Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121 results about "Stator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The stator is the stationary part of a rotary system, found in electric generators, electric motors, sirens, mud motors or biological rotors. Energy flows through a stator to or from the rotating component of the system. In an electric motor, the stator provides a rotating magnetic field that drives the rotating armature; in a generator, the stator converts the rotating magnetic field to electric current. In fluid powered devices, the stator guides the flow of fluid to or from the rotating part of the system.

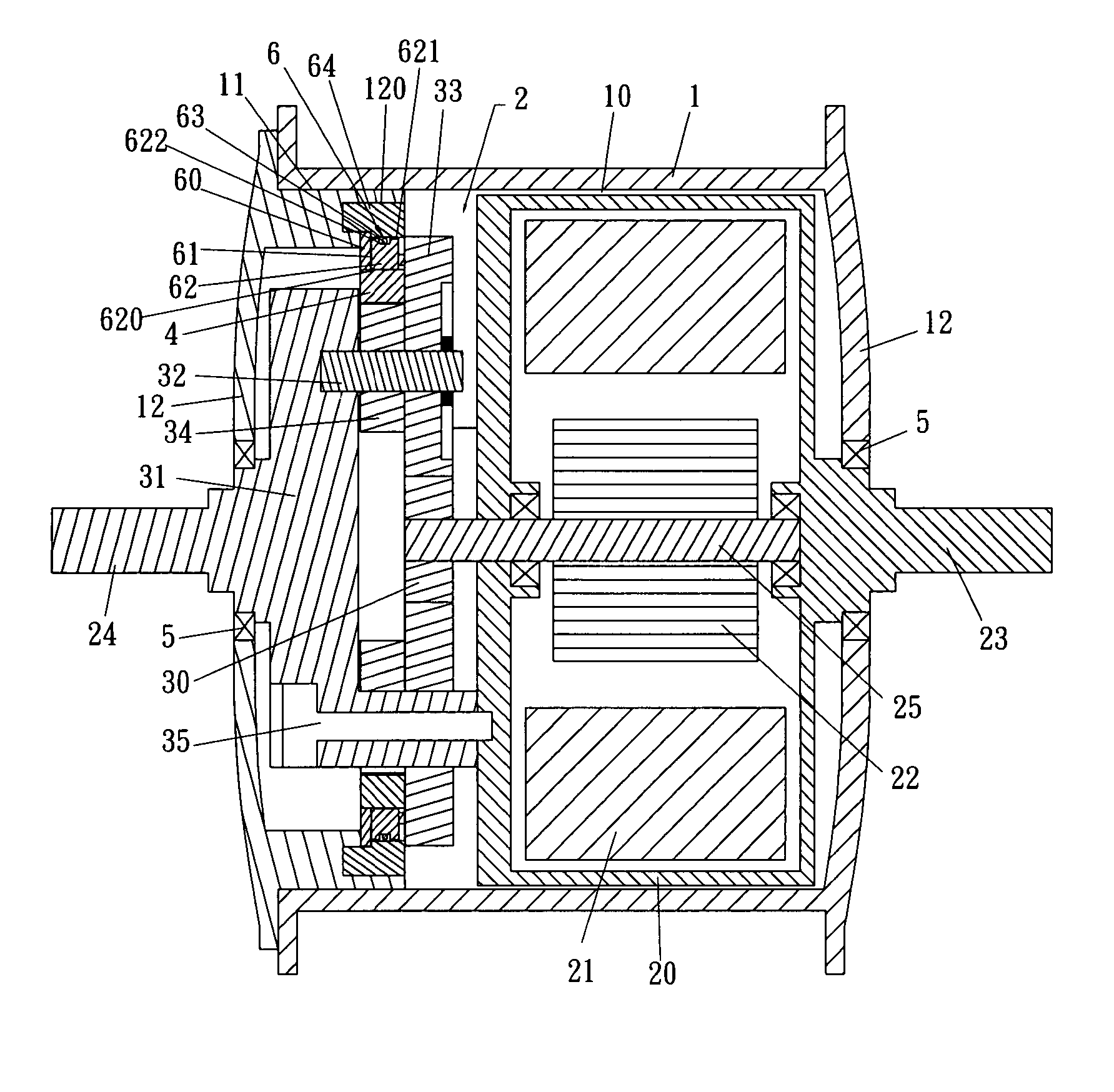

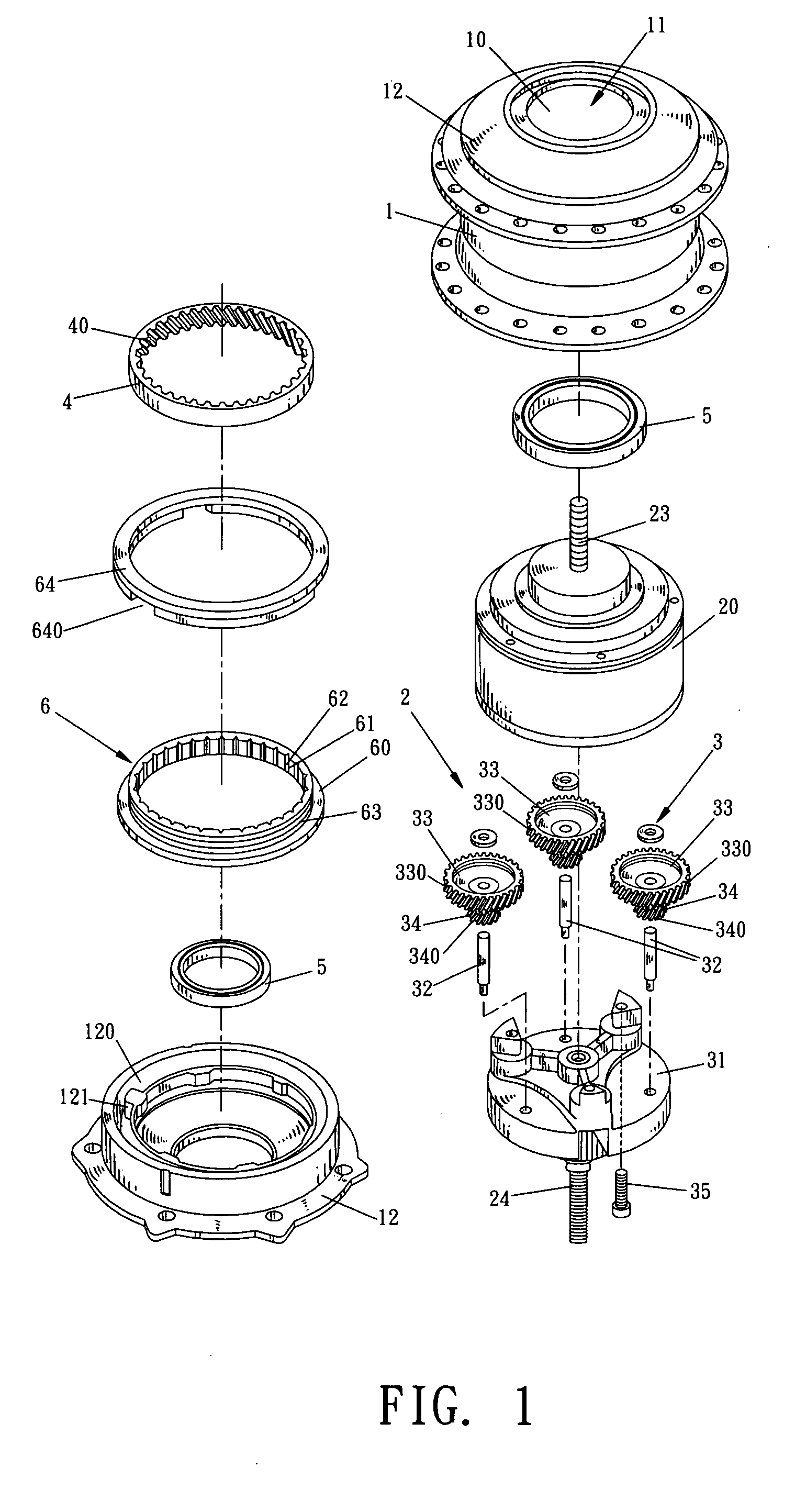

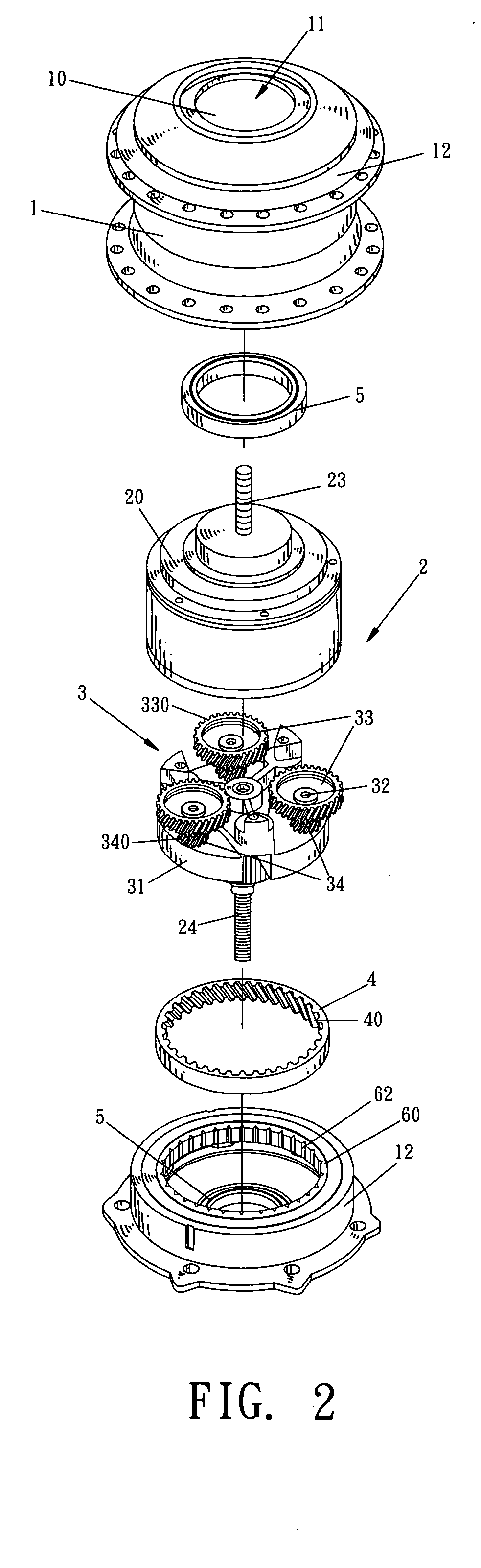

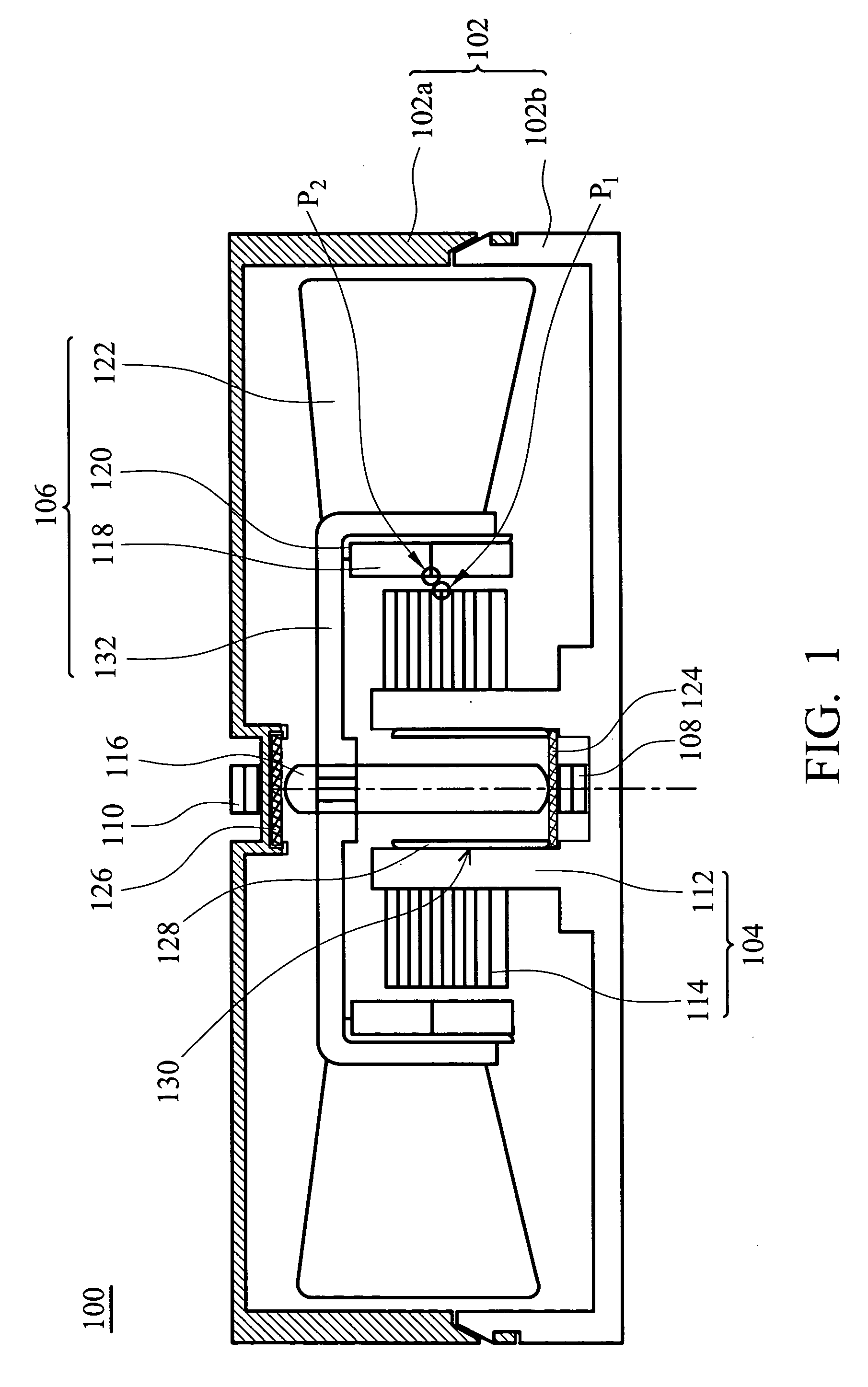

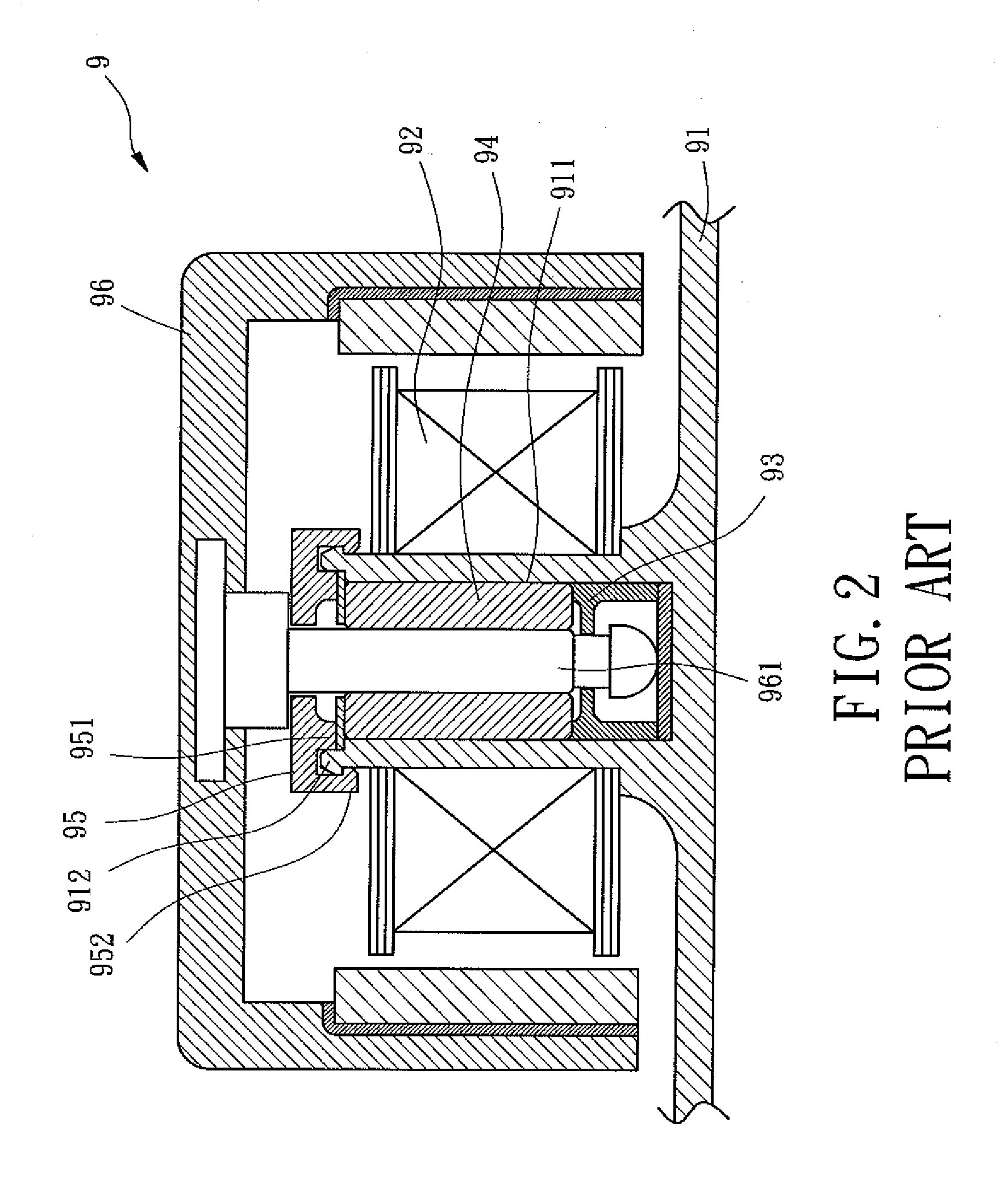

Hub motor mechanism

An electrically driven hub includes an electrical mechanism including an electrical motor and a planetary gear system connected to the electrical mechanism. A first fixed shaft is connected to the stator of the electrical motor and a second fixed shaft is connected to a second end of the stator of the electrical motor. The first and second fixed shafts are connected to the vehicle frame. A one-way clutch is connected between a cover of the hub and the planetary gear system so that the hub is rotated when the planetary gear system is activated by the motor.

Owner:LO CHIU HSIANG

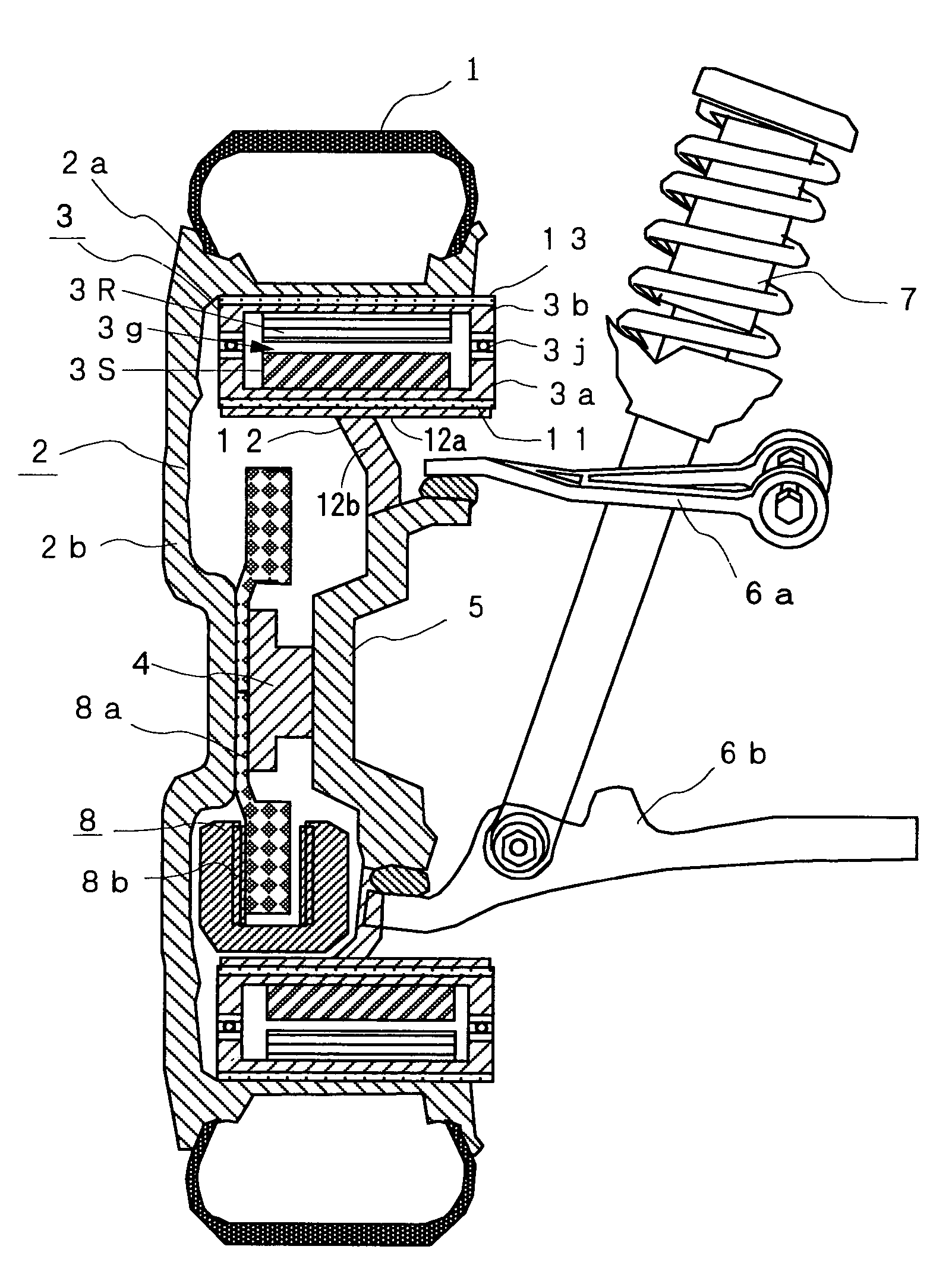

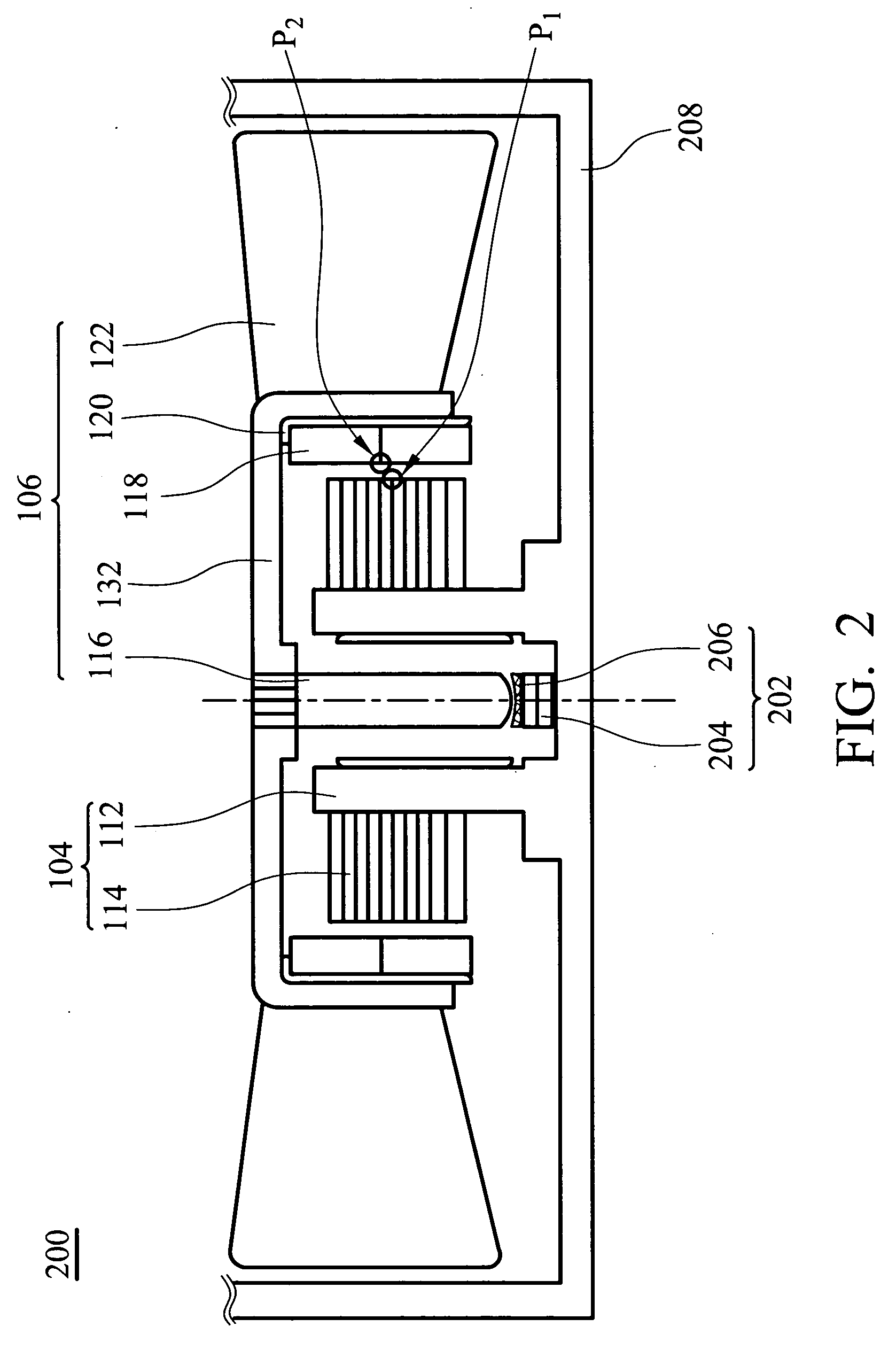

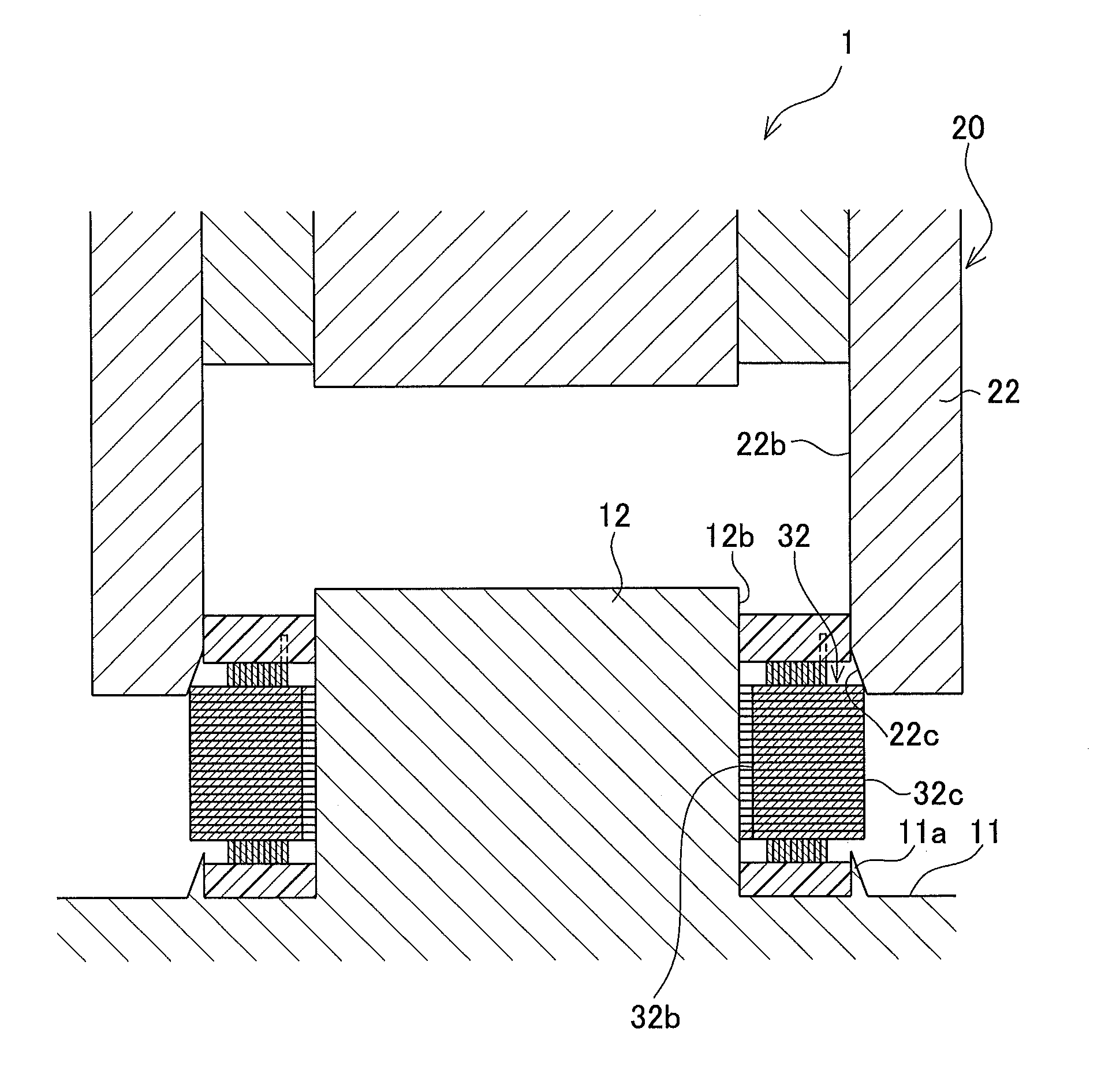

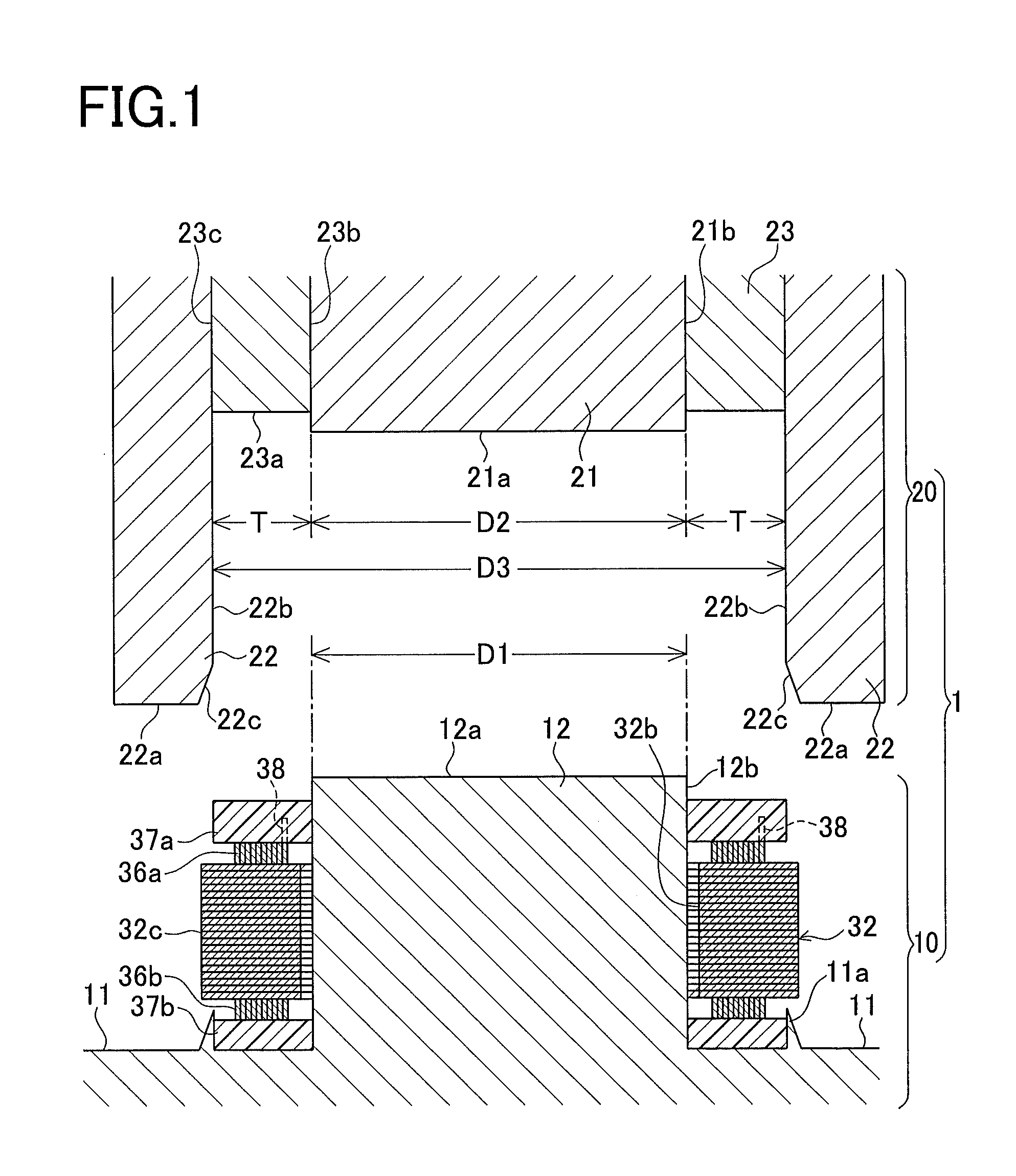

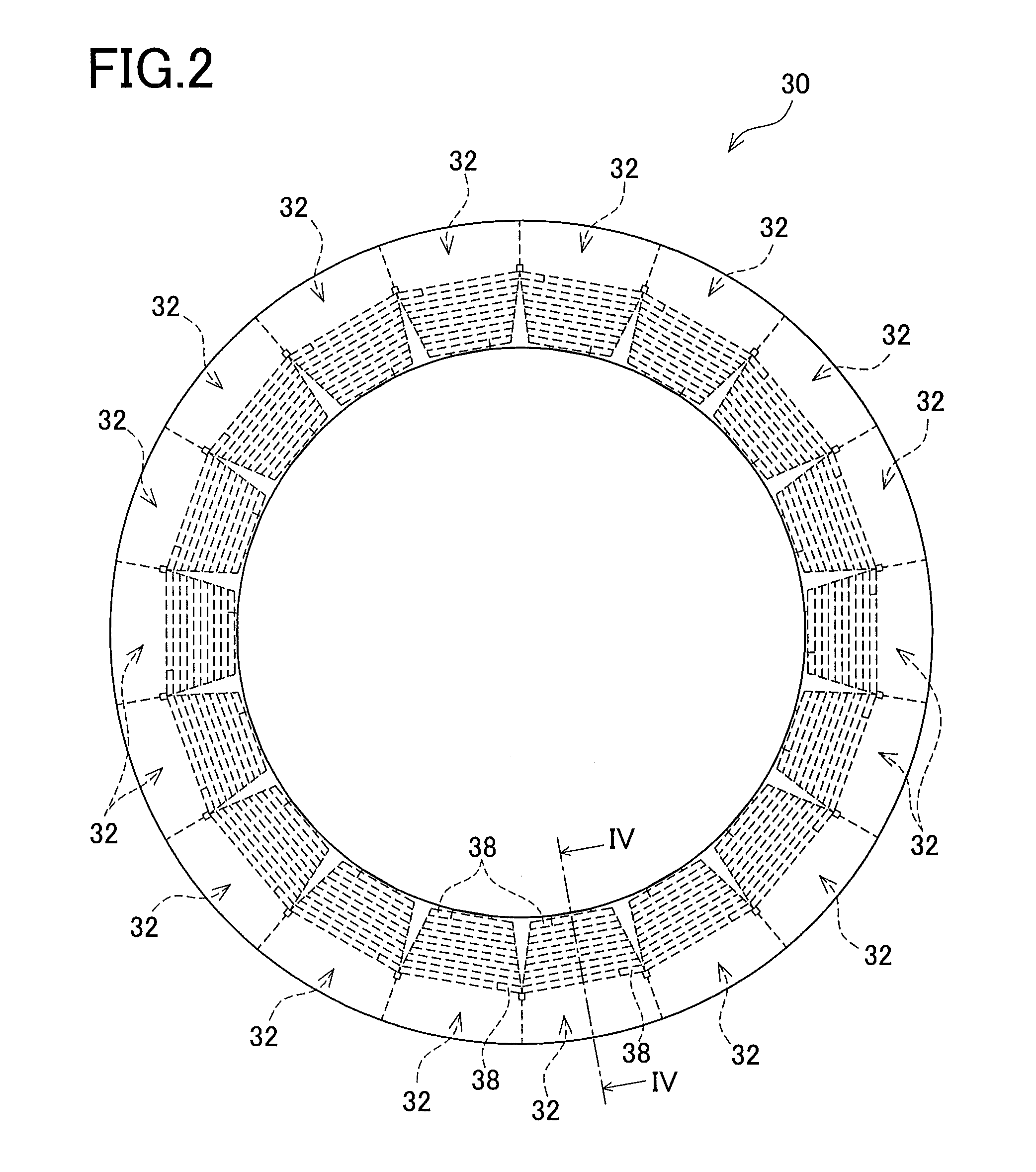

Fixing method of in-wheel motor and in-wheel motor system

InactiveUS7306065B2Reduce contact forceImprove road holding propertyRotating vibration suppressionNon-rotating vibration suppressionEngineeringElectric motor

Owner:BRIDGESTONE CORP

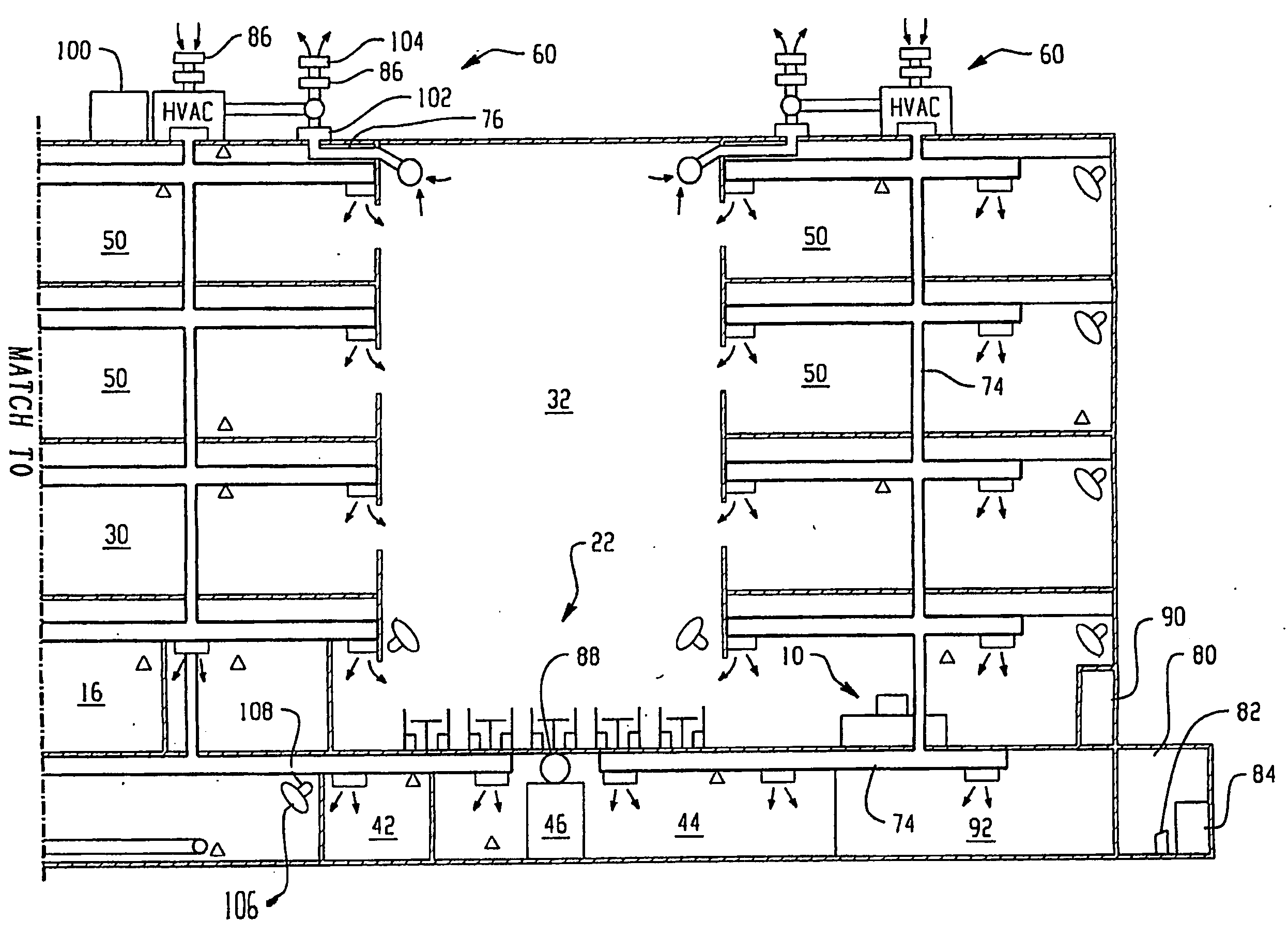

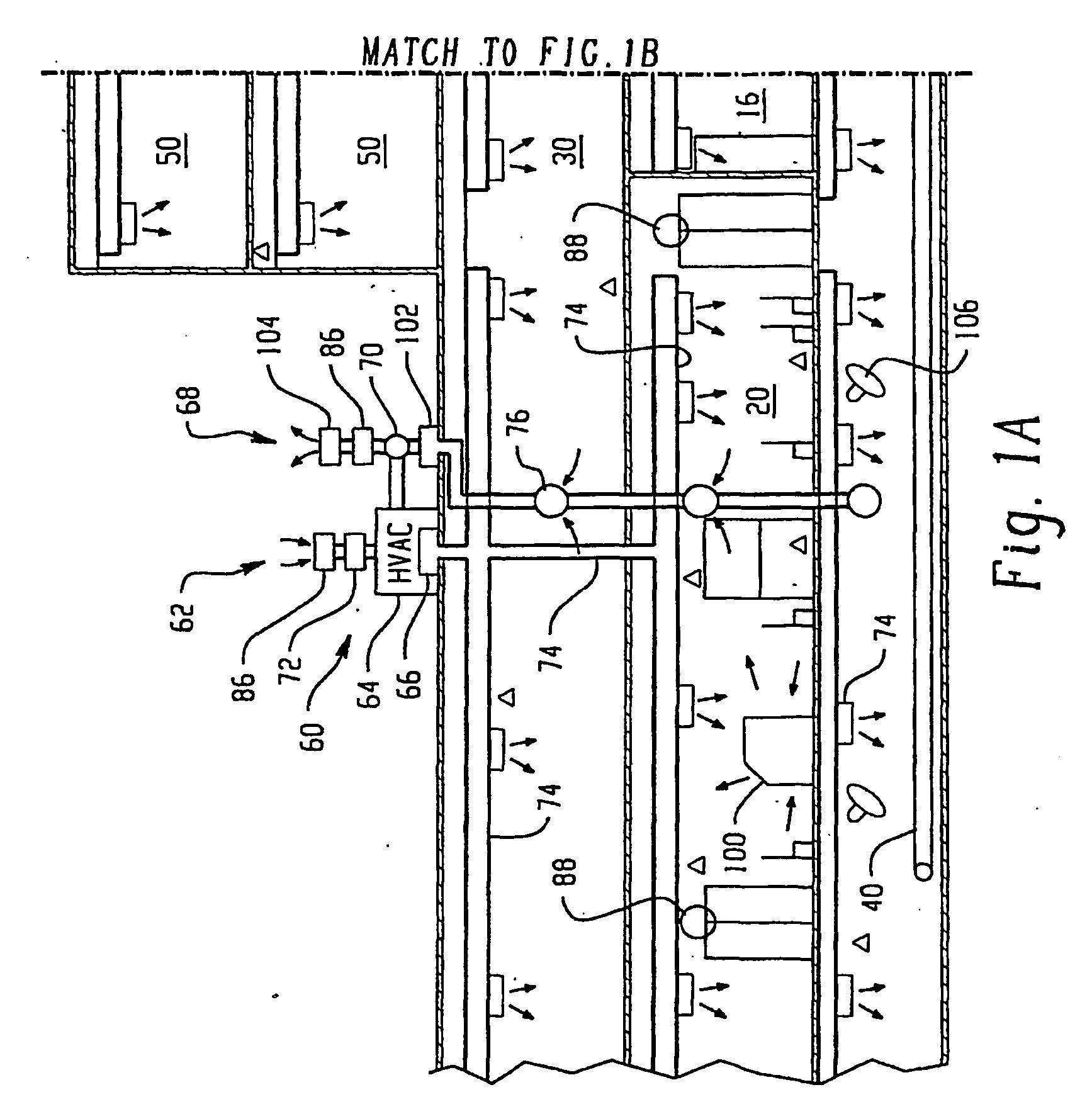

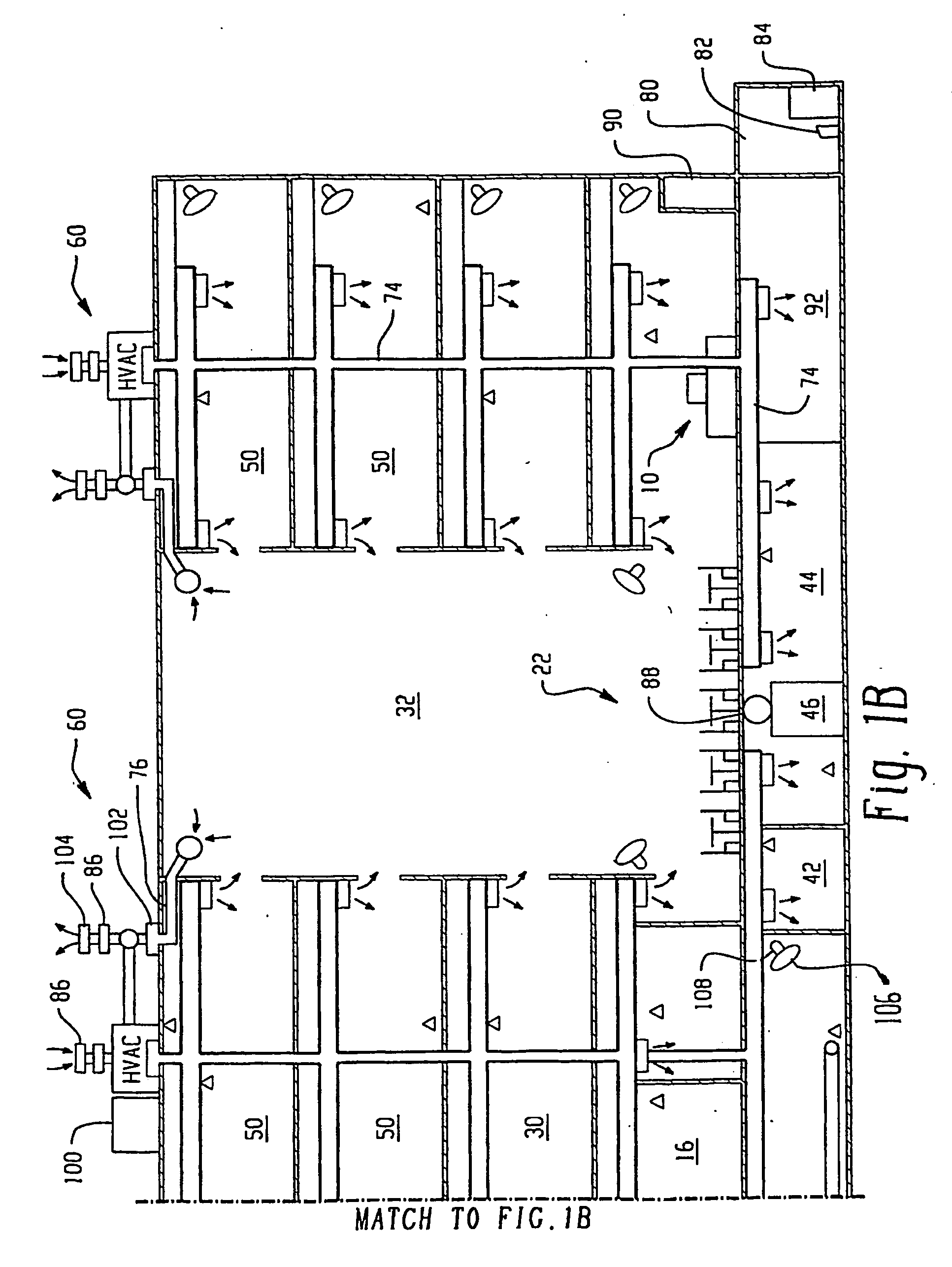

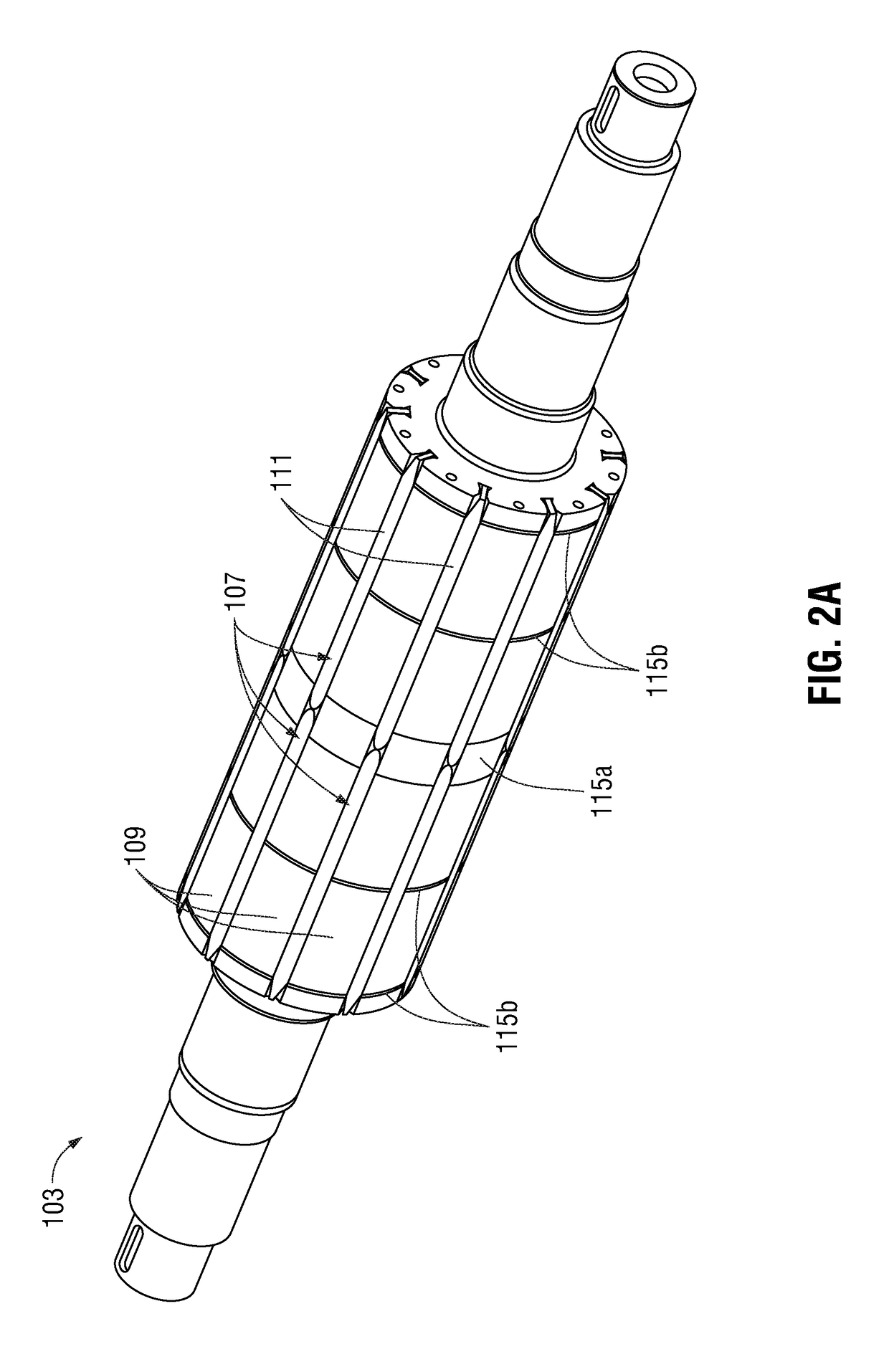

Integrated control and distribution system for the decontamination of large volume convoluted configuration spaces

ActiveUS20070140893A1Big spaceQuick implementationComponent separationSynthetic resin layered productsDistribution systemProcess engineering

Owner:STERIS CORP

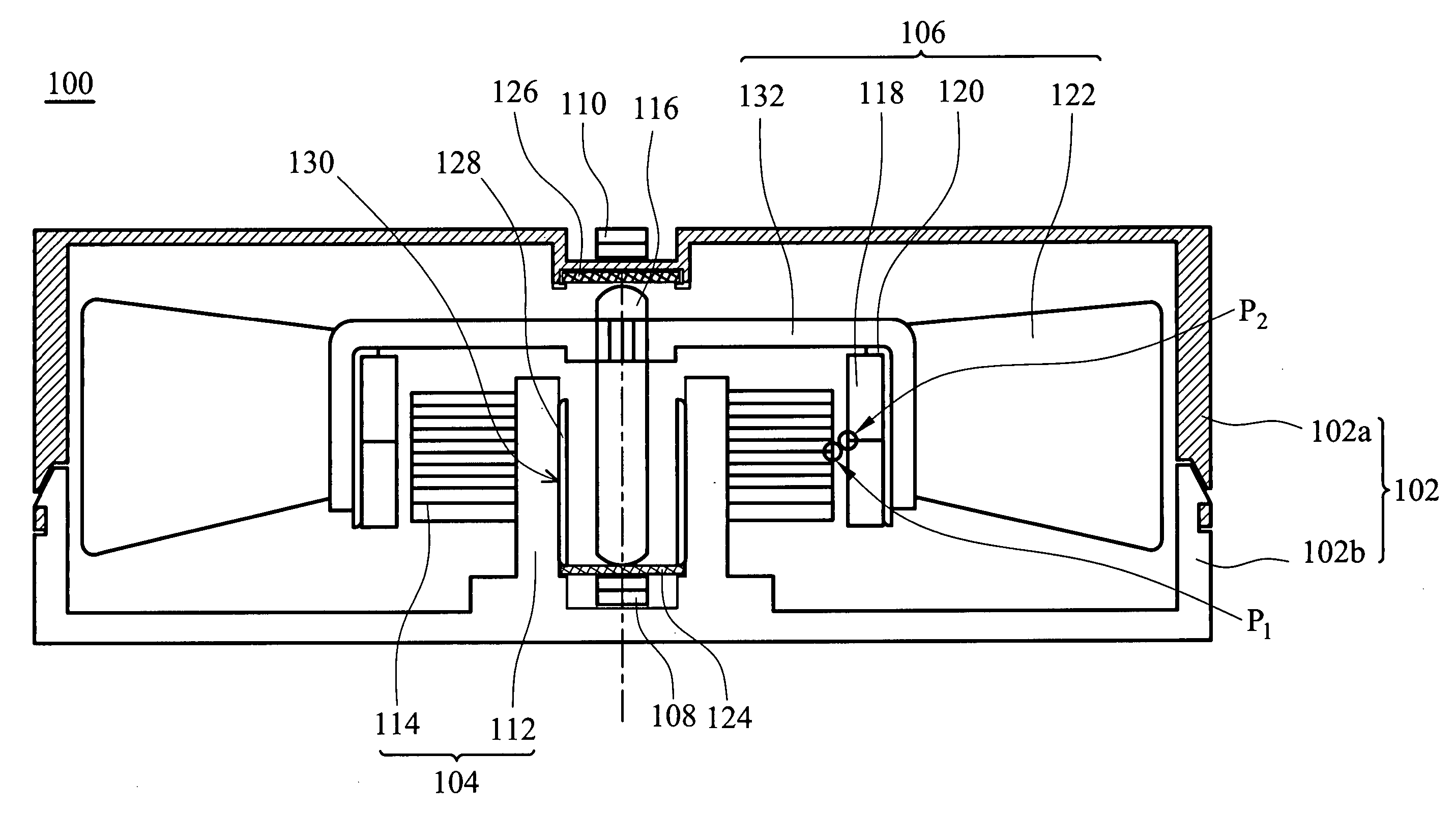

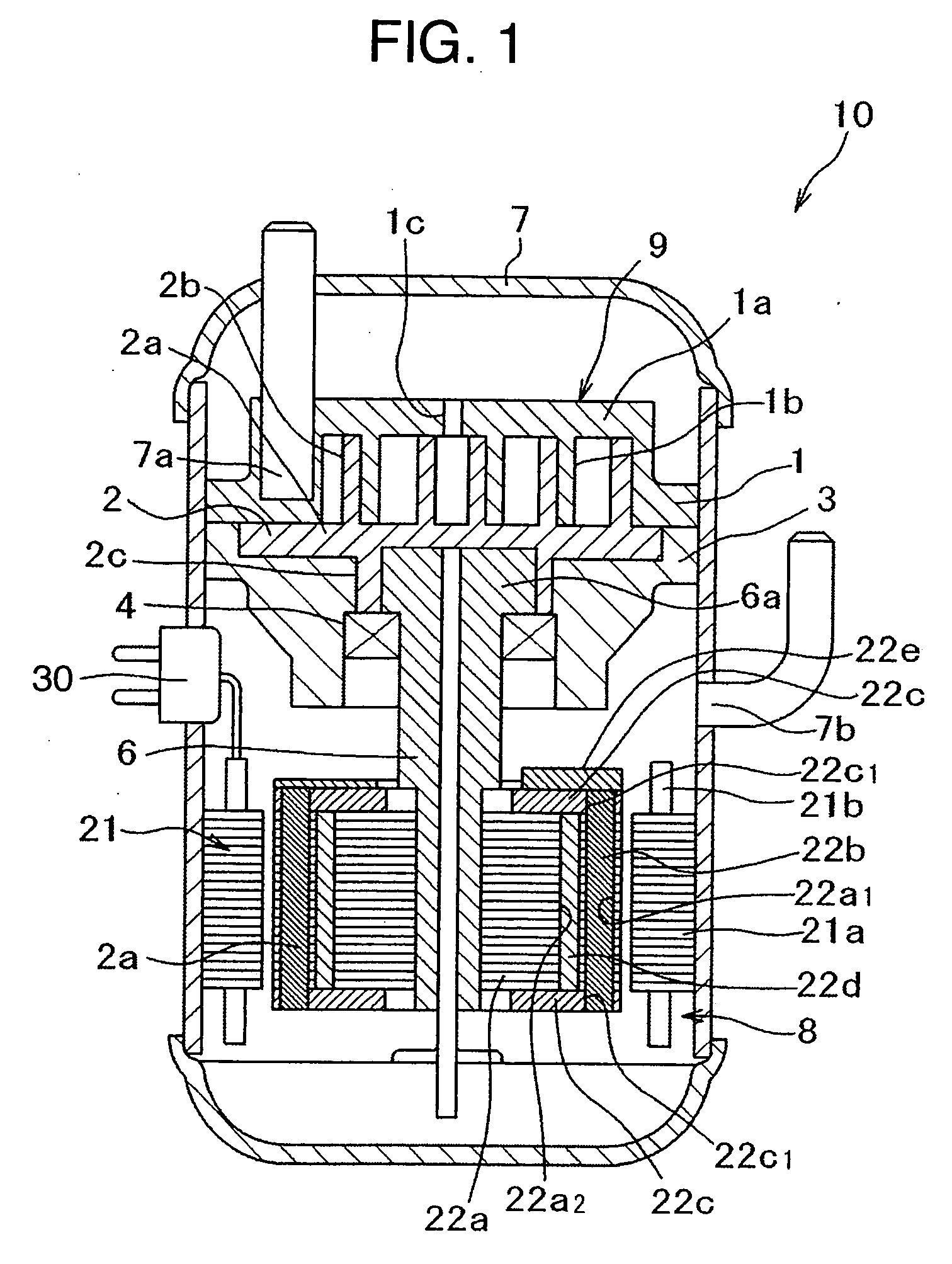

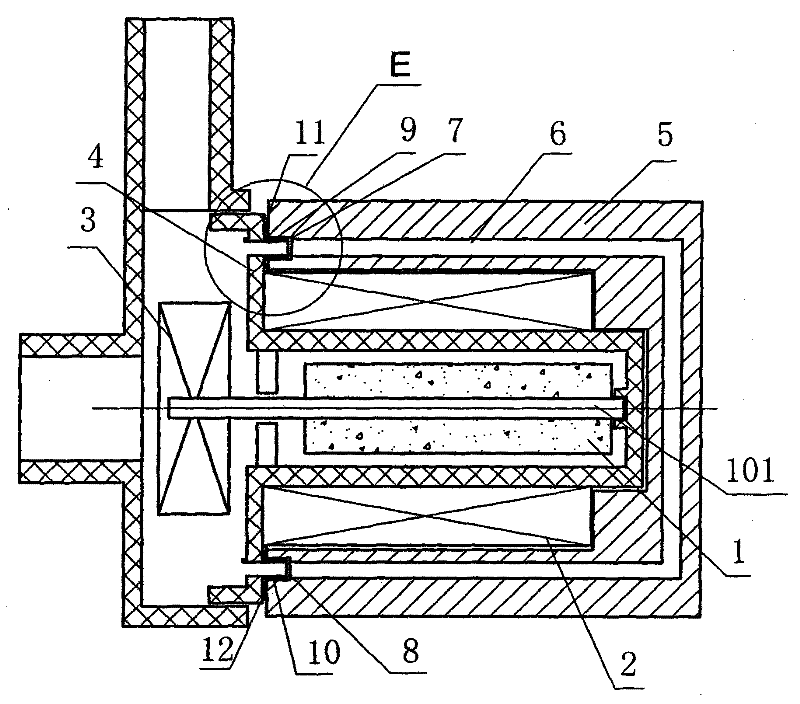

Motor

InactiveUS20050035670A1Reduce noiseExtended service lifePump componentsMagnetic circuitPhysicsMagnetic structure

Owner:DELTA ELECTRONICS INC

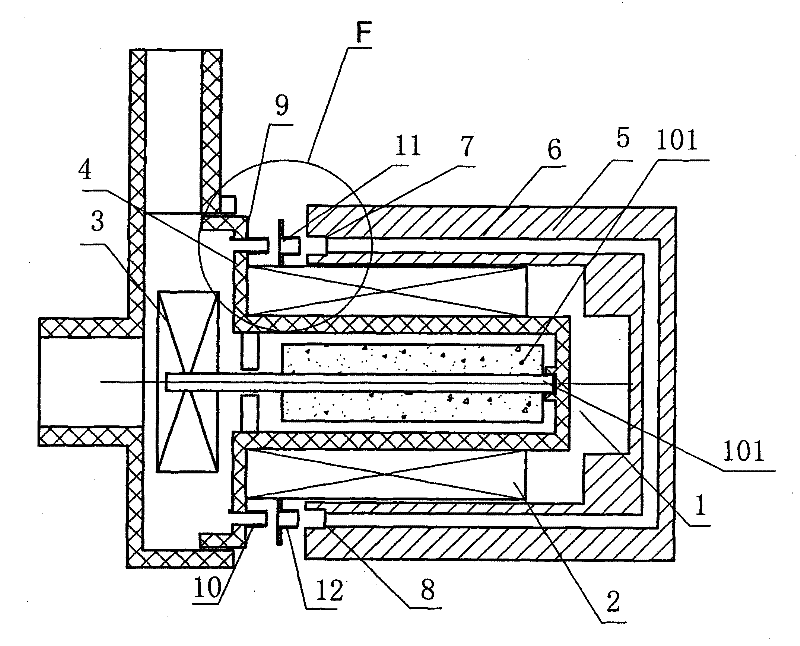

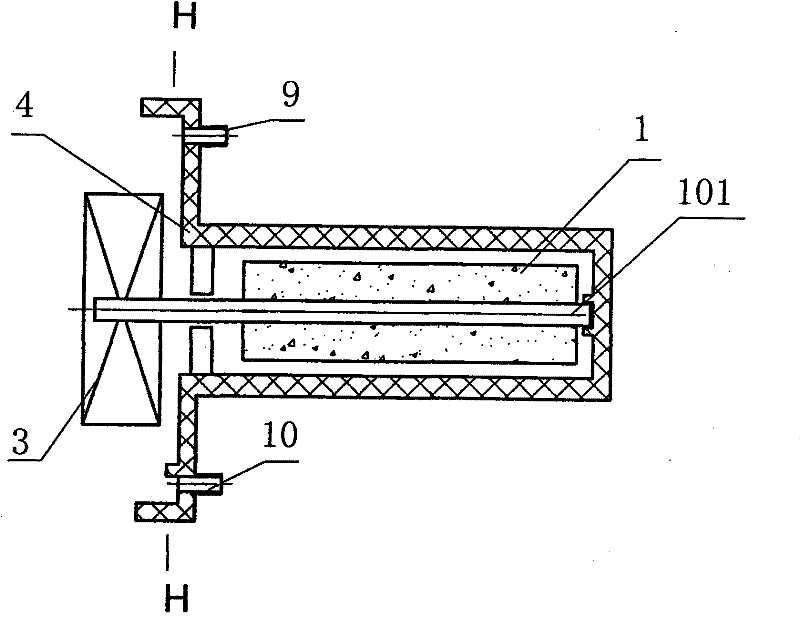

Motor

InactiveUS20100127588A1Prevent disengagementMagnetic circuit rotating partsPump componentsEngineeringSingle component

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Self-start synchronous motor, method for manufacturing the same and compressor

InactiveUS20060267441A1Inhibit deteriorationImprove efficiencySynchronous motorsStatorsElectrical conductorSynchronous motor

Owner:HITACHI APPLIANCES INC

Electric motor with liquid-cooled end windings

ActiveUS8093770B1Great and uniform coolingExtend motor lifeCooling/ventillation arrangementWindings conductor shape/form/constructionStatorConductor Coil

Owner:FORD GLOBAL TECH LLC

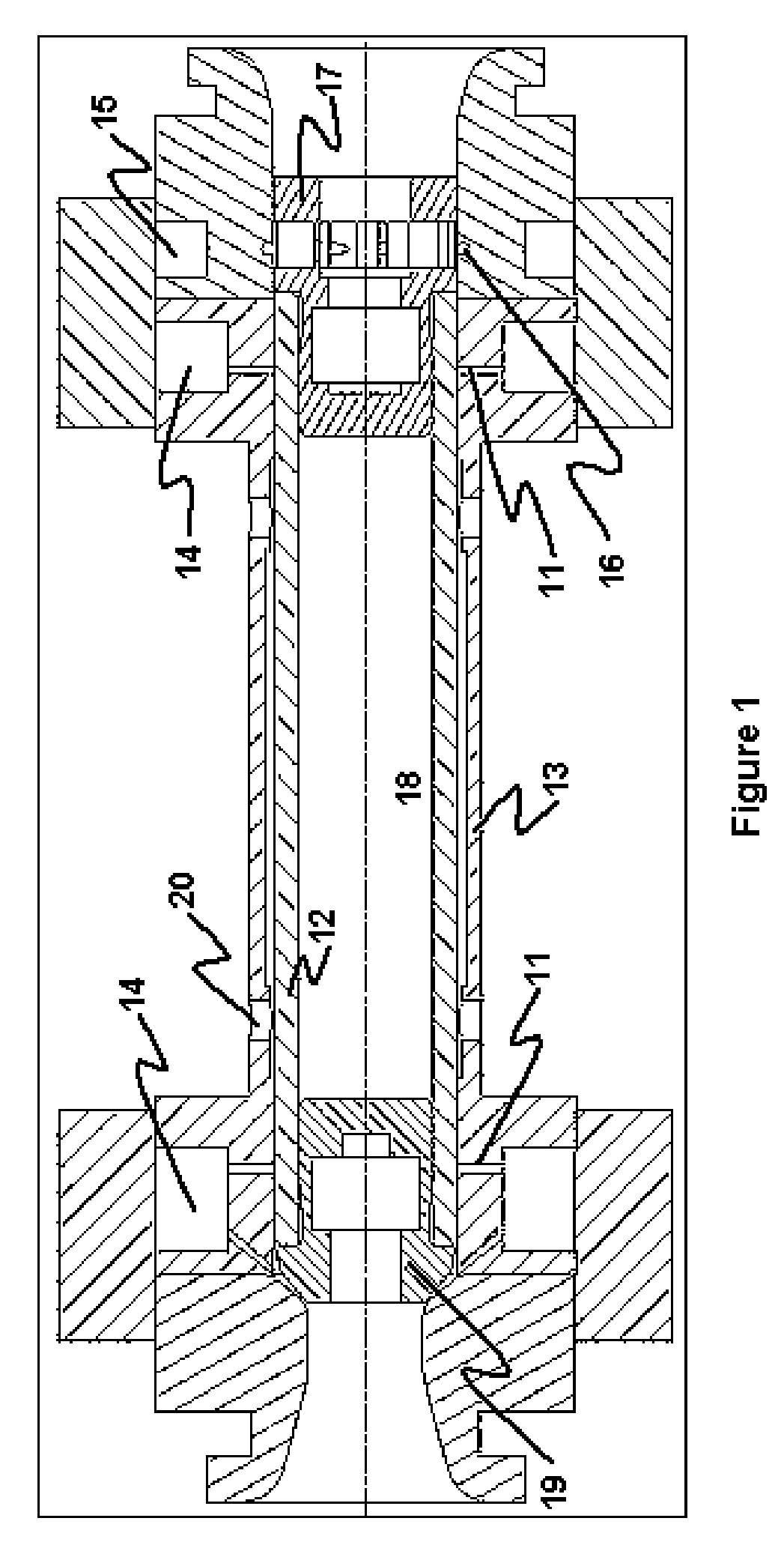

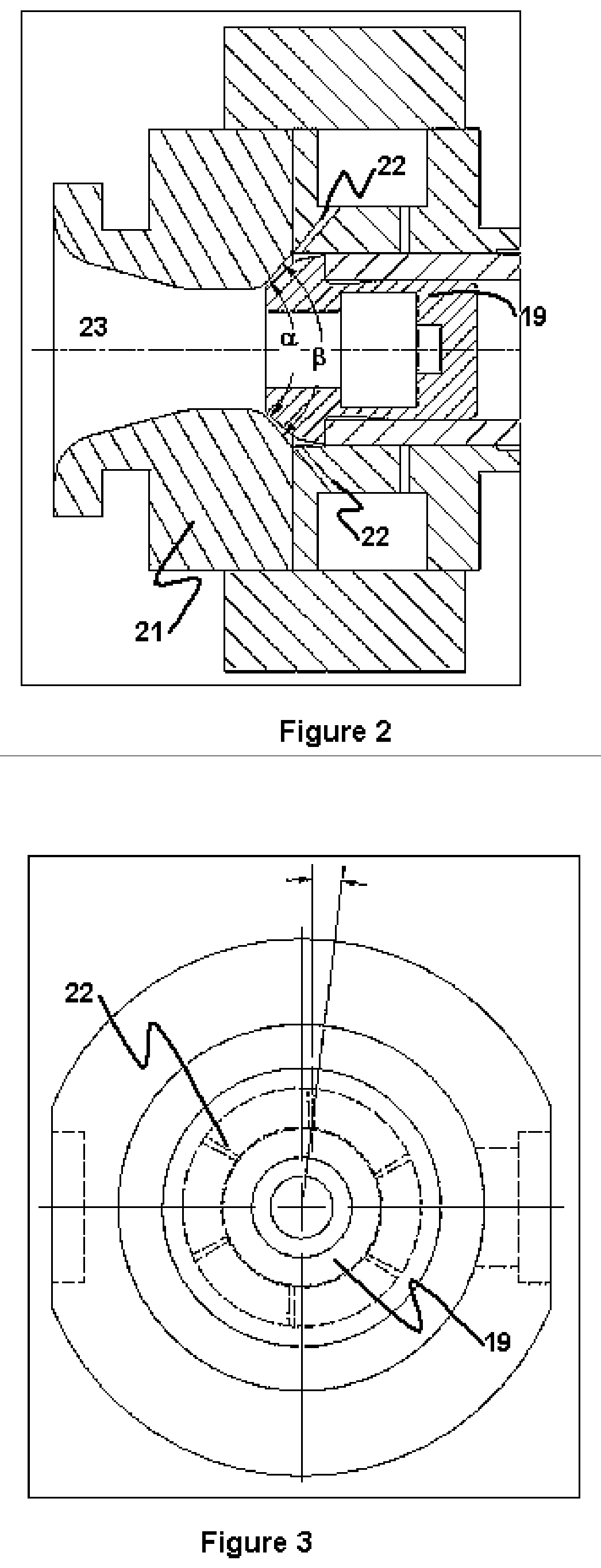

NMR MAS inflow bernoulli bearing

ActiveUS20060082371A1Improve stabilityIncrease stiffnessMagnetic circuit rotating partsMagnetic measurementsAxial pressureSurface velocity

Owner:DOTY SCI

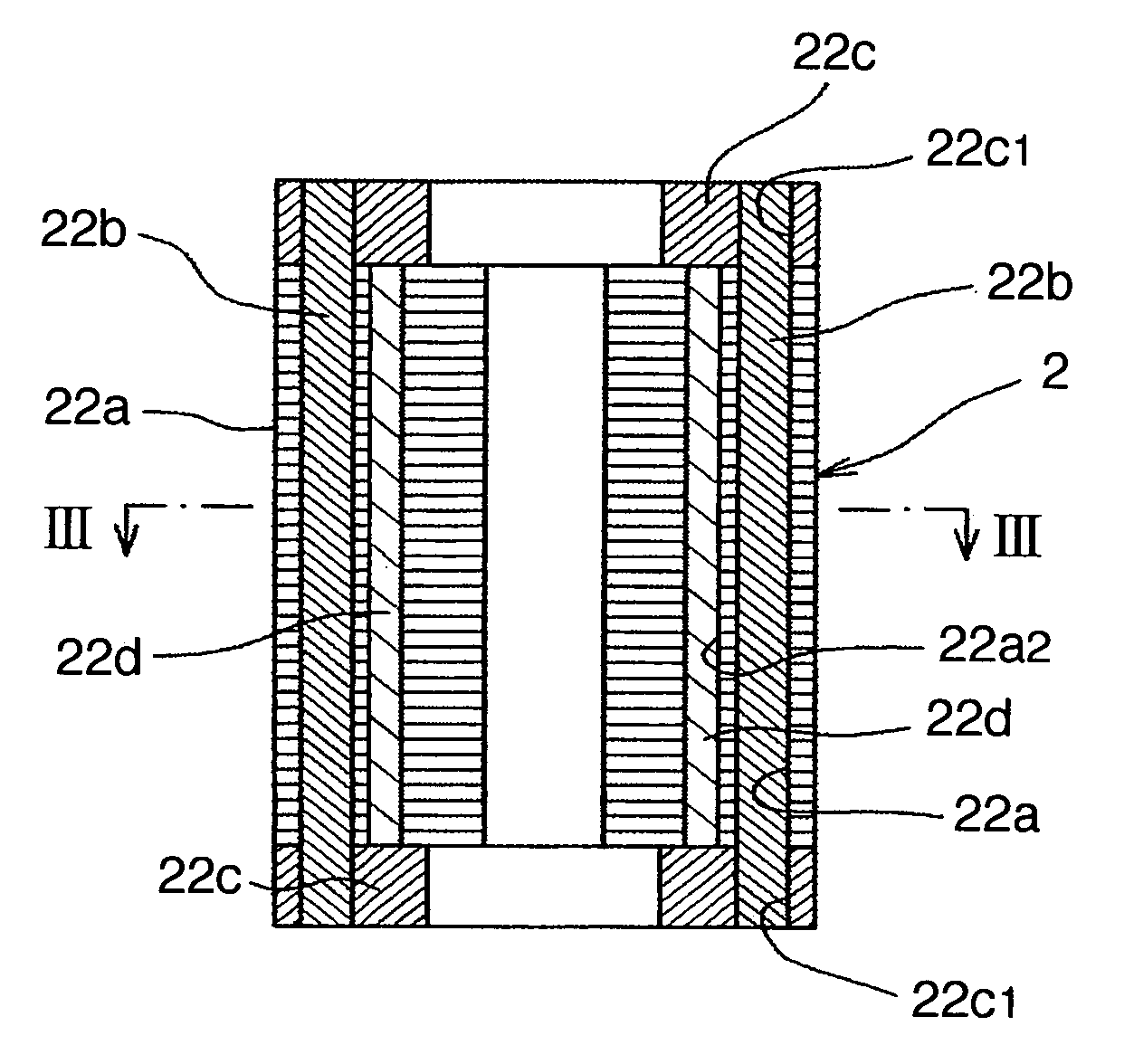

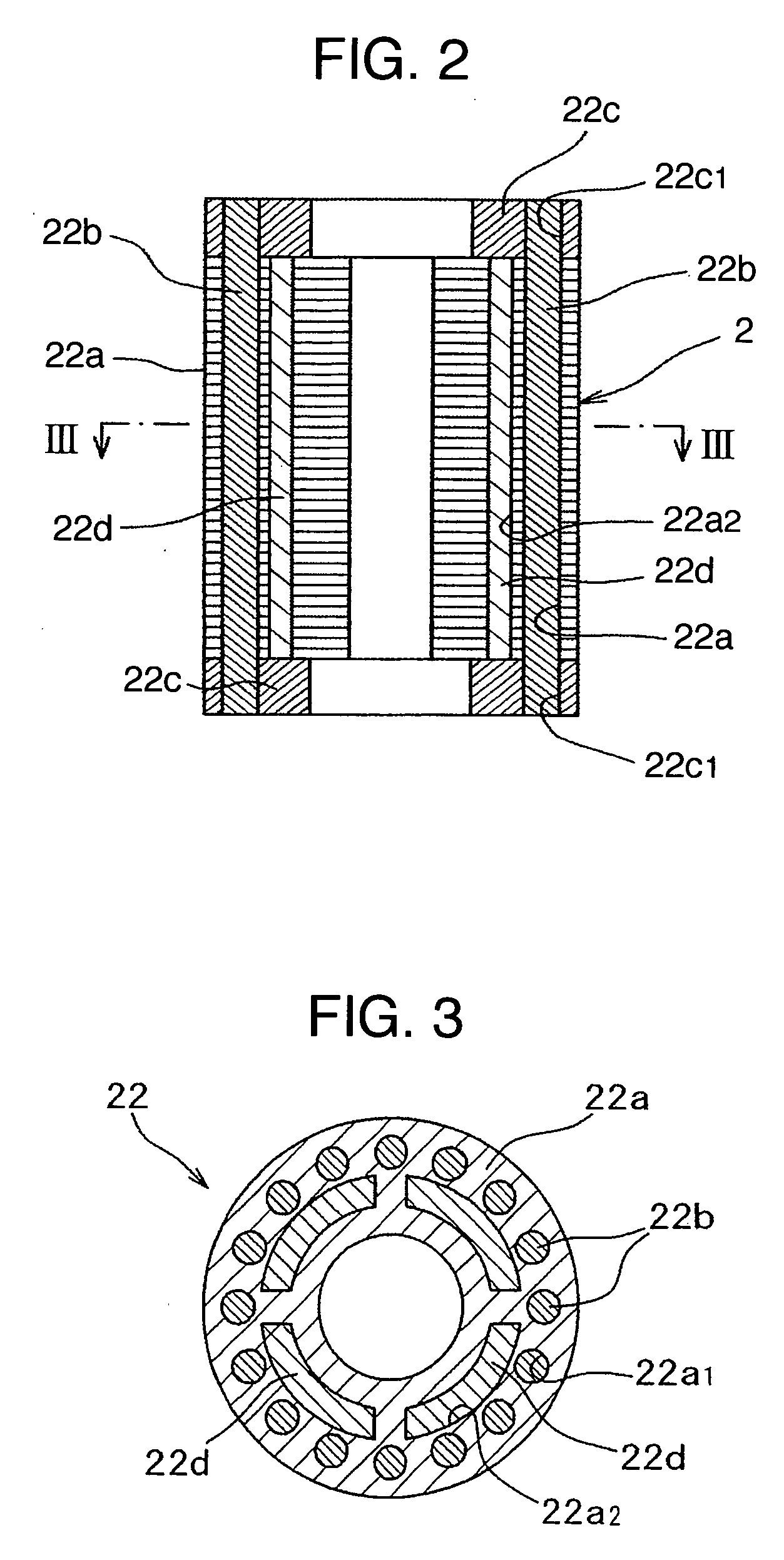

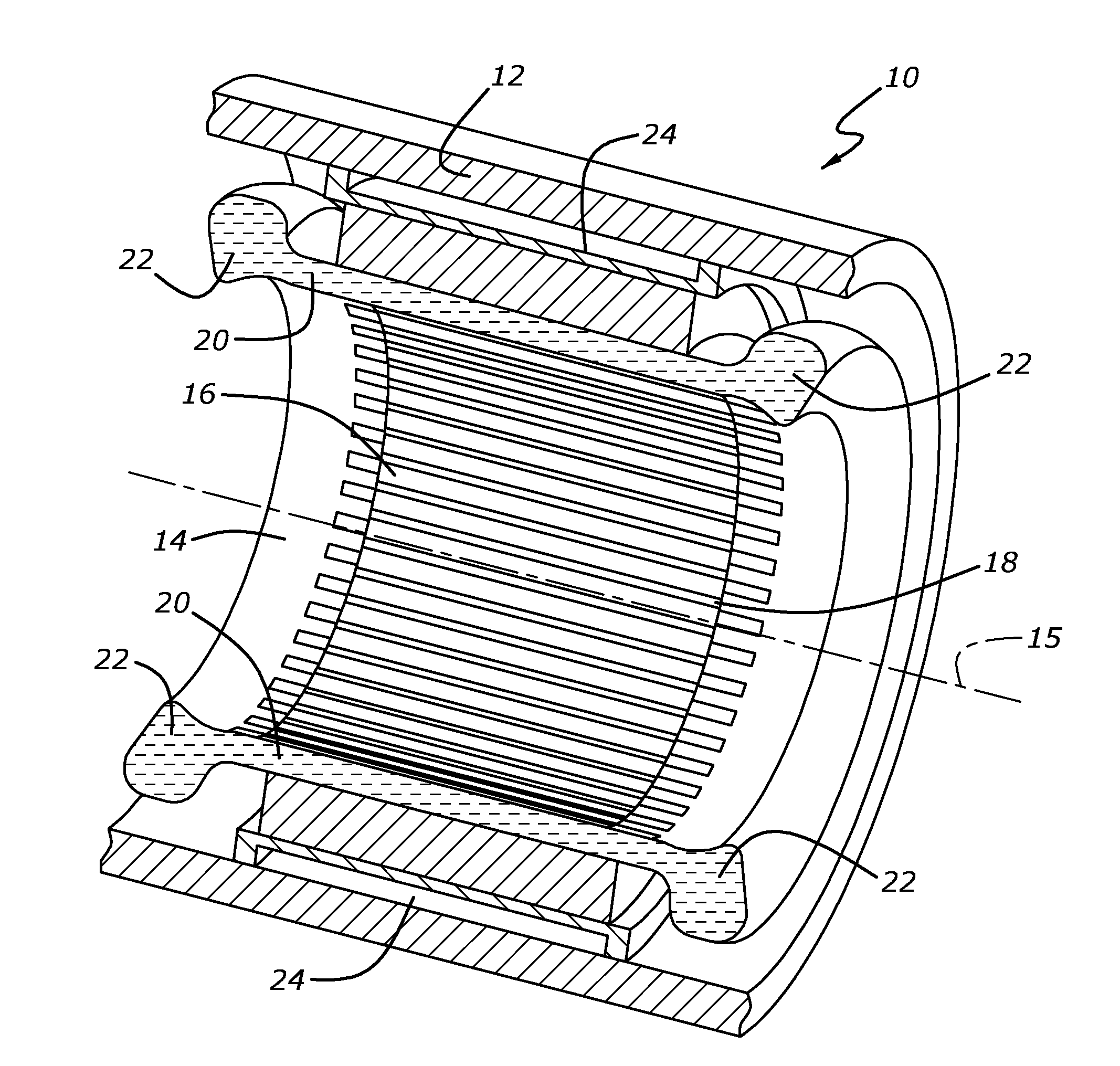

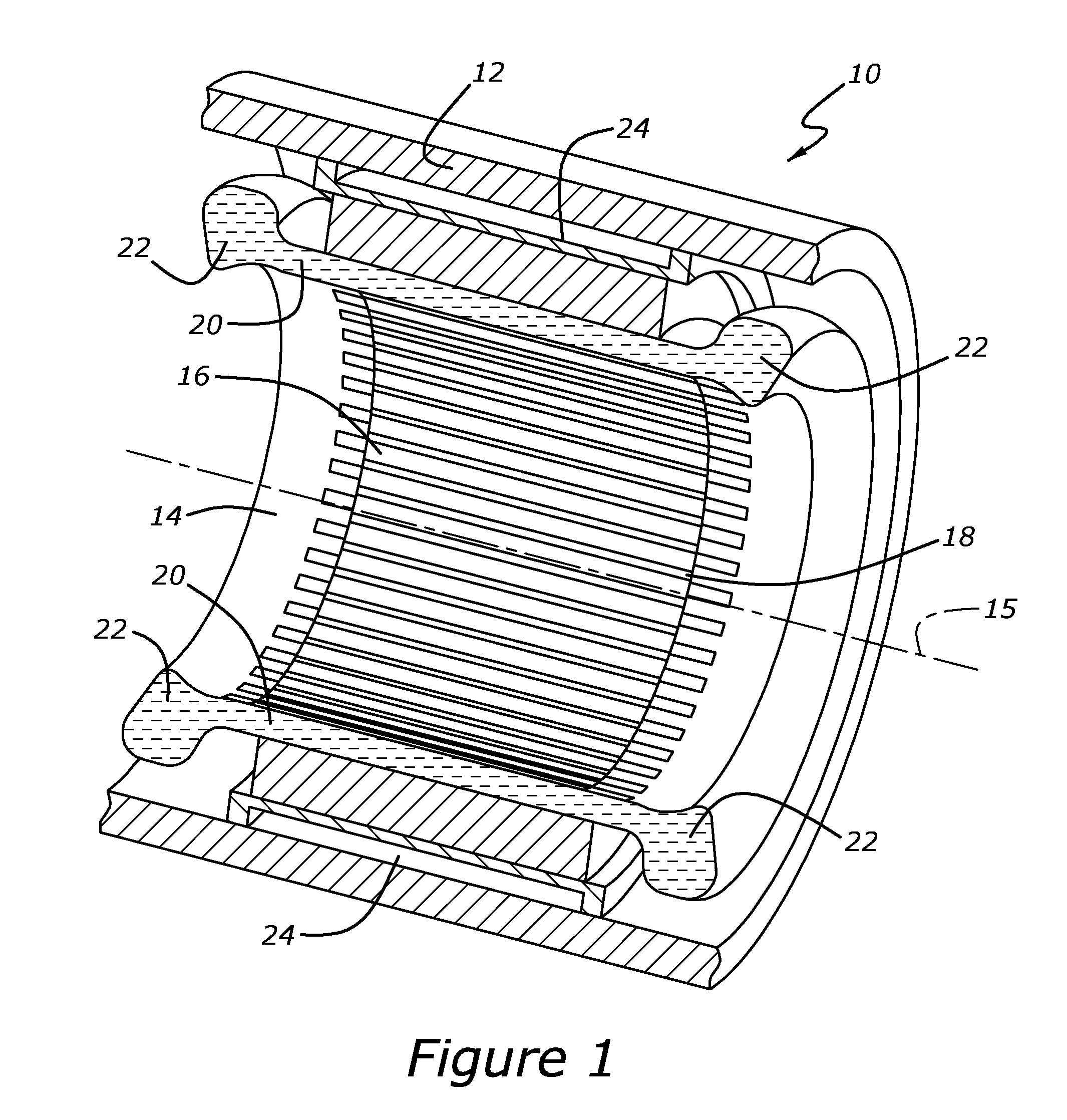

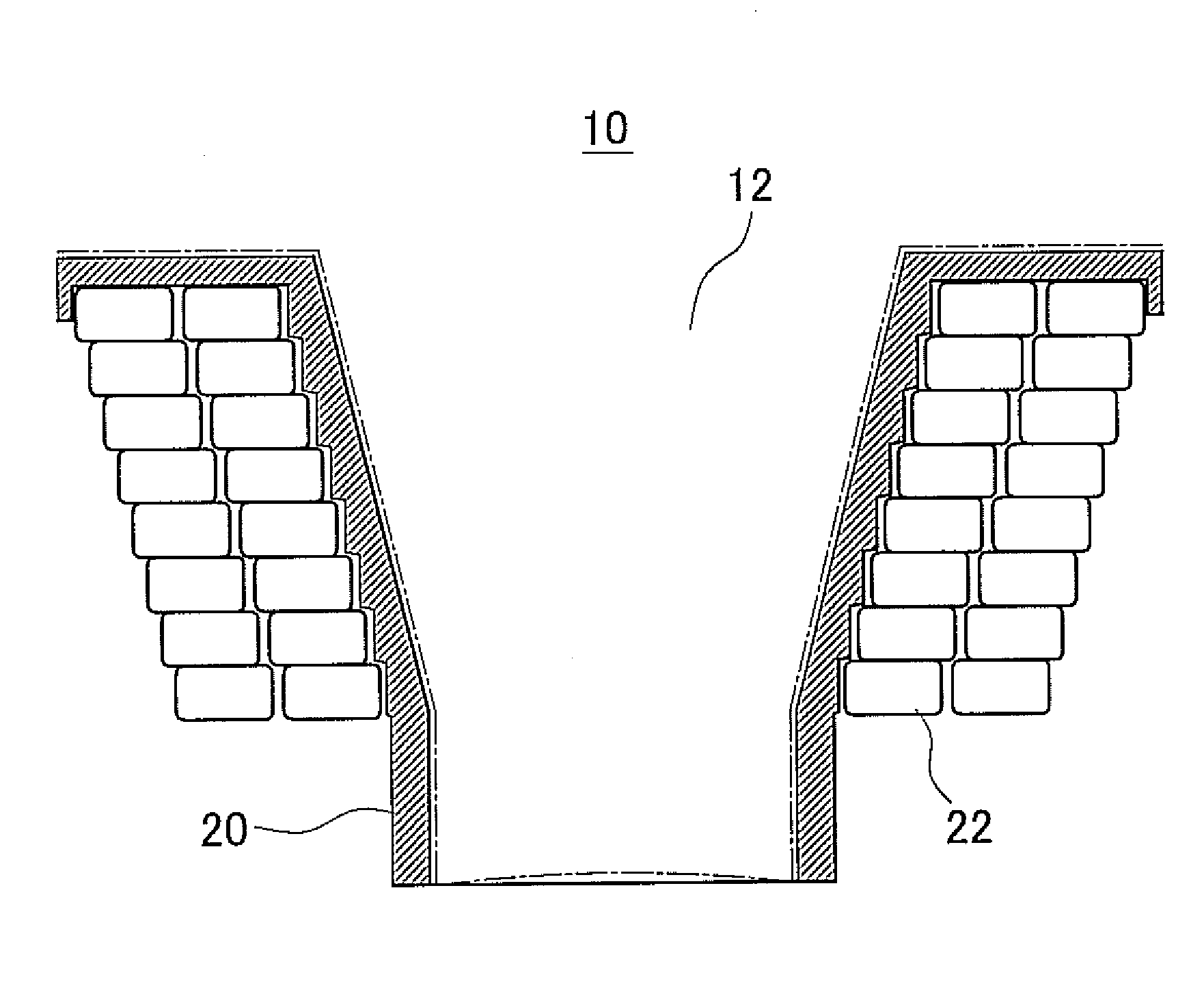

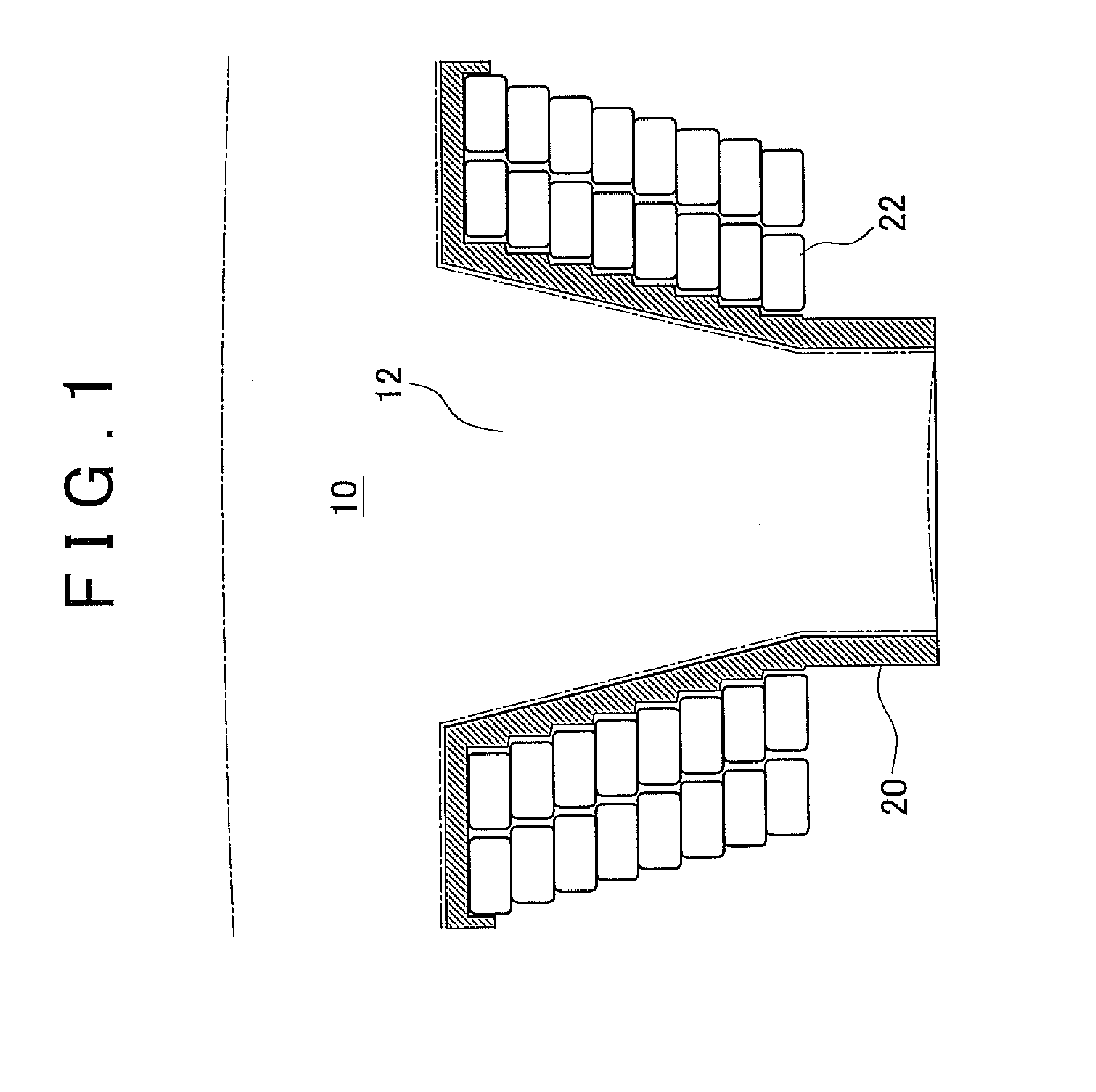

Stator

InactiveUS20120256511A1Sufficient fluidityImprove fill rateWindings insulation shape/form/constructionEngineeringVarying thickness

Owner:TOYOTA JIDOSHA KK

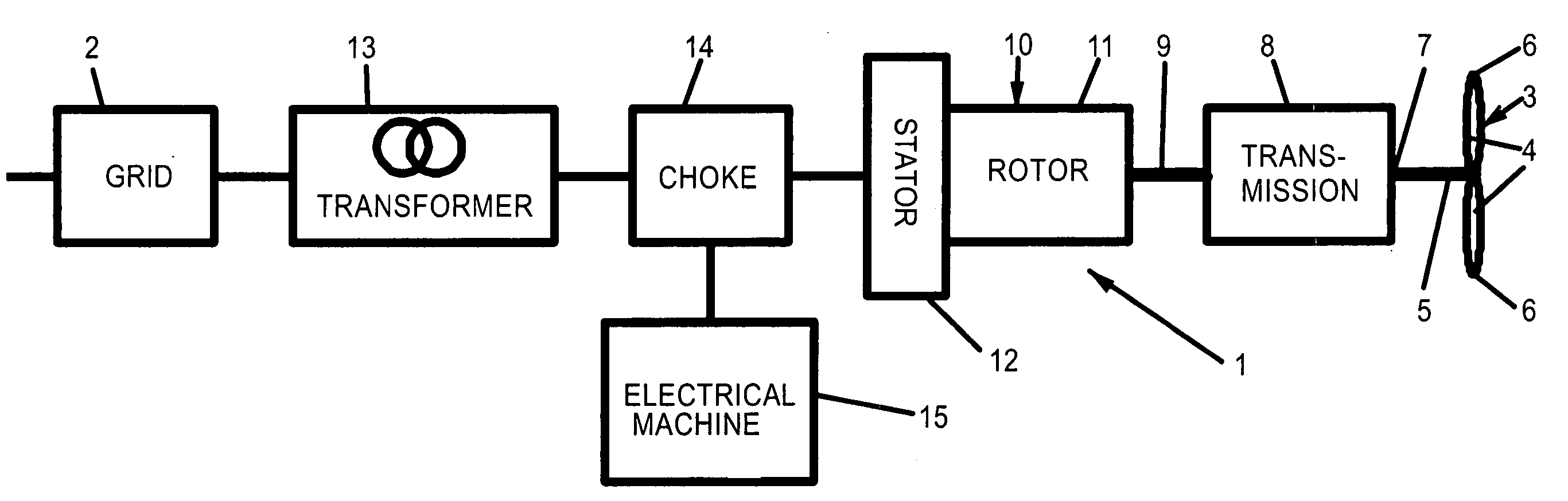

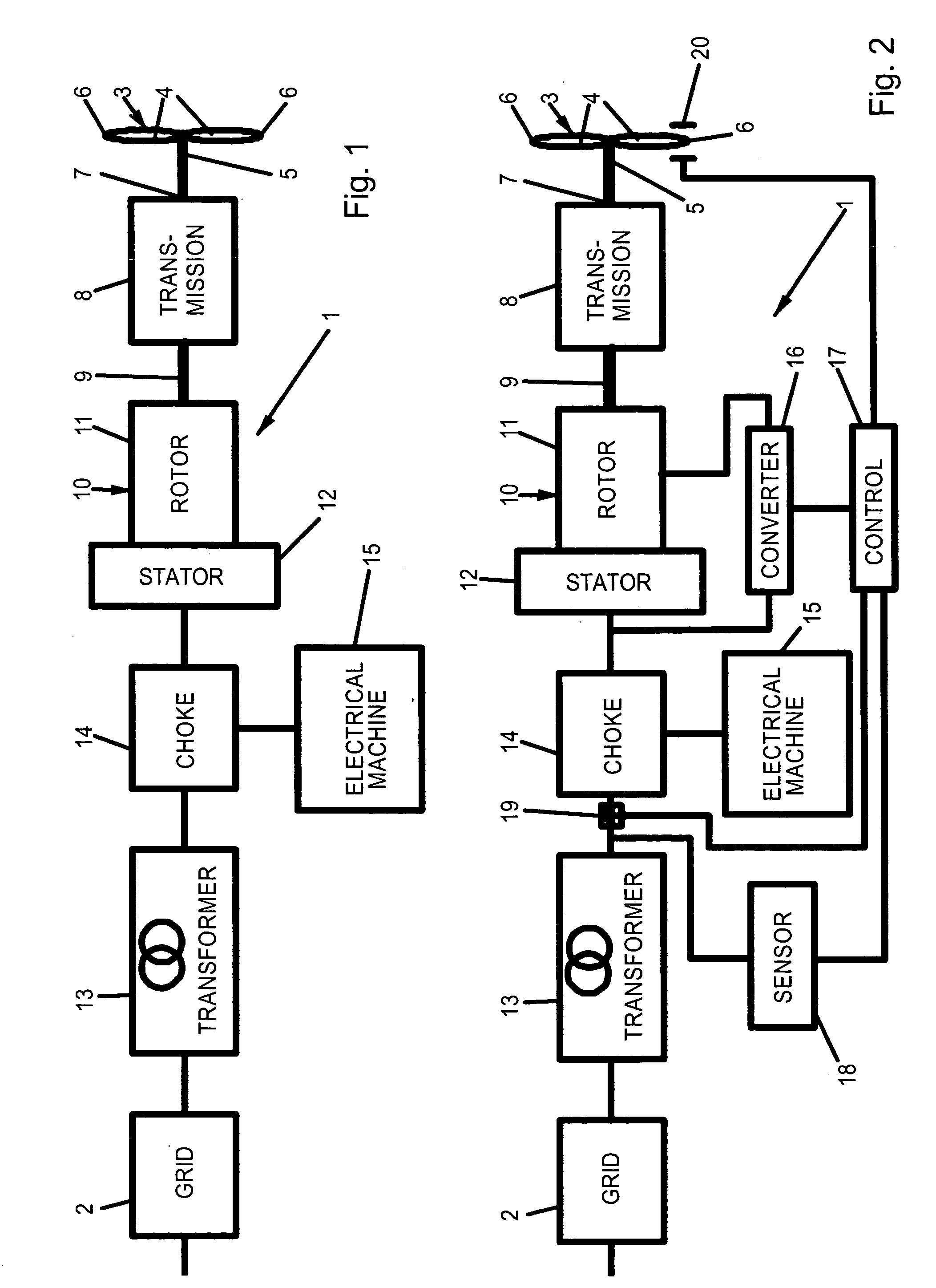

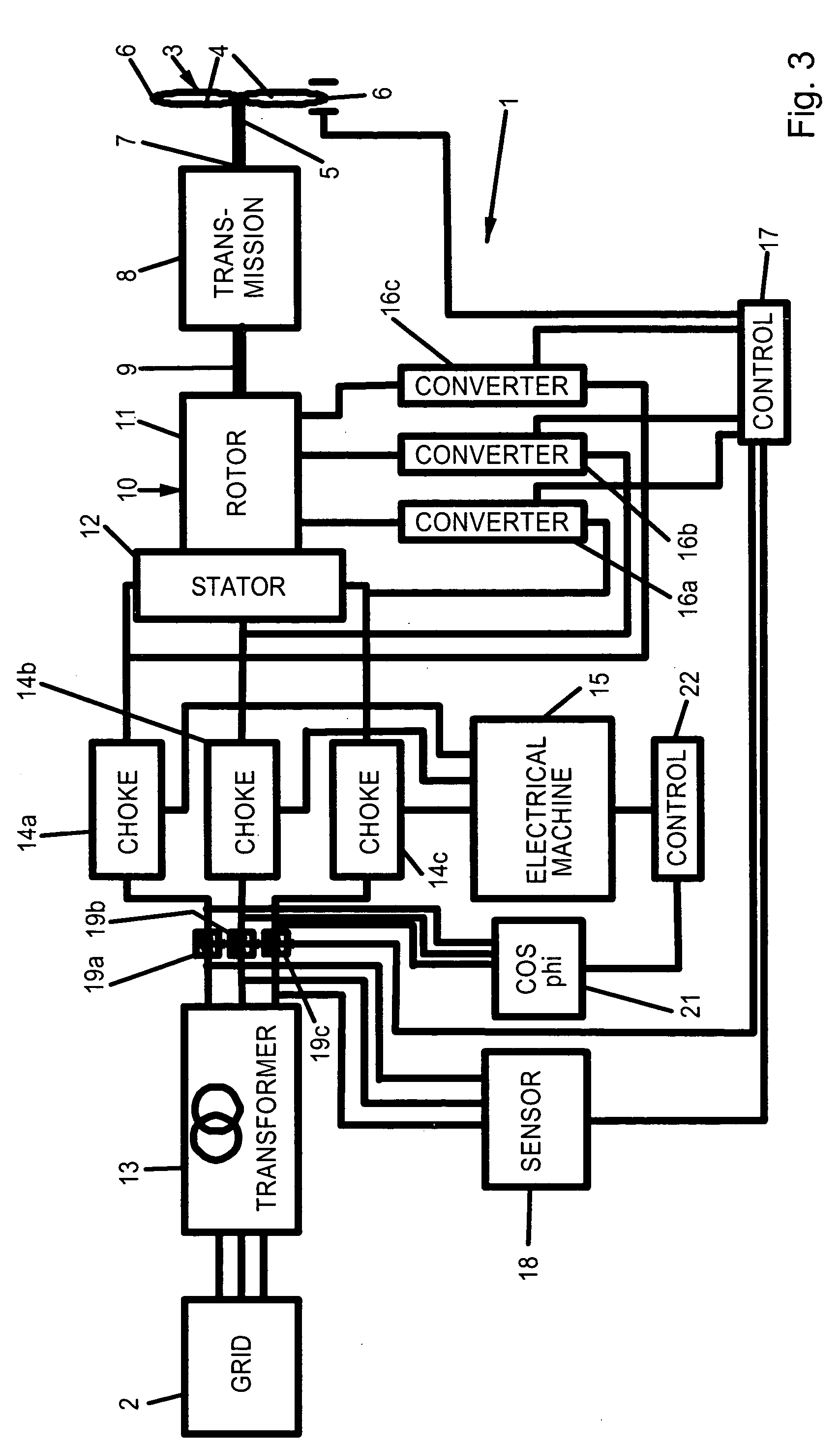

Protection for wind power station

InactiveUS20050236838A1Dc network circuit arrangementsSingle network parallel feeding arrangementsElectricityPower station

Owner:PILLER GMBH

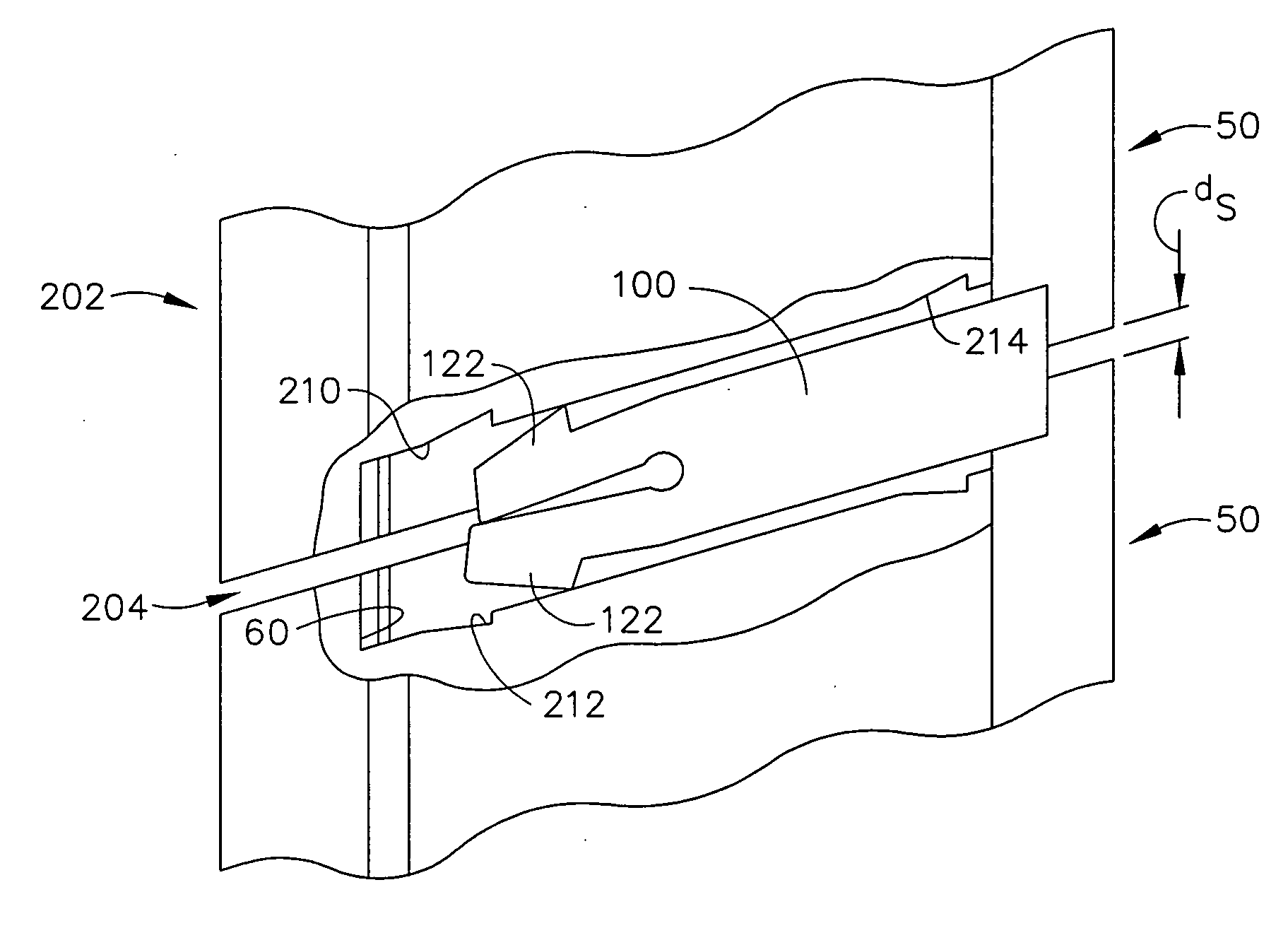

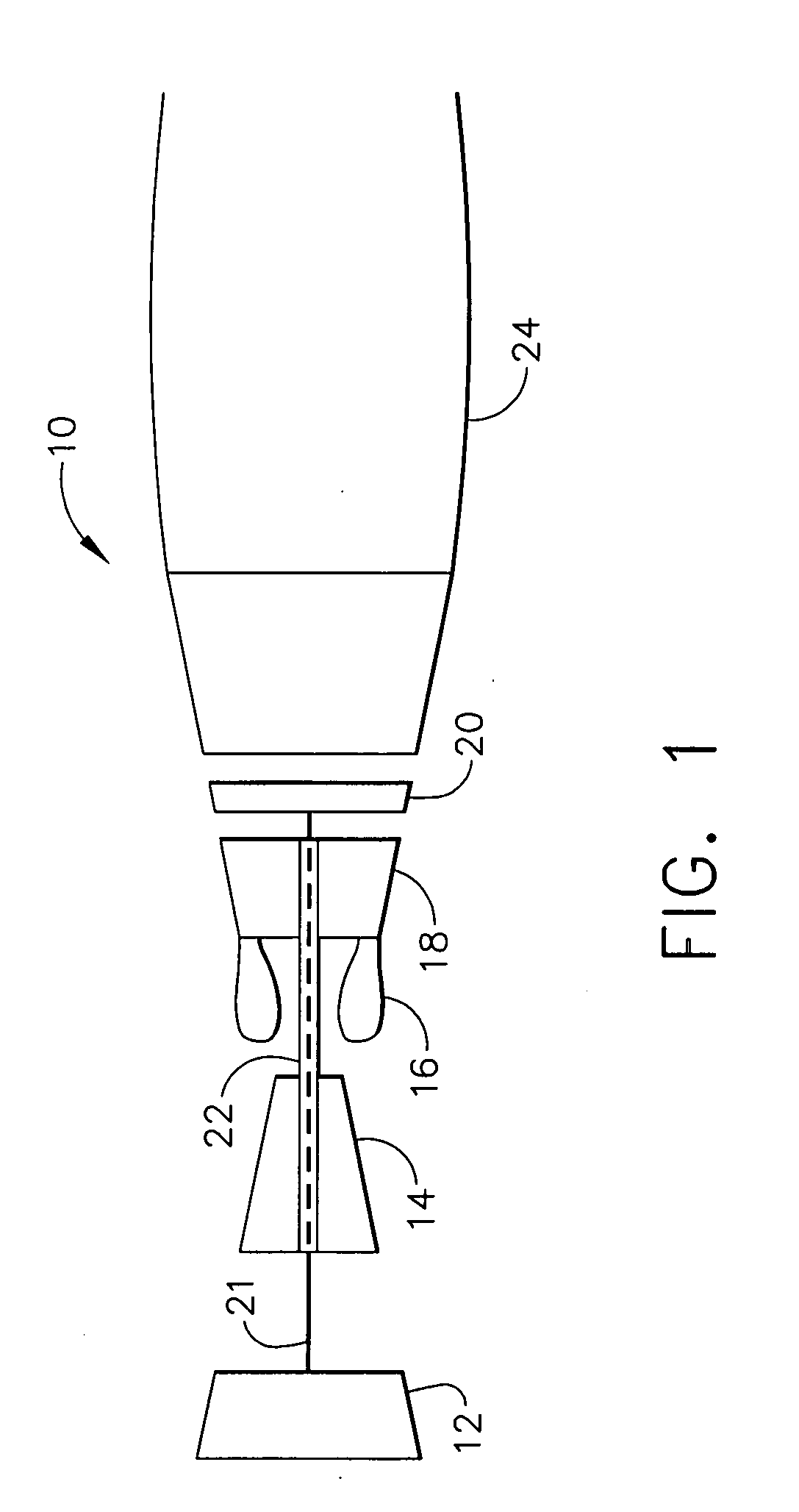

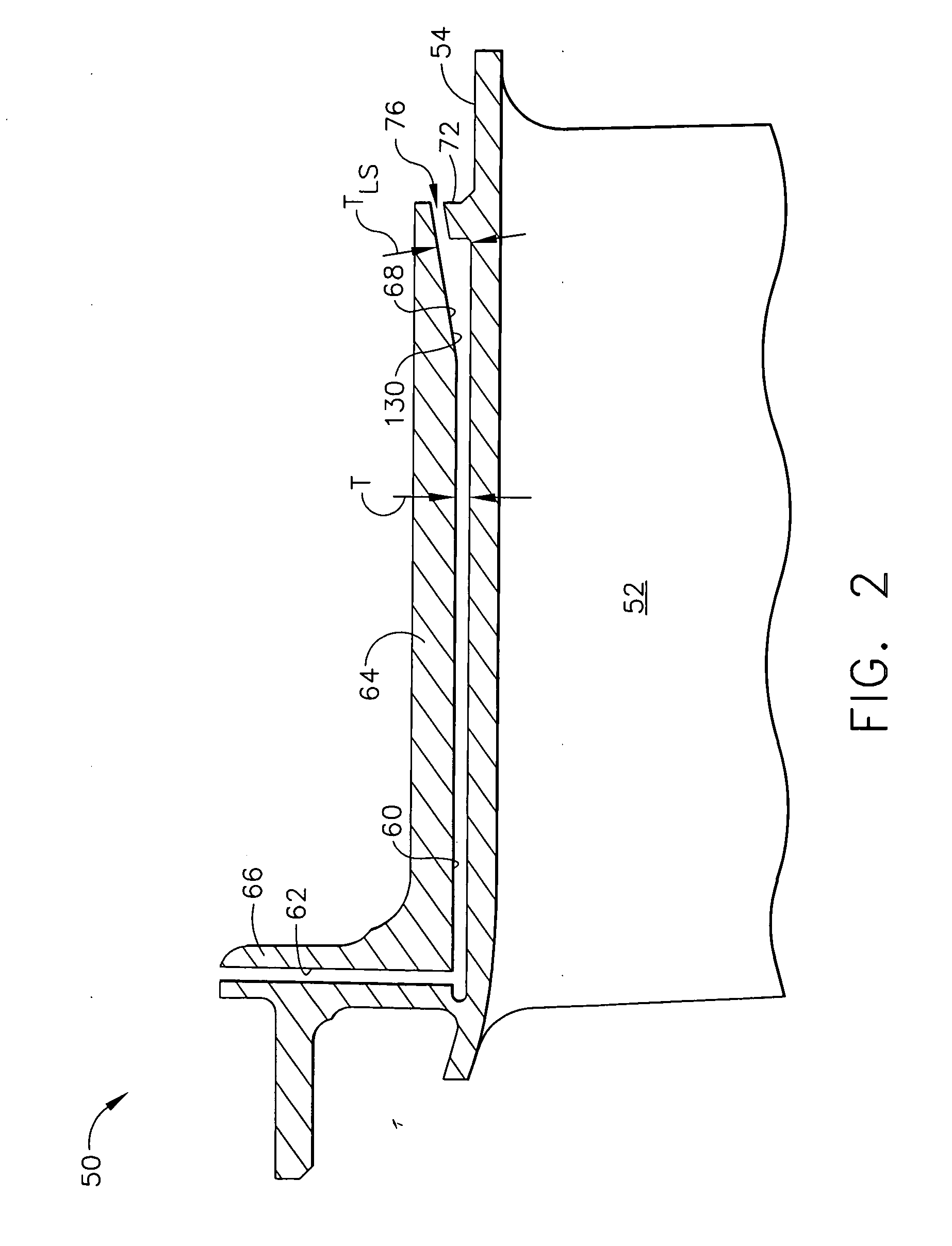

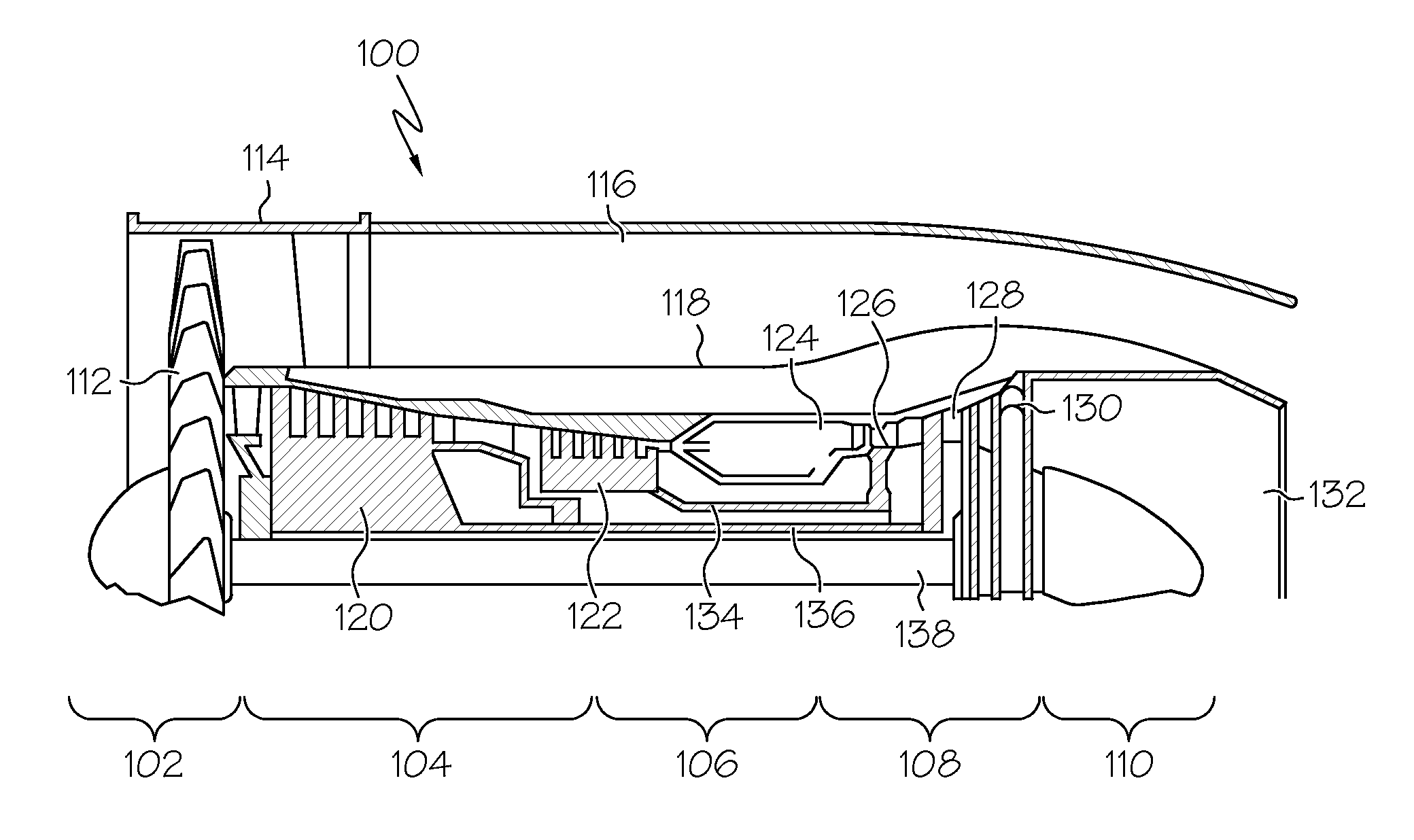

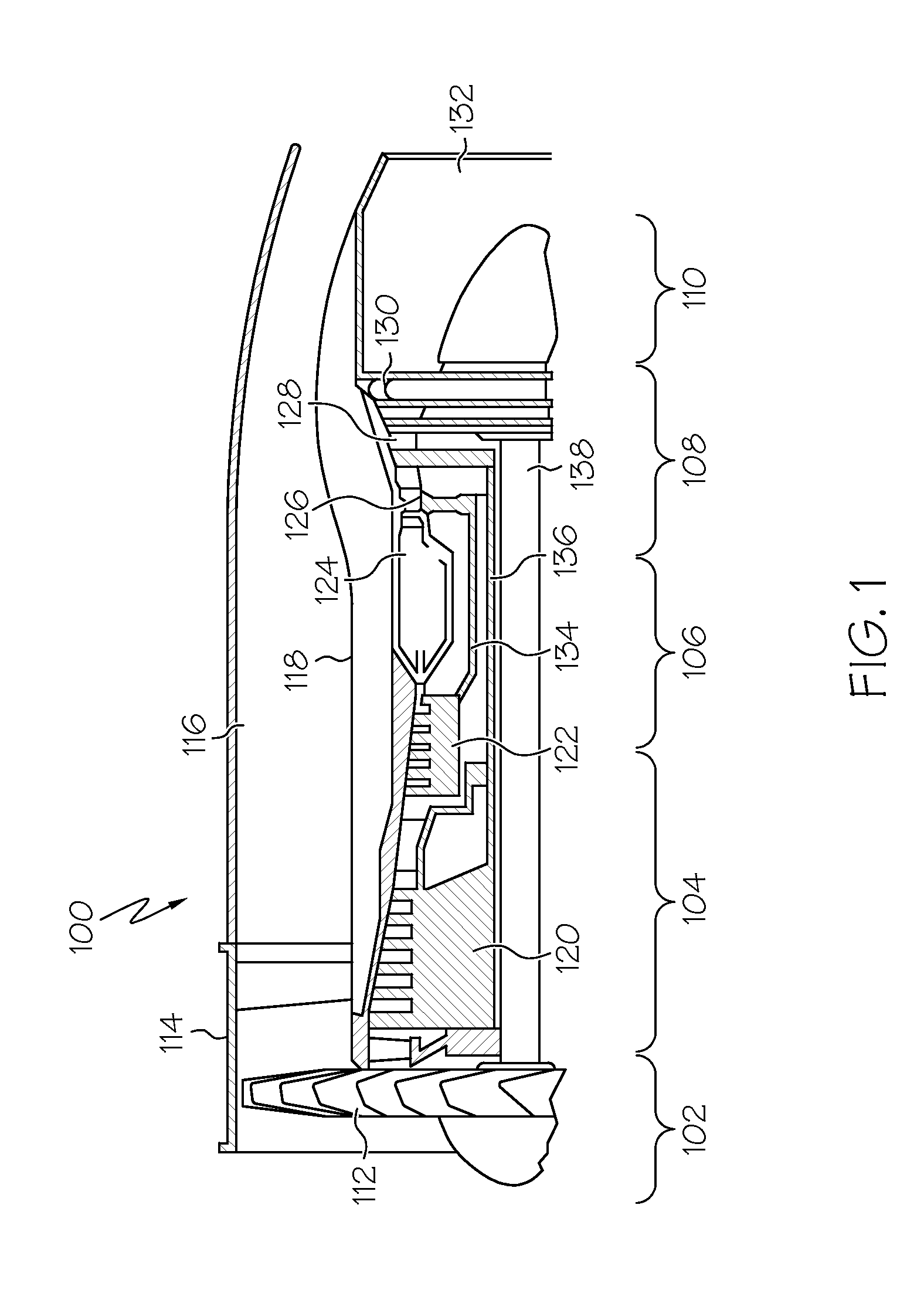

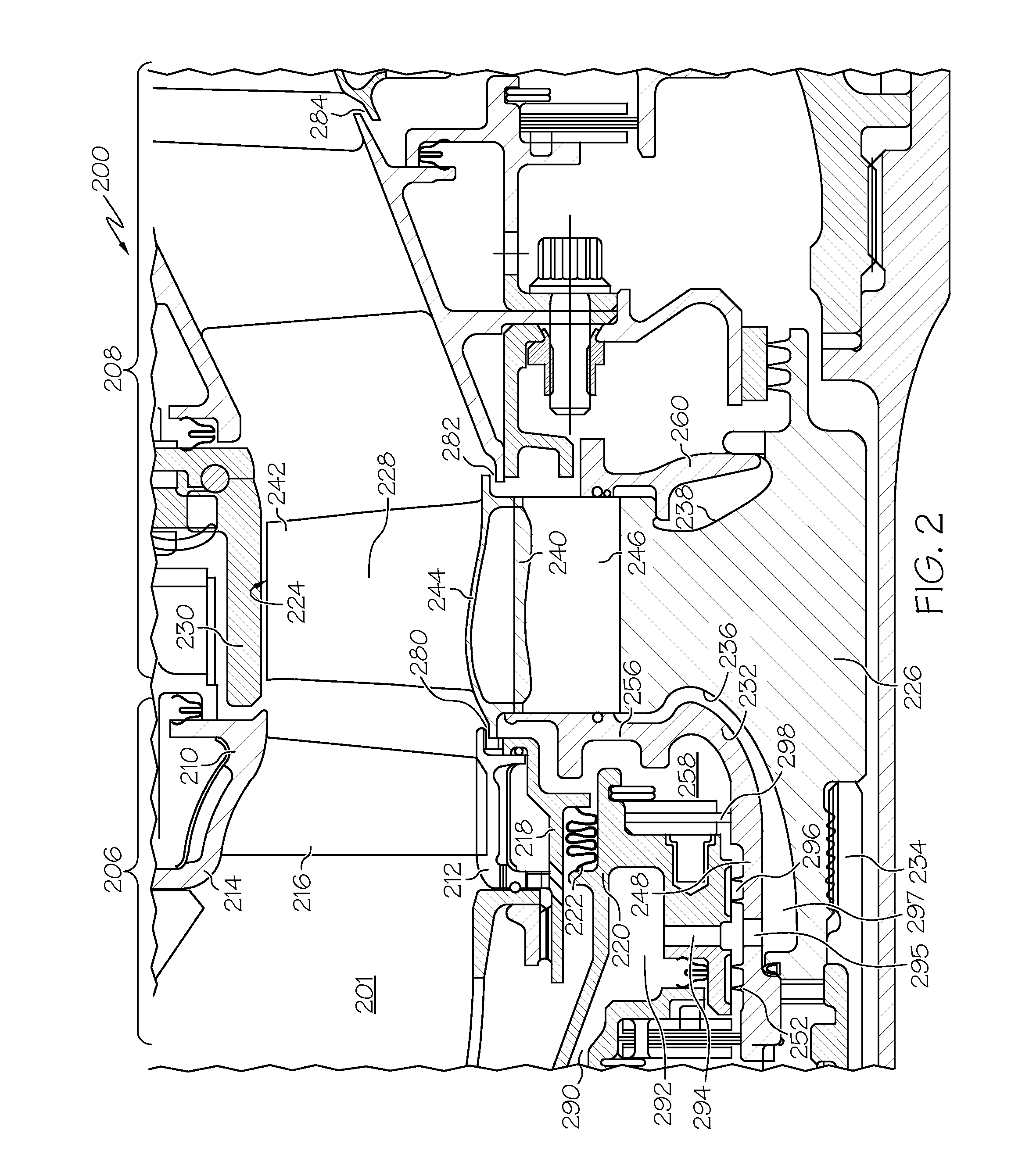

Methods and apparatus for assembling gas turbine engine stator assemblies

Owner:GENERAL ELECTRIC CO

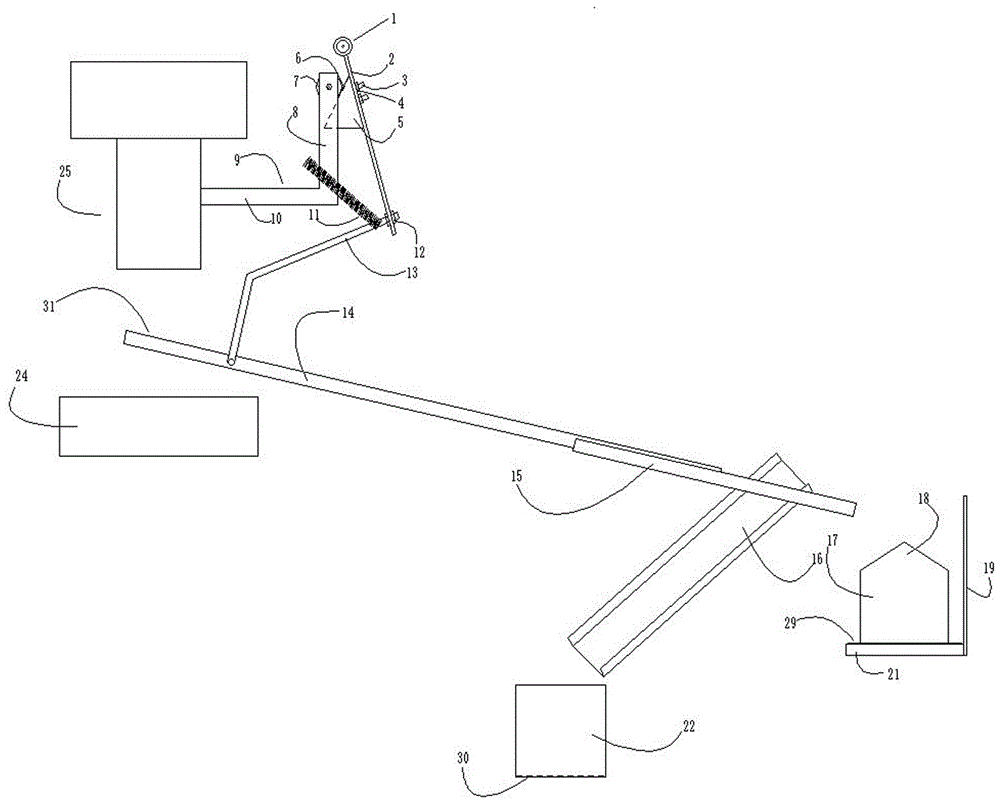

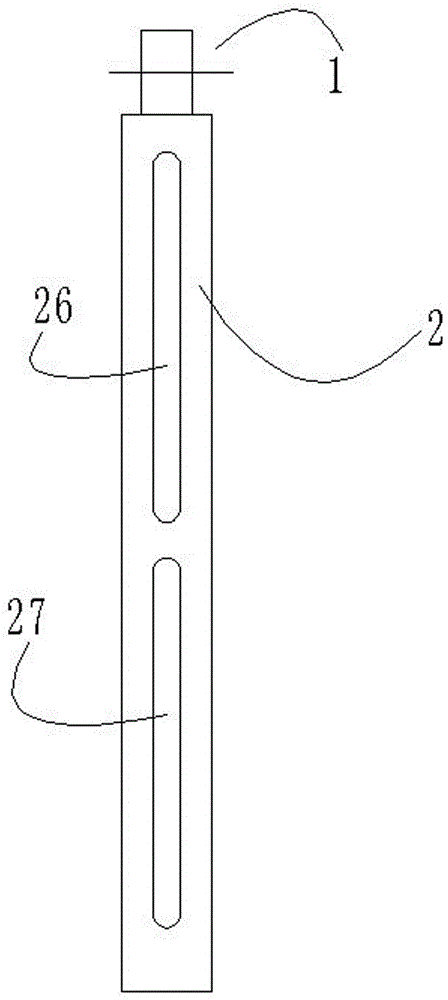

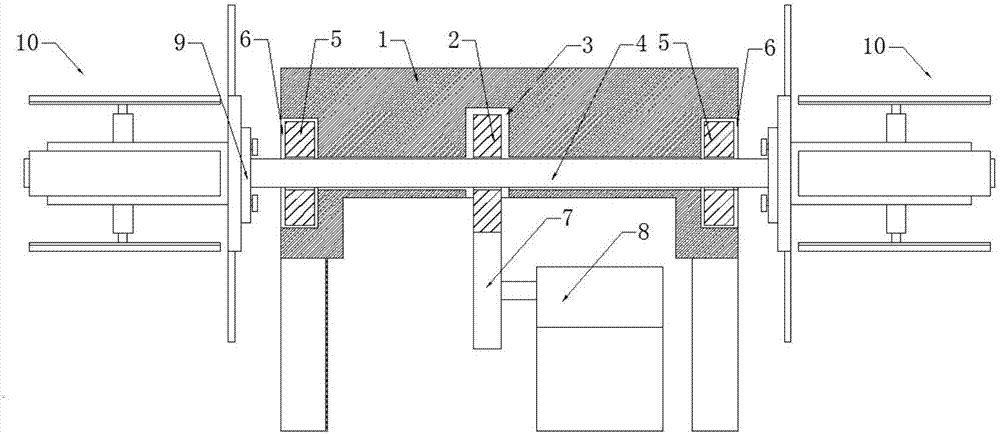

General assembly line for motor assembly

ActiveCN102820741AImprove assembly qualityImprove skill levelManufacturing dynamo-electric machinesGeneral assemblyEngineering

The invention provides a general assembly line for motor assembly. The general assembly line comprises a track, wherein a carrying flat wagon is arranged on the track; a plurality of stator outlet box mounting tables, at least one collector ring hot jacket table, at least one rotor air duct assembly table, a plurality of assembling and calibration small shaft tables, a plurality of cooler assembly tables and a plurality of motor warehousing tables are arranged on the two sides of the track in the track direction in sequence; a pneumatic suspension crane is arranged above the stator outlet box assembly tables; a rotor assembly machine is arranged beside the stator outlet box mounting tables; a collector ring heating roaster and a pneumatic suspension crane are arranged beside the collector ring hot sleeve table; and a track gantry tower crane is arranged above the cooler mounting tables. According to the general assembly line, a motor is carried through the carrying flat wagon and a turnover flat wagon, so that the potential knocking hazard is reduced, the time of waiting the crane during motor assembly is shortened, a production mode that fixed persons are allocated on fixed duties is conveniently adopted, the motor assembly quality is reliable, and the production efficiency is greatly increased.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Flow discouraging systems and gas turbine engines

Owner:HONEYWELL INT INC

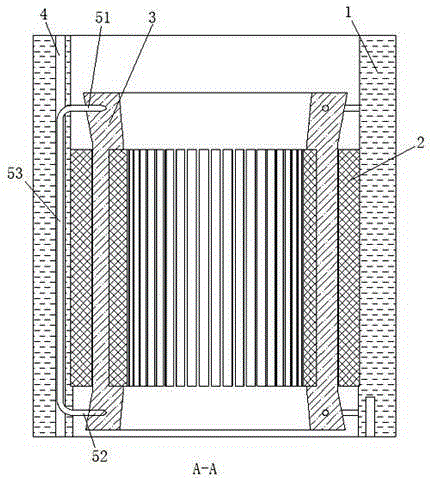

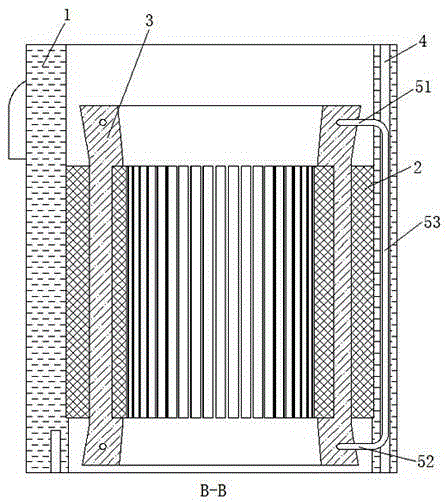

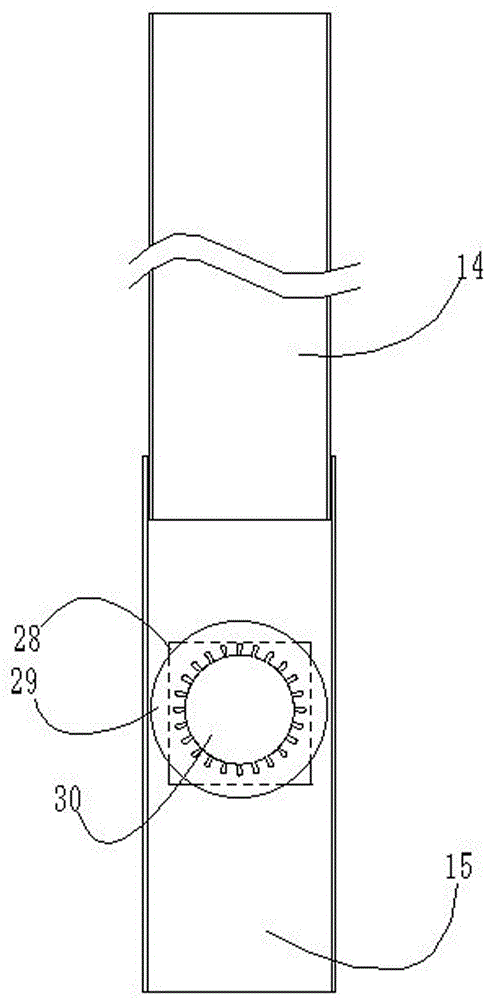

Motor stator heat radiation structure

InactiveCN105356671AGuaranteed cooling effectImprove thermal conductivityCooling/ventillation arrangementSupports/enclosures/casingsConductor CoilCooling pipe

Owner:HEFEI JUYI POWER SYST CO LTD

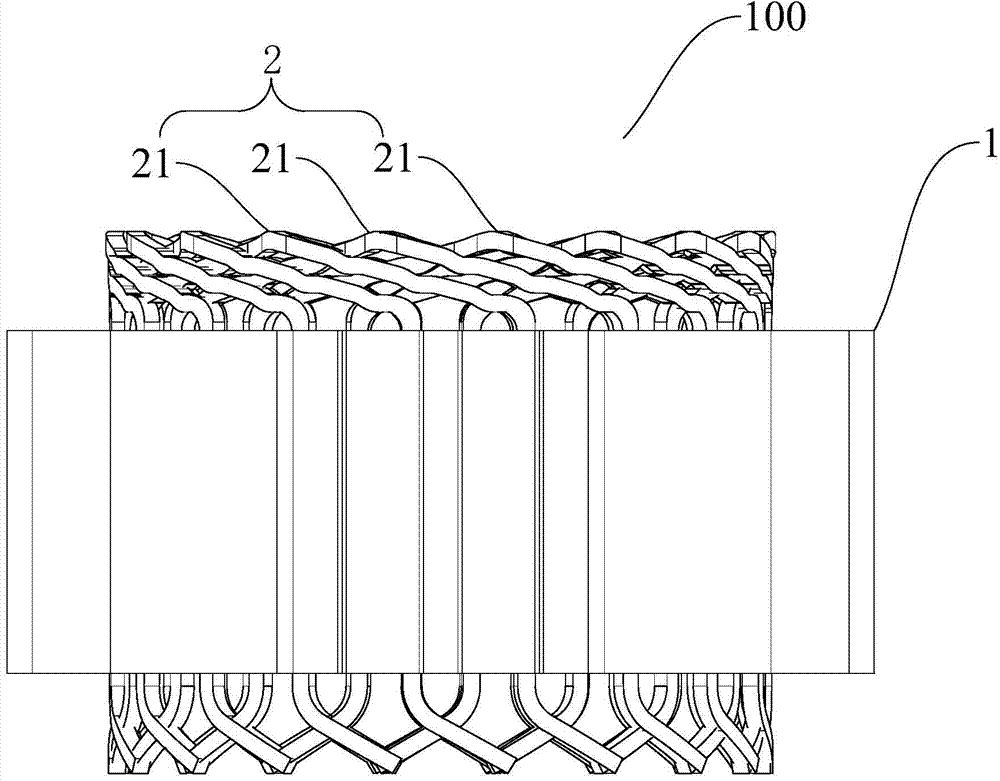

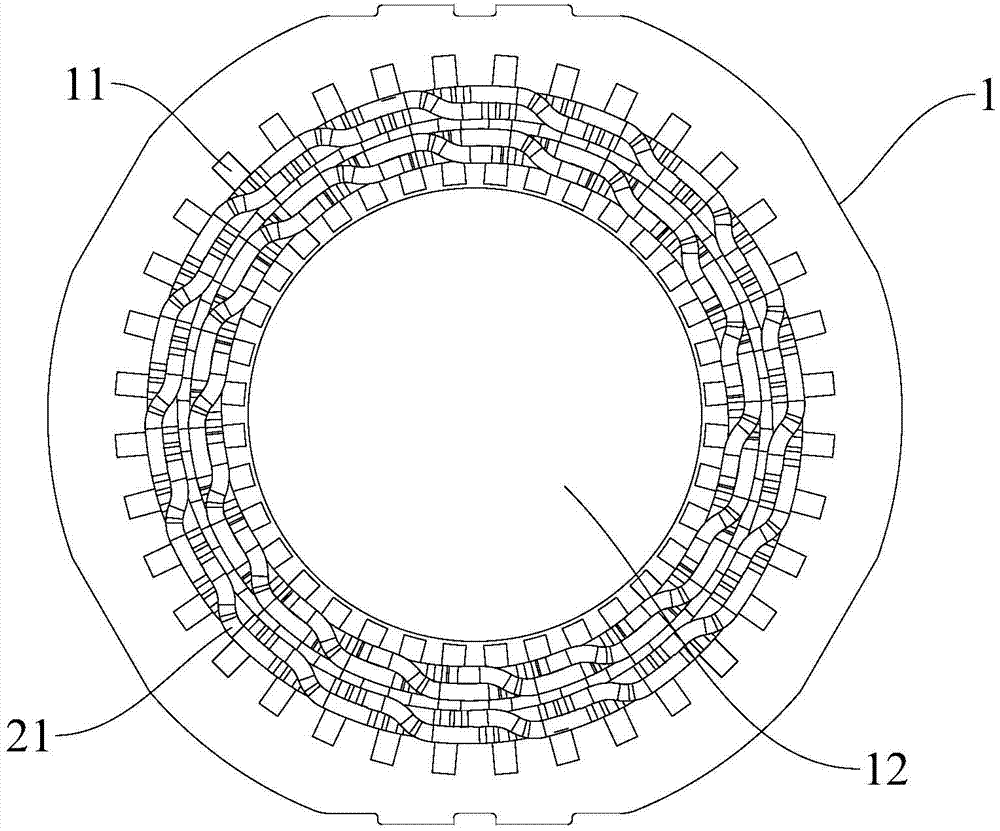

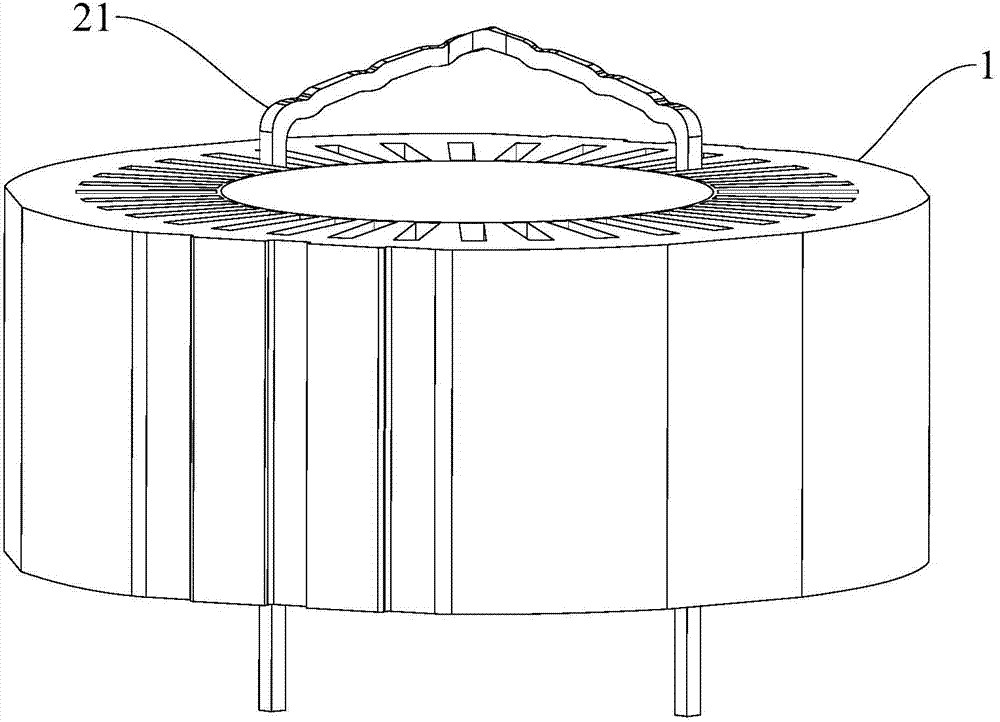

Stator for motor, manufacturing method thereof, motor and compressor

Owner:GUANGDONG MEIZHI COMPRESSOR +1

Harmonic shunting electric motor with faceted shaft for improved torque transmission

Owner:TRANE INT INC

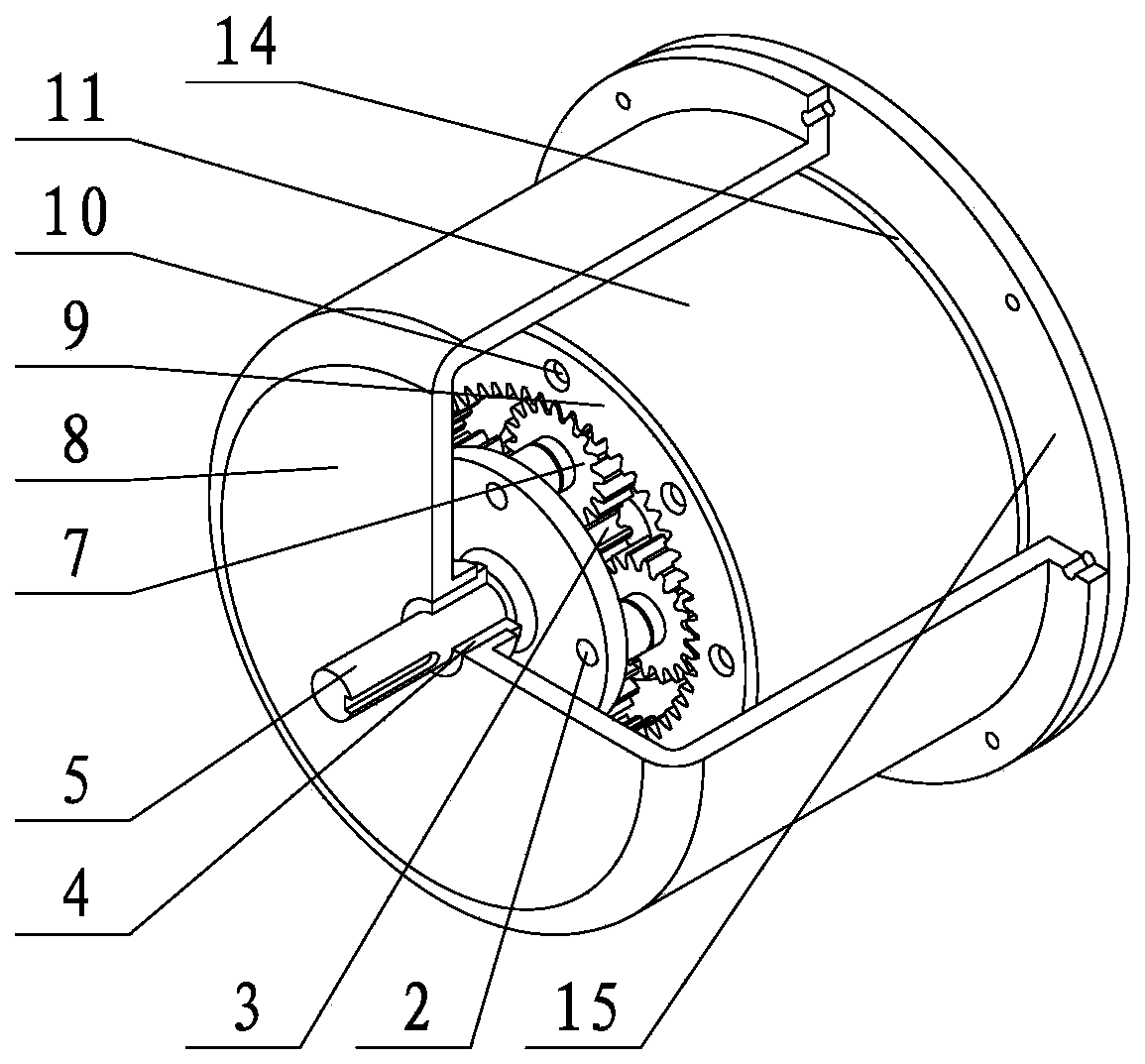

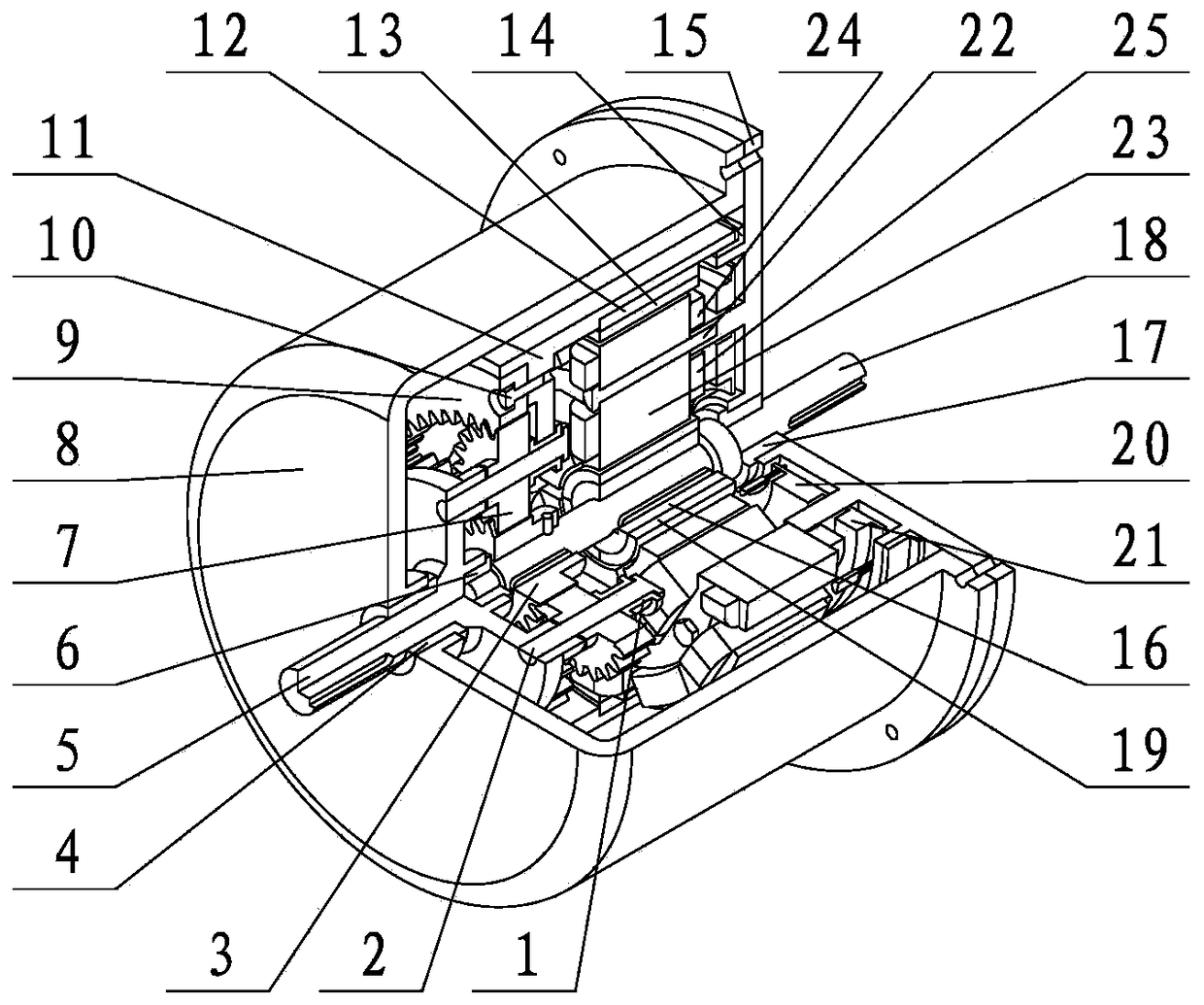

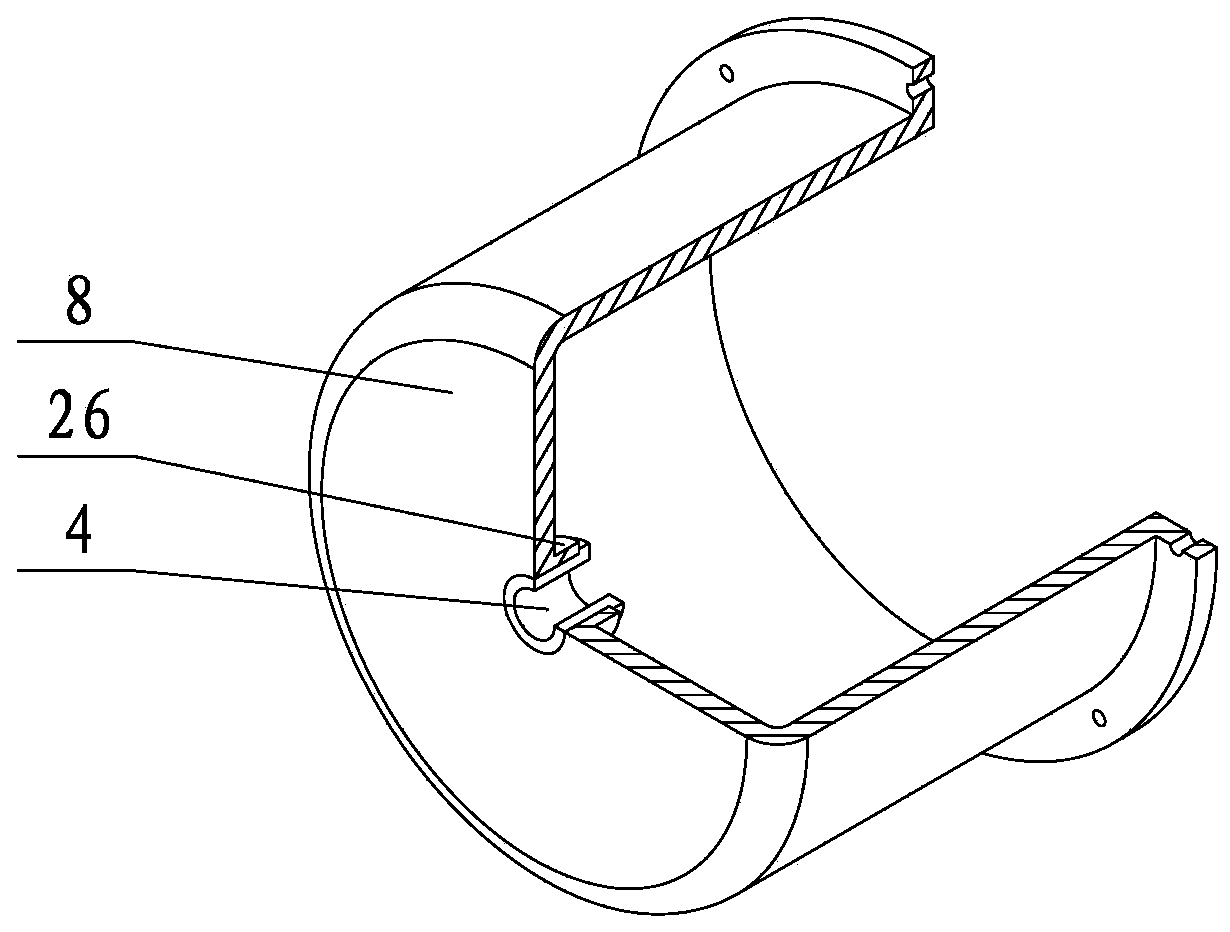

Dual-rotor input planet-gear speed reducer

The invention discloses a dual-rotor input planet-gear speed reducer, and relates to a speed reducer. The speed reducer comprises a shell component, an engine base component, a controller one, a controller two, a stator component, an external rotor component, an internal rotor component, a rotating shaft component, a gear ring, and a planet-gear component; in the operation process of the speed reducer, the output rotation speed of an output shaft one is related to rotation speed difference between two motor rotors; two motor rotors are always in the high-speed operation state, the rotating direction of the output shaft one of the speed reducer can be changed under the state of maintaining the unchanged rotation directions of two motor rotors, thereby driving a load device to realize the functions of frequently accelerating and reducing speed, frequently starting and stopping, even frequently changing the rotation direction of the load device. The speed reducer disclosed by the invention can ensure the motor to operate under the working state with high frequency, and improve the response speed when the speed reducer changes the rotation direction of the load device.

Owner:如皋久源传动机械有限公司

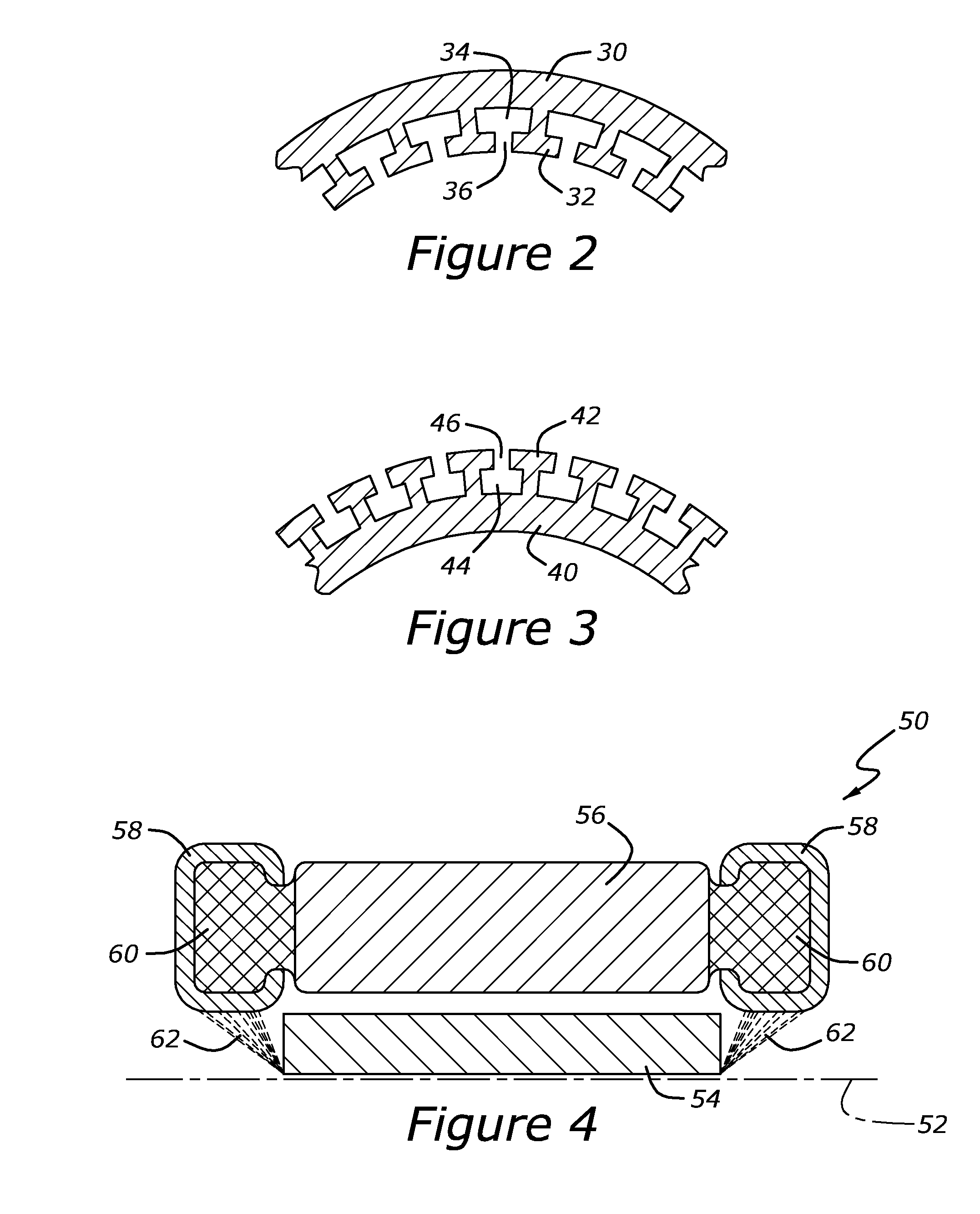

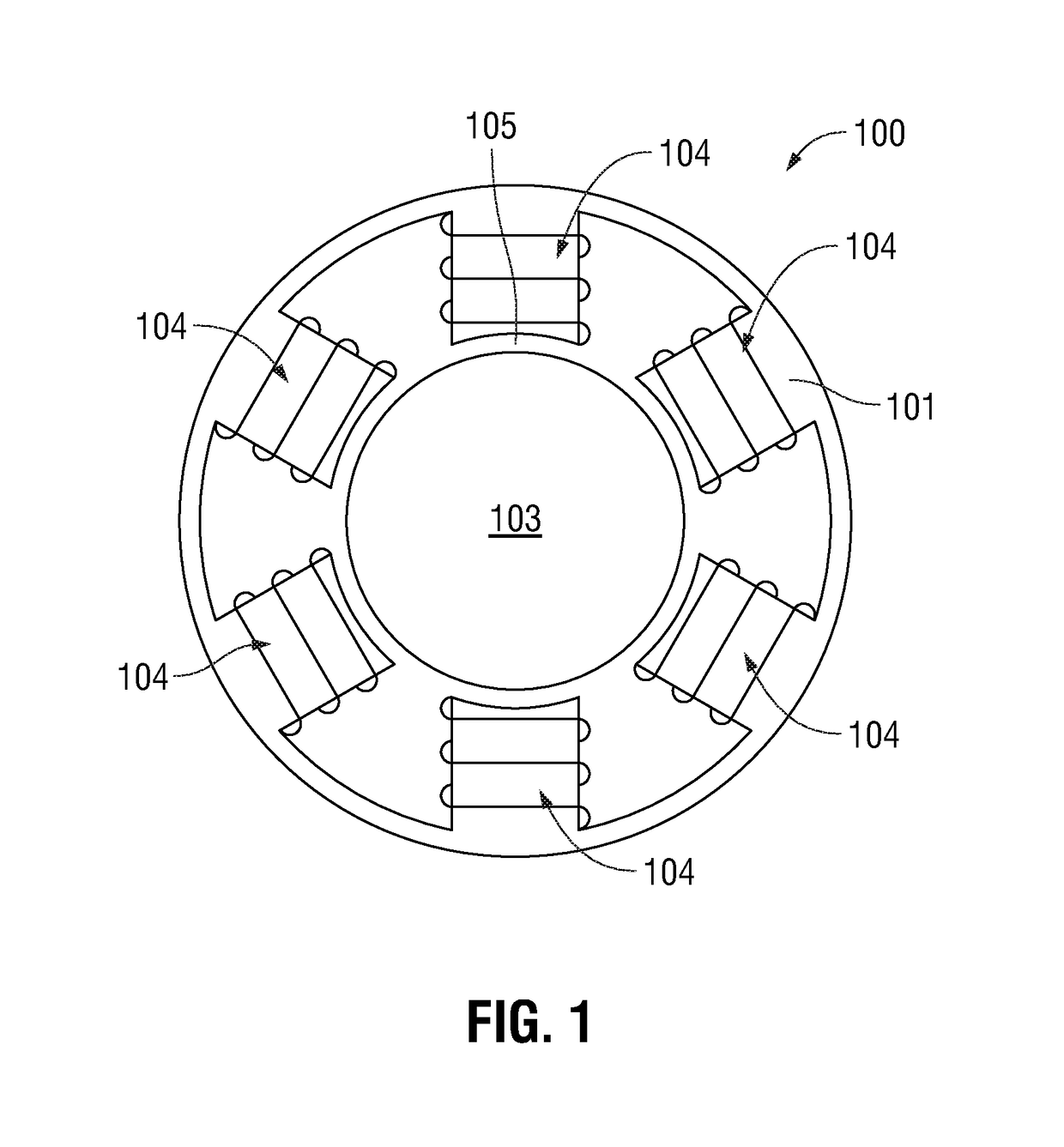

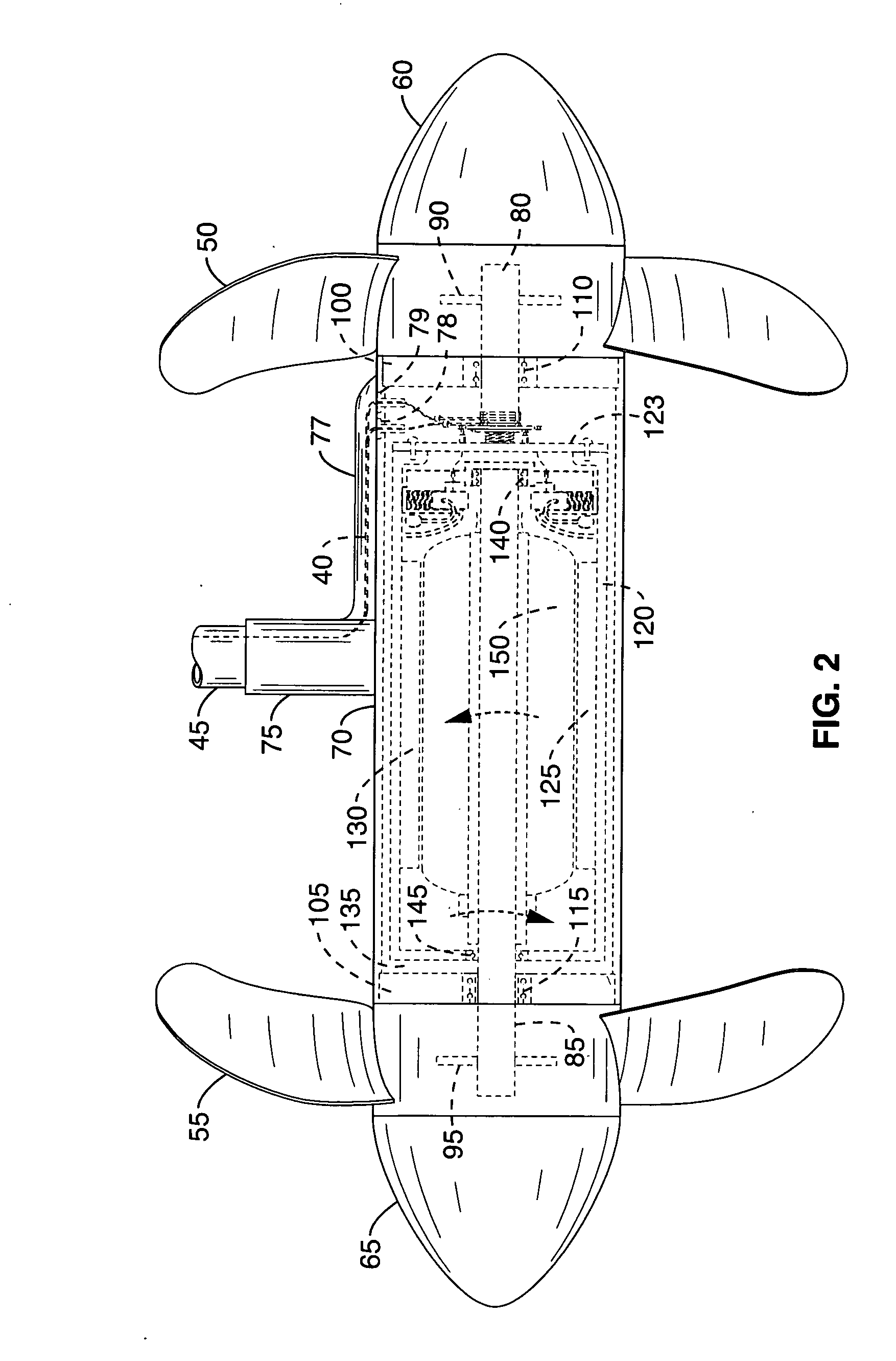

Slotless Ac Induction Motor

InactiveUS20080054733A1Increase in sizeIncrease currentWindings insulation shape/form/constructionMagnetic circuit rotating partsElectrical conductorInduction motor

The present invention is a rotating induction motor that is capable of providing higher peak torque than a conventional design, which achieves the shortcomings of the prior art by in regard to iron saturation by a slot-less design; removing the iron slot provides more space for the conductor. The motor comprises a stator and a concentric rotor, separated from the stator by an air gap. The rotor has rotor bars and rotor windings. The stator is slot-less and comprises surface mounted conductors separated from each other by suitable insulation. An advantage of this design is that the motor does not exhibit typical behavior at high currents; there is no saturation effect.

Owner:BOREALIS TECH LTD

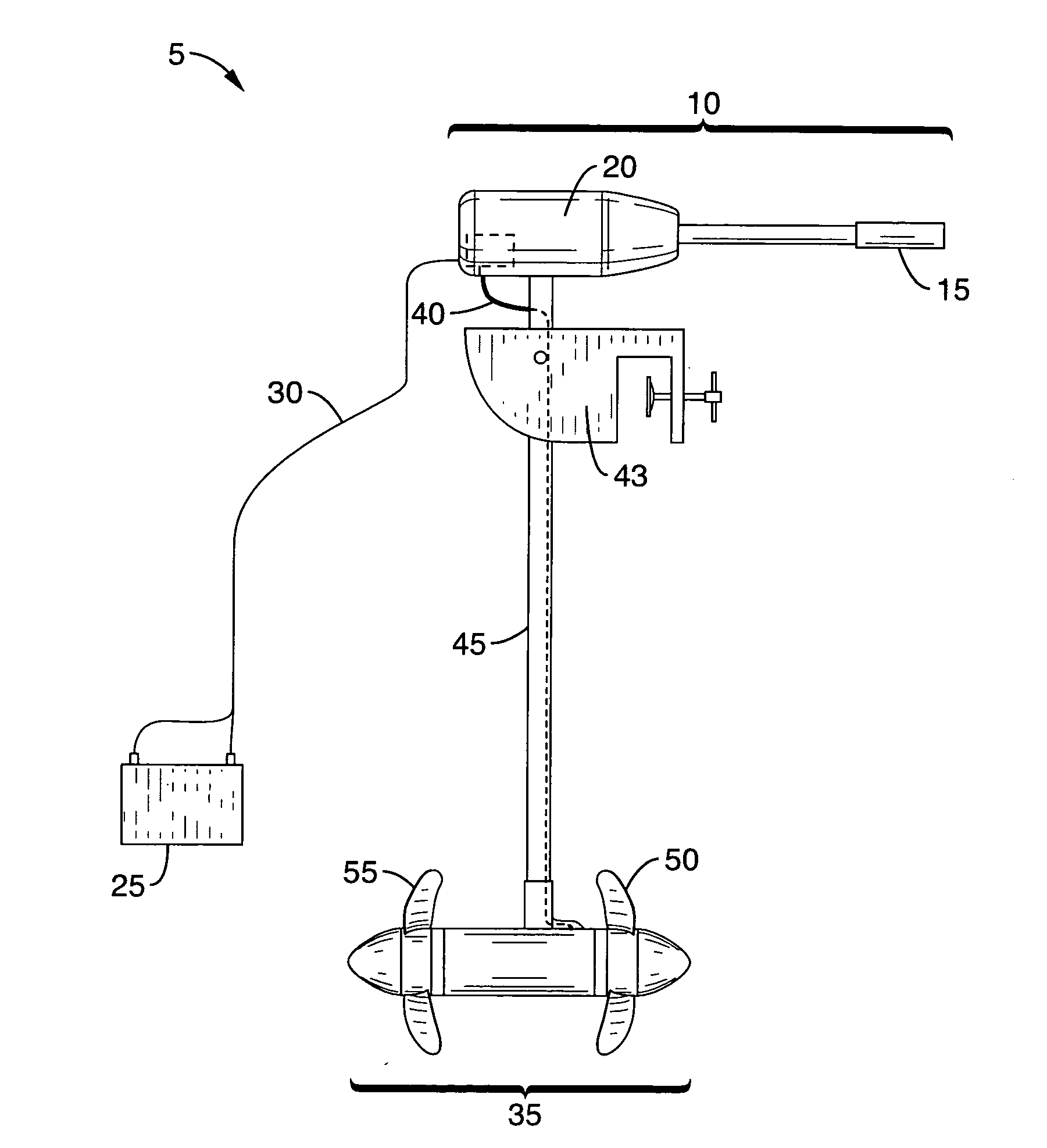

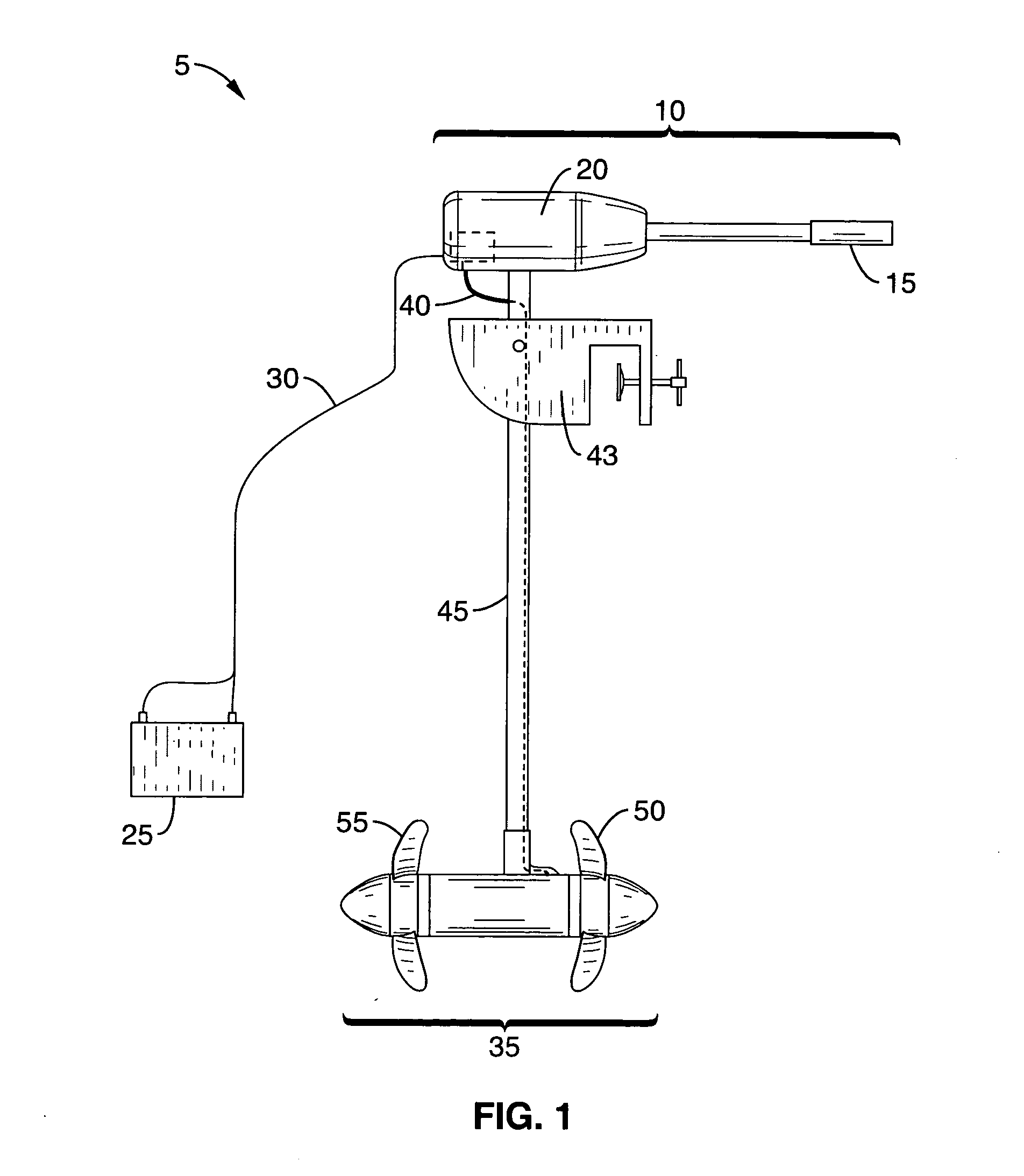

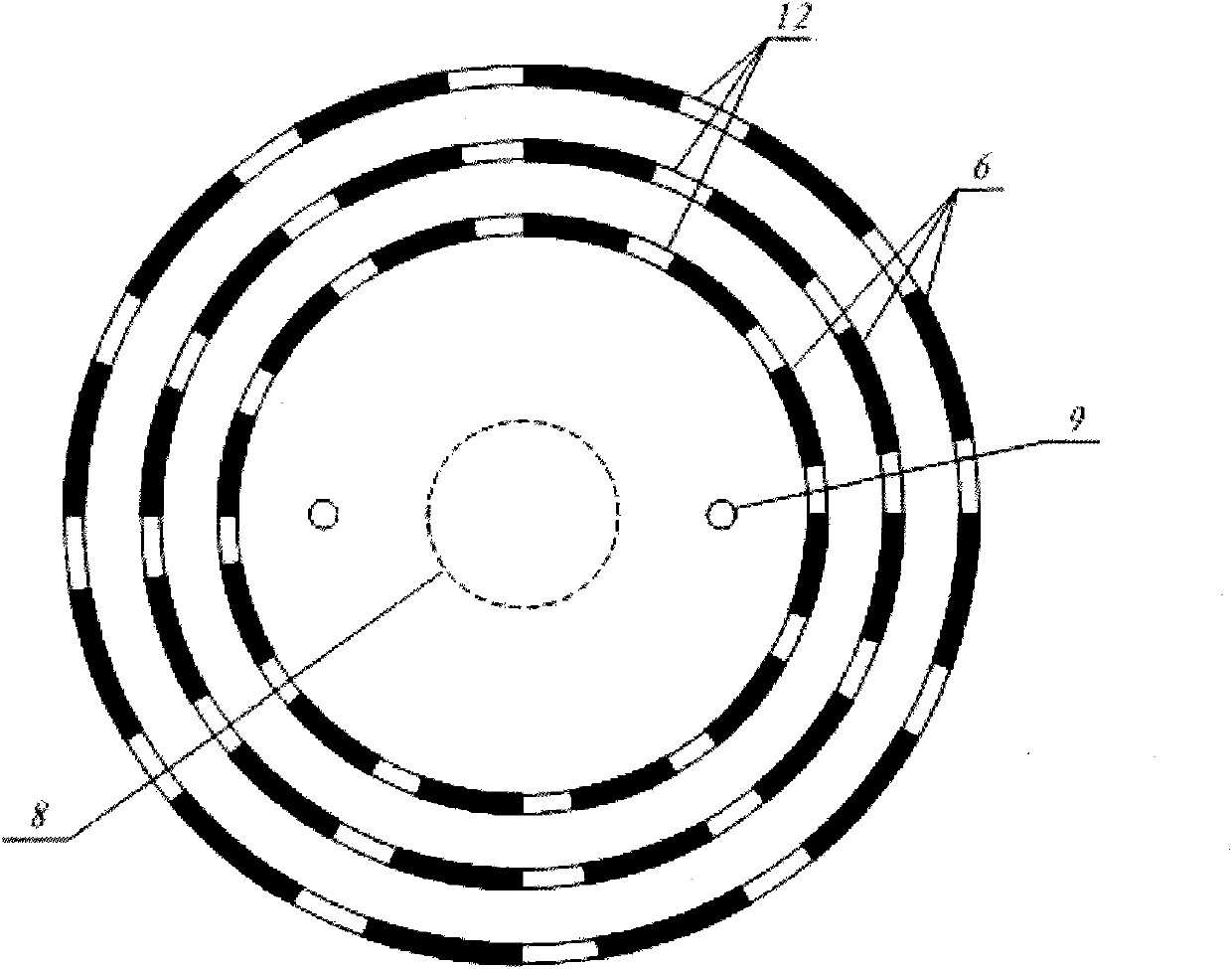

Increased efficiency counter-rotating electric motor for propelling a boat

ActiveUS20100003871A1Improve abilitiesReduce windRotary current collectorPropulsion power plantsElectricityElectrical connection

Owner:E WISH TECH

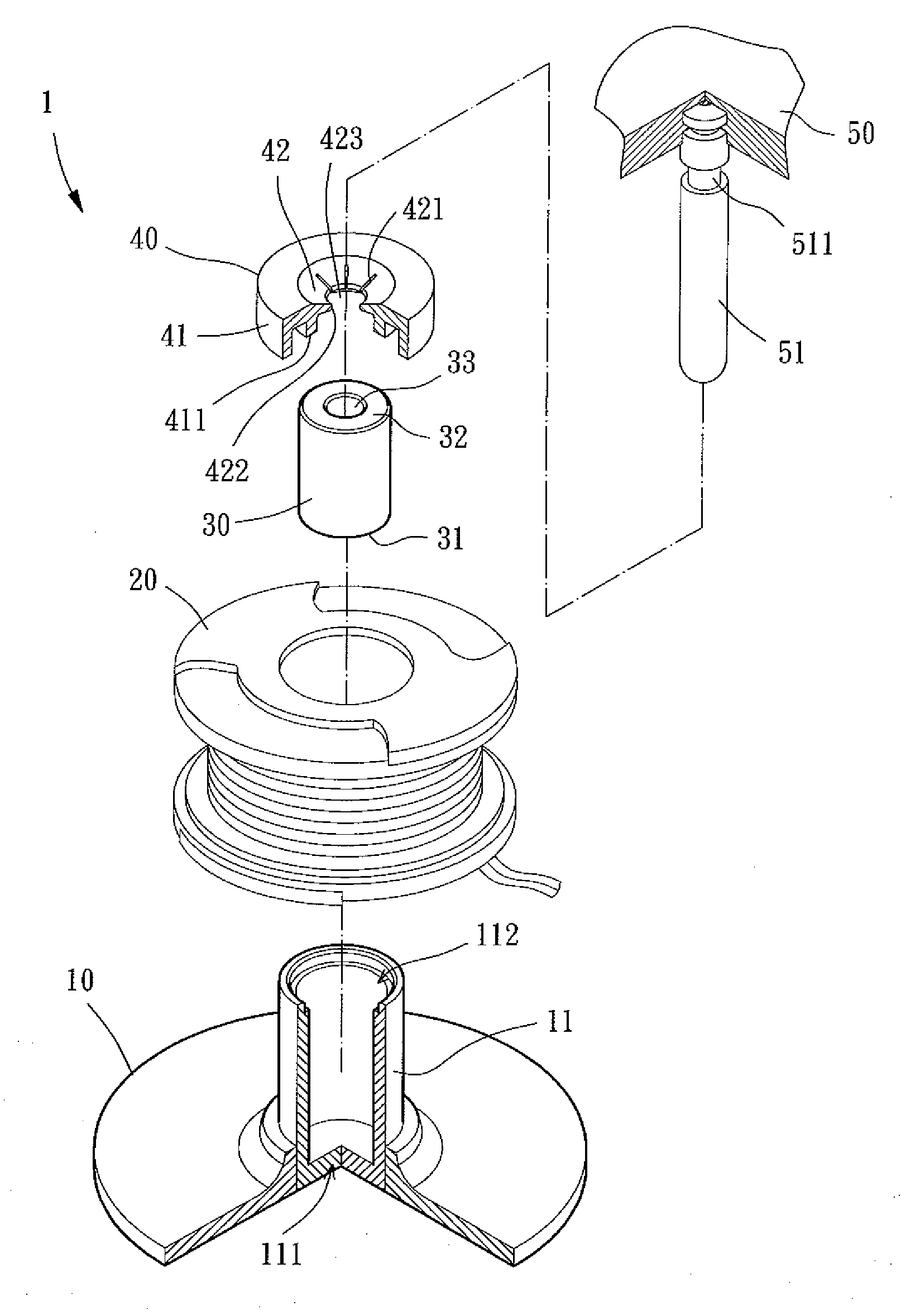

Stirring device of milk foam machine and milk foam machine with stirring device

InactiveCN103505079AControl thicknessReduce volumeKitchen equipmentEngineeringMechanical engineering

The invention relates to a stirring device of a milk foam machine and the milk foam machine with the stirring device. The stirring device (40) comprises a support (42), a stator (43) and a rotor (44) arranged on the stator in a sleeved mode. The stator (43) is connected with the support (42). The stator (43) drives the rotor (44) to rotate. The stirring device (40) is arranged in the milk foam machine (100) and connected to a stirring shaft in the milk foam machine (100) in a clamped mode. The stirring device (40) changes the rotation direction and / or the rotation speed of the stirring device (40) through a connection structure so as to control the thicknesses of milk foam. The stirring device and the milk foam machine are simple in structure, a containing device can be separated from a machine body but not provided with electric attachments, and the containing device is convenient to use and clean. A method of making the milk foam with different thicknesses by changing the rotation direction and / or the rotation speed of the stirring device is adopted and the milk foam with different thicknesses can meet taste needs of individuals.

Owner:SUNPOWER ELECTRICAL SHENZHEN +1

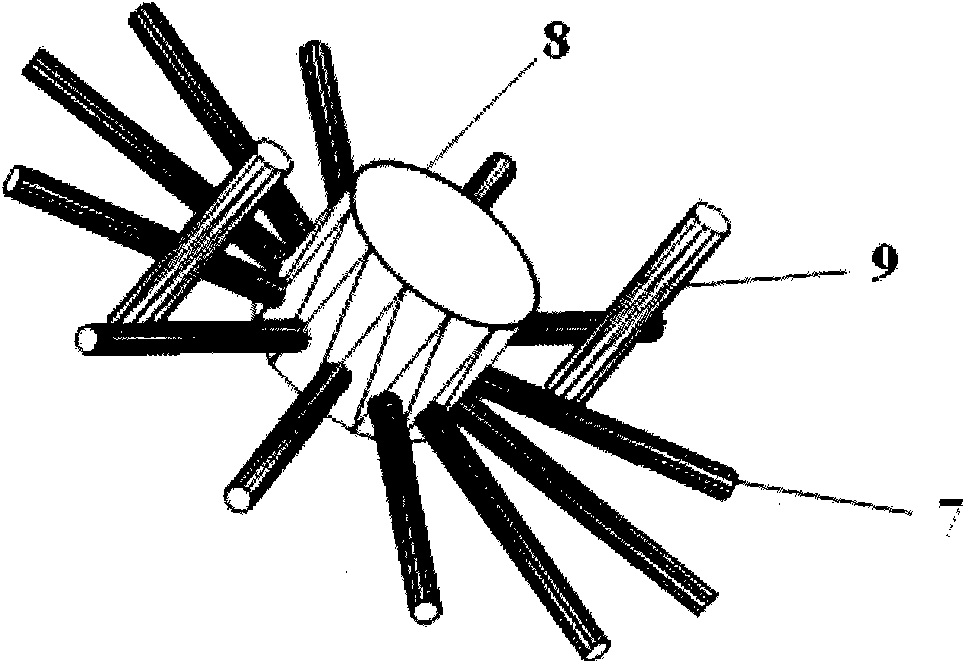

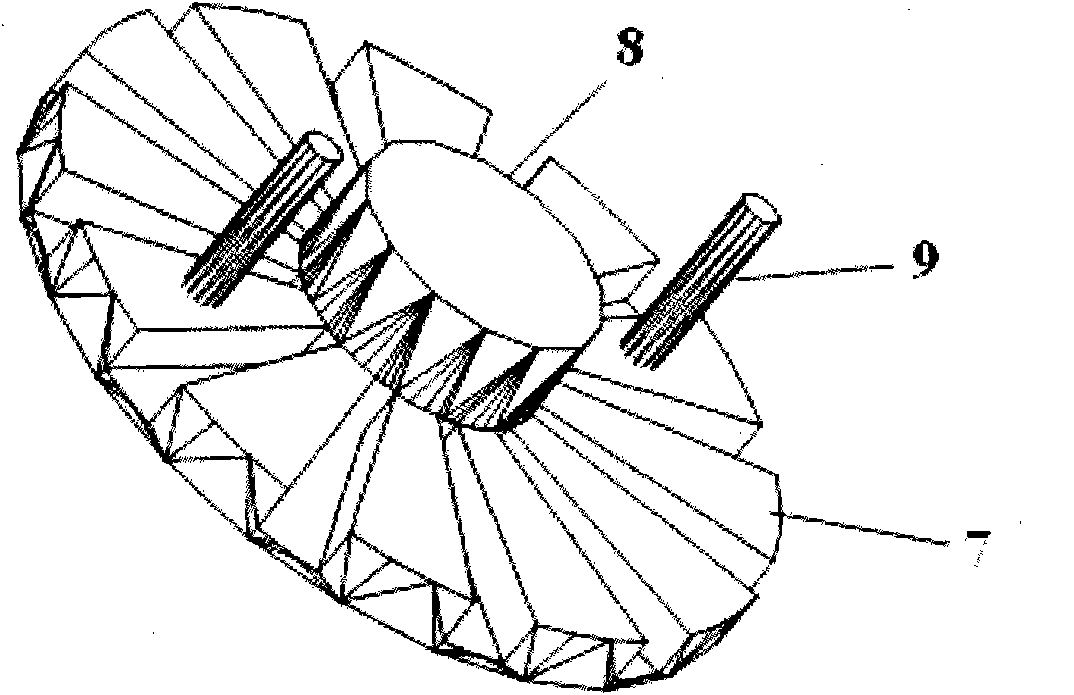

High-shear reactor with feed distribution device

InactiveCN101947427AAvoid cloggingUniform particle size distributionIsocyanic acid derivatives preparationOrganic compound preparationDrive shaftSolid particle

Owner:TIANJIN UNIV +1

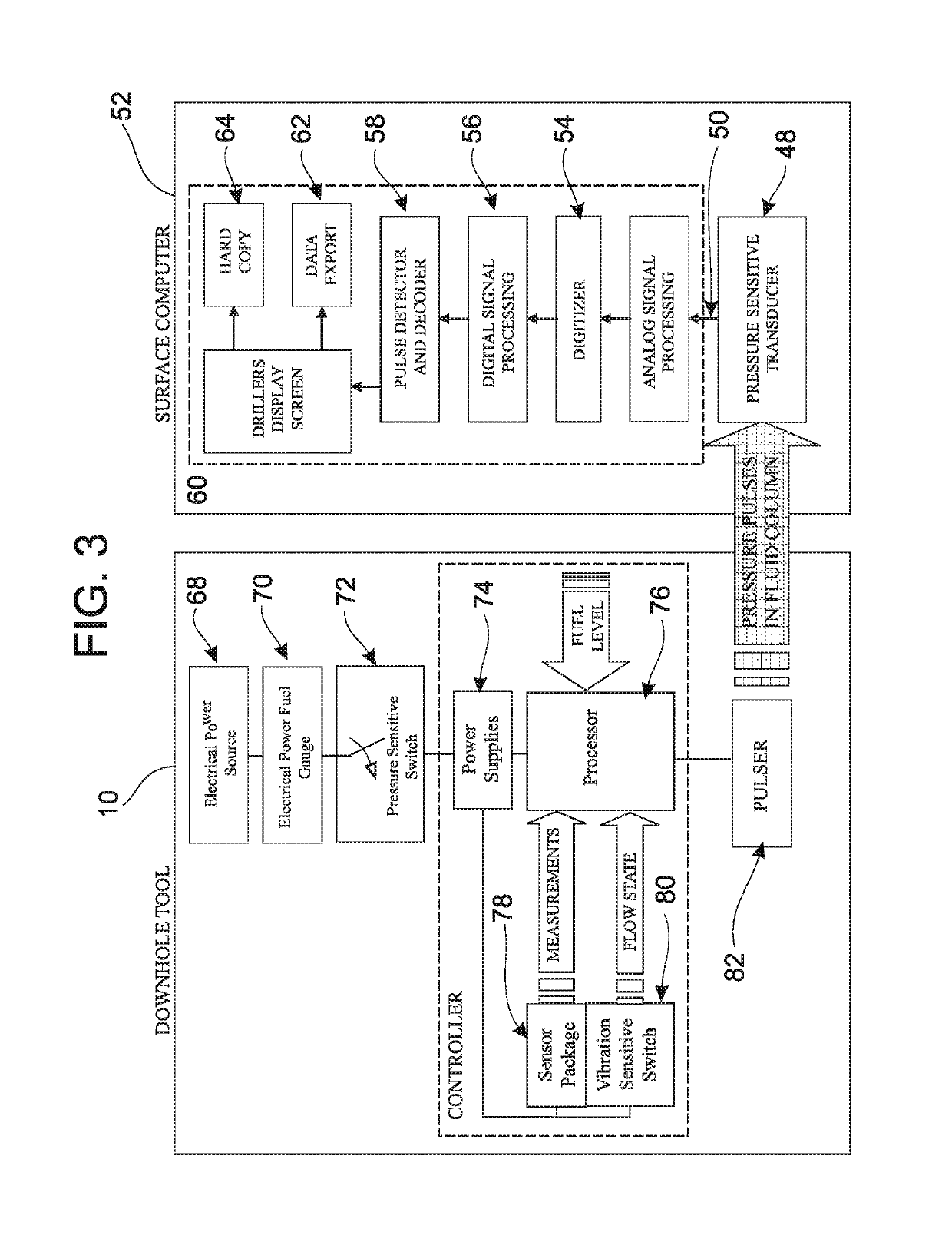

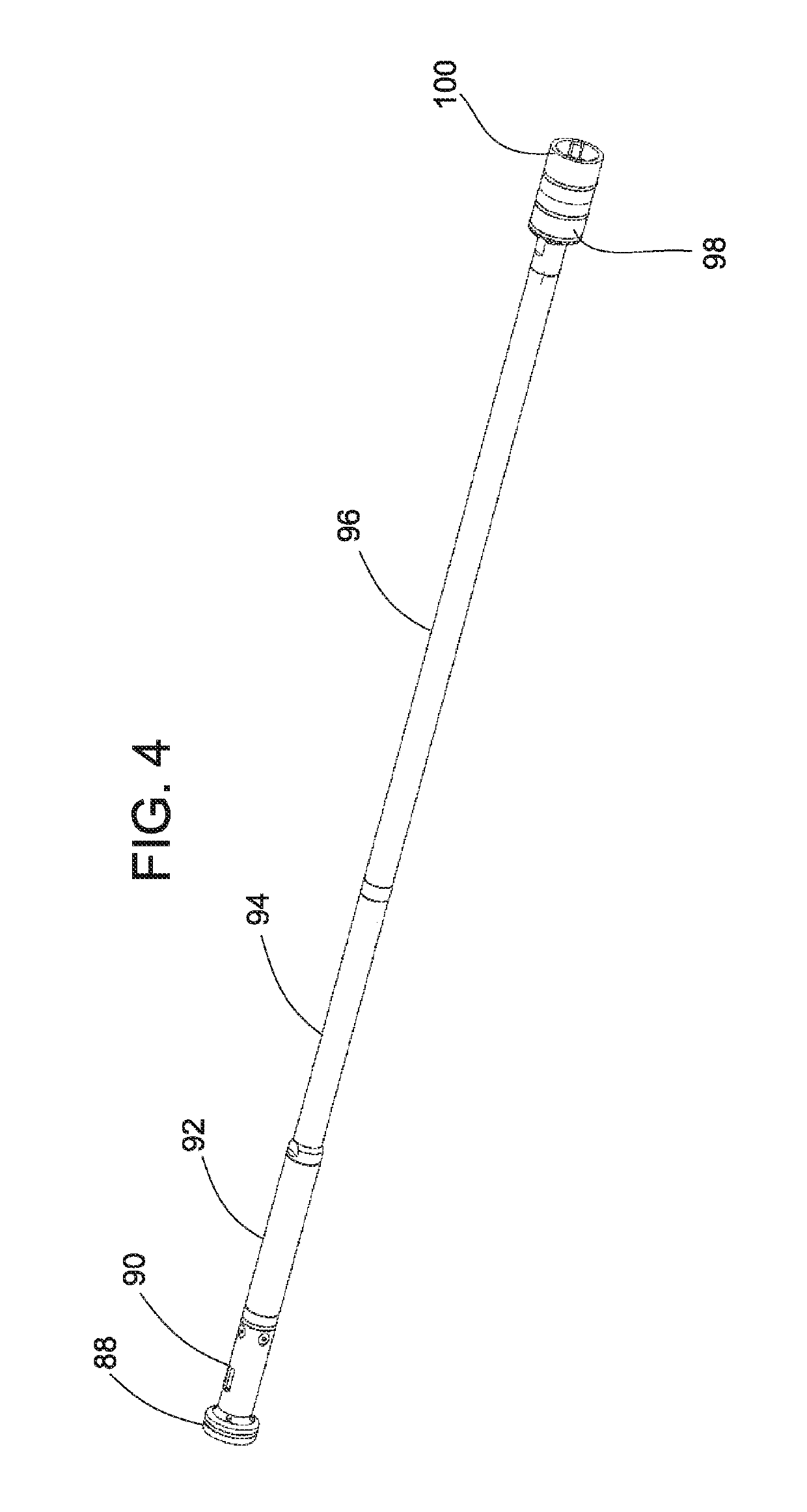

Measurement while drilling apparatus and method of using the same

Owner:NAT OILWELL DHT

Motor brake system

ActiveUS20200132149A1Association with control/drive circuitsAxially engaging brakesElectric machineControl theory

A motor includes a housing containing a rotor and stator. A brake assembly is adapted to restrain rotation of the rotor. A brake controller includes a brake diagnostics system. At least one vibration sensor is located in the housing and provides vibration data to the brake diagnostics system in response to a brake operation cycle of the brake assembly. The vibration data is used by the brake diagnostics system to assess an operative condition of the brake assembly.

Owner:ROCKWELL AUTOMATION TECH

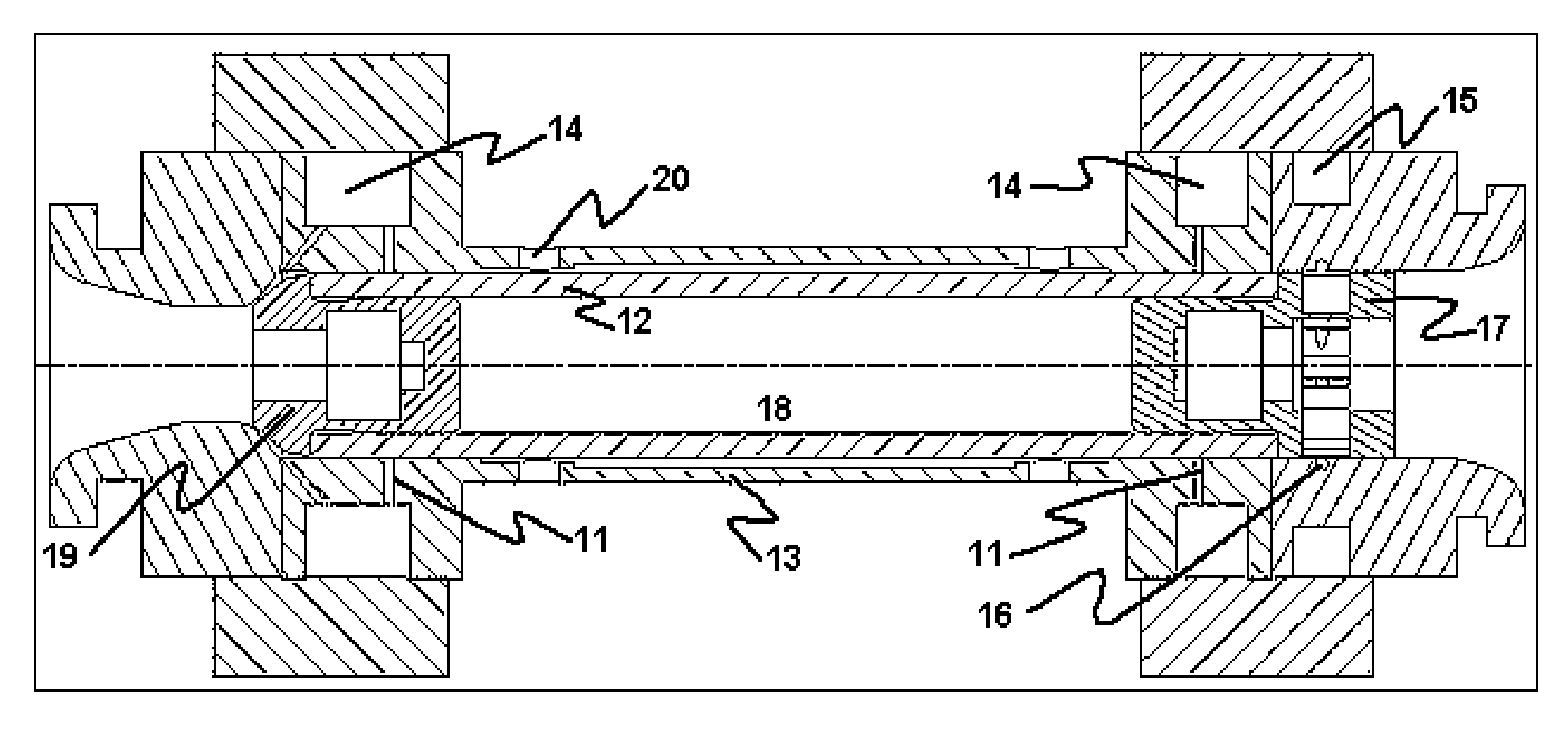

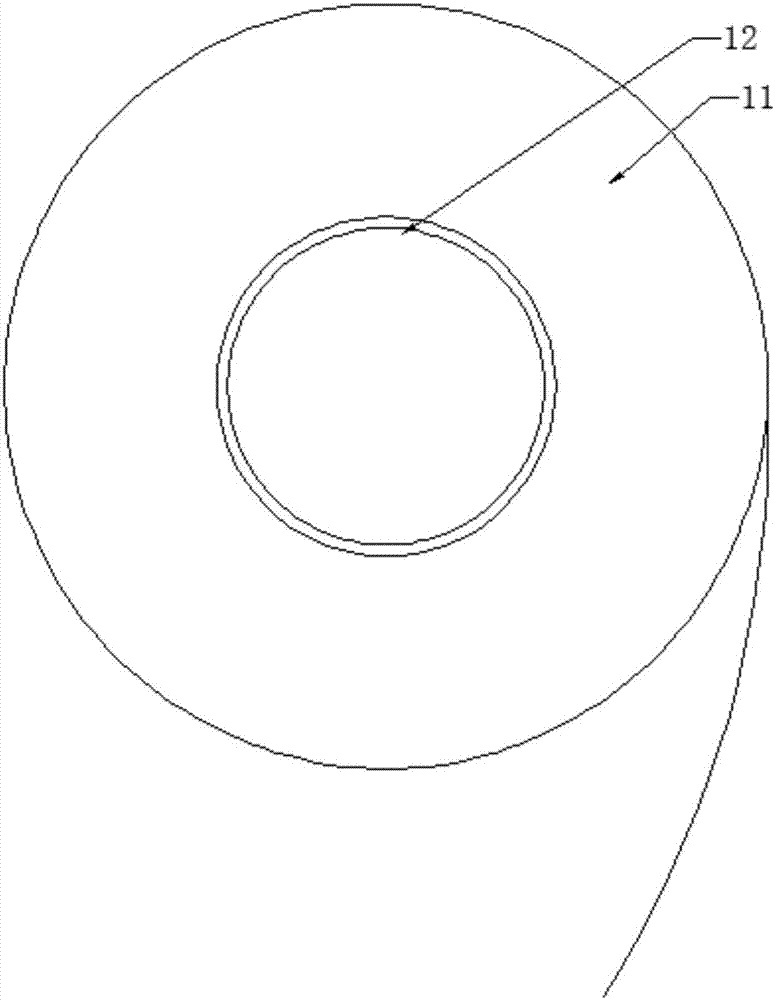

Pan-tilt motor and pan-tilt

ActiveCN104756373AShooting stabilityEnsure consistencyAircraft componentsMechanical energy handlingEngineeringMotor shaft

The invention discloses a pan-tilt motor (10), comprising a rotor component (11), a motor shaft (12) and a stator component (13). The motor shaft (12) comprises a shaft body (122), a first end (124) and a second end (126). The first end (124) if fixedly connected to the rotor component (11). The stator component (13) sleeves the periphery of the shaft body (122) and is connected to the motor shaft (12) in a rotating manner through a pair of bearings (15). The pair of bearings (15) are disposed near the first end (124) and the second end (126). The pan-tilt motor (10) also comprises a compressing piece (16) and an elastic body (18). The compressing piece (16) matches with the second end (126), and thereby the stator component (13) is positioned at the motor shaft (12) in an axial direction. The elastic piece (18) and a bearing pad (152) are both disposed between the compressing piece (16) and the bearing (15) adjacent to the second end (126). The bearing pad (152) clings to the bearing (15). The elastic piece (18) is disposed between the bearing pad (152) and the compressing piece (16). The elastic body (18) is elastically deformed through the compressing piece (16), and thereby the axial pretightening force of the pan-tilt motor (10) can be ensured.

Owner:SZ DJI OSMO TECH CO LTD

Stator manufacturing method and stator

Owner:TOYOTA JIDOSHA KK

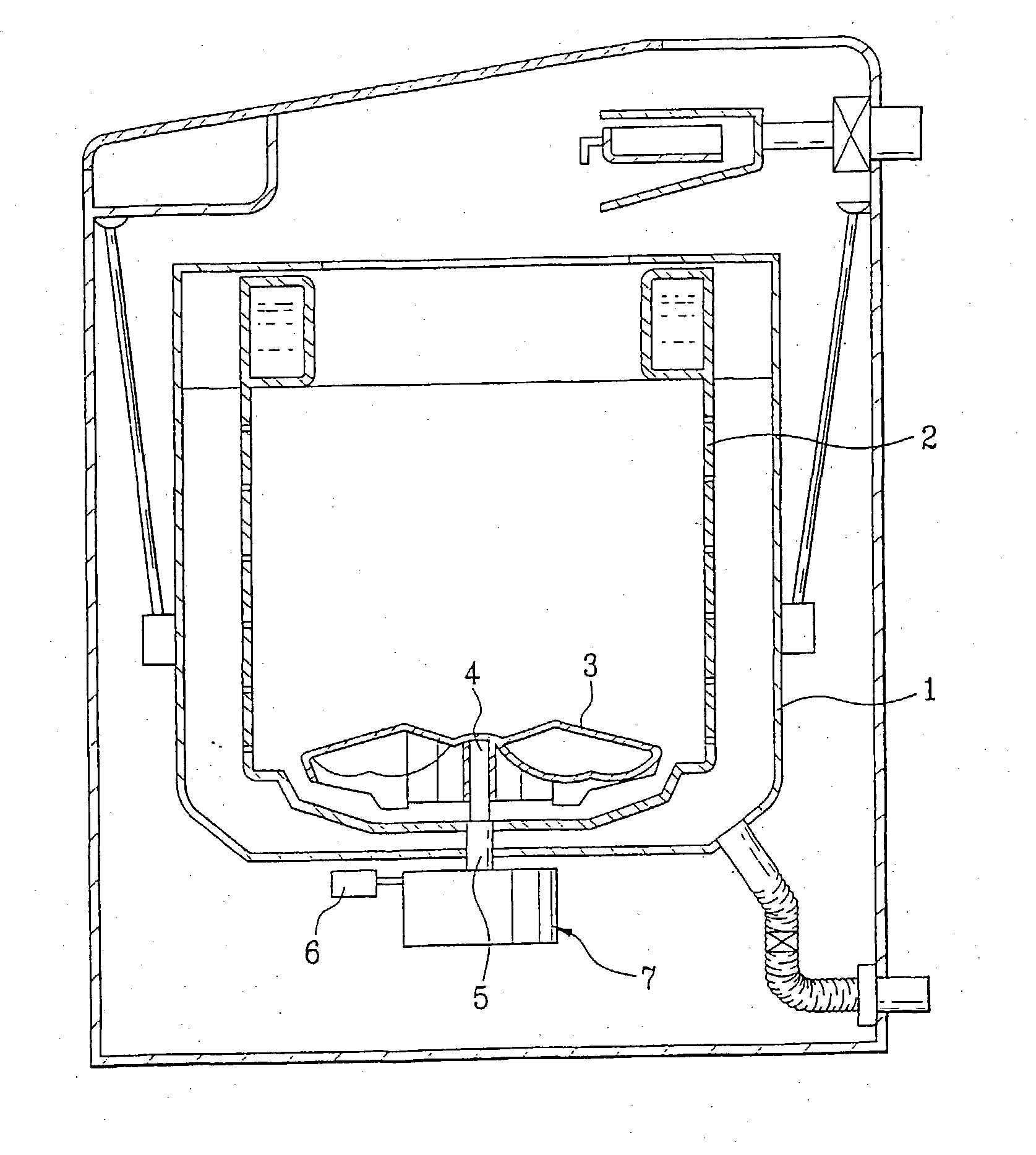

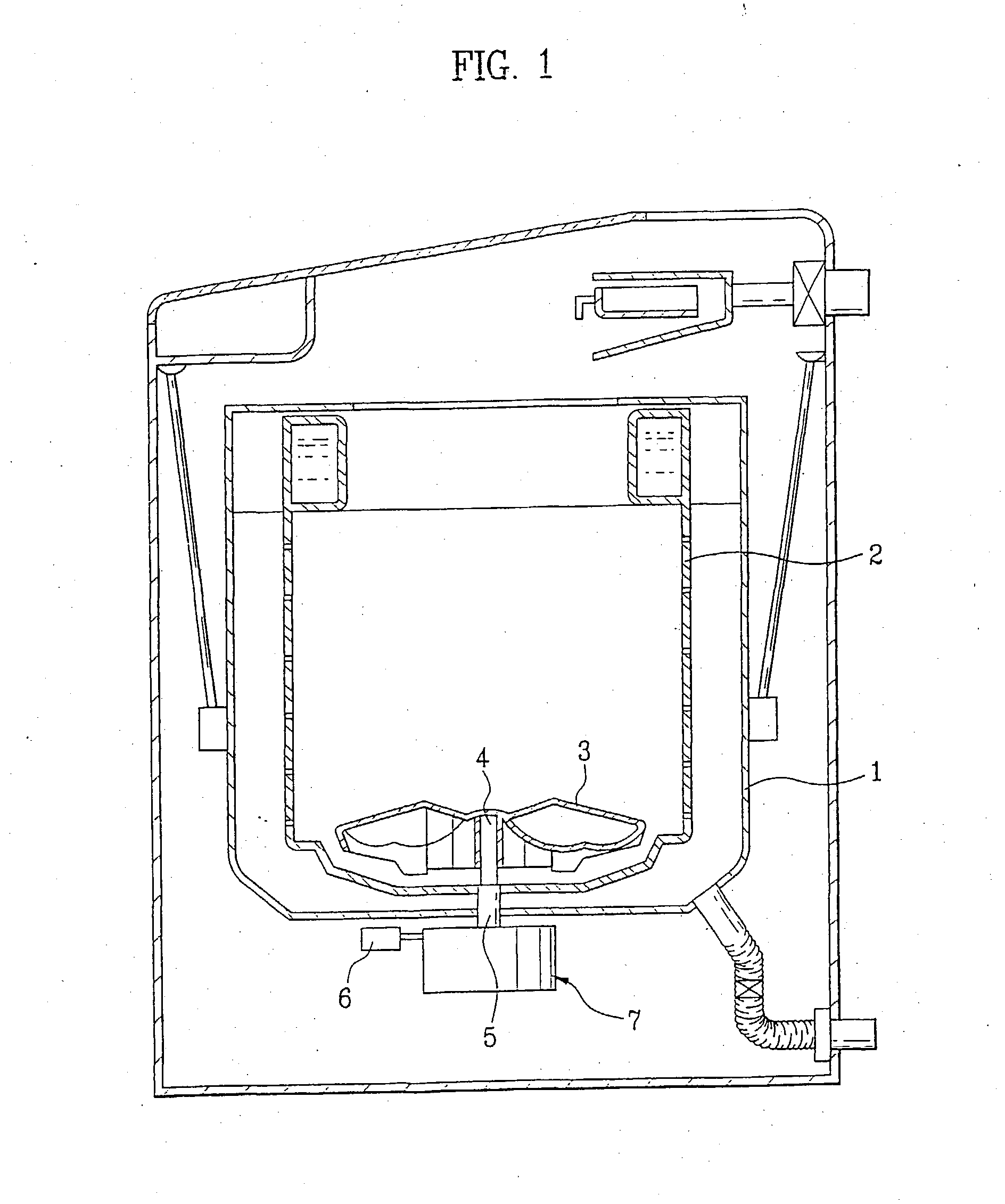

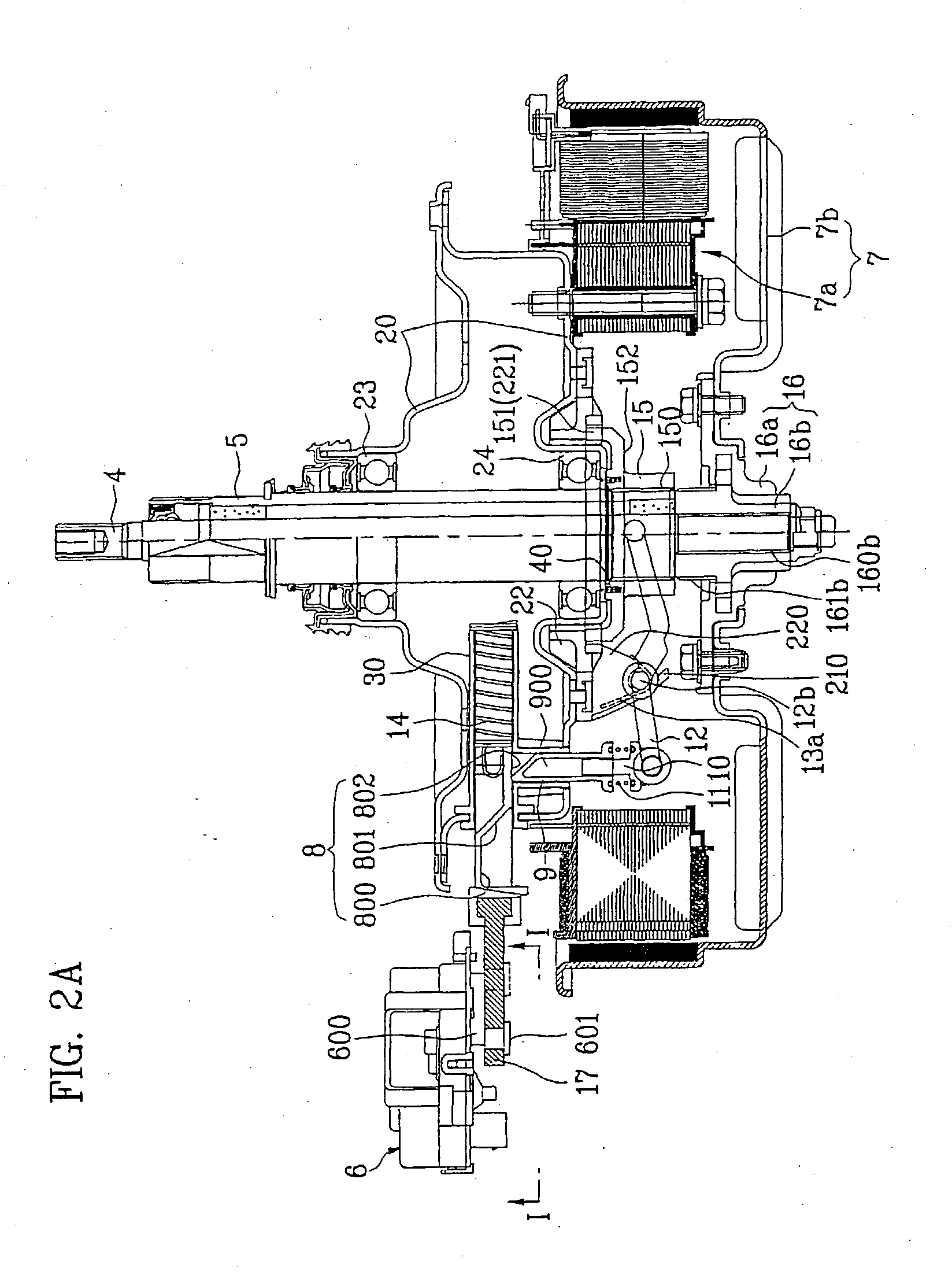

Full automatic washing machine and method for controlling the same

InactiveUS20030177794A1Short timeOther washing machinesControl devices for washing apparatusEngineeringClutch

Owner:LG ELECTRONICS INC

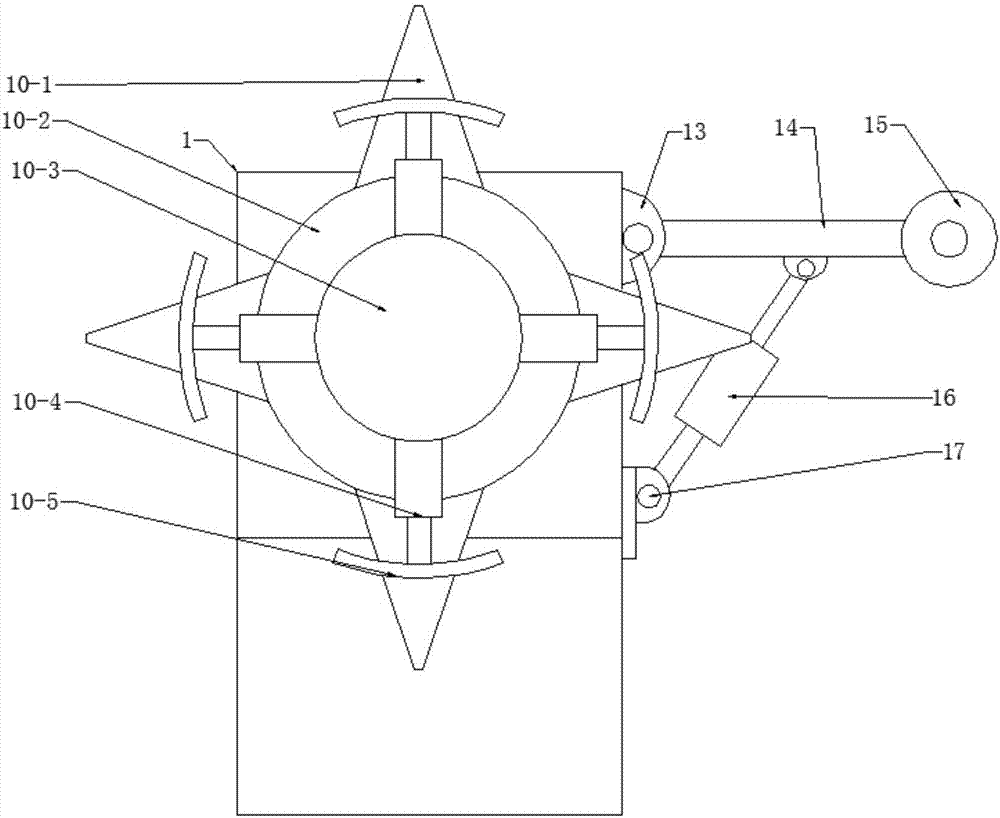

Machine tool and machine tool unit

ActiveUS20170326697A1No errors or impairmentsEasy to operateElectric/magnetic position measurementsMeasurement/indication equipmentsElectric power transmissionMotor drive

A motor-driven machine tool unit having a stator unit and at least one rotor unit having a rotor shaft that is rotatable about an axis of rotation. The rotor unit includes at least one first bearing unit arranged in the end region of a tool and / or workpiece receptacle, and a second bearing unit arranged at the opposite end region for mounting the rotor shaft in the stator unit. At least one electrical power transmission unit for transmitting electrical power between the stator unit and the rotor unit is provided. The problem addressed by the invention is that of better satisfying the increasing demands on modern machine tools or machine tool units. This problem is solved by the electrical power transmission unit is arranged in the end region opposite the tool and / or workpiece holder and / or on the second bearing unit.

Owner:FRANZ KESSLER GMBH

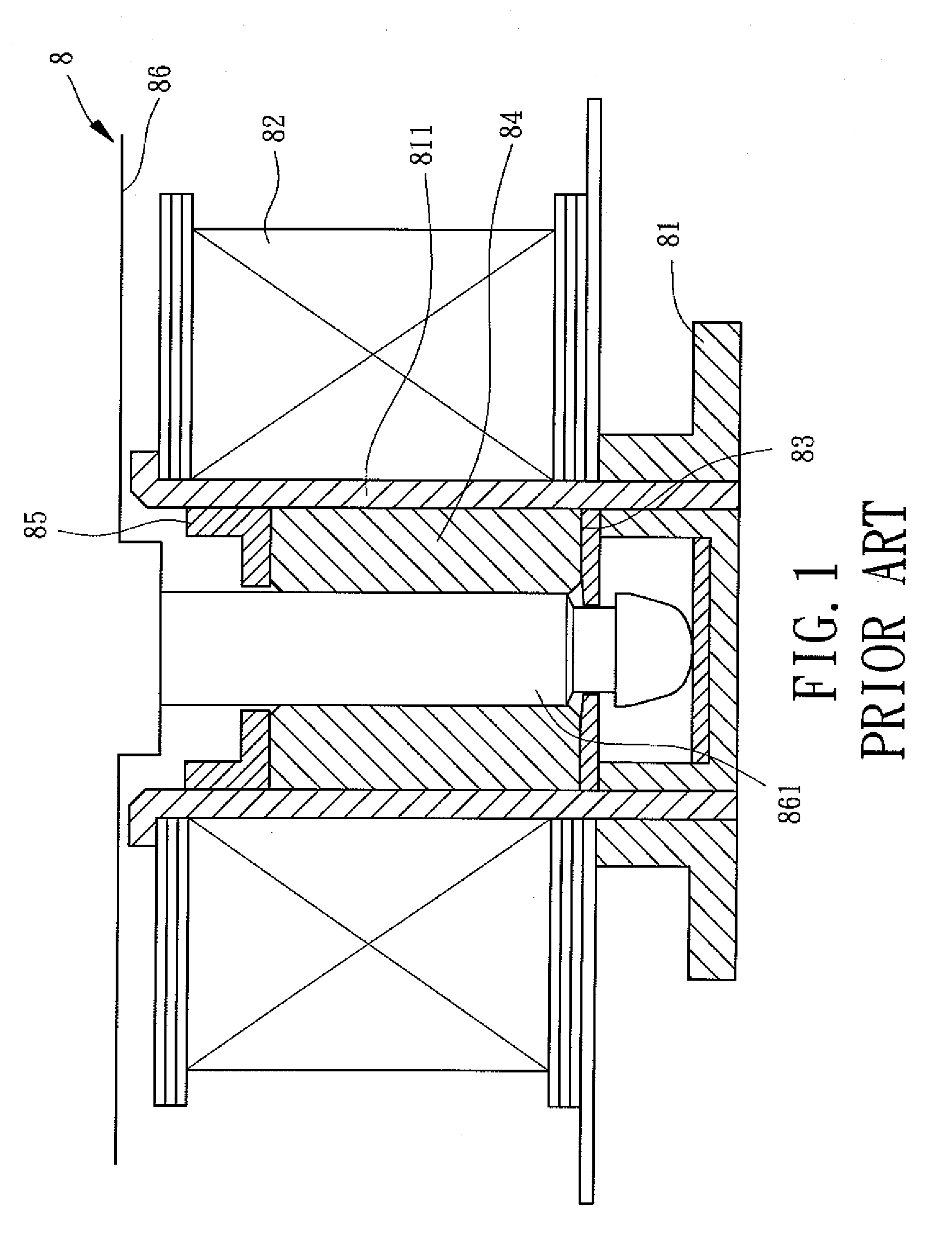

Motor punching manufacture apparatus and stator punching and rotor punching sorting device thereof

ActiveCN106270256AAvoid the labor-intensive problem of manual sortingImprove sorting efficiencyStripping-off devicesManufacturing stator/rotor bodiesPunchingEngineering

Owner:ZHENGZHOU DESHENGXIANG MOTOR MFG CO LTD

A small centrifugal pump with an inner rotor motor directly driving the impeller

Owner:HANYU GRP CO LTD

Strip steel feeding device for motor stator and rotor production

Owner:当涂县华胜电子元件制造厂

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap