Three-non-bevel-gear planetary-gear-train wide-narrow-row-spaced oblique-Z-shaped maize transplanting mechanism

A non-conical gear, planetary gear train technology, applied in transplanting machinery, belt/chain/gear, planting methods, etc., to achieve the effect of improving ventilation, stable work, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the drawings and embodiments.

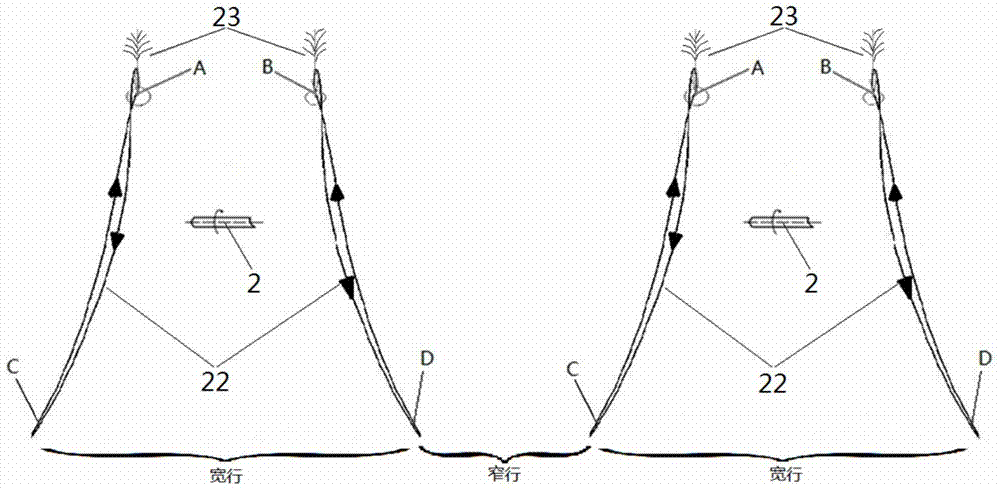

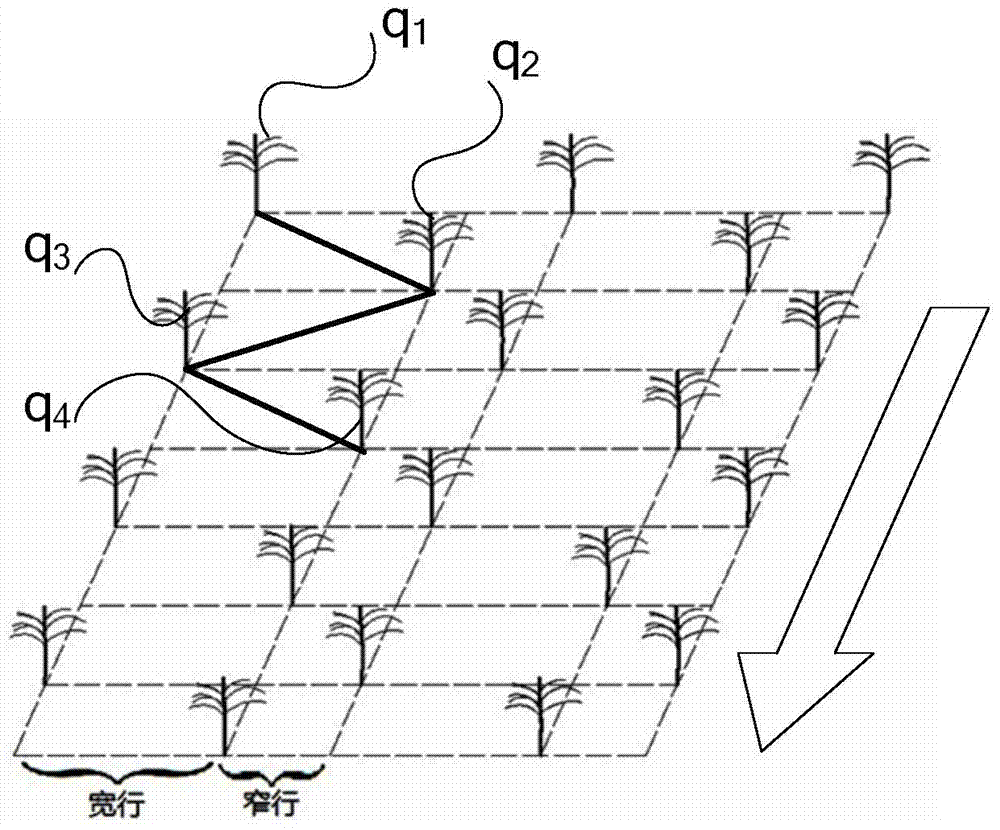

[0033] Such as figure 1 with figure 2 As shown, the corn planting realized by a three-non-conical gear planetary gear corn wide and narrow row oblique zigzag transplanting mechanism is a combination of wide and narrow row planting and oblique zigzag planting. Oblique Z-shaped planting means following the forward direction of the transplanting mechanism after planting, namely figure 2 Arrow direction, a corn seedling q 1 , Corn seedlings in adjacent rows 2 , Corn seedlings in adjacent rows in the same column q 3 And adjacent rows of corn seedlings q 4 The sequential connection between them is in an oblique Z-shape.

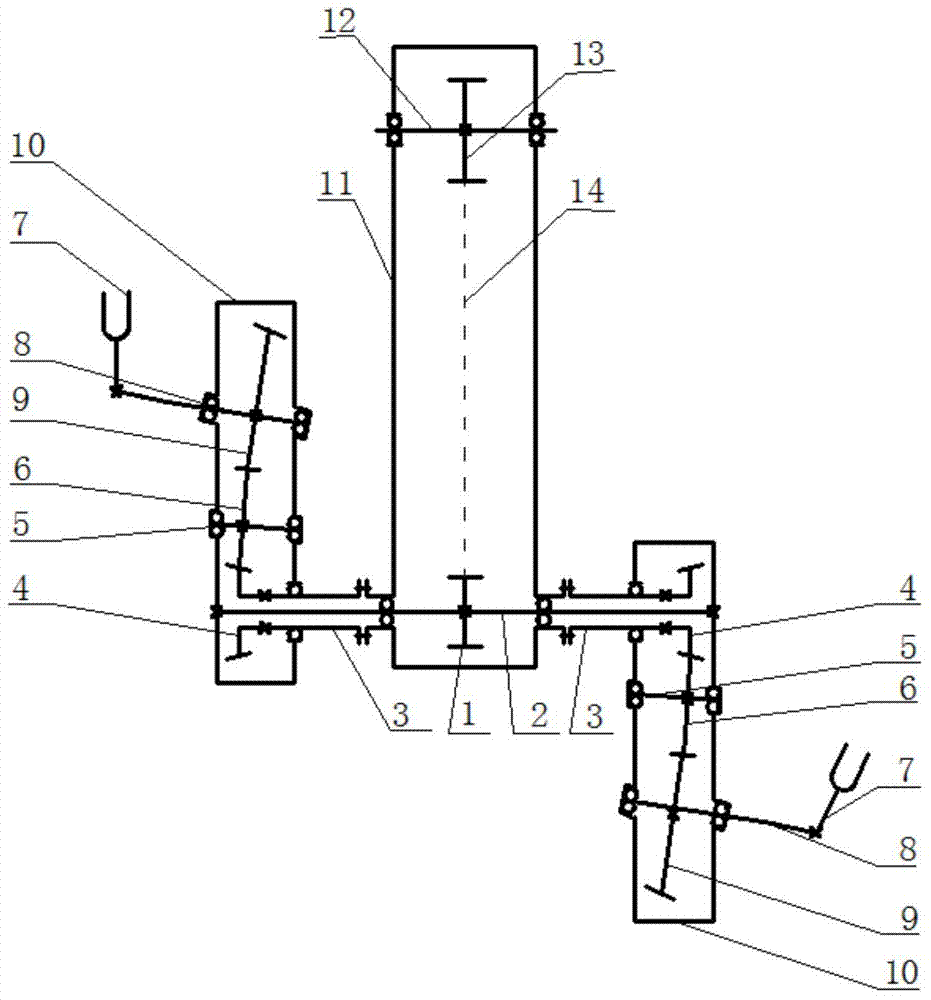

[0034] Such as image 3 , Figure 4 , Figure 5 with Image 6 As shown, the three-non-cone gear planetary gear corn wide-narrow-line oblique Z-shaped transplanting mechanism includes a power transmission component, a jaw flange 3 and a planting component; the two

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap