Double-planet-row converging type multi-gear multi-clutch transmission

A multi-clutch, double-planetary technology, applied in the direction of gear transmission, toothed components, belt/chain/gear, etc., can solve the problems of complex system structure, large space occupation, inconvenient maintenance and operation, etc., and achieve a compact overall structure , the effect of meeting the needs of multiple gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

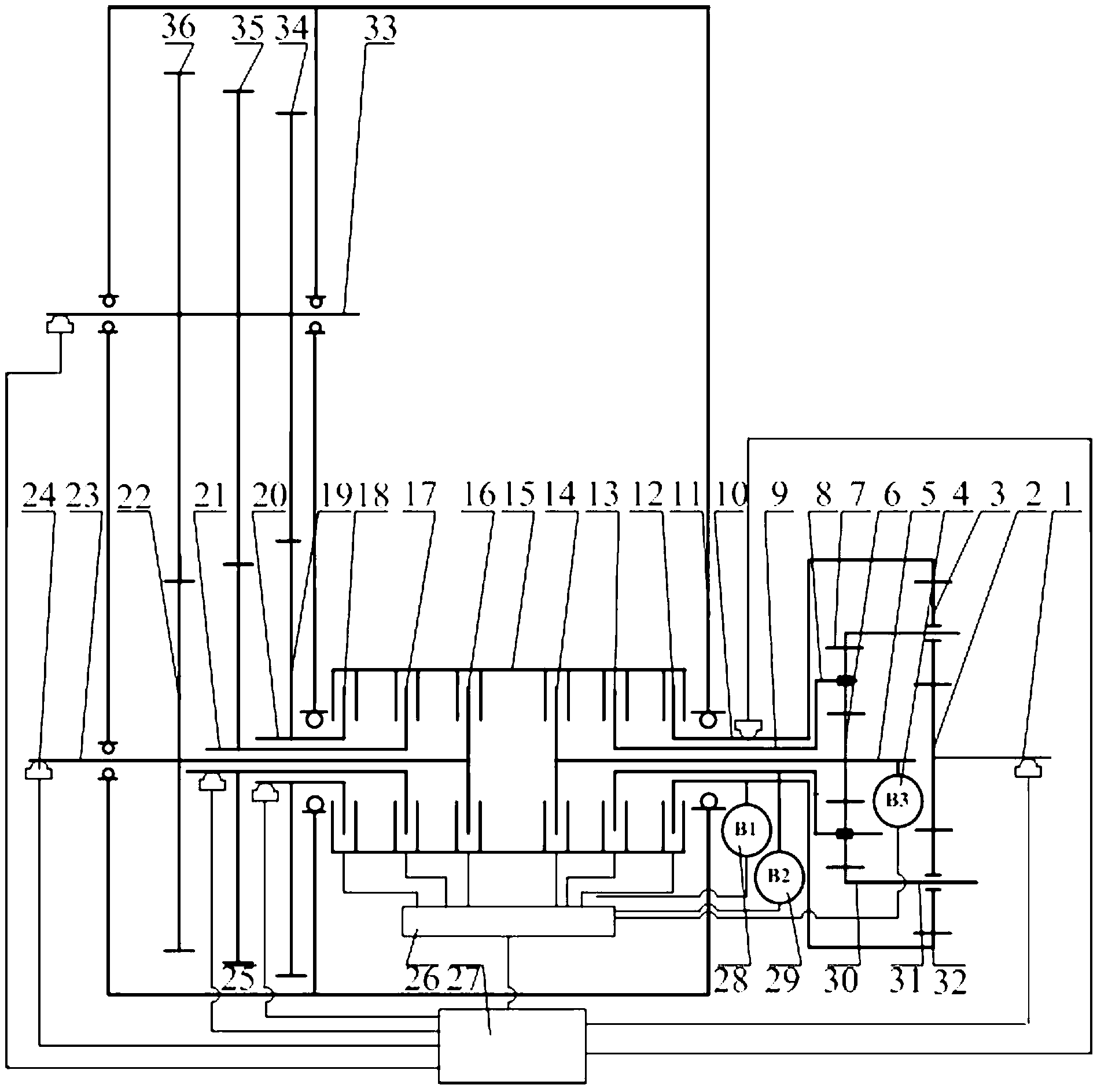

[0012] An embodiment of the present invention's dual-planetary confluence type multi-speed multi-clutch transmission is as follows figure 1 As shown, it is a dual-planetary confluence type multi-speed multi-clutch transmission used in a multi-speed tractor, which includes a housing 11, a main input shaft 33 for transmission connection with the output shaft of the engine, and a transmission for outputting torque to the outside of the transmission. The main output shaft 1, the multi-clutch and double-planetary converging mechanism also include a transmission control system composed of a corresponding clutch brake operating mechanism 26, a rotational speed sensor 24, an electronic control unit 27, and the like.

[0013] The multi-clutch includes a multi-clutch housing 15, three clutch input shafts, three clutch output shafts, and a clutch mechanism for selecting the corresponding clutch output shaft and one of the clutch input shafts according to the set selection and shift rules; th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap