Packaging box and method for producing packaging box

A production method and carton technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of pulling and squeezing, loss, and lack of beauty at joints, and achieve increased firmness, extended service life, and appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

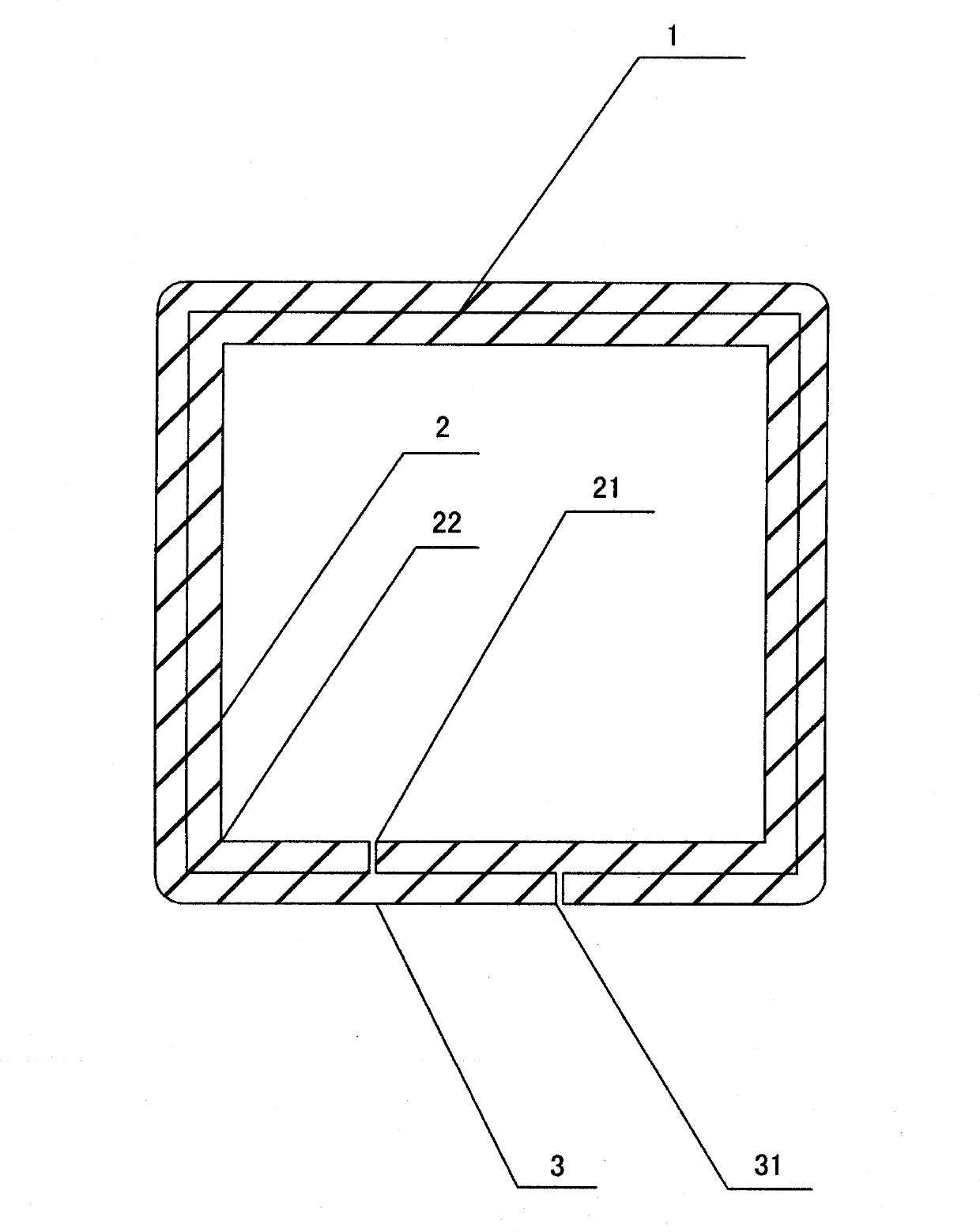

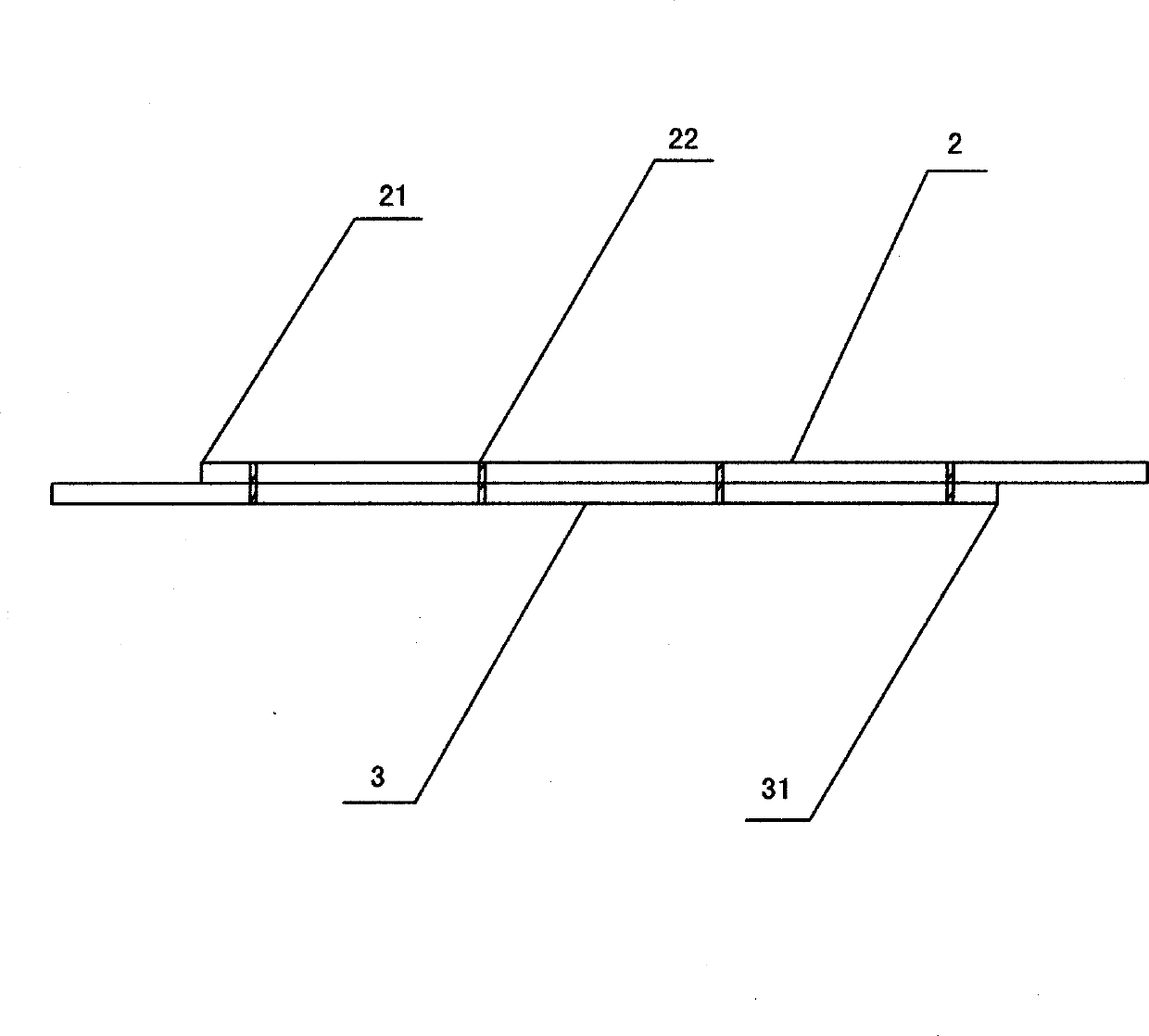

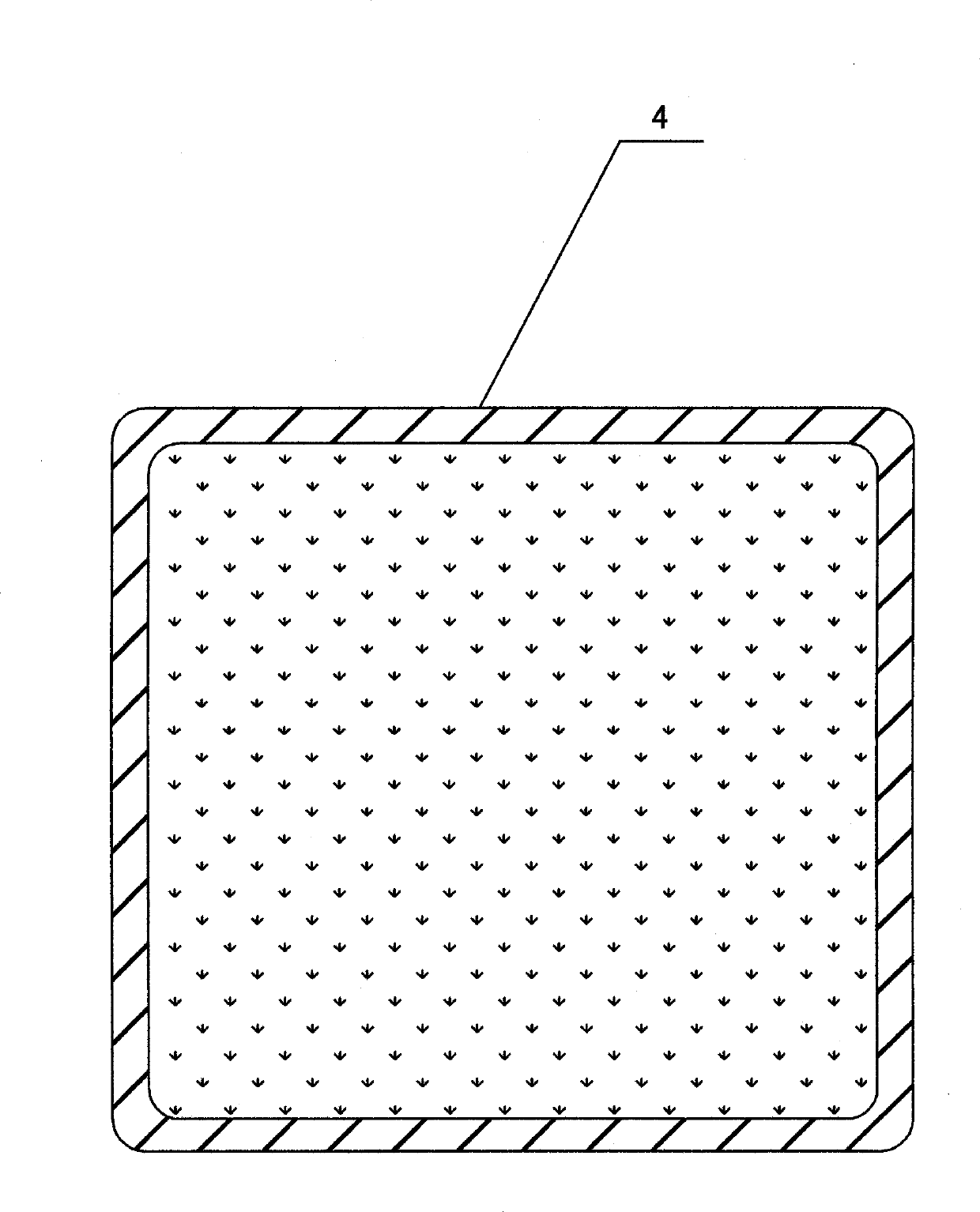

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a packing carton is characterized in that it includes a box main body 1, a top cover 4 and a bottom cover 5, the box main body 1 is composed of two rectangular cardboards with the same width bonded to each other; the top cover 4 and the The bottom cover 5 is an independent top cover 4 and an independent bottom cover 5; the two pieces of cardboard are an inner cardboard 2 and an outer cardboard 3 with interlaced joints; the two mutually bonded rectangular cardboards are provided with four indentations 22 The distance between the adjacent indentations 22 is 1 / 4 of the length of the inner cardboard 2; the two mutually bonded rectangular cardboards use vinyl acetate emulsion to bond the two inner cardboard joints 21 and Two said outer cardboard joints 31 .

[0038] The production process of a kind of packaging carton of the present invention is as follows: first calculate the area of the inner cardboard 2 an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap