Acid pump vacuum suction apparatus

A technology of vacuum suction and acid pump, which is applied in the direction of pumps, drive pumps, non-variable pumps, etc., which can solve the problems of easy damage and achieve the effect of preventing pump sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

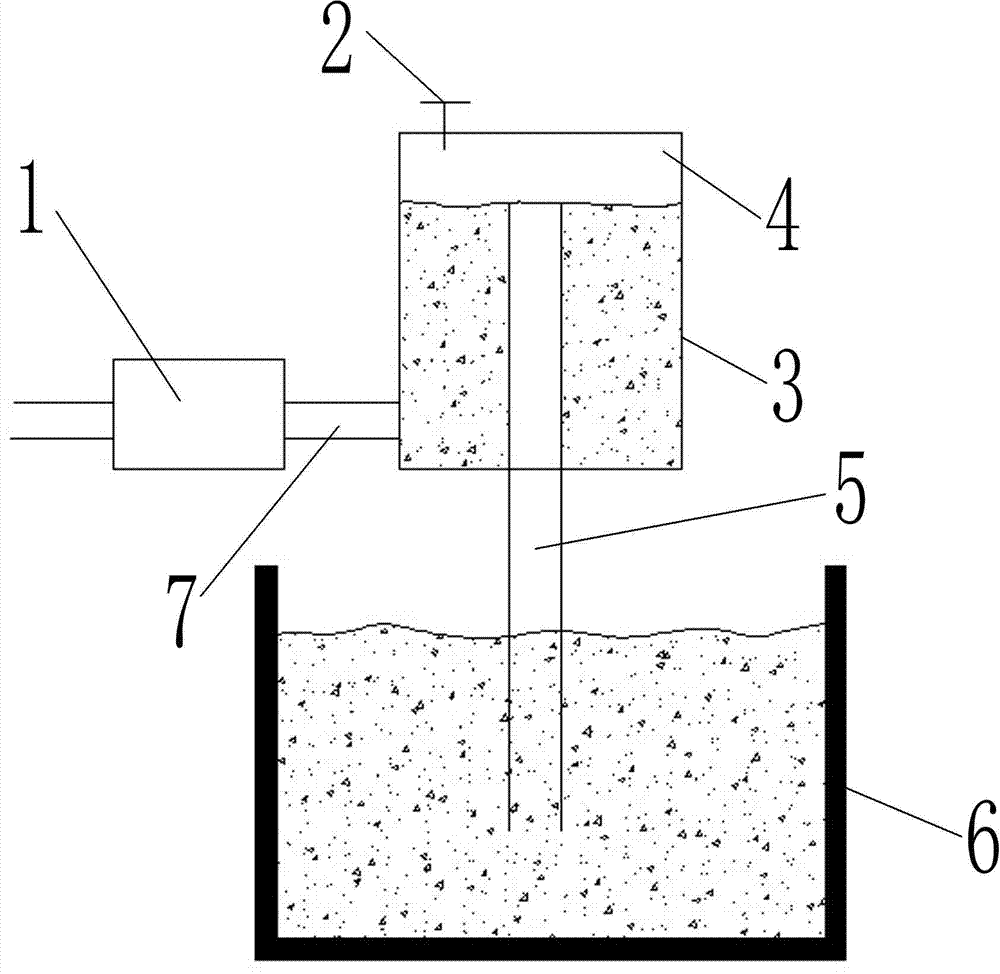

[0010] Attached below figure 1 The present invention will be further described.

[0011] The acid pump vacuum suction device includes a liquid storage tank 6, an airtight container 3 located above the liquid storage tank 6, a liquid suction pipe 5, and a liquid outlet pipe 7 arranged at the bottom of the airtight container 3, and the upper part of the liquid suction pipe 5 is located in the airtight container 3 In the inner chamber 4, its bottom is located in the liquid storage pool 6, the nozzle height of the suction pipe 5 is lower than the upper plane of the inner chamber 4, and the liquid outlet pipe 7 is connected to the centrifugal pump 1. Fill the airtight container 3 with liquid until the liquid level in the inner chamber 4 is flush with the upper mouth of the suction pipe 5, and then start the centrifugal pump 1, and the centrifugal pump 1 will make the inner chamber 4 under the action of centrifugal force. A vacuum zone is formed in the middle, and the acid solution in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap