Increased efficiency counter-rotating electric motor for propelling a boat

a counter-rotating, electric motor technology, applied in the direction of boat construction, marine propulsion, propulsive elements, etc., can solve the problems of high manufacturing cost, difficult fabrication, and difficult to manufacture, and achieve the effect of reducing the winding of weeds around the propeller, improving safety, and increasing the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

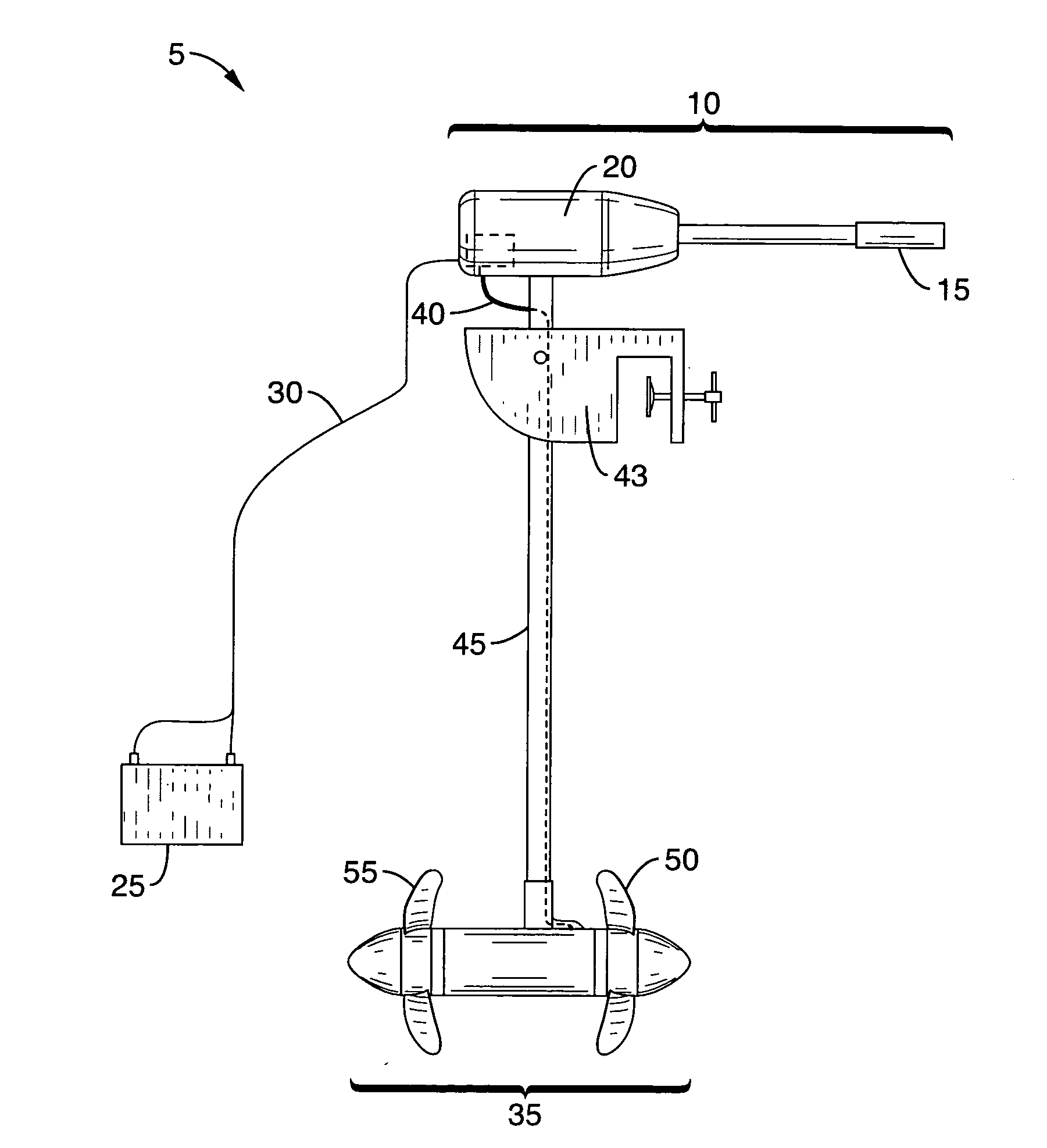

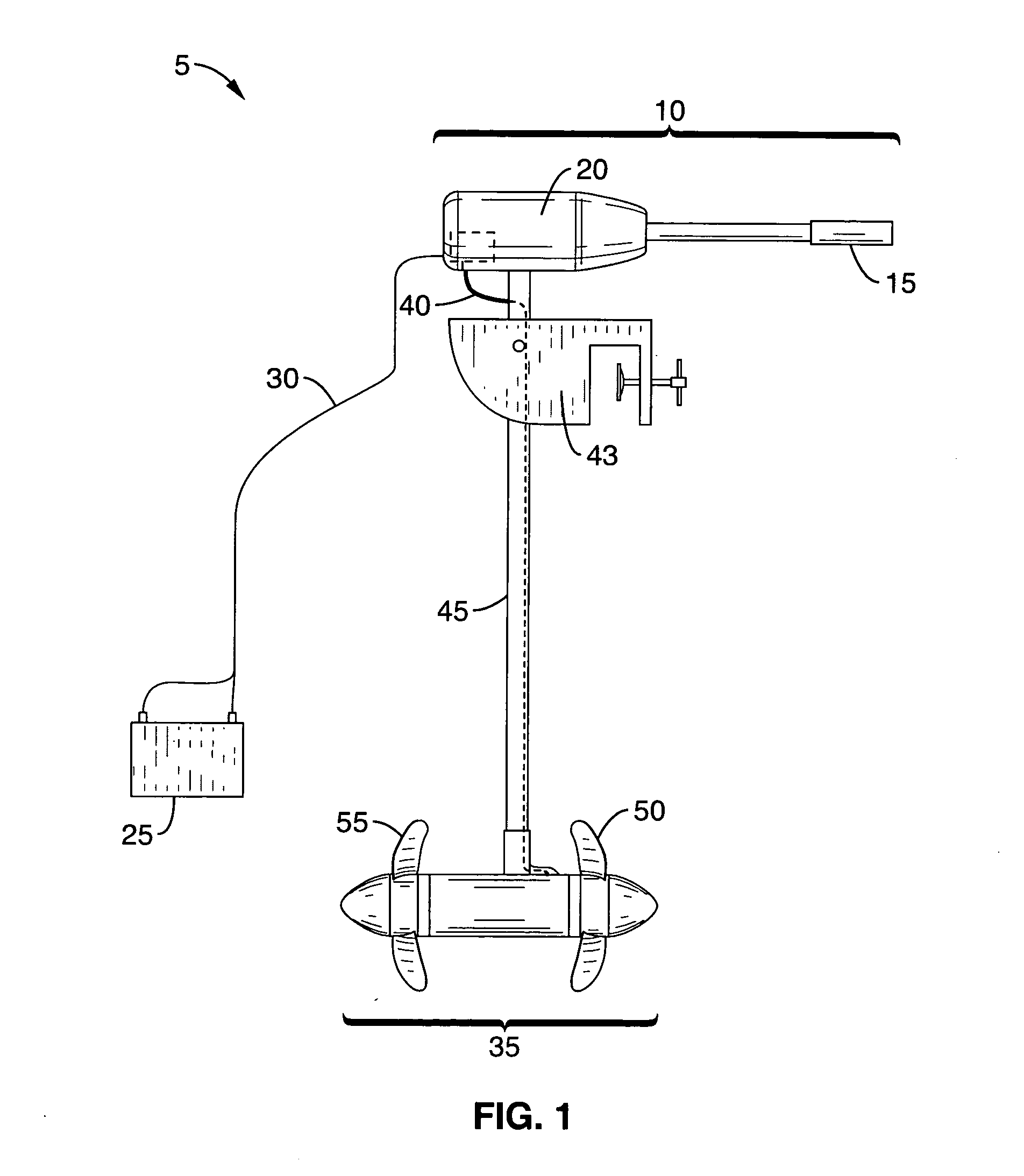

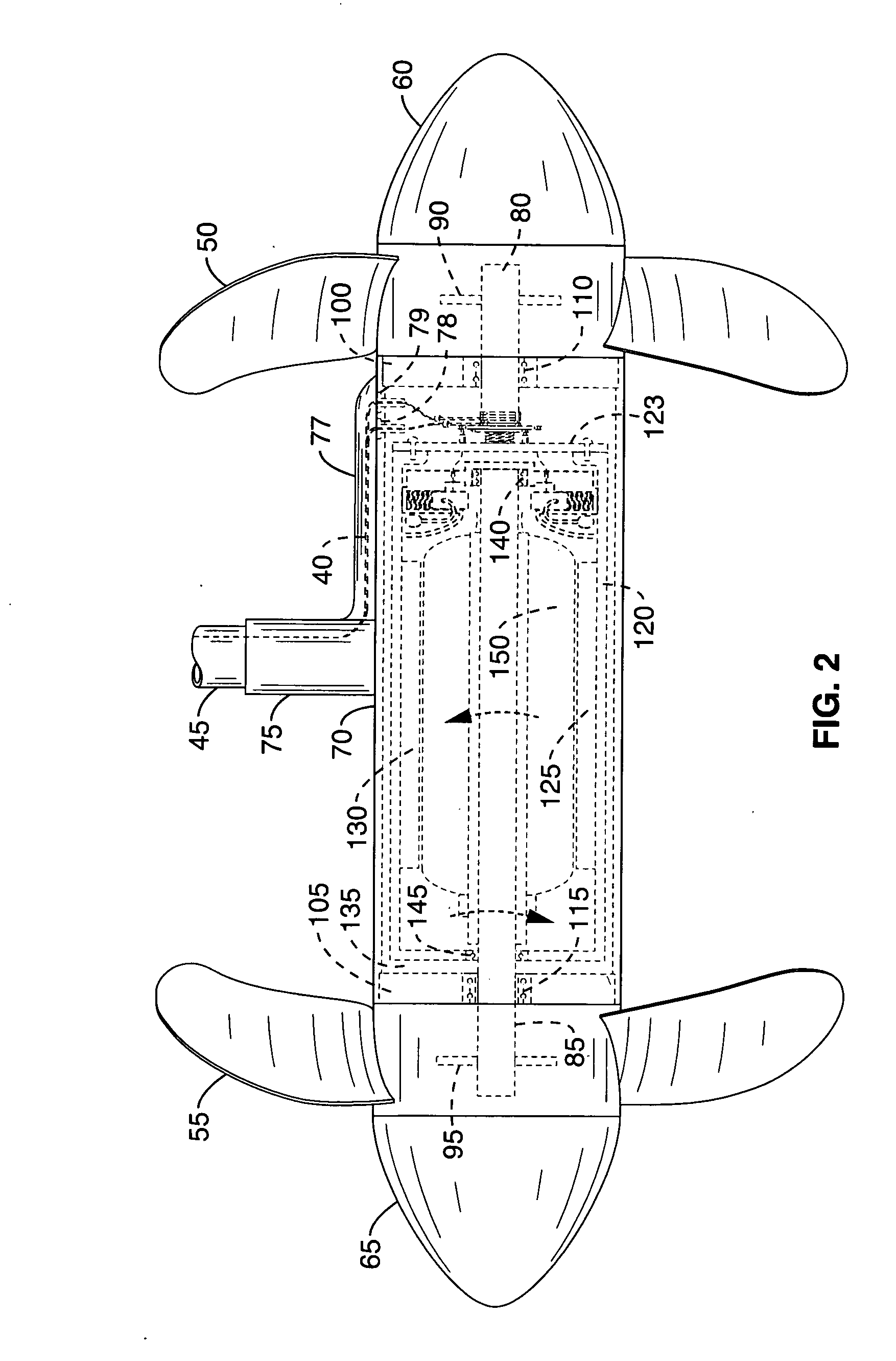

[0036]Referring more specifically to the drawings, for illustrative purposes the present invention is presented in the embodiments generally shown in FIG. 1 through FIG. 8. It will be appreciated that the subject apparatus may vary as to configuration and as to details of the parts without departing from the basic concepts as disclosed herein.

[0037]Generally, the subject invention is a counter-rotating electric motor and water-vehicle propulsion system utilizing the counter-rotating electric motor. The counter-rotating motor includes within a water-tight or secure motor housing a stator having first and second ends that rotates about a central axis in a first direction, an armature having first and second ends that rotates about the central axis in a second direction, wherein the stator surrounds at least a portion of the armature. A first axel is secured to the stator and extends along the central axis, wherein said first axel rotates in the first direction and a second axel is secure

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap