Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Woven fabric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Woven fabric is any textile formed by weaving. Woven fabrics are often created on a loom, and made of many threads woven on a warp and a weft. Technically, a woven fabric is any fabric made by interlacing two or more threads at right angles to one another.

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AImprove protectionImprove breathabilityLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolymer science

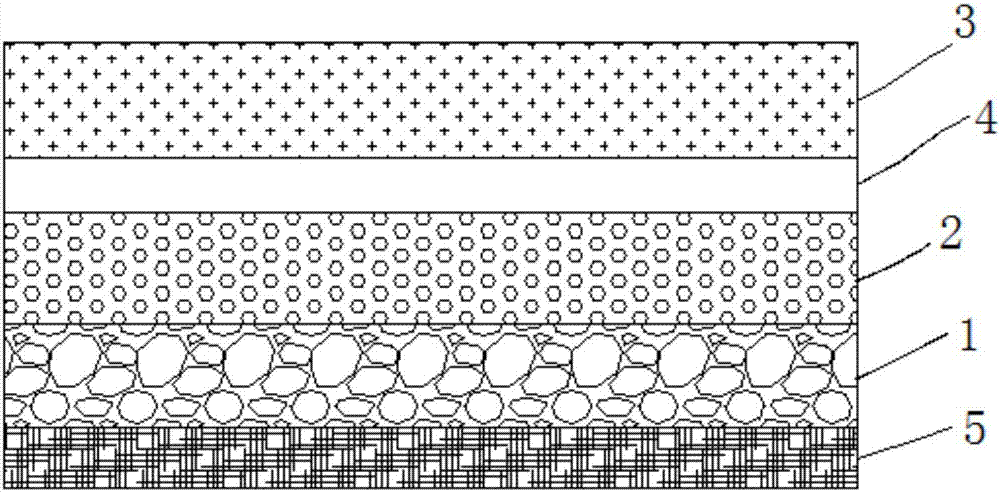

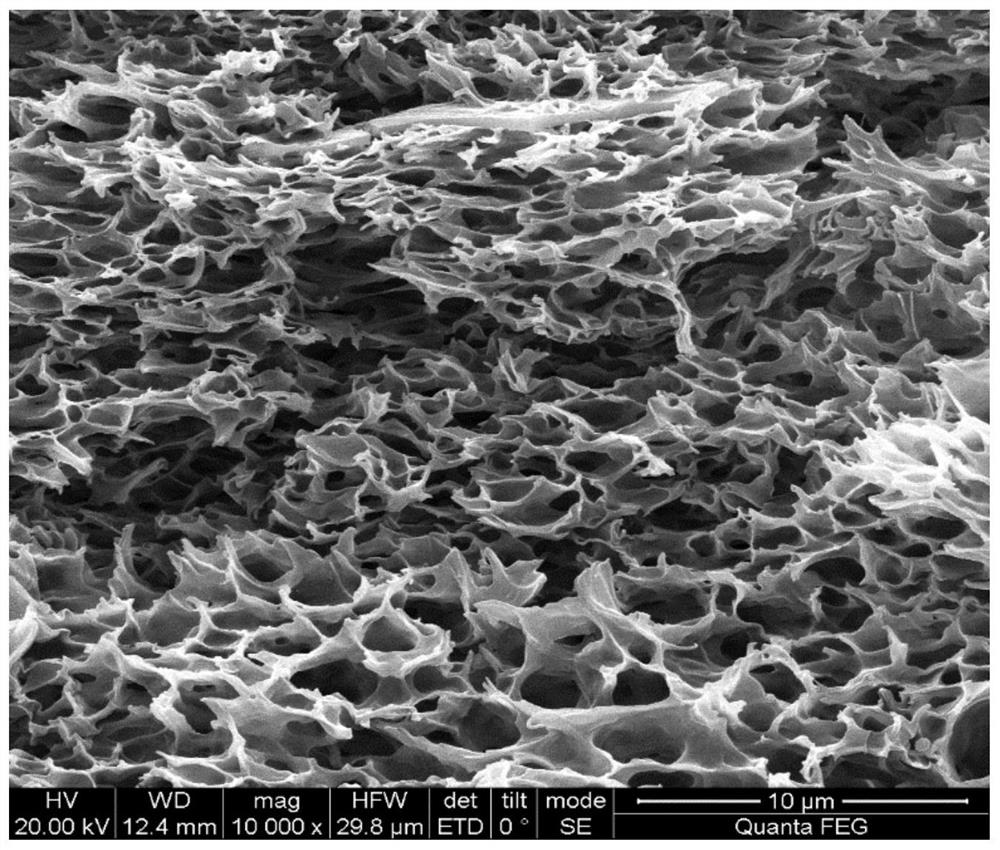

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

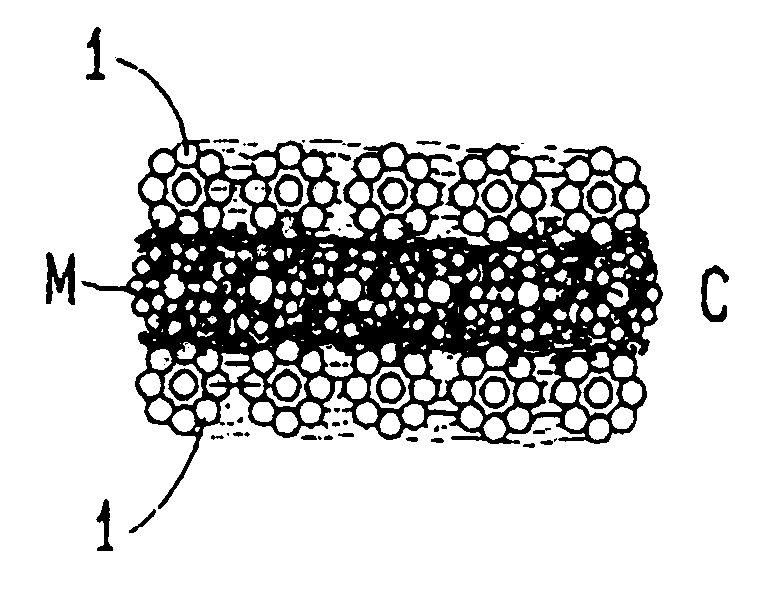

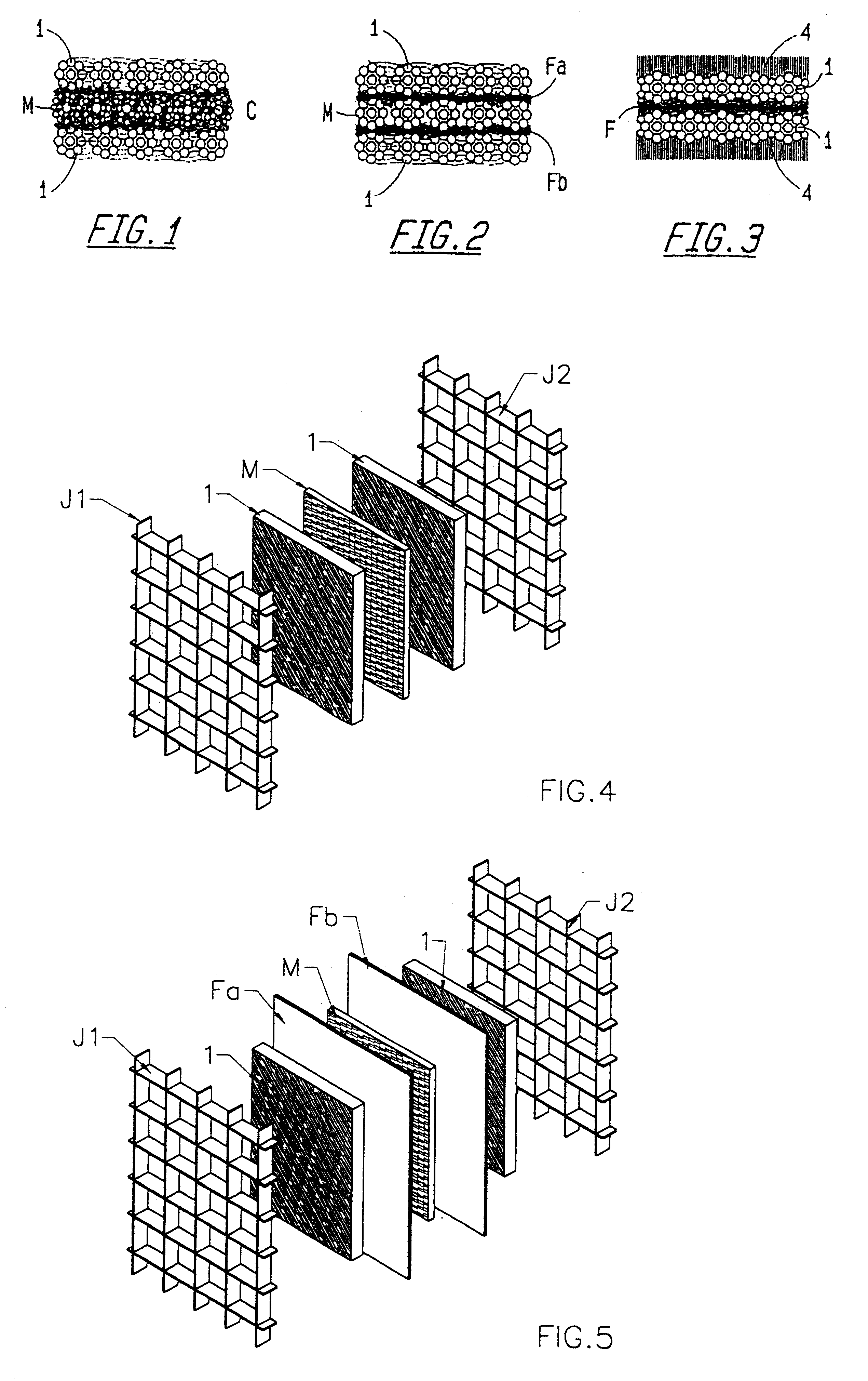

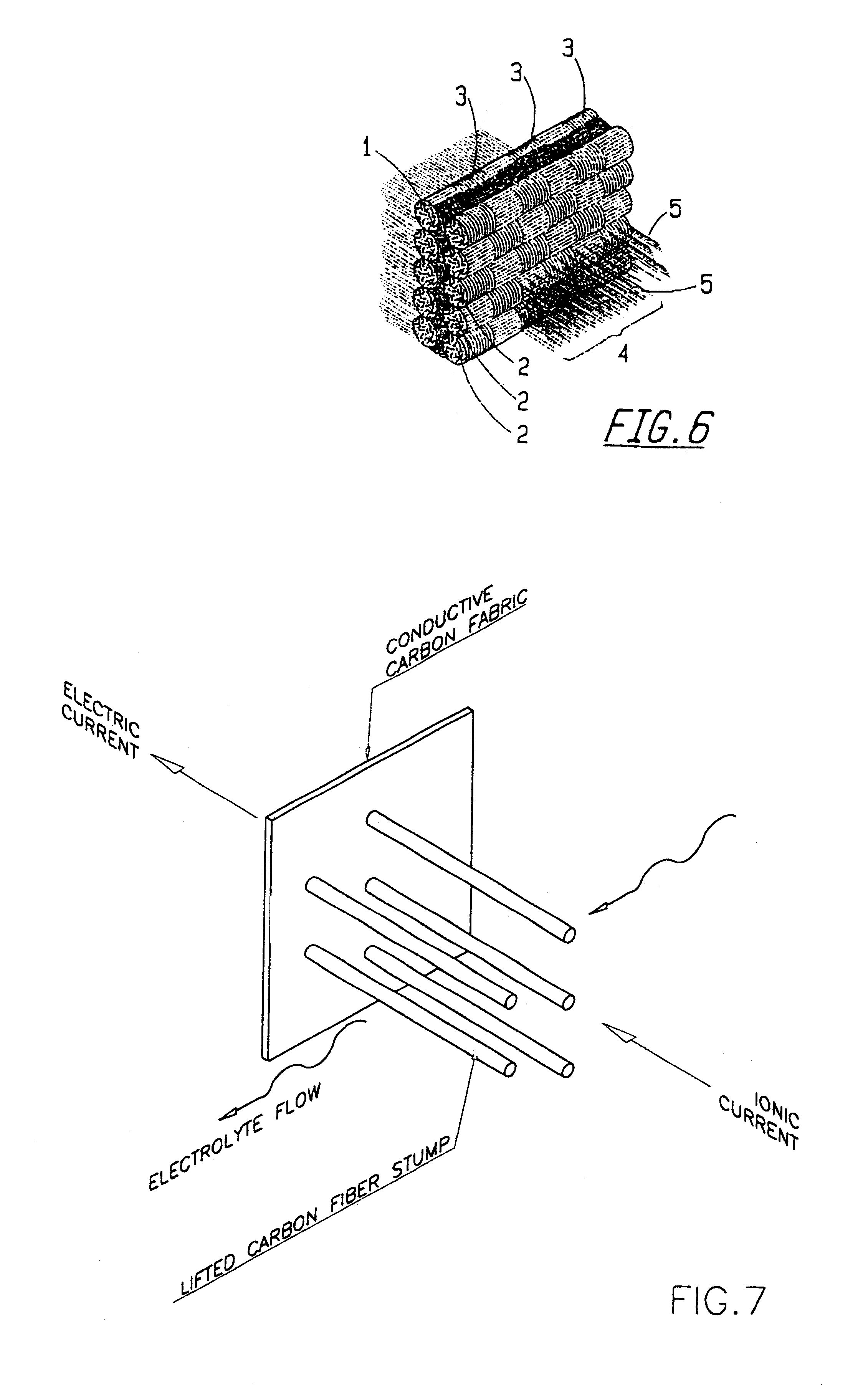

Bipolar electrode for electrochemical redox reactions

InactiveUS6296746B1Good electrical conductivityLower resistanceElectrode carriers/collectorsRegenerative fuel cellsElectrically conductiveWoven fabric

Owner:SQUIRREL HLDG

A vine tea mask capsule and a method of preparing the same

InactiveCN102552092ABacteriostaticWith whiteningCosmetic preparationsToilet preparationsIrritationToxin

Owner:FUJIAN AGRI & FORESTRY UNIV

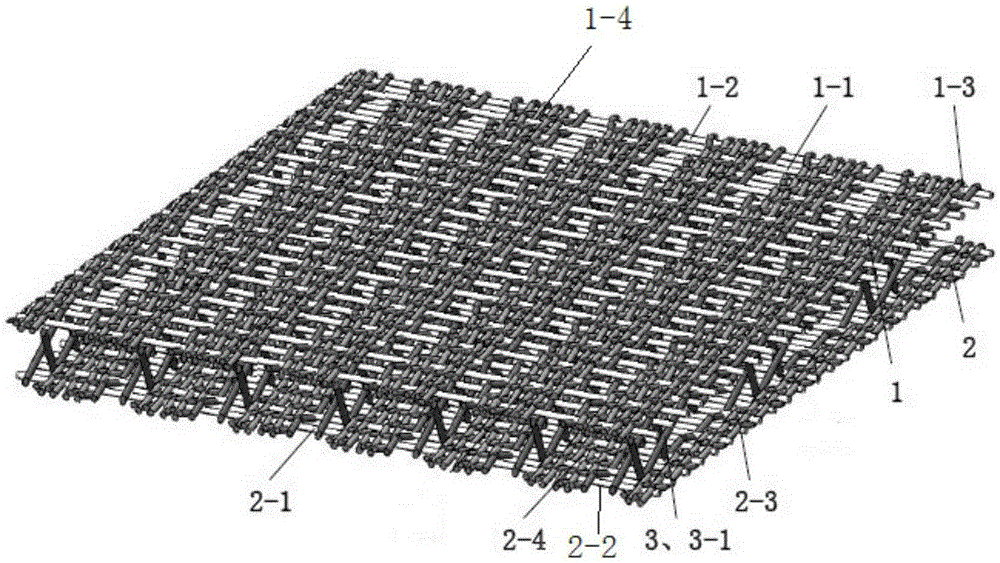

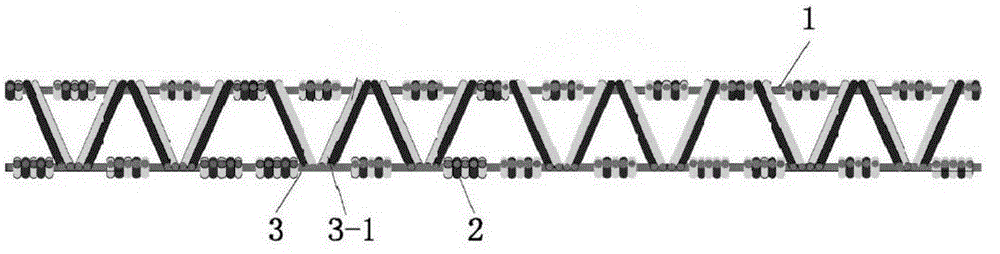

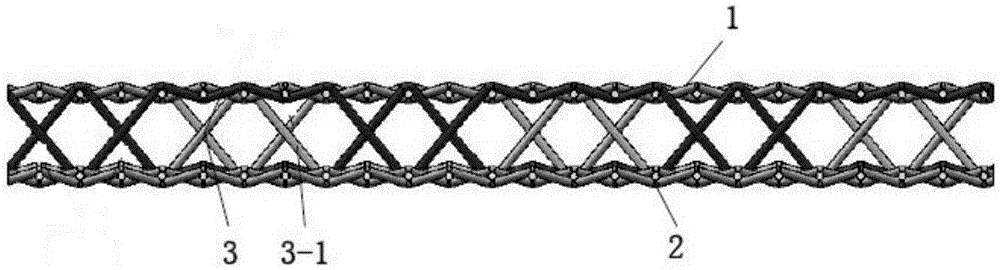

Plastic resin-impregnated three-dimensional hollow platelike woven fabric

Owner:CHANGZHOU YUECHENG NEW MATERIAL

Medical sterilization packaging bag

ActiveCN103072739AImprove packaging antibacterial rateGuarantee the safety of useBagsSacksSurface layerNonwoven fabric

Owner:SHANGHAI JIANZHONG MEDICAL PACKAGING

Decorative wall board with air purification function

Owner:ANHUI SANPIN TECH SERVICE CO LTD

Elastic pure cotton woven fabric with smooth surface and soft handle and preparation method thereof

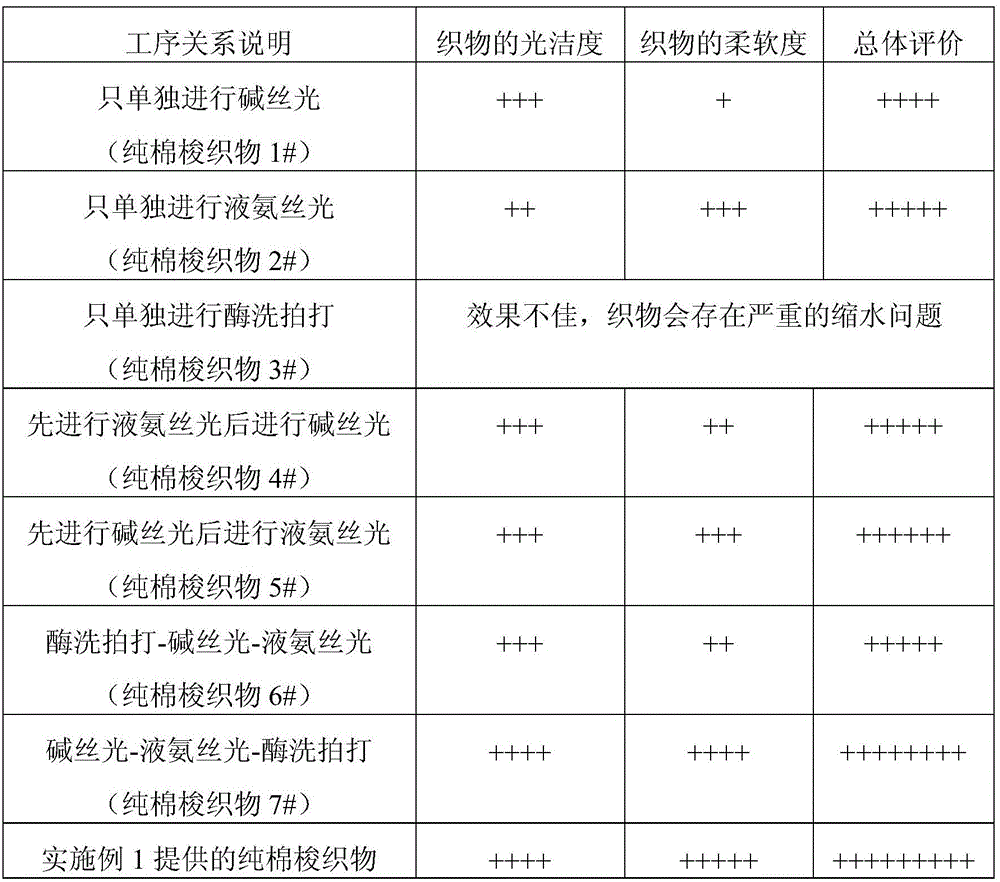

ActiveCN106012494AObvious bodyIncrease elasticityBiochemical treatment with enzymes/microorganismsGrip property fibresCellulaseProcess time

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Cured In Place Pipe Liner With Styrene Barrier

InactiveUS20100243154A1Promote migrationHigh hardnessPipe elementsRecord information storageEngineeringCured-in-place pipe

A liner for repairing damaged pipes, such as underground sewer or gas pipes is disclosed. The liner comprises a TPU coating on fibrous mat of non-woven fabric. The TPU coating contains a barrier layer to retard the migration of styrene from the liner to the media used to force the liner against the damaged pipe and to activate the thermoset resin. The thermoset resin converts the liner from a flexible state to a rigid state as the liner is cured in place inside the pipe.

Owner:LUBRIZOL ADVANCED MATERIALS INC

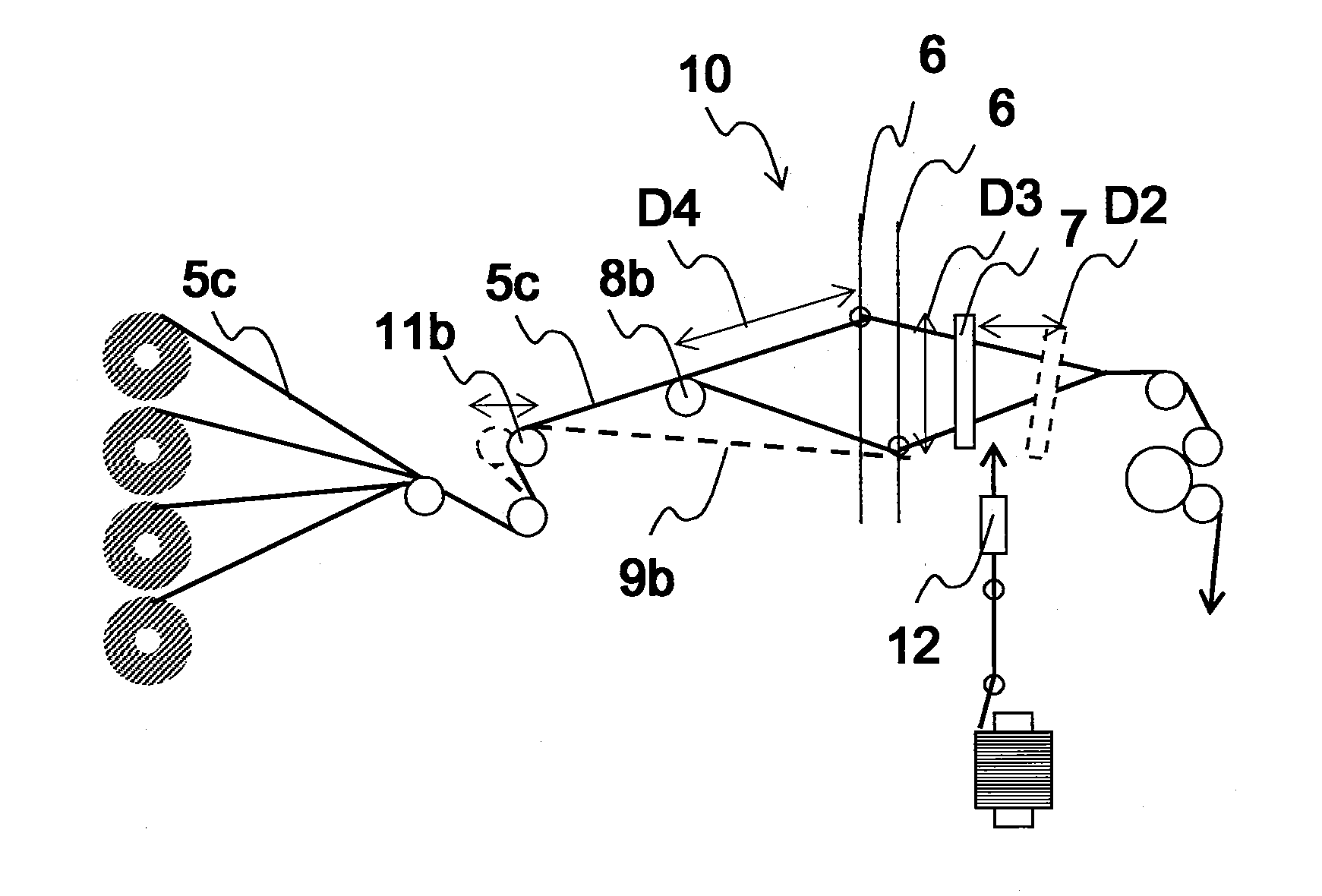

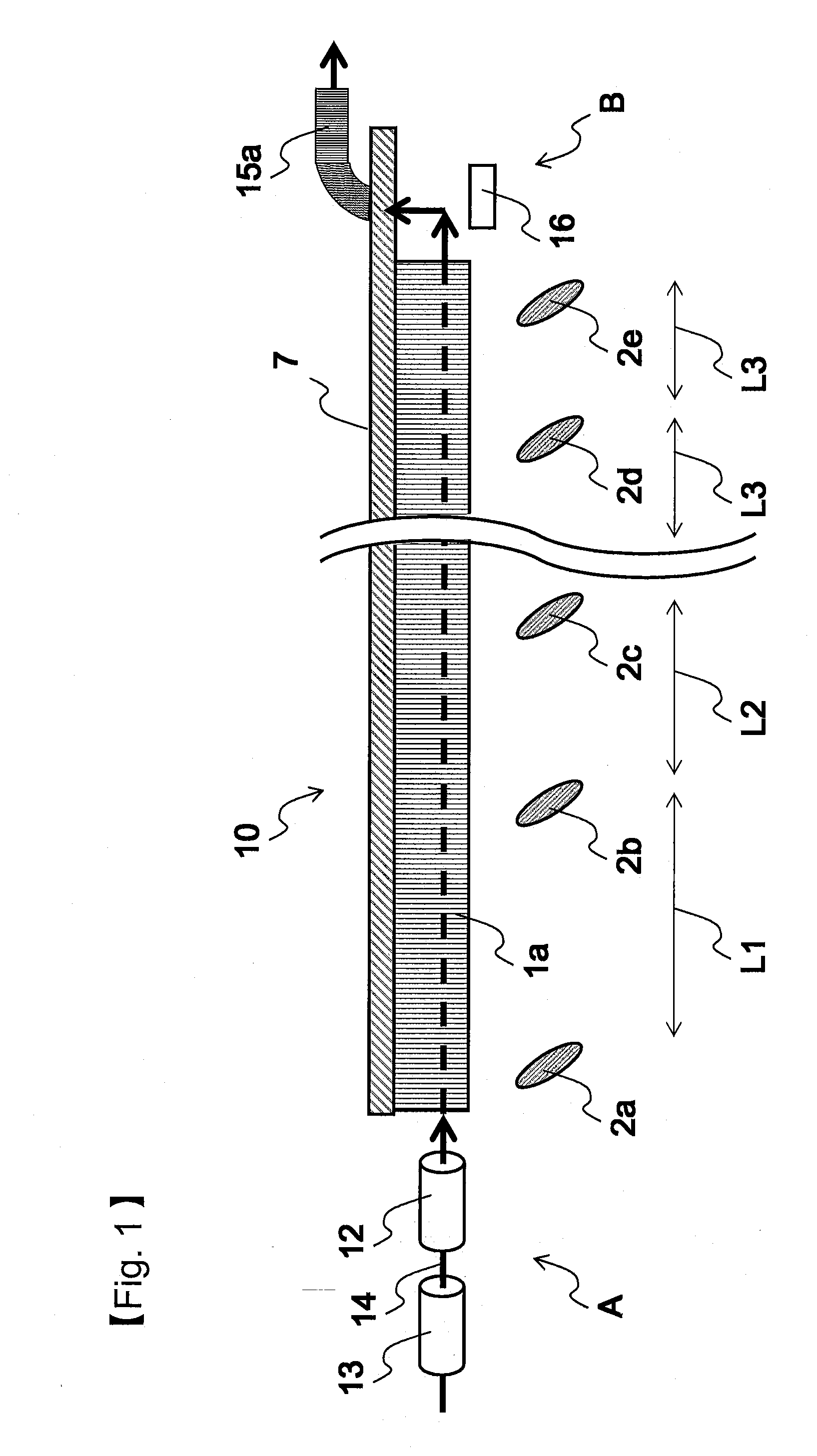

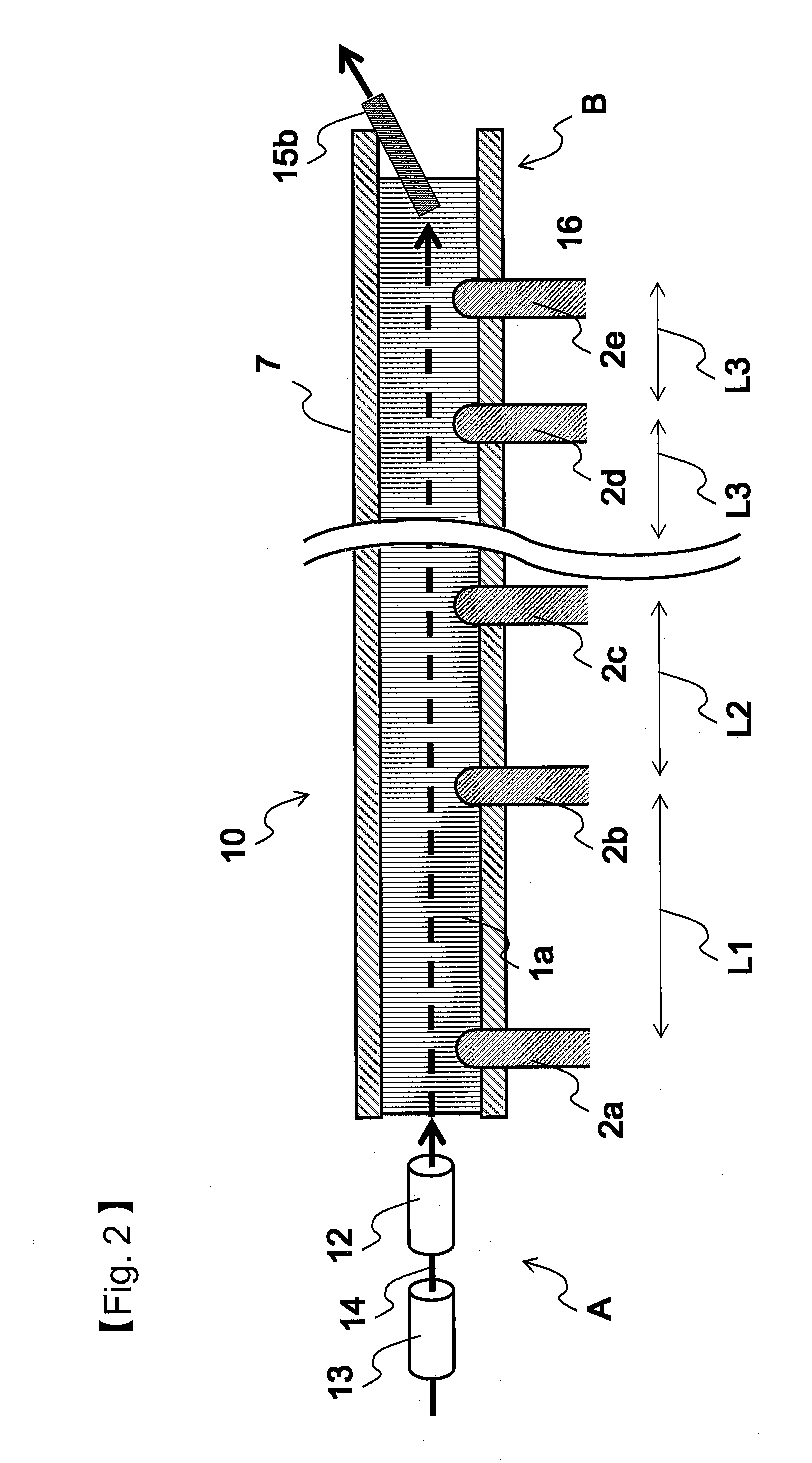

Method for producing carbon fiber woven fabric

ActiveUS20100032049A1Quality improvementImprove productivityLoomsWoven fabricsProduction rateCarbon fibers

Owner:TORAY IND INC

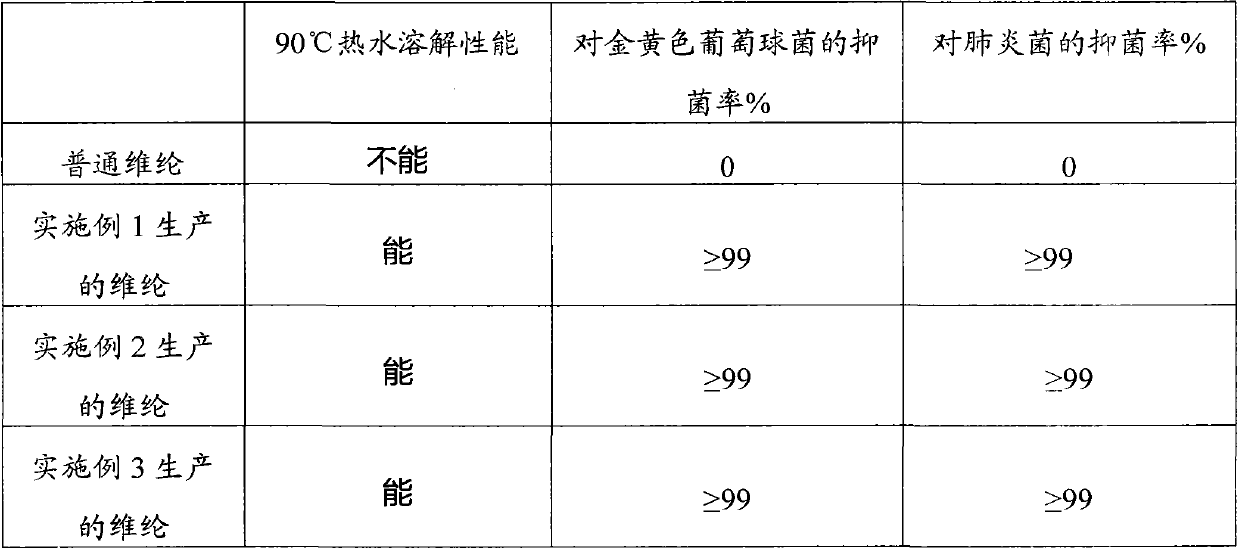

Antibacterial degradable vinylon and production method thereof

ActiveCN103388190AFibre typesMonocomponent synthetic polymer artificial filamentChemistryWoven fabric

Owner:HARVEST SPF TEXTILE

Automobile trim material combined with non-woven fabric and woven fabric

InactiveCN105034535ASignificant advantage effectLow priceSynthetic resin layered productsLaminationSodium bicarbonateWarm water

Owner:湖北南泽汽车复合材料有限公司

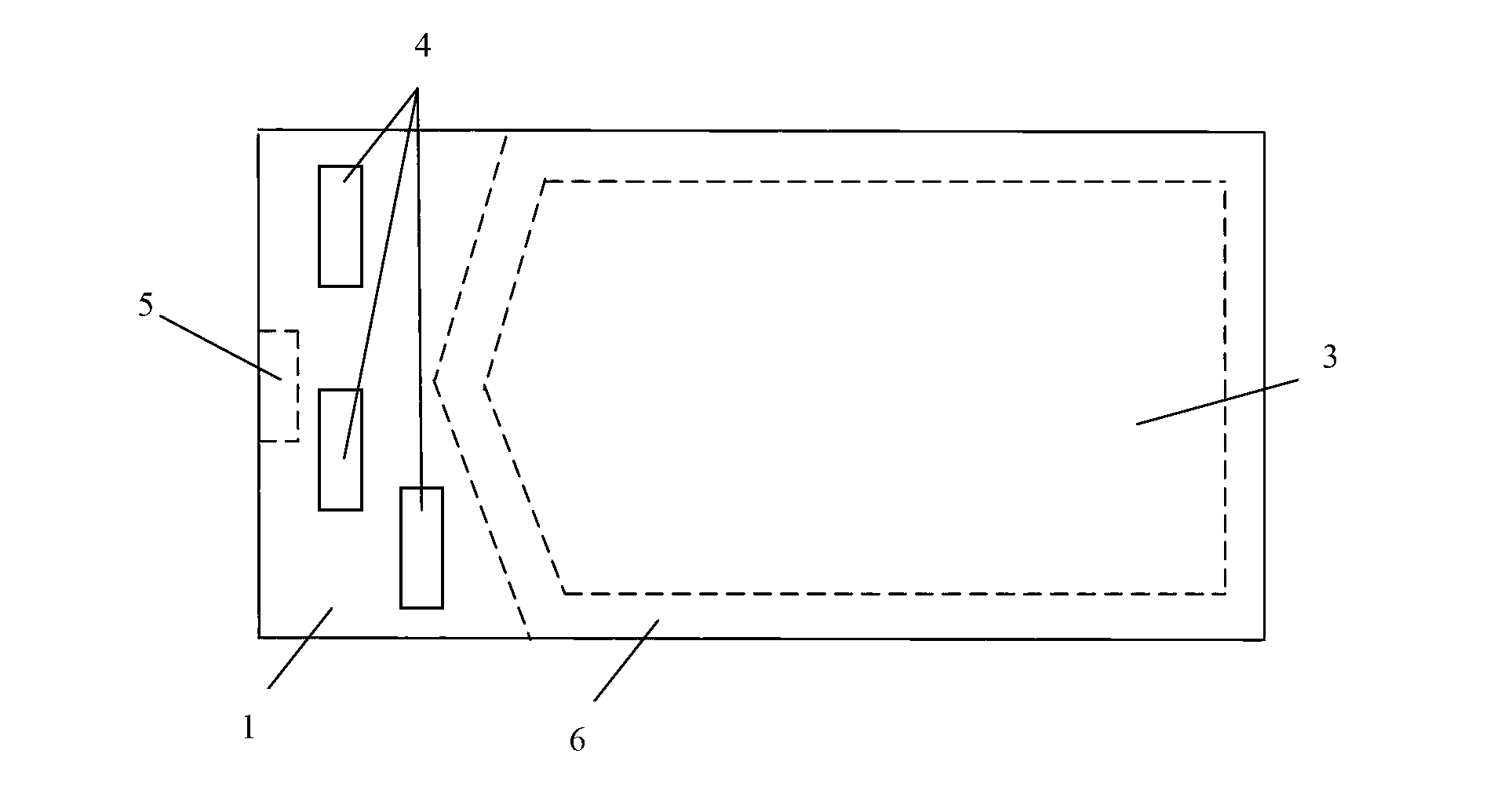

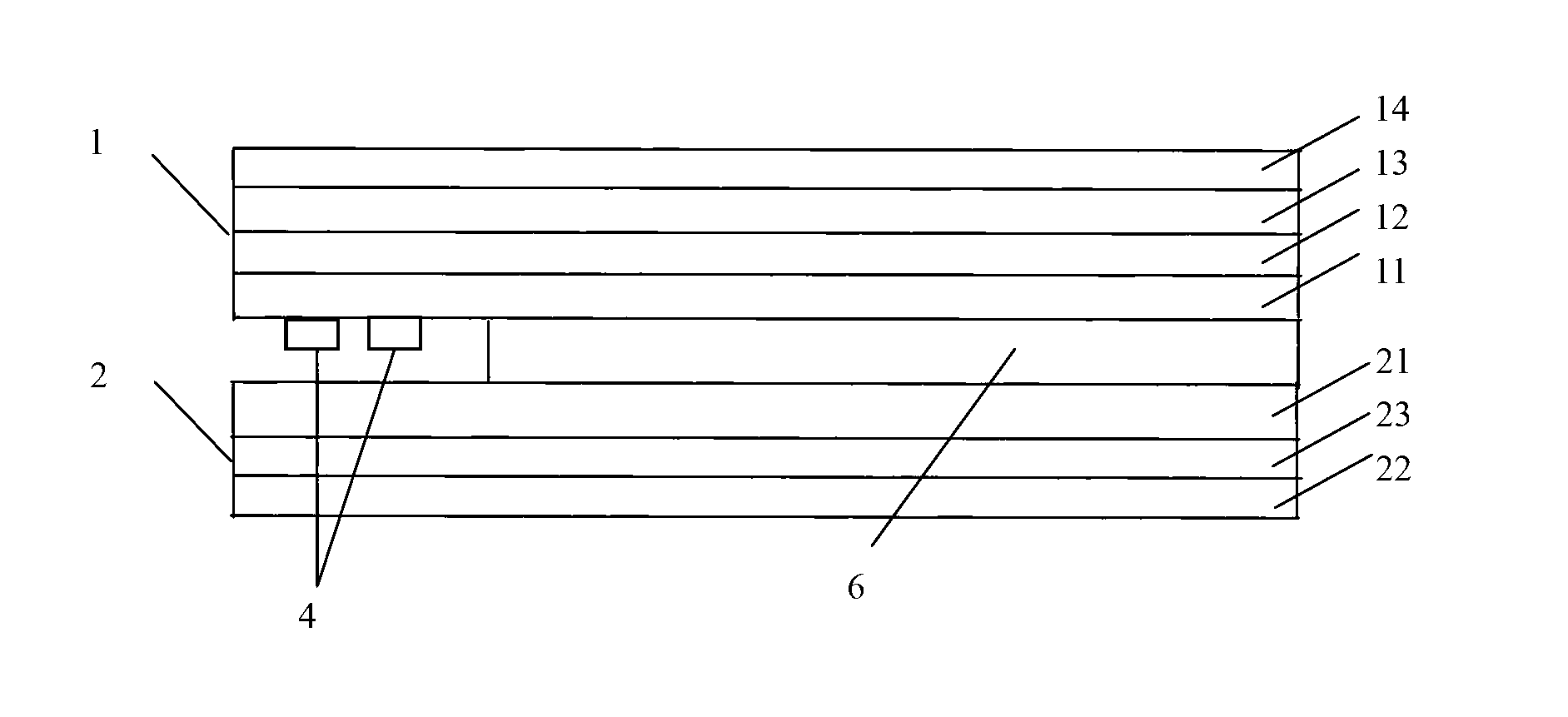

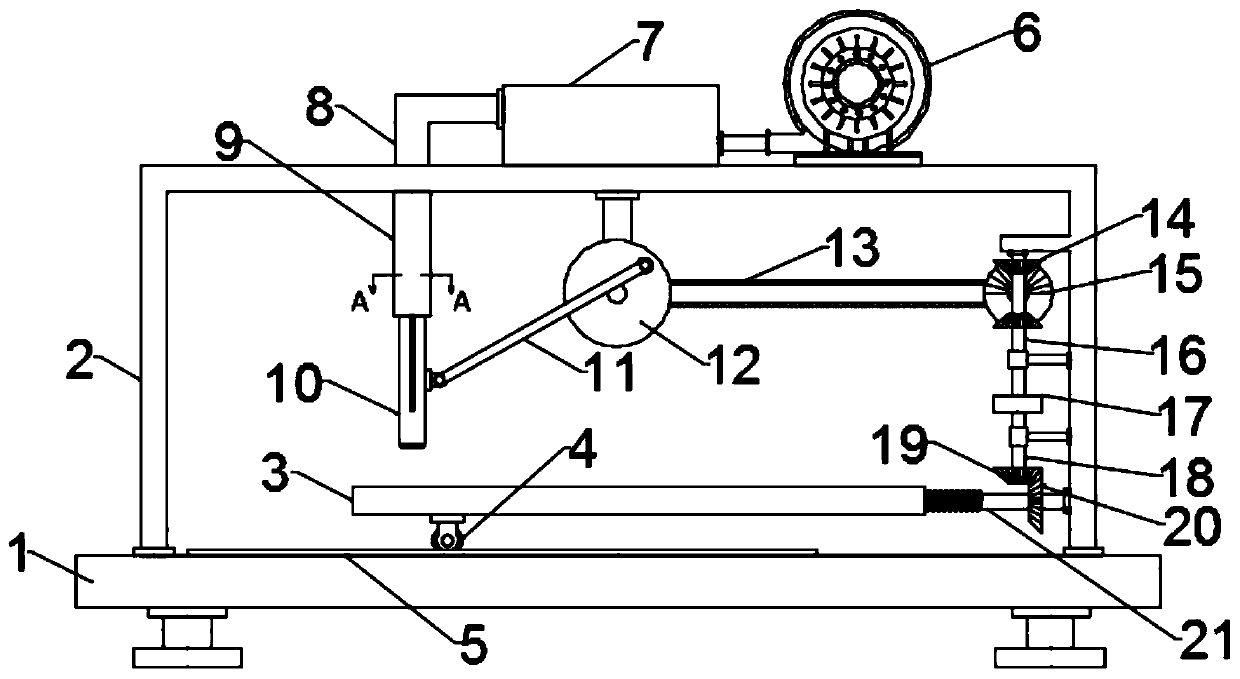

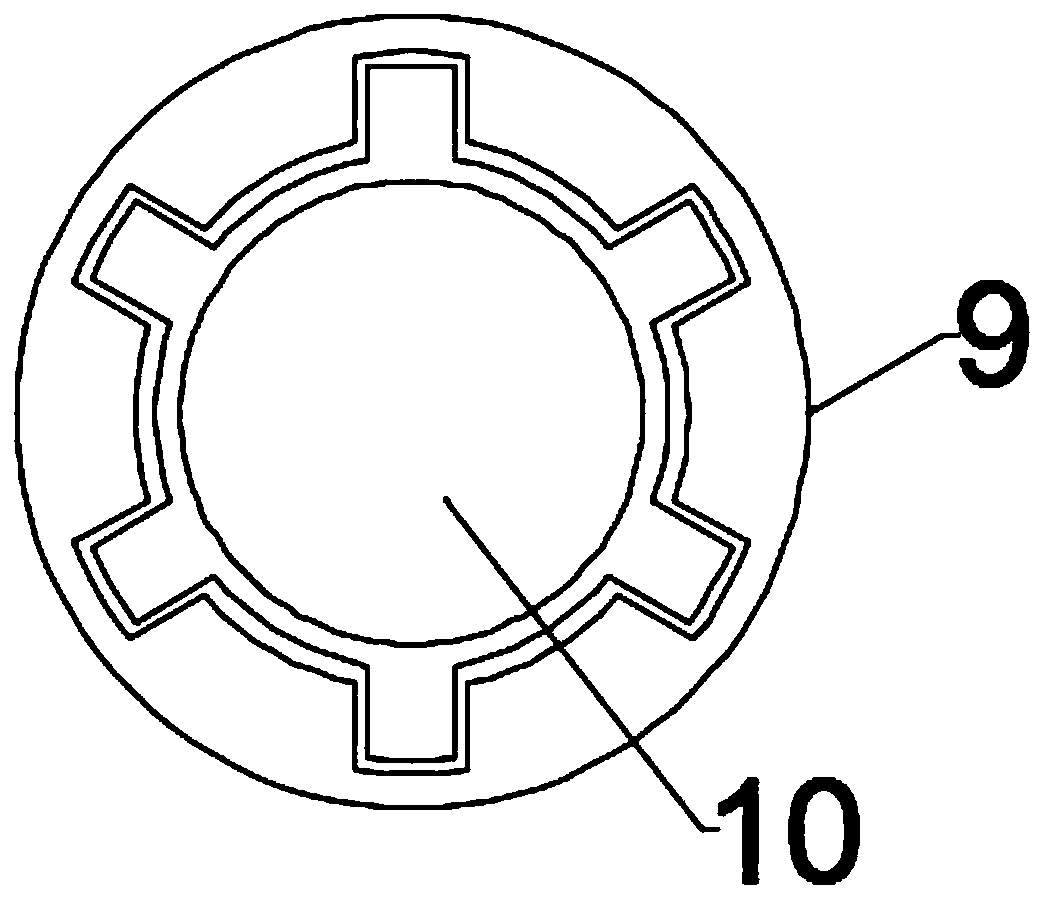

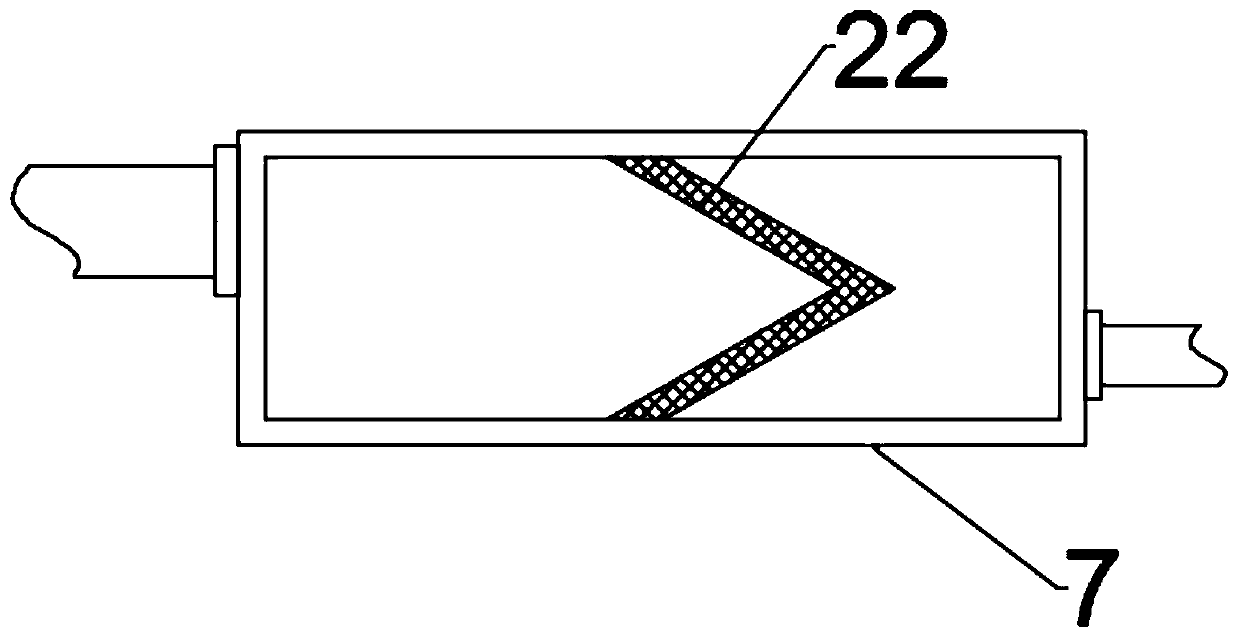

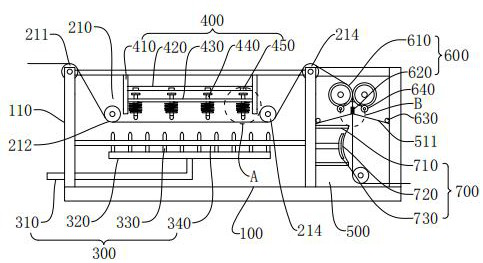

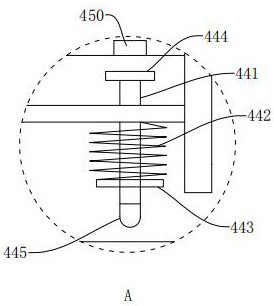

Non-woven fabric winding and cropping combined device

InactiveCN108622695AAchieve reductionIncrease productivityWebs handlingEngineeringMechanical engineering

The invention relates to a non-woven fabric winding and cropping combined device. The non-woven fabric winding and cropping combined device comprises winding equipment and cropping equipment which coordinate with each other. The winding equipment comprises a supporting frame. The cropping equipment comprises a material carrying assembly and a cropping assembly, wherein the material carrying assembly comprises a roll shaft frame and a plurality of first tension adjusting rollers, the roll shaft frame is installed on the supporting frame and extends towards one side of the supporting frame, andthe multiple tension adjusting rollers are rotationally installed on the roll shaft frame; and the cropping assembly comprises a supporting vertical plate, an abutting roller, a plurality of second tension adjusting rollers, an extending plate and a plurality of sets of cropping cutters, the supporting vertical plate is arranged on one side of the material carrying assembly and corresponds to theroll shaft frame, the abutting roller is installed on the side face of the supporting vertical plate and is perpendicular to the supporting vertical plate, the multiple second tension adjusting rollers are installed on the side face of the supporting vertical plate and located between the abutting roller and the roll shaft frame, the extending plate is installed on the side face of the supportingvertical plate and located over the abutting roller, and the multiple cropping cutter sets are arranged on the side face of the extending plate in a lifting manner and are arranged at intervals. The non-woven fabric winding and cropping combined device can wind non-woven fabric and crop the non-woven fabric in the length direction, and the production efficiency of the non-woven fabric is advantageously improved.

Owner:YANCHENG YUECHENG NON WOVEN FABRICS CO LTD

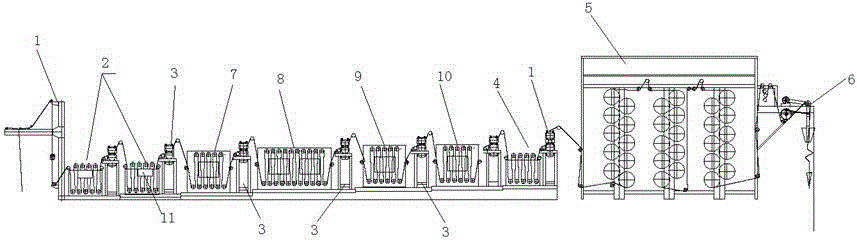

Woven fabric and jean desizing and boiling-off combined machine

InactiveCN104947339ASoft and comfortableSucessive textile treatmentsTextile treatment containersFiberDenim

Owner:扬州市江都区东盛印染机械厂

Chinese mugwort acupoint plaster

InactiveCN106551785AWide variety of sourcesLow priceDevices for heating/cooling reflex pointsTherapeutic coolingBiochemical engineeringMugwort

Owner:HUBEI DINGAI TECH CO LTD

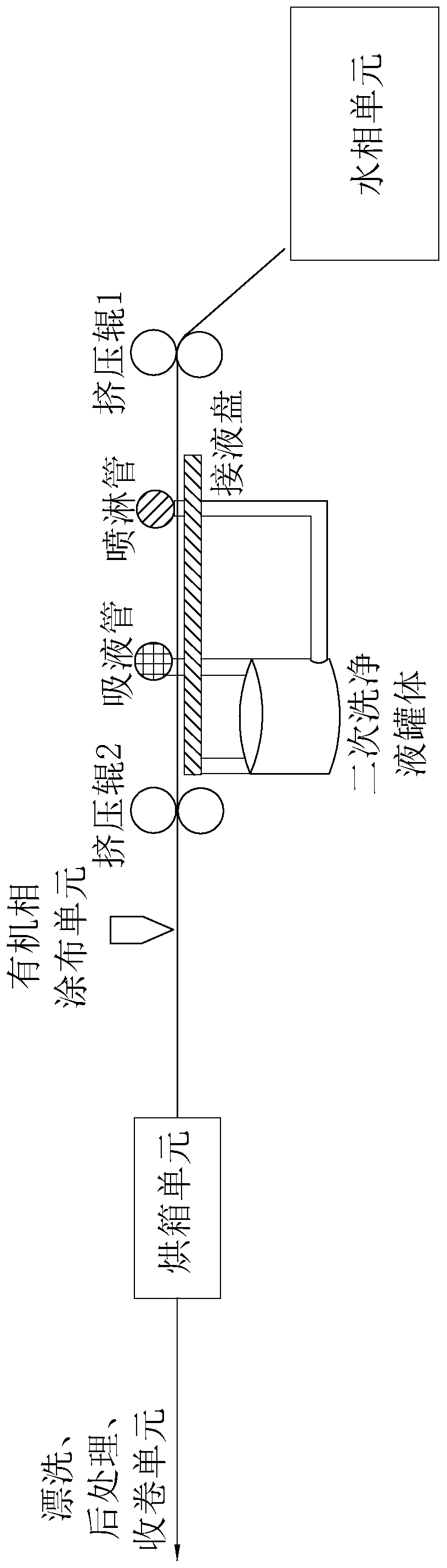

Preparation method of nanofiltration film

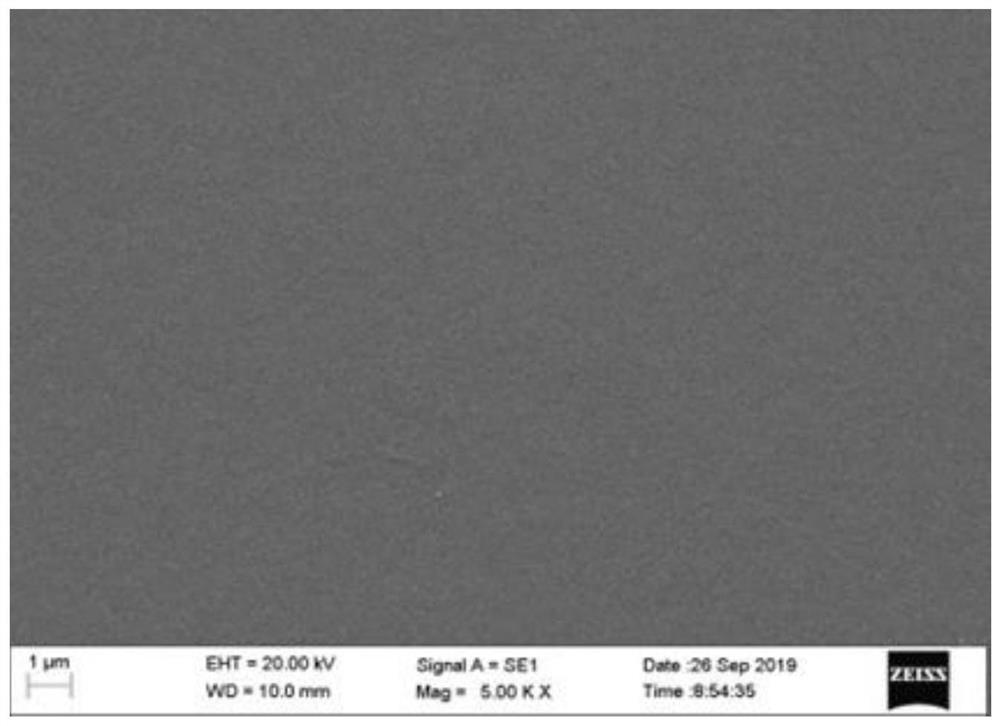

ActiveCN110327794AHigh molecular weightImprove hydrophilicitySemi-permeable membranesMembranesMaterials preparationSolvent

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

Collagen nano instant facial mask of yeast recombinant collagen and preparation method of facial mask

Owner:NOX BELLCOW COSMETICS CO LTD

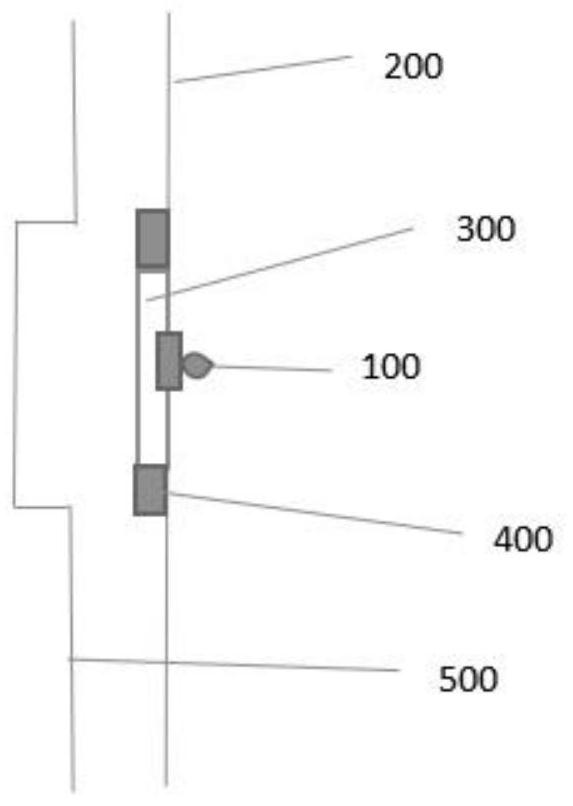

Electrocardio electrode plate with conductor and extremely high interference resistance

InactiveCN113303803AReasonable structural designIncrease contact surfaceSensorsDiagnostic recording/measuringHuman skinInterference resistance

Owner:陆殿发

Puncture-resistant structural layer and application thereof to preparation of puncture-resistant gloves

ActiveCN109677030AWith anti-slip effectImprove gripProtective equipmentGlovesEngineeringPlastic film

The invention discloses a puncture-resistant structural layer and an application thereof to preparation of puncture-resistant gloves. The puncture-resistant structural layer is puncture-resistant woven fabric, a plastic sheet, coated fabric or plastic composite fabric; the coated fabric comprises base cloth and a coating applied to the surface of the base cloth, and the base cloth is the puncture-resistant woven fabric; the plastic composite fabric is a sheet layer prepared from a plastic base material and the puncture-resistant woven fabric by high-temperature pressing. The puncture-resistantstructural layer is soft and has quite strong puncture-resistant and anti-cutting functions; the puncture-resistant gloves prepared from the puncture-resistant structural layer have excellent dexterity and comfort while realizing the puncture-resistant and anti-cutting functions.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

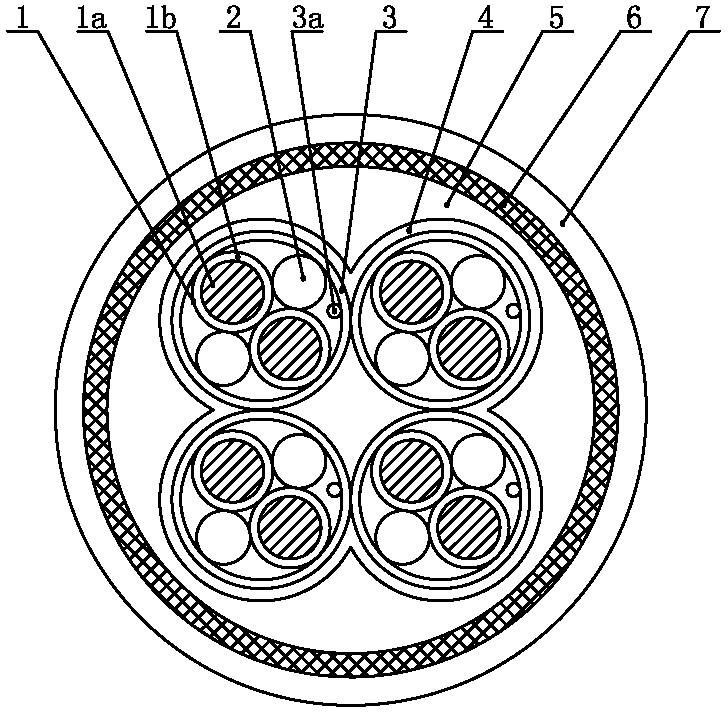

Pair-twist shielding instrument cable for flame-retardant fireproof boat and manufacturing method thereof

Owner:嘉兴君宏光学有限公司

Preparation method of non-woven fabric

InactiveCN108517621AImprove toughnessImprove wear resistanceBiochemical fibre treatmentNon-woven fabricsCardingPyrophosphate

Owner:徐冬

Isotactic polypropylene/tall oil acid/polybutadiene composite sound absorbing cotton and preparation method thereof

InactiveCN103726222AImprove breathabilityImprove tensile propertiesSynthetic resin layered productsNon-woven fabricsParaffin waxVoid ratio

Owner:芜湖跃飞新型吸音材料股份有限公司

Roll Cover

The invention relates to a roll cover for treating a paper, cardboard, tissue or other fibrous web in a machine for manufacturing and / or converting them, comprising one or more plastic layers, of which at least one is of compressible configuration, and at least one carrier element in the form of a woven fabric, laid scrim or the like. Here, the loading of the support structure is intended to be reduced by at least one carrier element being embedded into a compressible plastic layer.

Owner:VOITH PATENT GMBH

Sports outdoor clothing fabric for mass

InactiveCN108505336AAvoid discomfortLittle effect on material strengthFibre typesWoven fabricsPolyesterEpoxy

Owner:SUZHOU INST OF TRADE & COMMERCE

Novel charged nanofiltration membrane for removing organic matter and preparation method of novel charged nanofiltration membrane

ActiveCN112844076AReduce pH fluctuationReduce corrosionMembranesGeneral water supply conservationSodium acetateOrganosolv

Owner:恩泰环保科技(常州)有限公司

Non-woven fabric punching equipment capable of processing waste

InactiveCN111496902AInnovative designEasy to punchMetal working apparatusPunchingProcess engineering

Owner:温州晨曦工艺品有限公司

High-temperature-resisting glass fiber cloth

InactiveCN104908379ASynthetic resin layered productsGlass/slag layered productsWoven fabricMaterials science

Owner:安徽旌德青山玻纤厂

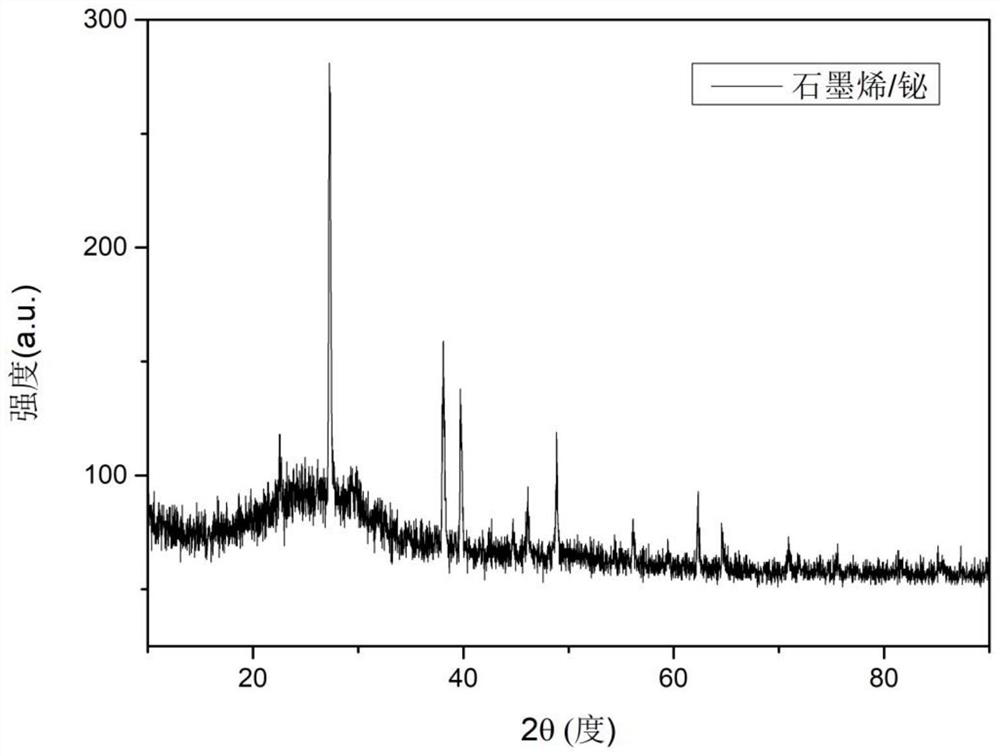

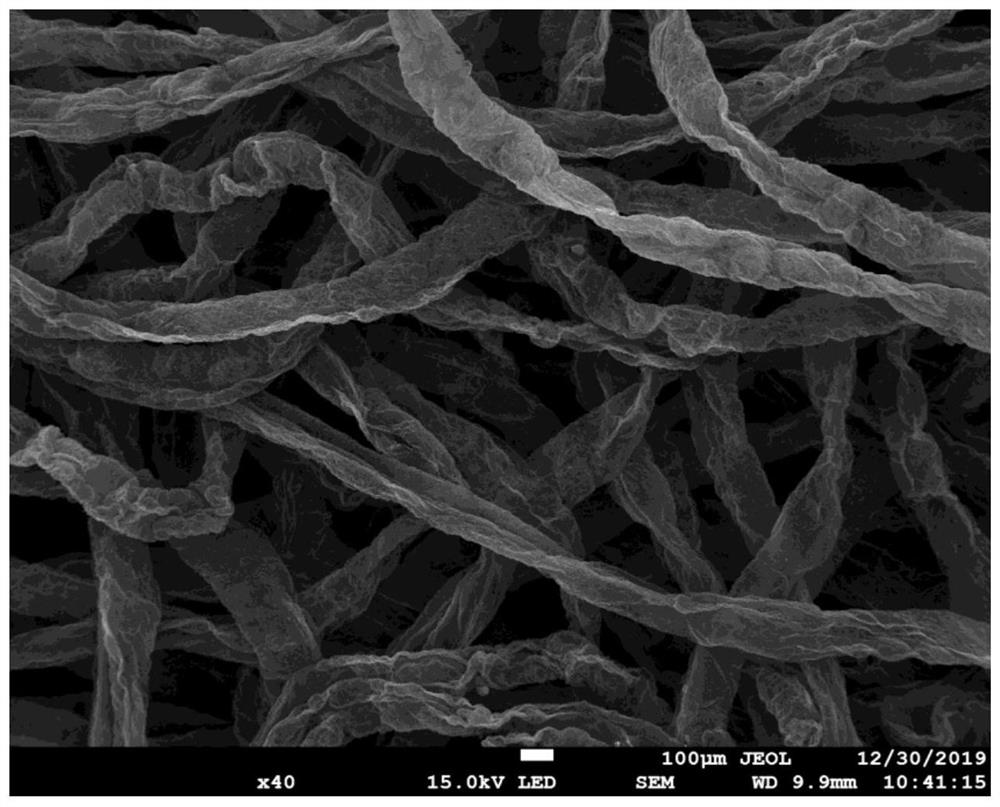

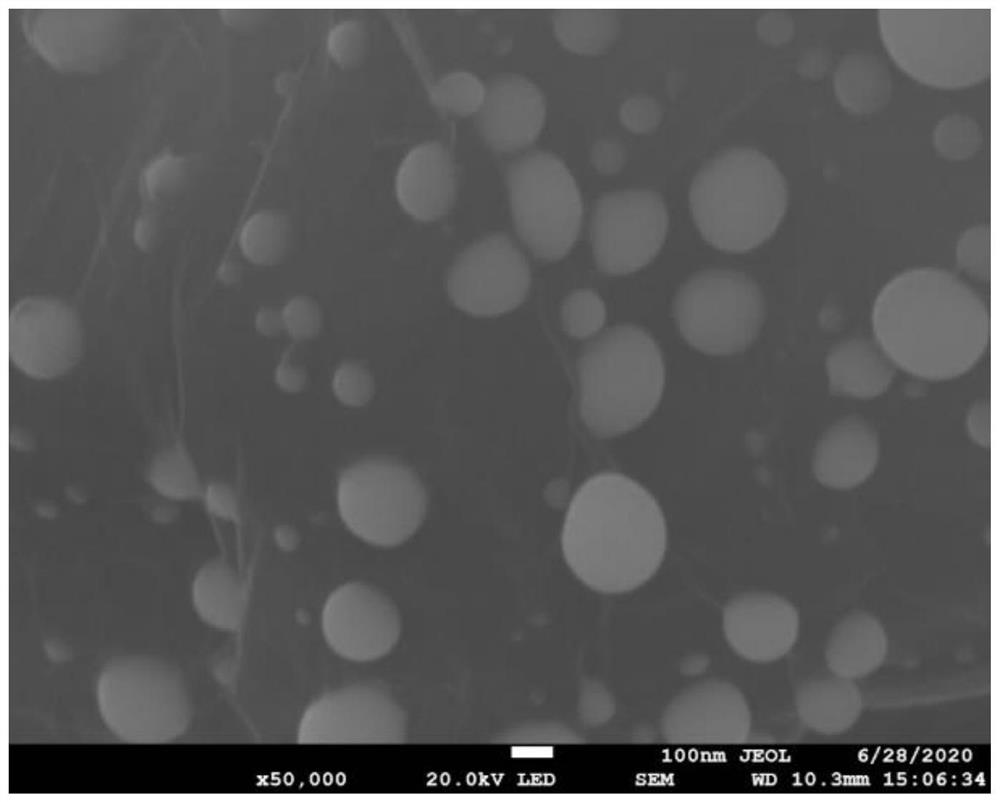

Method for preparing bismuth nanoparticles loaded on graphene fiber non-woven fabric by microwave induction

InactiveCN112941894AImprove cycle performanceImprove mechanical stabilityRadio/micro wave fibre treatmentNon-woven fabricsNonwoven fabricGraphene

Owner:HEBEI UNIV OF TECH

Rapid non-woven fabric cleaning, dewatering and clearing equipment for textile production

ActiveCN113279178AEasy to cleanImprove cleaning efficiencyMechanical cleaningPressure cleaningProcess engineeringNonwoven fabric

Owner:JINAN HAOXIN IND

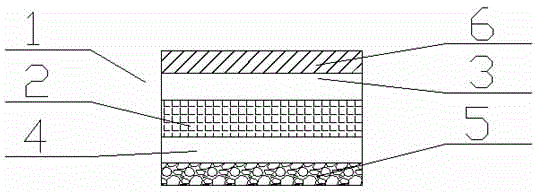

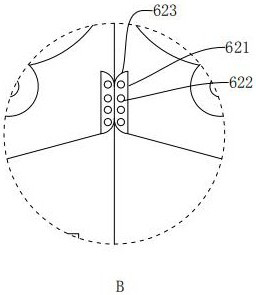

Non-woven fabric lapping machine with noise reduction function

The invention discloses a non-woven web laminating machine with noise reduction function, which comprises a frame. There are mesh guide rollers installed on both sides of the inner cavity of the frame, and the upper mesh curtain and the lower mesh curtain are respectively set on the mesh roller, and a compensation curtain is set between the upper mesh curtain and the lower mesh curtain. A motor is installed on the inner wall, and the motor is fixedly connected with a reduction box. The reduction box is set at one end of the shaft of the guide roller. At one end of the belt, a belt is set on the pulley, and a net-laying trolley is installed between the belts. A net-laying roller is installed on the net-laying trolley, and a web-forming curtain is arranged under the net-laying roller. The outer walls on both sides of the column are equipped with fixing seats, and a shell is installed on the fixing seats. The inner cavity of the shell is provided with a buffer rod.

Owner:YIZHENG HUAKAI NON WOVEN EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap