Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Cardboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cardboard is a generic term for heavy-duty paper-based products having greater thickness and superior durability or other specific mechanical attributes to paper; such as foldability, rigidity and impact resistance. The construction can range from a thick sheet known as paperboard to corrugated fiberboard which is made of multiple corrugated and flat layers.

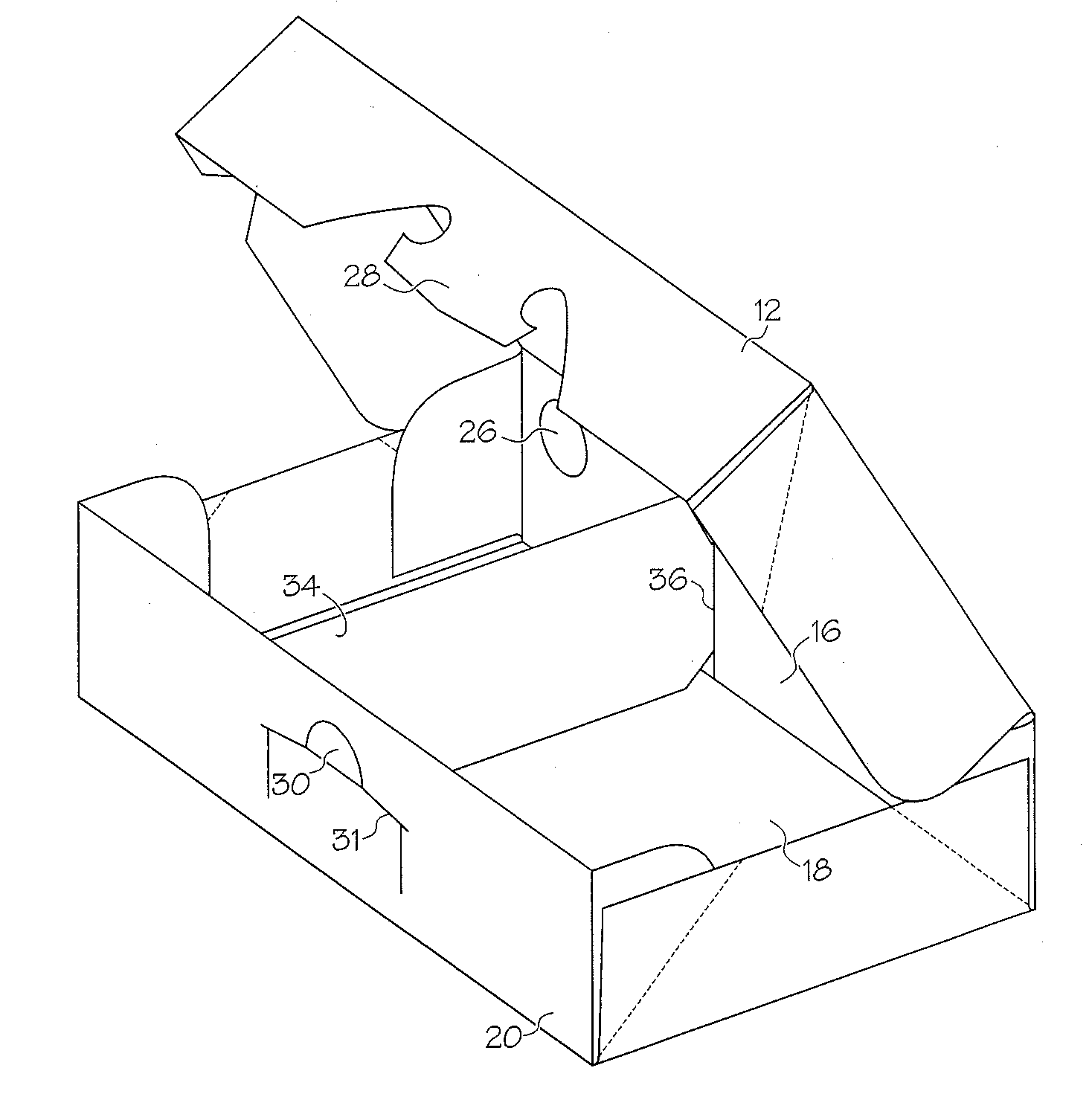

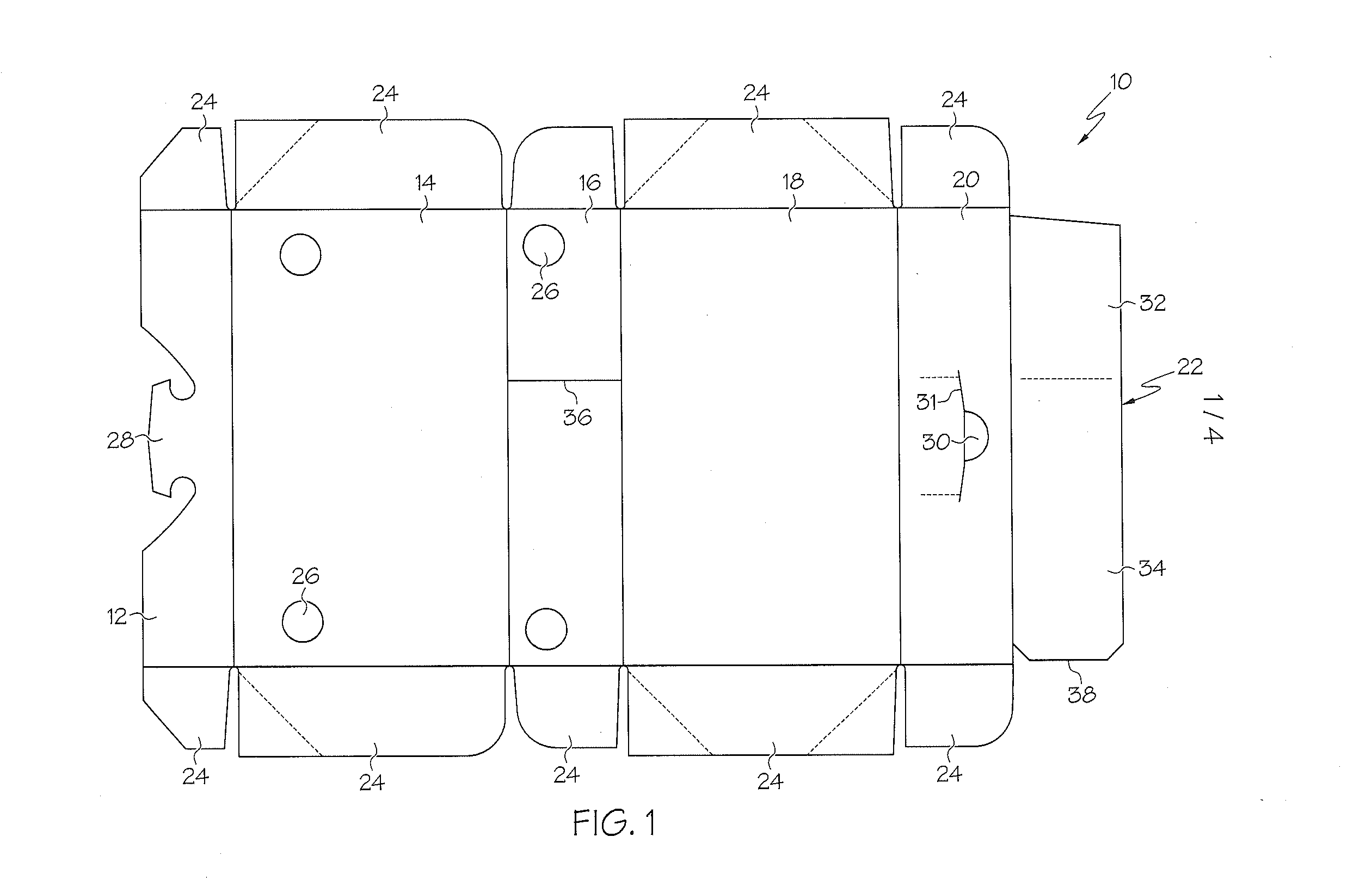

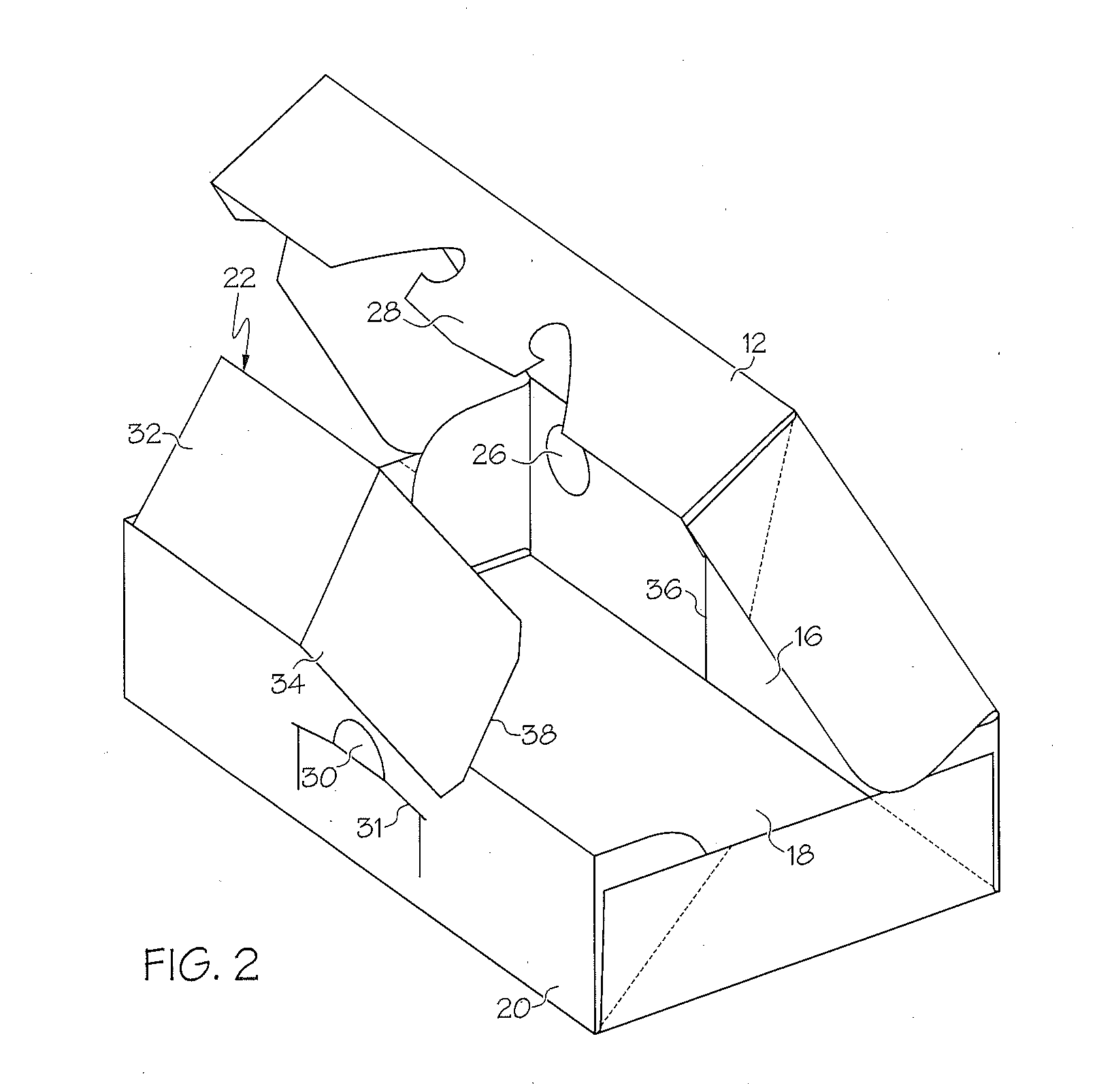

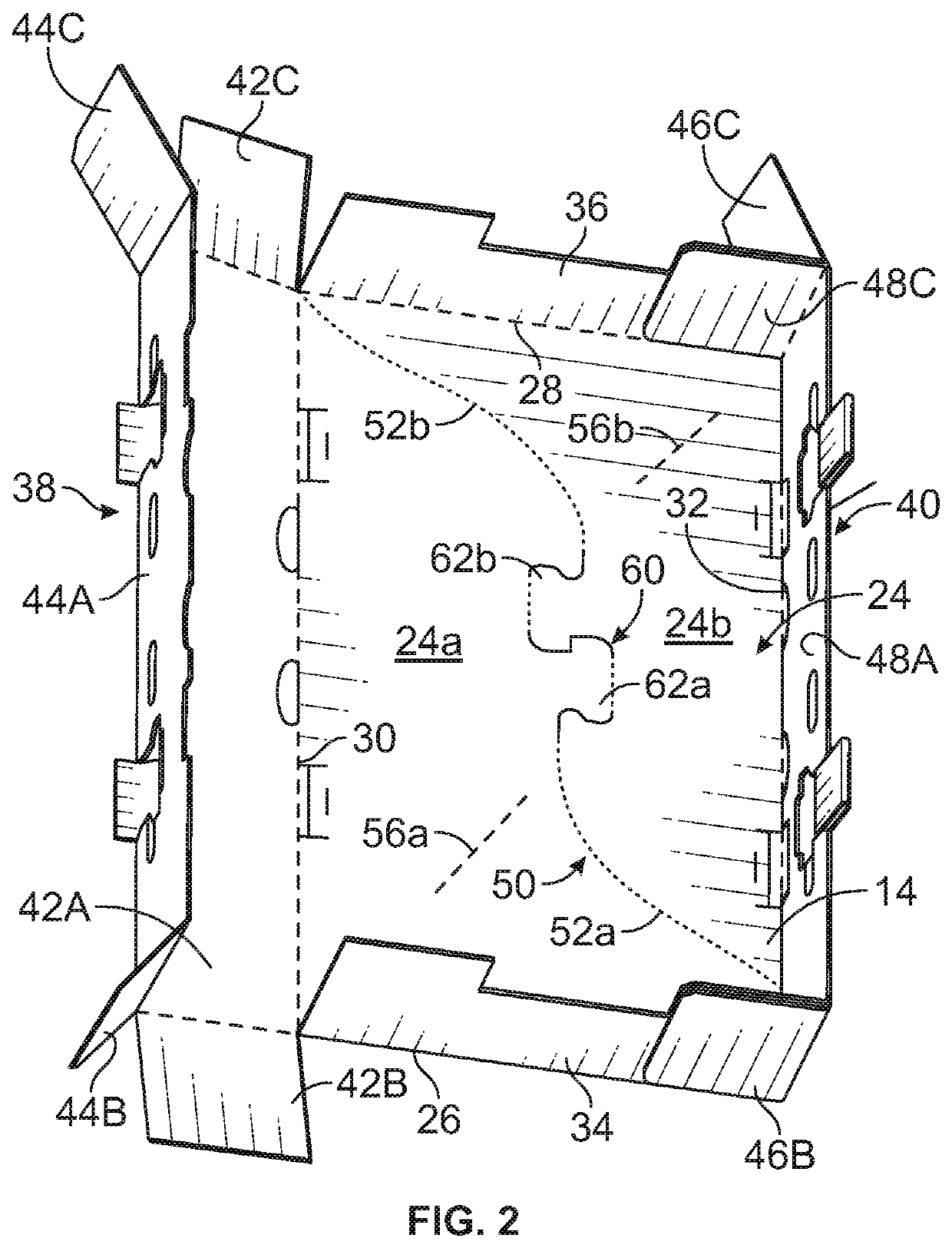

Carton with foldout partition

Owner:HUHTAMAKI INC

Corrugating linerboard, corrugated board, and methods of making the same

A method of making a corrugating linerboard includes supplying a web of coated linerboard having a first side, a second side and a thickness defined by a distance between the first side and the second side, the first side being coated with a moisture-repellant material; and impregnating the coated linerboard with a hydrophobic material from the second side such that the hydrophobic material penetrates into the thickness of the coated linerboard.

Owner:GEORGIA PACIFIC CORRUGATED

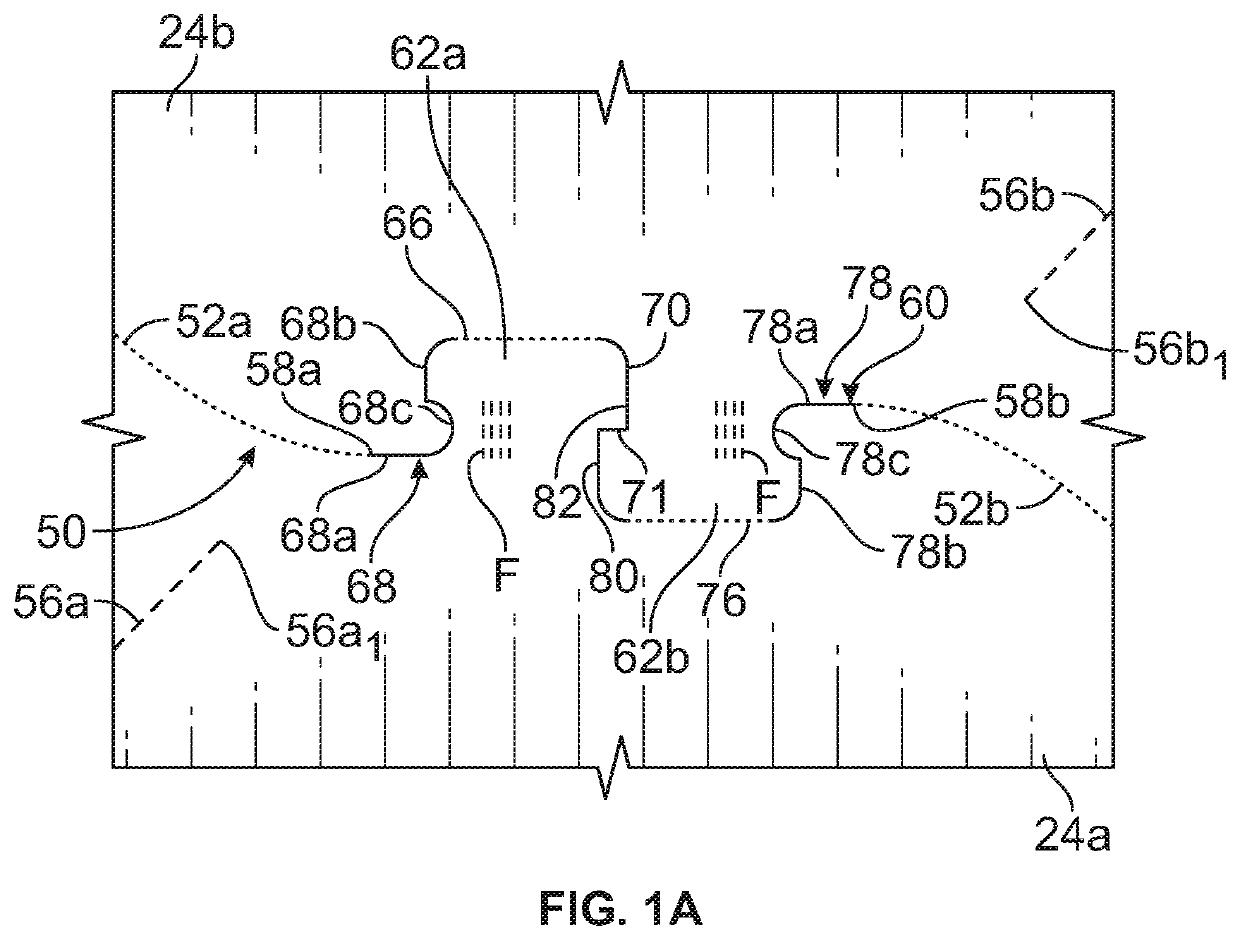

Canine waste receptacle

A waste receptacle particularly useful for scooping-up and removing canine waste and a blank for making the receptacle. The blank and receptacle are made from a single thin sheet of material such as cardboard. The receptacle can be used with only one hand. It is stored and transported nearly flat and can be popped into operative configuration by applying pressure on the sides. Further application of pressure on the sides changes the size and shape of the receptacle opening and controls the position of a flap over the opening for more control of the scooping and closing process. A hook structure is formed on one end of the receptacle. The receptacle has a tapered shape which allows use and control of the receptacle by people with large or small hands.

Owner:FONFRIAS RICHARD SALVATORE

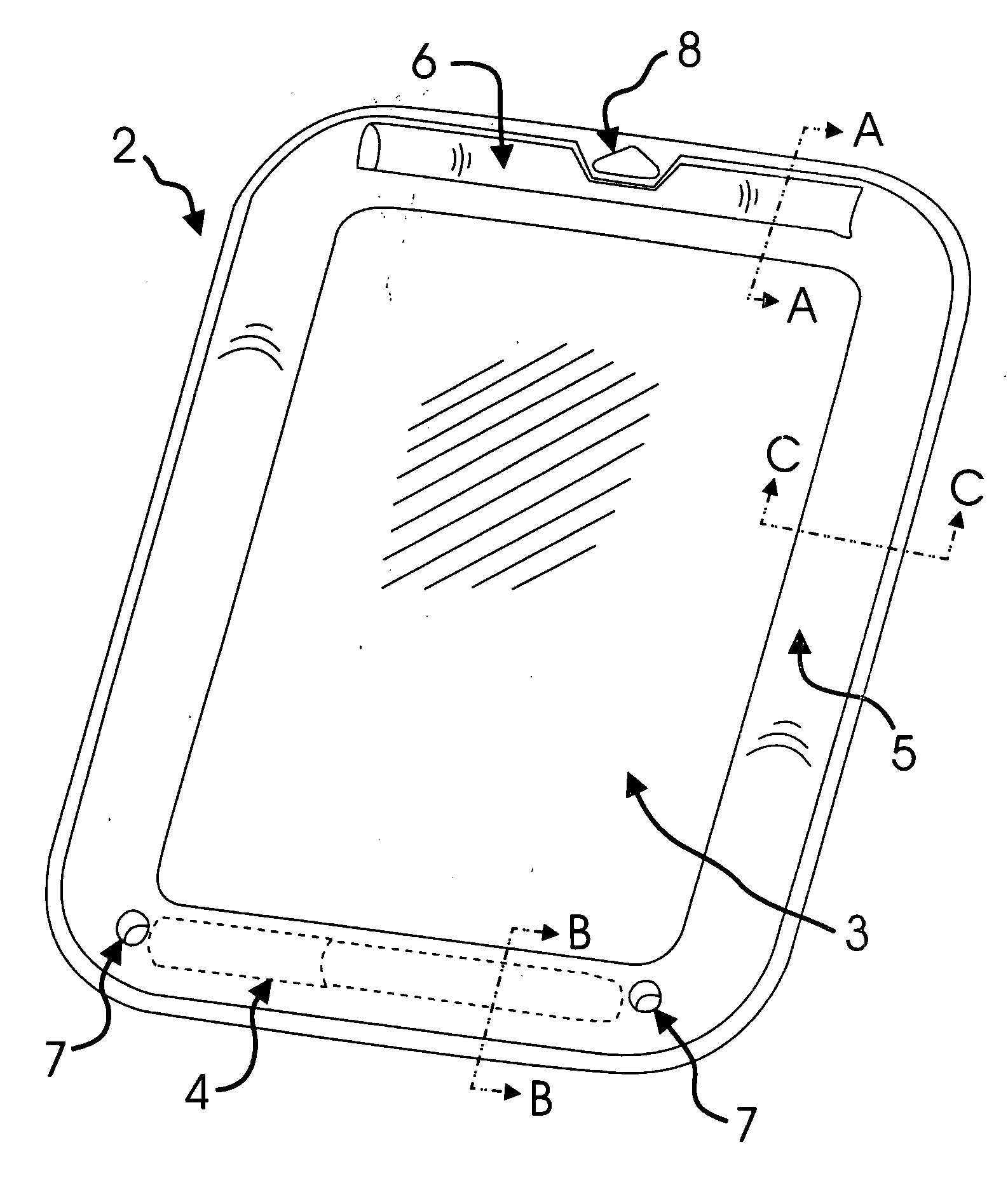

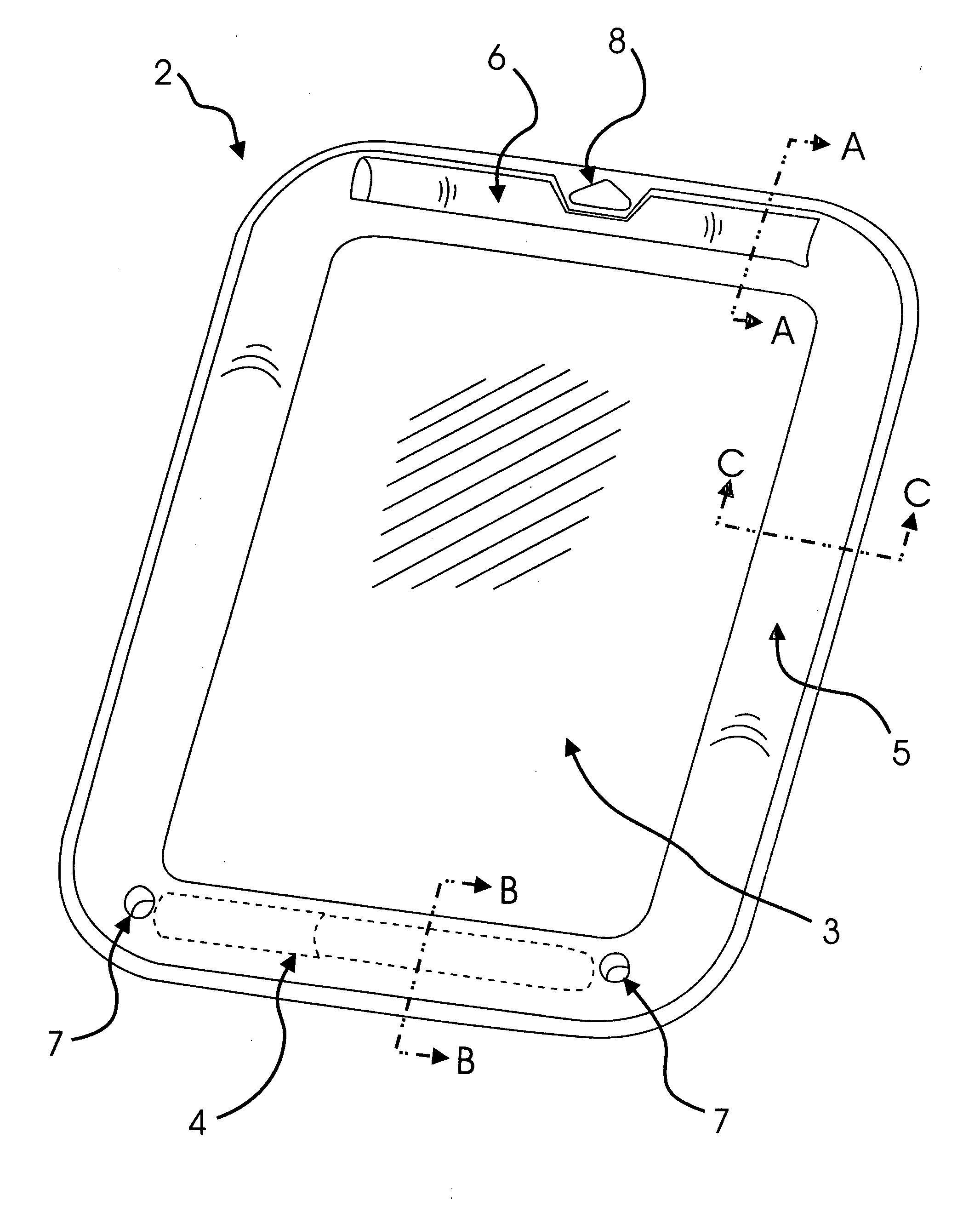

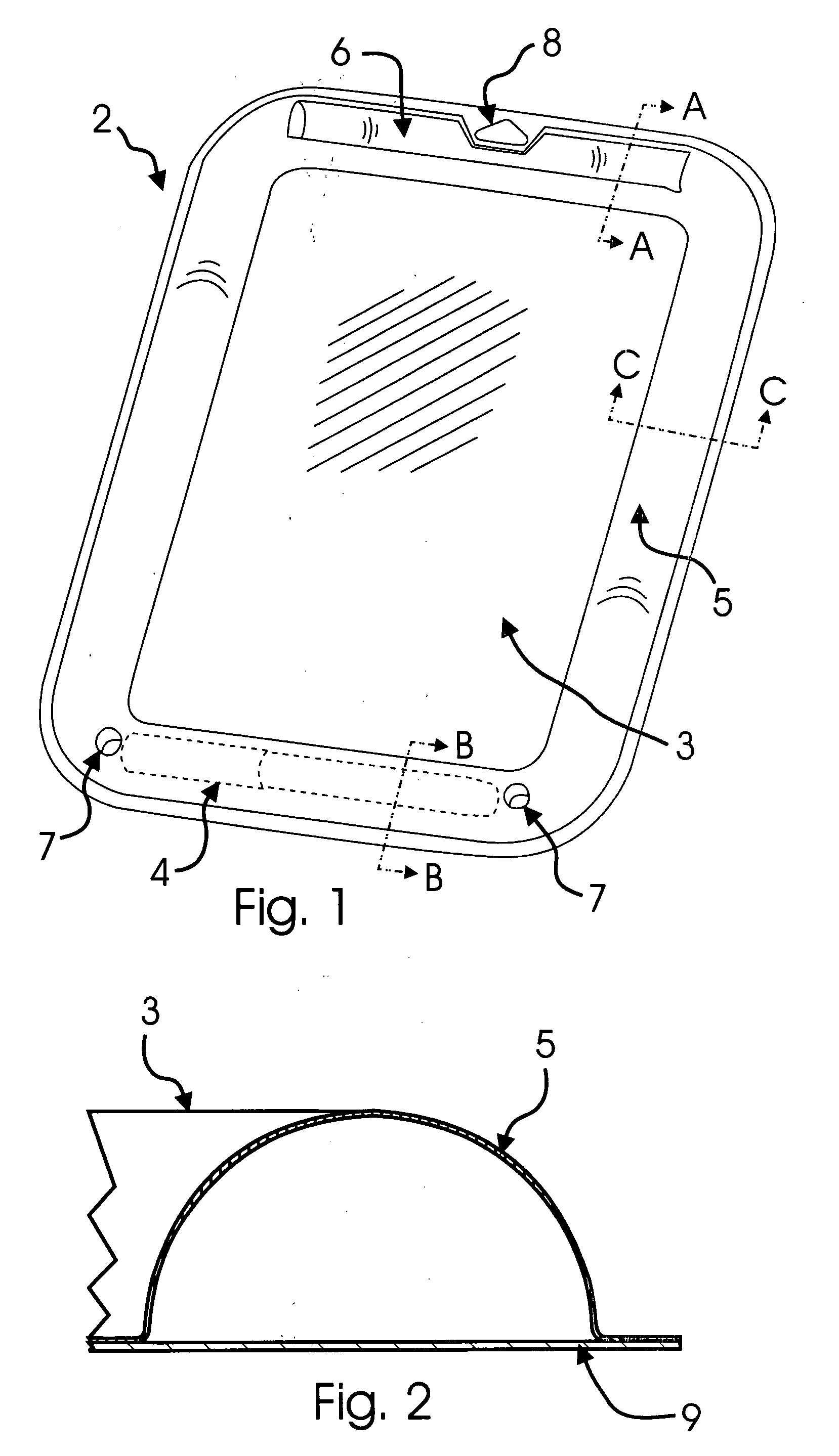

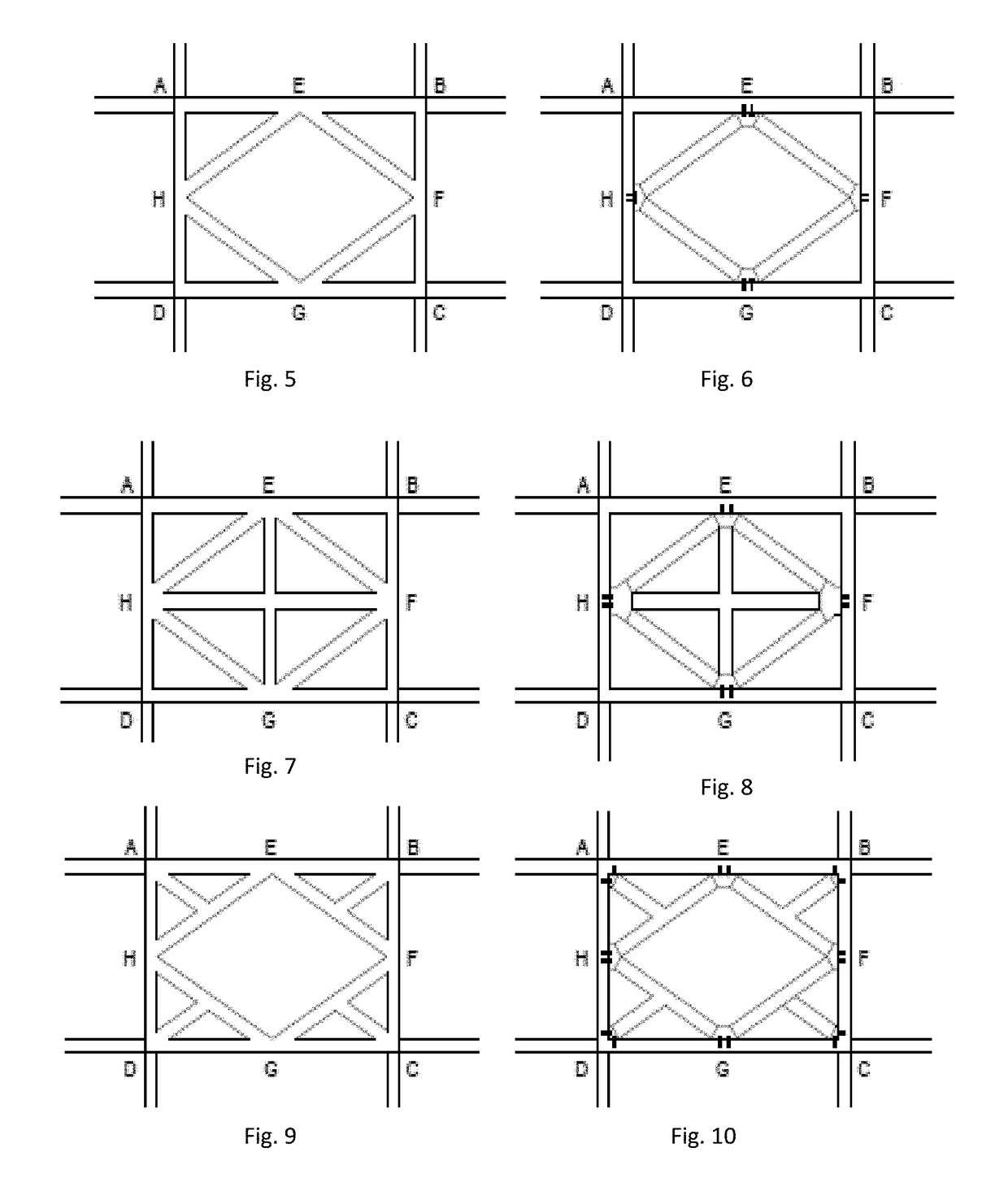

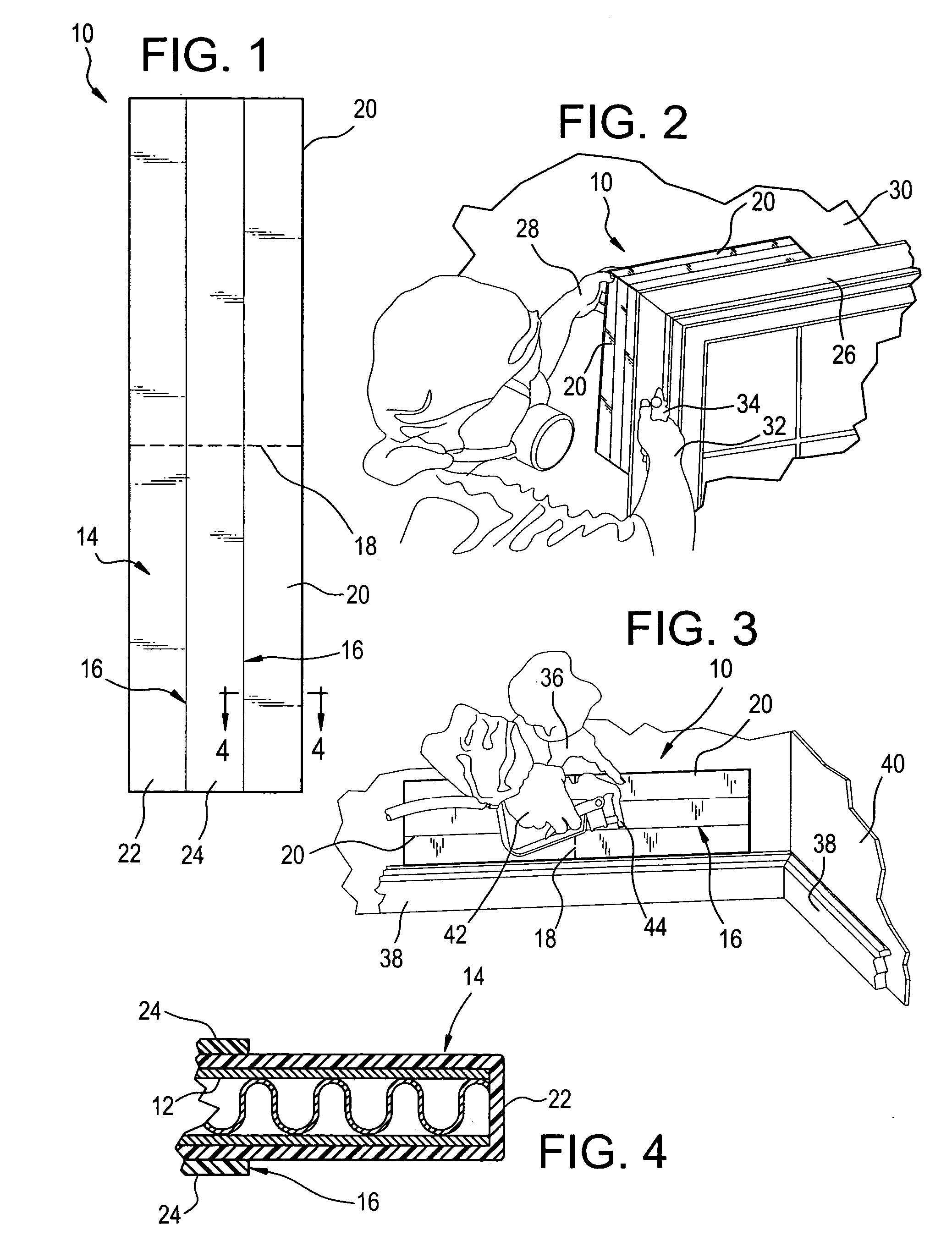

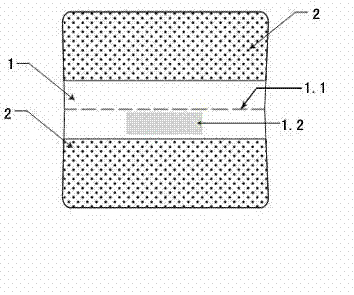

Dry erasable board in the form of a blister pack

InactiveUS20100233668A1Eliminate needEasy to manufactureWriting connectorsWriting boardsCardboardEngineering

Owner:KELSOE JEFFREY L +1

A method of constructing earthquake resistant structure with reinforced foundation and wall structure

Owner:YASHRAJ MAHESH +1

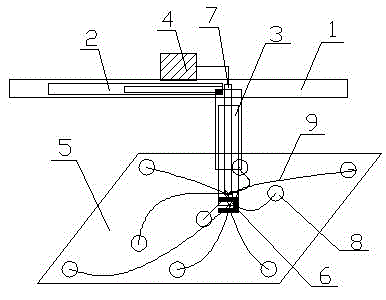

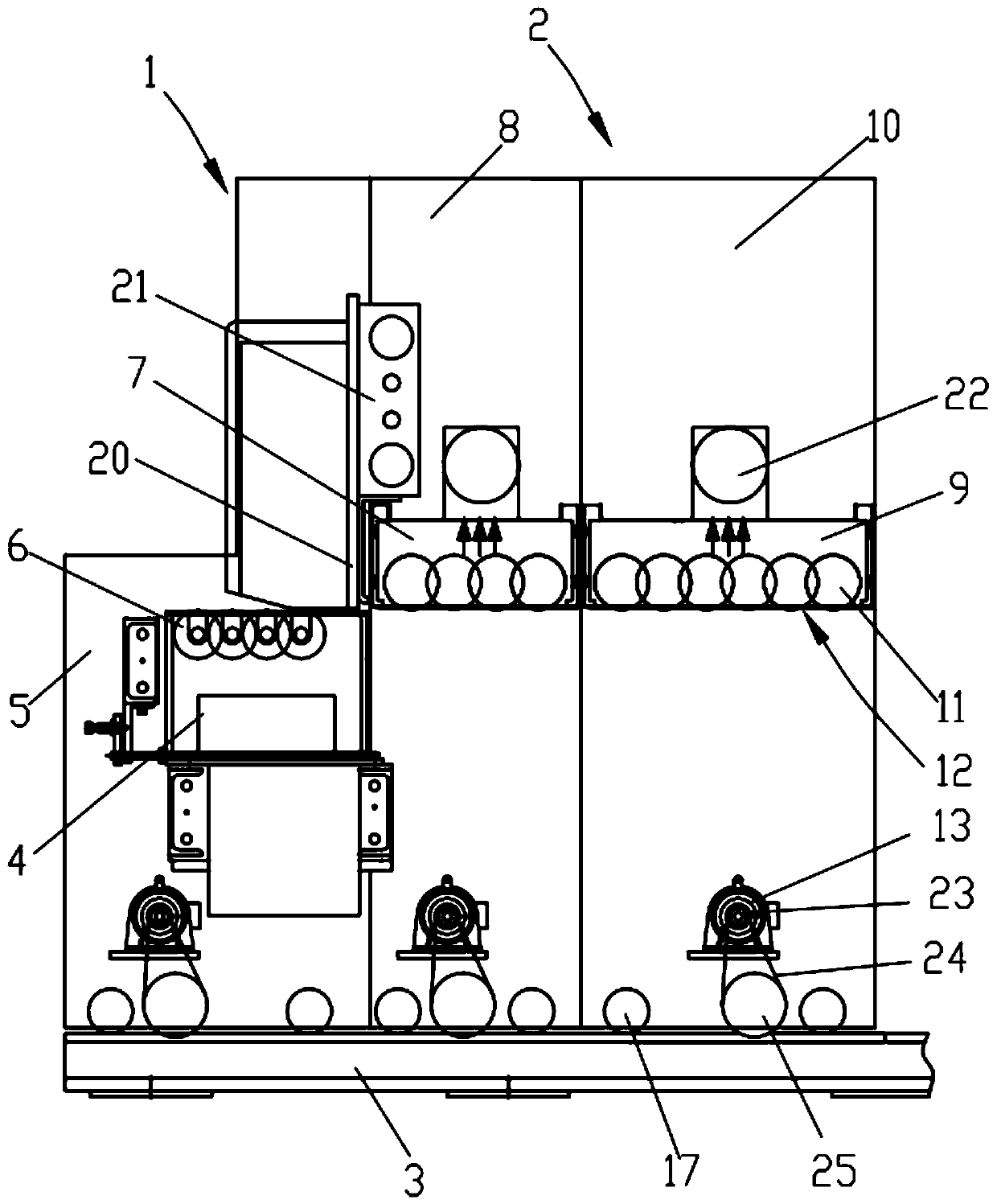

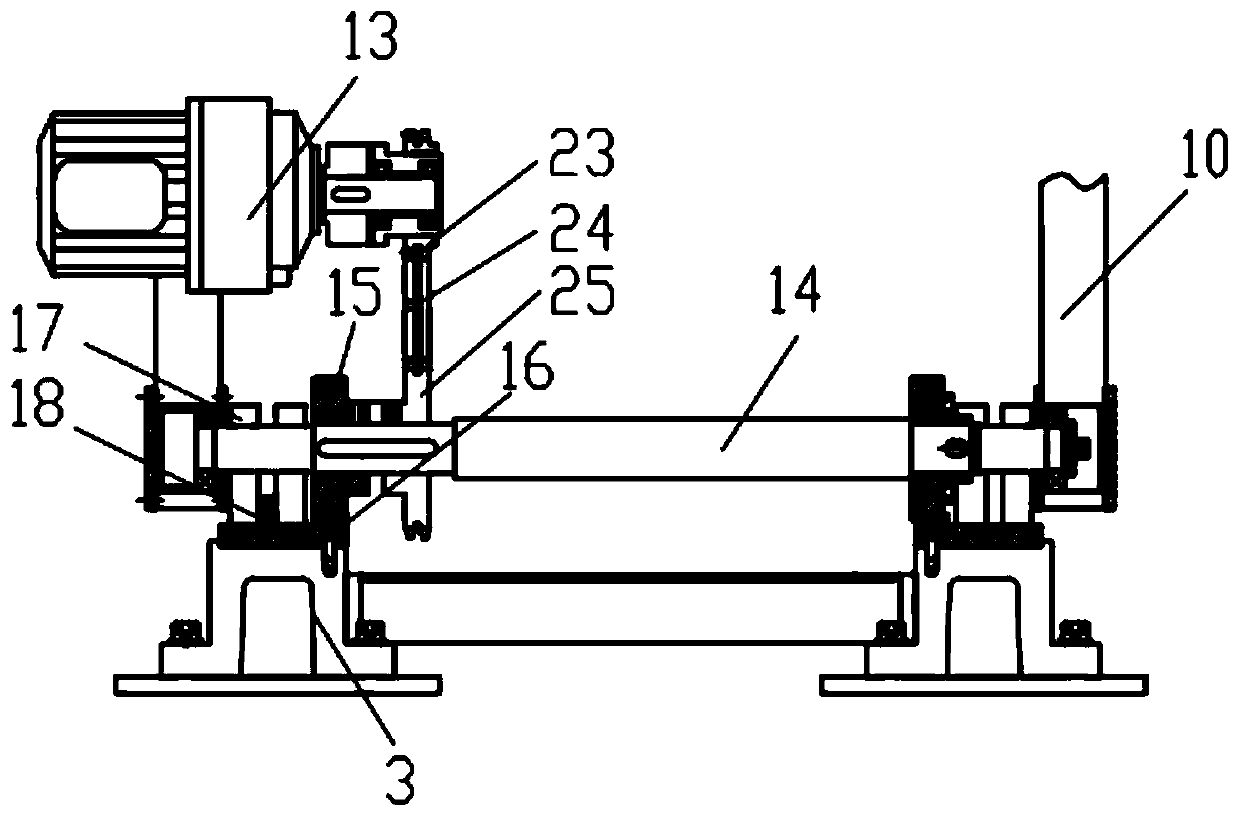

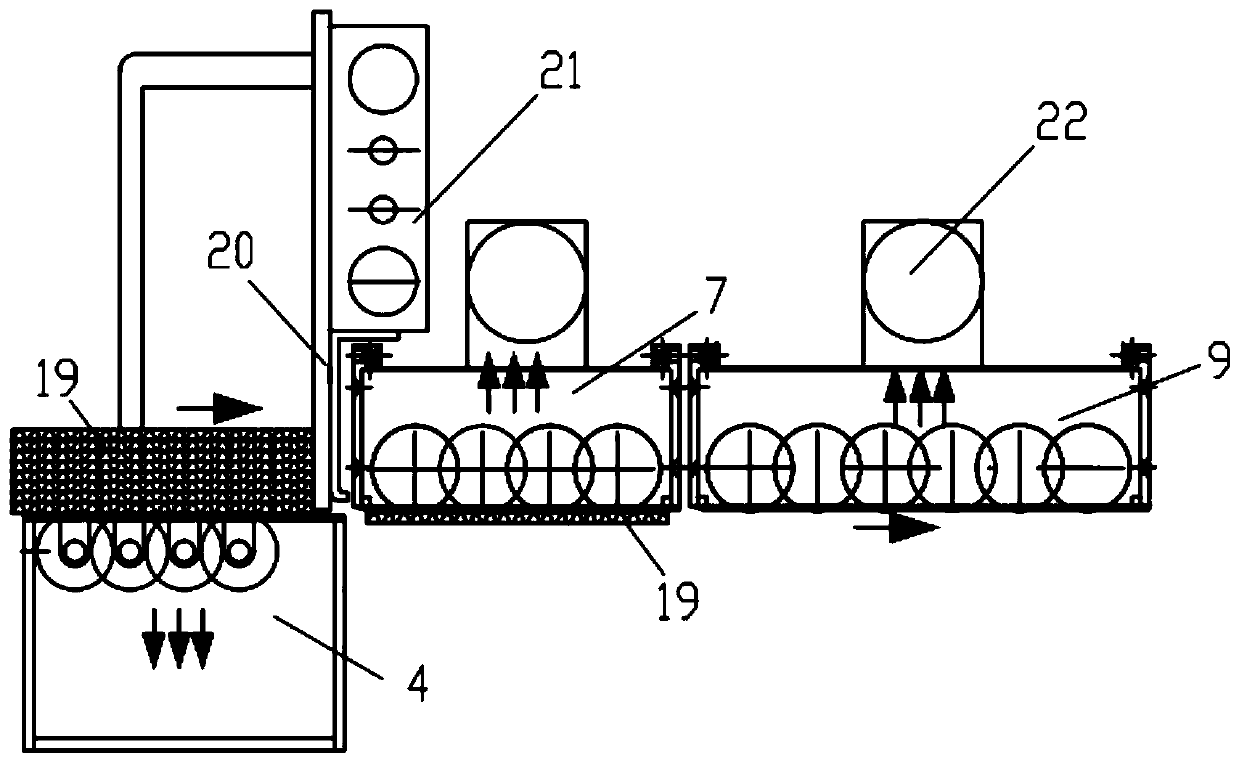

Suction type paper feeding device

Owner:CHANGZHOU SINAJET SCI & TECH

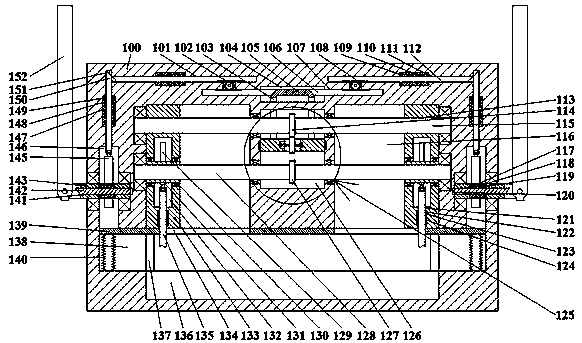

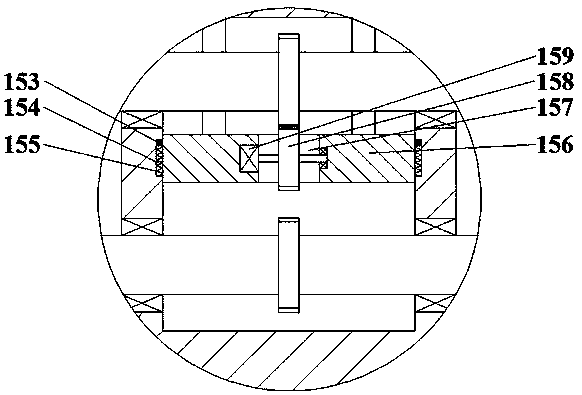

Roll Cover

The invention relates to a roll cover for treating a paper, cardboard, tissue or other fibrous web in a machine for manufacturing and / or converting them, comprising one or more plastic layers, of which at least one is of compressible configuration, and at least one carrier element in the form of a woven fabric, laid scrim or the like. Here, the loading of the support structure is intended to be reduced by at least one carrier element being embedded into a compressible plastic layer.

Owner:VOITH PATENT GMBH

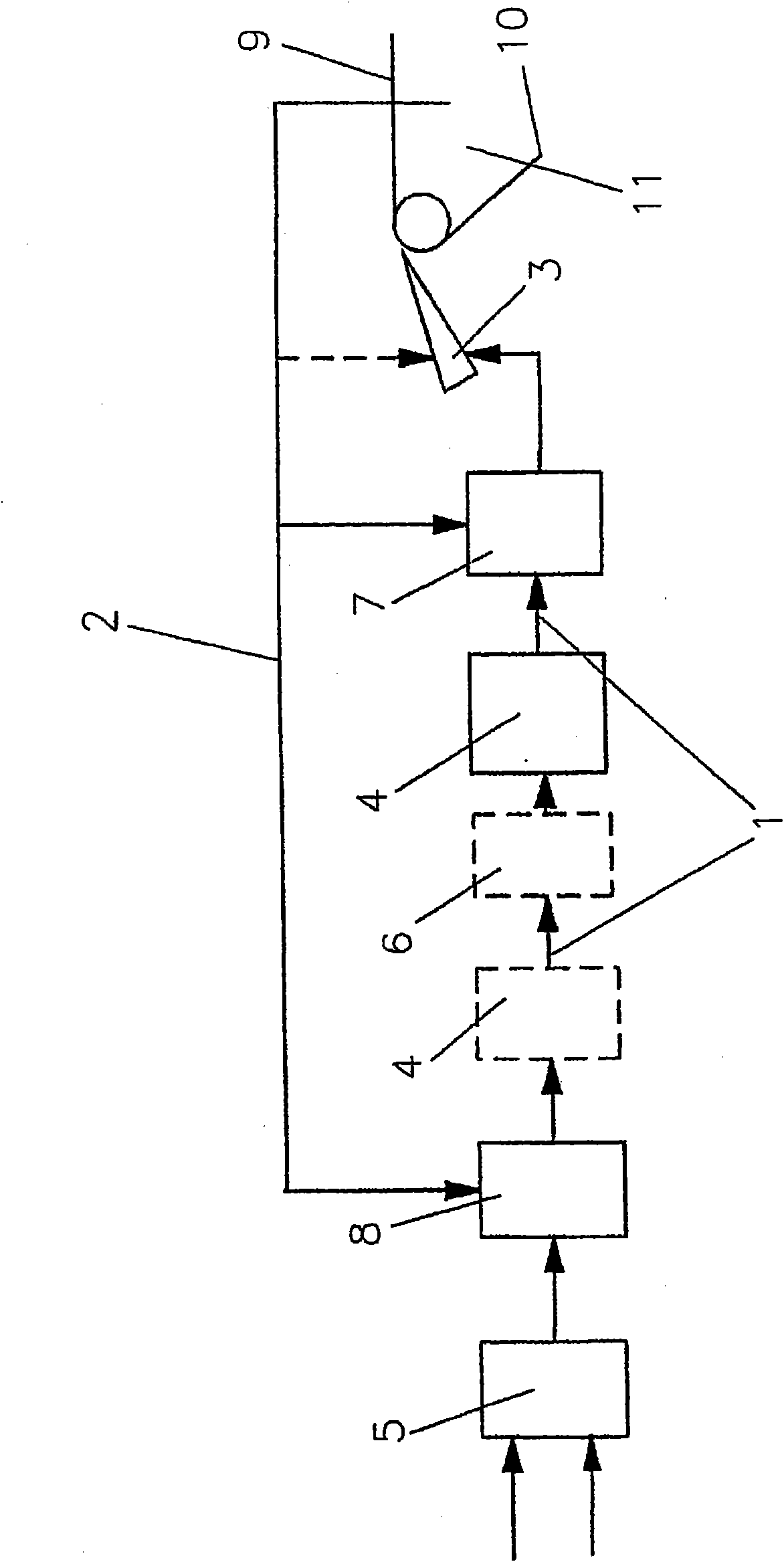

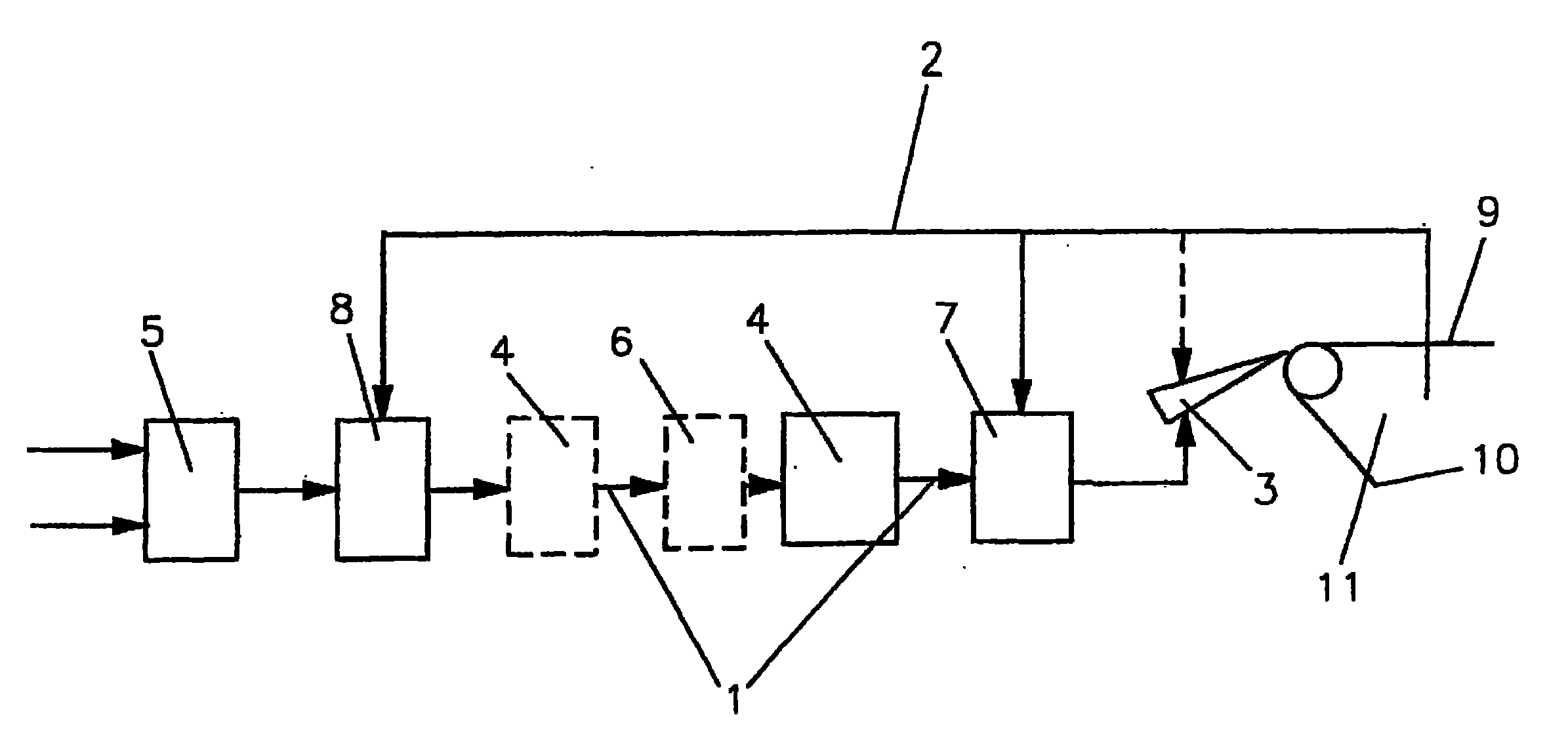

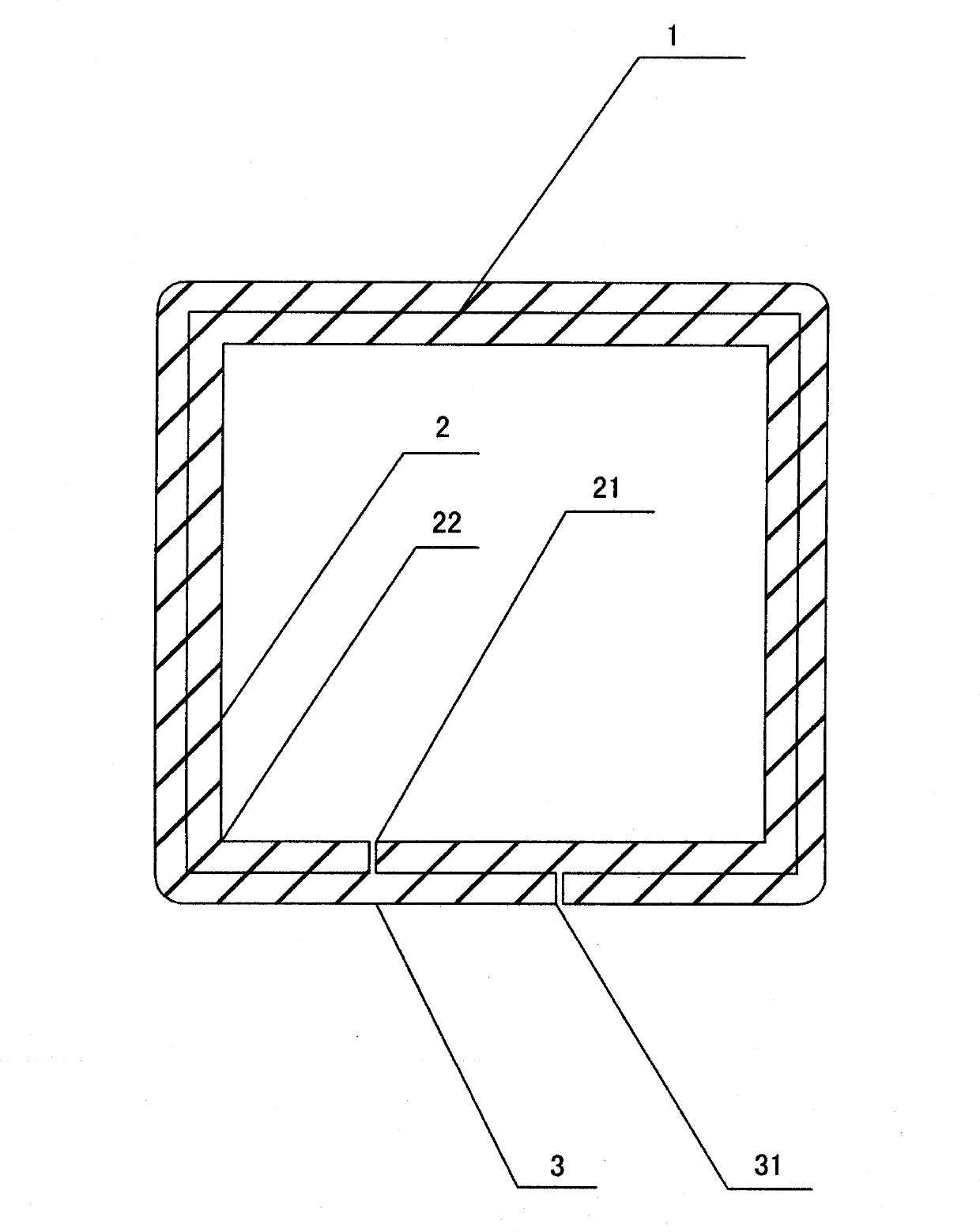

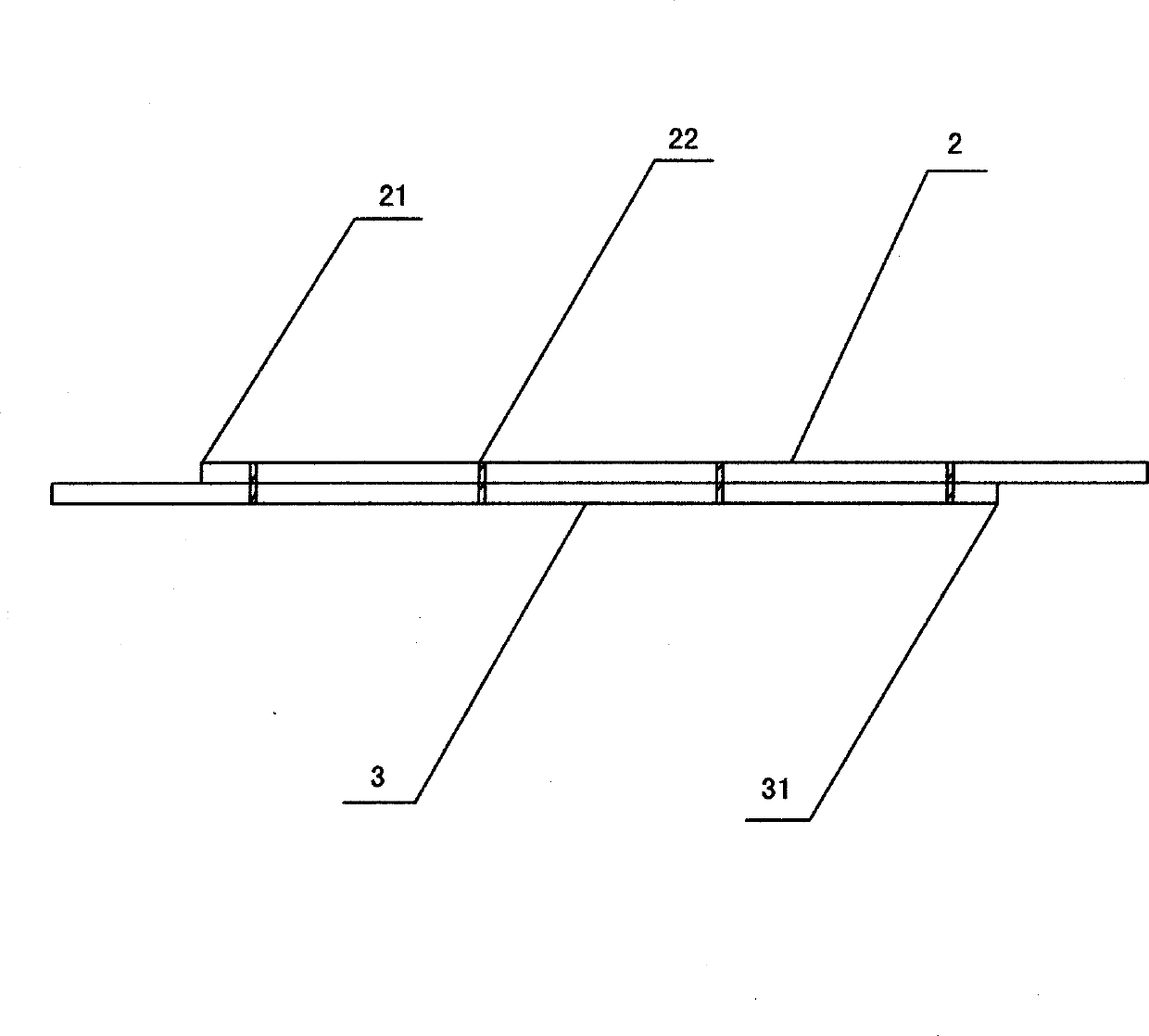

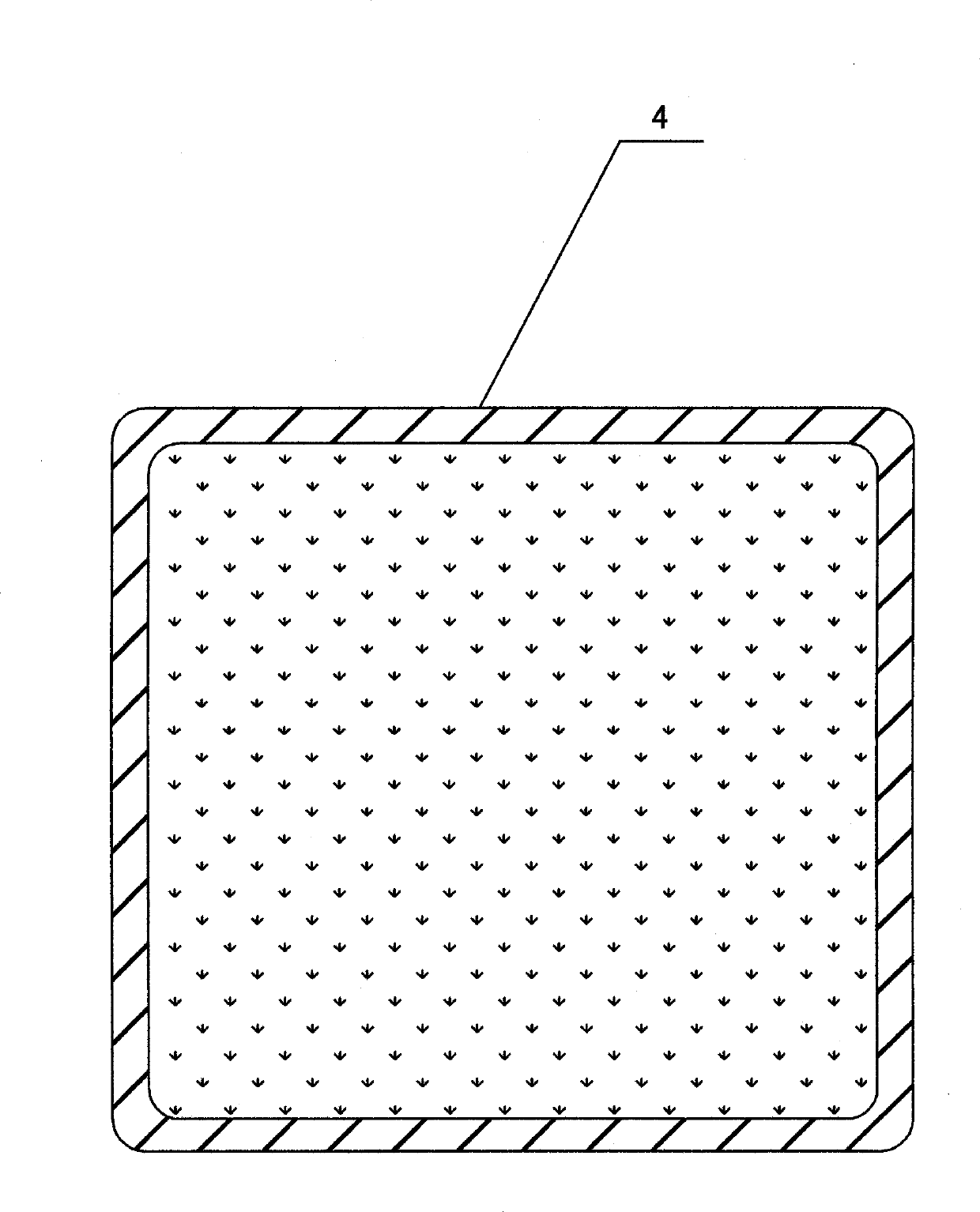

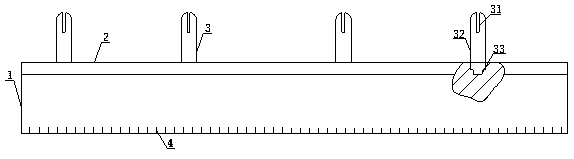

Split type corrugated board adsorption paper feeder

PendingCN110861348AEliminate corrugated crushEliminate collapsePaper-makingBox making operationsCardboardCarton

Owner:ZHUZHOU SINOVAN PACKAGING TECH

Paint shield

Owner:CRESWELL WENDY Q

Constant part for a paper machine

InactiveCN101784724AMachine wet endFiber suspensionCardboard

Owner:VOITH PATENT GMBH

Packaging box and method for producing packaging box

Owner:SUZHOU IND ZONE LANDUO PACKAGING ENG CO LTD

Container with improved breakdown features

Owner:INT PAPER CO

A kind of manufacturing method of anti-mold packaging lining cardboard

ActiveCN104018387BAvoid deformationGood flexibilityNon-fibrous pulp additionPaper/cardboardEnvironmental resistanceCardboard

Owner:JIANGYIN BESTO SPECIAL PAPERBOARD

Bag cover mold of two-sided sticky waterproof abrasive paper

Owner:江苏阳光毛纺服装技术开发有限公司

Wing connector

Owner:江苏云端智能科技有限公司

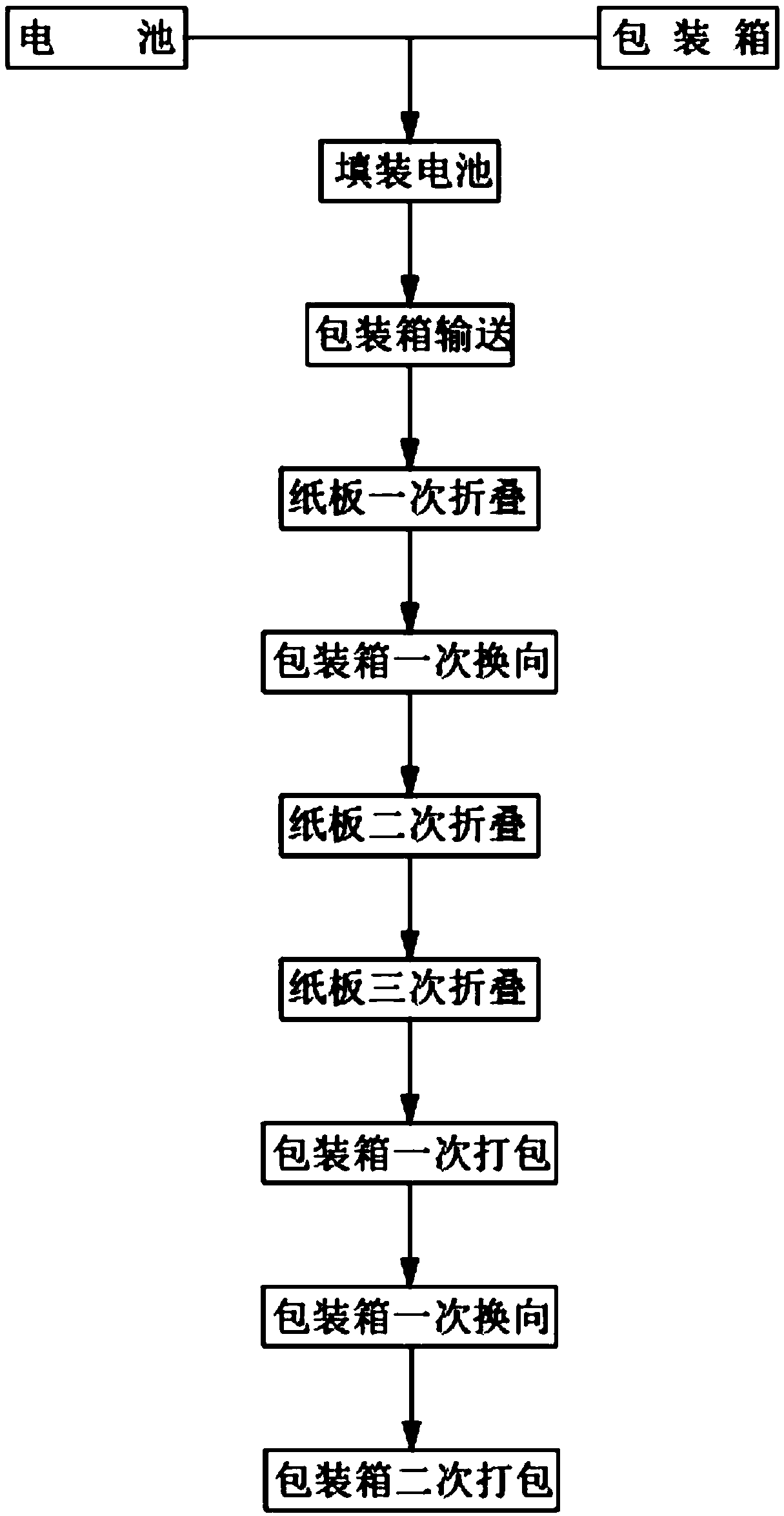

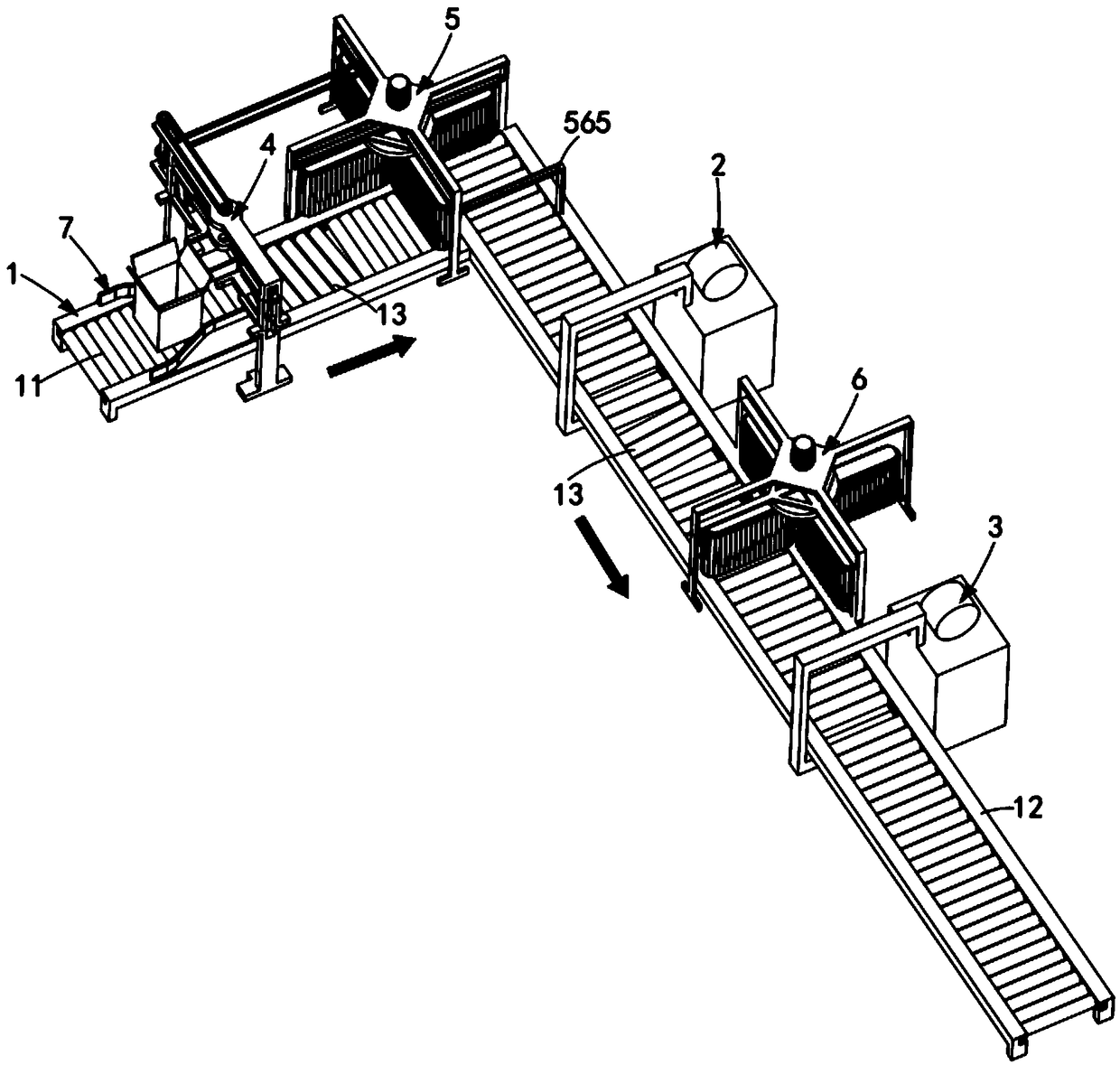

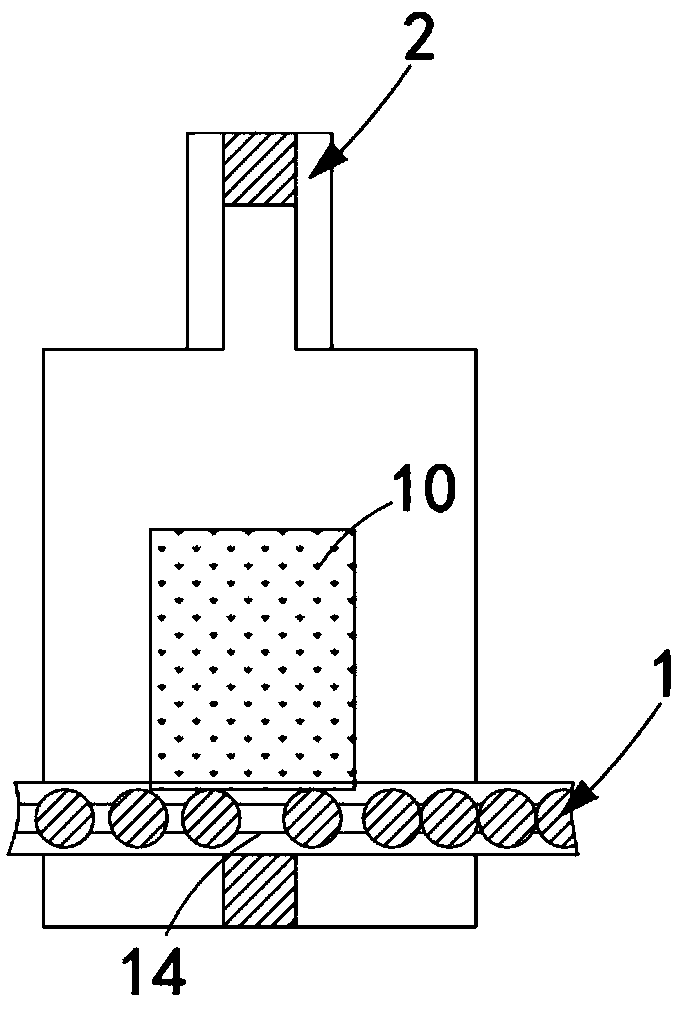

Automatic reversing side packaging method for lead-acid cell packaging box

ActiveCN109279066AQuick changeNo detachment from the packaging conveyor lineWrappingCardboardCentrifugal force

Owner:阜阳佰恩得新材料技术有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap