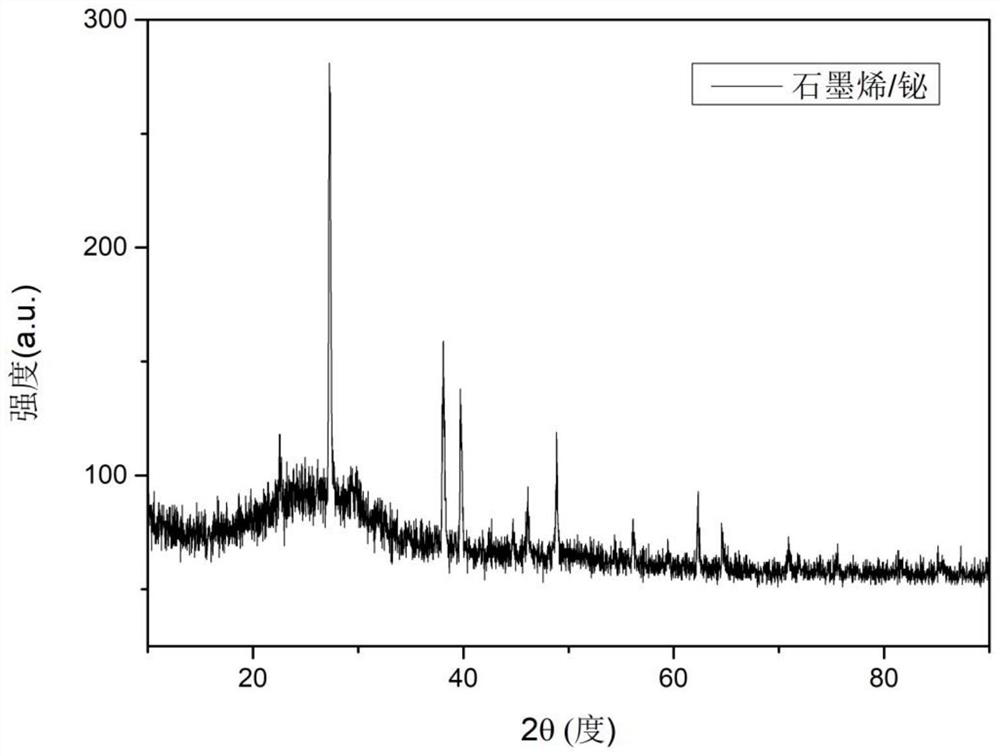

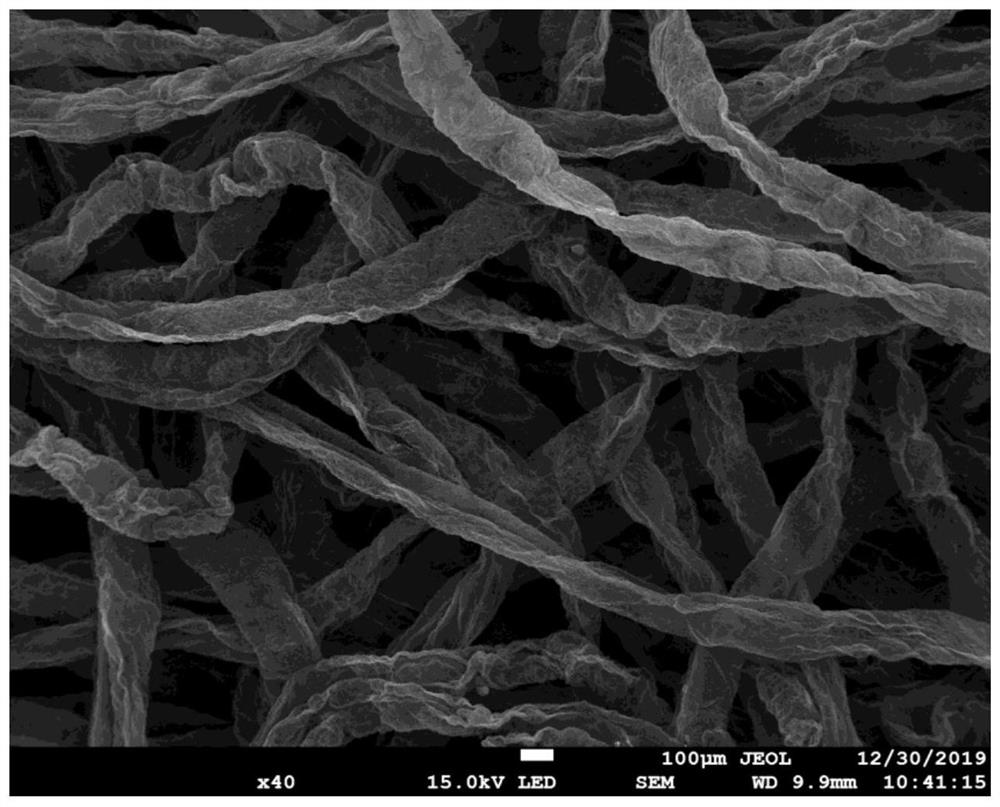

Method for preparing bismuth nanoparticles loaded on graphene fiber non-woven fabric by microwave induction

A graphene fiber, non-woven technology, applied in radiation wave/microwave fiber processing, fiber processing, fiber chemical characteristics, etc., can solve the problems of electrochemical reaction kinetics lag, low capacity, poor stability of flexible negative electrodes, etc. The effect of accelerating electrochemical reaction kinetics, good electrochemical performance, and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Put a graphene oxide aqueous solution with a concentration of 3 mg / mL in a centrifuge tube, and the graphene oxide aqueous solution accounts for 1 / 3 of the volume of the centrifuge tube. Then add 1 / 5 of the centrifuge tube volume of N,N-dimethylformamide, after configuring the mass ratio of each centrifuge tube, put it into the centrifuge, the speed is 9000rpm, the time is 25min, and the graphene oxide at the bottom is retained after centrifugation , remove the supernatant. The above steps were repeated twice to finally obtain a DMF dispersion of 6mg / mL graphene oxide;

[0040] Step 2: put the original bismuth powder into a mortar and grind for 40 minutes to obtain bismuth particles with a particle size of 40-60 μm;

[0041] Step 3: Weigh 10 mg of bismuth powder and add it to 5 mL of the graphene oxide / N,N-dimethylformamide (GO / DMF) obtained in step 1, and stir for 3 h with a magnetic stirrer to finally obtain graphene oxide / N-dimethylformamide (GO /

Embodiment 2

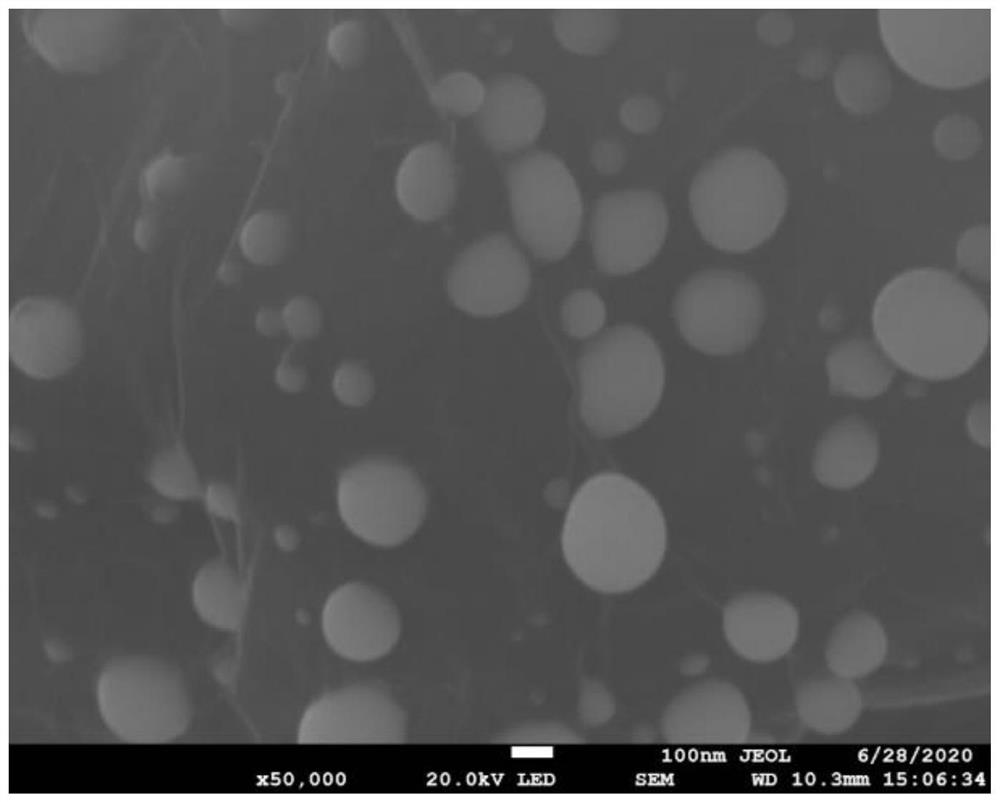

[0046] The other steps of the preparation method of this embodiment are the same as those of Embodiment 1, the main difference lies in the length of microwave time. Finally, a graphene non-woven sodium ion energy storage material loaded with bismuth nanoparticles with different particle size distributions was obtained;

[0047] Step 1: Put a graphene oxide aqueous solution with a concentration of 3 mg / mL in a centrifuge tube, and the graphene oxide aqueous solution accounts for 1 / 3 of the volume of the centrifuge tube. Then add 1 / 5 of the centrifuge tube volume of N,N-dimethylformamide, after configuring the mass ratio of each centrifuge tube, put it into the centrifuge, the speed is 9000rpm, the time is 25min, and the graphene oxide at the bottom is retained after centrifugation , remove the supernatant. The above steps were repeated twice to finally obtain a DMF dispersion of 6mg / mL graphene oxide;

[0048] Step 2: put the original bismuth powder into a mortar and gri

Embodiment 3

[0054] Step 1: Put a graphene oxide aqueous solution with a concentration of 3 mg / mL in a centrifuge tube, and the graphene oxide aqueous solution accounts for 1 / 3 of the volume of the centrifuge tube. Then add 1 / 5 of the centrifuge tube volume of N,N-dimethylformamide, after configuring the mass ratio of each centrifuge tube, put it into the centrifuge, the speed is 9000rpm, the time is 25min, and the graphene oxide at the bottom is retained after centrifugation , remove the supernatant. The above steps were repeated twice to finally obtain a DMF dispersion of 6mg / mL graphene oxide;

[0055] Step 2: put the original bismuth powder into a mortar and grind for 40 minutes to obtain bismuth particles with a particle size of 40-60 μm;

[0056] Step 3: Weigh 10 mg of bismuth powder and add it to 5 mL of the graphene oxide / N,N-dimethylformamide (GO / DMF) obtained in step 1, and stir for 3 h with a magnetic stirrer to finally obtain graphene oxide / N-dimethylformamide (GO /

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap