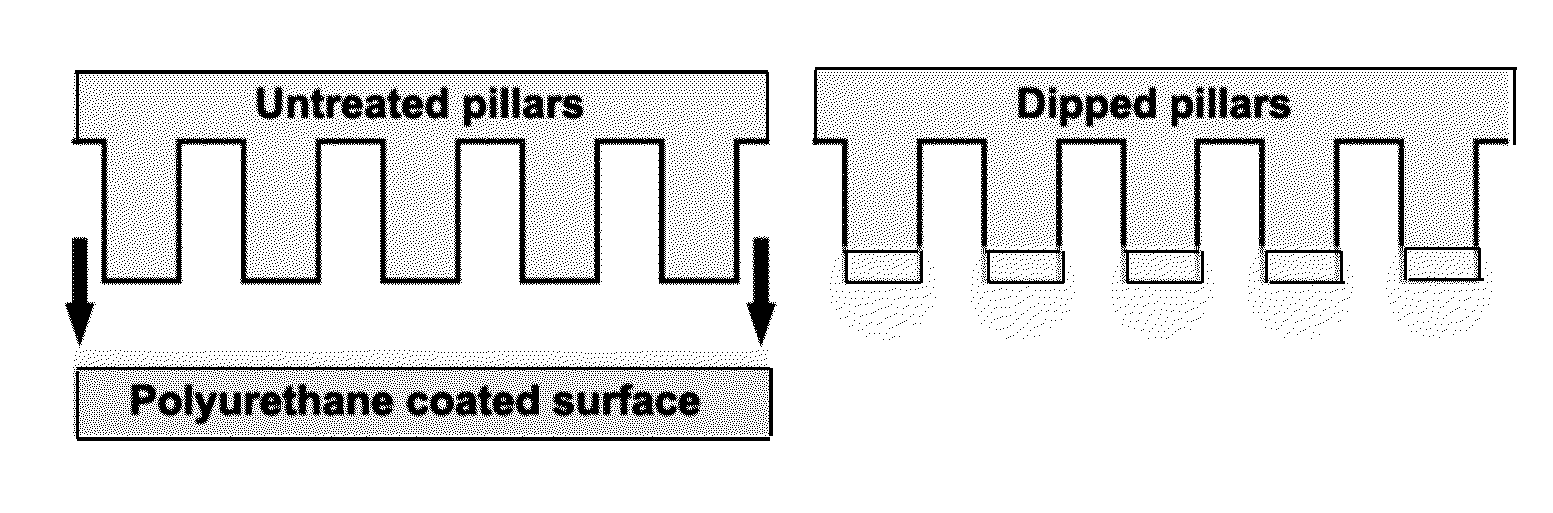

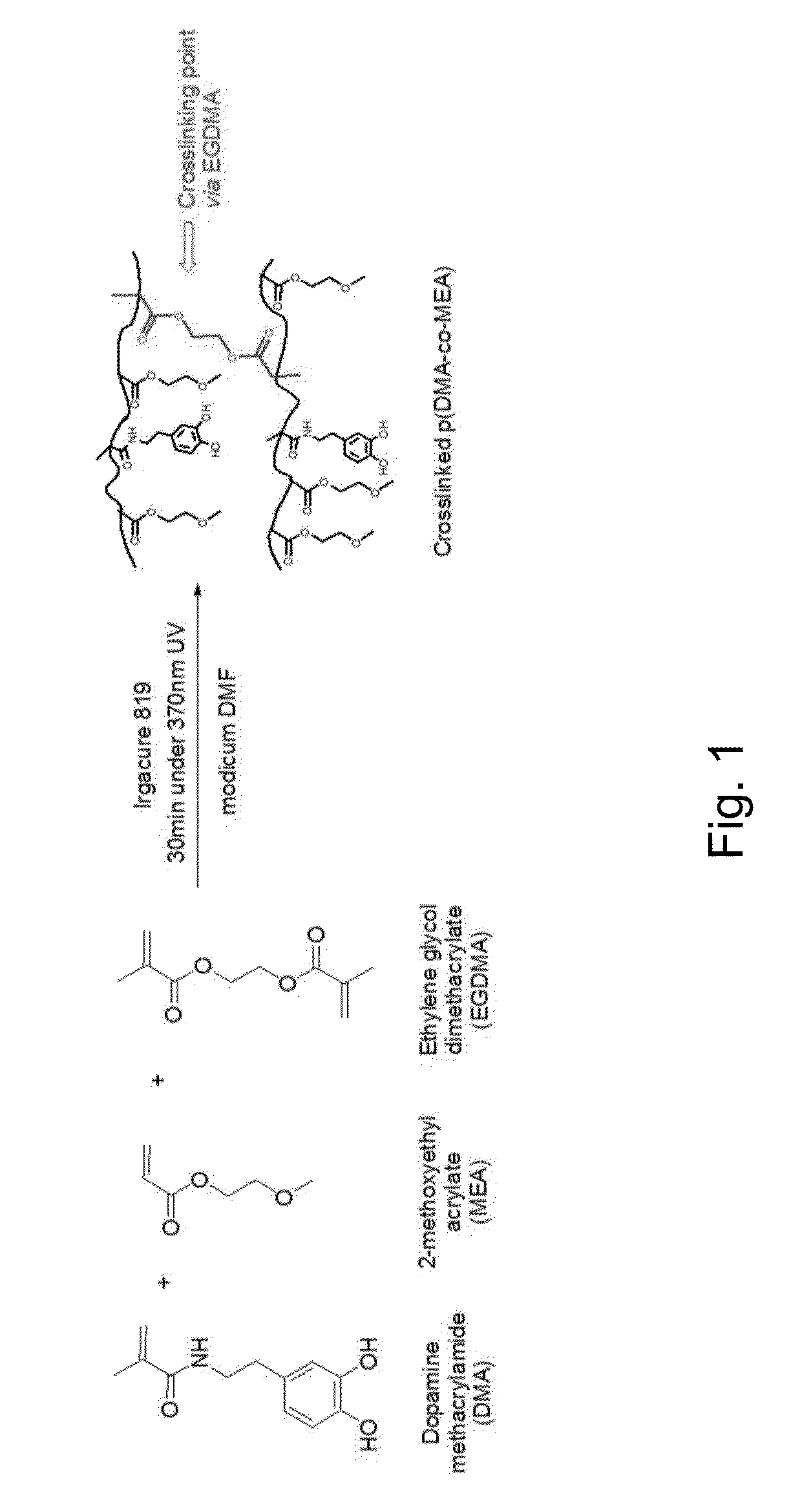

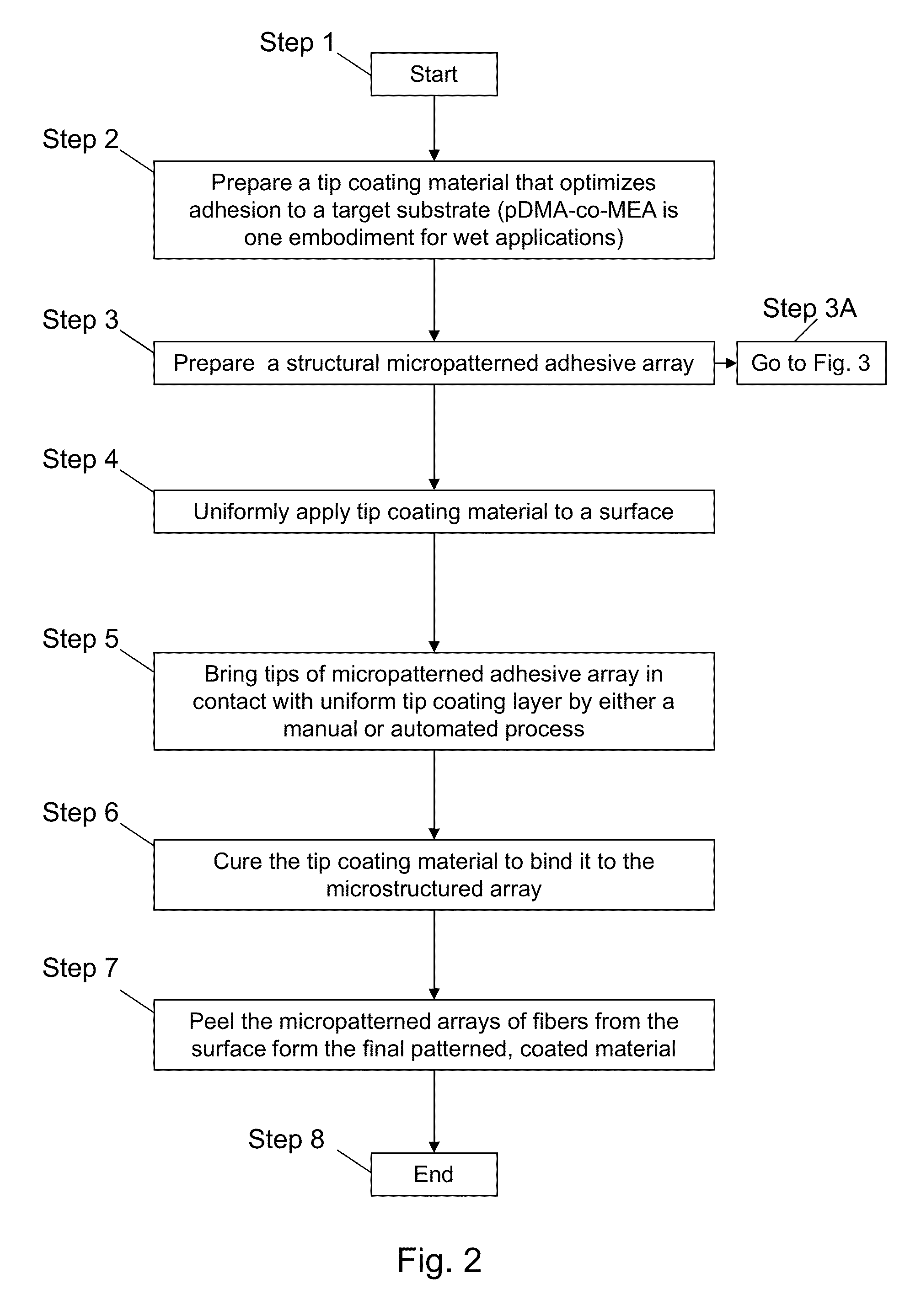

Micro-fiber arrays with tip coating and transfer method for preparing same

ActiveUS20130183481A1Performance deteriorationLayered productsPretreated surfacesMicron scaleElastomer

Owner:CARNEGIE MELLON UNIV CENT FOR TECH TRANSFER & ENTERPRISE CREATION

Fiber mat and process for making same

InactiveUS20060292952A1Improved tensileHigh tear strengthNatural cellulose pulp/paperSpecial paperFiberEngineering

Owner:BUILDING MATERIALS INVESTMENT

Technology for making double-layer knitted inner container thermal shirt

ActiveCN103960787AEnsure production efficiencyQuality assuranceWarp knittingNon-woven fabricsMechanical engineeringIndustrial engineering

Owner:苏州新超针纺织有限公司

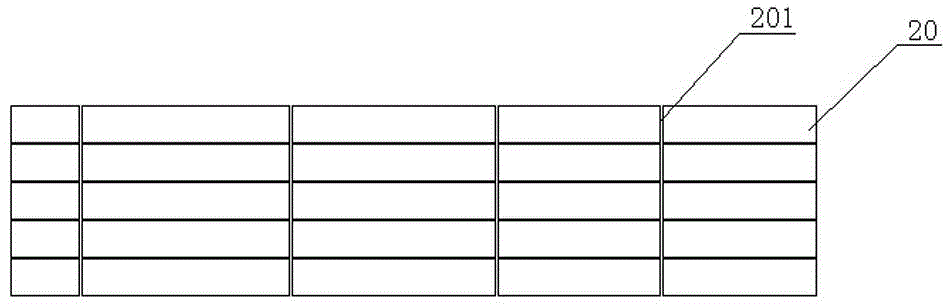

Textile fiber carding machine

InactiveCN105951305AAvoid one-sidednessSort out fullyCarding machinesNon-woven fabricsTextile fiberCarding

Owner:EASTERN LIAONING UNIV

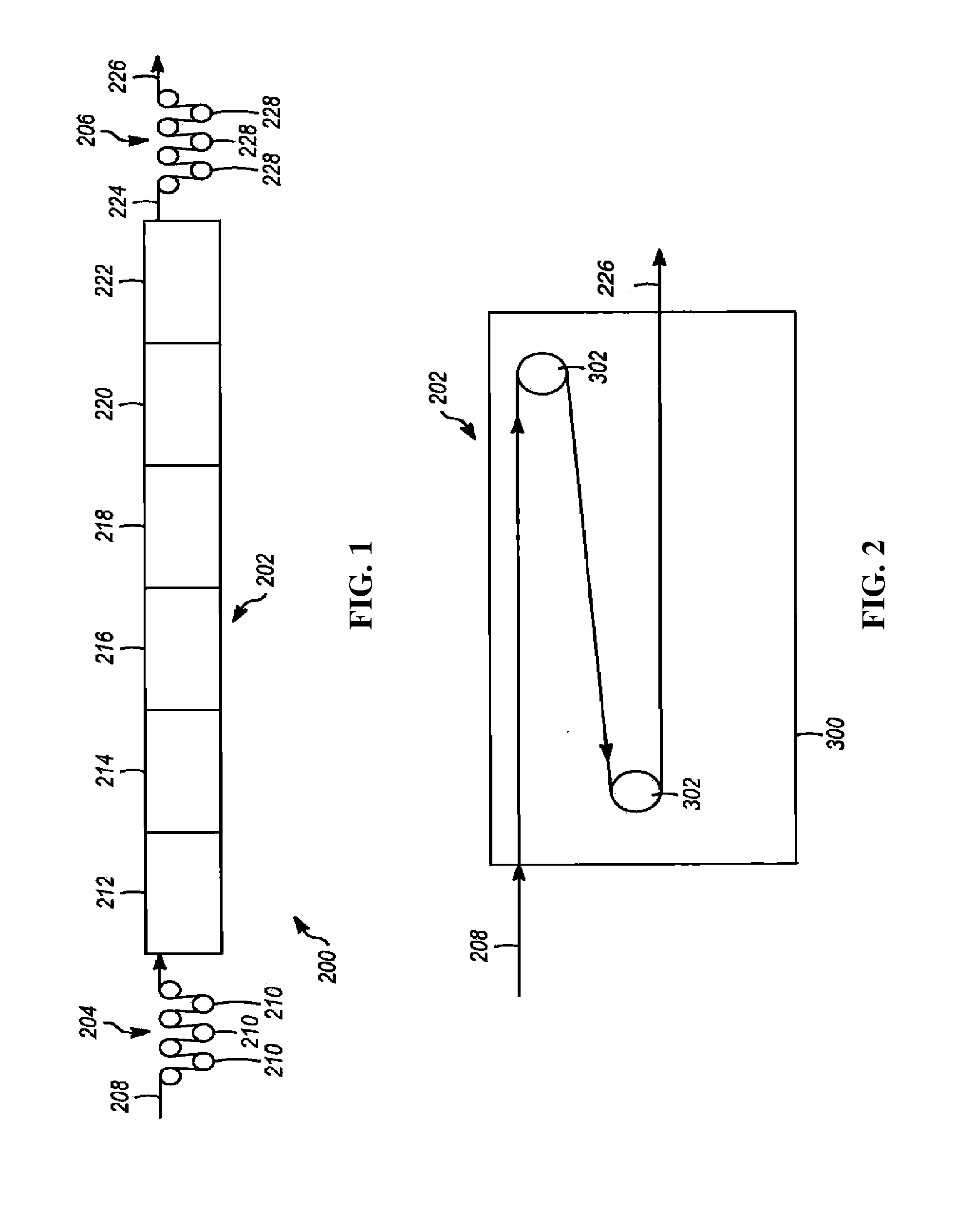

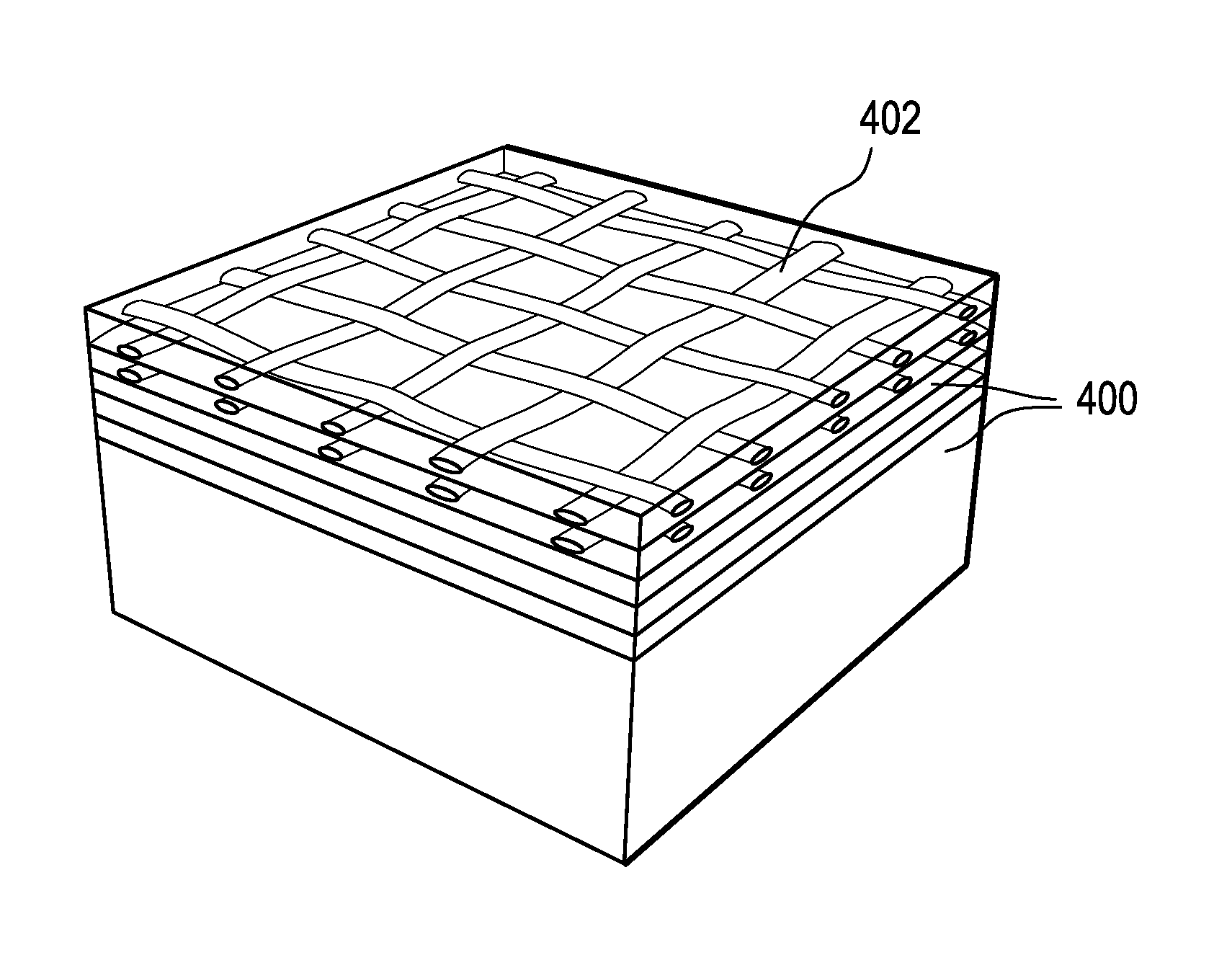

Cured In Place Pipe Liner With Styrene Barrier

InactiveUS20100243154A1Promote migrationHigh hardnessPipe elementsRecord information storageEngineeringCured-in-place pipe

A liner for repairing damaged pipes, such as underground sewer or gas pipes is disclosed. The liner comprises a TPU coating on fibrous mat of non-woven fabric. The TPU coating contains a barrier layer to retard the migration of styrene from the liner to the media used to force the liner against the damaged pipe and to activate the thermoset resin. The thermoset resin converts the liner from a flexible state to a rigid state as the liner is cured in place inside the pipe.

Owner:LUBRIZOL ADVANCED MATERIALS INC

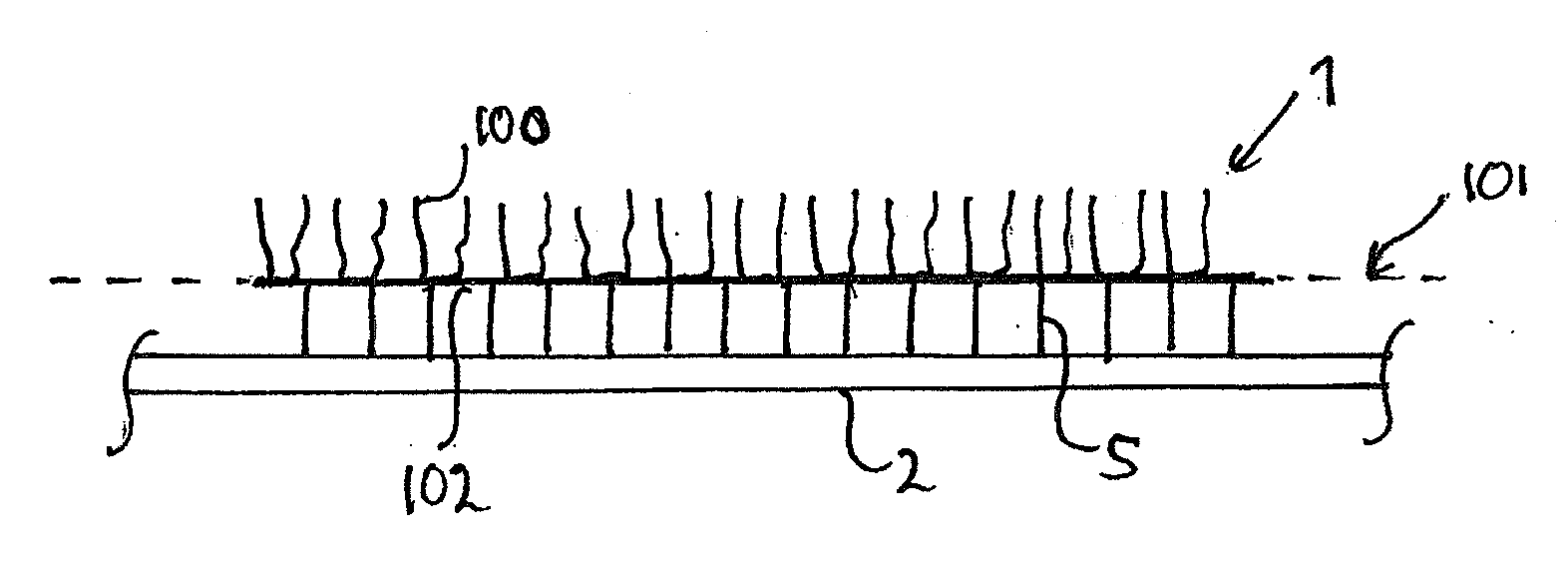

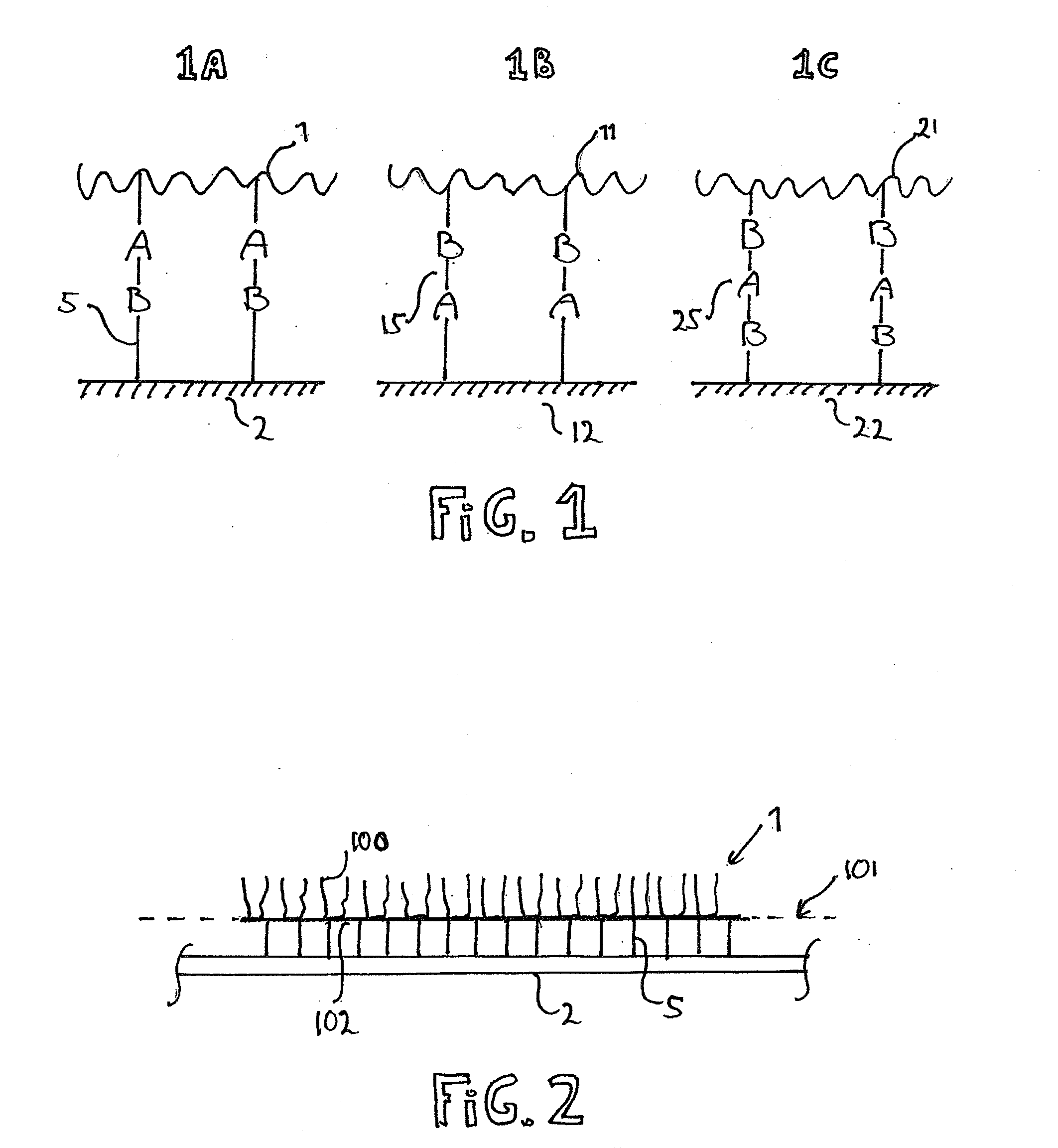

Velour-like pile articles and pile surface structures and methods of making

InactiveUS20050129905A1Convenient guidanceLittle torsional stabilityVehicle arrangementsSynthetic resin layered productsYarnStructural engineering

Owner:INVISTA NORTH AMERICA R L

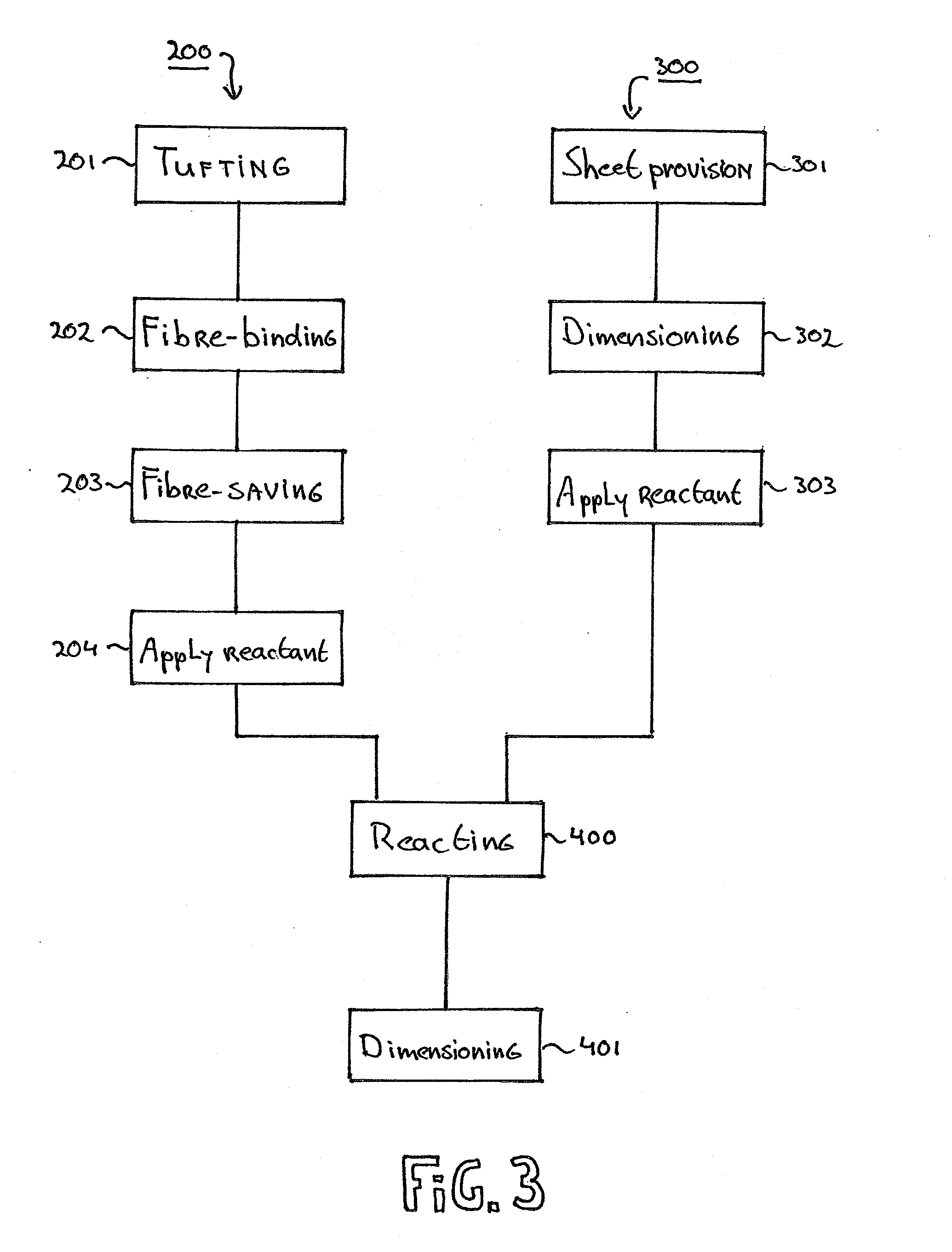

Method to Produce a Textile Product and a Textile Product Resulting from the Same

ActiveUS20130240117A1Reliable and easy connectionInexpensive materialsLiquid surface applicatorsLamination ancillary operationsYarnCovalent Interaction

Owner:COVESTRO NETHERLANDS BV

High melt flow fluoropolymer composition

The invention relates to very high melt flow fluoropolymer compositions, having low melt viscosities. The fluoropolymers have low molecular weights of from 5 kDa to 200 kDa and melt viscosities of less than 2 kilopoise (kP) at 232° C. and 100 s−1. One use for the high melt flow fluoropolymers is in the formation of very small diameters fibers, useful for melt-blown non-woven materials. Fiber diameters of less than 9 microns, and preferably 500 to 2000 nm can be produced.

Owner:ARKEMA INC

Sealing material for preventing rodents and pests from passing through and manufacturing process thereof

ActiveCN104542568ASo as not to damageImprove toughnessLamination ancillary operationsLaminationCardingVermin

Owner:SUZHOU DANGEWEI IND

High-adsorption polylactic acid composite biofilm carrier material and preparation method thereof

InactiveCN107841037ALarge surface activation areaImprove liquiditySustainable biological treatmentConjugated synthetic polymer artificial filamentsSodium BentoniteWater quality

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Method for preparing gold nanorod-loaded electrospun fiber

InactiveCN107761366ASimple methodEnhancement effect is goodFibre typesConjugated synthetic polymer artificial filamentsGold nanorodSelf-assembly

Owner:SHAANXI SHENGMAI PETROLEUM

Preparation method of non-woven fabric

InactiveCN108517621AImprove toughnessImprove wear resistanceBiochemical fibre treatmentNon-woven fabricsCardingPyrophosphate

Owner:徐冬

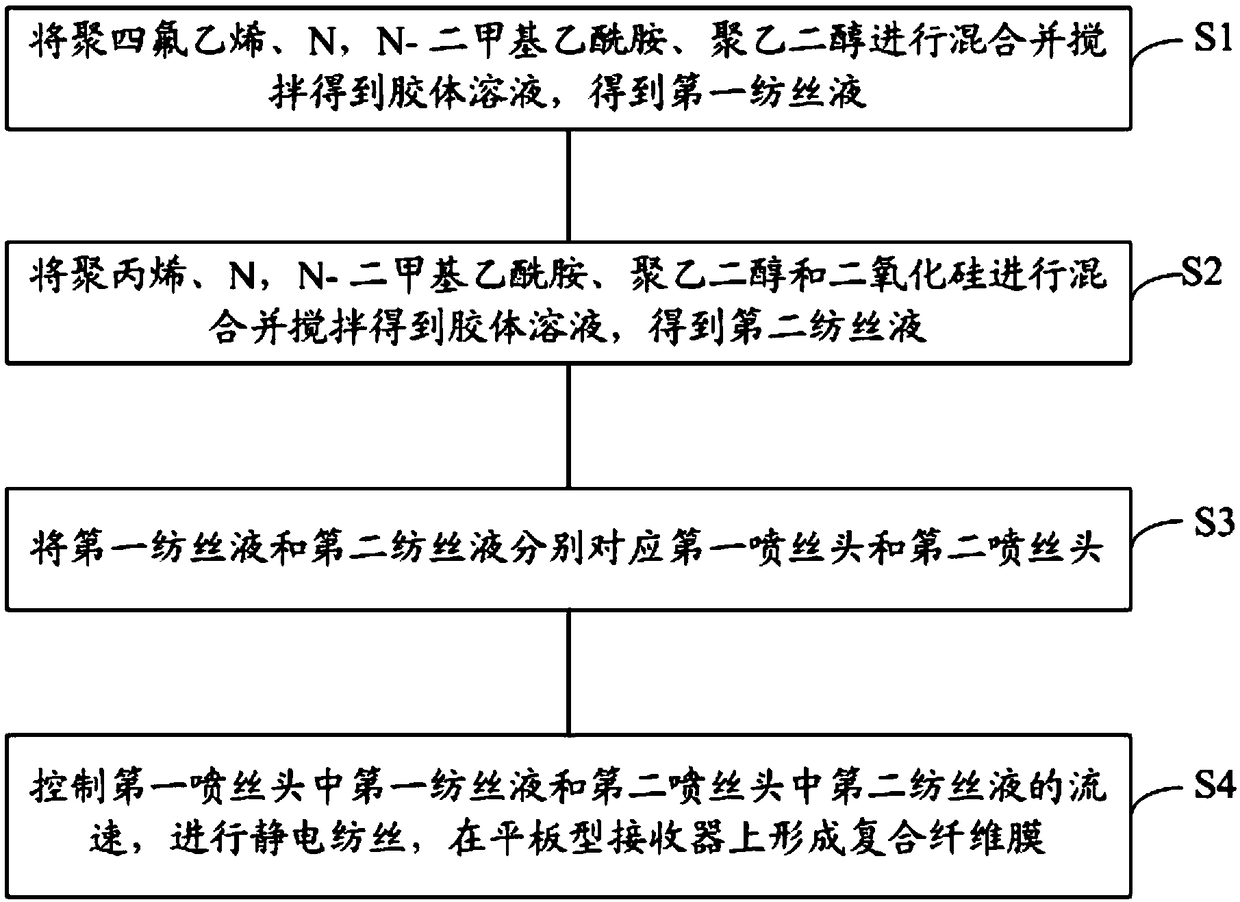

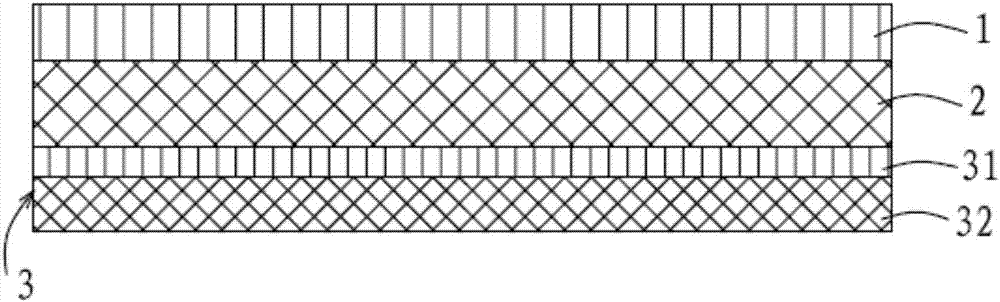

Preparation method of release-controllable electrospun fiber drug carrier with nested nanostructure

ActiveCN108030775AImprove biological activitySmooth releaseFilament/thread formingKetone active ingredientsFiberDrug release

The invention relates to a preparation method of a degradable and release-controllable polymer carrier, in particular to a preparation method of a release-controllable electrospun fiber drug carrier with a nested nanostructure. The method comprises the following four steps: preparing carrier particles, preparing electrostatic spinning fluid, preparing a spinning fiber membrane and carrying out aftertreatment on the fiber membrane; the obtained fiber membrane can be both applied to the exterior of a body and implanted into the body, and has good biological activity, biodegradability, antibacterial property and good drug loading property; furthermore, lignin nanoparticles wrapped in spinning fibers show a certain antibacterial property in a degradation process of the fiber membrane; in addition, the fiber membrane prepared by the method can be biodegraded in a long-term service period in the alkaline environment of body fluid, so that the stable release of a drug is ensured, and the drugis enabled to be fully and thoroughly released.

Owner:HEBEI UNIV OF TECH

Isotactic polypropylene/tall oil acid/polybutadiene composite sound absorbing cotton and preparation method thereof

InactiveCN103726222AImprove breathabilityImprove tensile propertiesSynthetic resin layered productsNon-woven fabricsParaffin waxVoid ratio

Owner:芜湖跃飞新型吸音材料股份有限公司

Melt-blown polypropylene material composition and preparation method thereof

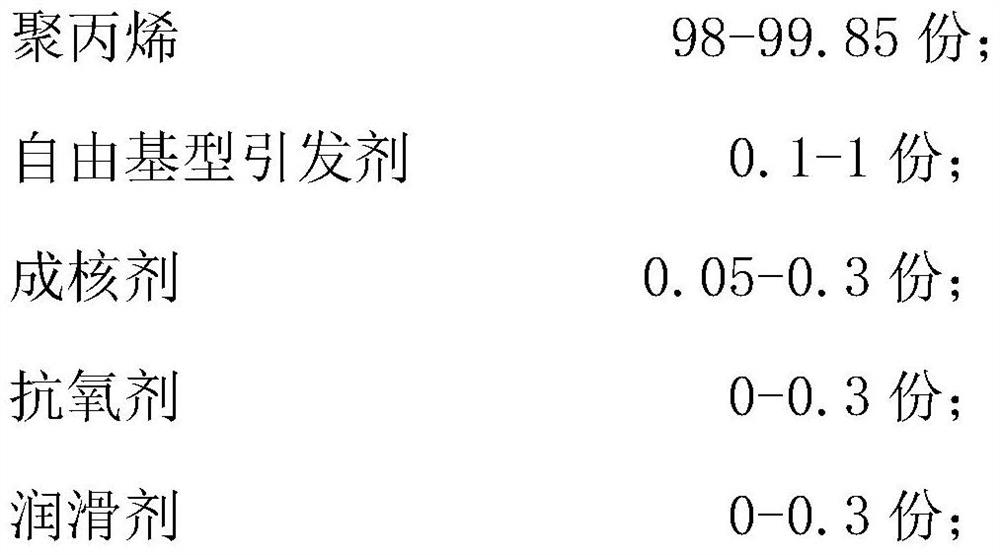

PendingCN112812429ANon-woven fabricsMonocomponent polyolefin artificial filamentHindered amine light stabilizersPolypropylene

Owner:广东国恩塑业发展有限公司

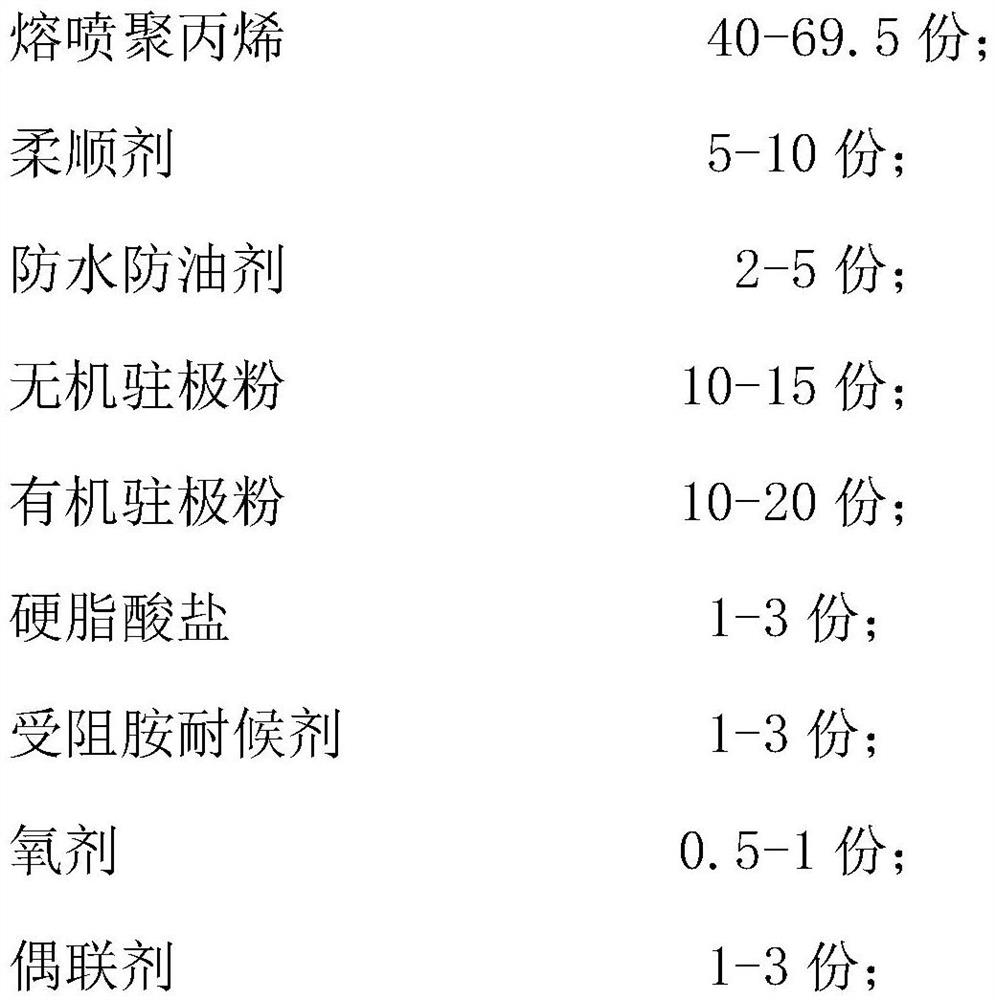

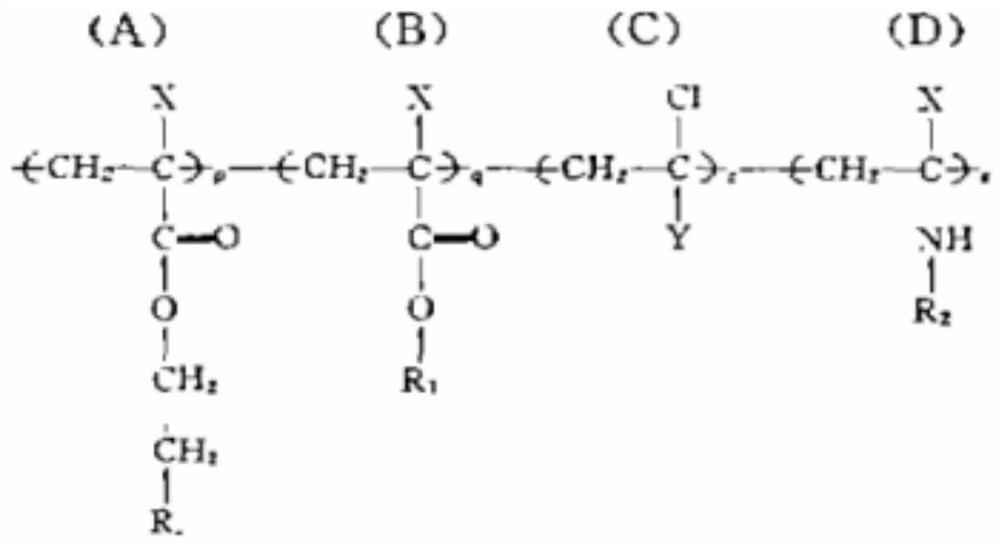

Preparation method of composite fiber membrane with efficient filtration

Owner:江苏弗瑞仕环保科技有限公司

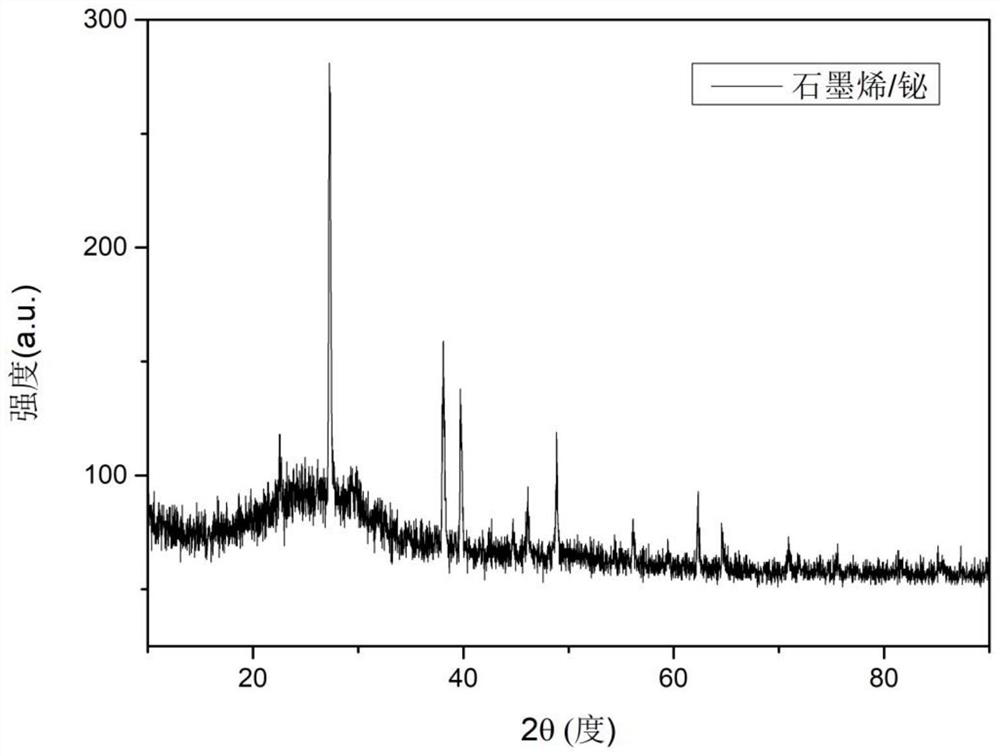

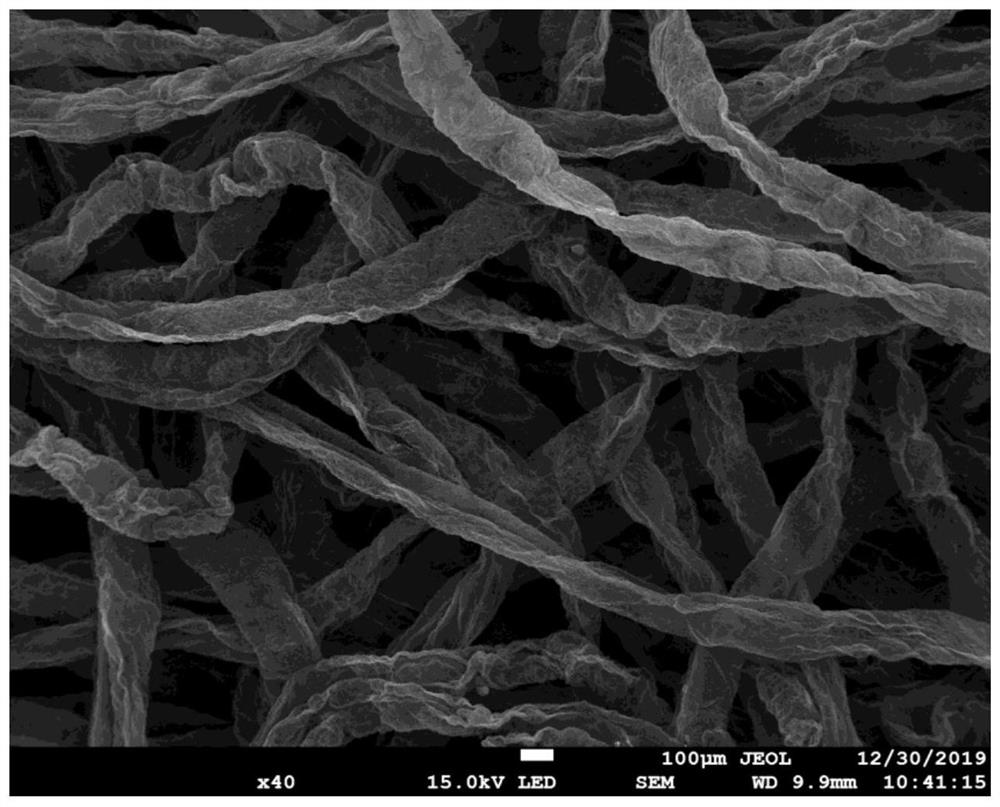

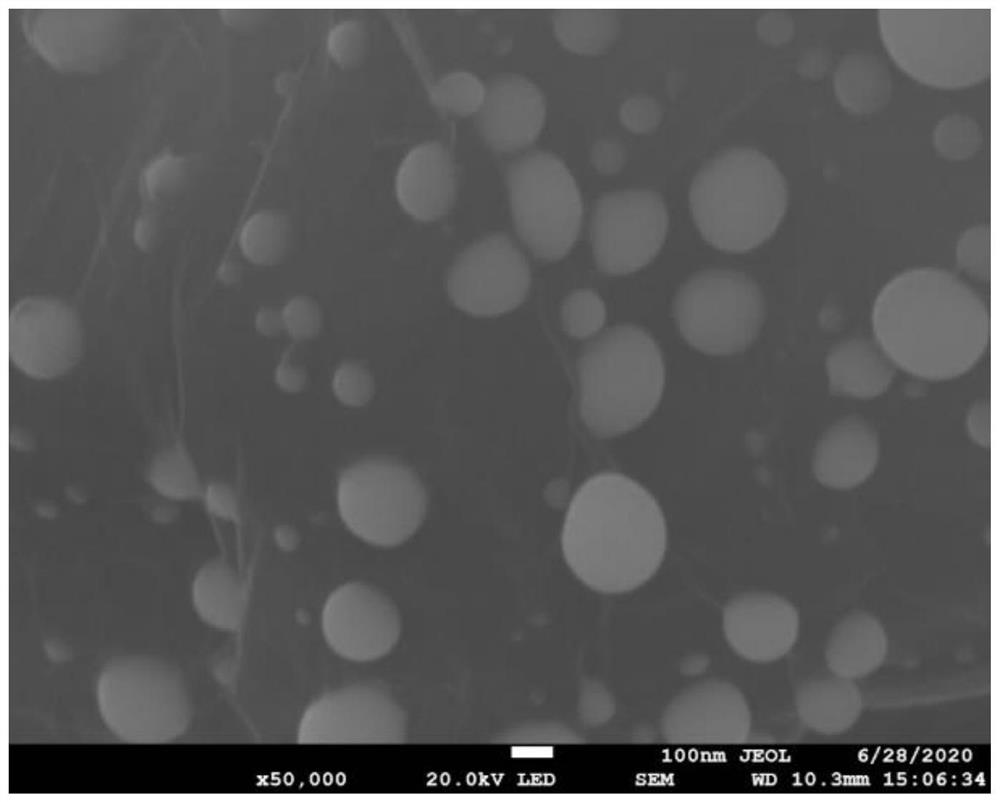

Method for preparing bismuth nanoparticles loaded on graphene fiber non-woven fabric by microwave induction

InactiveCN112941894AImprove cycle performanceImprove mechanical stabilityRadio/micro wave fibre treatmentNon-woven fabricsNonwoven fabricGraphene

Owner:HEBEI UNIV OF TECH

Non-woven fabric lapping machine with noise reduction function

The invention discloses a non-woven web laminating machine with noise reduction function, which comprises a frame. There are mesh guide rollers installed on both sides of the inner cavity of the frame, and the upper mesh curtain and the lower mesh curtain are respectively set on the mesh roller, and a compensation curtain is set between the upper mesh curtain and the lower mesh curtain. A motor is installed on the inner wall, and the motor is fixedly connected with a reduction box. The reduction box is set at one end of the shaft of the guide roller. At one end of the belt, a belt is set on the pulley, and a net-laying trolley is installed between the belts. A net-laying roller is installed on the net-laying trolley, and a web-forming curtain is arranged under the net-laying roller. The outer walls on both sides of the column are equipped with fixing seats, and a shell is installed on the fixing seats. The inner cavity of the shell is provided with a buffer rod.

Owner:YIZHENG HUAKAI NON WOVEN EQUIP

Super-dry hot-air nonwoven fabric

Owner:广东佳丝维新材料科技有限公司

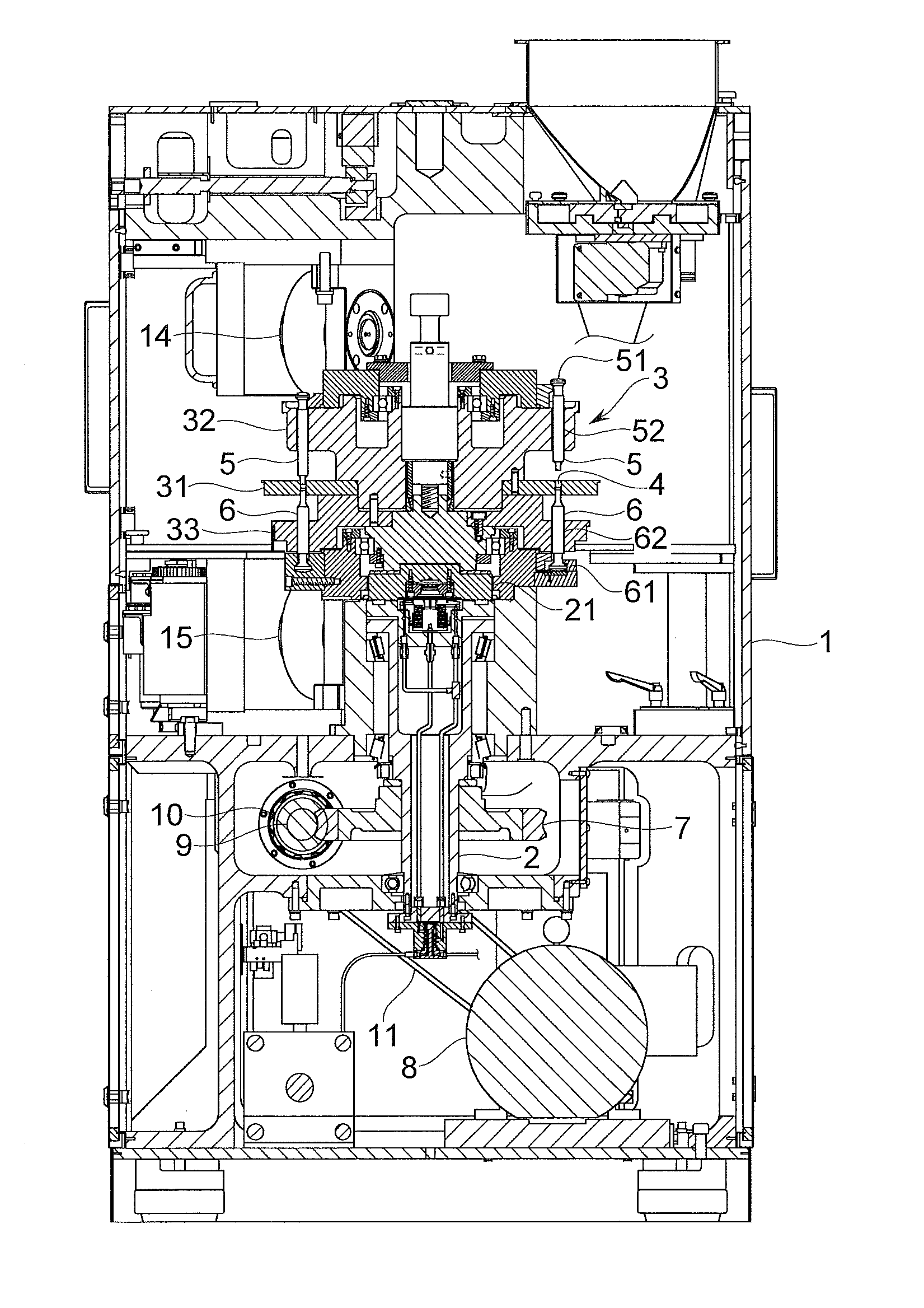

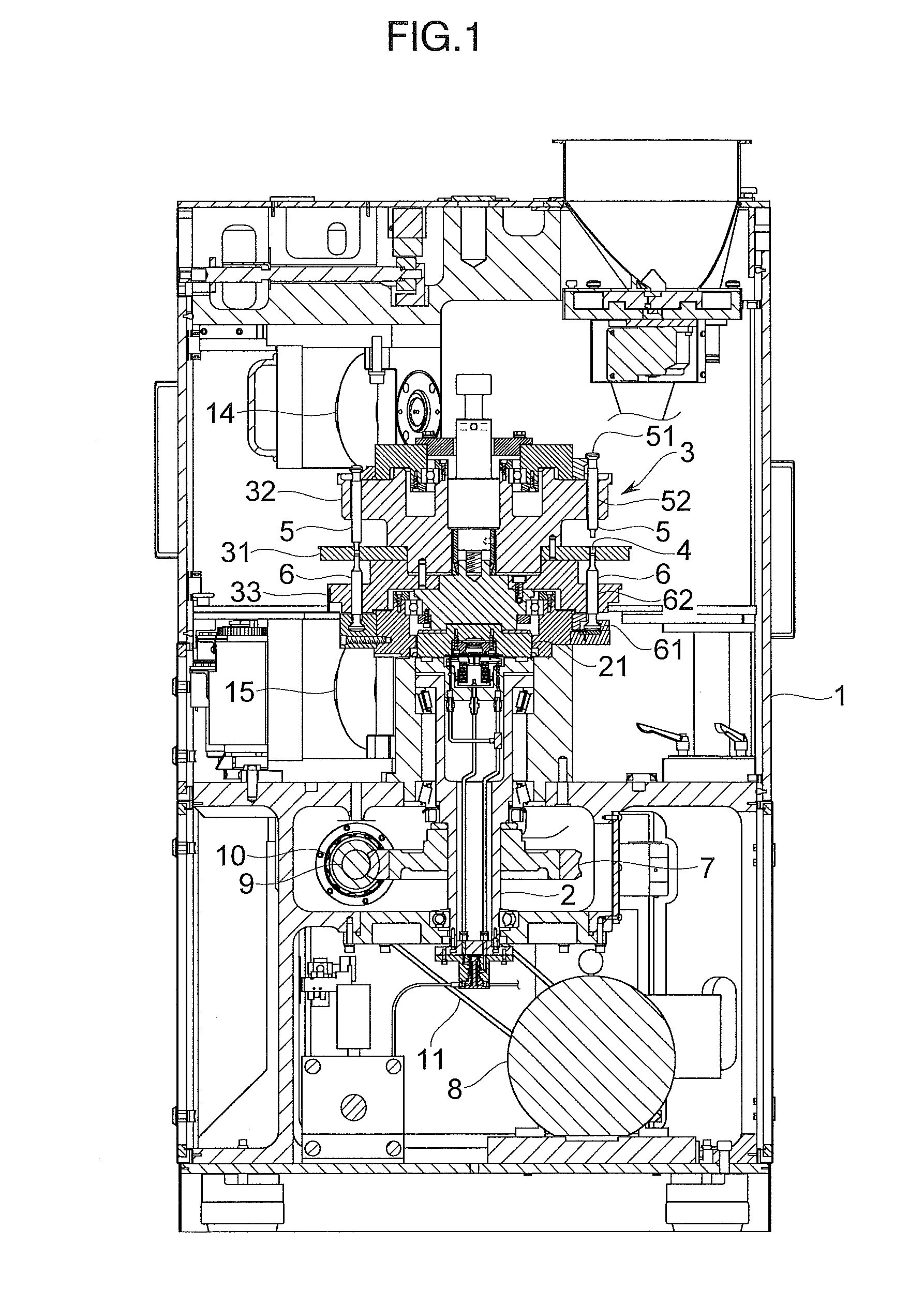

Compression Molding Machine and Method of Producing Molded Product

Owner:KIKUSUI SEISAKUSHO LTD

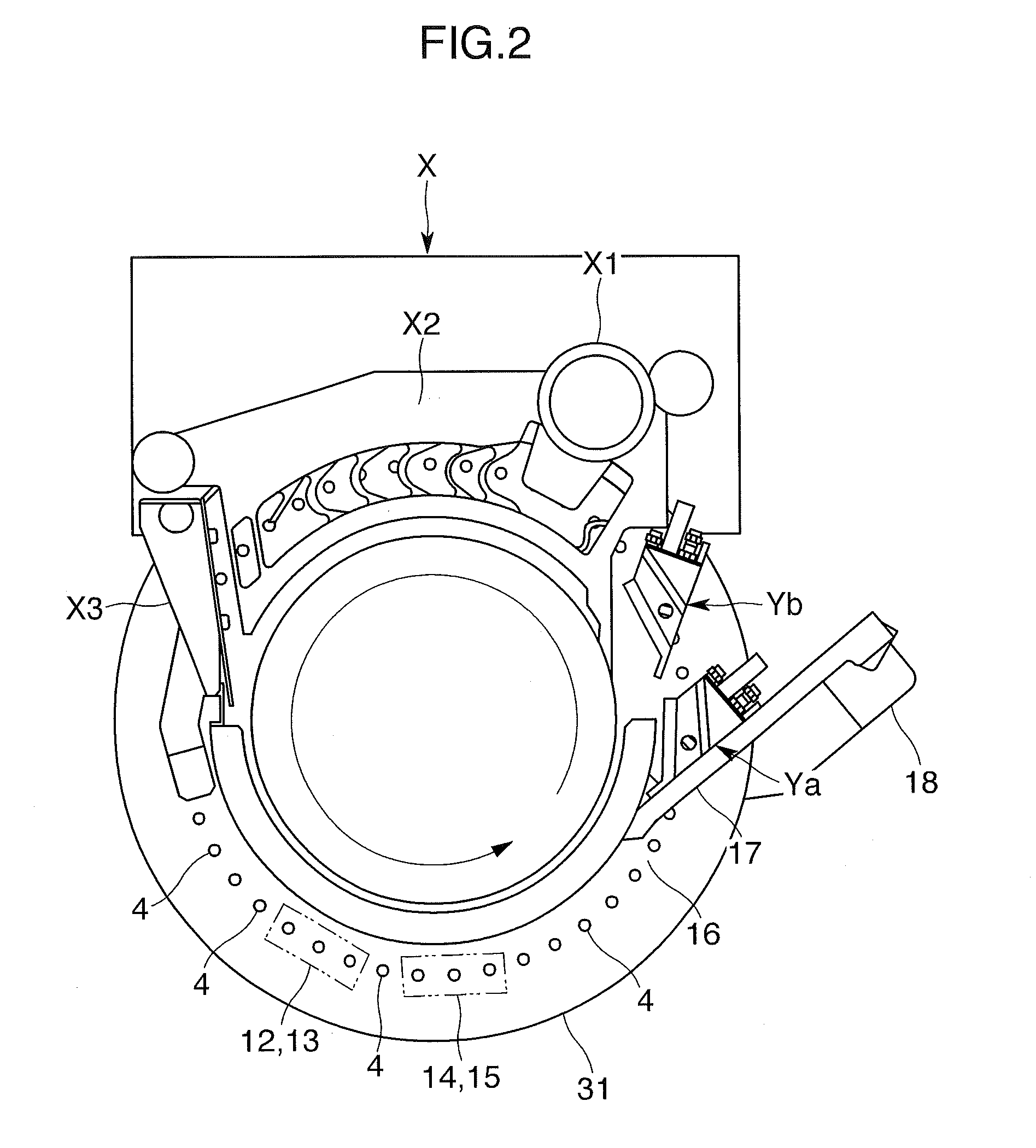

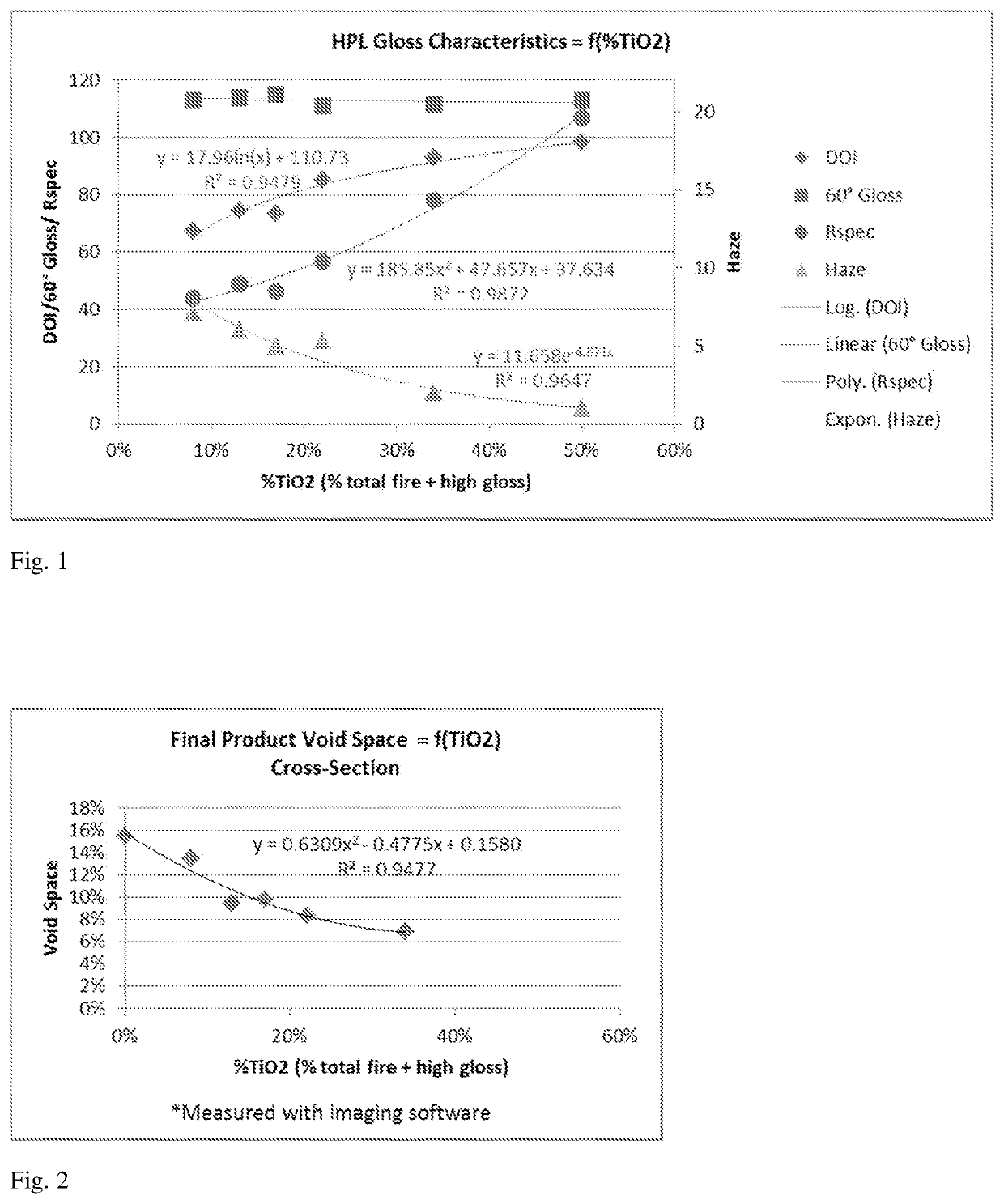

Fiberglass Veils Containing Fire-Retardant Minerals and Refractive Particles, and High Gloss and/or Fire-Retardant and/or Non-Combustible Laminates Containing Such Veils

PendingUS20220017713A1High glossLose weightProtective equipmentPaper/cardboard layered productsGlass fiberInorganic particle

Owner:THE DILLER

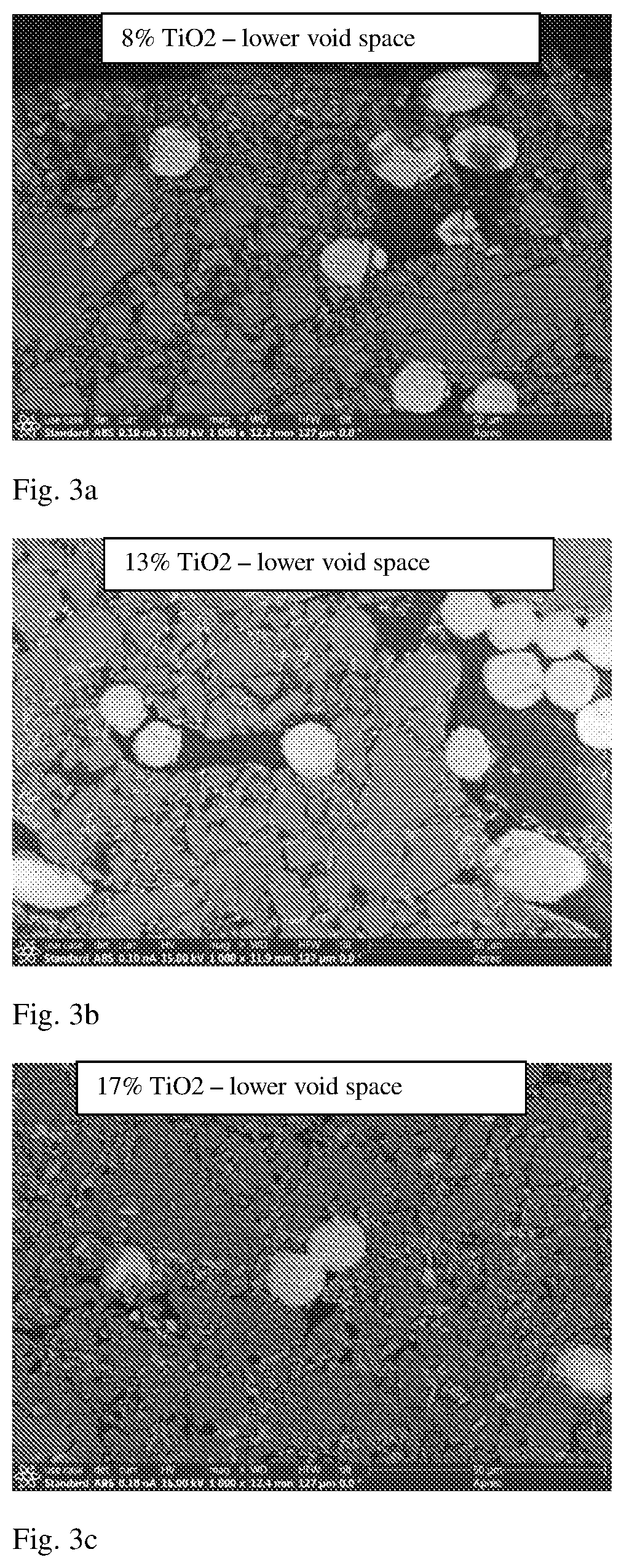

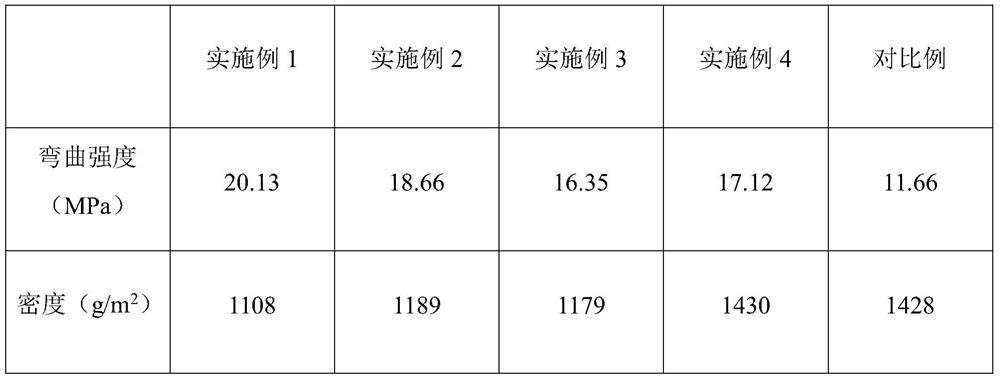

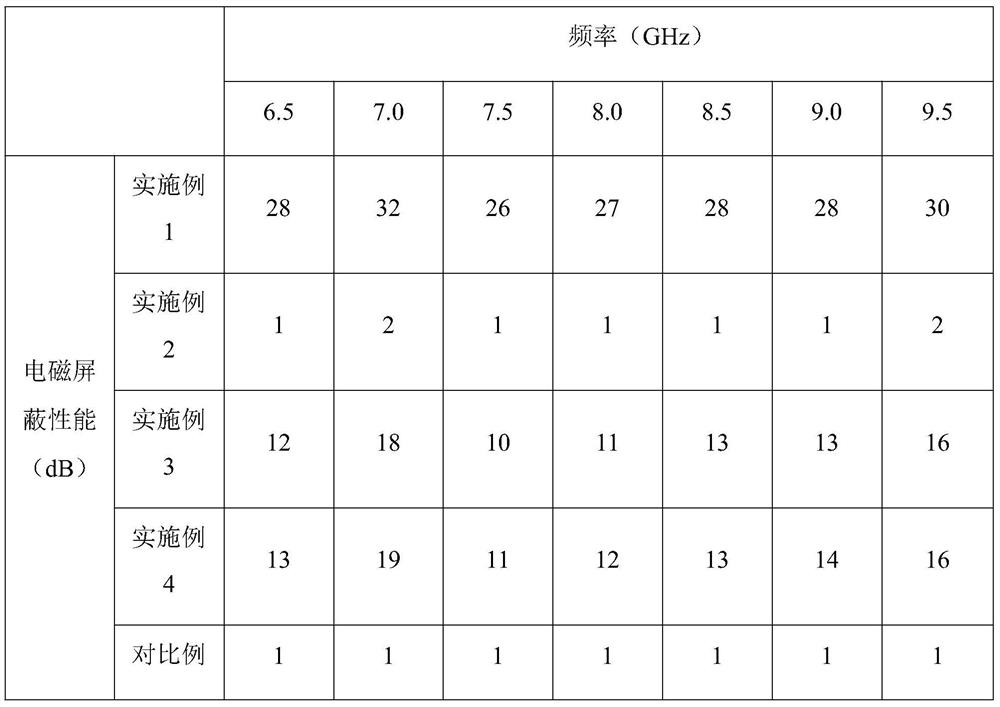

Composite board with electromagnetic shielding performance and preparation method thereof

ActiveCN113430713AImprove bindingImprove bending strengthNon-woven fabricsMonocomponent polyolefin artificial filamentPolyesterCellulose

Owner:SHENZHEN PENGHUI FUNCTIONAL MATERIAL CO LTD

Polypropylene grass and cold prevention fabric, preparation method thereof and application of fabric

Owner:刘鹏飞

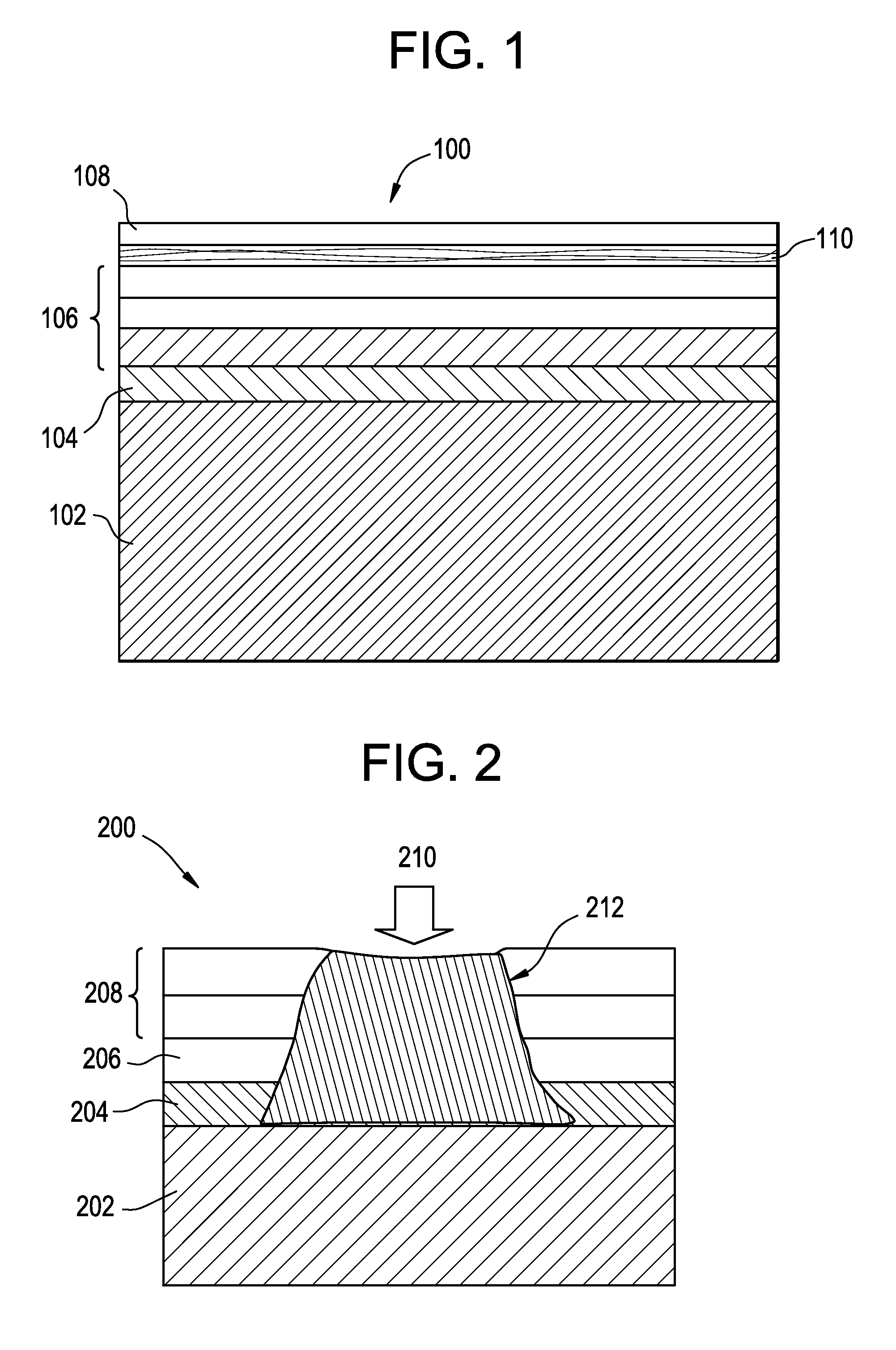

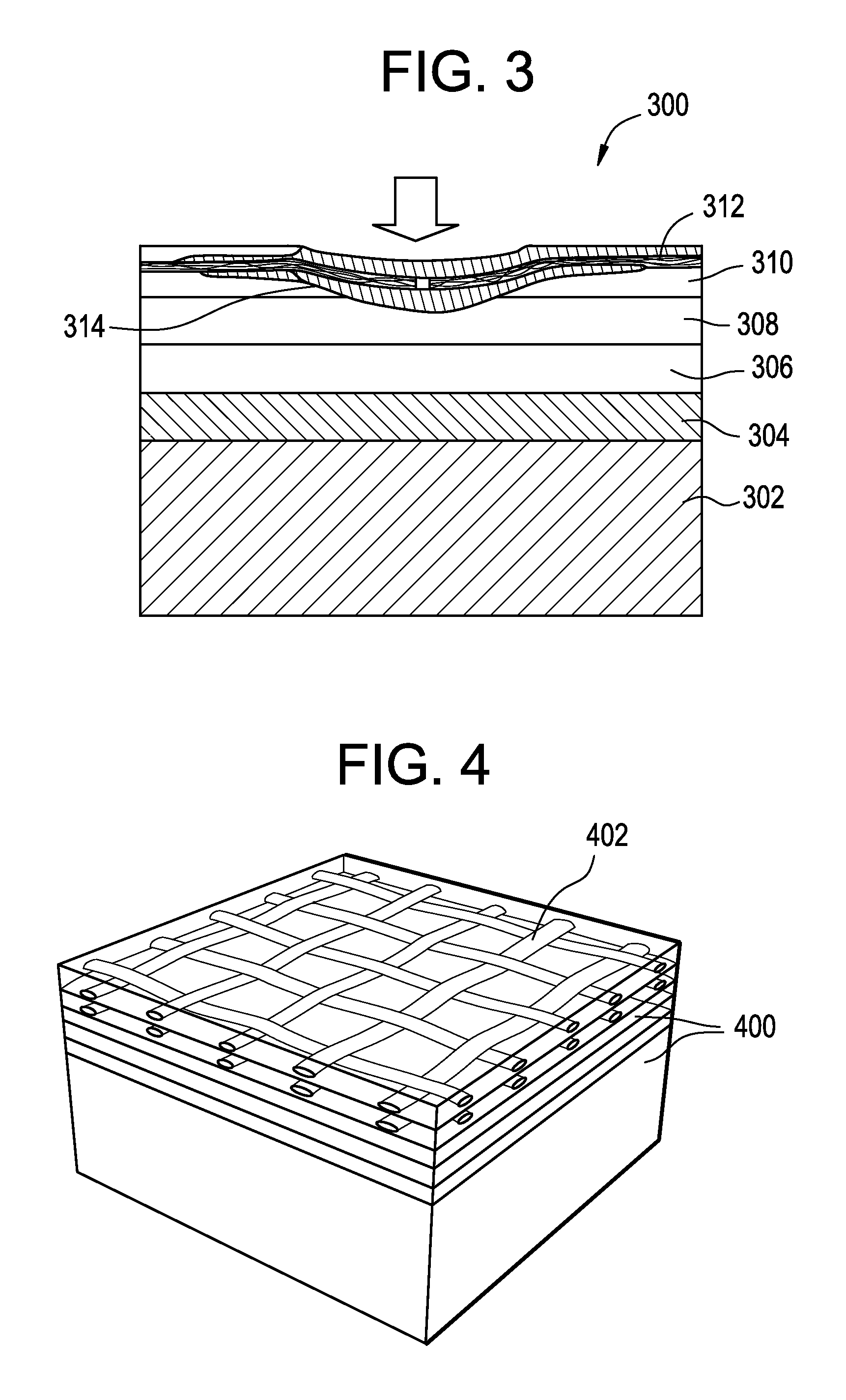

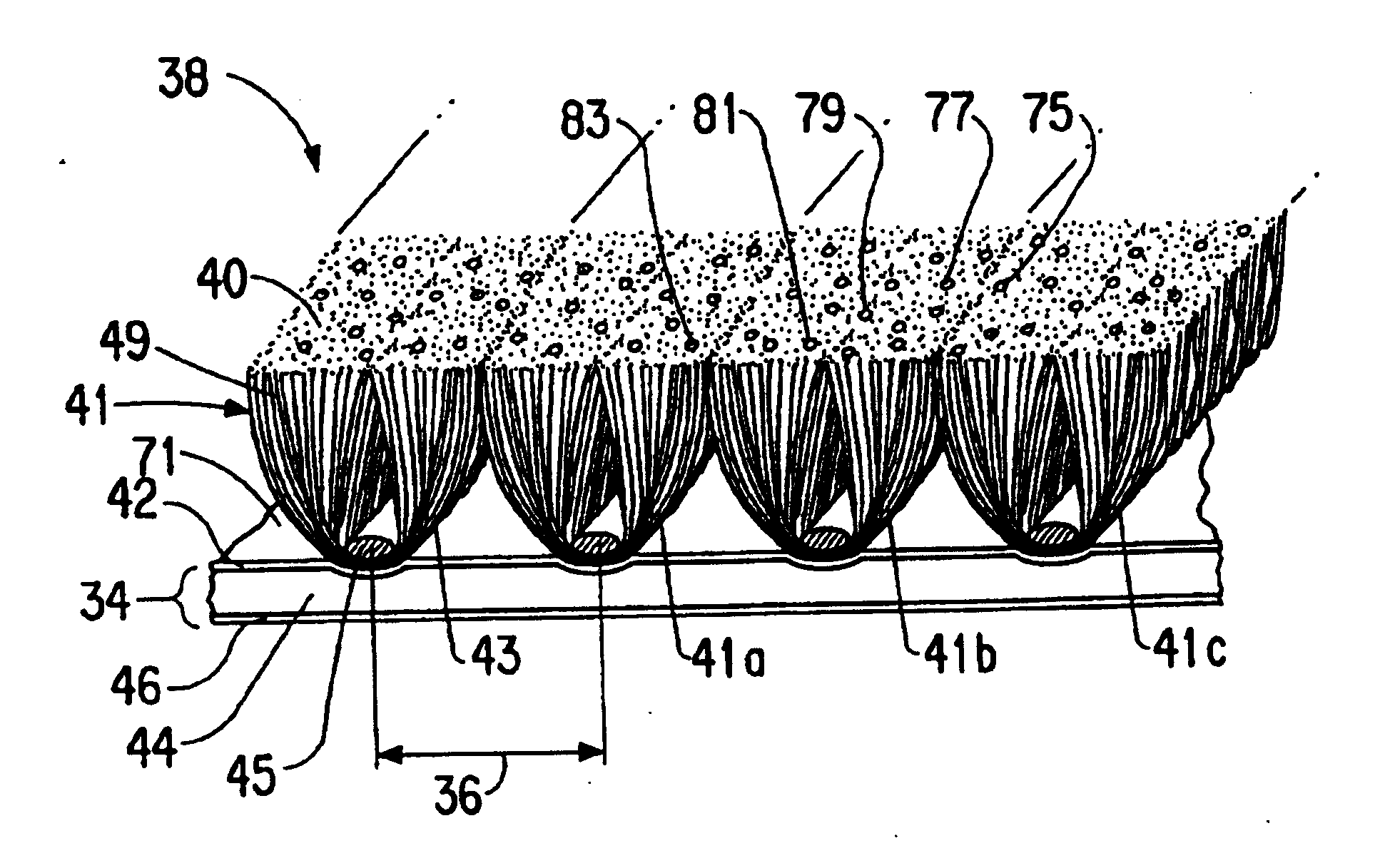

Absorbent articles with molede cellulosic webs

InactiveCN1297245CIncrease stickinessIncrease elasticityLayered productsSanitary towelsUltraviolet radiationBiomedical engineering

Absorbent articles comprising molded airlaid webs and other molded fibrous webs are disclosed. The molded webs can offer improved body fit, comfort, and / or improved fluid handling. Molded airlaid webs, for example, can be formed having a central longitudinal hump and flexure zones longitudinally removed from the central hump to provide good contact with the body and improved fit when the article is squeezed from the sides. Molding can be achieved when a binder material is activated by an energy source and the web is held against a molding substrate. Energy sources can include microwaves, heated air, heated metal surfaces, ultraviolet radiation, ultrasonic energy, and the like.

Owner:KIMBERLY CLARK WORLDWIDE INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap