Planetary reducer

A technology of planetary reducer and planetary carrier, which is applied in the direction of transmission parts, gear transmission, belt/chain/gear, etc., and can solve the problems of reducer damage, uneven load distribution between planetary gears, and low positioning accuracy of internal gears. , to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation scheme is described below in conjunction with the drawings.

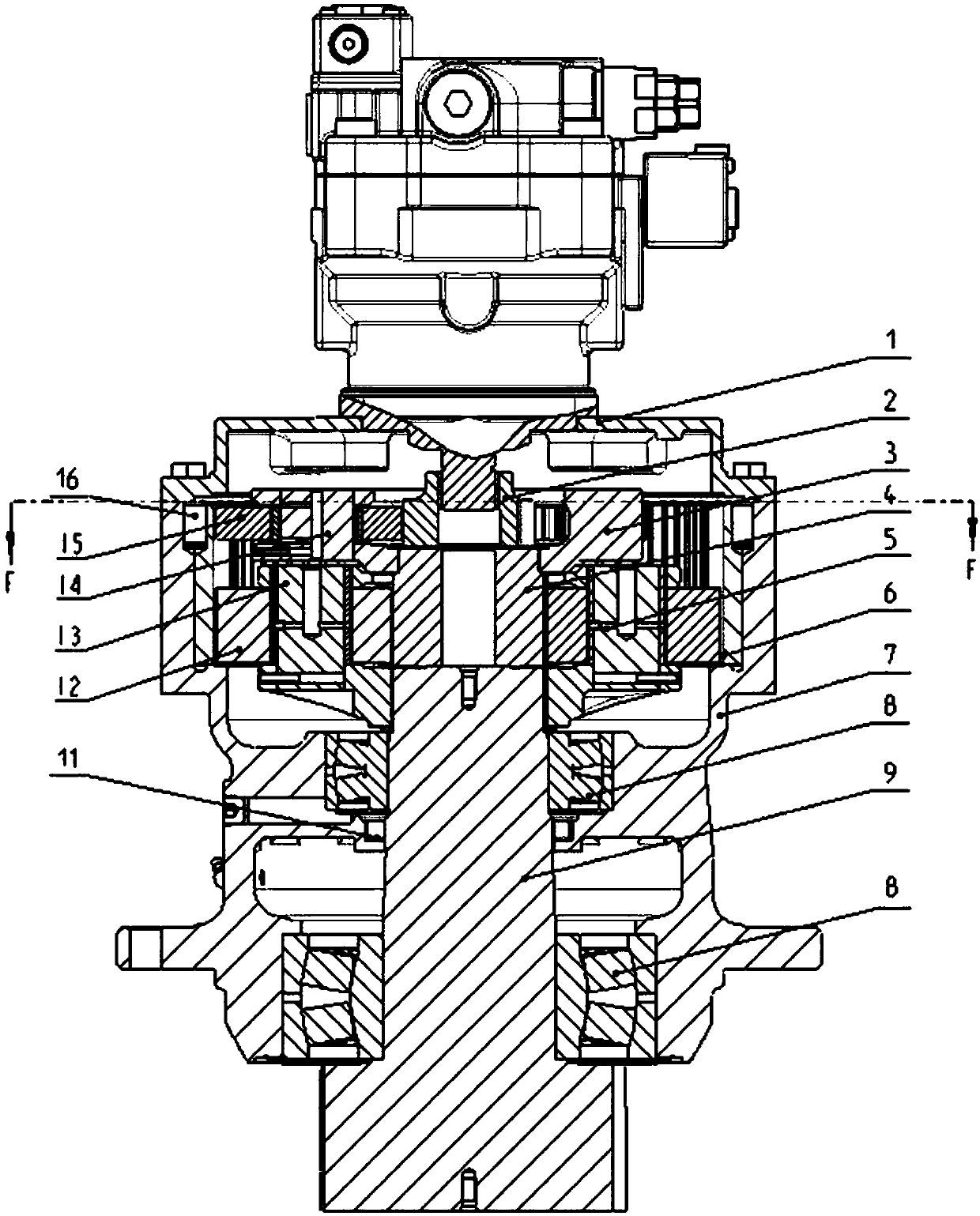

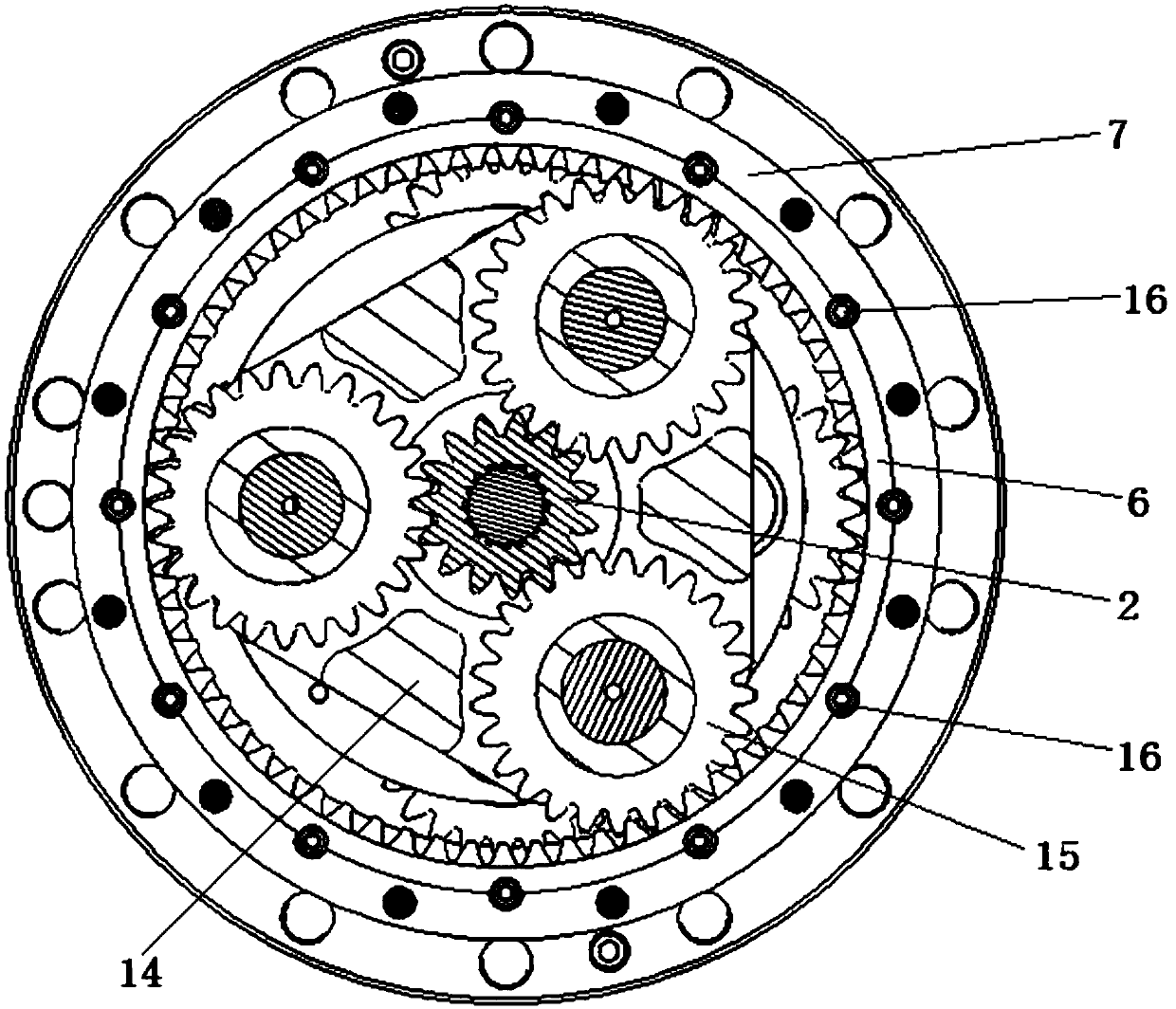

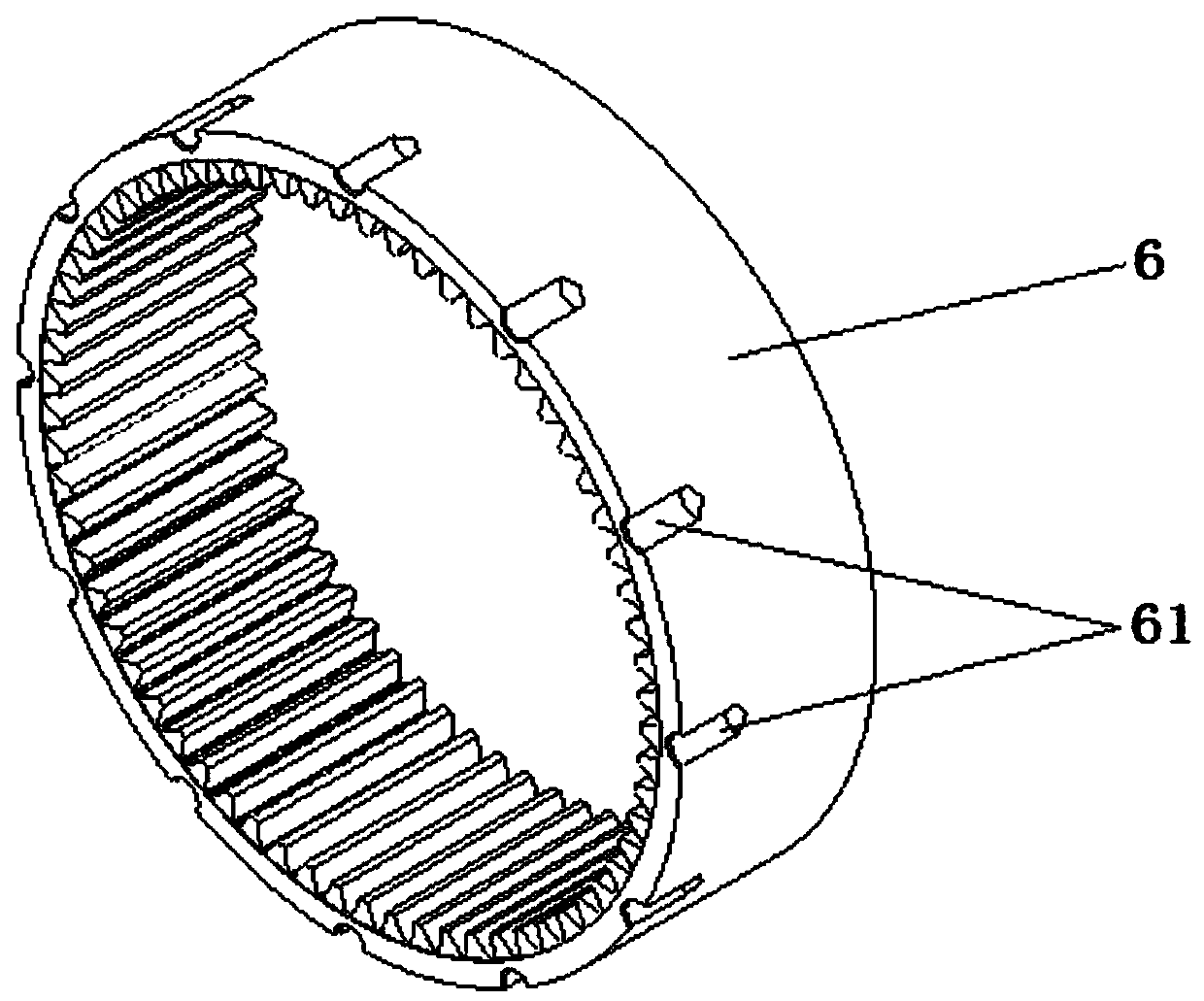

[0020] Such as figure 1 figure 2 As shown, the planetary reducer in this embodiment is a two-stage reduction planetary reducer, which is used in the slewing mechanism on an excavator, and includes a flange 1, a housing 7, a transmission gear 2, an output shaft gear 9, Internal gear 6, primary planet carrier assembly 3, secondary planet carrier assembly 5, transition gear 4 and other components. The casing 7 has circular openings at both ends, and the opening at one end is fixedly connected with the flange plate 1 by bolts. The output shaft gear 9 is installed in the casing through two pairs of spherical roller bearings 8 from the opening at the other end of the casing. Stick out. The transmission gear 2, the output shaft gear 9, the internal gear 6, the primary planet carrier assembly 3, the secondary planet carrier assembly 5, and the transition gear 4 are installed in the installatio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap