Medical sterilization packaging bag

A packaging bag and surface layer technology, which is applied in the field of medical sterilization packaging bags, can solve the problems of inconvenience for medical staff, difficulty in identification, and increased cost of materials, so as to improve the antibacterial rate of packaging, reduce costs, and ensure the safety of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

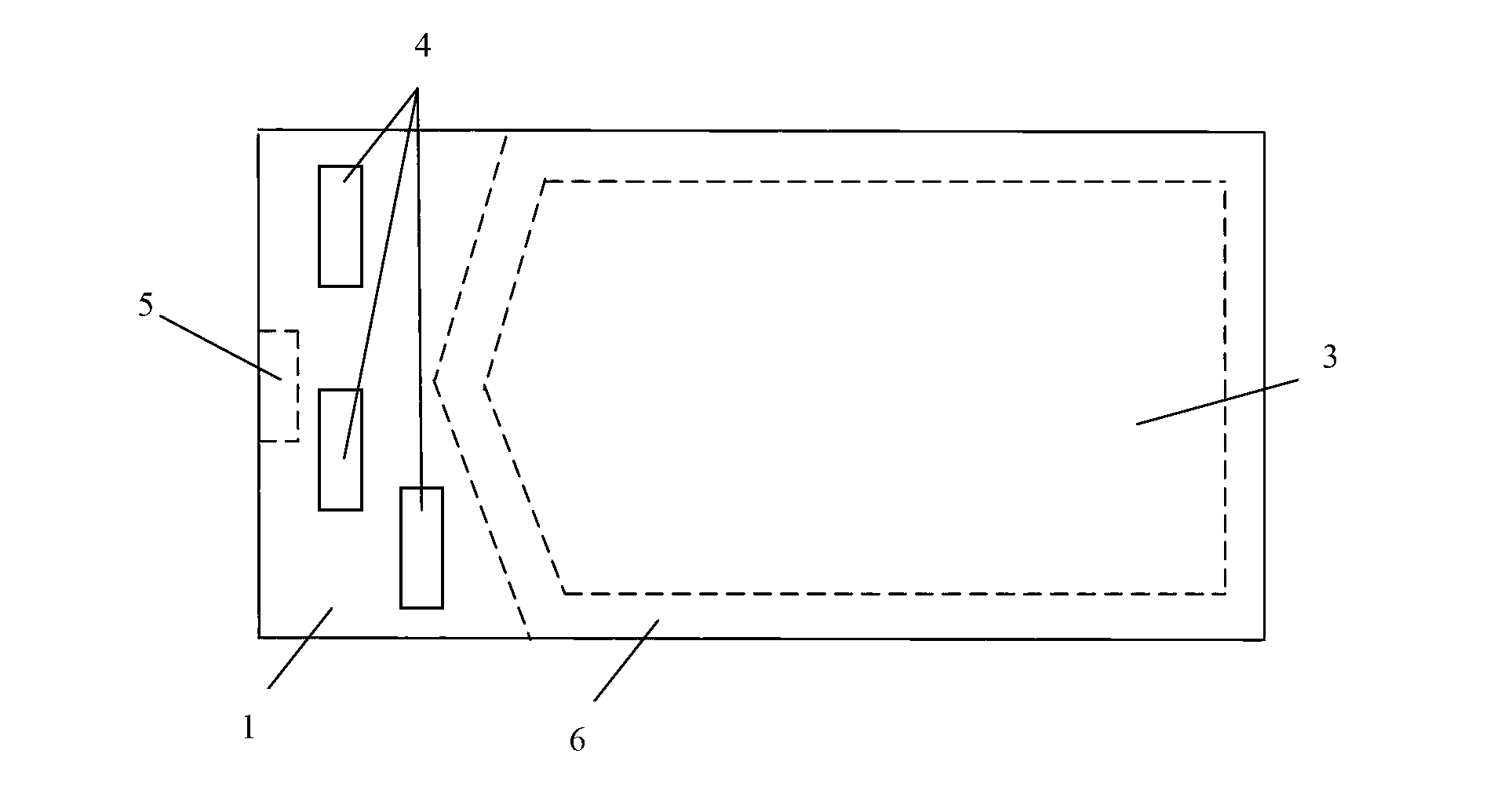

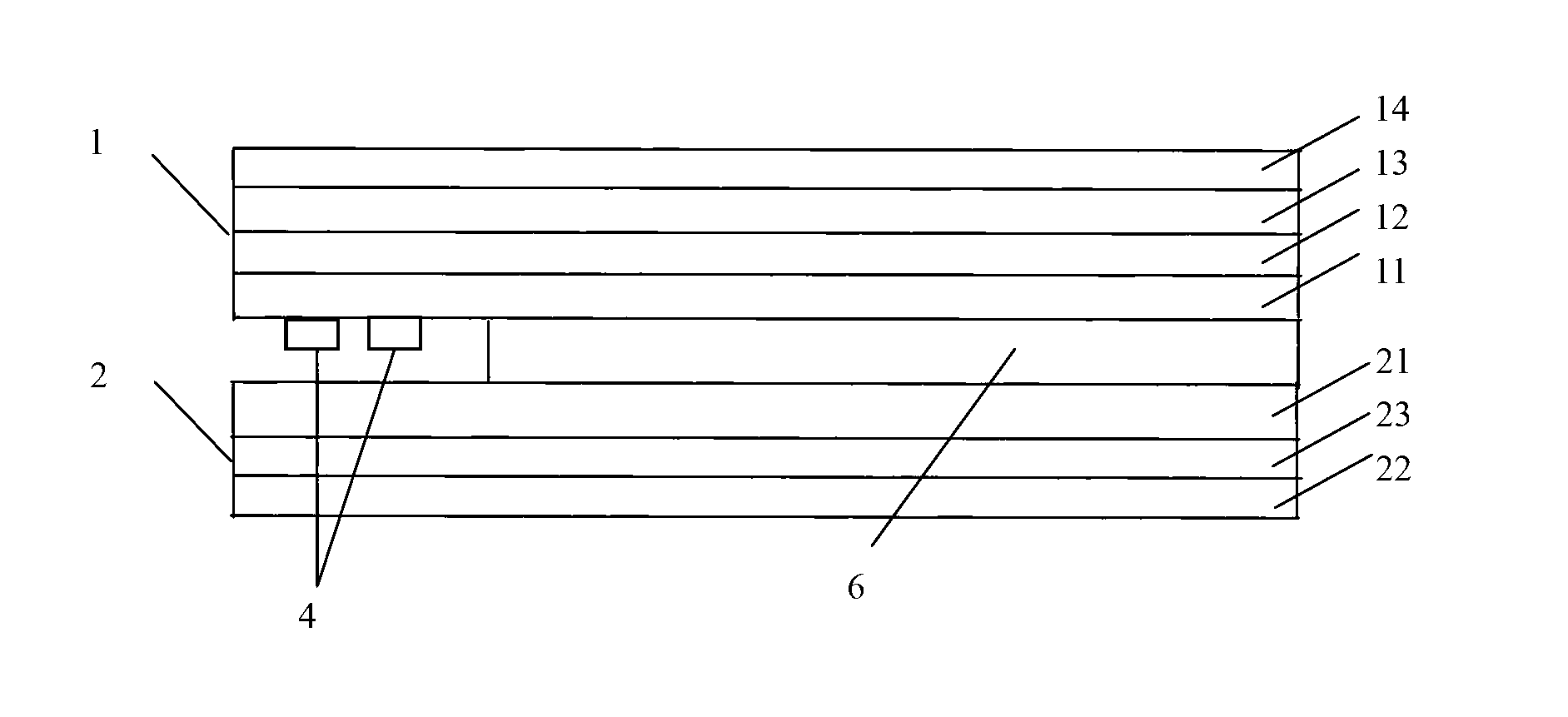

[0020] figure 1 , figure 2 The medical sterilization packaging bag of the present invention is shown, which includes a surface layer 1 and a bottom layer 2, and the surface layer 1 and the bottom layer 2 are connected to each other to form an airtight cavity 3 for accommodating articles, wherein the surface layer 1 is made of spunbond / melt Spray / meltblown / spunbond (SMMS) composite non-woven fabric, bottom layer 2 is made of polypropylene (CPP) and polyester (PET) composite film.

[0021] in such as figure 1 In the preferred embodiment shown, the top layer 1 and the bottom layer 2 are connected at least partially along their edges 6 by ironing. The so-called ironing refers to the bonding of two or more different materials with a set value under a mechanical balance pressure within a known temperature range.

[0022] The SMMS composite non-woven fabric (available for example from Foshan Nanhai Bidefu Non-woven Fabric Co., Ltd.) sequentially comprises a first spunbond laye

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap