Forced vibrating stirrer with balancing block for equal amplitude vibration of stirring shaft

A technology of stirring shaft and balance block, which is applied in the field of forced vibrating mixer equipment, can solve the problems of insufficient vibration stirring effect, poor stress condition of the vibration shaft support bearing, poor sealing of the shaft end of the stirring shaft, etc., so as to achieve easy sealing. , long service life, the effect of improving the stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

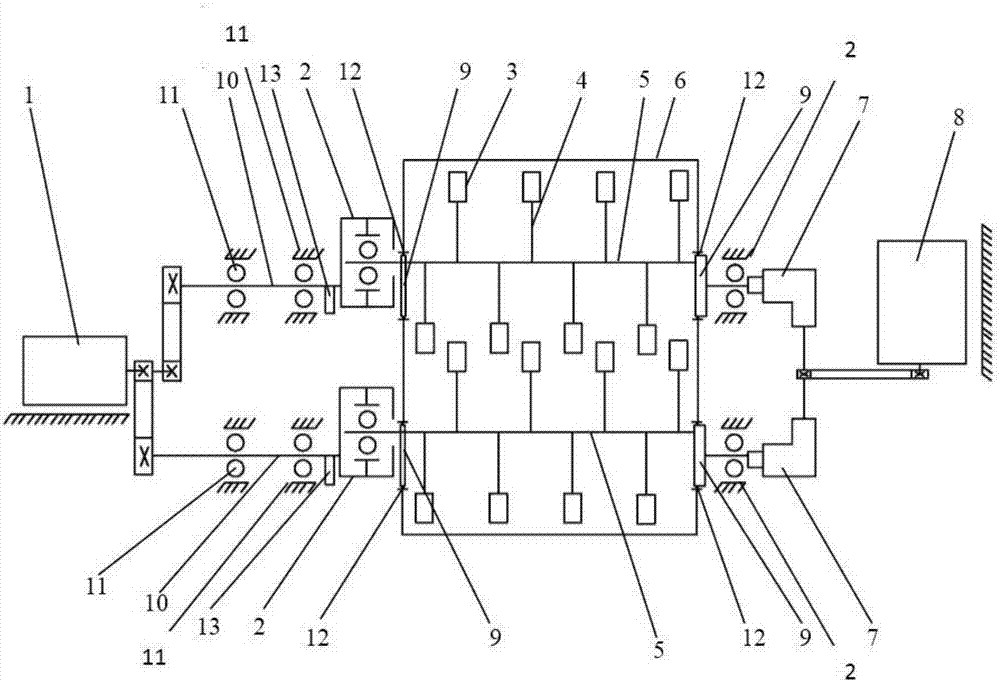

[0031] like figure 1 As shown, the stirring drive device of the vibrating mixer is composed of two identical stirring drive motors 8 and a reducer 7 . The motor shaft of the stirring drive motor 8 is connected with the input shaft of the speed reducer 7 through a belt transmission, and the input shafts of the two speed reducers 7 realize the synchronous rotation of the two speed reducers through the transmission shaft. The output shaft of the speed reducer 7 is connected with the stirring shaft 5, so as to realize the rotation of the stirring shaft during normal operation.

[0032] The vibrating device of the vibrating mixer consists of a vibrating drive motor 1 , a vibrating shaft 10 and a stirring shaft 5 . The motor shaft of the vibration drive motor 1 is connected to the left end of the vibration shaft 10 through a belt drive, and the right end of the vibration shaft 10 is eccentrically connected to the outer ring of a second support bearing 2, which drives the stirring shaf

Embodiment 2

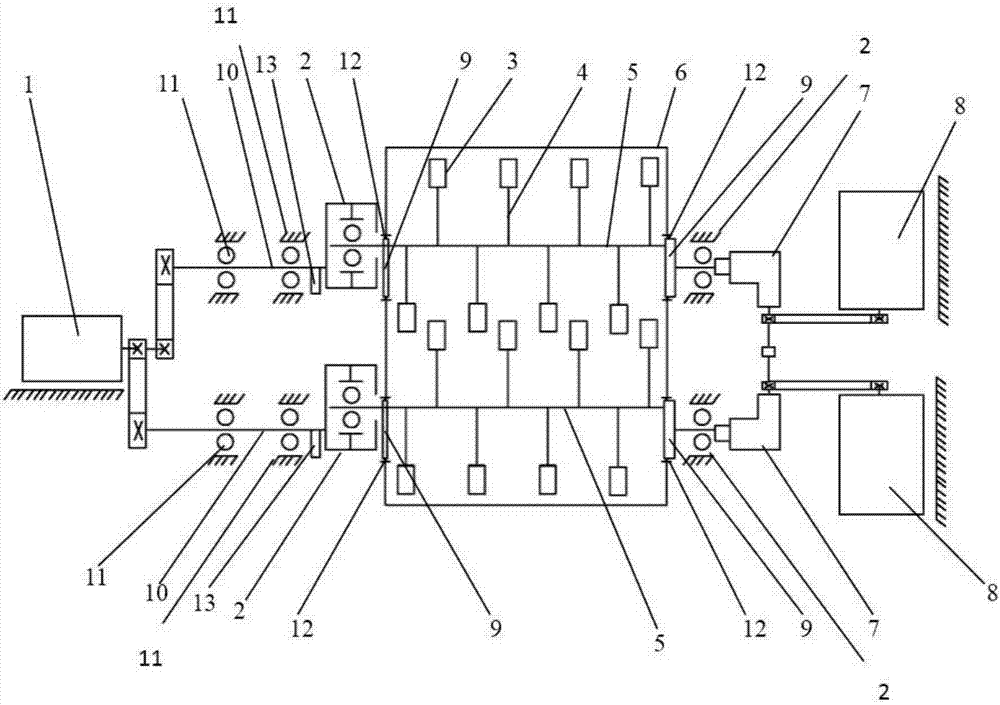

[0036] like figure 2As shown, the stirring drive device of the vibrating mixer is composed of a stirring drive motor 8 and two identical reducers 7 . The motor shaft of the stirring drive motor 8 is connected with the input shafts of the two reducers 7 through a belt transmission, and the two reducers 7 are driven by one stirring motor 8 to realize the synchronous rotation of the two reducers. The output shaft of the speed reducer 7 is connected with the stirring shaft 5, so as to realize the rotation of the stirring shaft during normal operation.

[0037] The vibrating device of the vibrating mixer consists of a vibrating drive motor 1 , a vibrating shaft 10 and a stirring shaft 5 . The motor shaft of the vibration drive motor 1 is connected to the left end of the vibration shaft 10 through a belt drive, and the right end of the vibration shaft 10 is eccentrically connected to the outer ring of a second support bearing 2, which drives the stirring shaft 5 to rotate around the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap