Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Centrifugal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In Newtonian mechanics, the centrifugal force is an inertial force (also called a "fictitious" or "pseudo" force) that appears to act on all objects when viewed in a rotating frame of reference. It is directed away from an axis passing through the coordinate system's origin and parallel to the axis of rotation. If the axis of rotation passes through the coordinate system's origin, the centrifugal force is directed radially outwards from that axis. The concept of centrifugal force can be applied in rotating devices, such as centrifuges, centrifugal pumps, centrifugal governors, and centrifugal clutches, and in centrifugal railways, planetary orbits and banked curves, when they are analyzed in a rotating coordinate system. The term has sometimes also been used for the reactive centrifugal force that may be viewed as a reaction to a centripetal force in some circumstances.

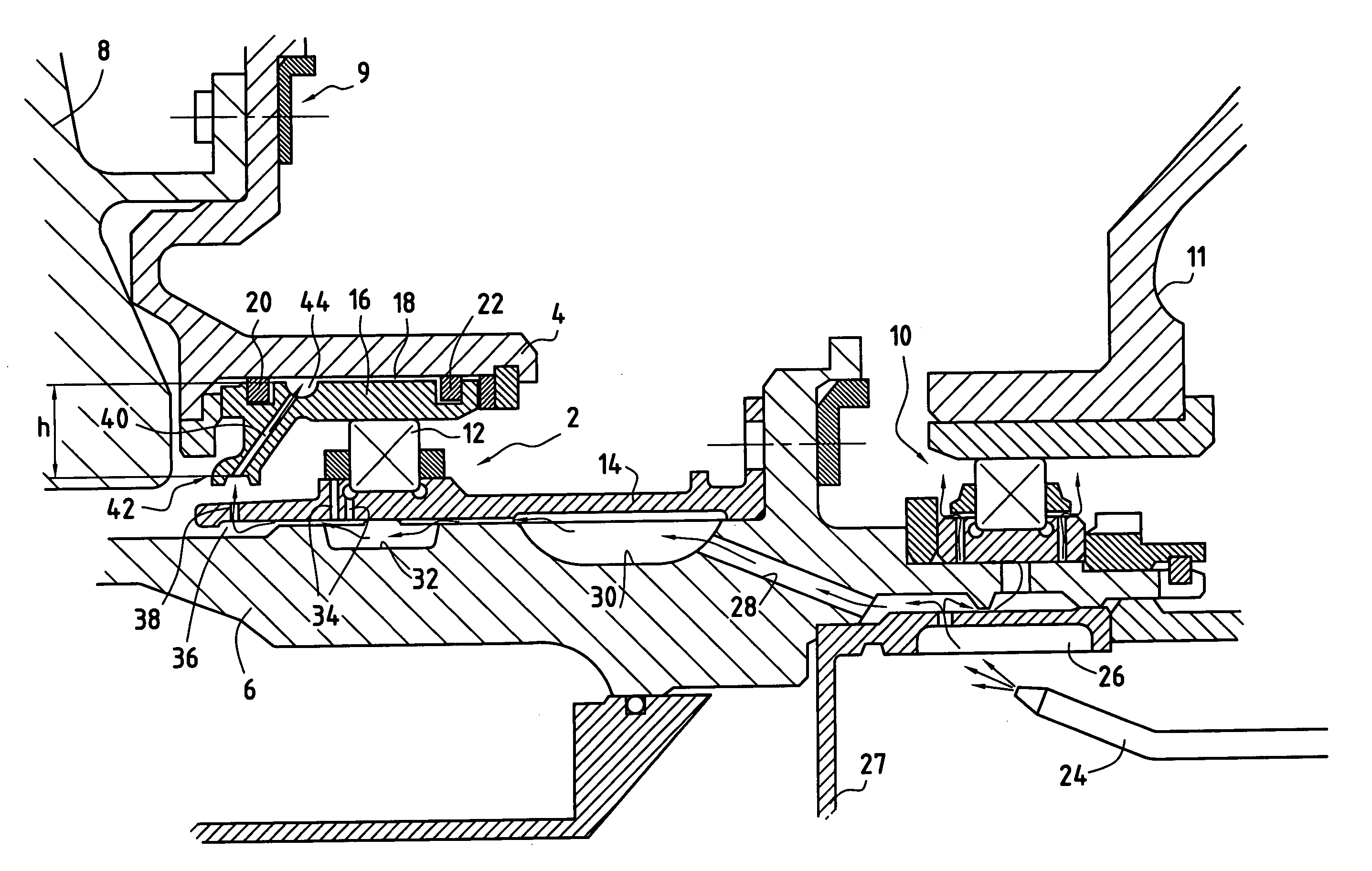

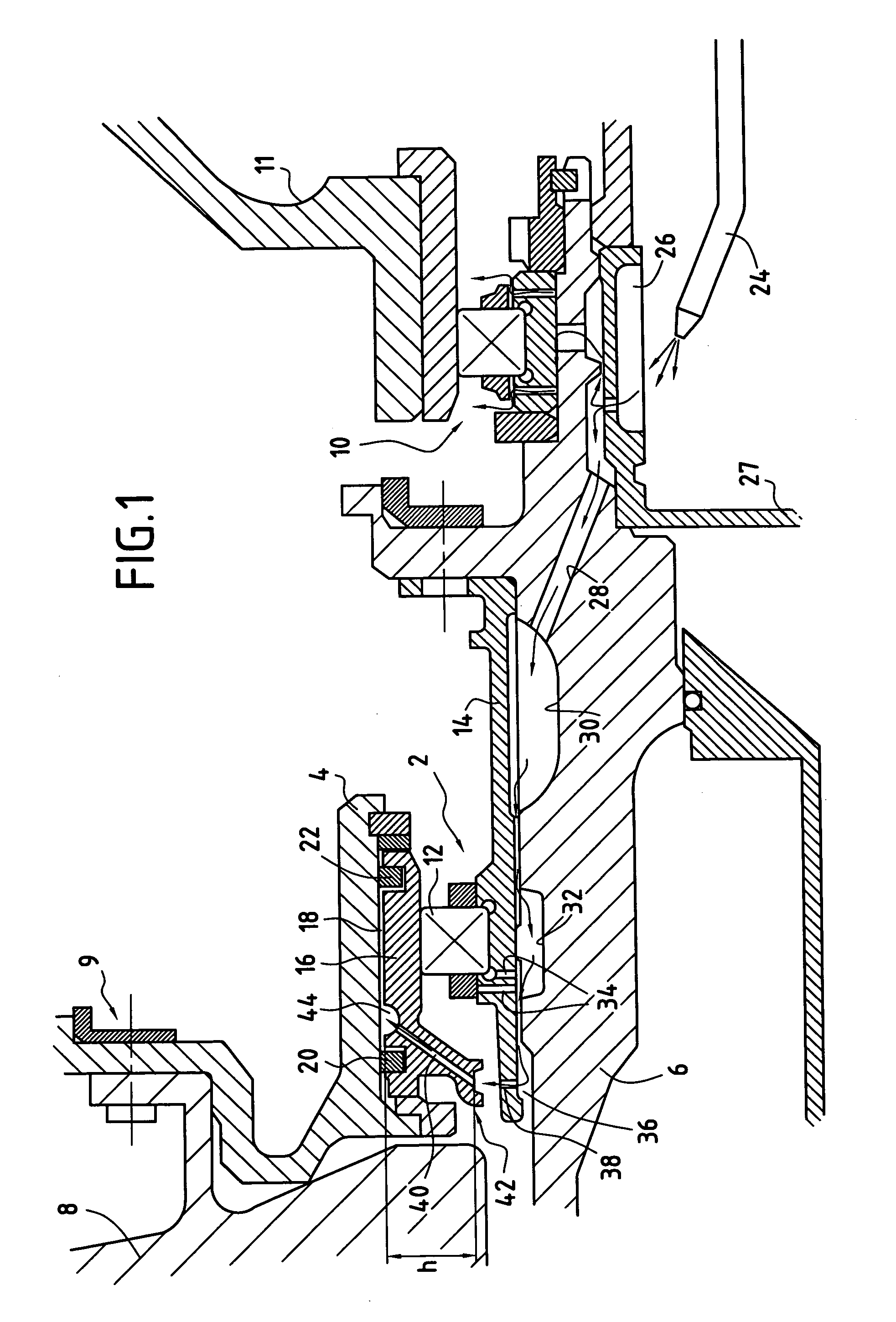

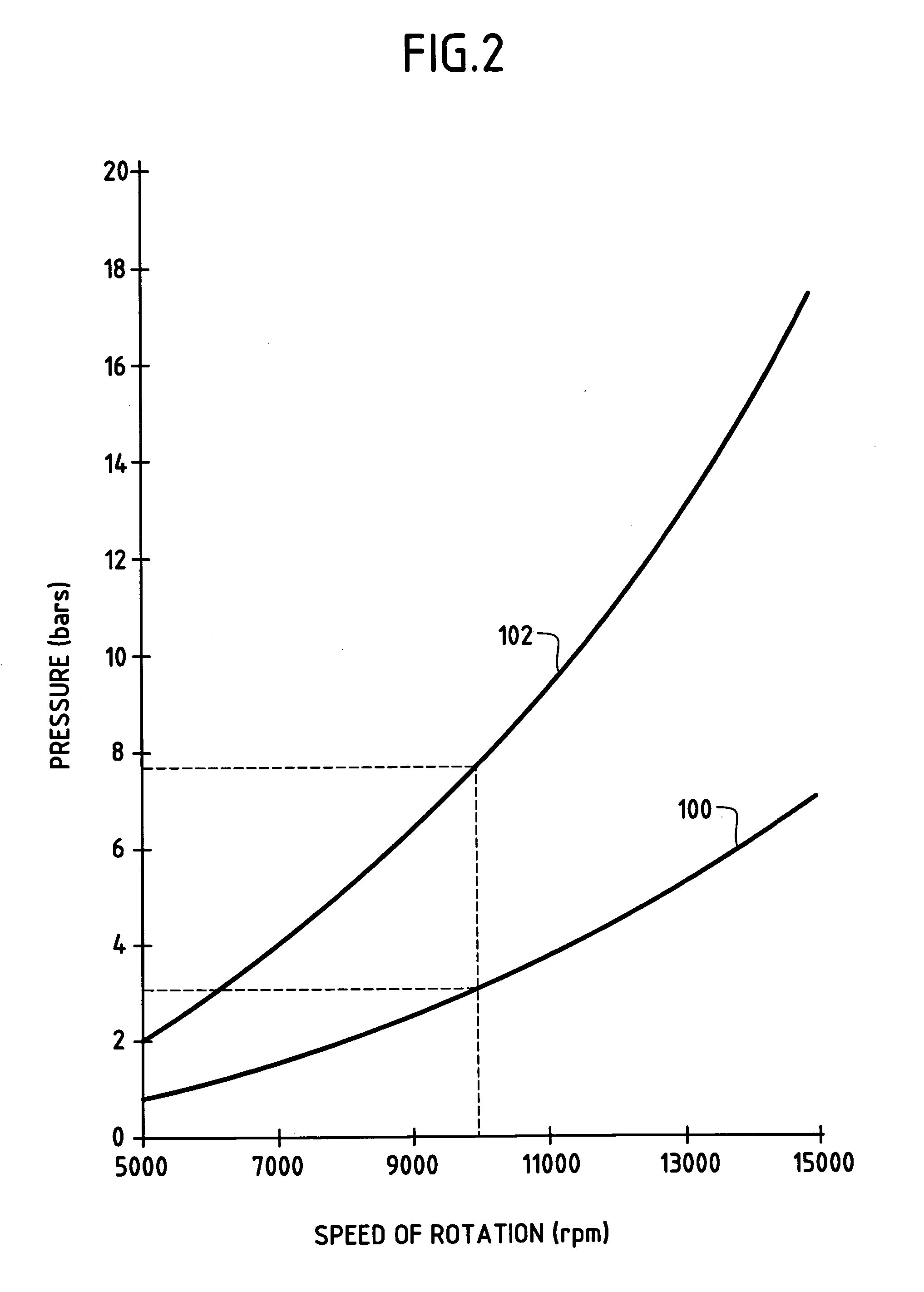

Oil-damped rolling bearing

ActiveUS20040062460A1Mitigate such drawbackRoller bearingsPump componentsRolling-element bearingEngineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

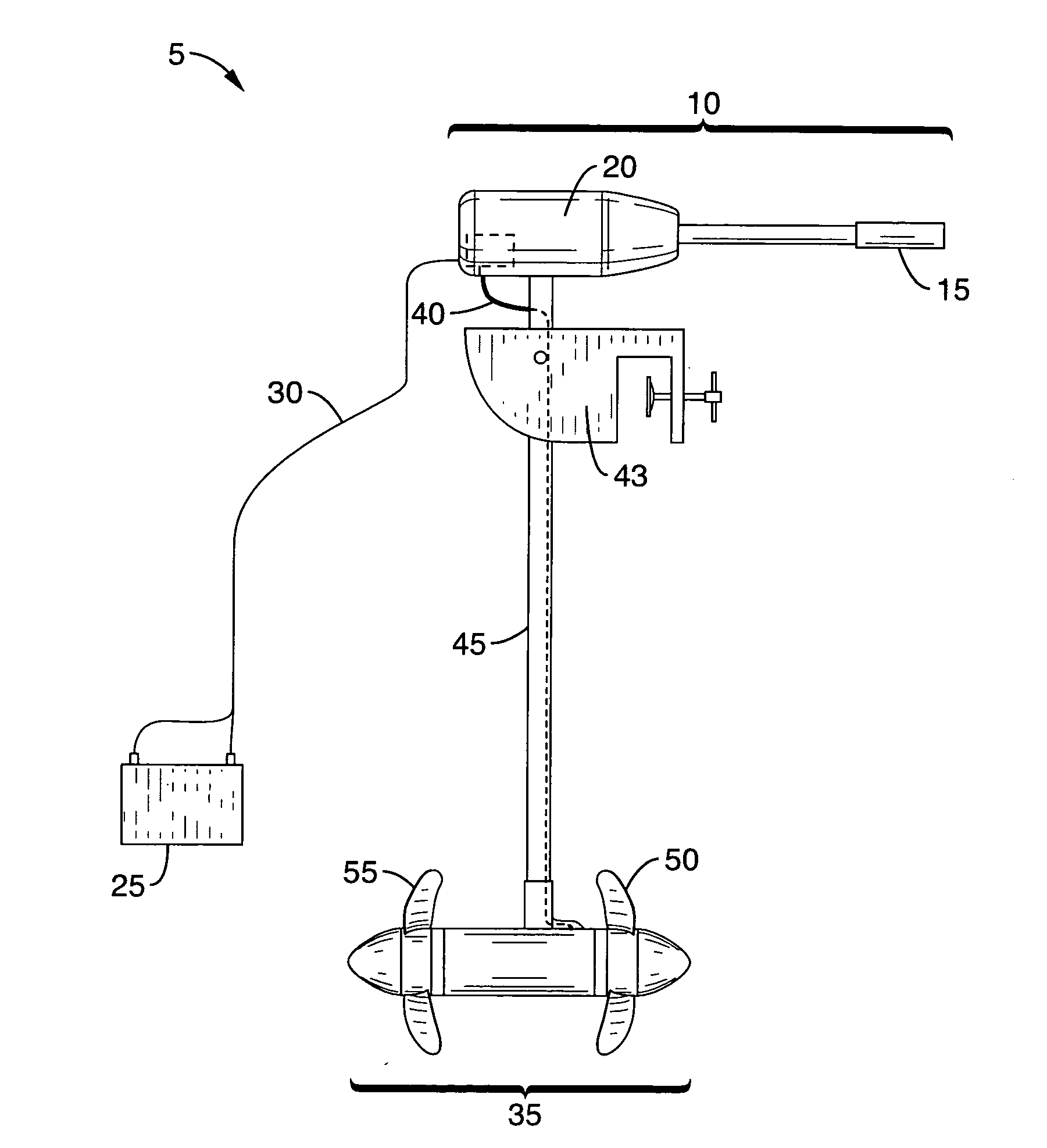

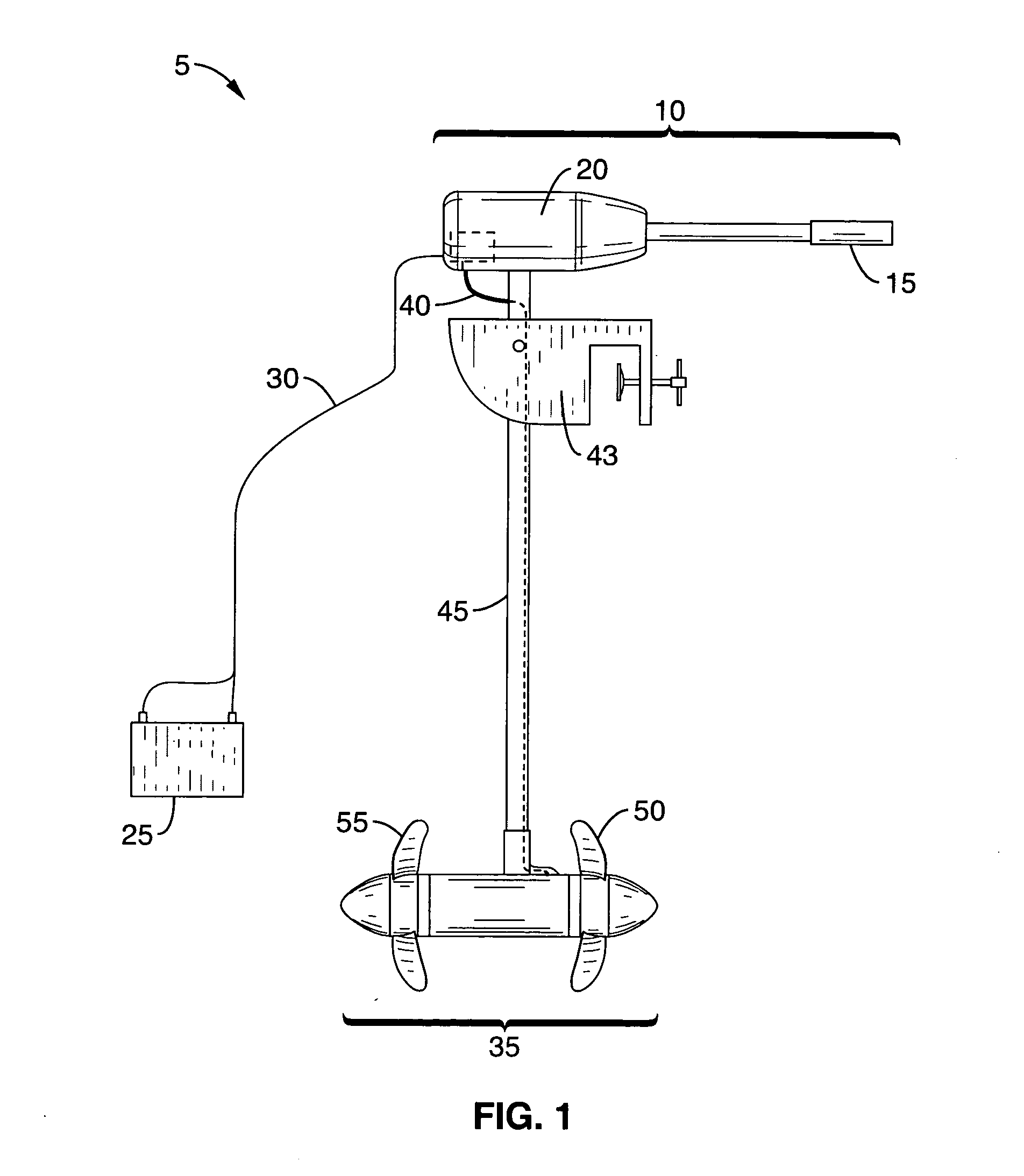

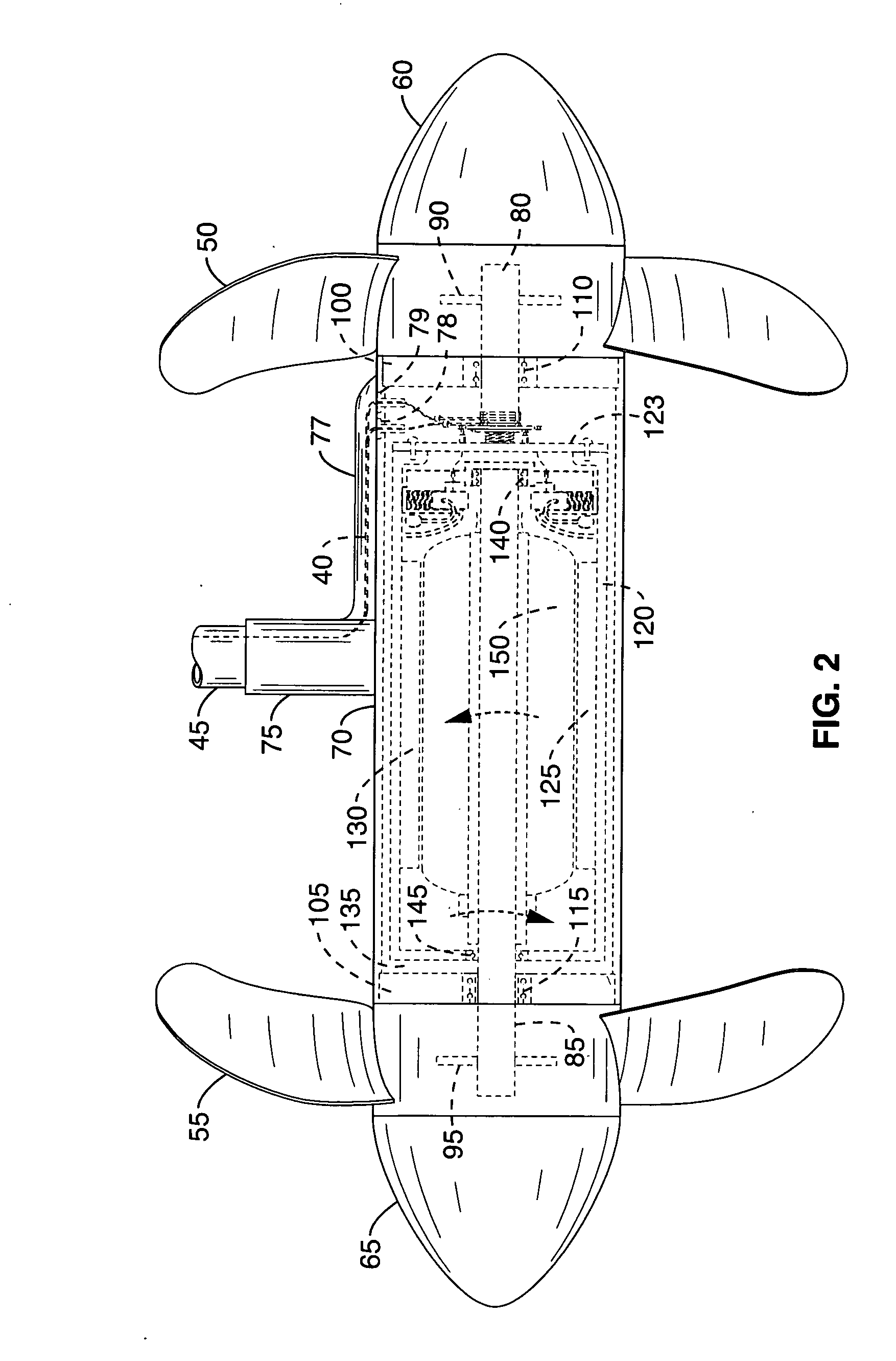

Increased efficiency counter-rotating electric motor for propelling a boat

ActiveUS20100003871A1Improve abilitiesReduce windRotary current collectorPropulsion power plantsElectricityElectrical connection

Owner:E WISH TECH

Device capable of preparing coconut juice directly in coconut shell, coconut juice machine using device and coconut juice machine use method

ActiveCN105725221AAchieve the effect of flexible scraping coconut cavityNovel structureJuice extractionPull forceDynamic balance

Owner:吕心雨

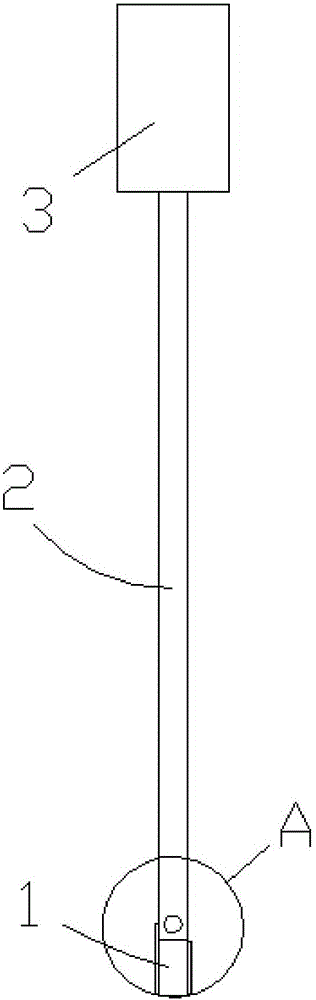

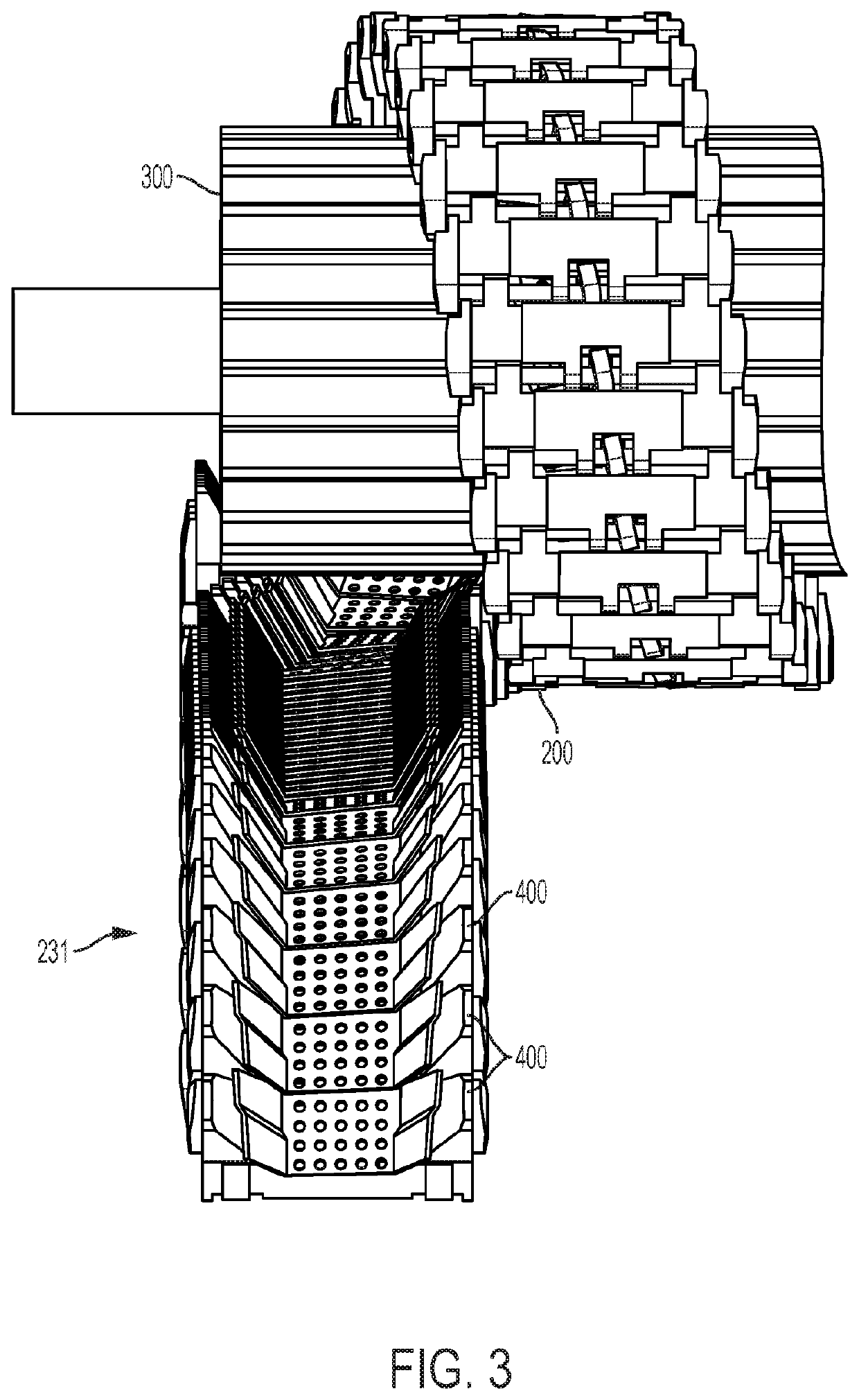

Energy Generation Method and Apparatus by the Harnessing of Centrifugal Force

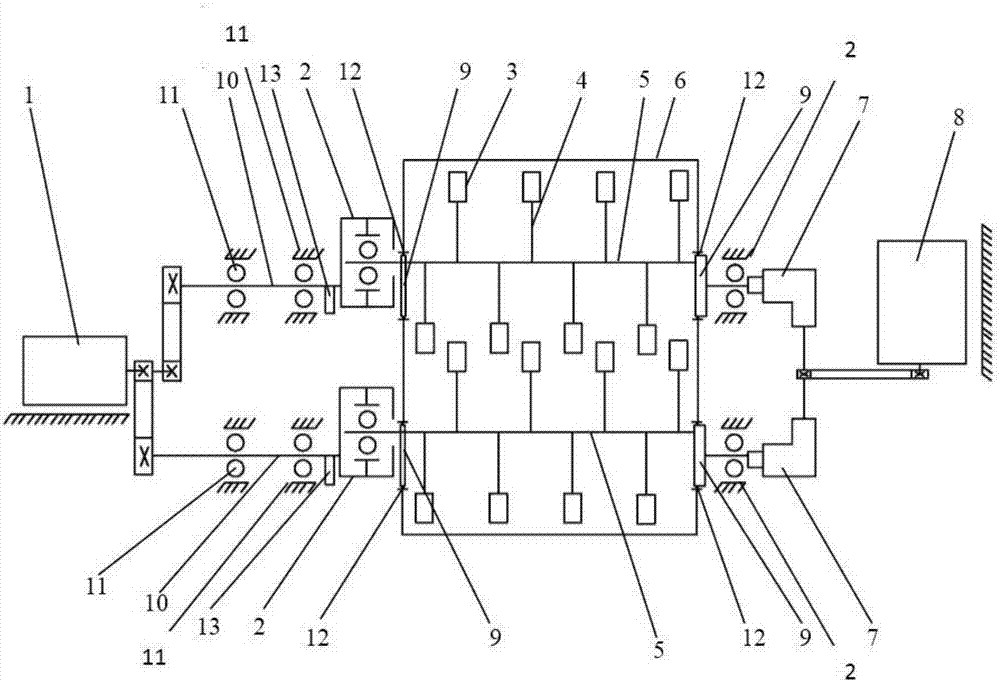

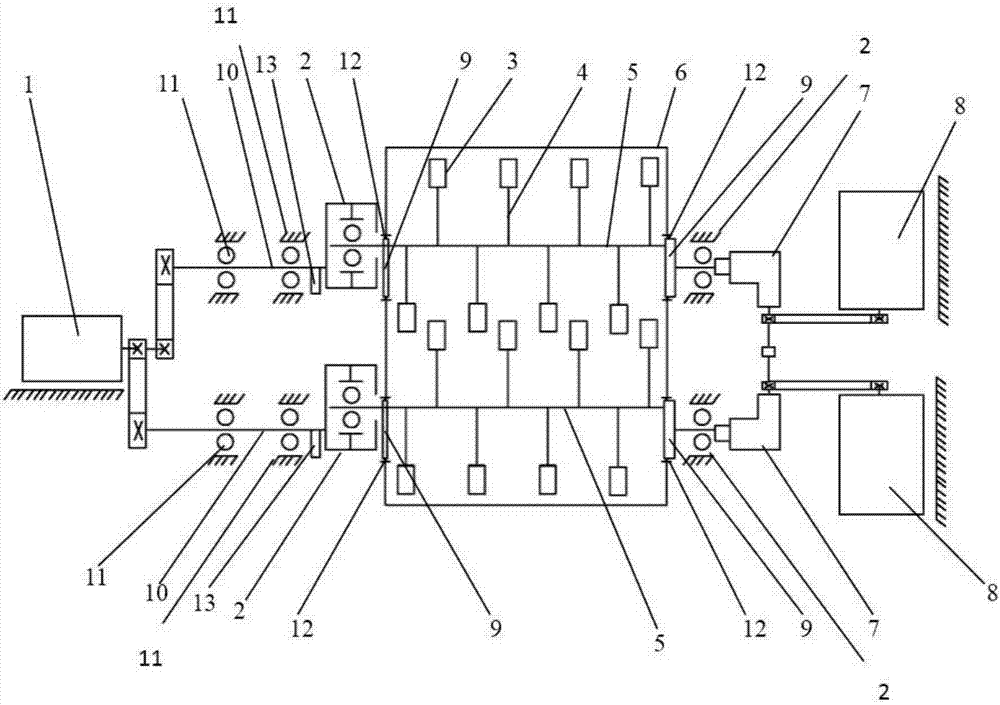

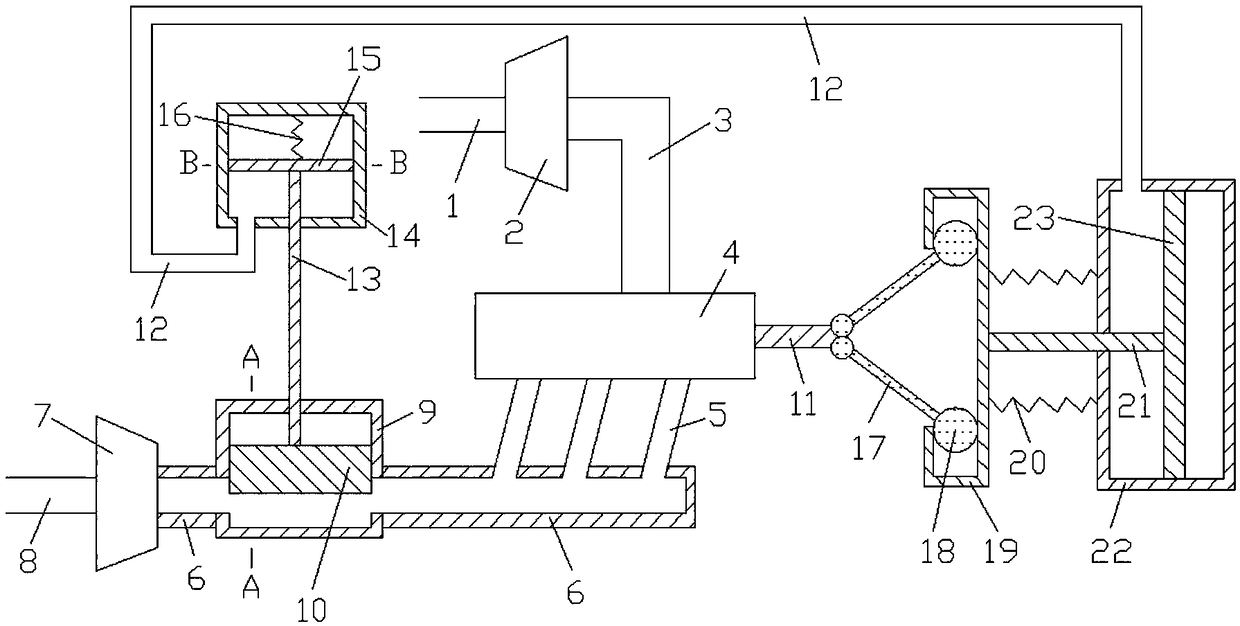

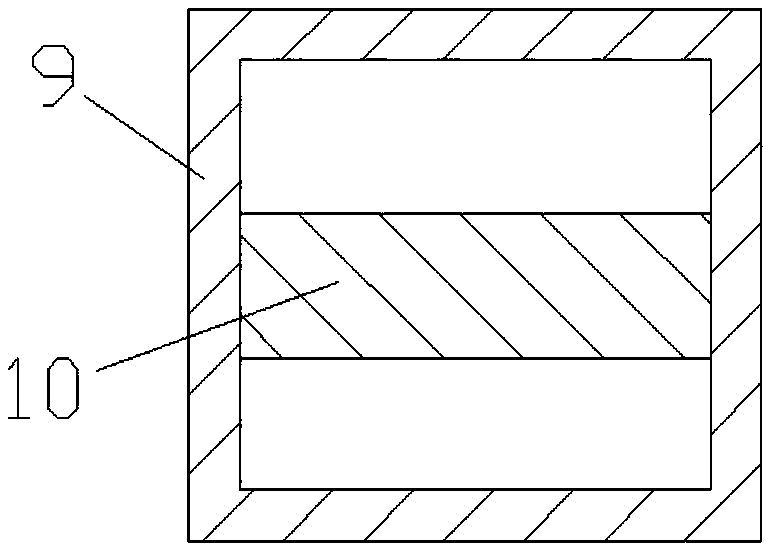

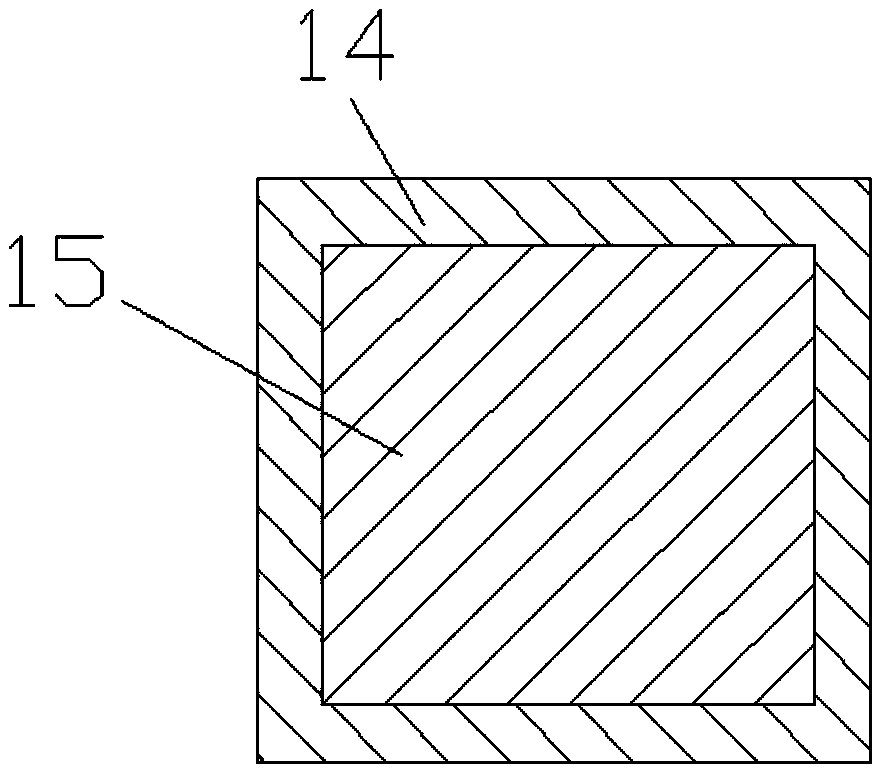

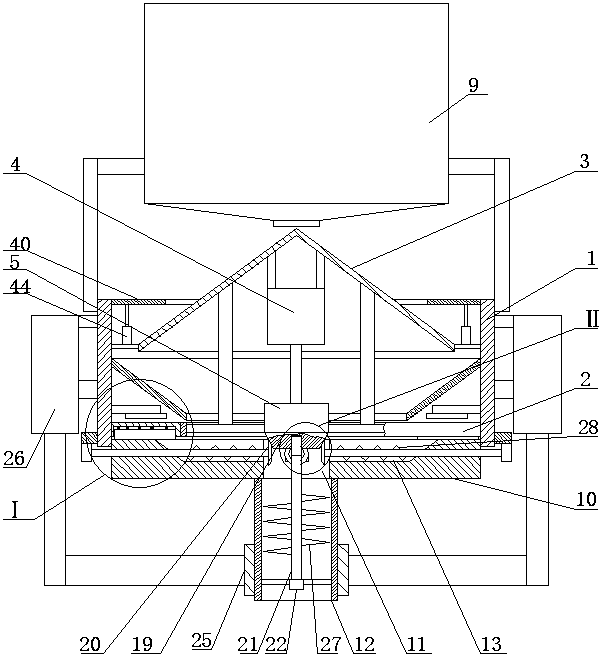

An energy generation apparatus uses centrifugal force to generate energy in a controlled manner. The apparatus includes a dual function input shaft and output shaft rotatably attached to opposite sides of a housing defining an axis of orbit, an output gear fixed upon the output shaft, an input sprocket rotatably mounted on the output shaft, and at least two frame gear assemblies, each having a frame gear and at least two weight gears. The frame gears rotate about their centres and also orbit around the output gear in response to an input from the input sprocket.

Owner:LEVINY GEOFFREY WILLIAM GOOD

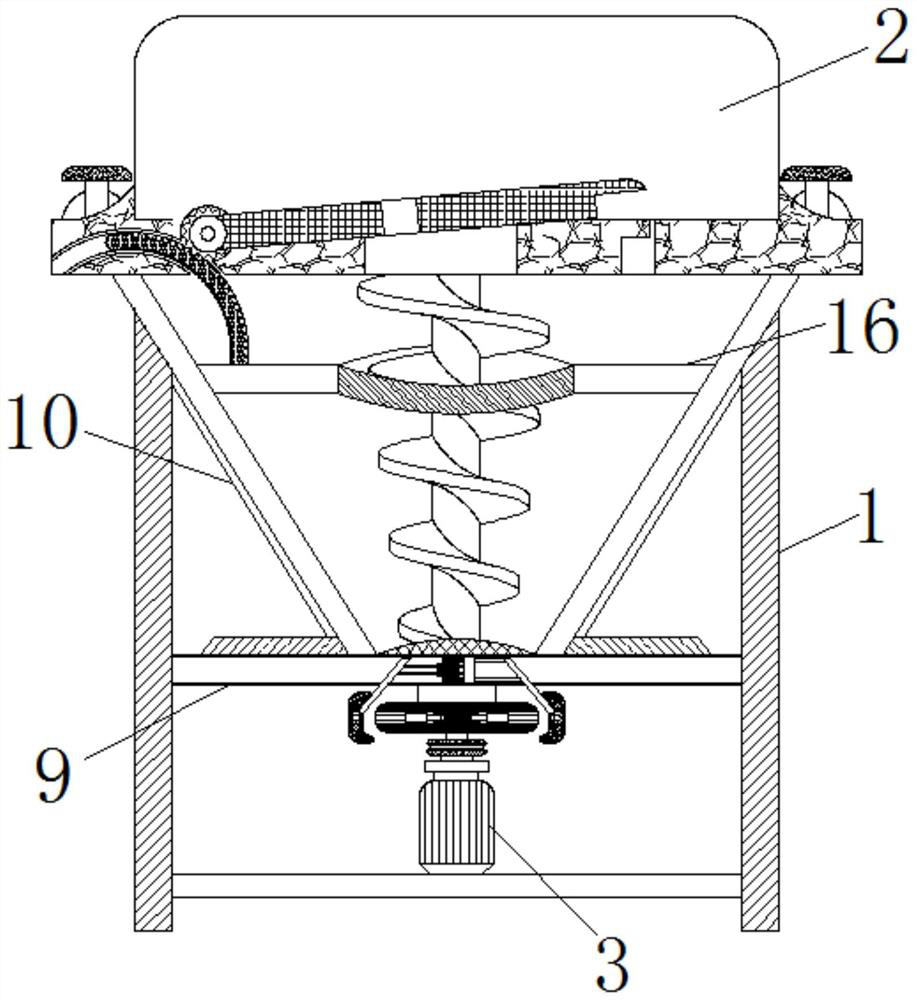

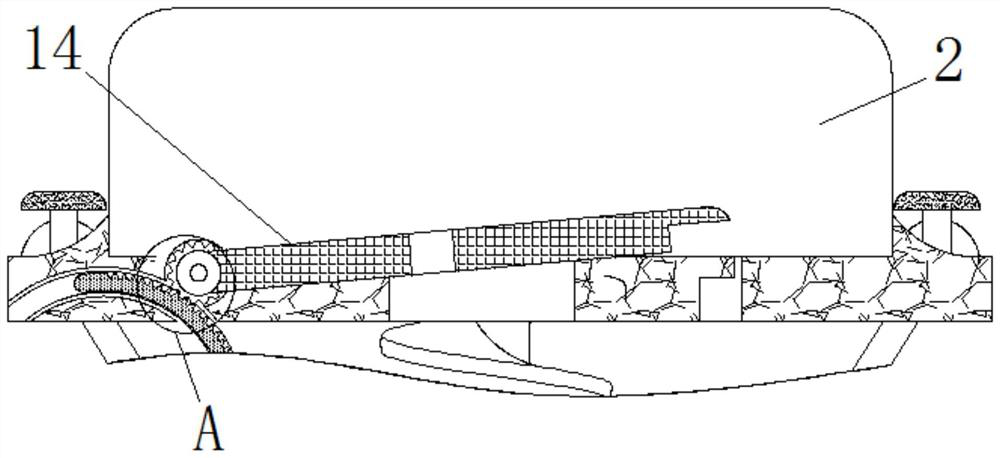

Left/right swinging type feed mixing equipment

InactiveCN107970819AImprove the mixing effectExpand the mixing rangeFeeding-stuffRotary stirring mixersEngineeringCentrifugal force

The invention discloses left / right swinging type feed mixing equipment which comprises a shell, wherein mounting bases are symmetrically and fixedly connected with the outer side wall of the shell; support columns are fixedly connected with the mounting bases; support plates are fixedly connected with top ends of the support columns; support bases are fixedly connected with the middle parts of thelower sides of the support plates; swinging columns are moveably hinged with the support bases; first motors are fixedly connected with the bottom ends of the swinging columns; first rotating shaftsare fixedly connected with output shafts of the first motors; two stirring devices are fixedly and symmetrically connected with bottom ends of the first rotating shafts; the stirring devices comprisehorizontal rods. The equipment has the beneficial effects that moving blocks on the stirring devices are moved away from the first rotating shafts because of a centrifugal force, at the same time thefirst springs are compressed, and then stirring bulges are driven by the moving blocks to change the stirring range; with the combination of pull devices and second springs, the stirring devices are swung leftwards and rightwards, so that the stirring range is effectively increased, and the feed mixing effect is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

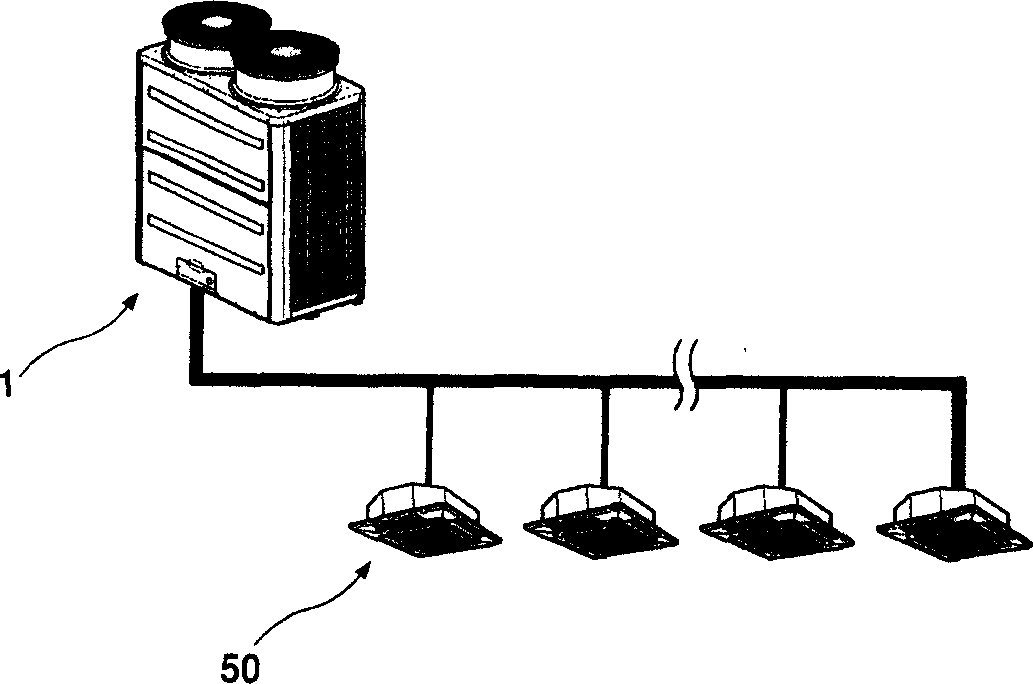

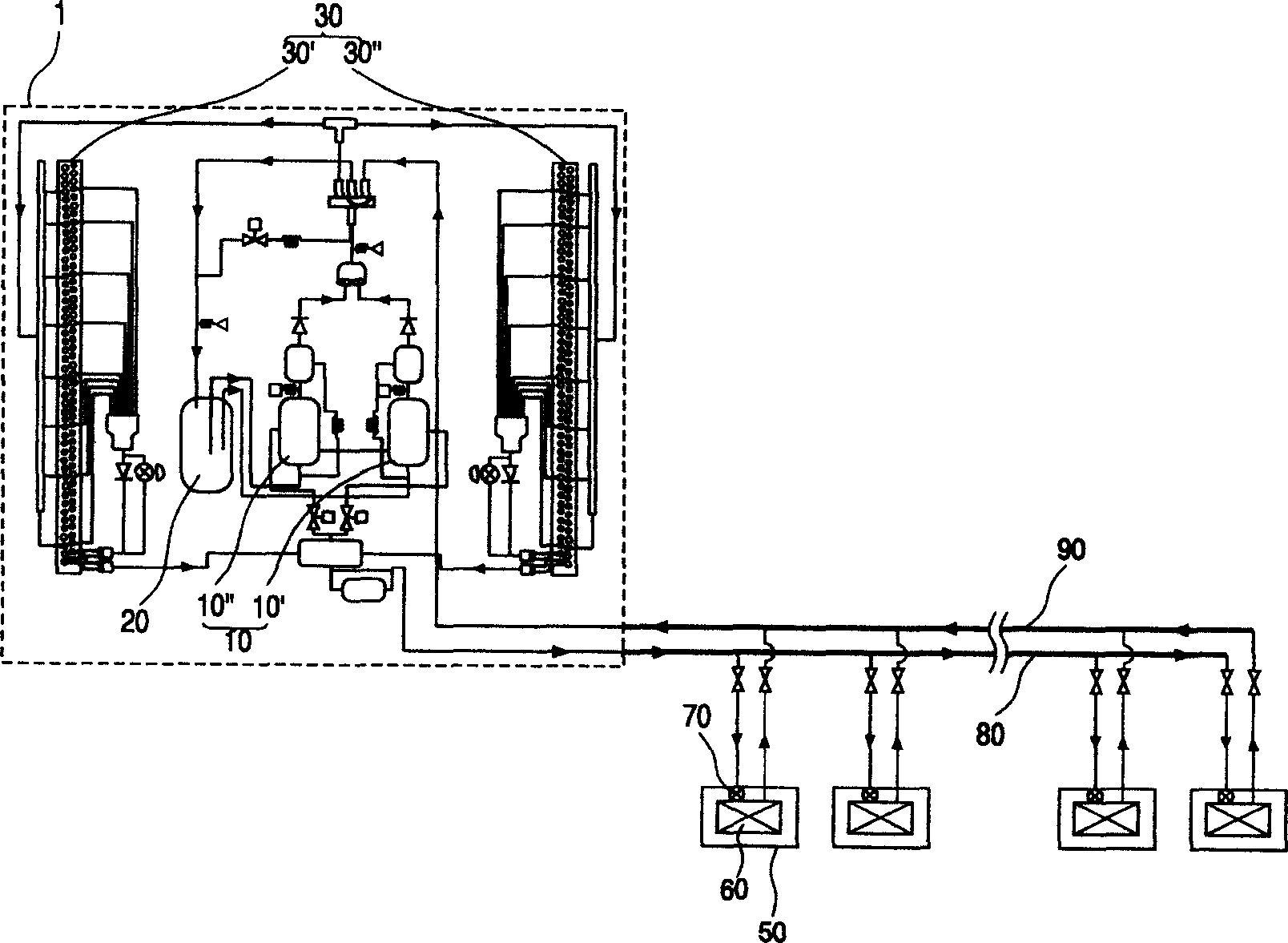

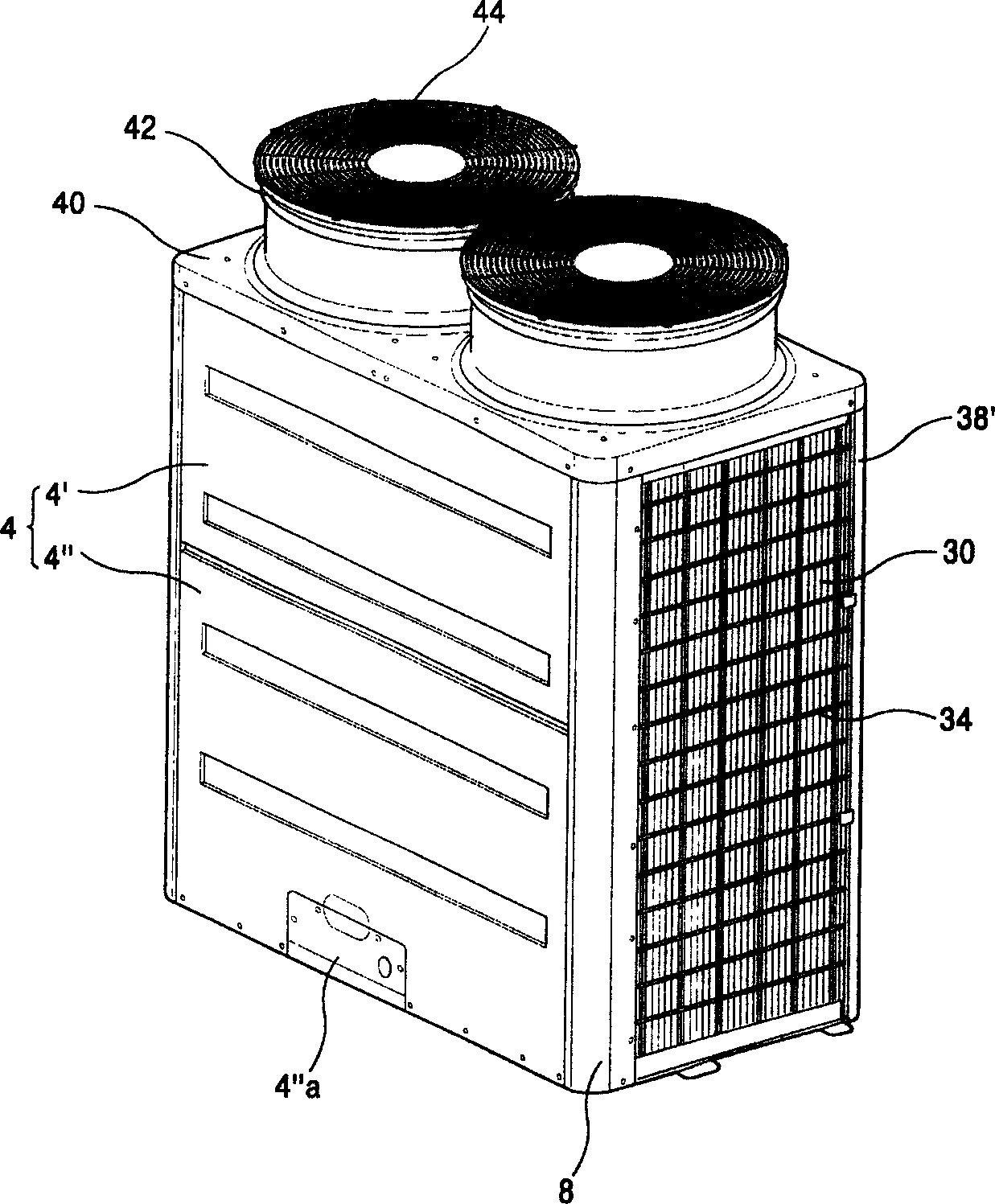

Oil distributing device for air conditioner

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

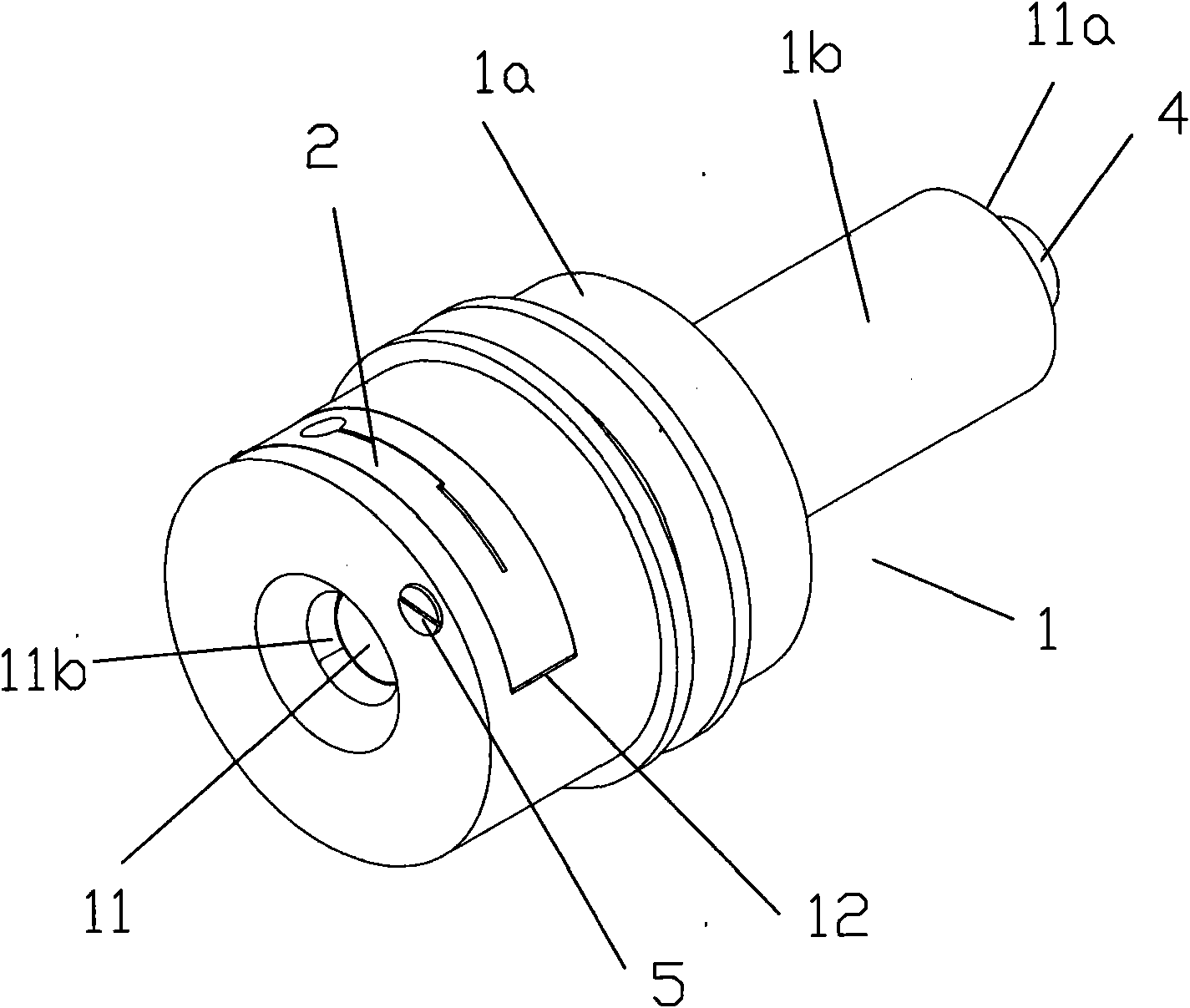

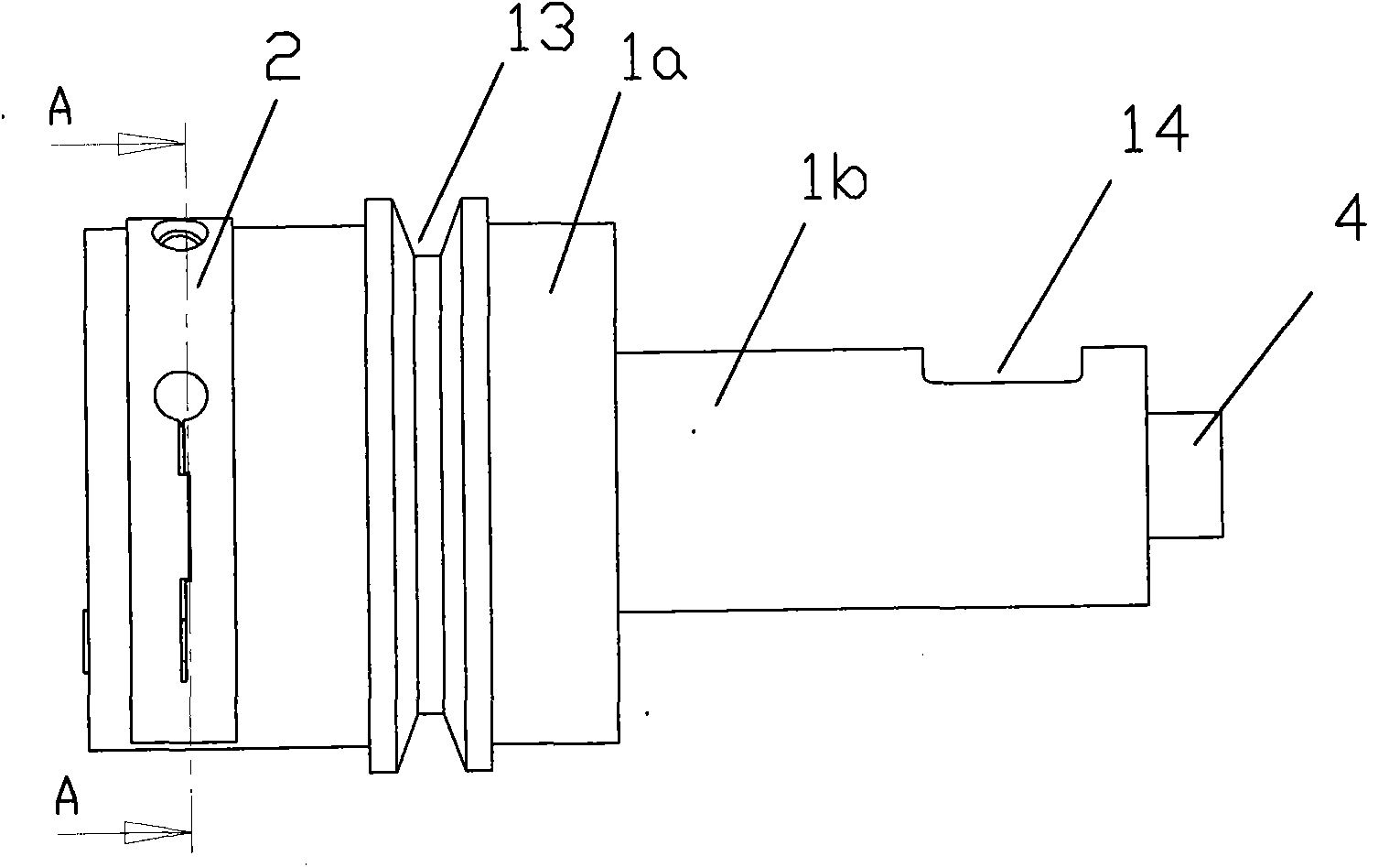

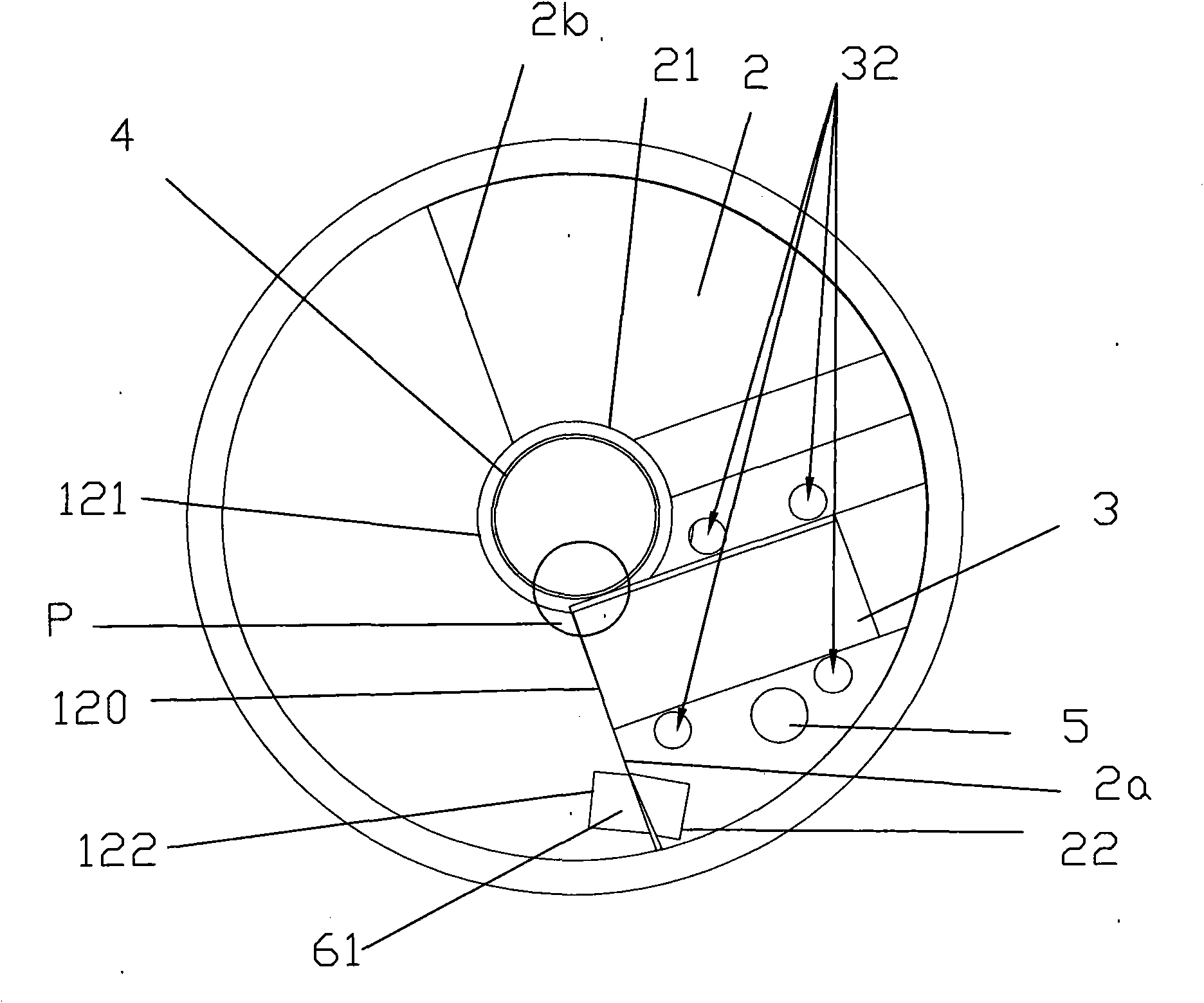

Rotary cutting tool and method for cutting pipe by same

ActiveCN102335926AOvercome resistanceOvercome frictionMetal working apparatusEngineeringCentrifugal force

Owner:AMSINO MEDICAL KUNSHAN

Drilling fluid sampler with anti-settling function for oil field

The invention relates to the technical field of oil field well drilling samplers, in particular to a drilling fluid sampler with an anti-sedimentation function for an oil field. The technical problems that deep drilling fluid cannot be sampled, silt in the drilling fluid in a water bucket can be precipitated and attached to the bottom and the wall of the water bucket after sampling, the silt is inconvenient to be completely taken out of the water bucket, and the test and detection result is influenced during test and detection are solved. Comprising a third shell interior, a sampling mechanism and an anti-settling mechanism; the sampling mechanism is fixedly connected to the upper portion in the third shell, and the anti-sedimentation mechanism is fixedly connected to the interior of the sampling mechanism. By arranging the anti-sedimentation mechanism, four reciprocating lead screws are driven by four second gears to rotate, sediment of drilling fluid in the four sampling barrels is prevented from sinking to the bottom during standing, four second sliding plates are driven by the four reciprocating lead screws to slide, and the situation that when the four sampling barrels rotate, the sediment in the drilling fluid in the four sampling barrels is blocked is avoided. Sediment in the drilling fluid in the sampling barrel adheres to the wall under the action of centrifugal force.

Owner:CHENGDU RUOKE TECH CO LTD

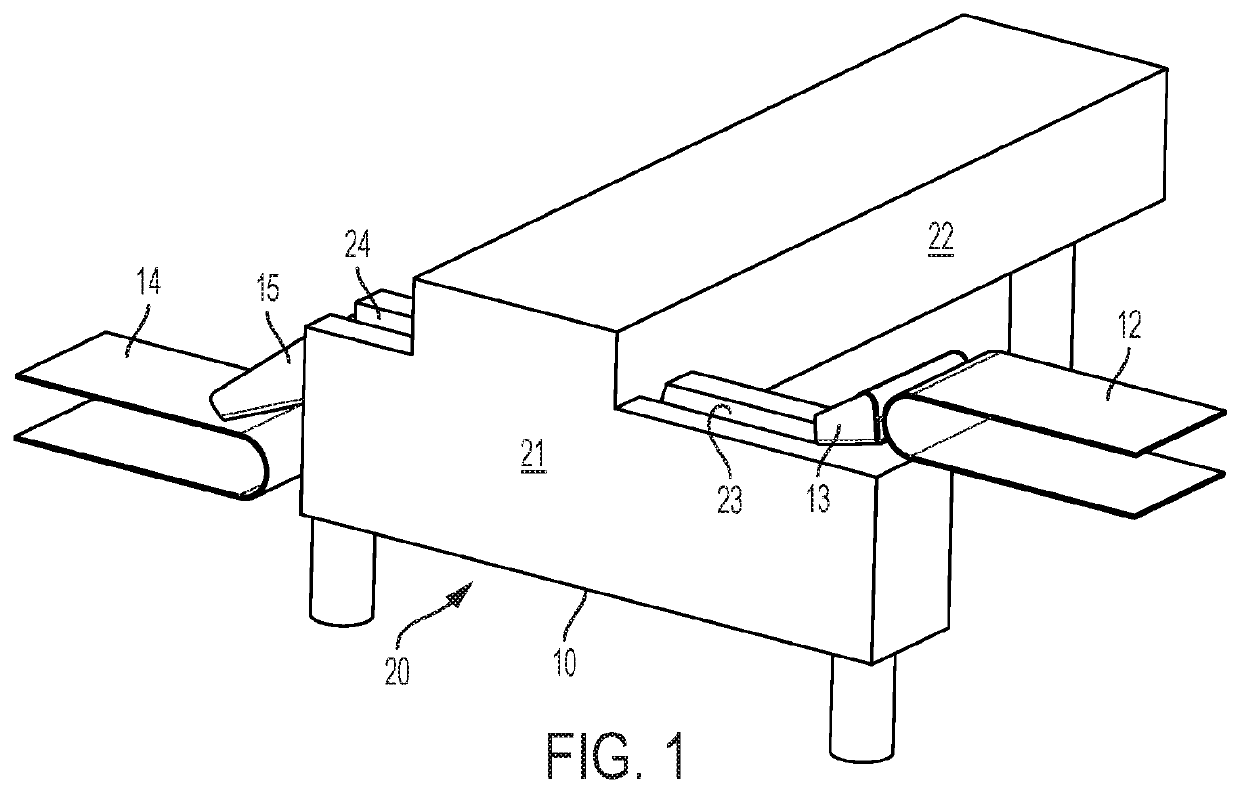

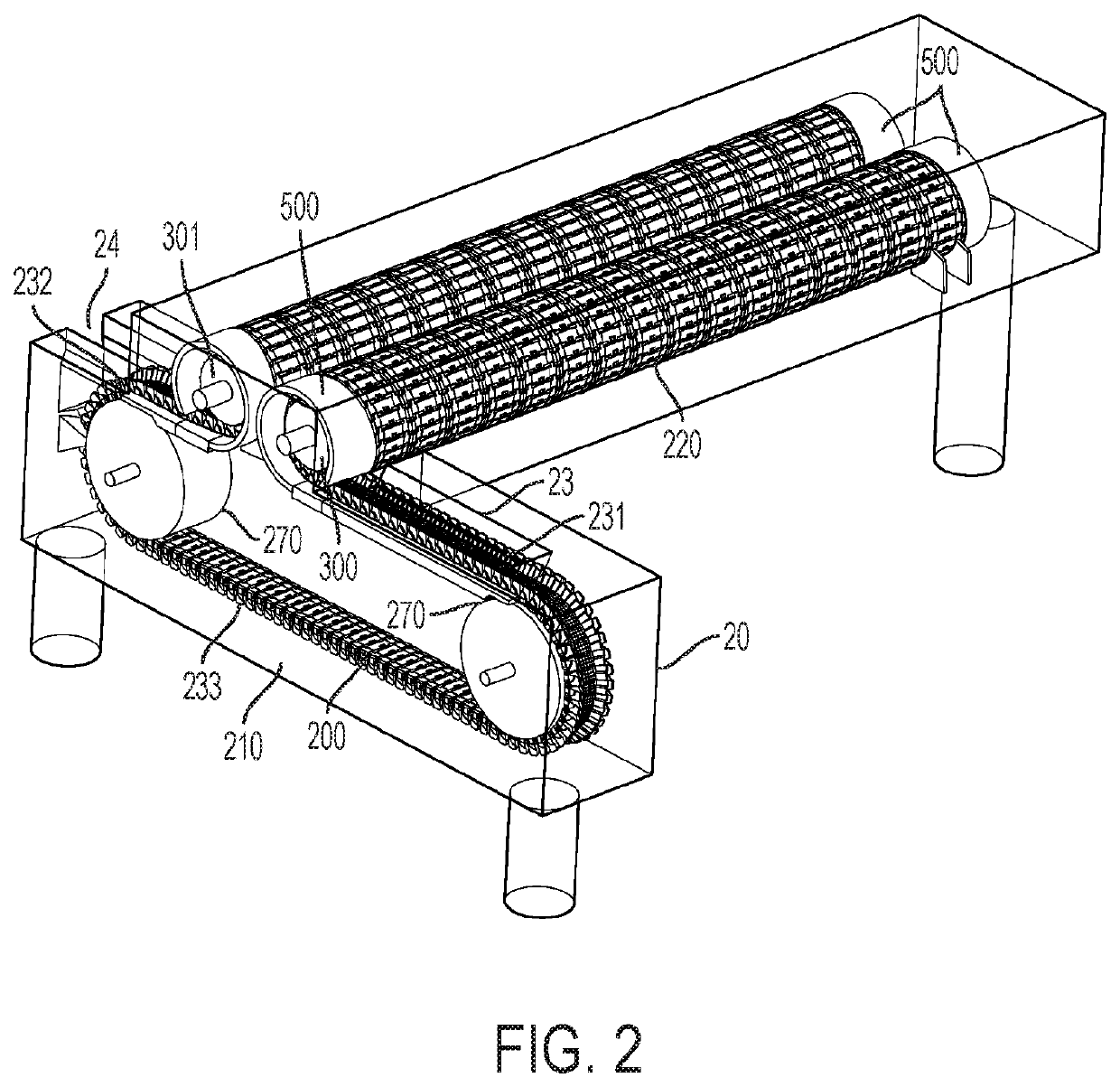

Centrifugal dewatering conveyor system

ActiveUS20200062510A1Promote formationConveyorsDrying solid materials without heatEngineeringStructural engineering

Owner:LAITRAM LLC

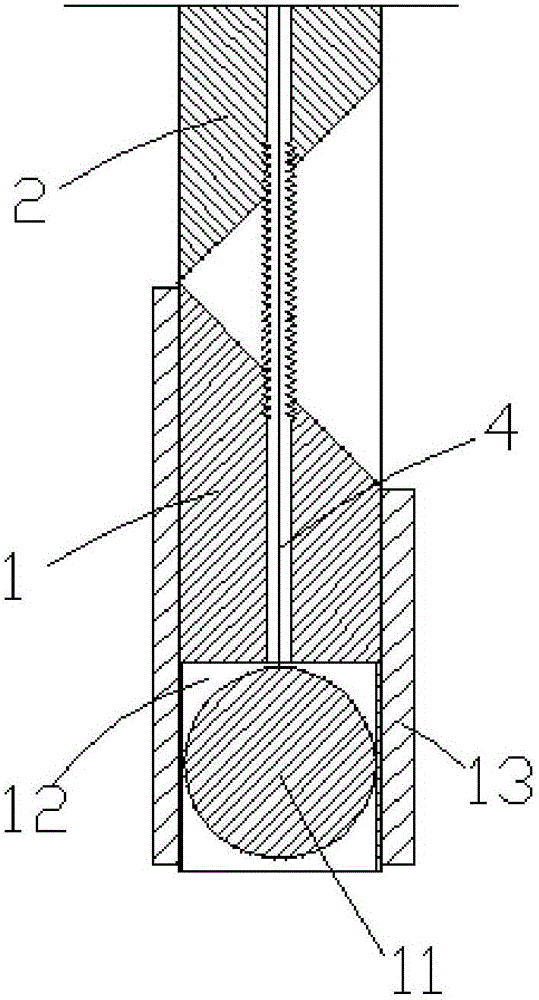

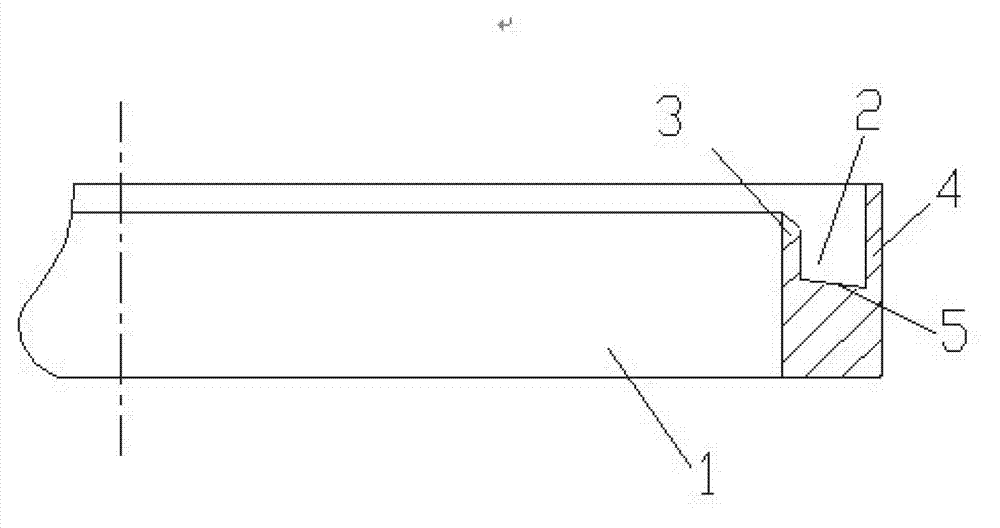

Oil scraper ring

InactiveCN102900651APrevent flying outPrevent backflowPositive displacement pump componentsPositive-displacement liquid enginesLow speedEngineering

Owner:SUZHOU WUZHONG DISTRICT DALU ELECTRIC EQUIP FACTORY

Paint spraying technology for water screen vortex roll spray room

InactiveCN104174519AImprove purification efficiencySimple structureSpray nozzlesLacquerVolumetric Mass Density

The invention discloses a paint spraying technology for a water screen vortex roll spray room. The technology comprises the following processes: a conveying fixture carrying a paint spraying product travels along a conveying track and the paint spraying product is then sprayed with paint by an automatic spray gun on one side of the conveying fixture; paint mist generated in the paint spraying process flows to a serration plate along with the air flow under the action of a suction groove; high-speed air flow and negative pressure are formed at notches of the serration plate due to the fact that the ventilation section area is suddenly decreased, so that water at the notches is atomized and the high-speed air flow passes through the serration plate and then enters a vortex roll plate; paint grains with greater density is in full contact with water under the action of centrifugal force and then collected and taken down by water; the rest of paint mist collides and in contact with atomized water repeatedly for many times in the vortex roll along with the air flow, condenses into water droplets containing paint mist and enters a circulating water pool. The paint spraying technology is good in paint mist capturing effect, and besides, the water screen vortex roll spray room is simple in structure, pipelines are less prone to blockage, and the purification efficiency is high.

Owner:CHANGXING HUARUI MACHINERY EQUIP

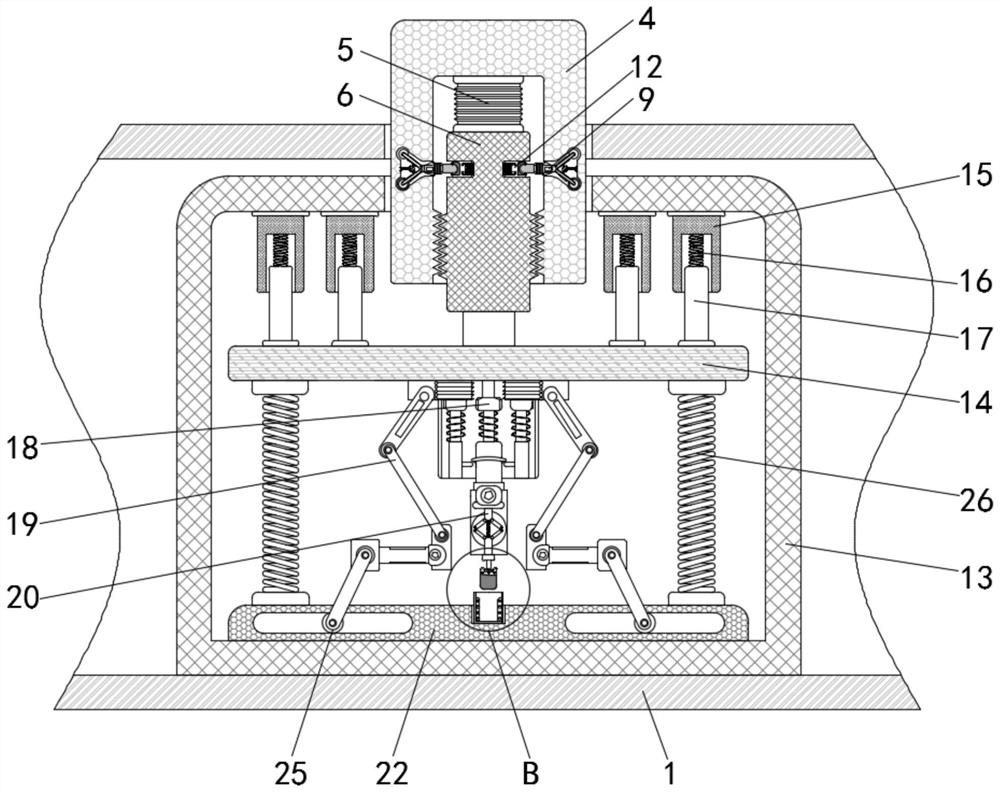

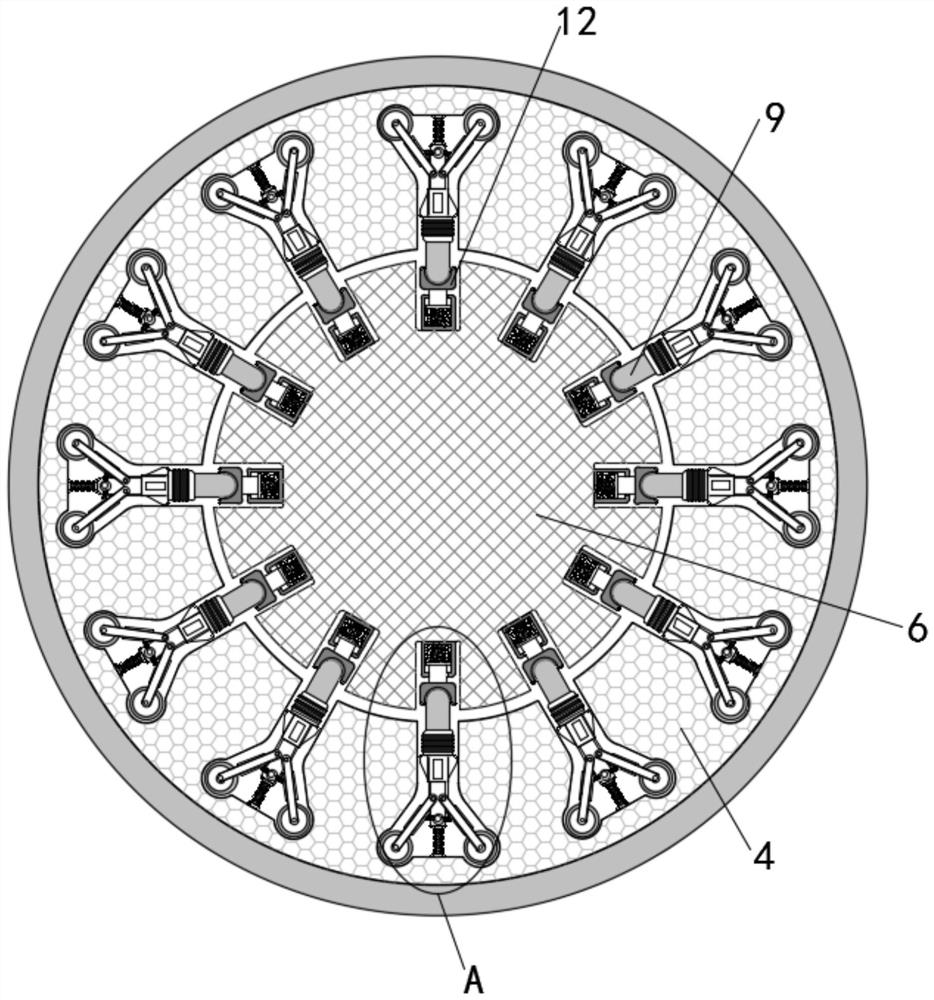

Forced vibrating stirrer with balancing block for equal amplitude vibration of stirring shaft

Owner:CHANGAN UNIV

Hydraulic regulation type turbocharging system

InactiveCN108757159AReasonable designSimple structureInternal combustion piston enginesDrive shaftControl engineering

Owner:中国人民解放军92942部队

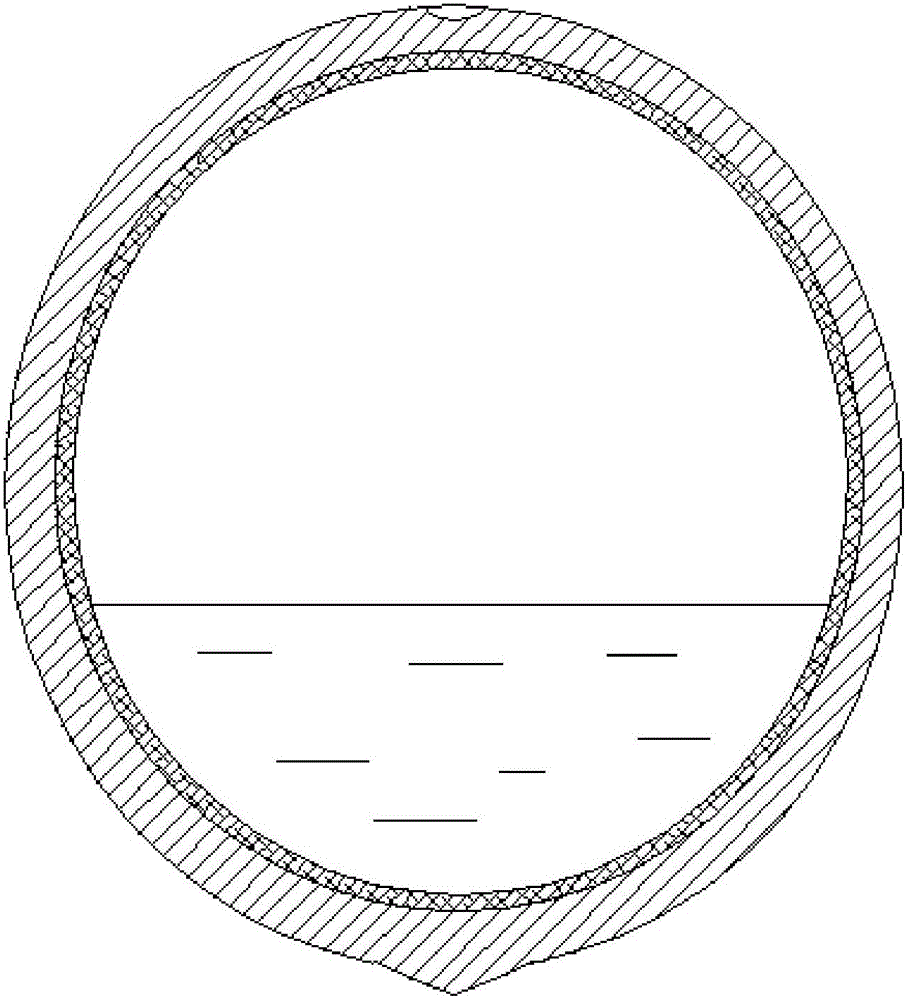

Environment-friendly inner end surface grinding device for polyethylene pipe

ActiveCN110202444AIncrease flow rateEnvironmental protectionEdge grinding machinesGrinding machine componentsEngineeringCentrifugal force

The invention provides an environment-friendly inner end surface grinding device of a polyethylene pipe. The device comprises a detachable plate, a polishing assembly and an adsorption assembly, wherein the detachable plate is movably connected below the outer end surface, the polishing assembly is arranged above the interior of the outer end surface, and the adsorption assembly is arranged in themiddle of the interior of the outer end surface. According to the grinding device, a set of first supporting shaft and a set of second supporting shaft are correspondingly arranged on each grinding roller, meanwhile, the outer surfaces of the grinding rollers are uniformly provided with flow guide grooves in a embedding mode, the tail ends of the flow guide grooves are aligned with inclined surface grooves, the tail ends of the flow guide grooves are aligned with the inclined surface grooves, when the flow guide grooves rotate along with the grinding rollers, the gas is driven by the centrifugal force generated by rotation of the grinding rollers to move along the flow guide grooves, and is matched with the inclined surface grooves to enable the flow rate of the gas being larger, furthermore the pipe residue polished by the grinding rollers is moved to the inside of the device, the same non-conductive pipe debris can be further adsorbed, so that the device is more environment-friendlywhen being used.

Owner:SUZHOU LINGYU PLASTIC PIPE TECH CO LTD

Multifunctional livestock raising smashing equipment capable of preventing fodder from caking

InactiveCN111545279AIncrease speedQuick grindingFeeding-stuffGrain treatmentsAgricultural scienceCrop livestock

Owner:TARIM UNIV

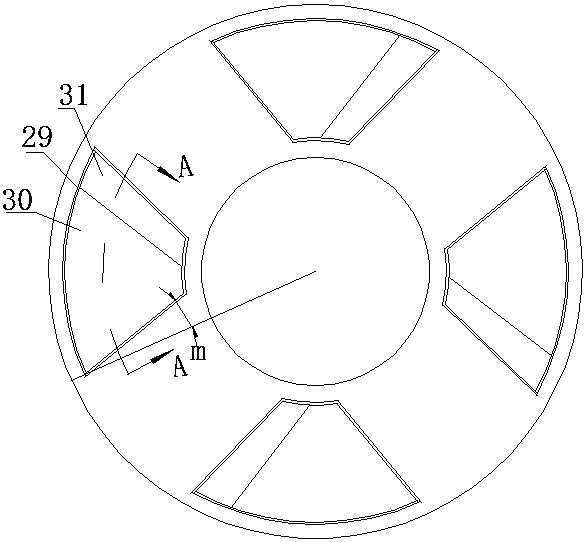

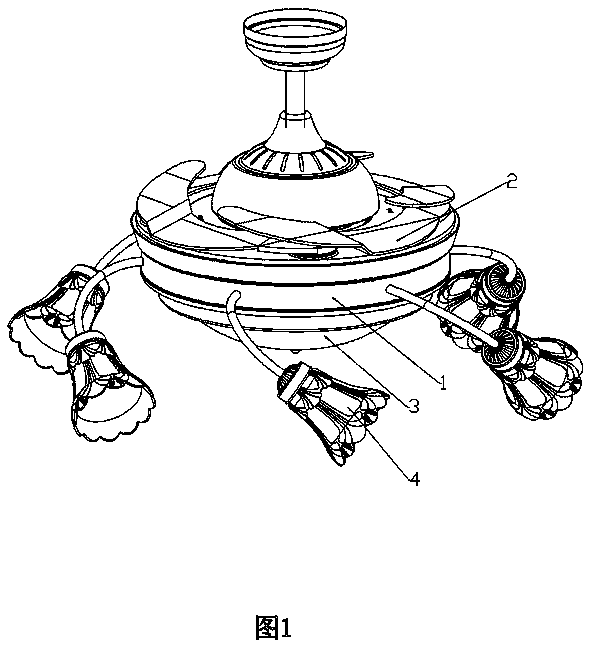

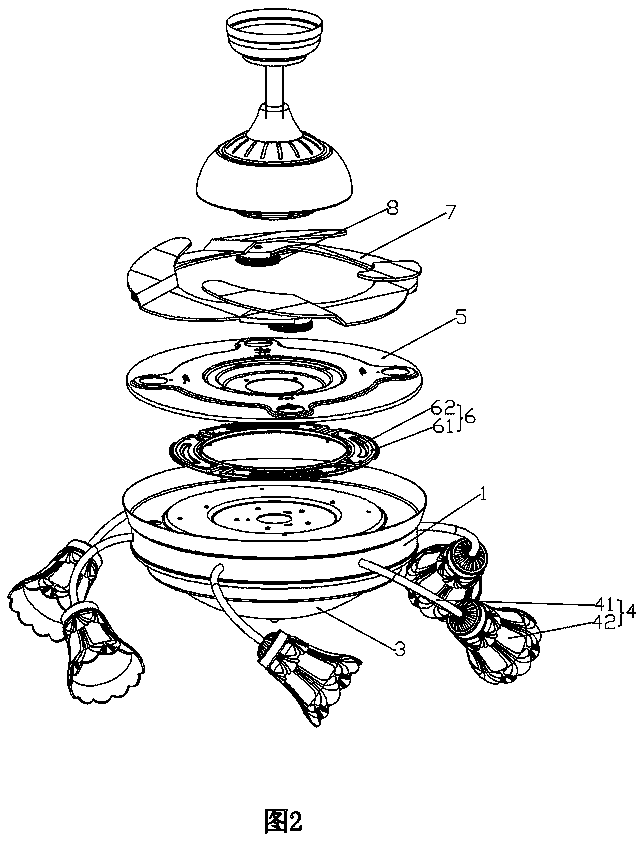

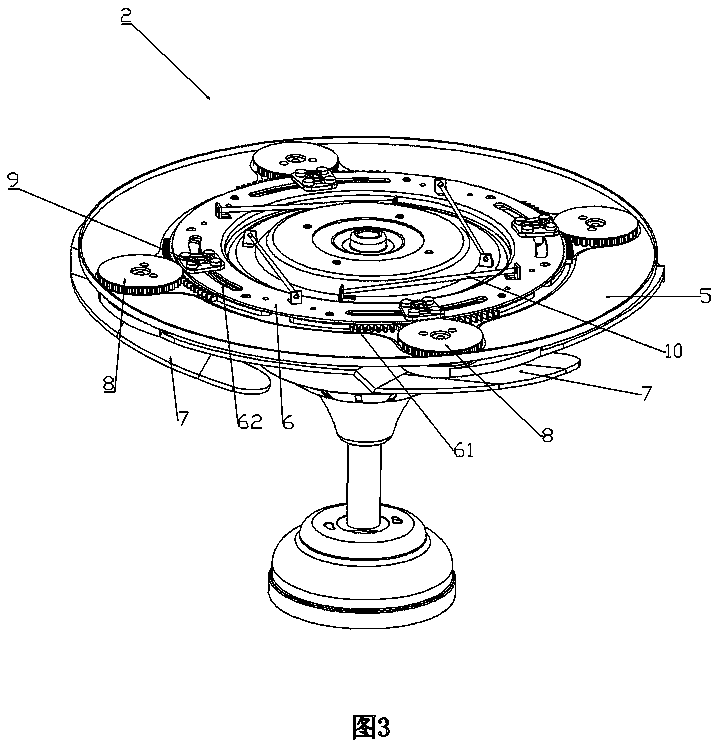

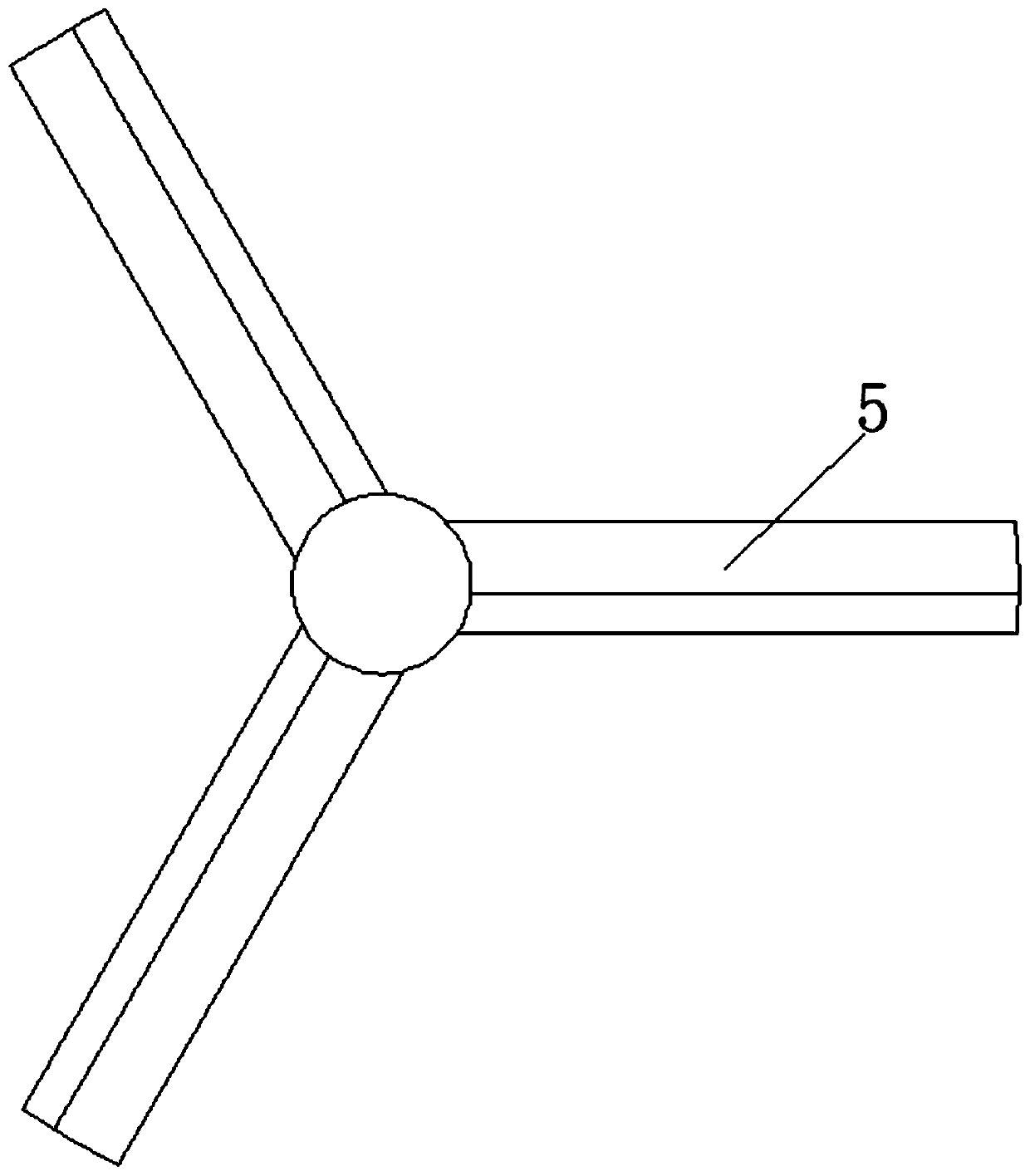

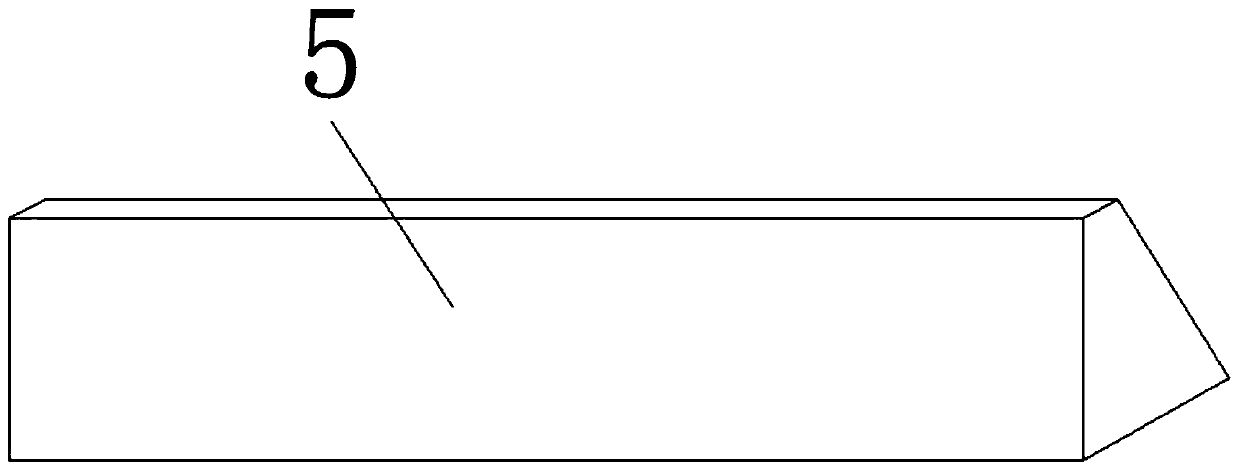

Fan lamp

PendingCN109812745AExtended lighting rangeWon't hurtPump componentsLighting support devicesEngineeringFan blade

Owner:ZHONGSHAN FENGMEI LIGHTING TECH CO LTD

Flue gas catalytic desulfurization solid-liquid separation system

InactiveCN111195448AAutomatically adjust the spin speedMoving filtering element filtersThermodynamicsFlue gas

Owner:海积(北京)科技有限公司 +1

Tail driving device for centralized collection of particulate matter

InactiveCN112551133APlay a telescopic propulsionPrevent large thrustConveyor partsParticulatesEngineering

Owner:王佳平

Biopesticide compounding and mixing device

InactiveCN113694760AFully proportionedRaise the ratioRotary stirring mixersMixer accessoriesAnimal scienceMedicine

The invention relates to a biopesticide compounding and mixing device, which structurally comprises a compounding cylinder, an auxiliary rotary table, a supporting frame and a driving motor, the two ends of the compounding cylinder are connected with the interior of the supporting frame in a welded mode, the right side of the supporting frame and the driving motor are integrally fixed through bolts, the left end of the driving motor is movably matched with the interior of the auxiliary rotary table, and the auxiliary rotary table is integrally connected with the left end of the supporting frame in an embedded mode. The compounding cylinder comprises a stirring disc, a barrel body, a feeding pipe and a pesticide discharging pipe, the mixing barrel is driven by the driving shaft, so that a wall scraping piece at the top of the mixing barrel scrapes powder adhering to the barrel wall under the jacking action of a counterweight column, the powder is mixed with biopesticide liquid, the powder soaked in the liquid and solidified into blocks expands the external expansion stirring blades under the centrifugal force of the crushing blocks, and the solidified powder with different sizes in the liquid is crushed, so that the dosage ratio of the biopesticide in the compounding process is effectively complete, the dosage ratio degree of the biopesticide is improved in a disguised manner, the drug property is indirectly improved, and compounding and mixing with stable drug property are ensured.

Owner:JIANGXI NEW DRAGON BIOTECH

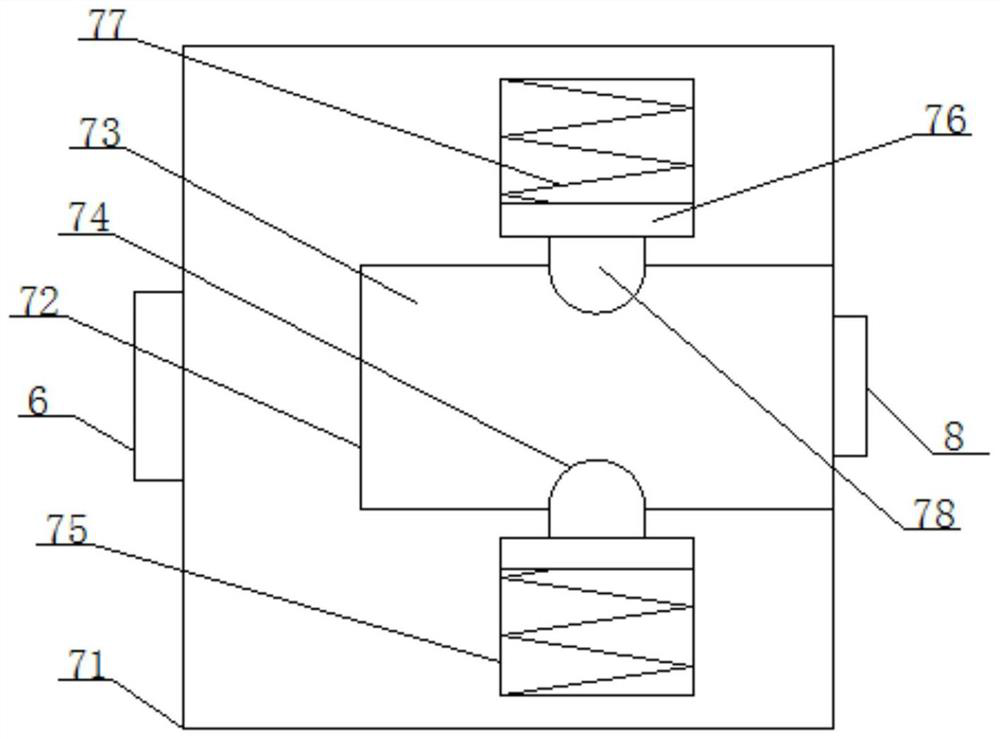

Building lime stirring device for controlling water adding amount based on centrifugal force

InactiveCN112140338AReduce powerReduce the facing areaCement mixing apparatusLiquid ingredients supply apparatusCapacitanceWater leakage

Owner:包金凤

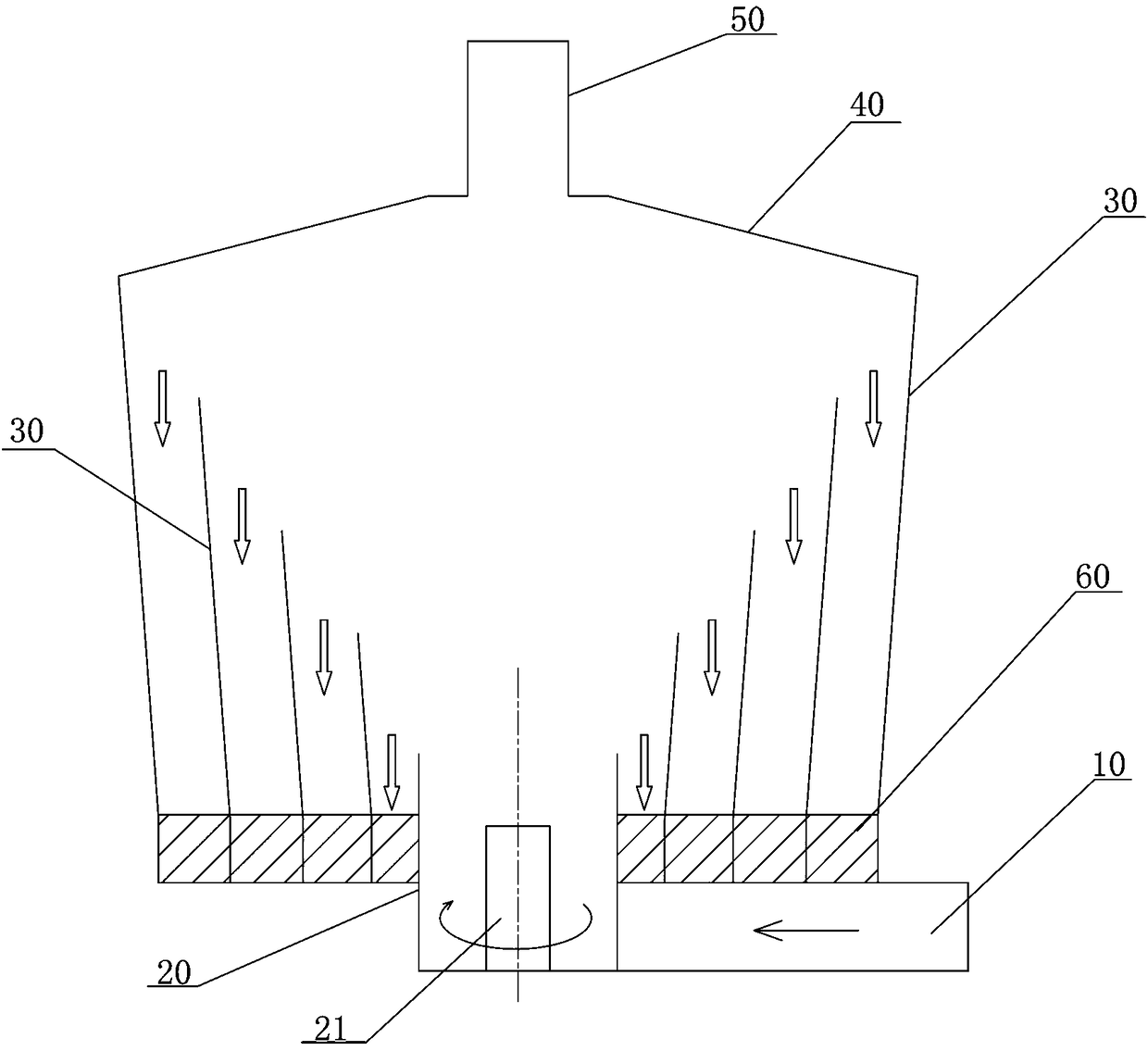

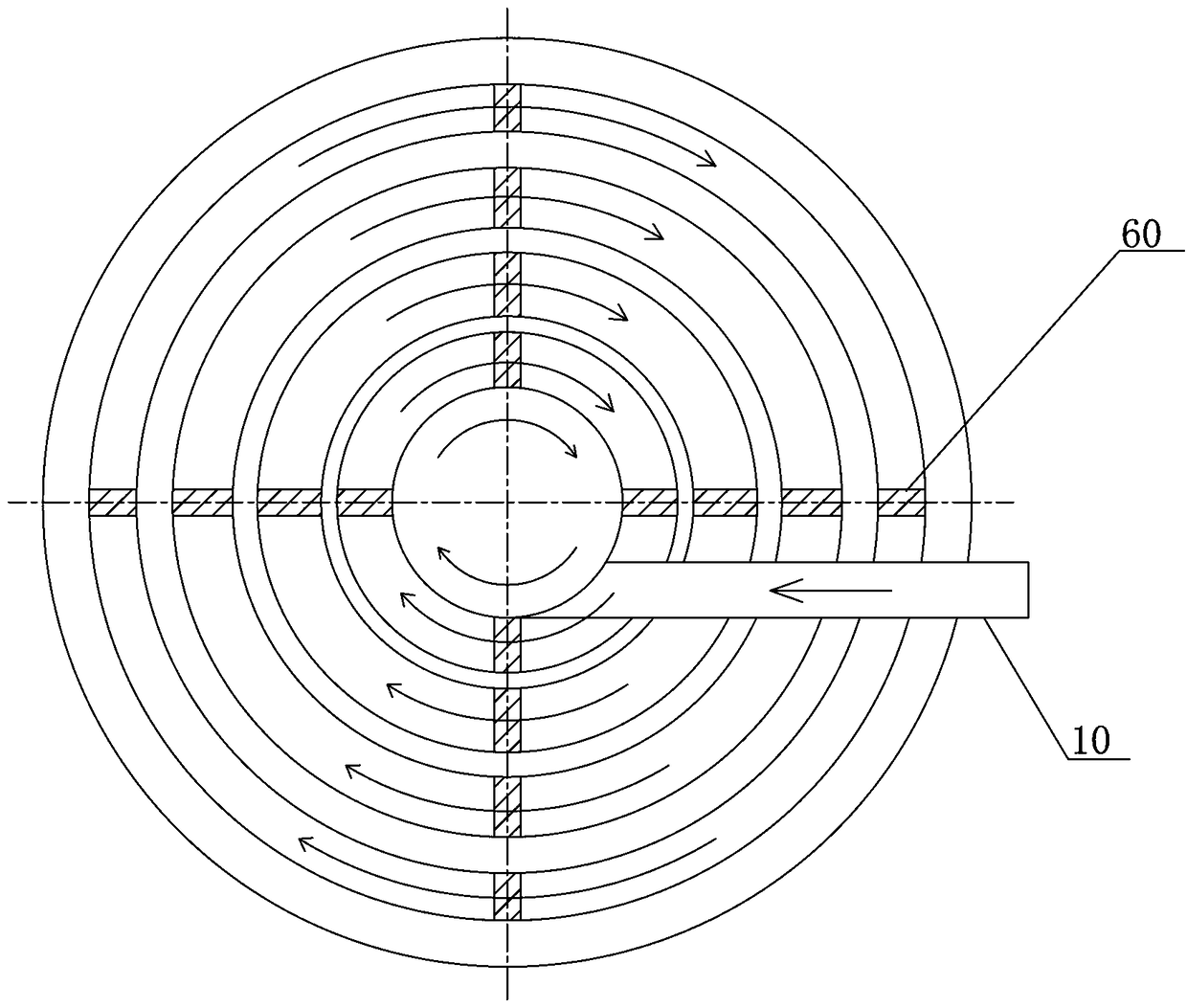

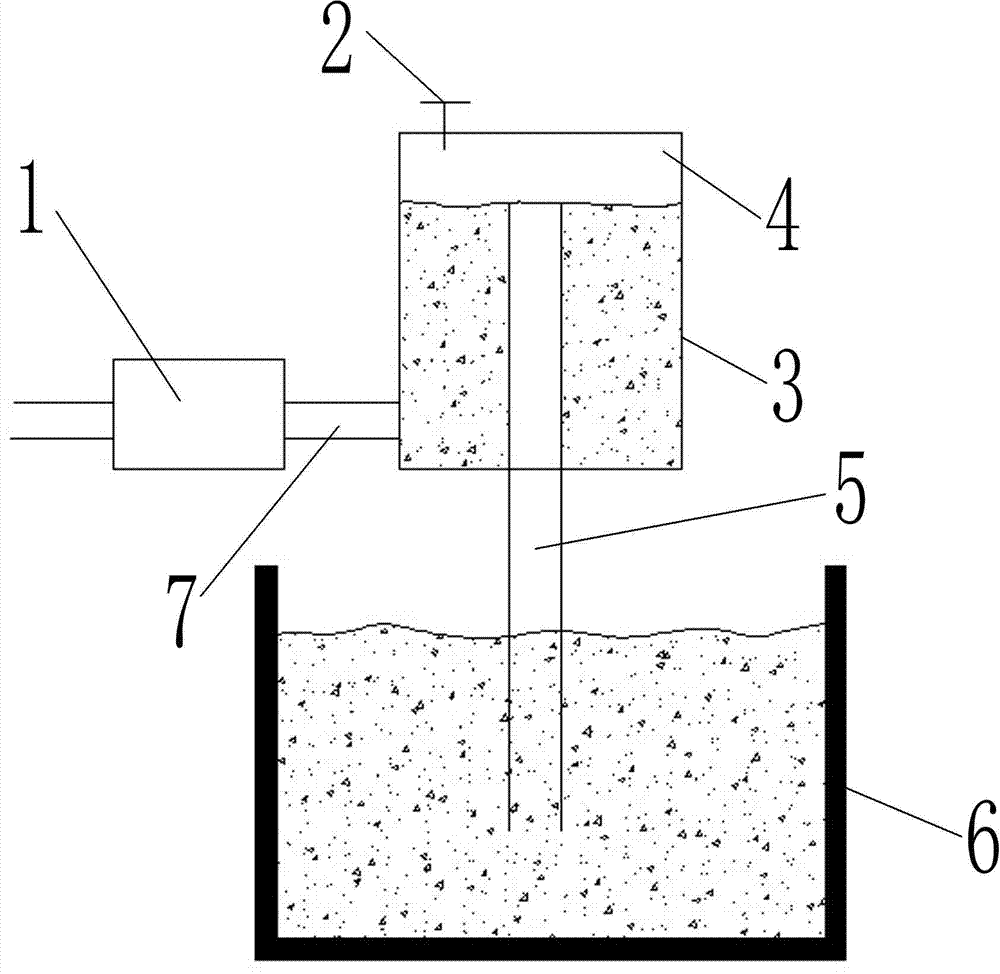

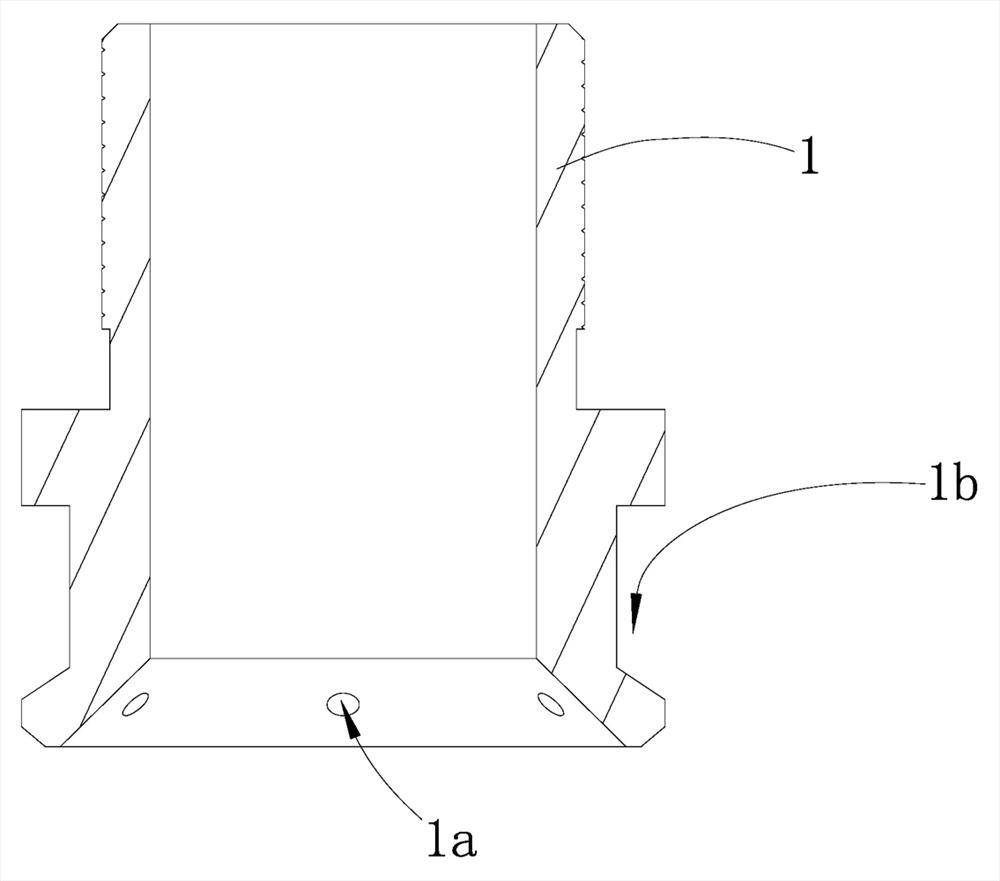

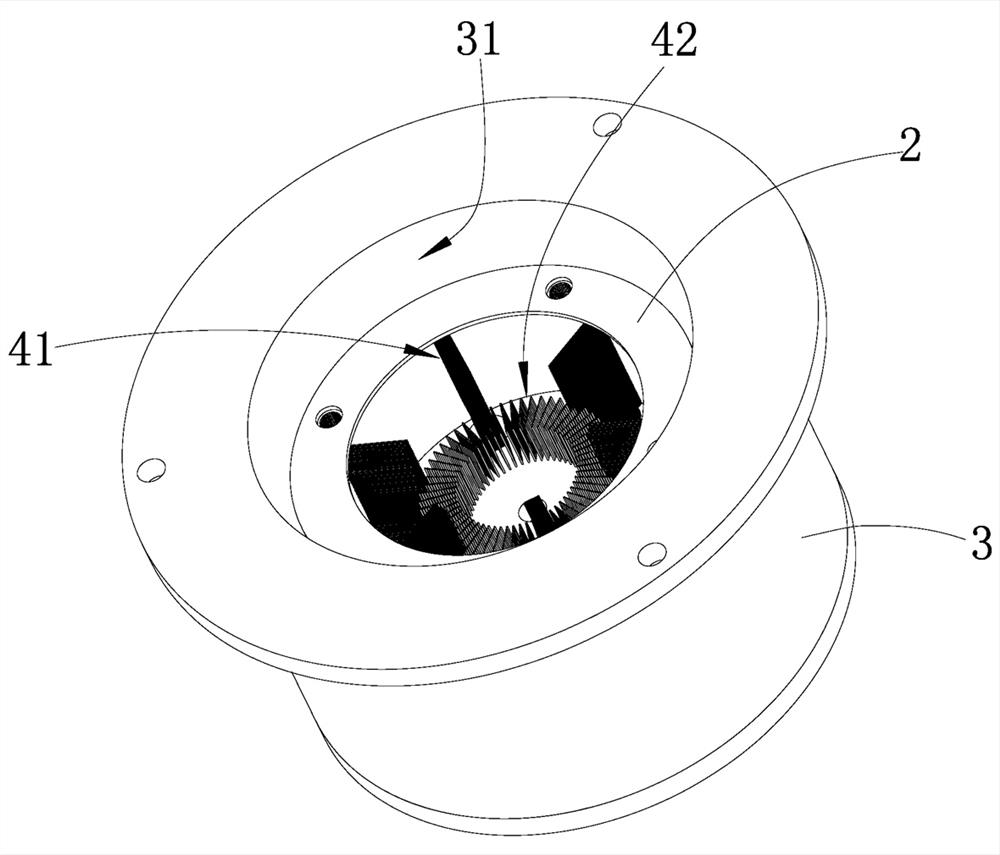

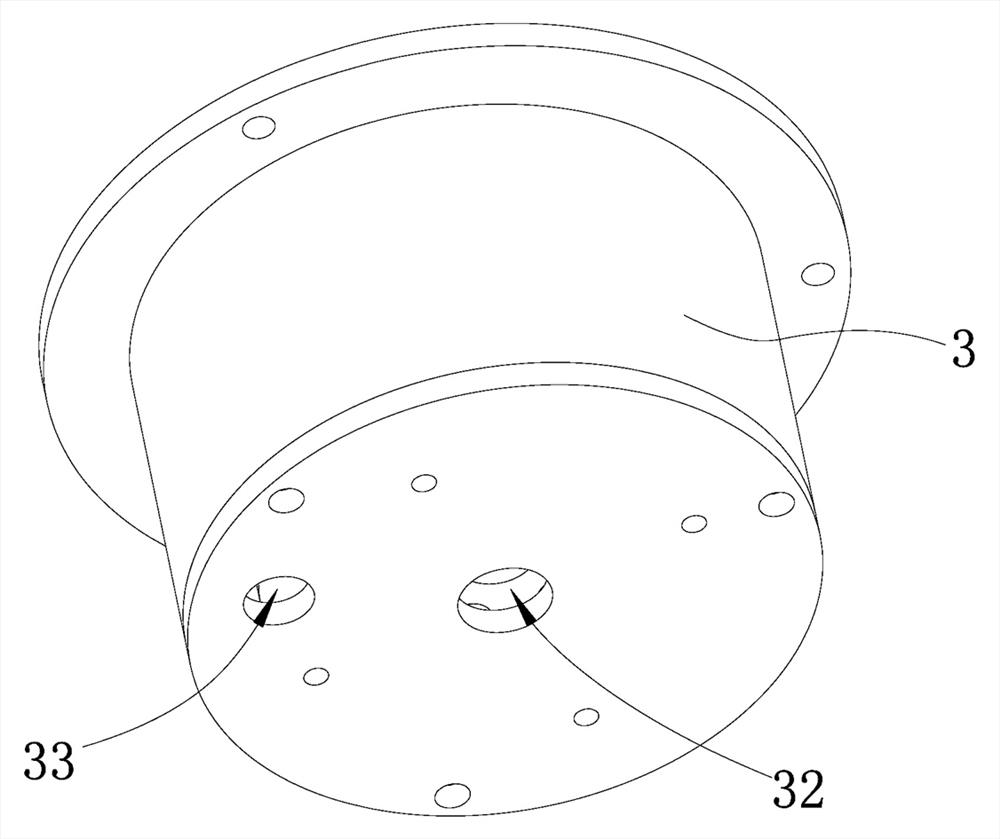

High-silicon iron ore sintering pretreatment device based on centrifugal force principle

InactiveCN113332900AEvenly distributedUniform injectionRotating receptacle mixersMixer accessoriesCentrifugationCentrifugal force

The invention relates to the field of iron ore, in particular to a high-silicon iron ore sintering pretreatment device based on the centrifugal force principle. The technical problem is to provide a high-silicon iron ore sintering pretreatment device based on the centrifugal force principle. According to the technical scheme, the high-silicon iron ore sintering pretreatment device based on the centrifugal force principle comprises a pretreatment assembly, a mixing assembly, a discharging assembly, a control screen, a first electric sliding rail, a first sliding block and a first limiting cylinder; the pretreatment assembly is connected with the mixing assembly; and the pretreatment assembly is in contact with the first limiting cylinder. When the device is used, high-silicon iron ore crushed aggregates are automatically limited and fixed into a cylindrical shape, the position where the crushed aggregates are low in content is automatically detected, fine inner blended coal is automatically and uniformly injected into a cylindrical crushed aggregate mixture through centrifugation, meanwhile, the phenomenon that the fine inner blended coal is gathered on the lower portion of the cylindrical crushed aggregate mixture due to gravity is prevented, and the inner blended coal is uniformly distributed in the high-silicon iron ore.

Owner:段善荣

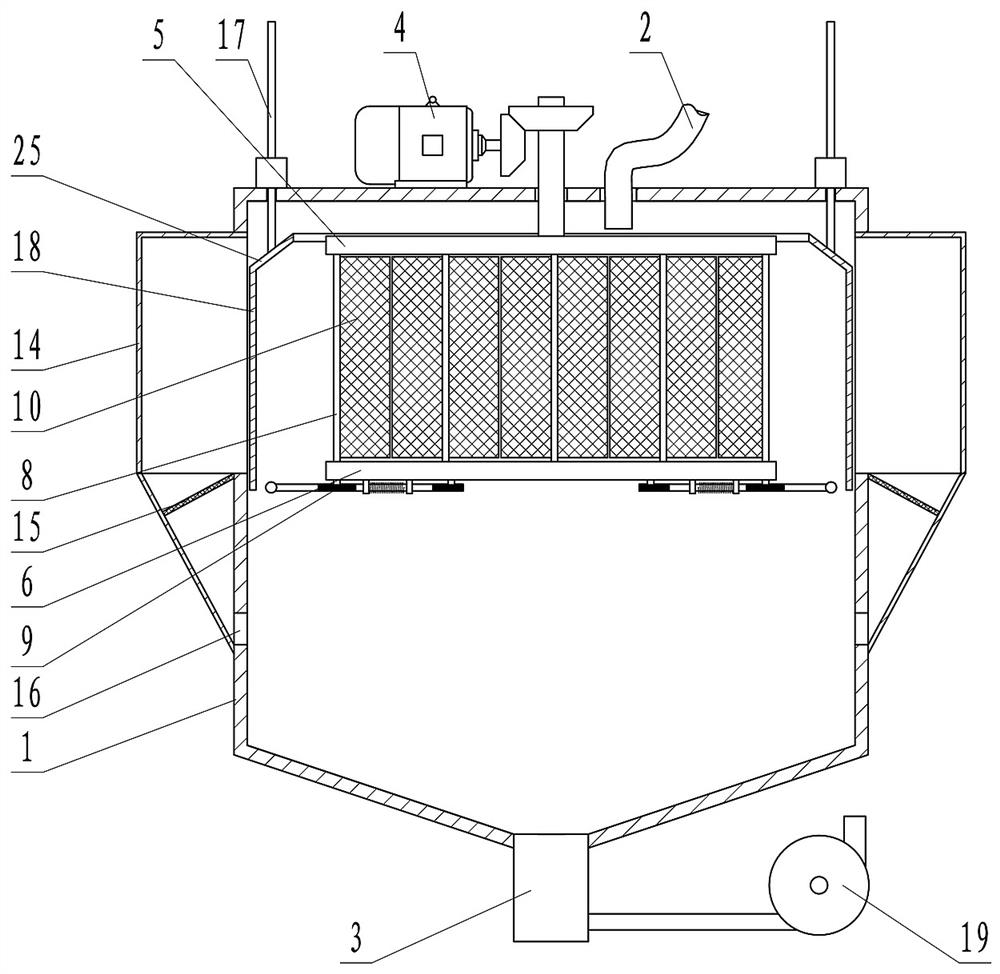

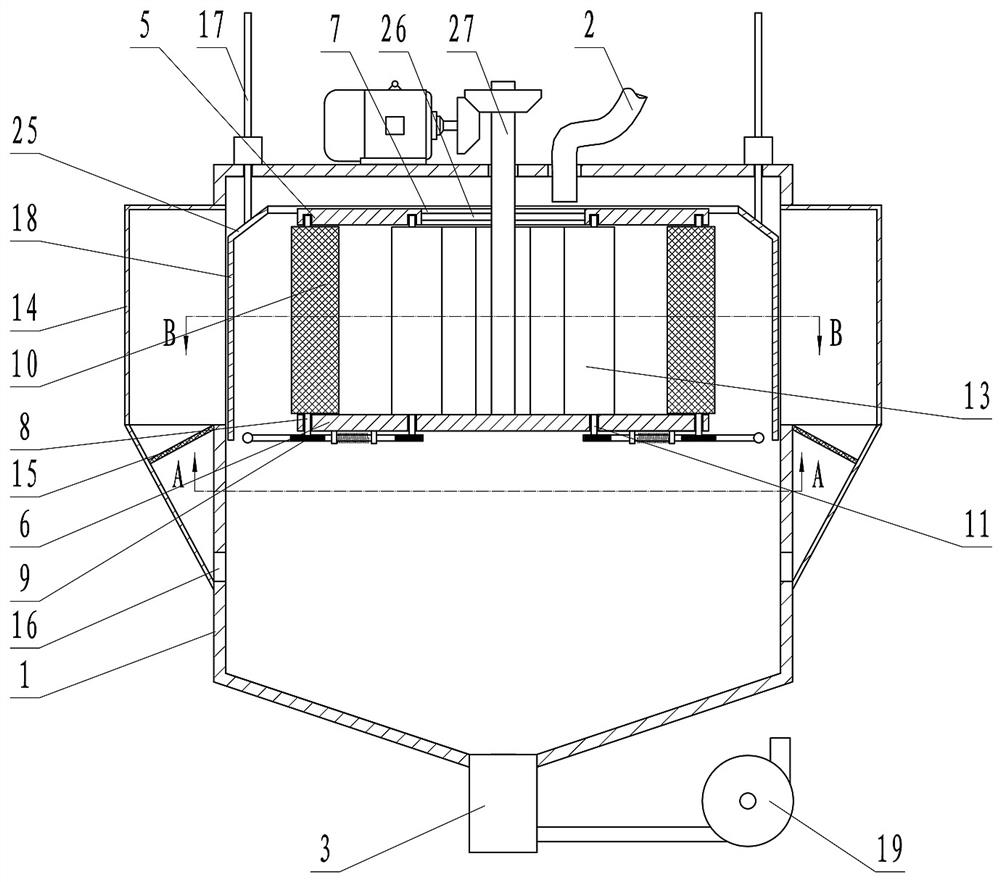

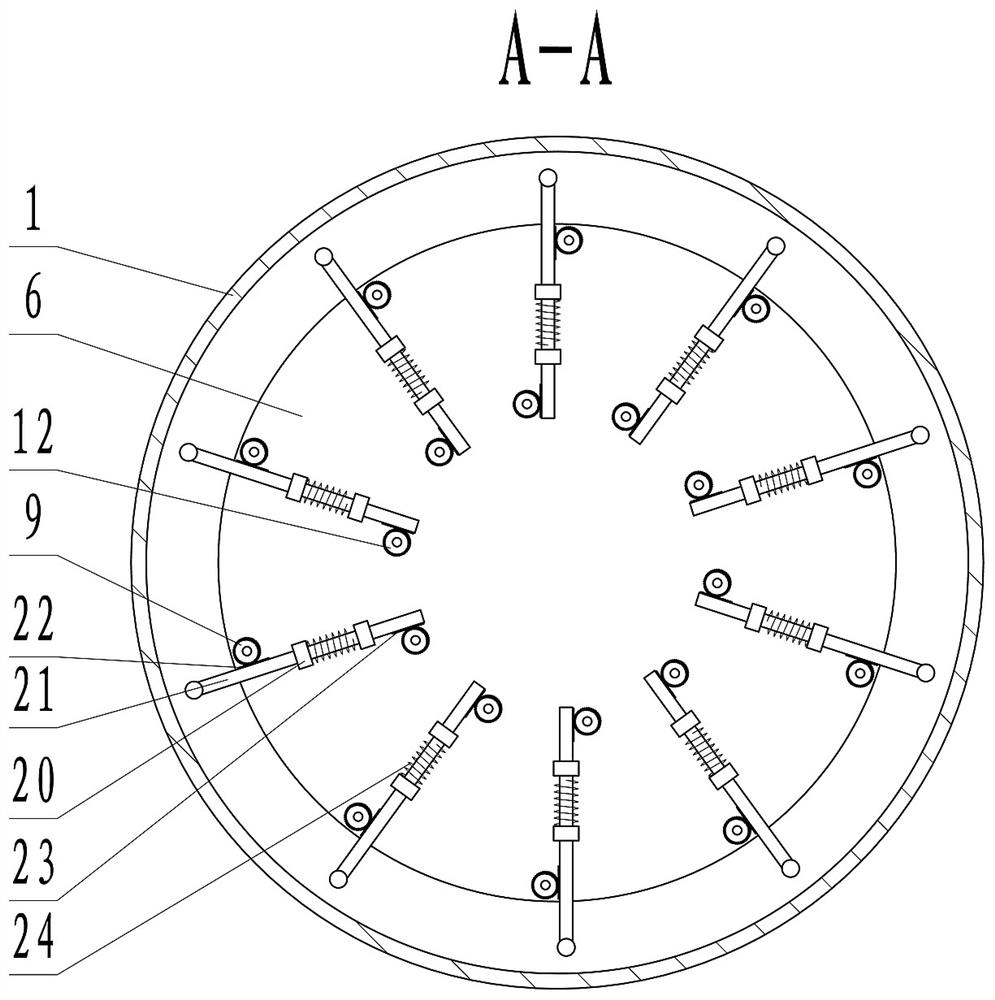

Cyclone separation device and method for smashed material particles according to particle size

PendingCN108380403APurify the working environmentSorting speed is fastReversed direction vortexParticulatesCyclone

Owner:SHENZHEN YIHEQIN ENVIRONMENTAL PROTECTION TECH

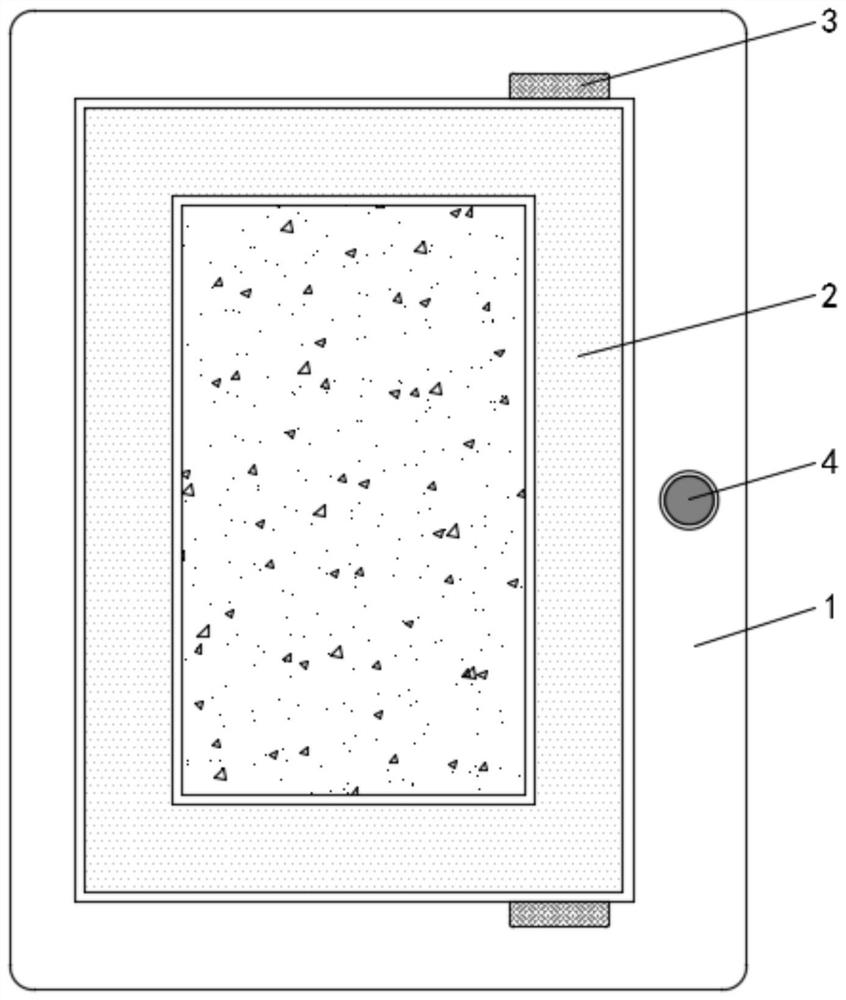

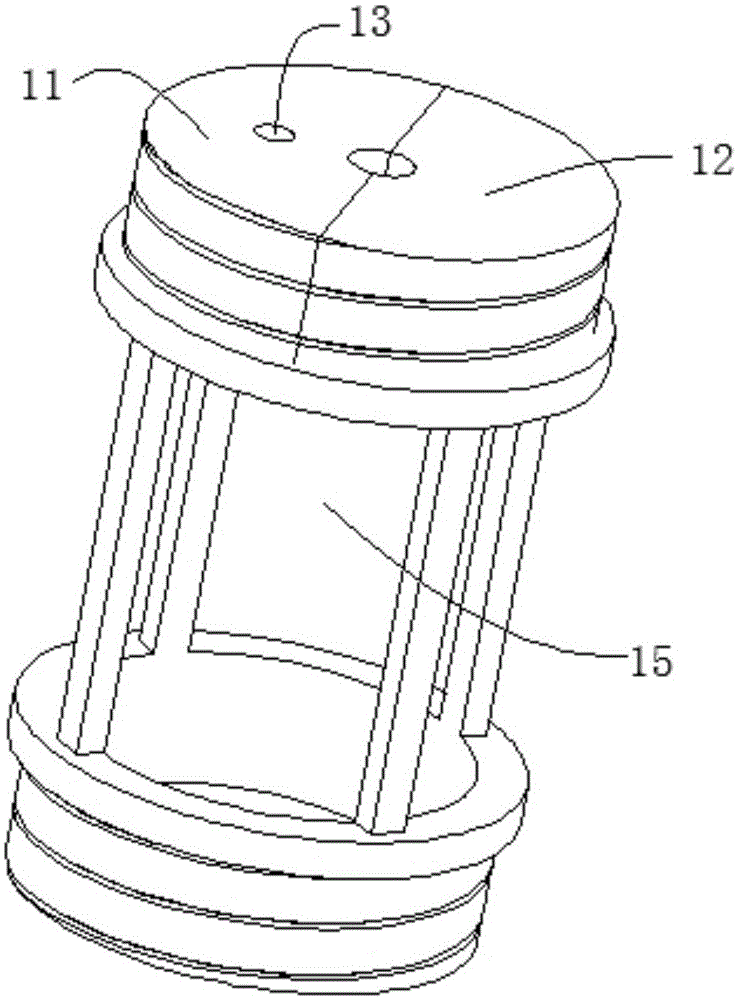

Filter of self-cleaning solar drinker

InactiveCN105148600AImprove sealingPrevent water leakageStationary filtering element filtersEngineeringCentrifugal force

Owner:黄石市民生太阳能科技有限公司

Machining cutting water filtering device

ActiveCN112691431AQuick net clearingImprove filtering effectMoving filtering element filtersWater filterGear wheel

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

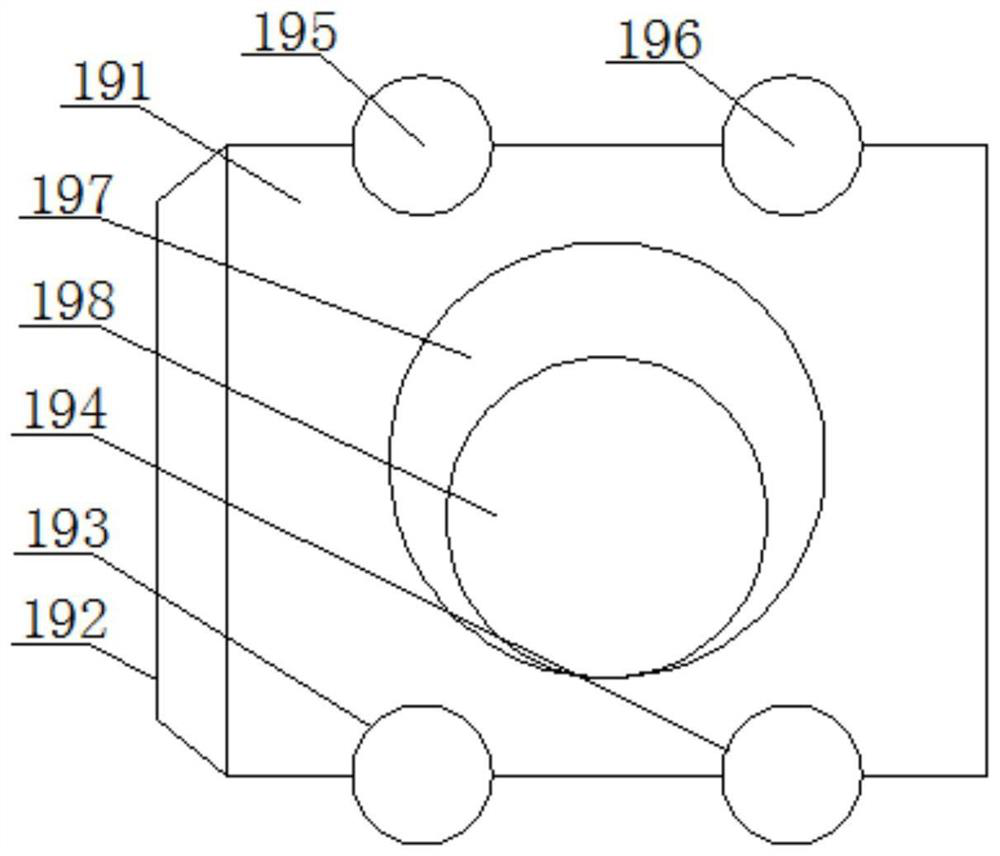

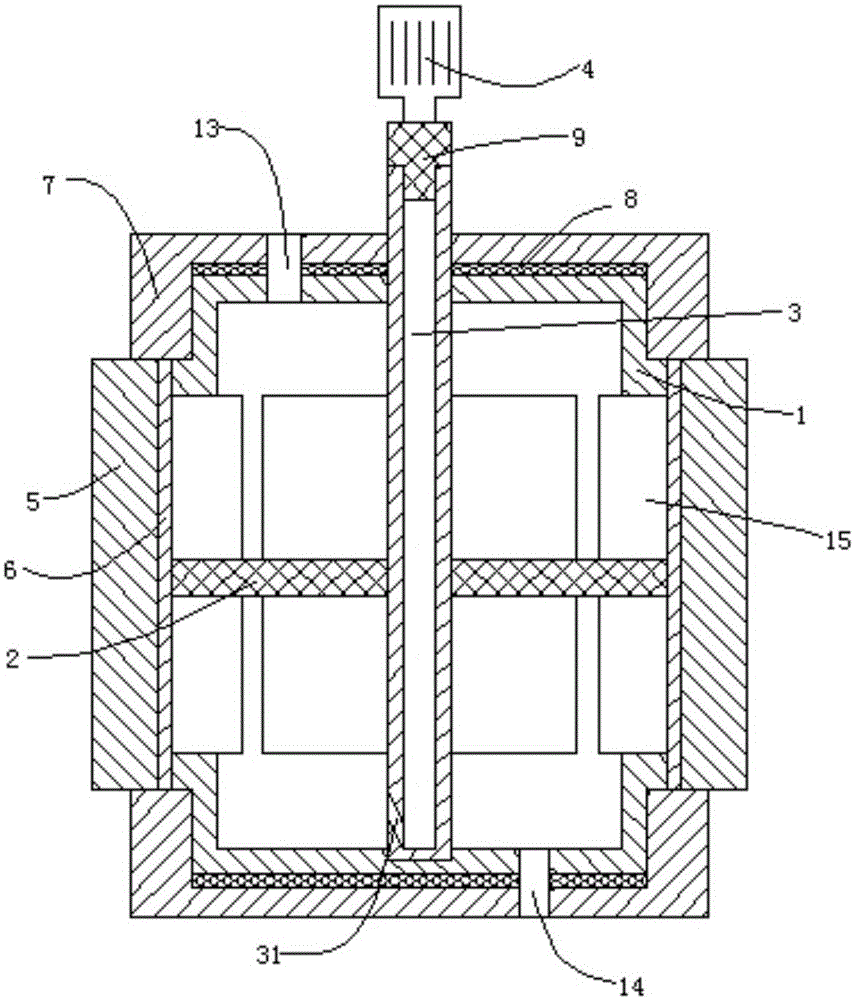

Continuous conveying device for crystal precipitation

The invention provides a continuous conveying device for crystal precipitation. The continuous conveying device comprises a grid defining a cylinder, a spring-shaped conveying blade and a cylindrical shell. The inner circumference of the conveying blade is matched with the outer circumference of the cylindrical grid. The outer circumference of the conveying blade is matched with the inner circumference of the cylindrical shell. The cylindrical grid, the conveying blade and the cylindrical shell are sequentially embedded to form a three-layer embedded structure. A driving end cover driven by a motor is arranged at one end in the cylindrical shell, and one end of the conveying blade is fixed to the driving end cover. A discharging hole matched with the conveying blade is formed in one end of the cylindrical shell. In the continuous conveying device, due to rotation of the conveying blade, generated materials are tightly attached to the inner wall of the cylindrical shell due to centrifugal force; and due to the fact that the conveying blade is of a structure similar to a screw extruder, the materials are continuously pushed out of a discharging port, and the continuous production capability is improved.

Owner:NINGXIA DONGWU AGROCHEM

Acid pump vacuum suction apparatus

InactiveCN103498798APrevent damage to pump sealsPriming pumpNon-positive displacement fluid enginesPulp and paper industryCentrifugal force

Owner:JINAN LUXECOTE FERTILIZER

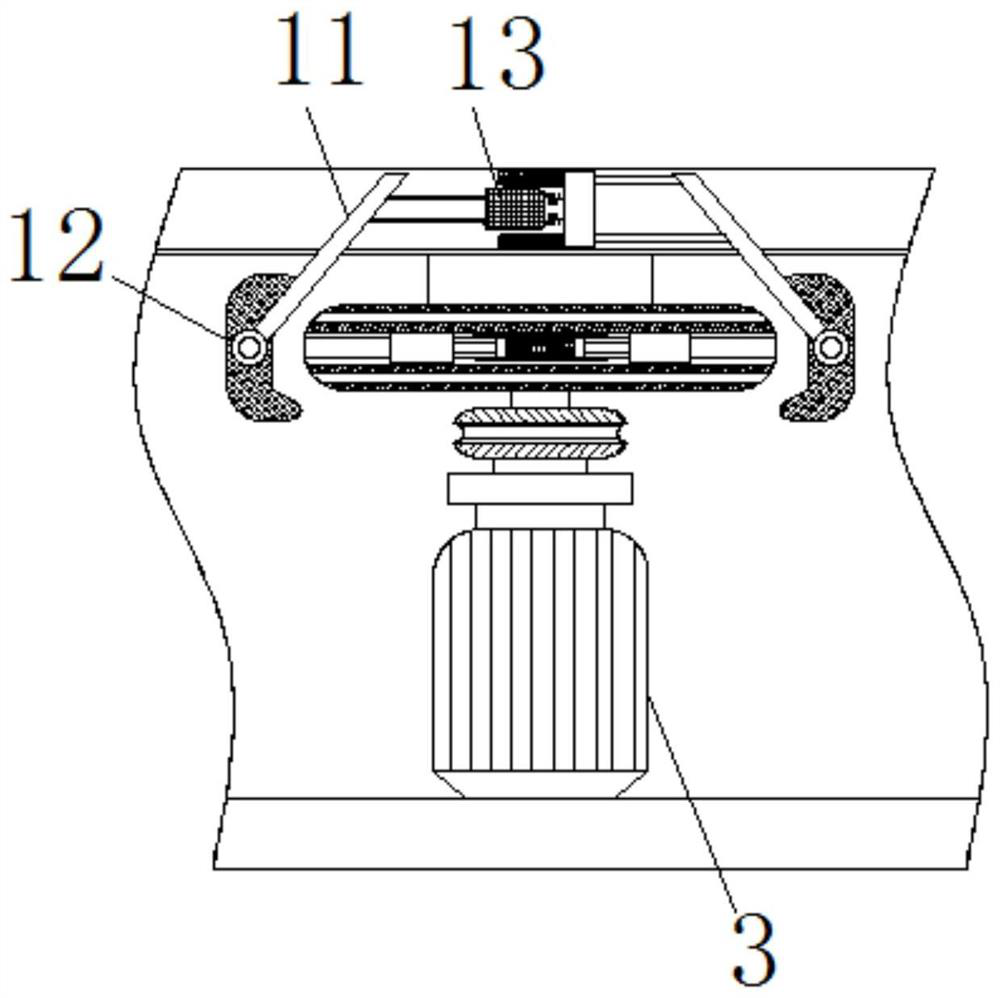

Wiping mechanism for polyurethane foaming mixing head

PendingCN112643960AImprove cleaning efficiencyReasonable structureCleaning using toolsPolymer scienceElectric machinery

Owner:蚌埠中正聚氨酯发泡设备有限公司

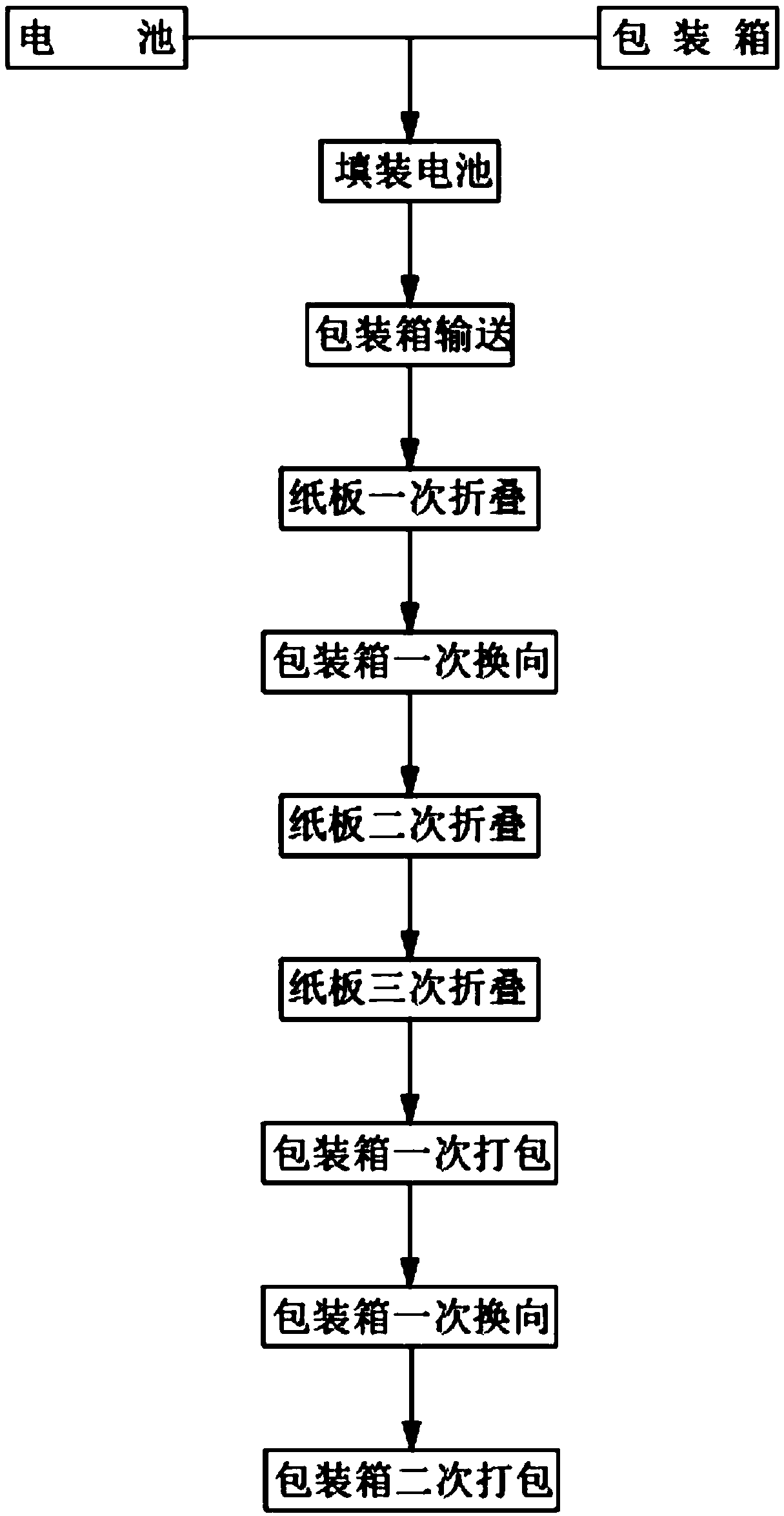

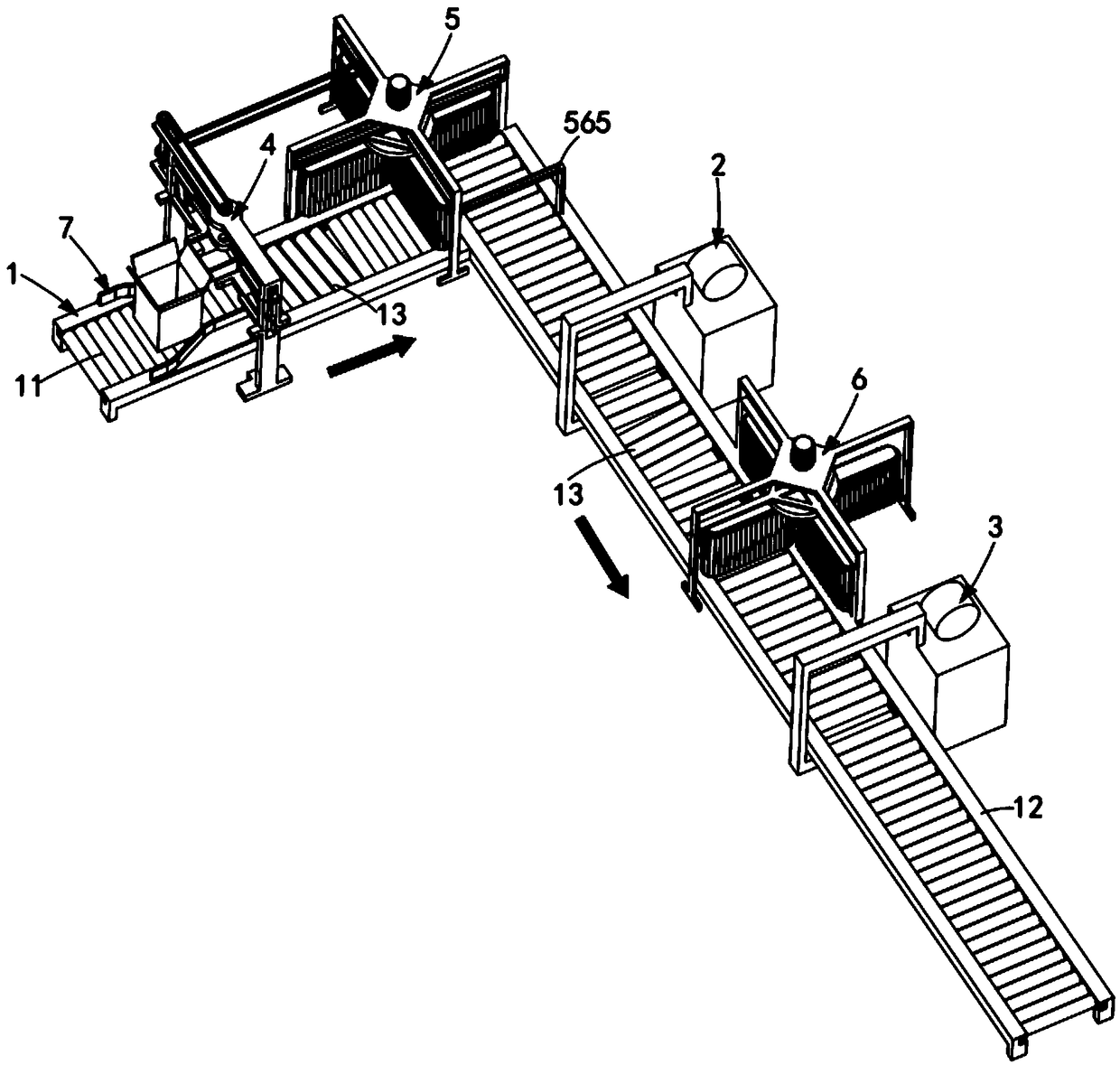

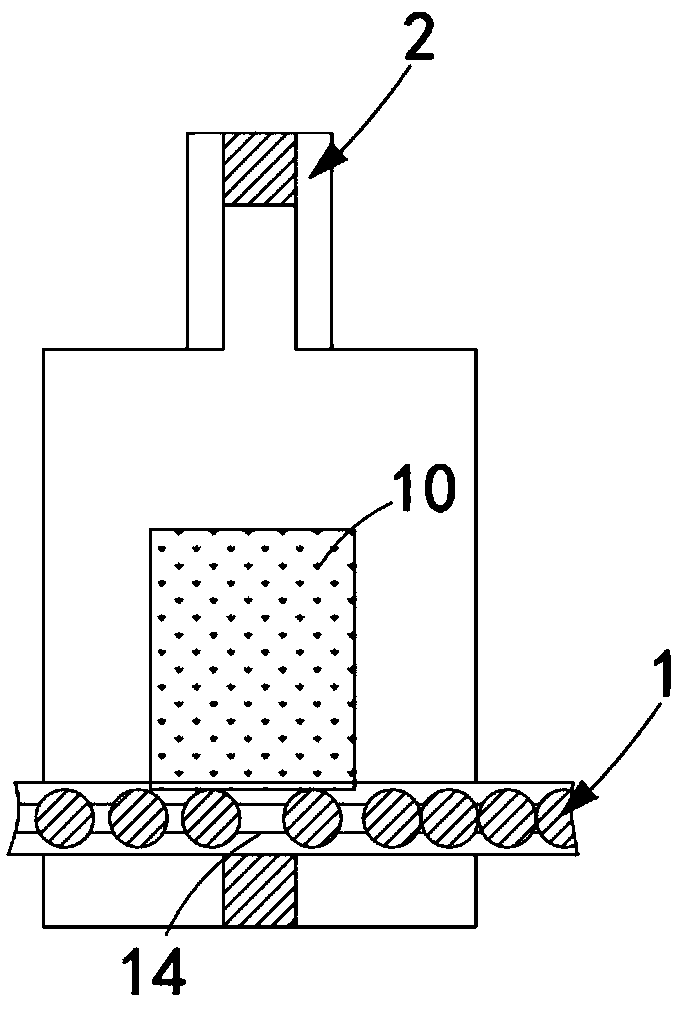

Automatic reversing side packaging method for lead-acid cell packaging box

ActiveCN109279066AQuick changeNo detachment from the packaging conveyor lineWrappingCardboardCentrifugal force

Owner:阜阳佰恩得新材料技术有限公司

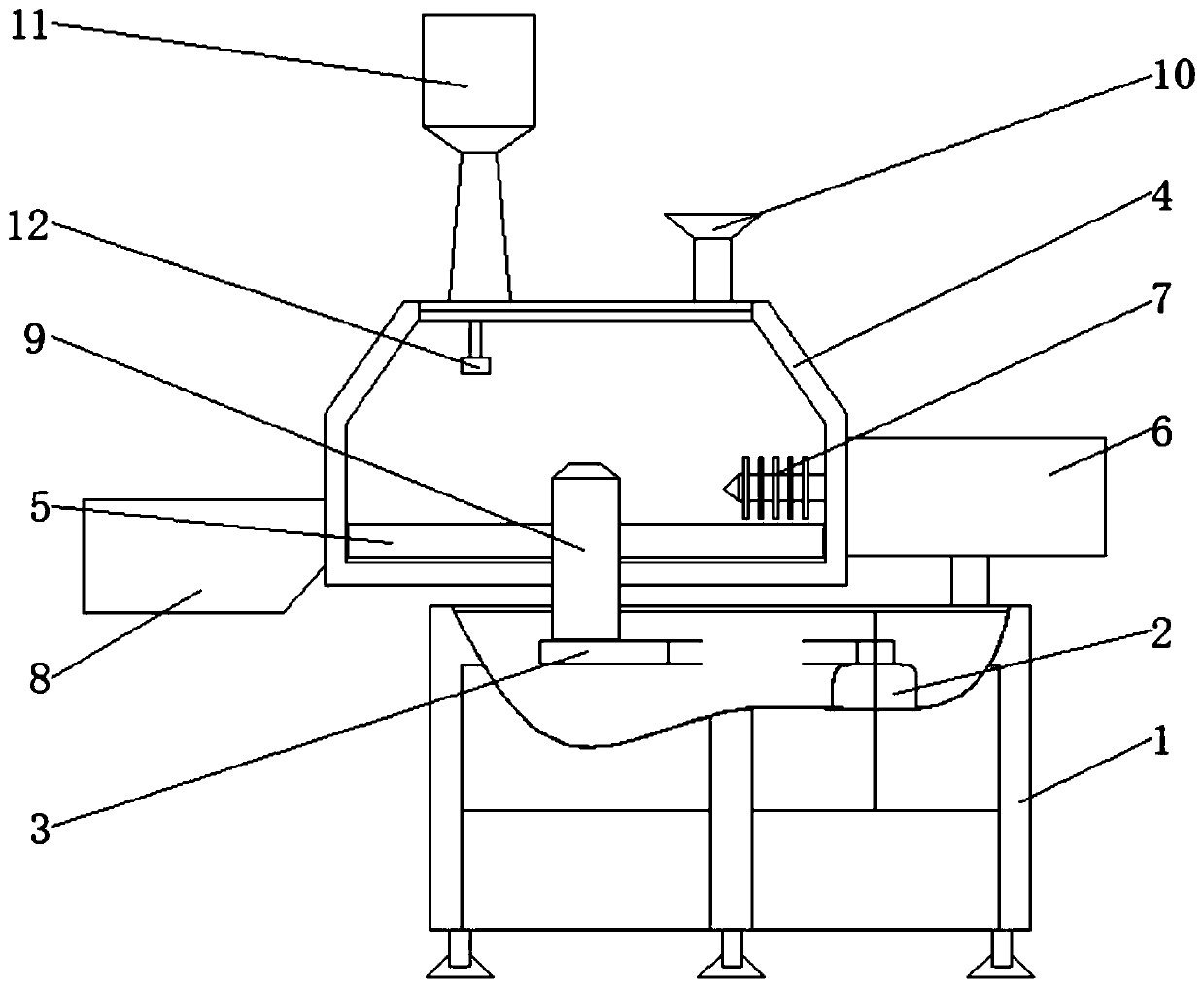

High-speed mixing granulator

InactiveCN110813187AImprove cycle performanceImprove mixing efficiencyGranulation in stationary drums/troughsElectric machineryEngineering

Owner:吴文地

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap