Cyclone separation device and method for smashed material particles according to particle size

A particle size and sorting device technology, which is applied in the direction of swirling devices and devices whose axial direction can be reversed, can solve the problems of low sorting accuracy, complex structure, and fluctuating sorting results, and achieve the goal of The effect of fast selection, simple operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

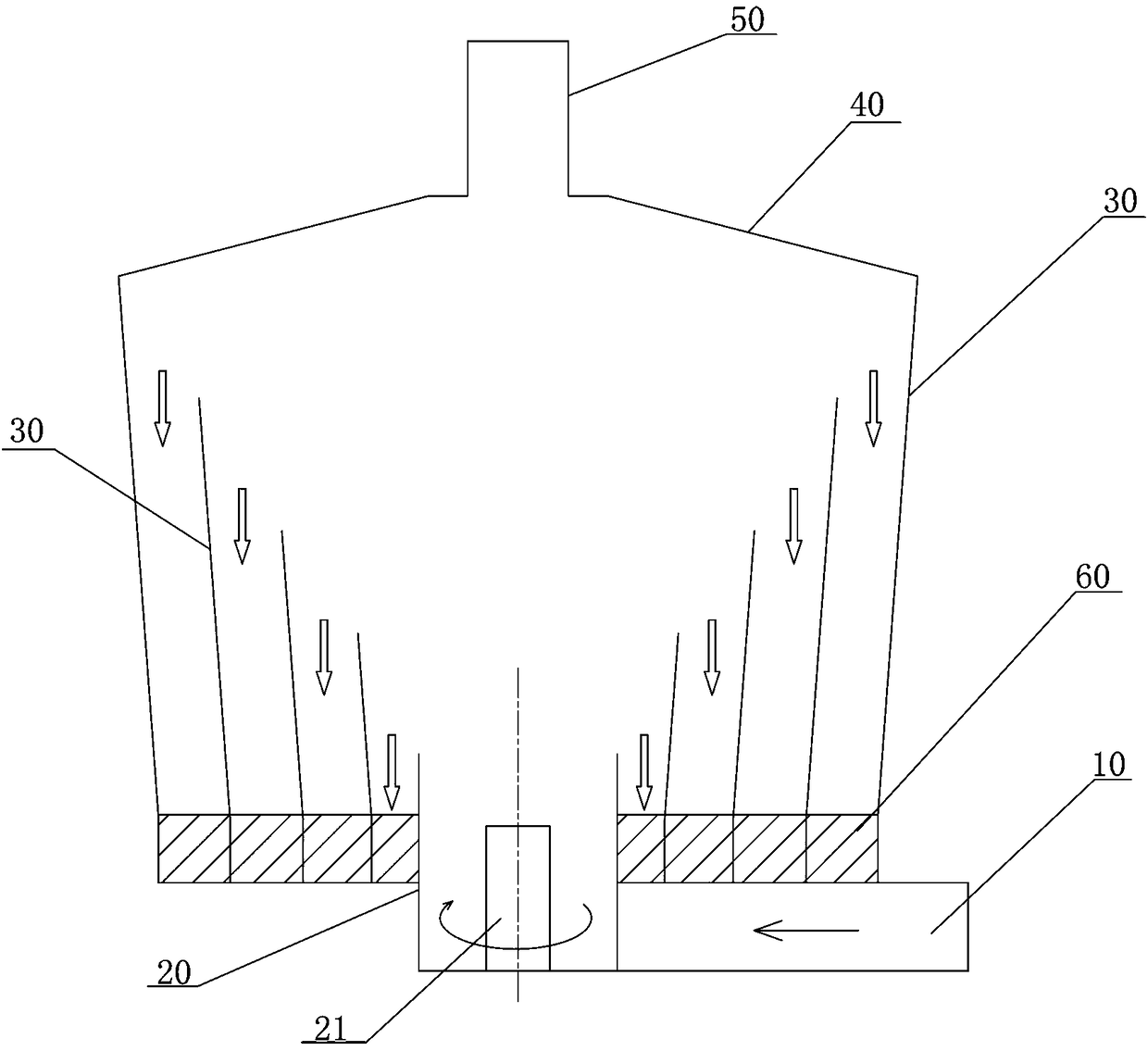

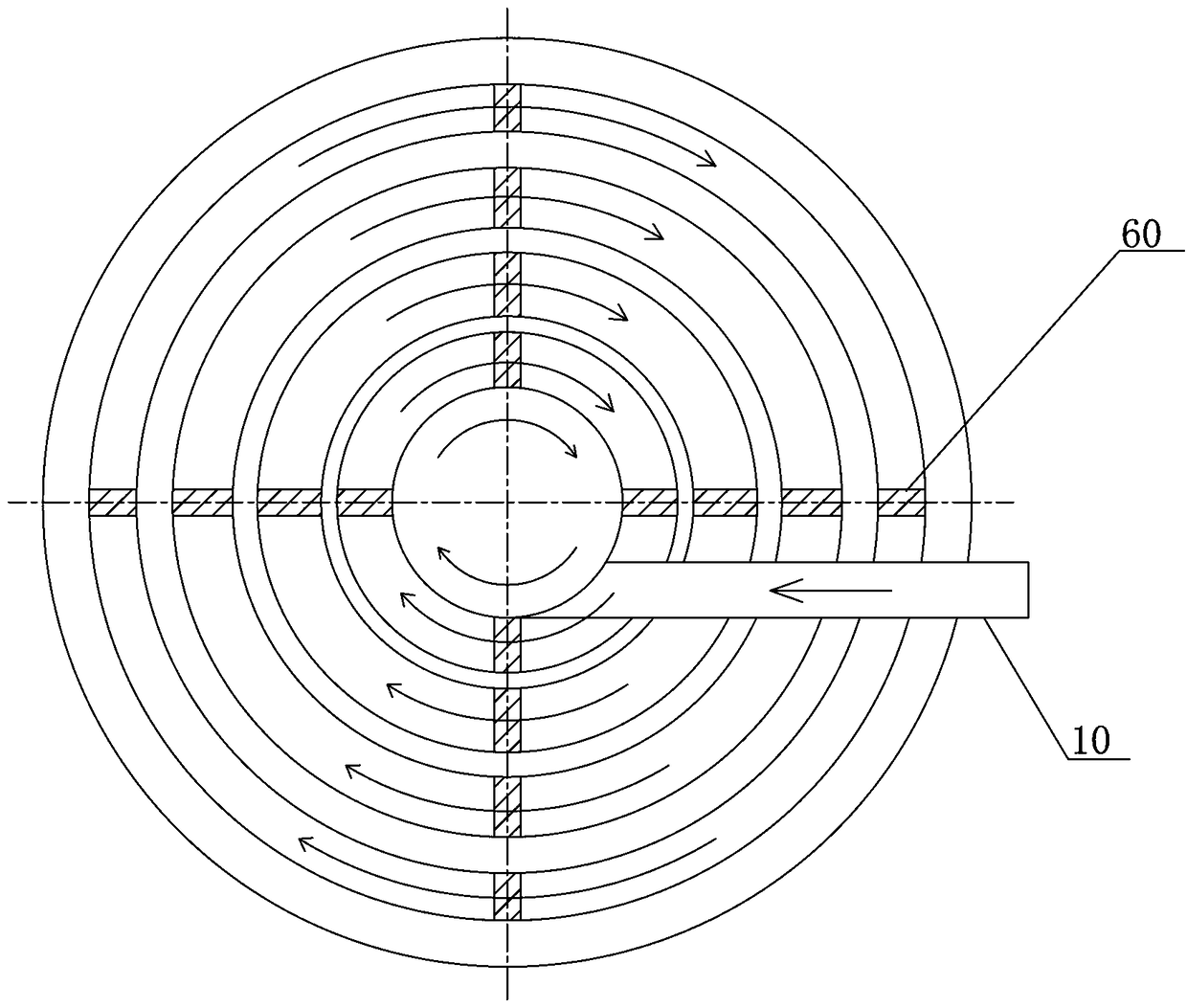

[0020] Figure 1 to Figure 2 , which is a preferred embodiment of the cyclone sorting device for particle size of pulverized material provided by the present invention. Such as Figure 1 to Figure 2 As shown, the cyclone sorting device for the particle size of the pulverized material includes an air inlet pipe 10 for entering the airflow and the particle mixture, and the air inlet pipe 10 is connected with a cyclone cylinder 20 for swirling the airflow and the particle mixture, The swirl tube 20 is provided with a swirl guide core column 21 for guiding the swirl flow, and the swirl tube 20 is provided with a coaxial center and the diameter increases sequentially for the particle mixture in the swirl flow to change according to the particle size according to the gravity. A plurality of outer expansion cylinders 30 that collect particles of d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap