Machining cutting water filtering device

A water filtration and machining technology, applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of frequent filter cloth replacement, slow cutting fluid filtration, easy clogging, etc. effect, the effect of improving the efficiency of net cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

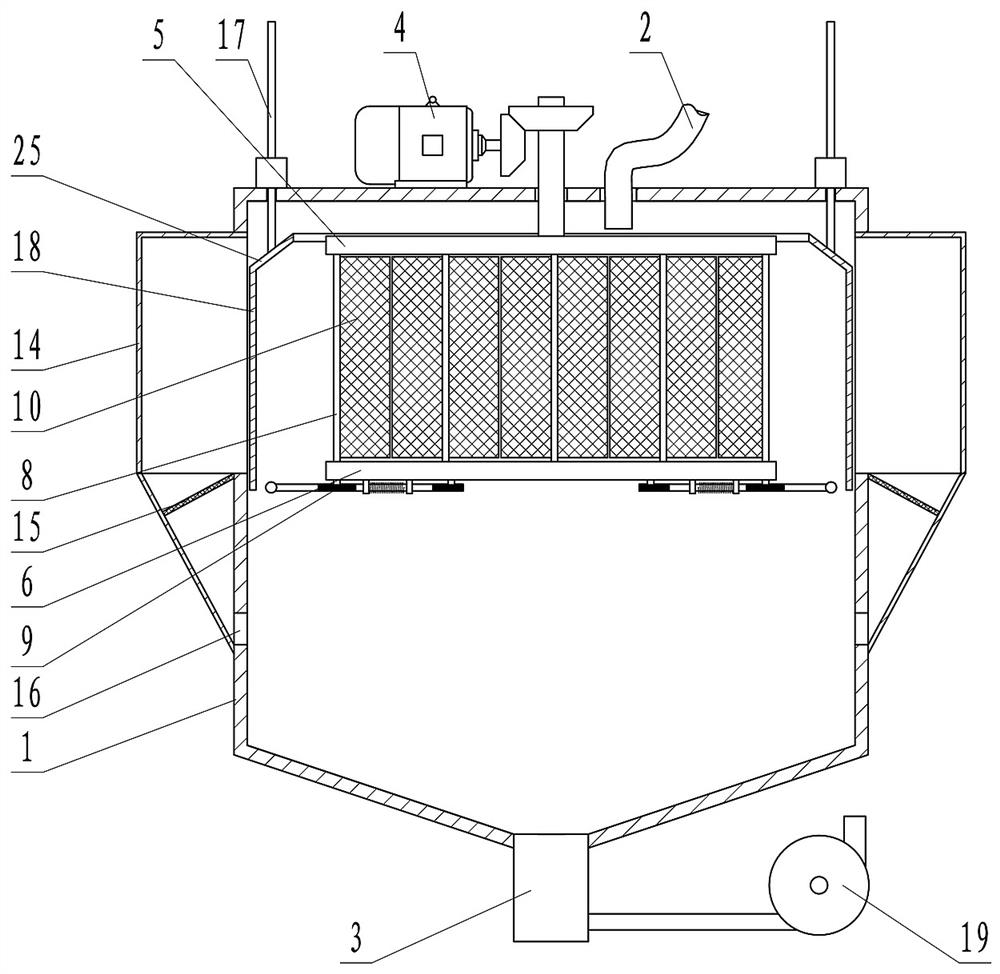

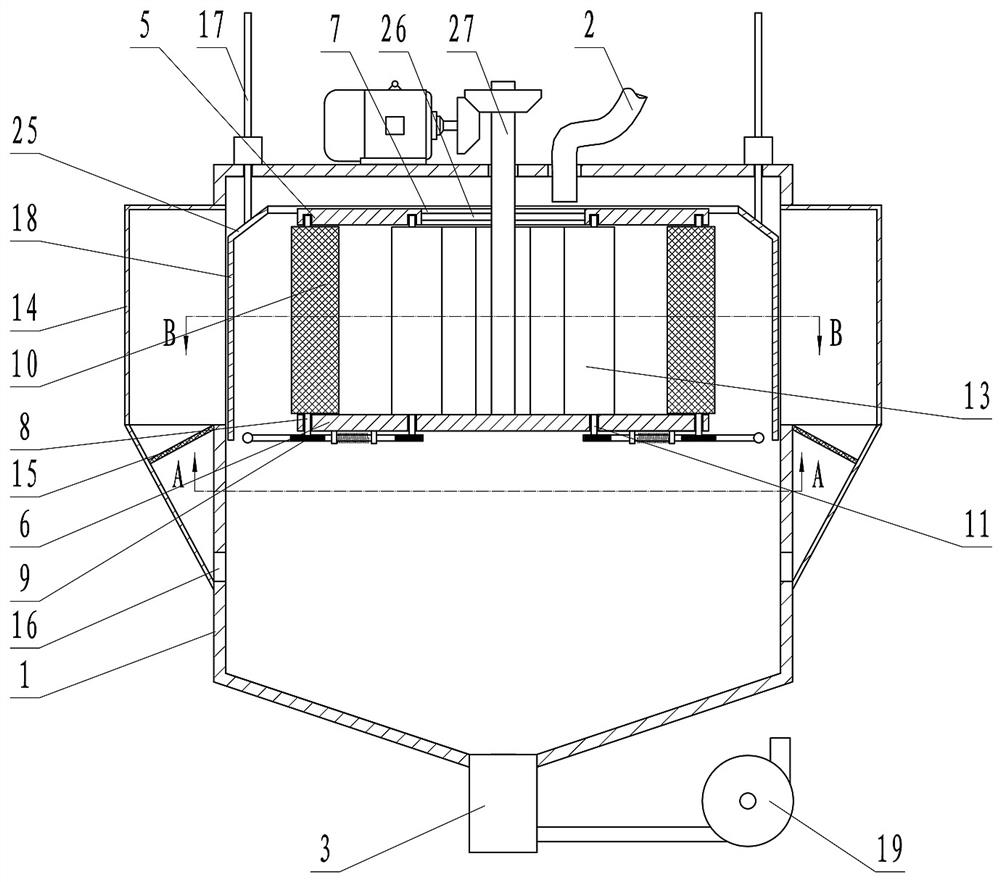

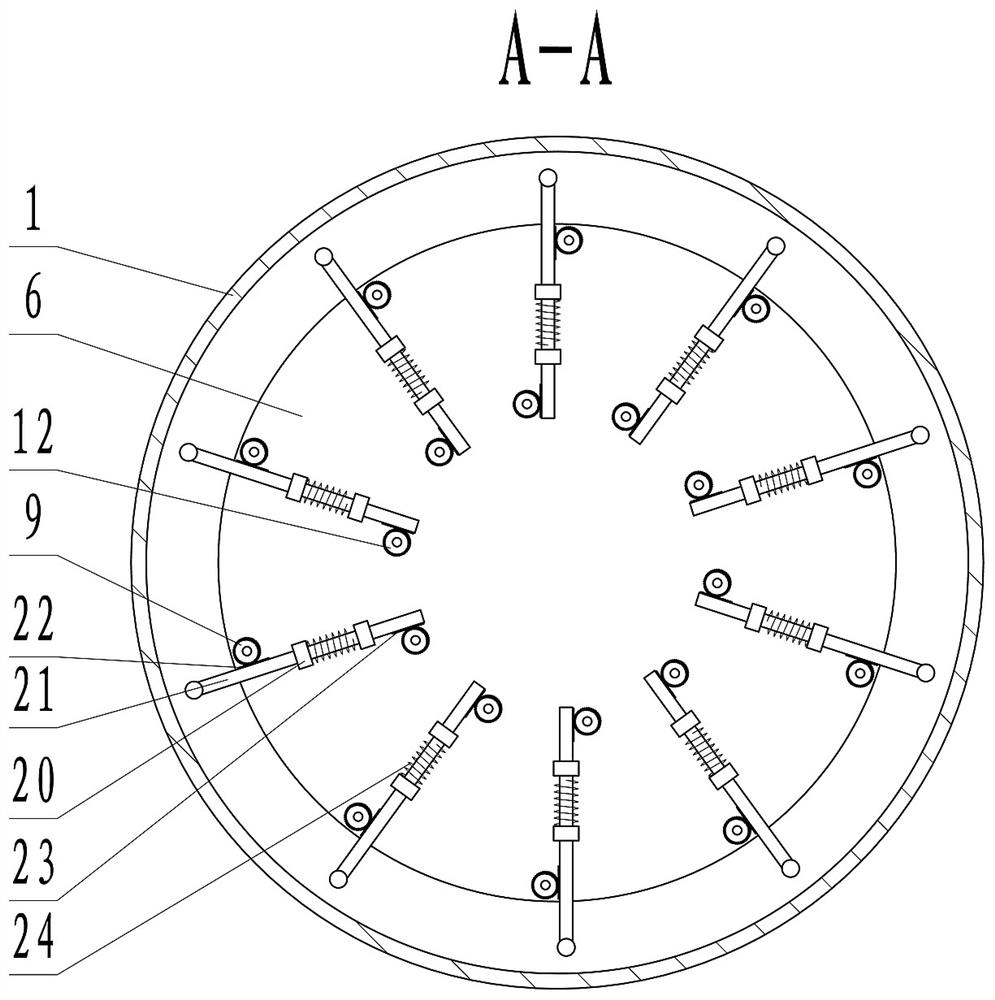

[0015] Depend on Figure 1 to Figure 5 Given, the present invention includes a casing 1, the top of the casing 1 is provided with a water inlet pipe 2, the bottom is provided with a water outlet pipe 3, the inside of the casing 1 is provided with a filter body, and the filter body is driven by a motor 4 to rotate;

[0016] Described filter body comprises the top board 5 that places horizontally, and the bottom of top board 5 is arranged with bottom plate 6 parallelly; A plurality of first rotating shafts 8 and second rotating shafts 11 are evenly distributed on the circumference, the second rotating shafts 11 are located inside the first rotating shafts 8, and the lower end of the first rotating shafts 8 passes through the bottom plate 6 and is equipped with a first gear 9; each second rotating shaft 8 A vertical filter sc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap