Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Planet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A planet is an astronomical body orbiting a star or stellar remnant that is massive enough to be rounded by its own gravity, is not massive enough to cause thermonuclear fusion, and has cleared its neighbouring region of planetesimals.

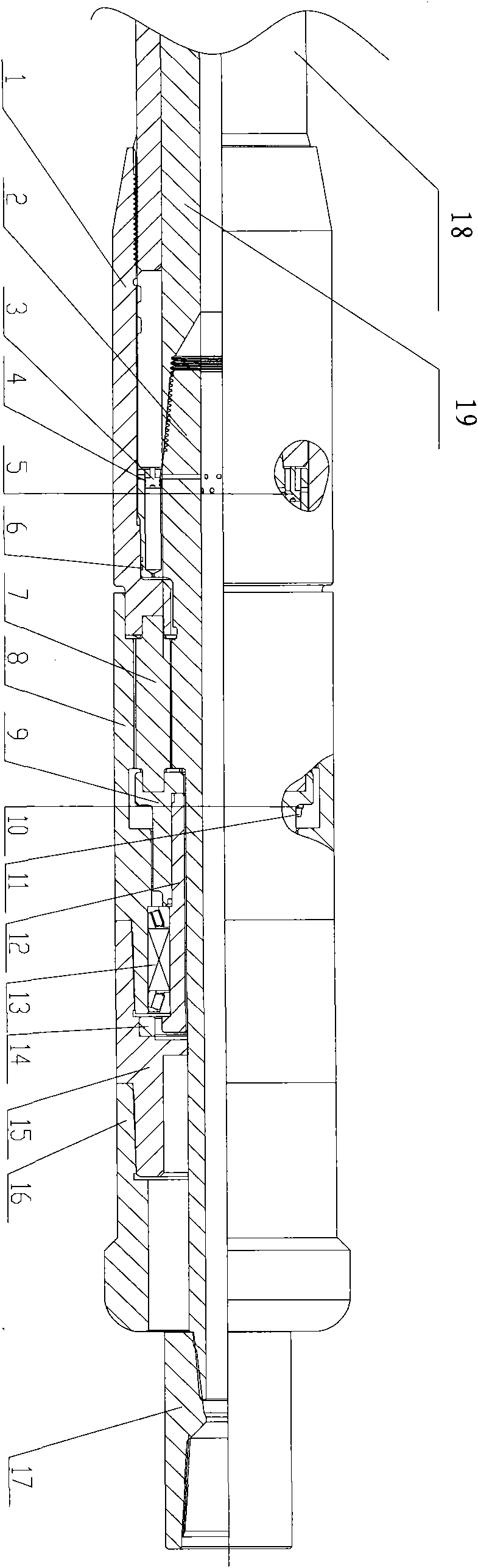

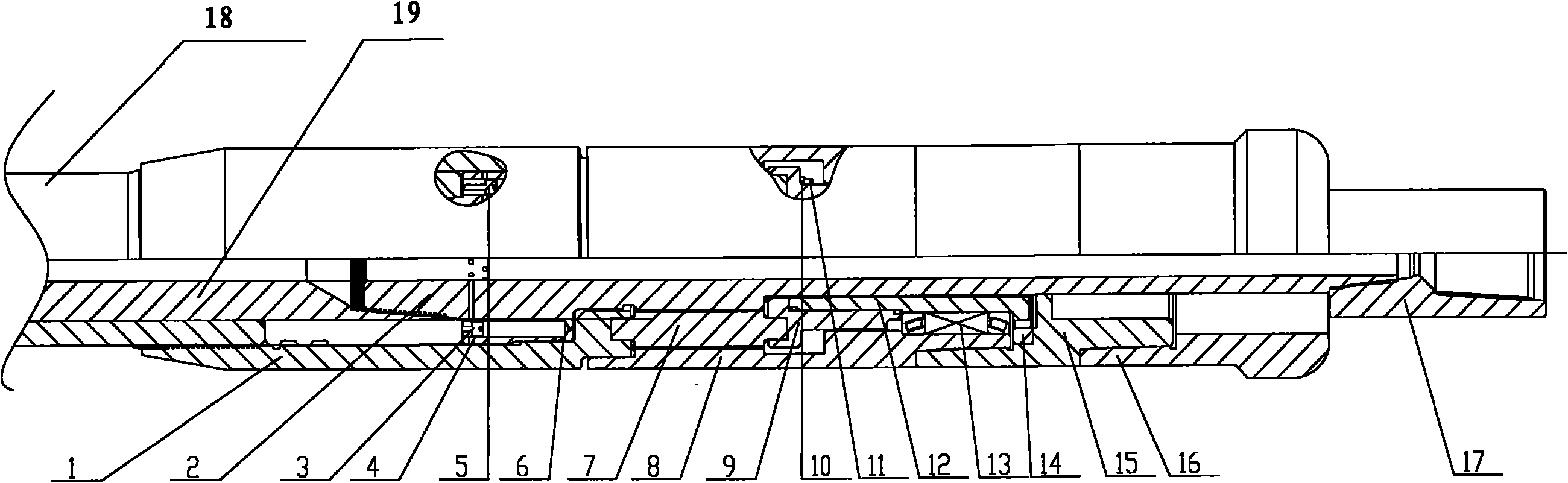

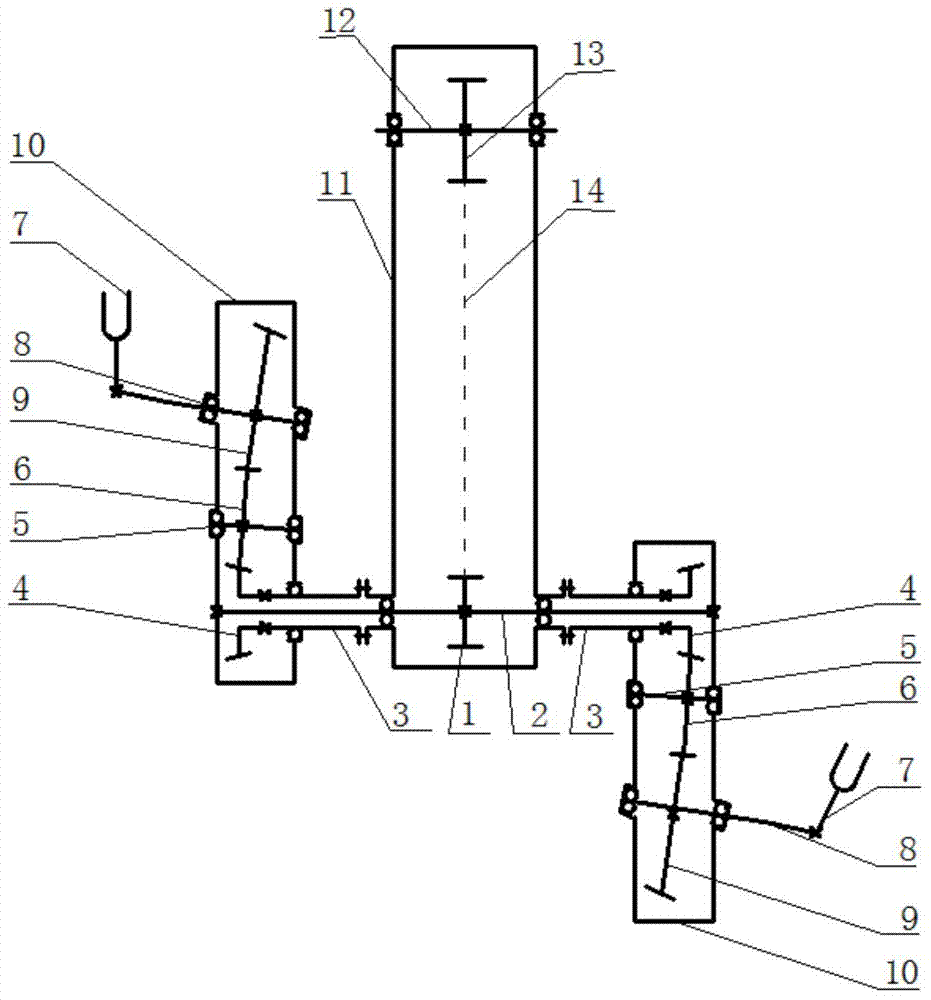

Planetary drill bit assembly for balancing reactive torque of drilling equipment in well drilling

ActiveCN101871328AImprove stabilityIncreased directional control capabilitiesDrilling rodsDirectional drillingWell drillingDrive shaft

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

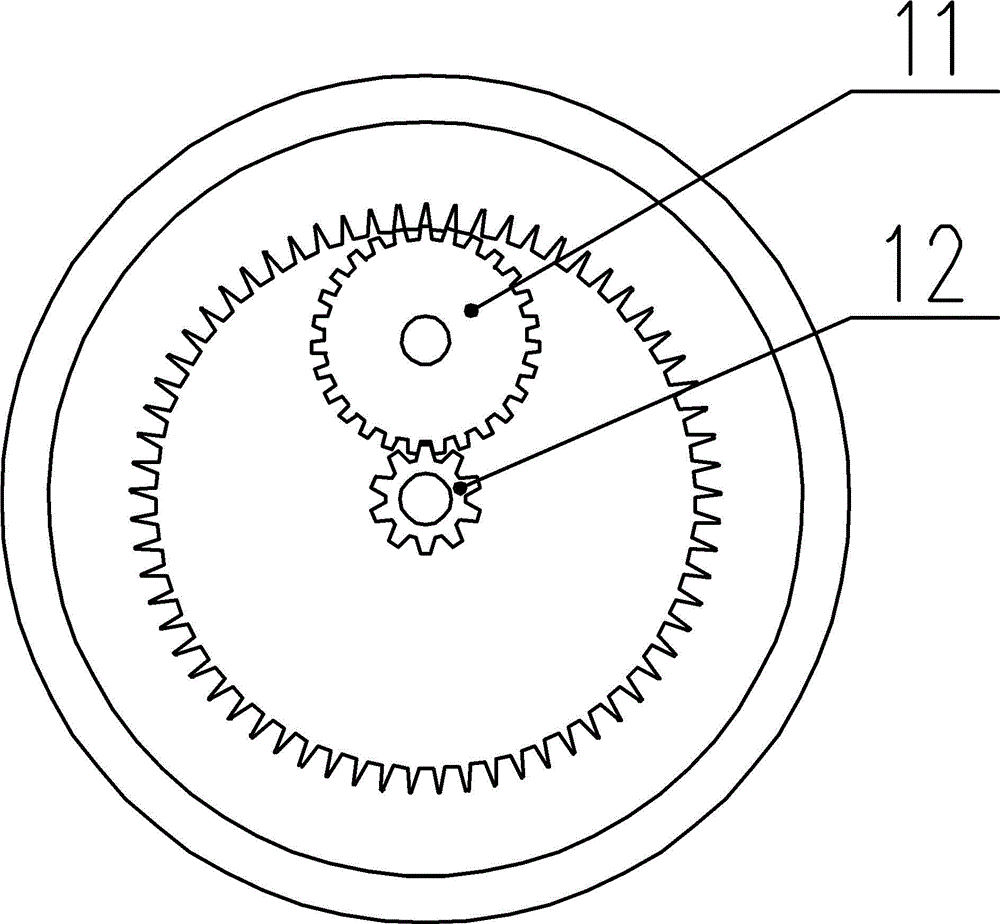

Planetary transmission device of coating machine

ActiveCN103934167AImprove coating qualitySave time at workLiquid surface applicatorsToothed gearingsEngineeringMechanical engineering

Owner:CHANGZHOU JUNHE TECH

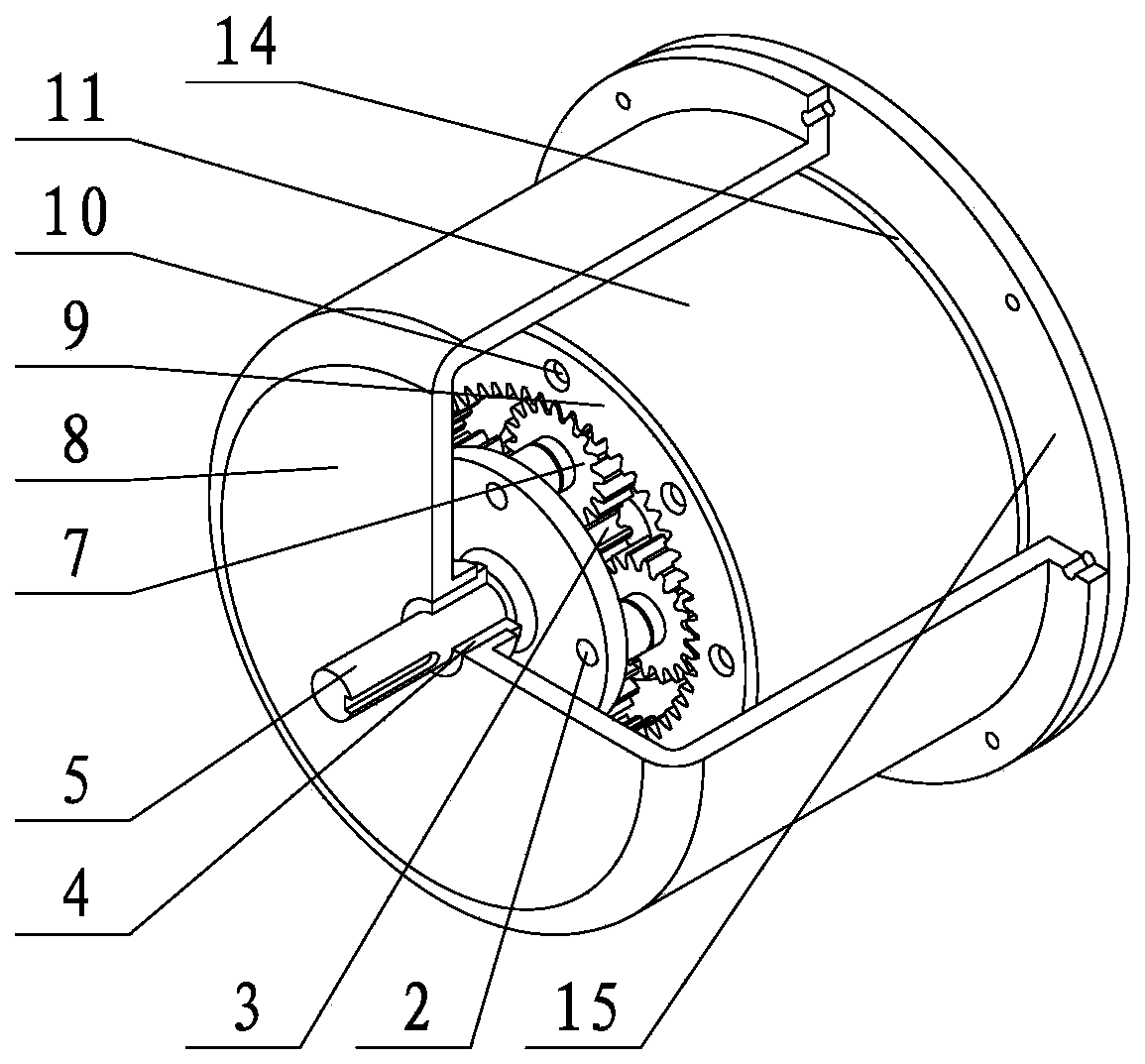

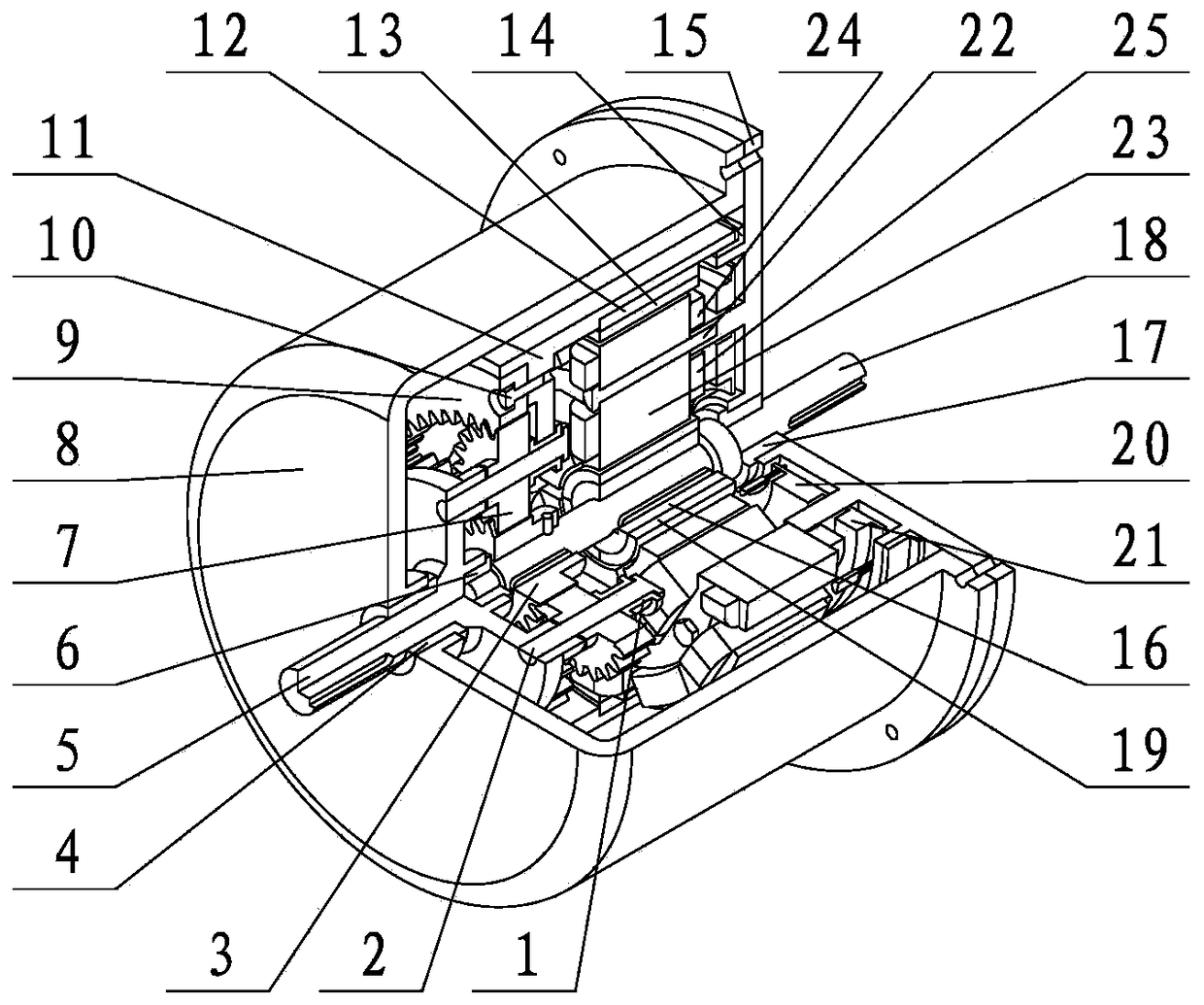

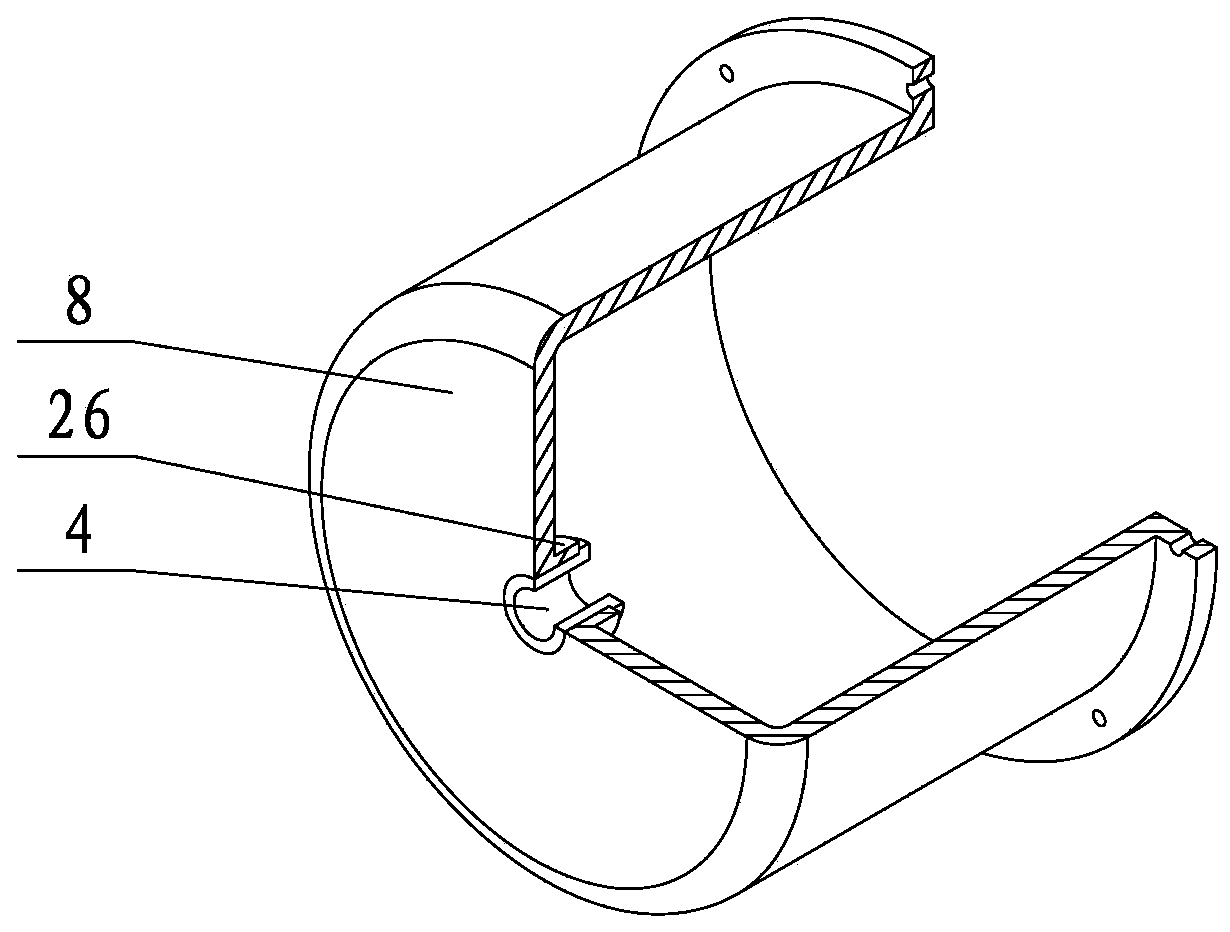

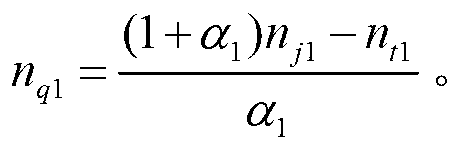

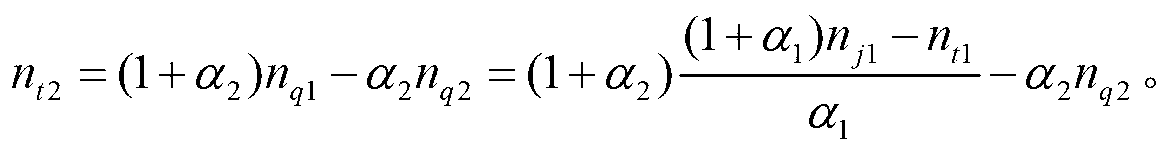

Dual-rotor input planet-gear speed reducer

The invention discloses a dual-rotor input planet-gear speed reducer, and relates to a speed reducer. The speed reducer comprises a shell component, an engine base component, a controller one, a controller two, a stator component, an external rotor component, an internal rotor component, a rotating shaft component, a gear ring, and a planet-gear component; in the operation process of the speed reducer, the output rotation speed of an output shaft one is related to rotation speed difference between two motor rotors; two motor rotors are always in the high-speed operation state, the rotating direction of the output shaft one of the speed reducer can be changed under the state of maintaining the unchanged rotation directions of two motor rotors, thereby driving a load device to realize the functions of frequently accelerating and reducing speed, frequently starting and stopping, even frequently changing the rotation direction of the load device. The speed reducer disclosed by the invention can ensure the motor to operate under the working state with high frequency, and improve the response speed when the speed reducer changes the rotation direction of the load device.

Owner:如皋久源传动机械有限公司

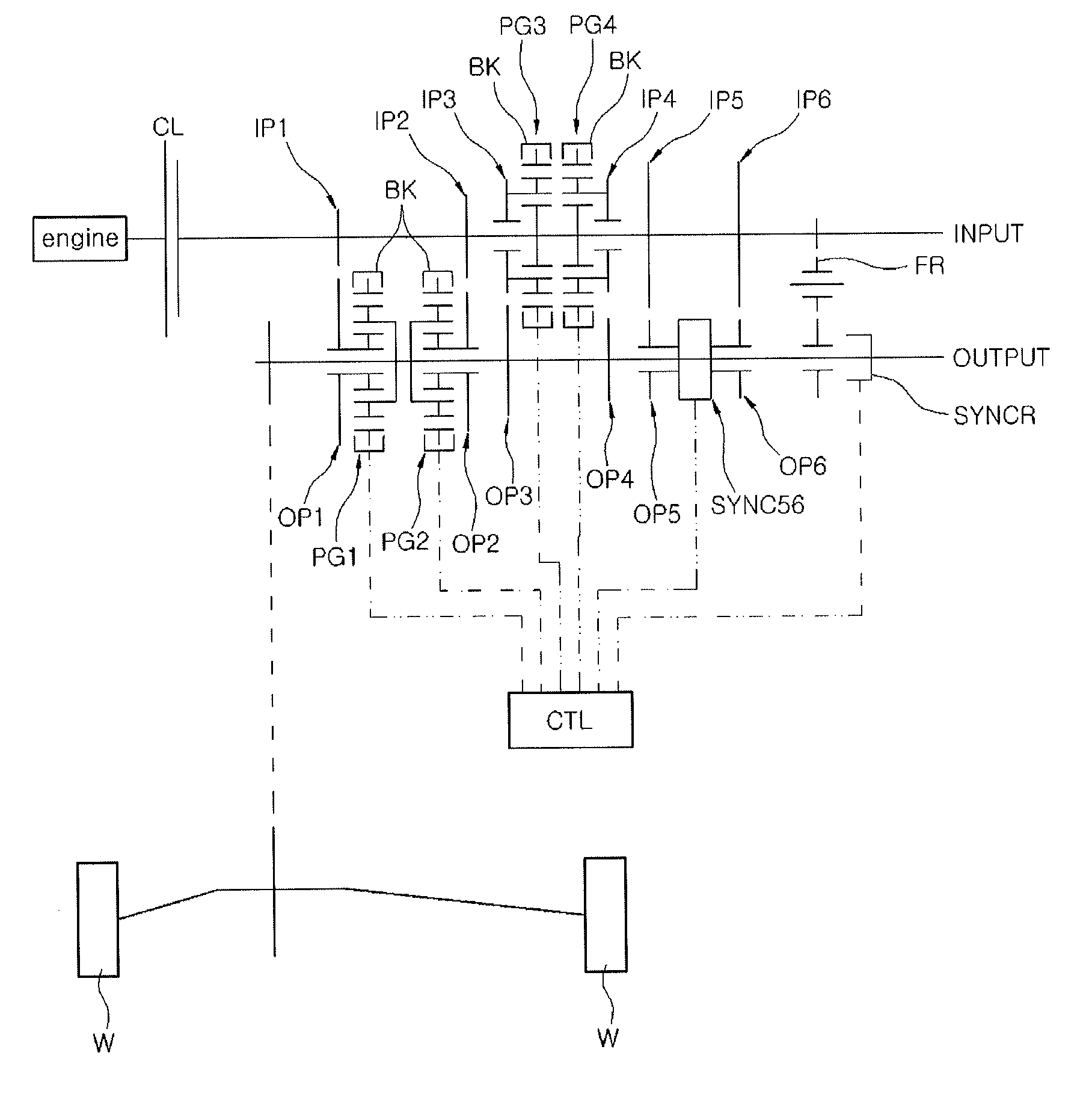

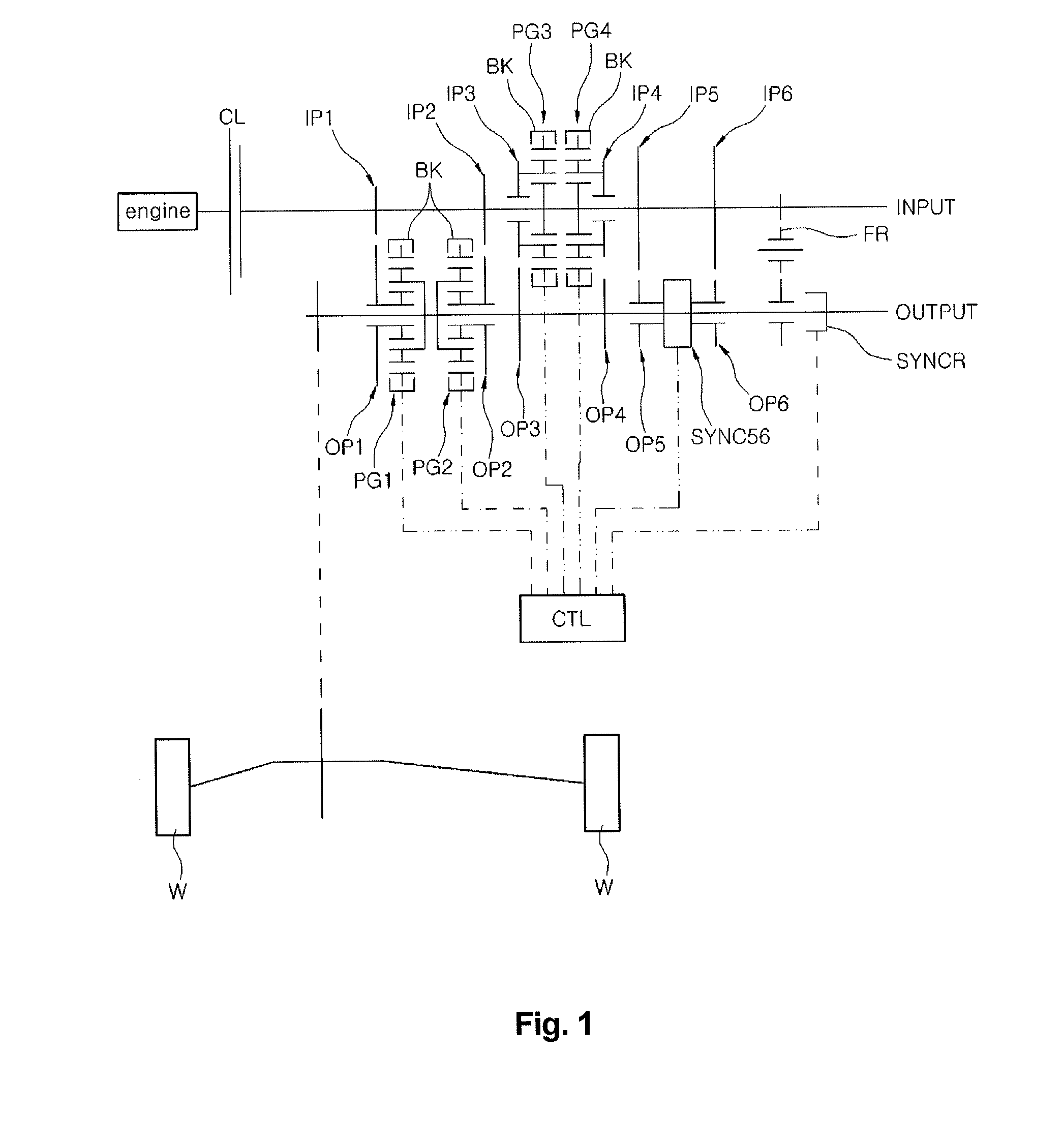

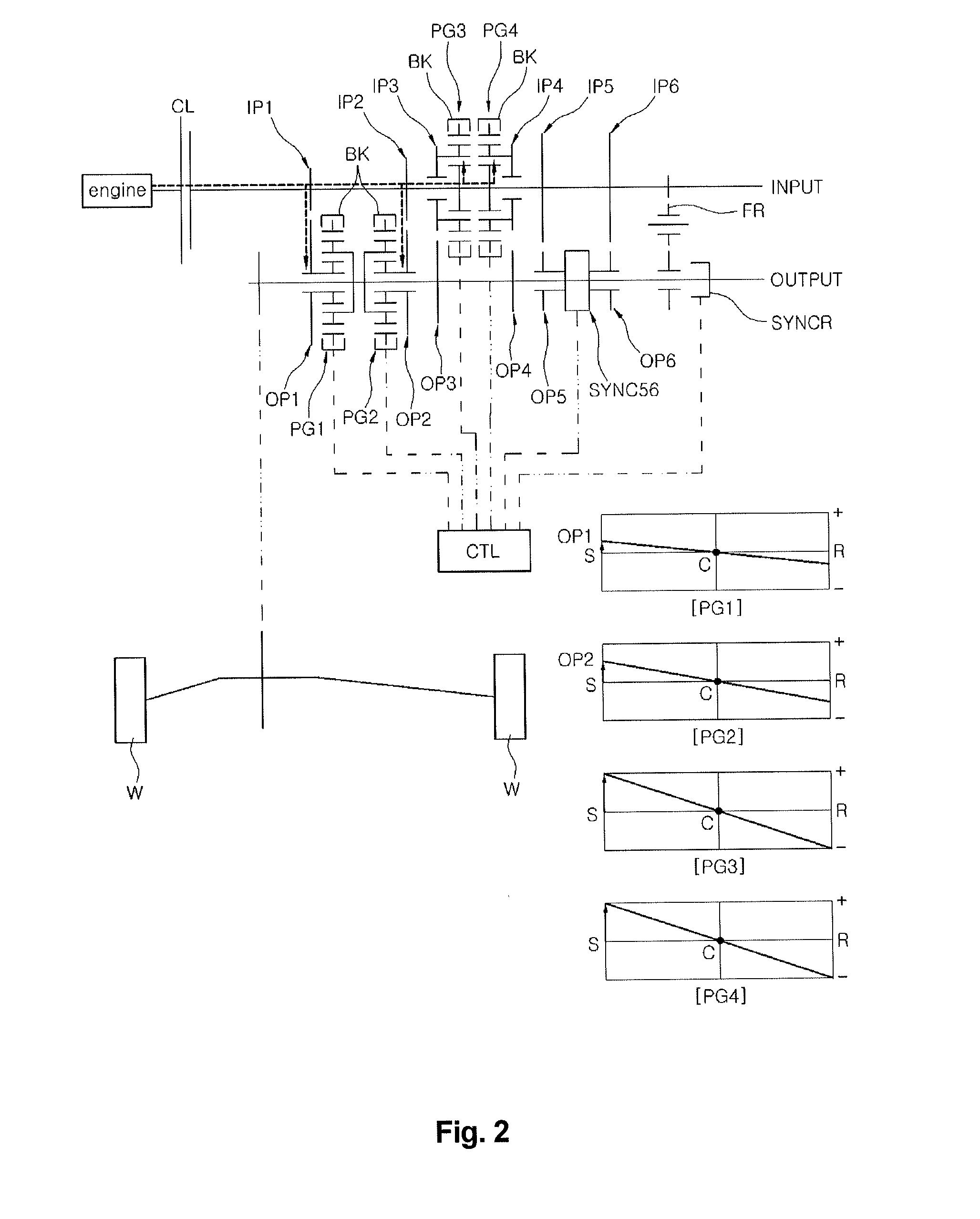

Automated manual transmission for vehicle

ActiveUS20140371022A1Smooth and reliable gear shift sensationImprove marketabilityToothed gearingsGearing controlGear wheelEngineering

Owner:HYUNDAI MOTOR CO LTD

Planetary gear train built-in construction winch device

Owner:ANHUI KUDZUVINE ROOT PRODUCTIVITY PROMOTION CENT CO LTD

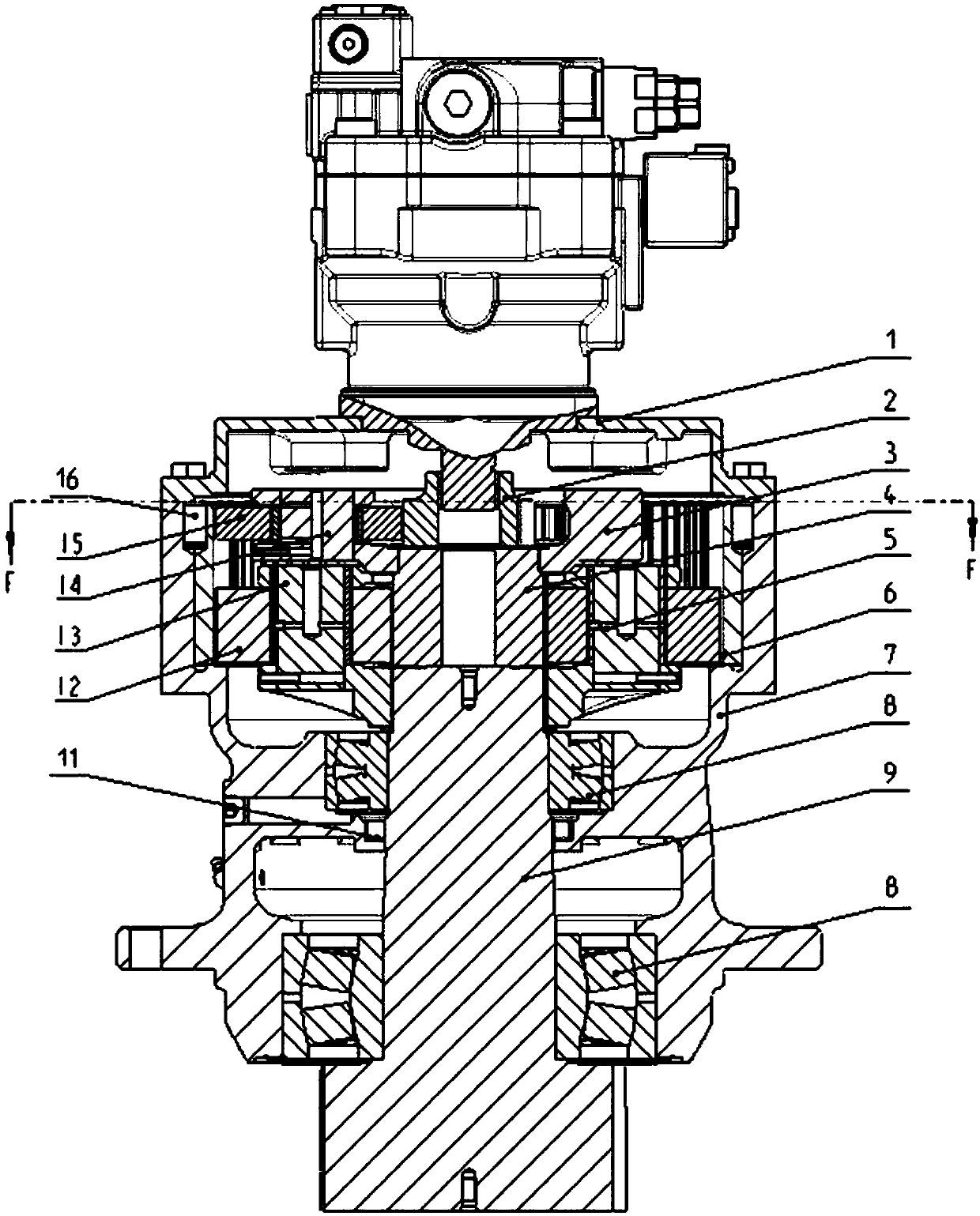

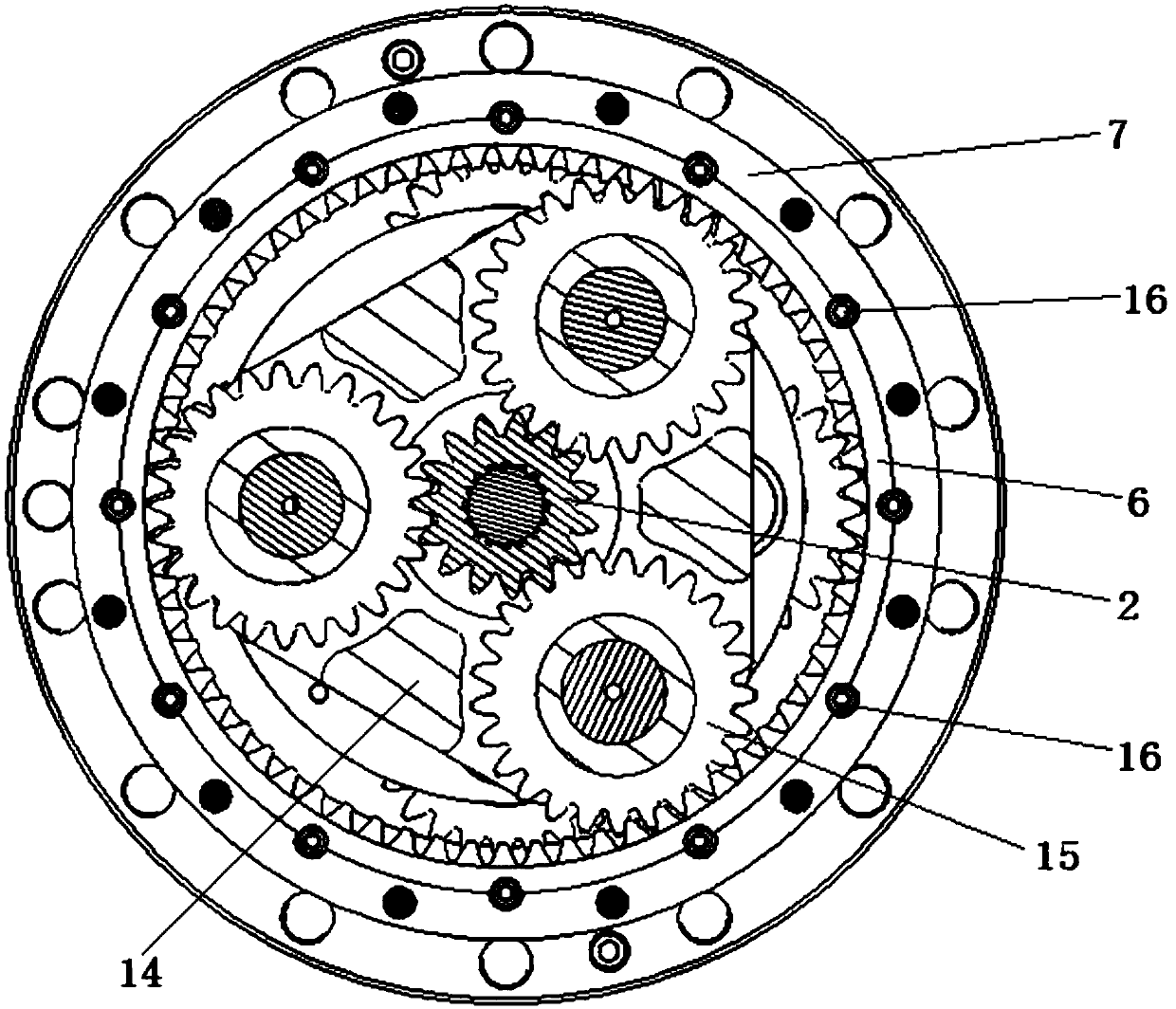

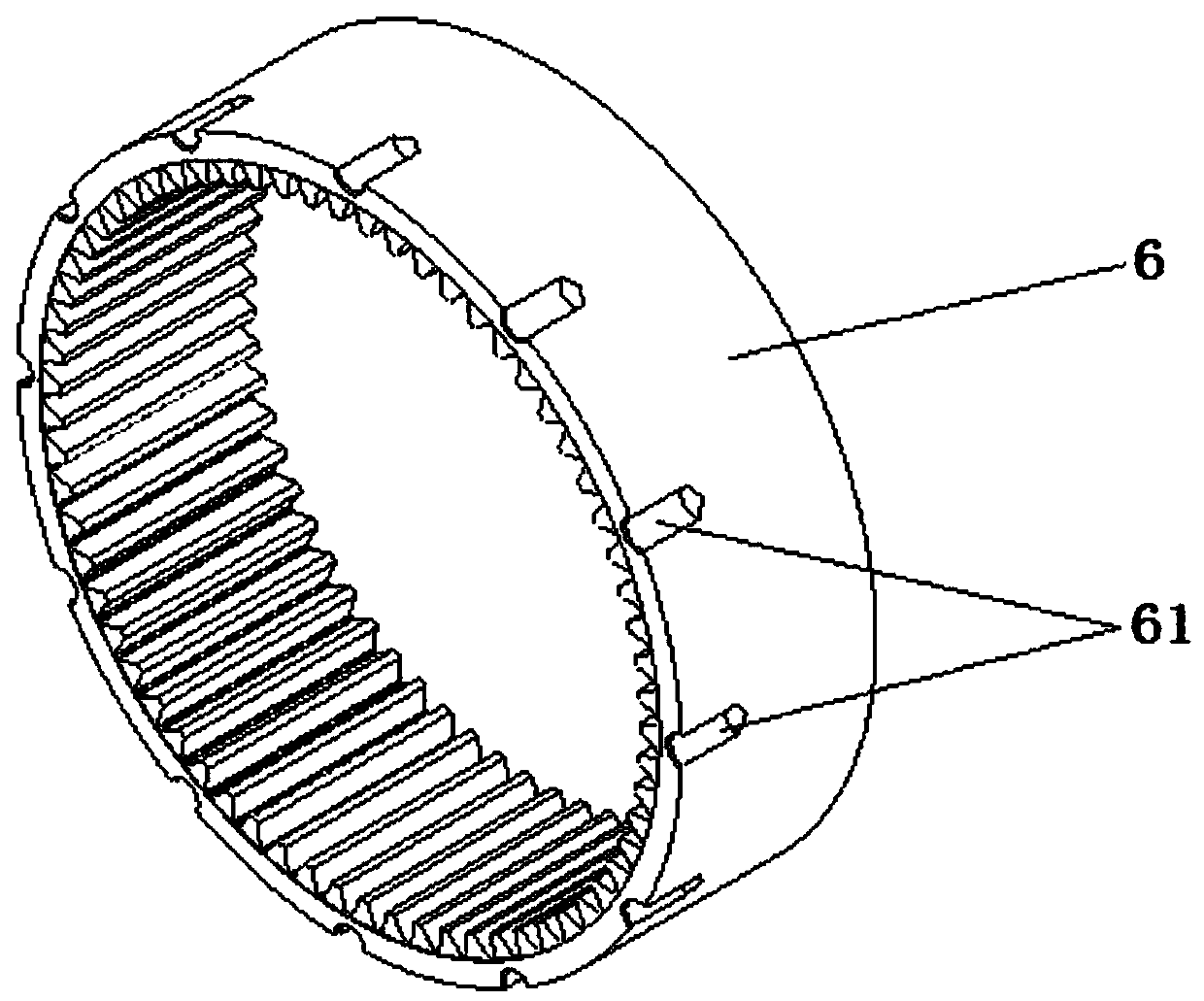

Planetary reducer

Owner:GUANGXI LIUGONG MASCH CO LTD

Hydraulic hybrid turbo transmission

InactiveUS20090313984A1Energy lossLess componentsRotary clutchesFluid gearingsMulti-valveEnergy transfer

Improvements in a transmission is provided for transferring power from a power source to a work unit. The pump transfers energy received from the power source into a fluid or gas. The first turbine is fixed to output shaft, and a plurality of additional turbines are fixed on either one-way overrunning clutches or multi-disc clutches and these clutches are fixed to the output shaft and after each turbine is a multi-valves that discharges the fluid or gas. After all of the multi-stage turbines a first planetary gear set connects the transmission to the vehicle or work unit. The second planetary gear set is located between the last turbine and the first planetary gear set. During braking the planetary gear set reverses turning direction of the turbines and convert the turbines into pumps where they will pump low pressure fluid to a high pressure accumulator.

Owner:MUSTAFA REZ

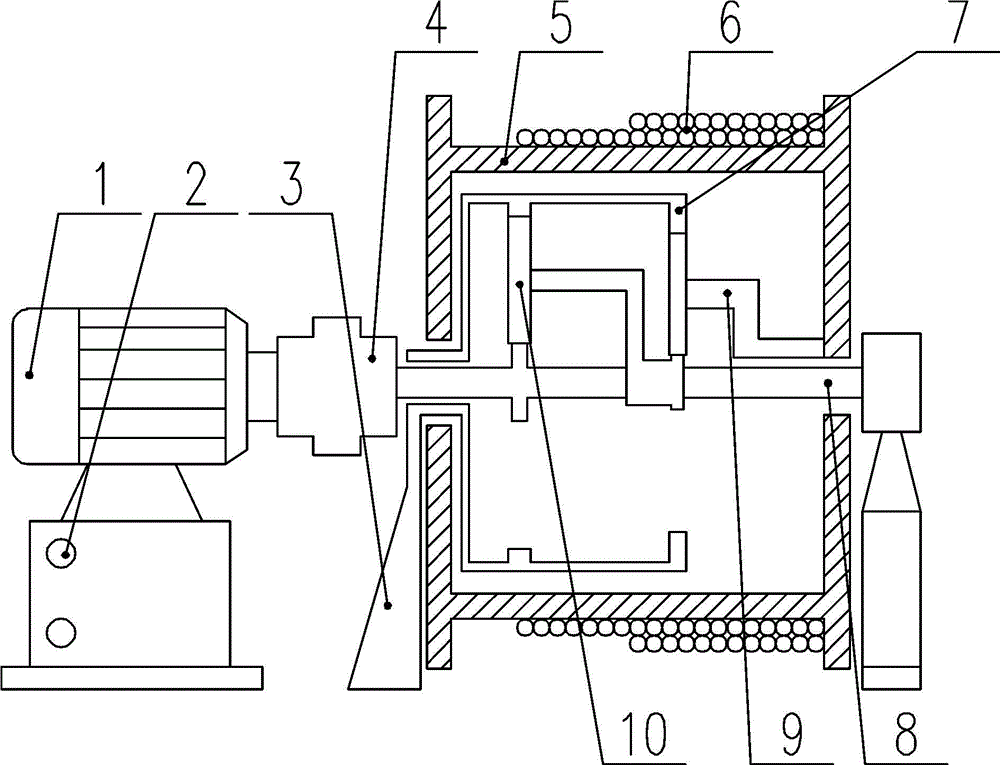

Cutter system for super-speed cutting of numerically-controlled machine tool

ActiveCN107020535AHigh cutting speedImprove machining accuracyDriving apparatusNumerical controlAviation

The invention discloses a cutter system for super-speed cutting of a numerically-controlled machine tool. The system comprises a main shaft, a housing, a locking sleeve and a cutter. The system is characterized in that the upper end of the main shaft is connected with the numerically-controlled machine tool; an input bearing is mounted at the lower end of the main shaft and positioned on the housing; the main shaft is connected with a rotating frame, and a crankshaft is mounted on the rotating frame; an epicycloidal wheel and a cycloidal wheel bearing are mounted in the middle part of the crankshaft, and a planet gear which is engaged with a sun gear is mounted at the lower end of the crankshaft; an output bearing is mounted on the sun gear and positioned on the housing; the sun gear is connected with the upper end of the locking sleeve, and the lower end of the locking sleeve is connected with the cutter. The system has the beneficial effects that the cutting rotation speed is extremely high during the processing of aviation and precision optical devices; the processing effect is good; the processing accuracy is high; extremely high surface roughness can be obtained; the actual engineering requirement of high-speed cutting can be met; the technological gaps can be filled; and moreover, the social benefit and the economic benefit are high.

Owner:TIANJIN POLYTECHNIC UNIV

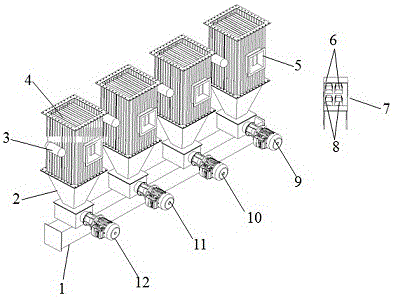

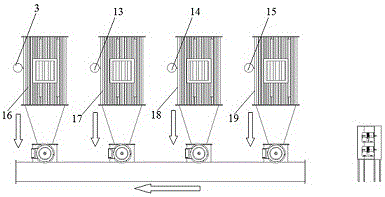

Tail ash recovering device for bag-type dust remover

Owner:GUANGXI LIANZHUANG SCI & TECH CO LTD

Two-gear transmission of electric automobile

InactiveCN107143645AReduce volumeReduce weightLiquid resistance brakesFluid clutchesMotor speedEngineering

The invention discloses a two-gear transmission of an electric automobile, and belongs to the field of transmissions. The two-gear transmission comprises a shell. A first driven gear, a magnetic powder clutch, a second driven gear and a magnetic powder brake, all of which are sequentially connected, are arranged in the shell. The shell is internally further provided with a planetary gear structure. The planetary gear structure comprises a planet carrier. Four planet wheels are connected to the two ends of the planet carrier. A sun wheel is connected among the four planet wheels. The two-gear transmission further comprises a gear ring. One side of the gear ring is engaged with the planet wheels, and the other side of the gear ring is engaged with the second driven gear. The planet carrier is engaged with the first driven gear through a gear. An electromagnetic brake and an electromagnetic clutch are adopted in the two-gear transmission to replace traditional hydraulic clutches, the size is small, and the weight is small; in combination with the excellent character of motor speed adjusting of a blade electric vehicle, the work slip frequency section between the electromagnetic brake and the electromagnetic clutch is small; and in combination of the rapid response character of the electromagnetic brake and the clutch, the heating amount of the whole transmission is low, and reliability is high.

Owner:NANJING AUTOMOBILE GROUP CORP

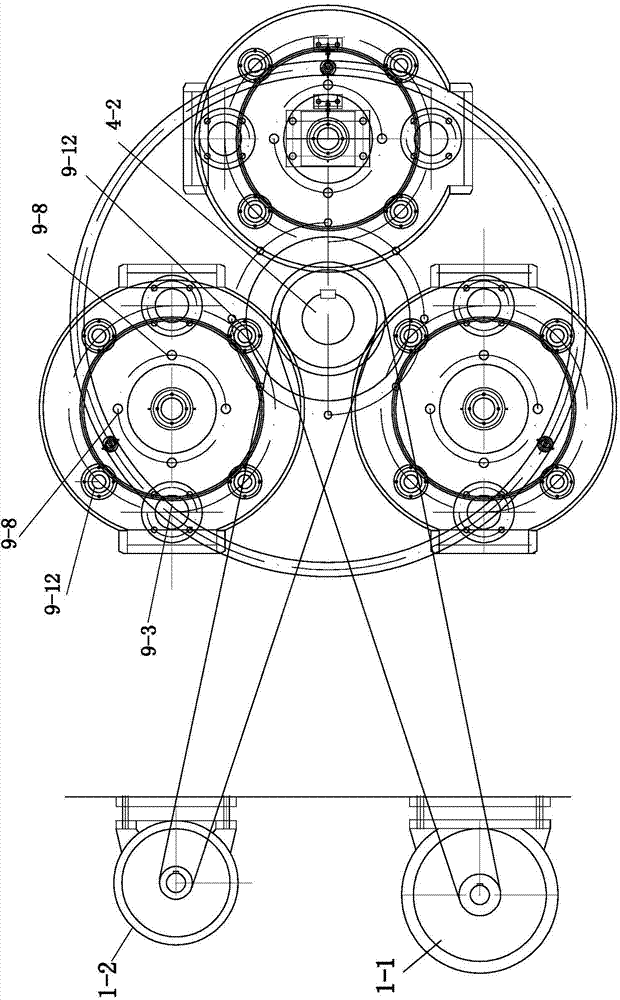

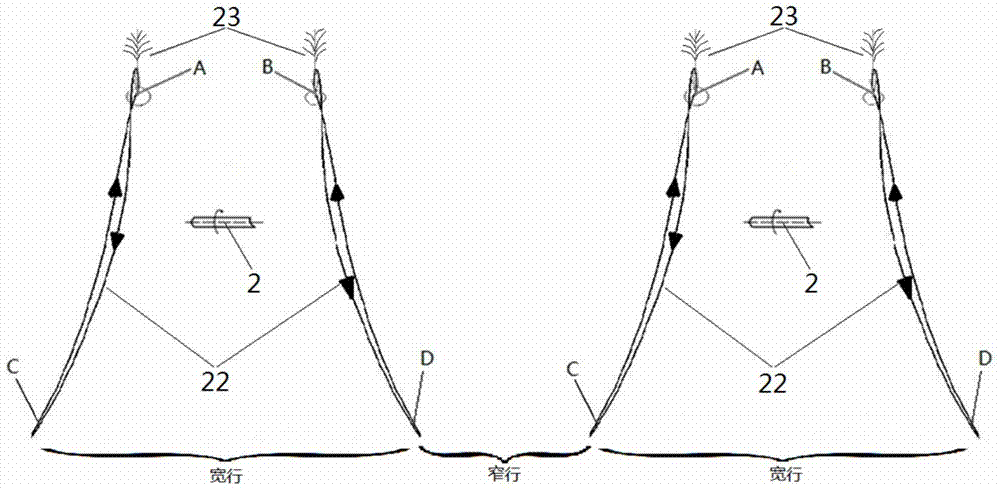

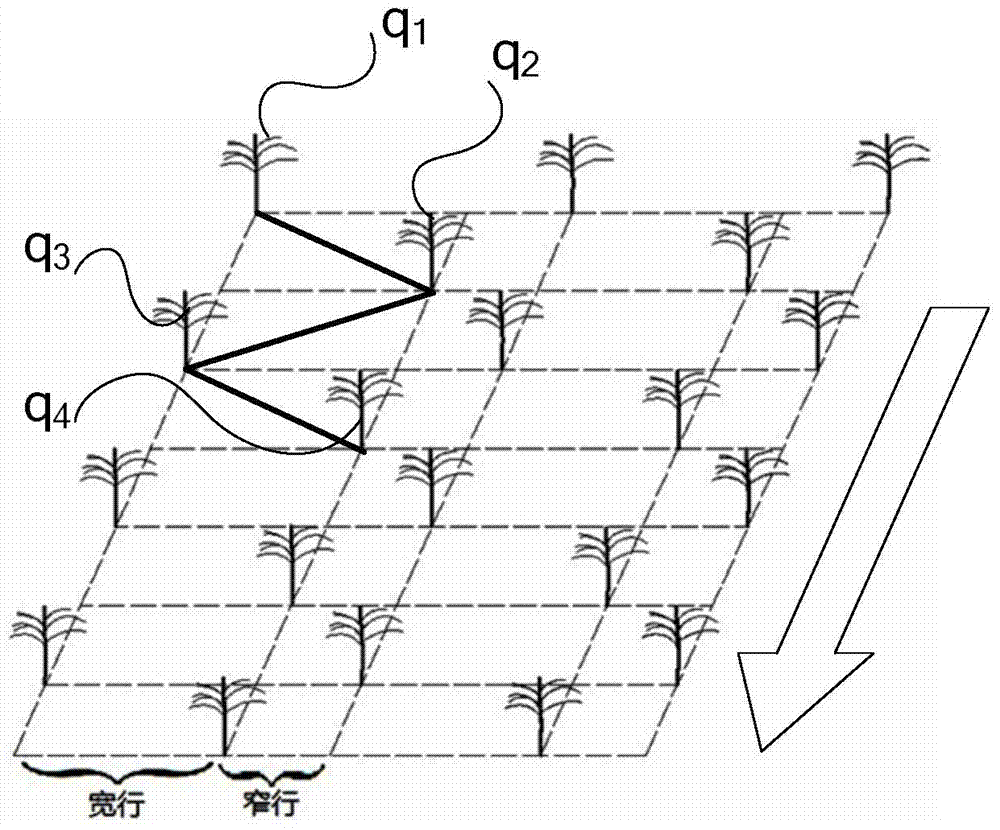

Three-non-bevel-gear planetary-gear-train wide-narrow-row-spaced oblique-Z-shaped maize transplanting mechanism

ActiveCN103493633AChange sizeRealize oblique zigzag plantingGearboxesTransplantingGear wheelMedial axis

Owner:江苏金洋建设工程有限公司

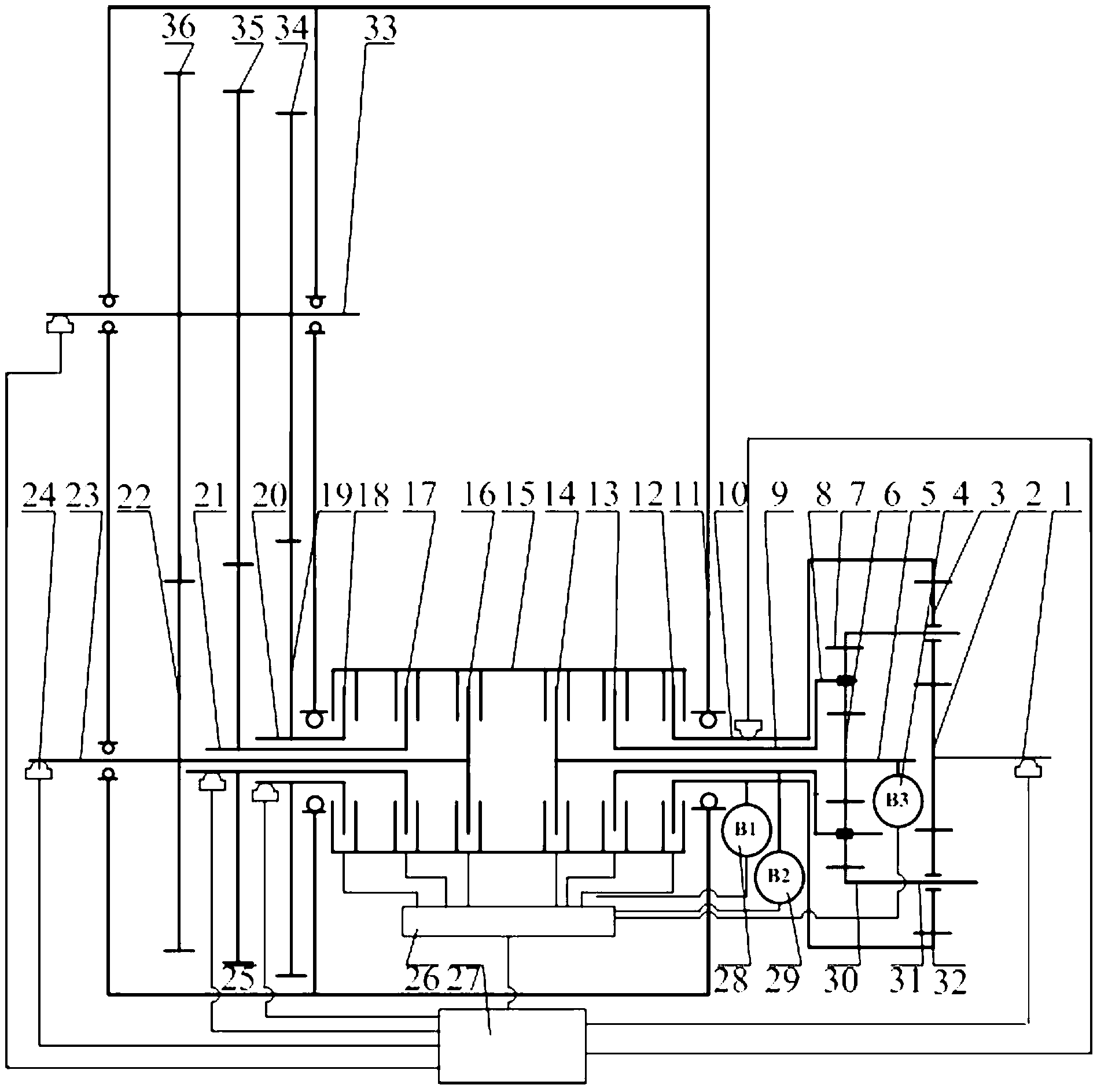

Double-planet-row converging type multi-gear multi-clutch transmission

InactiveCN103256352AMeet the needs of multiple gearsCompact structureToothed gearingsGearing controlEngineeringDouble planet

Owner:HENAN UNIV OF SCI & TECH

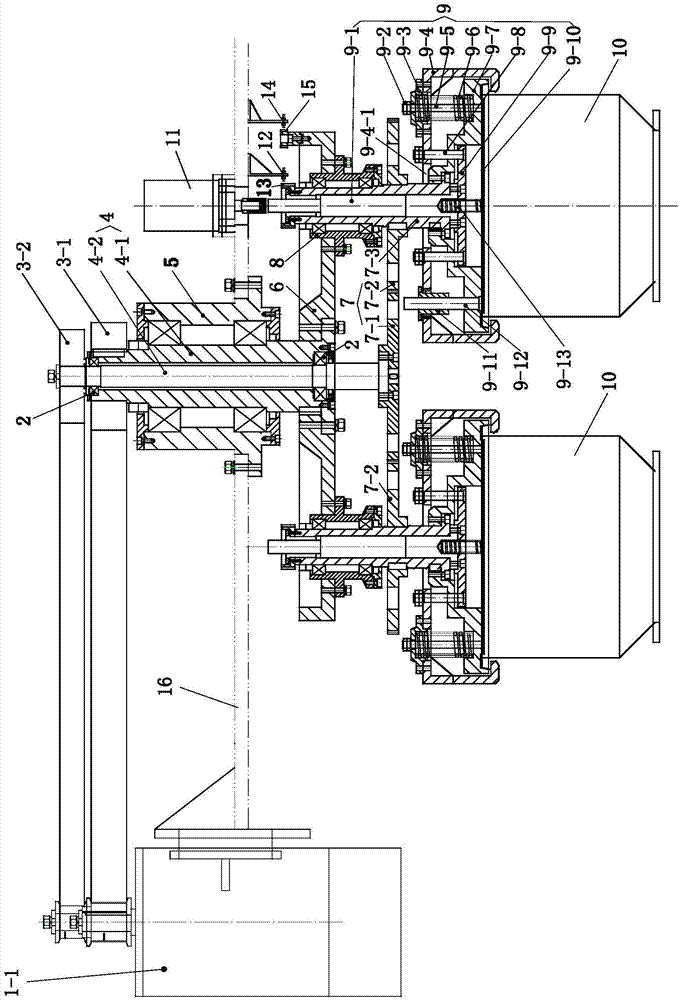

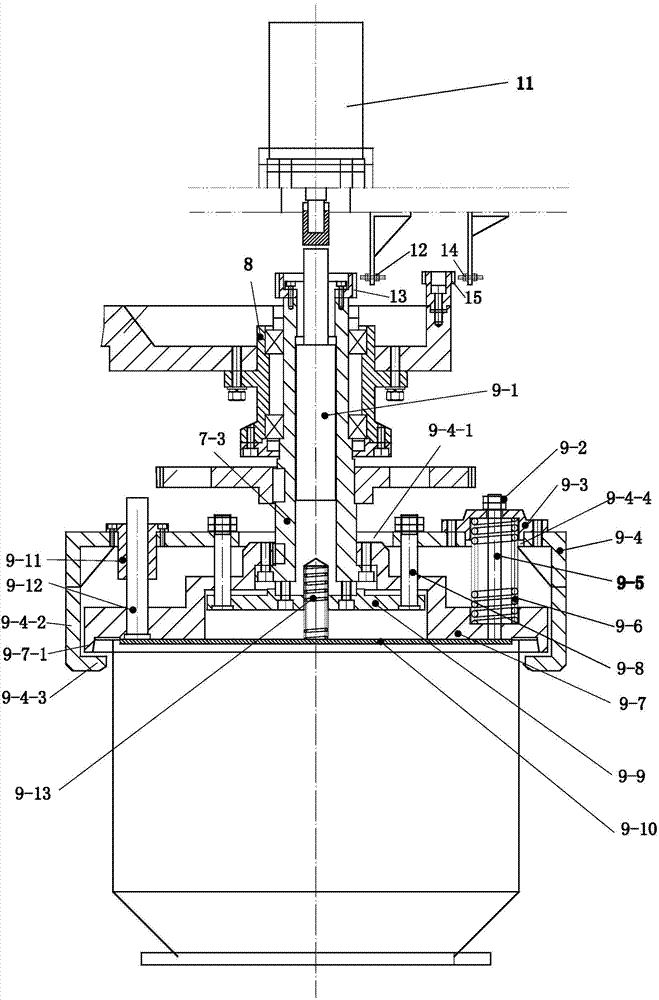

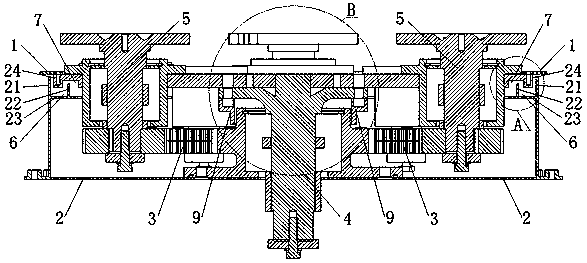

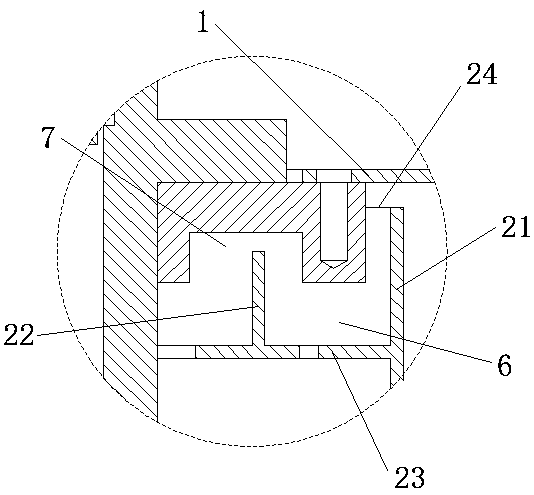

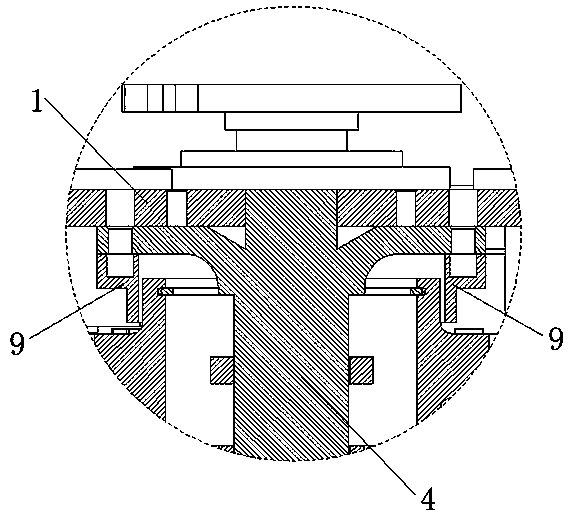

Static-pressure labyrinth gear box of planet ball mill

PendingCN109058439AGuaranteed oil seal effectOil seal effect is goodEngine sealsGearing detailsDrive shaftAgricultural engineering

Owner:长沙天创粉末技术有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap